Technical and Economic Viability of Distributed Recycling of Low-Density Polyethylene Water Sachets into Waste Composite Pavement Blocks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material Collection and Processing

2.2. Pavement Tiles Fabrication Process

2.2.1. Melting and Mixing

2.2.2. Pressing and Cooling

2.3. Testing

2.3.1. Elastic Modulus

2.3.2. Compressive Strength

2.3.3. Water Absorption Test

2.4. Economic Analysis

3. Results

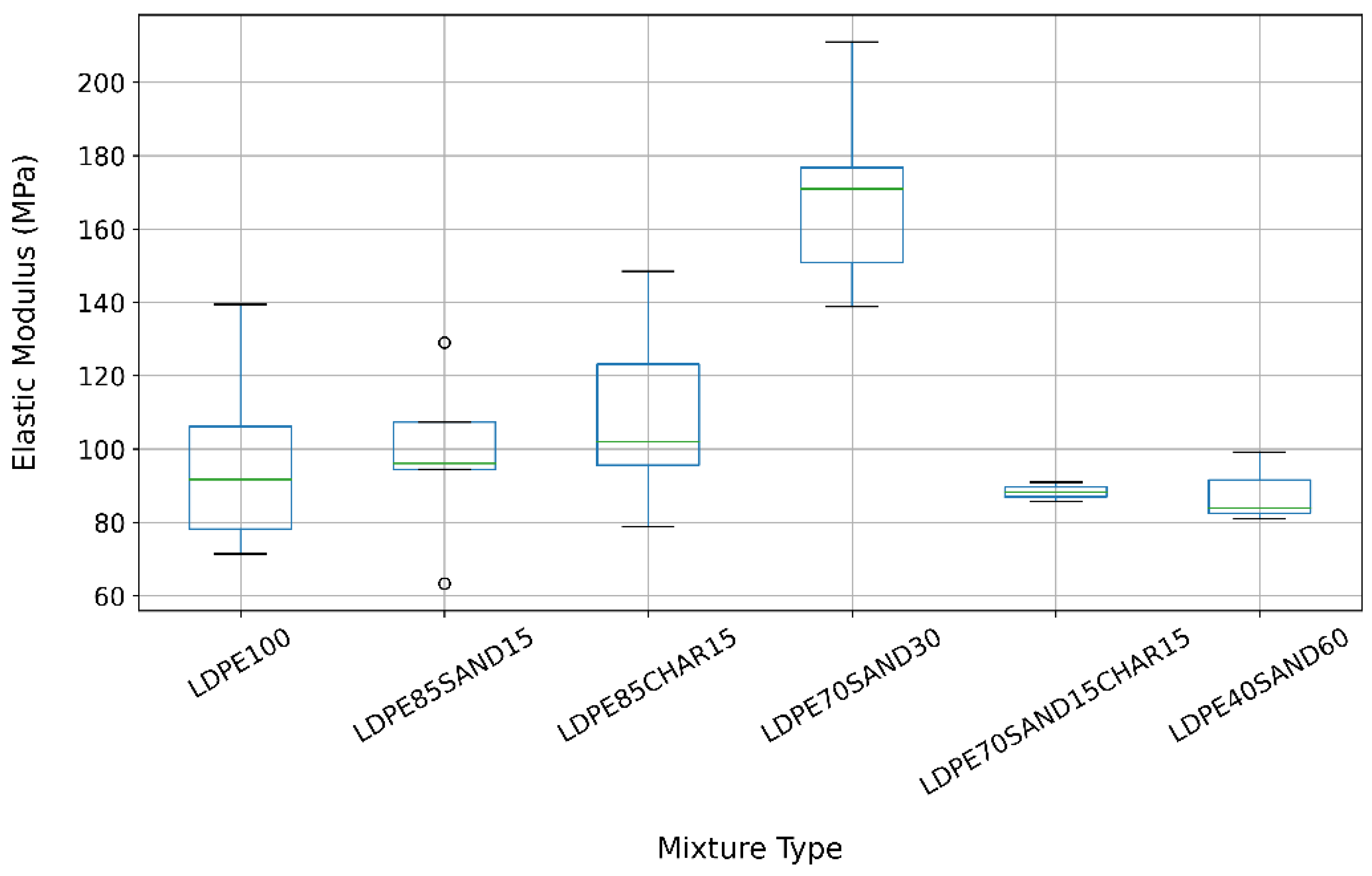

3.1. Tensile Tests Results

3.2. Compressive Strength Test Results

3.3. Water Absorptivity Test Results

3.4. Economic Analysis Results

4. Discussion

4.1. Technical Discussion of the Proposed Composite Use

4.2. Economic Implications

4.3. Limitations and Future Work

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- D’Ambrières, W. Plastics Recycling Worldwide: Current Overview and Desirable Changes. Field Actions Sci. Rep. J. Field Actions 2019, 19, 12–21. [Google Scholar]

