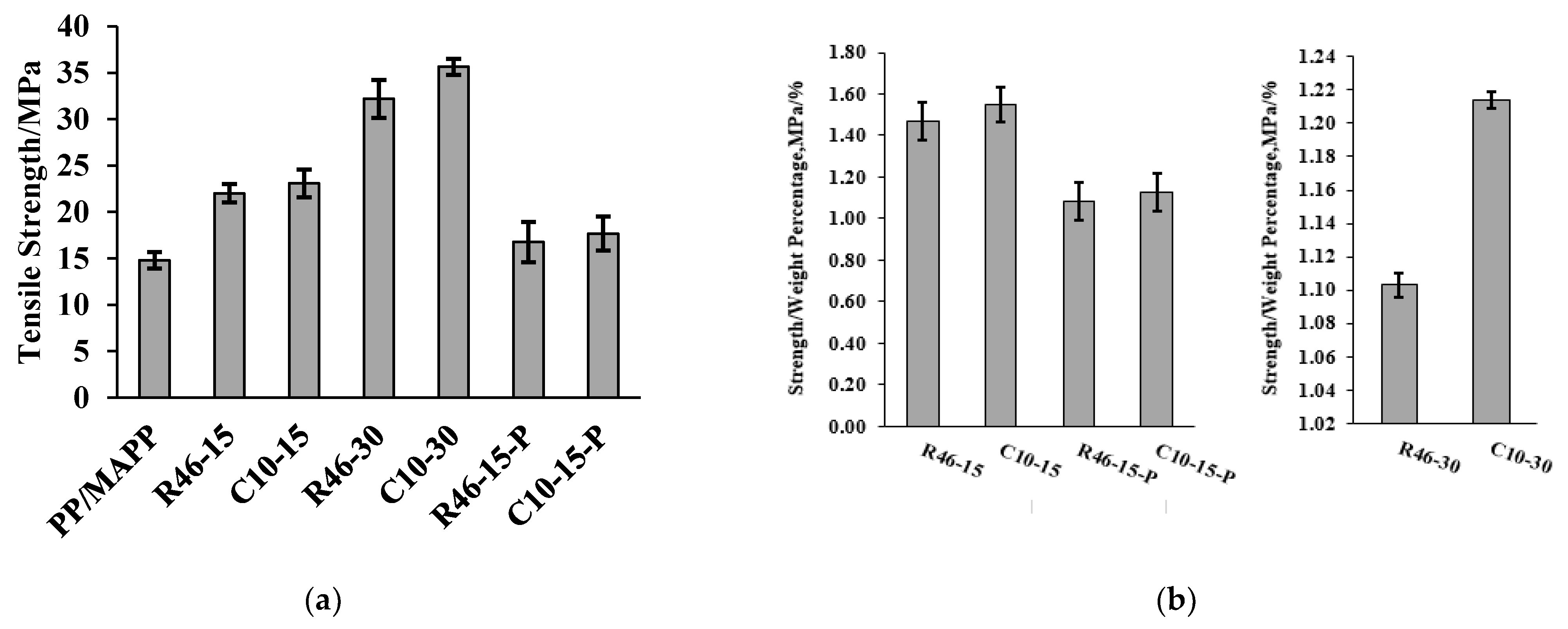

3.2.1. Using Optical Microscopic Images

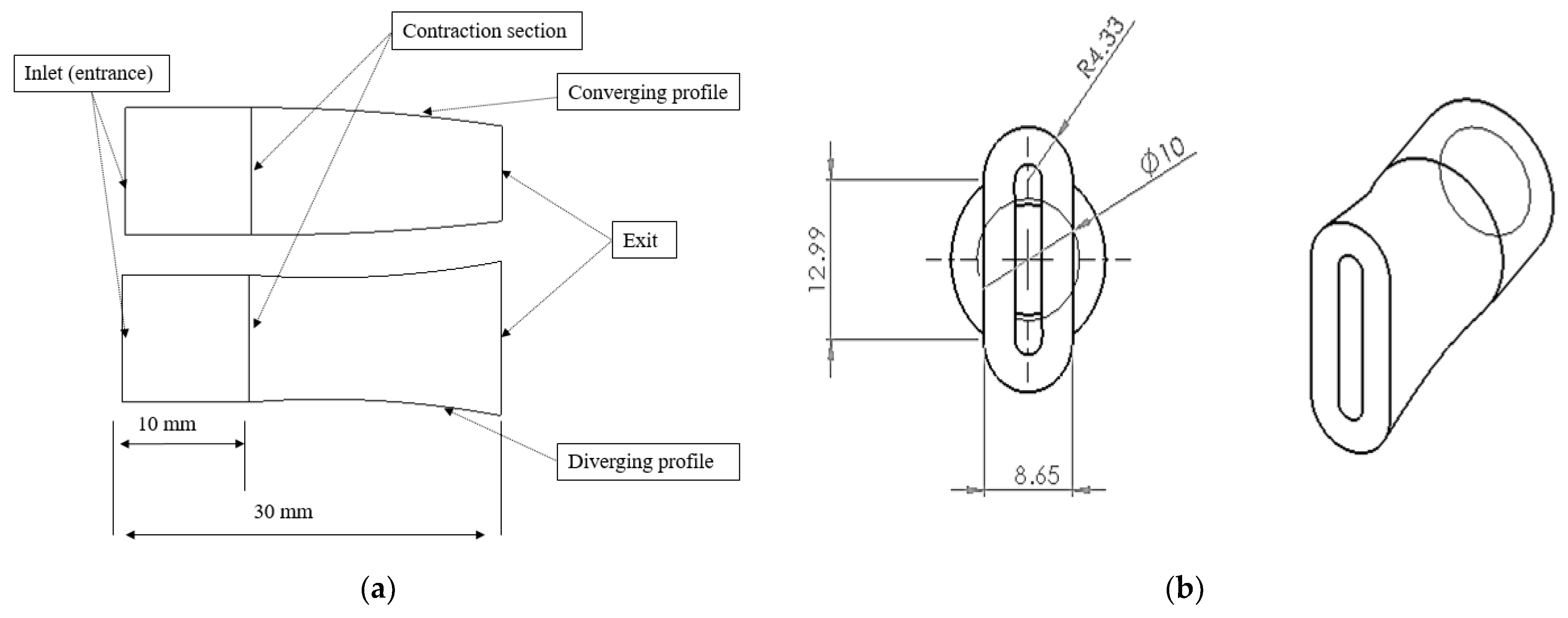

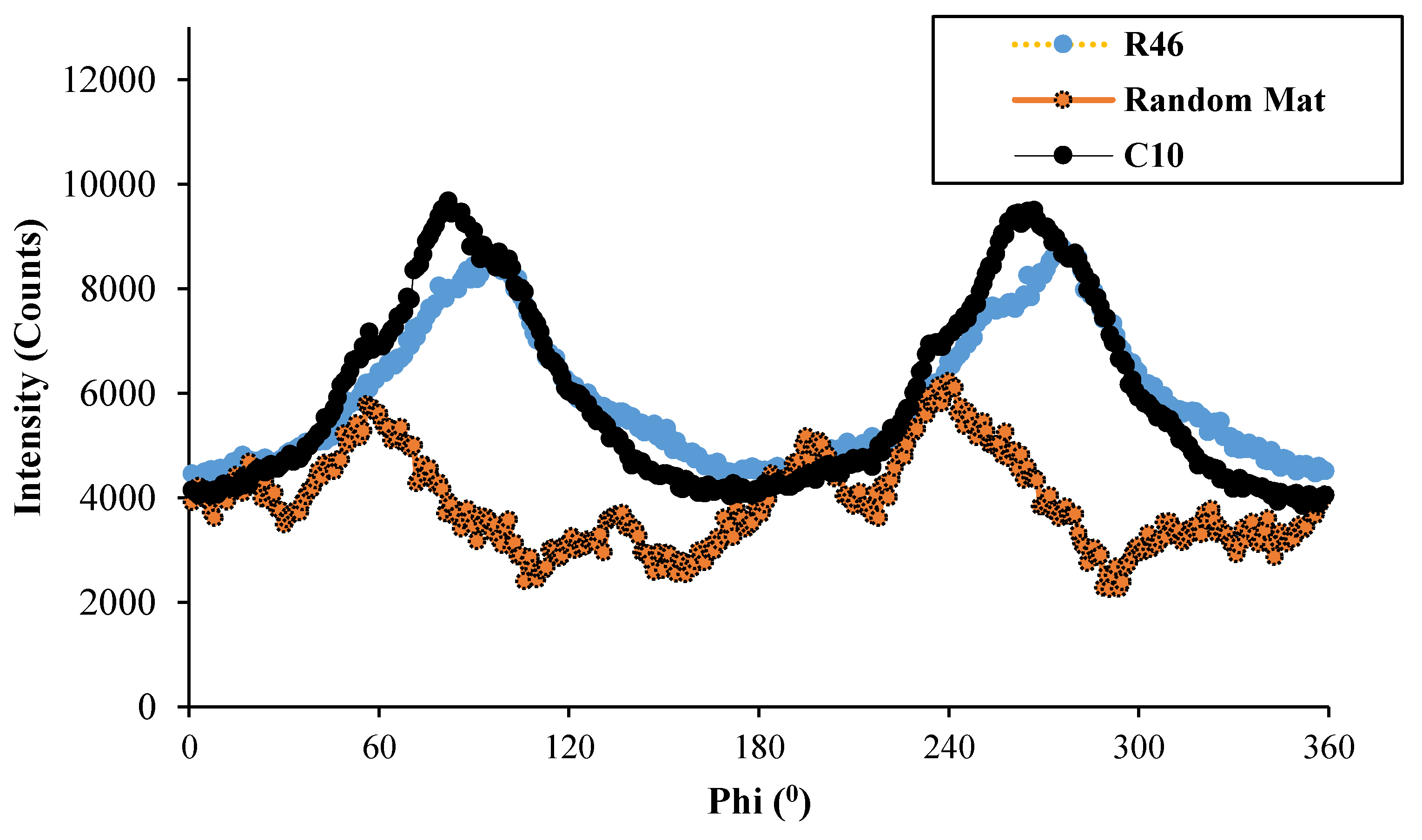

Figure 6 shows the fibre orientation distribution profiles obtained for the mats and fibre bundles (highly aligned sample) using the OrientationJ plug-in available with ImageJ software. Commonly, the orientation is indicated by the predominant peak of an orientation distribution profile [

15,

16]. As can be seen, the profile obtained for the random mats appeared to have a relatively small broad peak (almost a flat curve). In contrast, the profiles obtained for the fibre bundles and fibre mats appeared to have a relatively sharp predominant peak around 0° (±8°). These predominant peaks around the preferred direction (0°) for the mats produced using DSF compared to the largely flat profile (with a small peak around −40°) of random mats support that alignment is produced using the dynamic sheet former. However, the profiles obtained for the mats produced using DSF were relatively wider than for the highly aligned bundles, indicating a lower degree of orientation [

17,

18].

In addition to the calculation of predominant or preferred orientation of fibres in an image, the OrientationJ program also calculated a ‘coherency factor’ to that orientation [

19]. This factor is calculated based on the amount of pixels that are in line in a particular direction and is bound between 0 and 1, with 0 and 1 indicating isotropic and anisotropic orientations, respectively [

20]. The coherency factors generated by the OrientationJ plugin are represented in

Table 4. As can be seen, the highest coherency factors were obtained for the fibre bundles followed by the fibre mats produced using DSF and the random mats.

