Effects of Alkali-Treatment and Feeding Route of Henequen Fiber on the Heat Deflection Temperature, Mechanical, and Impact Properties of Novel Henequen Fiber/Polyamide 6 Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Surface Treatment of Henequen Fiber

2.3. Processing of Henequen Fiber/PA6 Composites

2.4. Characterization

2.4.1. Fiber Surface Observation

2.4.2. Heat Deflection Temperature Measurement

2.4.3. Tensile Test

2.4.4. Flexural Test

2.4.5. Impact Test

3. Results and Discussion

3.1. Temperature Effect on the Surface Topography and the Property of Henequen Fiber

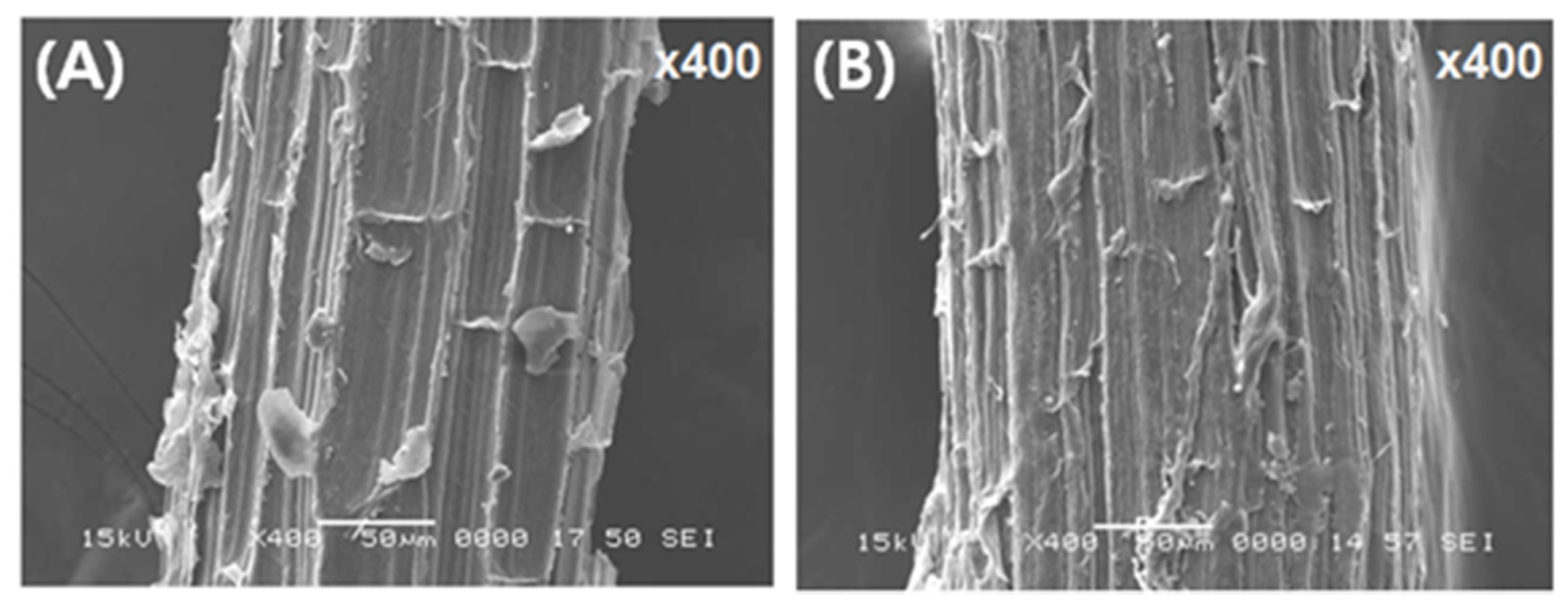

3.2. Alkali treatment Effect on the Henequen Fiber Surface Topography

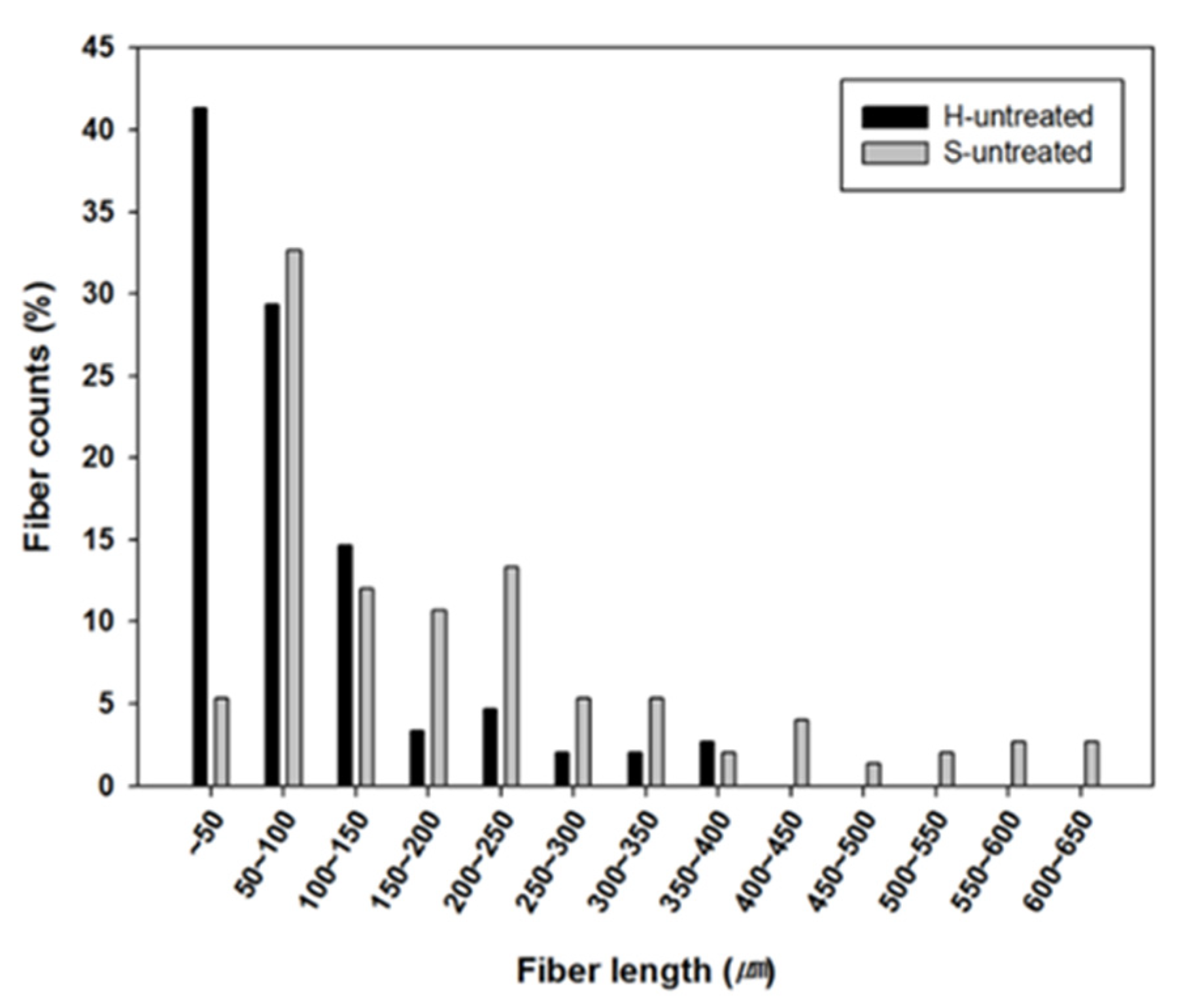

3.3. Henequen Fiber Length Distribution