- Debrah, J.K.; Vidal, D.G.; Dinis, M.A.P. Innovative Use of Plastic for a Clean and Sustainable Environmental Management: Learning Cases from Ghana, Africa. Urban Sci. 2021, 5, 12. [Google Scholar] [CrossRef]

- Nkwachukwu, O.I.; Chima, C.H.; Ikenna, A.O.; Albert, L. Focus on Potential Environmental Issues on Plastic World towards a Sustainable Plastic Recycling in Developing Countries. Int. J. Ind. Chem. 2013, 4, 34. [Google Scholar] [CrossRef]

- The World Bank Solid Waste Management. Available online: https://www.worldbank.org/en/topic/urbandevelopment/brief/solid-waste-management (accessed on 21 March 2022).

- Kondoh, E.; Bodjona, M.B.; Aziable, E.; Tchegueni, S.; Kili, K.A.; Tchangbedji, G. Etat Des Lieux de La Gestion Des Déchets Dans Le Grand Lomé. Int. J. Biol. Chem. Sci. 2019, 13, 2200–2209. [Google Scholar] [CrossRef]

- Adeleke, O.; Akinlabi, S.; Jen, T.-C.; Dunmade, I. Towards Sustainability in Municipal Solid Waste Management in South Africa: A Survey of Challenges and Prospects. Trans. R. Soc. S. Afr. 2021, 76, 53–66. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018; ISBN 978-1-4648-1329-0. [Google Scholar]

- Veidis, E.M.; LaBeaud, A.D.; Phillips, A.A.; Barry, M. Tackling the Ubiquity of Plastic Waste for Human and Planetary Health. Am. J. Trop. Med. Hyg. 2022, 106, 12–14. [Google Scholar] [CrossRef]

- Dwicania, E.; Rinanti, A.; Fachrul, M.F. Biodegradation of LLDPE Plastic by Mixed Bacteria Culture of Pseudomonas Aeruginosa and Brevibacterium sp. J. Phys. Conf. Ser. 2019, 1402, 022105. [Google Scholar] [CrossRef]

- Parker, L. A Whopping 91% of Plastic Isn’t Recycled. Available online: https://www.nationalgeographic.com/science/article/plastic-produced-recycling-waste-ocean-trash-debris-environment (accessed on 4 March 2022).

- Jambeck, J.; Hardesty, B.D.; Brooks, A.L.; Friend, T.; Teleki, K.; Fabres, J.; Beaudoin, Y.; Bamba, A.; Francis, J.; Ribbink, A.J.; et al. Challenges and Emerging Solutions to the Land-Based Plastic Waste Issue in Africa. Mar. Policy 2018, 96, 256–263. [Google Scholar] [CrossRef]

- Cook, E.; Velis, C. Global Review on Safer End of Engineered Life; Royal Academy of Engineering: London, UK, 2021. [Google Scholar]

- Okaka, F.O.; Odhiambo, B.D.O. Relationship between Flooding and out Break of Infectious Diseases in Kenya: A Review of the Literature. J. Environ. Public Health 2018, 2018, 5452938. [Google Scholar] [CrossRef]

- Rochman, C.M.; Browne, M.A.; Halpern, B.S.; Hentschel, B.T.; Hoh, E.; Karapanagioti, H.K.; Rios-Mendoza, L.M.; Takada, H.; Teh, S.; Thompson, R.C. Classify Plastic Waste as Hazardous. Nature 2013, 494, 169–171. [Google Scholar] [CrossRef] [PubMed]

- Stoler, J. Improved but Unsustainable: Accounting for Sachet Water in Post-2015 Goals for Global Safe Water. Trop. Med. Int. Health 2012, 17, 1506–1508. [Google Scholar] [CrossRef] [PubMed]

- Stoler, J.; Weeks, J.R.; Fink, G. Sachet Drinking Water in Ghana’s Accra-Tema Metropolitan Area: Past, Present, and Future. J. Water Sanit. Hyg. Dev. 2012, 2, 223–240. [Google Scholar] [CrossRef]

- Uhrin, A.V.; Schellinger, J. Marine Debris Impacts to a Tidal Fringing-Marsh in North Carolina. Mar. Pollut. Bull. 2011, 62, 2605–2610. [Google Scholar] [CrossRef]