Among the fibre mats produced using DSF with different nozzles, there was a trend of increasing fibre orientation for nozzles with increasing contraction ratio, as indicated by the increasing predominant orientation peak heights (

Figure 6) and coherency factors (

Table 4). However, this increase in fibre alignment was only significant for extreme cases (lower versus higher contraction ratios) when measured using this approach. Additionally, the exit shape of a nozzle was found to have less influence on fibre orientation as there were no significant differences (confirmed by Student’s

t-test) in fibre orientation between the mats made with nozzles of similar contraction ratios (R46, C46 and R35, C35). When compared to the current nozzle (R46), coherency factor was found to increase by about 35% with the C10 nozzle. These results indicate that the exit shape of a nozzle is less significant for fibre orientation in DSF. This agrees with previous studies that have reported that in a simple shear flow, nozzle exit area largely affects the alignment of fibres. If the nozzle exit area is large, although fibres near to the wall are aligned towards the flow direction, at the centre, fibres are aligned perpendicular to the flow direction. In contrast, if the nozzle exit area is small, the core region slowly disappears and increases the tendency of the fibres in the suspension to align towards the flow direction [

21]. It has also been reported that fibre suspension experiences extensional flow due to the sudden flow acceleration (change in velocity of suspension) by the contraction section of a nozzle and can result in more alignment of fibres towards the flow direction [

22].