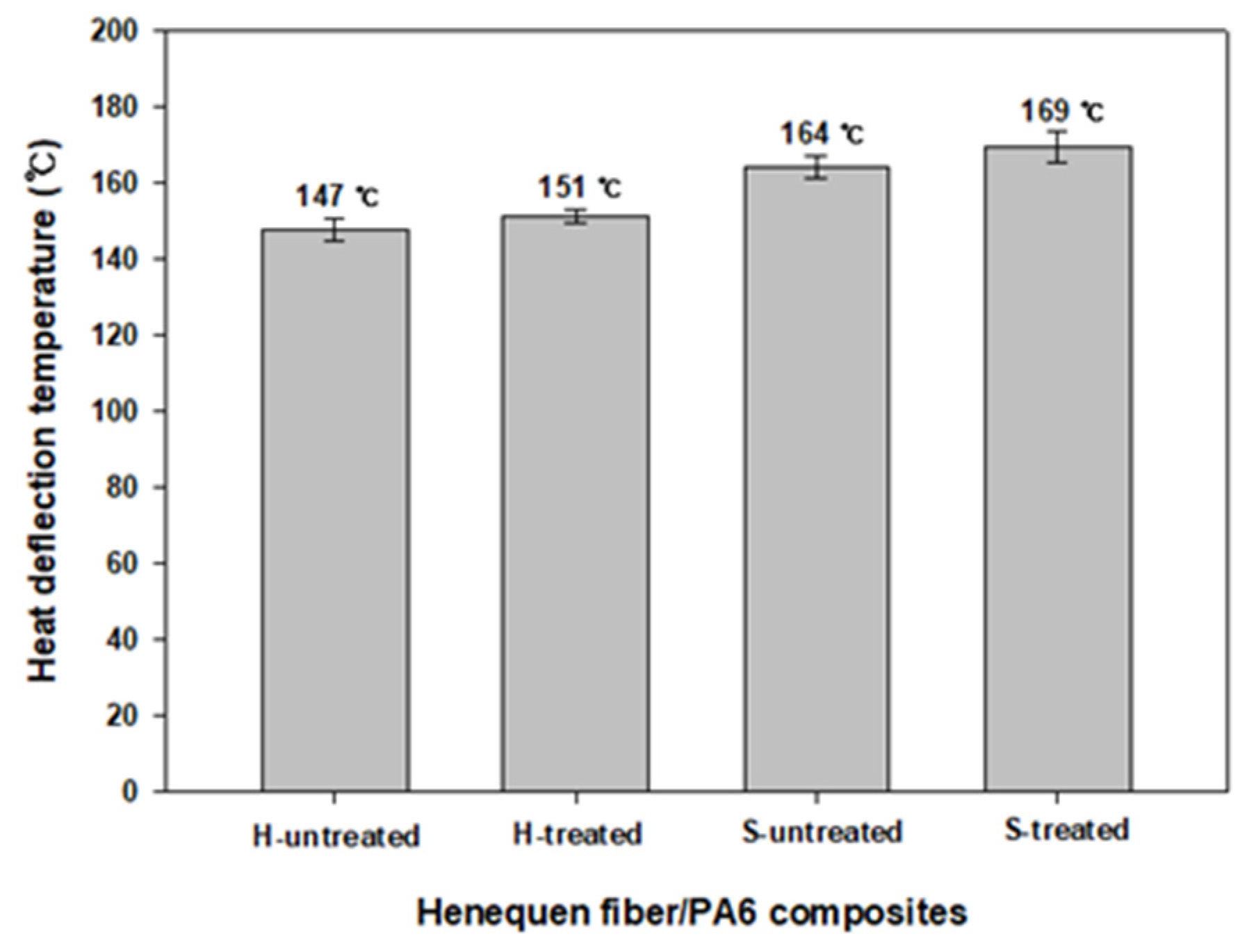

3.4. Heat Deflection Temperature

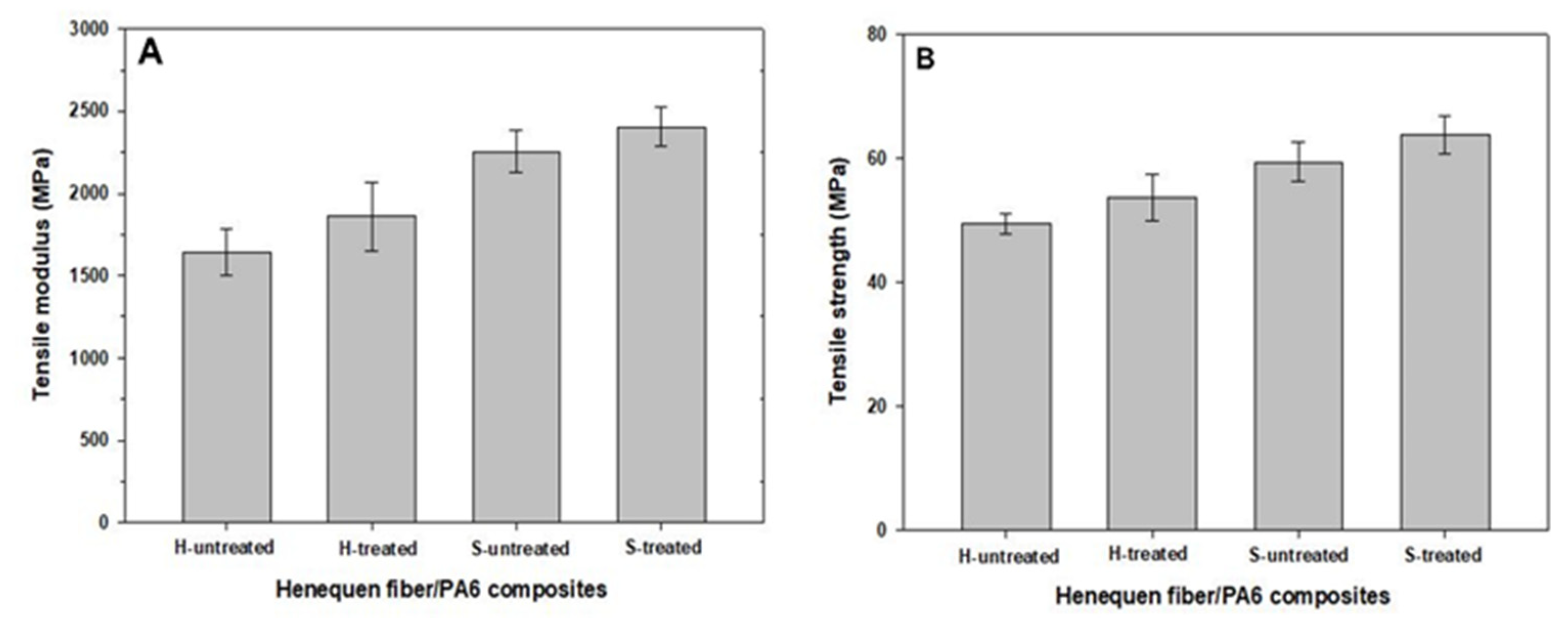

3.5. Tensile Properties

3.6. Flexural Properties

3.7. Izod Impact Strength

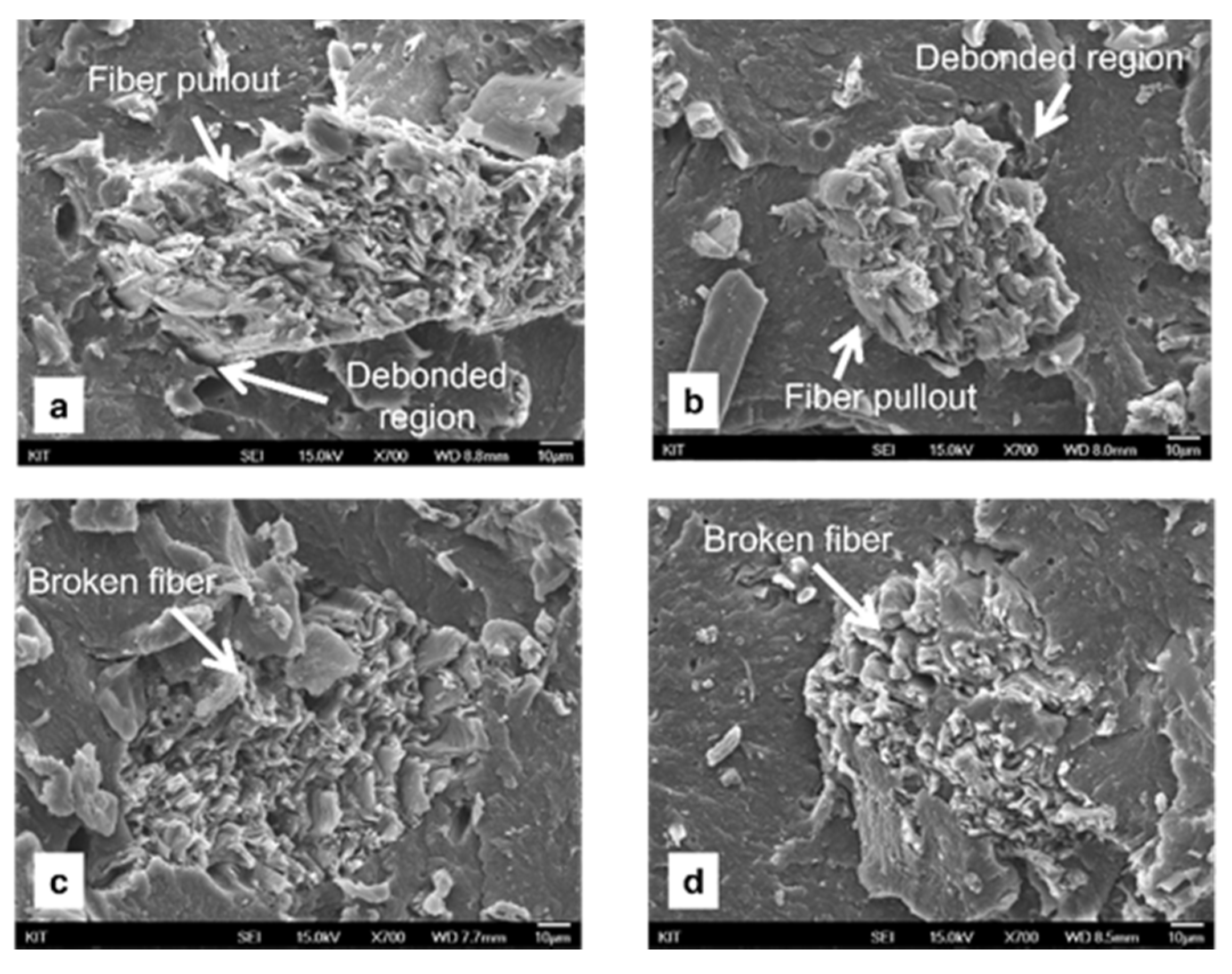

3.8. Fracture Surface Topography

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cho, D.; Lee, S.G.; Park, W.H.; Han, S.O. Eco-friendly biocomposite materials using biofibers. Polym. Sci. Technol. 2002, 46, 460–476. [Google Scholar]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A 2004, 35, 371–378. [Google Scholar] [CrossRef]

- Fisher, R. Natural fibers and green composites. Compos. Manufac. 2006, 3, 20–23. [Google Scholar]