- Cheng, K.; Hao, W.; Wang, Y.; Yi, P.; Zhang, J.; Ji, W. Understanding the Emission Pattern and Source Contribution of Hazardous Air Pollutants from Open Burning of Municipal Solid Waste in China. Environ. Pollut. 2020, 263, 114417. [Google Scholar] [CrossRef]

- Astrup, T.; Møller, J.; Fruergaard, T. Incineration and Co-Combustion of Waste: Accounting of Greenhouse Gases and Global Warming Contributions. Waste Manag. Res. 2009, 27, 789–799. [Google Scholar] [CrossRef]

- Ni, H.-G.; Lu, S.-Y.; Mo, T.; Zeng, H. Brominated Flame Retardant Emissions from the Open Burning of Five Plastic Wastes and Implications for Environmental Exposure in China. Environ. Pollut. 2016, 214, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Nakao, T.; Aozasa, O.; Ohta, S.; Miyata, H. Formation of Toxic Chemicals Including Dioxin-Related Compounds by Combustion from a Small Home Waste Incinerator. Chemosphere 2006, 62, 459–468. [Google Scholar] [CrossRef] [PubMed]

- Dertinger, S.C.; Gallup, N.; Tanikella, N.G.; Grasso, M.; Vahid, S.; Foot, P.J.S.; Pearce, J.M. Technical Pathways for Distributed Recycling of Polymer Composites for Distributed Manufacturing: Windshield Wiper Blades. Resour. Conserv. Recycl. 2020, 157, 104810. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. The Green Fablab Concept: A Local and Distributed Recycling Approach for Open Source Additive Manufacturing. In Proceedings of the 2nd Journée de l’Innovation Abbé Grégoire (JAG), Paris, France, 22 March 2017. [Google Scholar]

- Zhong, S.; Pearce, J.M. Tightening the Loop on the Circular Economy: Coupled Distributed Recycling and Manufacturing with Recyclebot and RepRap 3-D Printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- GAUDESI, A. Correlation between Additive Manufacturing and Circular Economy: An Economic Analysis of Distributed Recycling in Beijing. Master’s Thesis, Polytechnic University of Milan, Milan, Italy, 2019. [Google Scholar]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life Cycle Analysis of Distributed Recycling of Post-Consumer High Density Polyethylene for 3-D Printing Filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Kreiger, M.; Anzalone, G.C.; Mulder, M.L.; Glover, A.; Pearce, J.M. Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. MRS Online Proc. Libr. 2012, 1492, 101–106. [Google Scholar] [CrossRef] [Green Version]

- Craighill, A.L.; Powell, J.C. Lifecycle Assessment and Economic Evaluation of Recycling: A Case Study. Resour. Conserv. Recycl. 1996, 17, 75–96. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of Recycled Plastic in Concrete: A Review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Uvarajan, T.; Gani, P.; Chuan, N.C.; Zulkernain, N.H. Reusing Plastic Waste in the Production of Bricks and Paving Blocks: A Review. Eur. J. Environ. Civ. Eng. 2021, 1–34. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing Waste Plastics into Cleaner Asphalt Pavement Materials: A Critical Literature Review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

- Meyer, T.K.; Tanikella, N.G.; Reich, M.J.; Pearce, J.M. Potential of Distributed Recycling from Hybrid Manufacturing of 3-D Printing and Injection Molding of Stamp Sand and Acrylonitrile Styrene Acrylate Waste Composite. Sustain. Mater. Technol. 2020, 25, e00169. [Google Scholar] [CrossRef]

- Tulashie, S.K.; Boadu, E.K.; Kotoka, F.; Mensah, D. Plastic Wastes to Pavement Blocks: A Significant Alternative Way to Reducing Plastic Wastes Generation and Accumulation in Ghana. Constr. Build. Mater. 2020, 241, 118044. [Google Scholar] [CrossRef]

- Themelis, N.J.; Castaldi, M.J.; Bhatti, J.; Arsova, L. Energy and Economic Value of Non-Recycled Plastics (NRP) and Municipal Solid Wastes (MSW) that are Currently Landfilled in the Fifty States. In EEC Study of Non-Recycled Plastics; Columbia University: New York, NY, USA, 2011; p. 33. [Google Scholar]

- Quartey, E.T.; Tosefa, H.; Danquah, K.A.B.; Obrsalova, I. Theoretical Framework for Plastic Waste Management in Ghana through Extended Producer Responsibility: Case of Sachet Water Waste. Int. J. Environ. Res. Public Health 2015, 12, 9907–9919. [Google Scholar] [CrossRef] [PubMed]