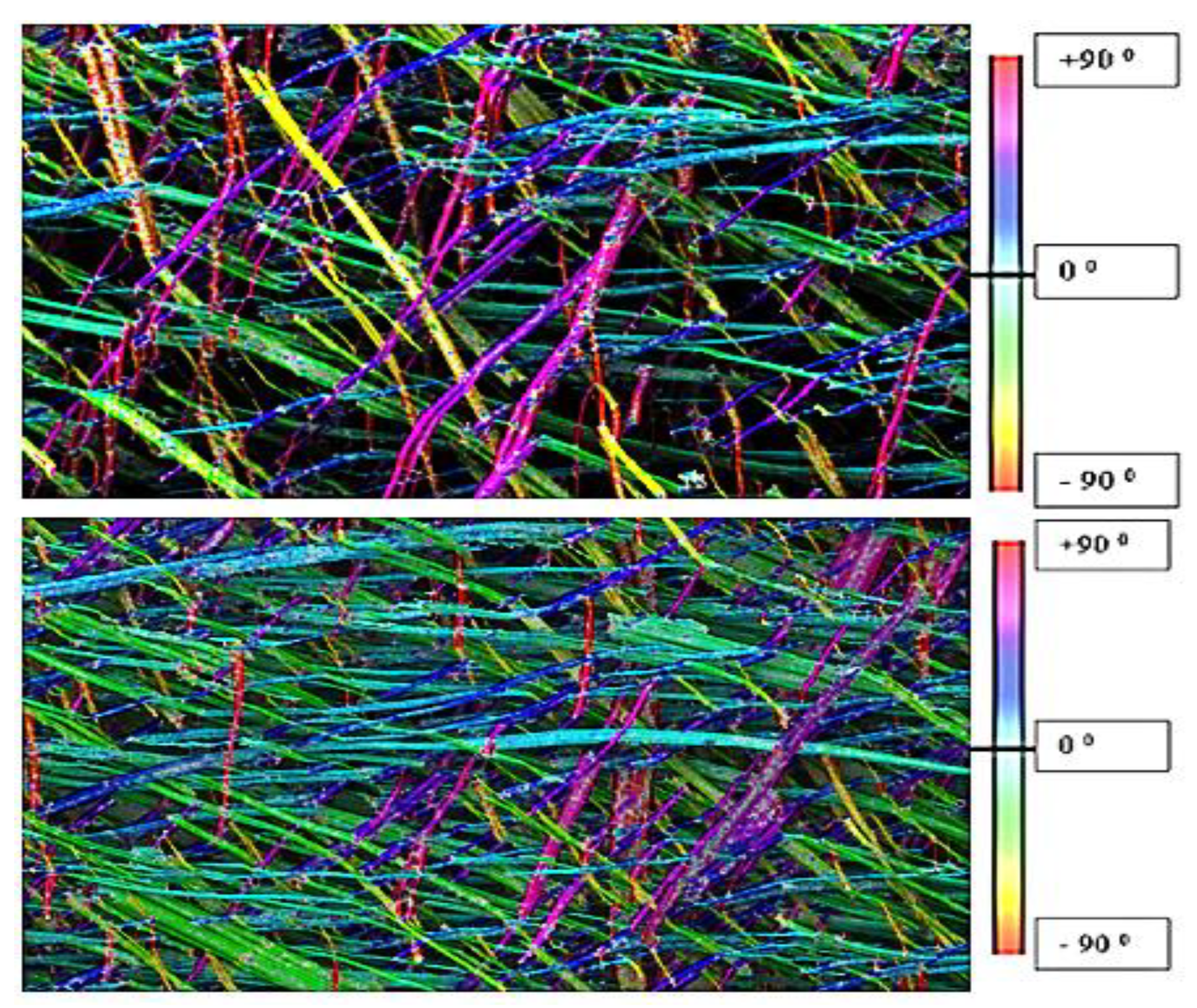

Qualitative visual representations of orientation distribution (colour coded maps of local angles) are also available with OrientationJ in Hue Saturation and Brightness mode [

9,

11]. The colour coded maps obtained for the highly aligned control sample, the random mat and the selected mats (R46, C10) produced using DSF, are shown in

Figure 7. The data visualisations are in good agreement with the data acquired for the orientation distribution profiles. As can be seen, apart from the fibre bundles, the fibre mats made with the C10 nozzle (

Figure 7d) revealed more orientated fibres towards 0° compared to the fibre mats made with the R46 nozzle (

Figure 7c) which were more aligned than the random mat (

Figure 7b).

The frequency ratio, i.e., the ratio of maximum to minimum frequency, for the aforementioned fibre orientation distribution profiles are also provided in

Table 4. The reported average frequency ratio can be considered as an indication of degree of orientation of fibres within a mat. Among the mats produced using DSF with different nozzles, the mats made with the C10 nozzle exhibited the highest average frequency ratio. The nozzles of a similar contraction ratio but with different exit shapes (i.e., rectangular-round or circular) were also compared based on the average frequency ratio and no significant differences were observed.

The full width at half maximum (FWHM) is commonly used to describe the width of a peak at the mid-height position [

23]. Generally, a profile with low FWHM indicates a high degree of orientation. The FWHM obtained using a Gaussians fit for each fibre orientation distribution profile, except for the random mats are also presented in

Table 4. The flat profile for the random mats made FWHM difficult. Unsurprisingly, the lowest FWHM was shown for the fibre bundles. A decreasing trend for FWHM among the fibre mats produced using DSF with different nozzles was shown with increases in contraction ratios of nozzles. However, statistical analysis (Student’s

t-test) did not support significant differences between these results.