- Cho, D.; Lee, H.S.; Han, S.O. Effect of fiber surface modification on the interfacial and mechanical properties of kenaf fiber-reinforced thermoplastic and thermosetting polymer composites. Compos. Interf. 2009, 16, 711–729. [Google Scholar] [CrossRef]

- Canche-Escamilla, G.; Rodriguez-Laviada, J.; Cauich-Cupul, J.I.; Mendizabal, E.; Puig, J.E.; Herrera-Franco, P.J. Flexural, impact and compressive properties of a rigid-thermoplastic matrix/cellulose fiber reinforced composites. Compos. Part A 2002, 33, 539–549. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-Gonzalez, A. Mechanical properties of continuous natural fibre reinforced polymer composites. Compos. Part A 2004, 35, 339–345. [Google Scholar] [CrossRef]

- Pang, Y.; Cho, D.; Han, S.O.; Park, W.H. Interfacial shear strength and thermal properties of electron beam-treated henequen fiber reinforced unsaturated polyester composites. Macromol. Res. 2005, 13, 453–459. [Google Scholar] [CrossRef]

- Cho, D.; Lee, H.S.; Han, S.O.; Drzal, L.T. Effects of e-beam treatment on the interfacial and mechanical properties of henequen/polypropylene biocomposites. Adv. Compos. Mater. 2007, 16, 315–334. [Google Scholar] [CrossRef]

- Bismarck, A.; Mishra, S.; Lampke, T. Plant fibers as reinforcement for green composites. In Natural Fibers, Biopolymers, and Biocomposites; Mohanty, A.K., Misra, M., Drzal, L.T., Eds.; Taylor and Francis: Boca Raton, FL, USA, 2005; pp. 37–108. [Google Scholar]

- Lee, S.; Shi, S.; Groom, L.H.; Xue, Y. Properties of unidirectional kenaf fiber-polyolefin laminates. Polym. Compos. 2010, 31, 1067–1074. [Google Scholar] [CrossRef]

- Kim, J.; Cho, D. Effects of waste expanded polypropylene as recycled matrix on the flexural, impact, and heat deflection temperature properties of kenaf fiber/polypropylene composites. Polymers 2020, 12, 2578. [Google Scholar] [CrossRef]

- Jung, S.; Cho, D. Effect of fiber feeding route upon extrusion process on the electromagnetic, mechanical, and thermal properties of nickel-coated carbon fiber/polypropylene composites. Compos. Part B 2020, 187, 107861. [Google Scholar] [CrossRef]

- Cho, D.; Kim, H.J.; Drzal, L.T. Surface treatment and characterization of natural fiber: Effects on the properties of biocomposites. In Polymer Composites Volume 3: Biocomposites; Thomas, S., Joseph, K., Malhotra, S.K., Goda, K., Sreekala, M.S., Eds.; Wiley-VCH Verlag GmbH & Co.: Weinhein, Germany, 2013; pp. 133–177. [Google Scholar]