- Wardrop, N.A.; Dzodzomenyo, M.; Aryeetey, G.; Hill, A.G.; Bain, R.E.S.; Wright, J. Estimation of Packaged Water Consumption and Associated Plastic Waste Production from Household Budget Surveys. Environ. Res. Lett. 2017, 12, 074029. [Google Scholar] [CrossRef]

- Adjalo, D.K.; Houedakor, K.Z.; Zinsou-Klassou, K. Usage Des Emballages Plastiques Dans La Restauration de Rue et Assainissement Des Villes Ouest-Africaines: Exemple de Lomé Au Togo. Int. J. Biol. Chem. Sci. 2020, 14, 1646–1656. [Google Scholar] [CrossRef]

- World Bank Photo Collection Cook Stove Liners. 2015. Available online: https://www.flickr.com/photos/worldbank/25393402999/in/photostream/ (accessed on 25 July 2022).

- ASTM International Standard Test Method for Tensile Properties of Plastics. Available online: https://www.astm.org/d0638-14.html (accessed on 10 August 2022).

- De Schutter, G.; Audenaert, K. Evaluation of Water Absorption of Concrete as a Measure for Resistance against Carbonation and Chloride Migration. Mat. Struct. 2004, 37, 591–596. [Google Scholar] [CrossRef]

- Izzati, M.Y.N.; Hani, A.S.; Shahiron, S.; Shah, A.S.; Hairi, O.M.; Zalipah, J.; Azlina, A.H.N.; Akasyah, W.A.M.N.; Amirah, K.N. Strength and Water Absorption Properties of Lightweight Concrete Brick. IOP Conf. Ser. Mater. Sci. Eng. 2019, 513, 012005. [Google Scholar] [CrossRef]

- Wilson, M.A.; Carter, M.A.; Hoff, W.D. British Standard and RILEM Water Absorption Tests: A Critical Evaluation. Mat. Struct. 1999, 32, 571–578. [Google Scholar] [CrossRef]

- Hayibo, K.; Pearce, J.; Cairns, P. LDPE Recycling into Pavement in Togo CAD Drawing; Open Science Framework (Center for Open Science): Charlottesville, VA, USA, 2022. [Google Scholar] [CrossRef]

- Pereira, R.A.; Mano, E.B.; Dias, M.L.; Acordi, E.B. Comparative Study on the Lamellar Crystal Structure of High and Low Density Polyethylenes. Polym. Bull. 1997, 38, 707–714. [Google Scholar] [CrossRef]

- Chan, C.-M. Influence of Deposition Density on Undrained Shear Strength Parameters of Mining Sand. AIP Conf. Proc. 2017, 1891, 020034. [Google Scholar] [CrossRef]

- Imuran, A.S.; Salawu, G.A.; Odeniyi, O.M.; Azeez, M.A.; Oloyede, F. Agglomeration of Wood Dust and Charcoal Powder for Solid Fuel Production. IJRES 2021, 9, 10–13. [Google Scholar]

- Charpin, M.; Fontodji, J.K. Etude Approfondie sur la Dynamique de L’utilisation du Bois-Energie au Togo 2017; Ministere de L’environnement et des Ressources Forestieres: Lomé, Togo, 2017.

- 24Heure Info. Gaz Butane: Les Prix ont Quasiment Doublé au Togo. Site Togolais D’Information D’Actualités 2022. Available online: https://24heureinfo.com/economie/gaz-butane-les-prix-ont-quasiment-double-au-togo/ (accessed on 10 August 2022).

- Edoh, E. Togo: Baisse du Prix du gaz Butane, Après une Hausse Record. TogoFirst 2022. Available online: https://www.togofirst.com/fr/energies/1908-10451-togo-baisse-du-prix-du-gaz-butane-apres-une-hausse-record (accessed on 10 August 2022).

- Schindler, R. Pricing Strategies: A Marketing Approach; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2012; ISBN 978-1-4129-6474-6. [Google Scholar]

- Velmurugan, V. Rebuilding of Plastic Waste to Pavement Bricks. IJRASET 2019, 7, 927–931. [Google Scholar] [CrossRef]

- Mondal, M.K.; Bose, B.P.; Bansal, P. Recycling Waste Thermoplastic for Energy Efficient Construction Materials: An Experimental Investigation. J. Environ. Manag. 2019, 240, 119–125. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Shah, T. Investigation of Fibre Reinforced Mud Brick as a Building Material. Constr. Build. Mater. 2005, 19, 313–318. [Google Scholar] [CrossRef]

- Ahmed, M.; Mallick, J.; Hasan, M.A. Abul Hasan, Mohd. A Study of Factors Affecting the Flexural Tensile Strength of Concrete. J. King Saud Univ. -Eng. Sci. 2016, 28, 147–156. [Google Scholar] [CrossRef]

- Sowmya, C.B. Flexural Strength of Concrete. EngineeringCivil.org 2020. Available online: https://engineeringcivil.org/articles/structural-engineering/flexural-strength-of-concrete/ (accessed on 10 August 2022).