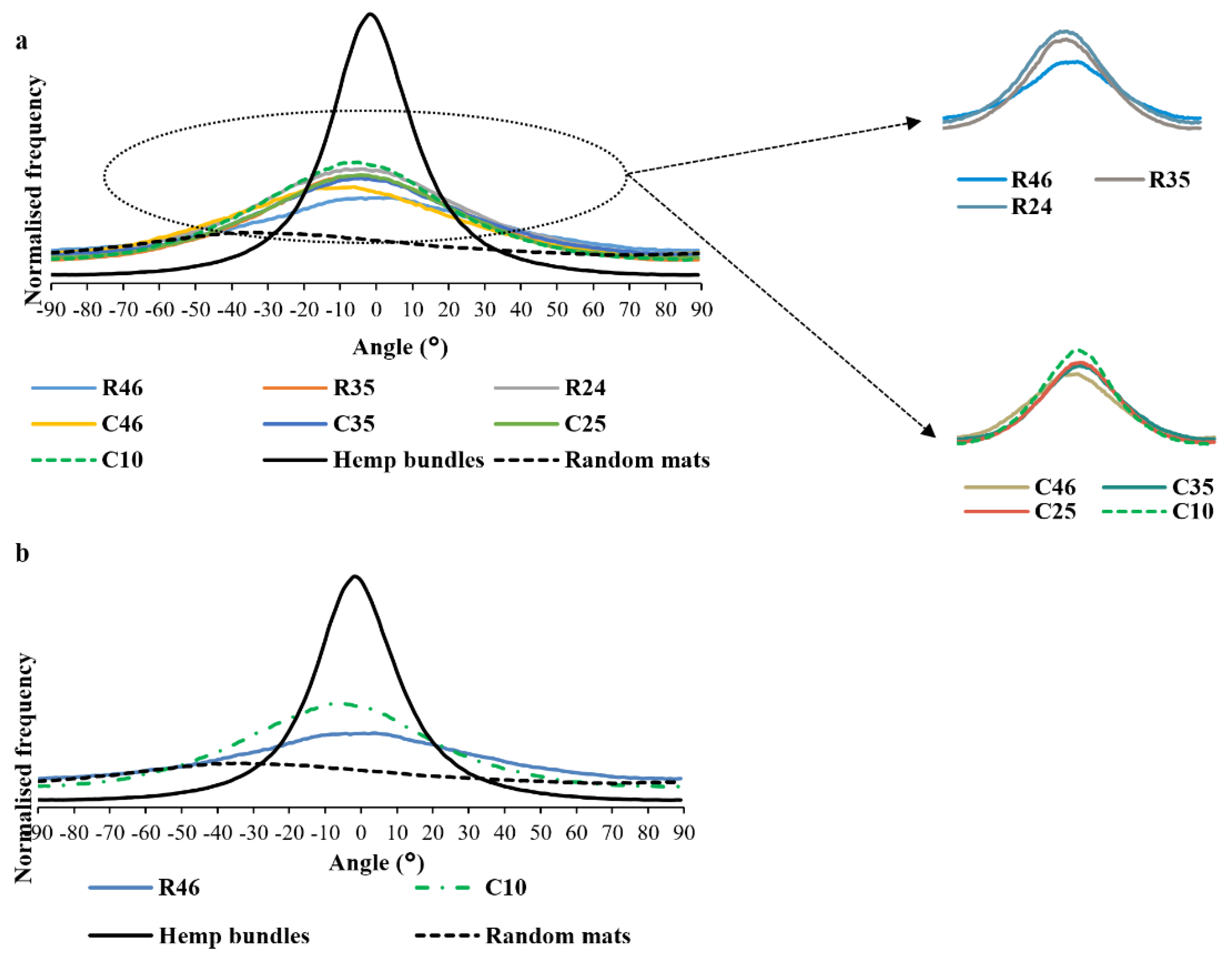

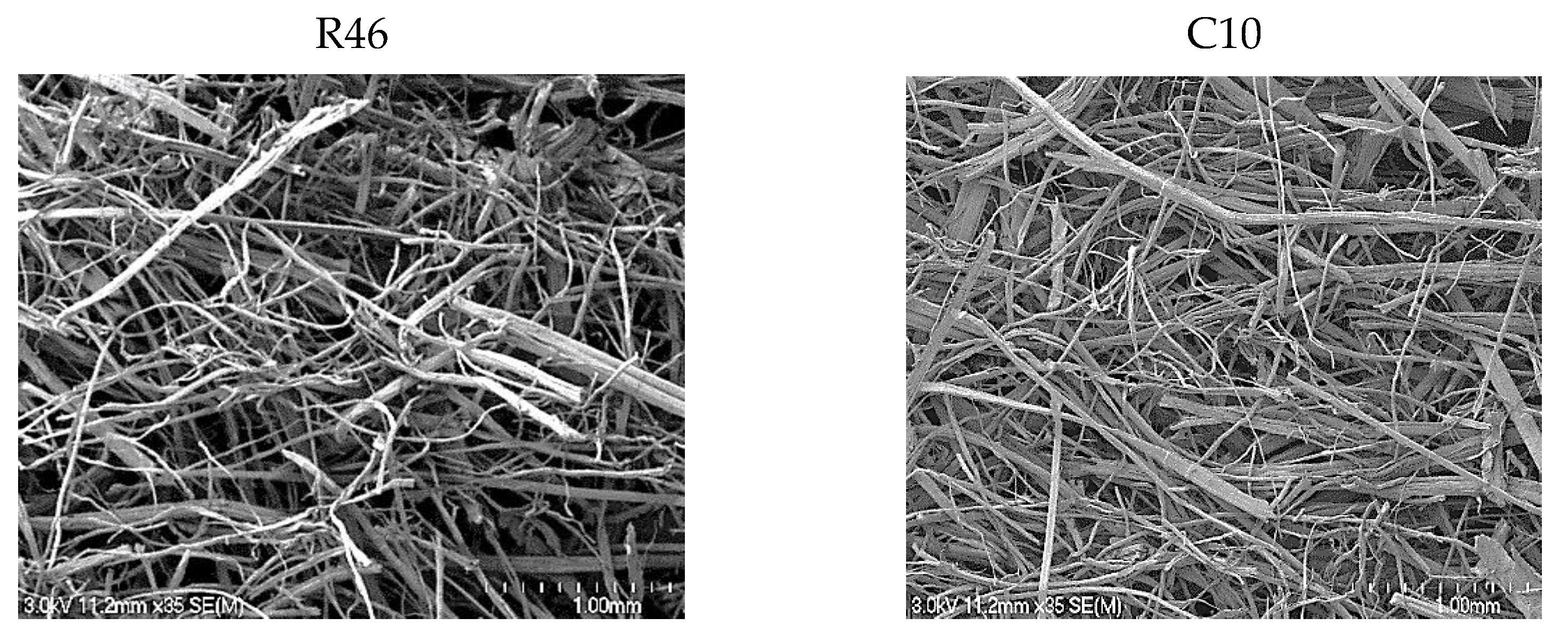

3.2.2. Using Scanning Electron Micrographs

Figure 8 shows the scanning electron micrographs (SEM) of selected fibre mats (R46 and C10) produced using DSF with different nozzles. As can be seen, it is hard to visually distinguish differences between distributions of orientations of fibres within the mats. The micrographs of these selected fibre mats (R46 and C10) were assessed using OrientationJ. The data obtained was analysed using the three aforementioned approaches. The results were relatively consistent with that found for OrientationJ analysis with optical microscopic images.

Figure 9 represents the fibre orientation distribution profiles of these mats. The predominant orientation peak height was higher for the fibre mats made with the C10 nozzle compared to the R46 nozzle. Qualitative visual representation of fibre orientation distribution within these mats can be seen in

Figure 10. As expected, the scanning electron micrographs provided better visual distinction of orientation of fibres within the selected mats compared to the optical microscopic images.

Table 5 displays the generated coherency factor, calculated frequency ratio and FWHM of the fibre orientation distribution profiles for these mats. The trends were similar to the results obtained for the optical microscopic images of these fibre mats.

Overall, the trend of increasing fibre orientation for nozzles with increasing contraction ratios was more consistent with the fibre orientation distribution profiles and the frequency ratio approaches compared to the FWHM approach.