- Lee, H.S.; Cho, D. Effect of natural fiber surface treatments on the interfacial and mechanical properties of henequen/polypropylene biocomposites. Macromol. Res. 2008, 16, 411–417. [Google Scholar] [CrossRef] [Green Version]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-González, A. Fiber-matrix adhesion in natural fiber composites. In Natural Fibers, Biopolymers, and Biocomposites; Mohanty, A.K., Misra, M., Drzal, L.T., Eds.; Taylor and Francis: Boca Raton, FL, USA, 2005; pp. 177–230. [Google Scholar]

- Nada, A.M.A.; Kamel, S.; Sakhawy, M.E. Thermal behaviour and infrared spectroscopy of cellulose carbamates. Polym. Degrad. Stab. 2000, 70, 347–355. [Google Scholar] [CrossRef]

- Cho, D.; Yoon, S.B.; Drzal, L.T. Cellulose-based natural fiber topography and the interfacial shear strength of henequen/unsaturated polyester composites: Influence of water and alkali treatments. Compos. Interf. 2009, 16, 769–779. [Google Scholar] [CrossRef]

- Asumani, O.M.L.; Reid, R.G.; Paskaramoorthy, R. The effects of alkali-silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos. Part A 2012, 43, 1431–1440. [Google Scholar] [CrossRef]

- Aziz, S.H.; Ansell, M.P. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: Part 1–polyester resin matrix. Compos. Sci. Technol. 2004, 64, 1219–1230. [Google Scholar] [CrossRef]

- Edeerozey, A.M.M.; Akil, H.M.; Azhar, A.B.; Ariffin, M.I.Z. Chemical modification of kenaf fibers. Mater. Lett. 2007, 61, 2023–2025. [Google Scholar] [CrossRef]

- Lee, S.M.; Cho, D.; Park, W.H.; Lee, S.G.; Han, S.O.; Drzal, L.T. Novel silk/poly (butylene succinate) biocomposites: The effect of short fiber content on their mechanical and thermal properties. Compos. Sci. Technol. 2005, 65, 647–657. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly (lactic acid) (PLA) and kenaf fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Ishiaku, U.S.; Yang, X.Y.; Leong, Y.W.; Hamada, H.; Semba, T.; Kitagawa, K. Effects of fiber content and alkali treatment on the mechanical and morphological properties of poly (lactic acid)/poly (carprolactone) blend jute fiber-filled biodegradable composites. J. Biobased Mater. Bioener. 2007, 1, 78–86. [Google Scholar] [CrossRef]

- Qin, L.; Qiu, J.; Liu, M.; Ding, S.; Shao, L.; Lu, S.; Zhang, G.; Zhao, Y.; Fu, X. Mechanical and thermal properties of poly(lactic acid) composites with rice straw fiber modified by poly (butyl acrylate). Chem. Eng. J. 2011, 166, 772–778. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties. J. Appl. Polym. Sci. 1997, 66, 821–835. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.S.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites-a review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Gassan, J.; Bledzki, A.K. Possibilities for improving the mechanical properties of jute/epoxy composites by alkali treatment of fibres. Compos. Sci. Technol. 1999, 59, 1303–1309. [Google Scholar] [CrossRef]

- Sreenivasan, S.; Bahama, I.P.; Krishnan, K.R.I. Influence of delignification and alkali treatment on the fine structure of coir fibres (Cocos Nucifera). J. Mater. Sci. 1996, 31, 721–726. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Cho, D. Effects of Alkali-Treatment and Feeding Route of Henequen Fiber on the Heat Deflection Temperature, Mechanical, and Impact Properties of Novel Henequen Fiber/Polyamide 6 Composites. J. Compos. Sci. 2022, 6, 89. https://doi.org/10.3390/jcs6030089

Kim J, Cho D. Effects of Alkali-Treatment and Feeding Route of Henequen Fiber on the Heat Deflection Temperature, Mechanical, and Impact Properties of Novel Henequen Fiber/Polyamide 6 Composites. Journal of Composites Science. 2022; 6(3):89. https://doi.org/10.3390/jcs6030089

Chicago/Turabian StyleKim, Jeonghoon, and Donghwan Cho. 2022. "Effects of Alkali-Treatment and Feeding Route of Henequen Fiber on the Heat Deflection Temperature, Mechanical, and Impact Properties of Novel Henequen Fiber/Polyamide 6 Composites" Journal of Composites Science 6, no. 3: 89. https://doi.org/10.3390/jcs6030089