- Jimbah, I. Price of Pavement Blocks in Ghana. Ghana Insider 2022. Available online: https://ghanainsider.com/price-of-pavement-blocks-in-ghana/ (accessed on 10 August 2022).

- Wage Indicator Salaire Minimum. Available online: https://votresalaire.org/togo/salaire/salaire-minimum-tarifs (accessed on 8 August 2022).

- World Population Review Lome Population 2022 (Demographics, Maps, Graphs). Available online: https://worldpopulationreview.com/world-cities/lome-population (accessed on 11 August 2022).

- Dzodzomenyo, M.; Dotse-Gborgbortsi, W.; Lapworth, D.; Wardrop, N.; Wright, J. Geographic Distribution of Registered Packaged Water Production in Ghana: Implications for Piped Supplies, Groundwater Management and Product Transportation. Water 2017, 9, 142. [Google Scholar] [CrossRef] [Green Version]

- Helal, J.; Sofi, M.; Mendis, P. Non-Destructive Testing of Concrete: A Review of Methods. Electron. J. Struct. Eng. 2015, 14, 97–105. [Google Scholar] [CrossRef]

- Cole, M.; Lindeque, P.; Halsband, C.; Galloway, T.S. Microplastics as Contaminants in the Marine Environment: A Review. Mar. Pollut. Bull. 2011, 62, 2588–2597. [Google Scholar] [CrossRef] [PubMed]

| Composite Sample Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Percent LDPE Plastic (%) * | 100 | 70 | 70 | 70 | 85 | 85 | 85 |

| Percent Sand (%) | 0 | 30 | 0 | 15 | 15 | 0 | 7.5 |

| Percent Charcoal (%) | 0 | 0 | 30 | 15 | 0 | 15 | 7.5 |

| Sample Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| LDPE Plastic (%) | 100 | 70 | 70 | 70 | 85 | 85 | 85 |

| Sand (%) | 0 | 30 | 0 | 15 | 15 | 0 | 7.5 |

| Charcoal (%) | 0 | 0 | 30 | 15 | 0 | 15 | 7.5 |

| Absorptivity (%) | 6.7 | 2.2 | 15.0 | 10.4 | 6.9 | 7.0 | 6.2 |

| Instrument Error (±%) | 1.1 | 0.2 | 0.4 | 0.4 | 0.4 | 0.3 | 0.6 |

| Price per Brick (XOF) | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

|---|---|---|---|---|---|---|---|

| Hourly Wage per Worker (XOF/hour) | −383 | −174 | 34 | 243 | 451 | 659 | 868 |

| Average Monthly Salary per Worker (XOF/month) * | −66,300 | −30,189 | 5922 | 42,033 | 78,144 | 114,256 | 150,367 |

| Price per Brick (XOF) | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

|---|---|---|---|---|---|---|---|

| Hourly Wage per Worker (XOF/hour) | 110 | 319 | 527 | 735 | 944 | 1152 | 1360 |

| Average Monthly Salary per Worker (XOF/month) * | 19,139 | 55,250 | 91,361 | 127,472 | 163,583 | 199,694 | 235,806 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsala-Mbala, C.; Hayibo, K.S.; Meyer, T.K.; Couao-Zotti, N.; Cairns, P.; Pearce, J.M. Technical and Economic Viability of Distributed Recycling of Low-Density Polyethylene Water Sachets into Waste Composite Pavement Blocks. J. Compos. Sci. 2022, 6, 289. https://doi.org/10.3390/jcs6100289

Tsala-Mbala C, Hayibo KS, Meyer TK, Couao-Zotti N, Cairns P, Pearce JM. Technical and Economic Viability of Distributed Recycling of Low-Density Polyethylene Water Sachets into Waste Composite Pavement Blocks. Journal of Composites Science. 2022; 6(10):289. https://doi.org/10.3390/jcs6100289

Chicago/Turabian StyleTsala-Mbala, Celestin, Koami Soulemane Hayibo, Theresa K. Meyer, Nadine Couao-Zotti, Paul Cairns, and Joshua M. Pearce. 2022. "Technical and Economic Viability of Distributed Recycling of Low-Density Polyethylene Water Sachets into Waste Composite Pavement Blocks" Journal of Composites Science 6, no. 10: 289. https://doi.org/10.3390/jcs6100289