Conducting Polymer Nanocomposites for Electromagnetic Interference Shielding—Radical Developments

Abstract

:1. Introduction

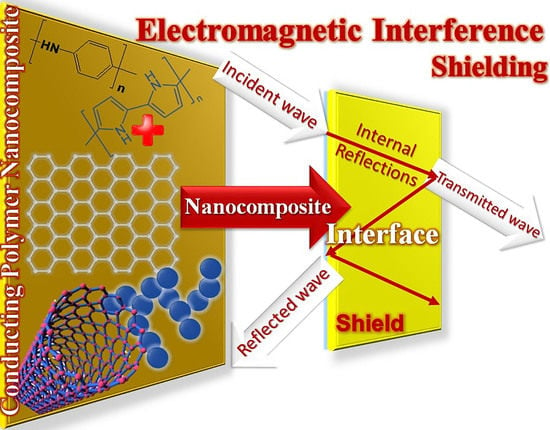

2. EMI Shielding

3. Conducting Polymers in EMI Shielding

4. Conducting Polymer Nanocomposites in EMI Shielding

5. Future Forecasts

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chandra, R.J.; Shivamurthy, B.; Kumar, M.S.; Prabhu, N.N.; Sharma, D. Mechanical and Electrical Properties and Electromagnetic-Wave-Shielding Effectiveness of Graphene-Nanoplatelet-Reinforced Acrylonitrile Butadiene Styrene Nanocomposites. J. Compos. Sci. 2023, 7, 117. [Google Scholar] [CrossRef]

- Akram, S.; Ashraf, M.; Javid, A.; Abid, H.A.; Ahmad, S.; Nawab, Y.; Rasheed, A.; Xue, Z.; Nosheen, A. Recent advances in electromagnetic interference (EMI) shielding textiles: A comprehensive review. Synth. Met. 2023, 294, 117305. [Google Scholar] [CrossRef]

- Kallambadi Sadashivappa, P.; Venkatachalam, R.; Pothu, R.; Boddula, R.; Banerjee, P.; Naik, R.; Radwan, A.B.; Al-Qahtani, N. Progressive Review of Functional Nanomaterials-Based Polymer Nanocomposites for Efficient EMI Shielding. J. Compos. Sci. 2023, 7, 77. [Google Scholar] [CrossRef]

- Mudhar, R.; Mucolli, A.; Ford, J.; Lira, C.; Yazdani Nezhad, H. Electrical and Magnetic Properties of 3D Printed Integrated Conductive Biodegradable Polymer Nanocomposites for Sustainable Electronics Development. J. Compos. Sci. 2022, 6, 345. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F. A review on recent advancement of electromagnetic interference shielding novel metallic materials and processes. Compos. Part B Eng. 2019, 176, 107207. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Cao, M. Confinedly implanted NiFe2O4-rGO: Cluster tailoring and highly tunable electromagnetic properties for selective-frequency microwave absorption. Nano Res. 2018, 11, 1426–1436. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.; Wang, J.; Wang, S.; Ma, X.; Huang, J.; Zhao, G.; Liu, Y. Facile preparation of multiscale graphene-basalt fiber reinforcements and their enhanced mechanical and tribological properties for polyamide 6 composites. Mater. Chem. Phys. 2018, 217, 315–322. [Google Scholar] [CrossRef]

- Yang, Z.; Hao, X.; Chen, S.; Ma, Z.; Wang, W.; Wang, C.; Yue, L.; Sun, H.; Shao, Q.; Murugadoss, V. Long-term antibacterial stable reduced graphene oxide nanocomposites loaded with cuprous oxide nanoparticles. J. Colloid Interface Sci. 2019, 533, 13–23. [Google Scholar] [CrossRef]

- Wang, C.; Murugadoss, V.; Kong, J.; He, Z.; Mai, X.; Shao, Q.; Chen, Y.; Guo, L.; Liu, C.; Angaiah, S. Overview of carbon nanostructures and nanocomposites for electromagnetic wave shielding. Carbon 2018, 140, 696–733. [Google Scholar] [CrossRef]

- Jiang, D.; Murugadoss, V.; Wang, Y.; Lin, J.; Ding, T.; Wang, Z.; Shao, Q.; Wang, C.; Liu, H.; Lu, N. Electromagnetic interference shielding polymers and nanocomposites—A review. Polym. Rev. 2019, 59, 280–337. [Google Scholar] [CrossRef]

- Kargar, F.; Barani, Z.; Balinskiy, M.; Magana, A.S.; Lewis, J.S.; Balandin, A.A. Dual-functional graphene composites for electromagnetic shielding and thermal management. Adv. Electron. Mater. 2019, 5, 1800558. [Google Scholar] [CrossRef] [Green Version]

- Shen, Q.; Li, H.; Lin, H.; Li, L.; Li, W.; Song, Q. Simultaneously improving the mechanical strength and electromagnetic interference shielding of carbon/carbon composites by electrophoretic deposition of SiC nanowires. J. Mater. Chem. C 2018, 6, 5888–5899. [Google Scholar] [CrossRef]

- Wu, H.-Y.; Zhang, Y.-P.; Jia, L.-C.; Yan, D.-X.; Gao, J.-F.; Li, Z.-M. Injection molded segregated carbon nanotube/polypropylene composite for efficient electromagnetic interference shielding. Ind. Eng. Chem. Res. 2018, 57, 12378–12385. [Google Scholar] [CrossRef]

- Jia, L.-C.; Yan, D.-X.; Jiang, X.; Pang, H.; Gao, J.-F.; Ren, P.-G.; Li, Z.-M. Synergistic effect of graphite and carbon nanotubes on improved electromagnetic interference shielding performance in segregated composites. Ind. Eng. Chem. Res. 2018, 57, 11929–11938. [Google Scholar] [CrossRef]

- Kaczor-Urbanowicz, K.E.; Martín Carreras-Presas, C.; Kaczor, T.; Tu, M.; Wei, F.; Garcia-Godoy, F.; Wong, D.T. Emerging technologies for salivaomics in cancer detection. J. Cell. Mol. Med. 2017, 21, 640–647. [Google Scholar] [CrossRef]

- Glyva, V.; Kovalenko, V.; Levchenko, L.; Tykhenko, O. Research into protective properties of electromagnetic screens based on the metal-containing nanostructures. East.-Eur. J. Enterp. Technol. 2017, 3, 50–56. [Google Scholar] [CrossRef] [Green Version]

- González, M.; Pozuelo, J.; Baselga, J. Electromagnetic shielding materials in GHz range. Chem. Rec. 2018, 18, 1000–1009. [Google Scholar] [CrossRef]

- Gupta, S.; Sharma, S.K.; Pradhan, D.; Tai, N.-H. Ultra-light 3D reduced graphene oxide aerogels decorated with cobalt ferrite and zinc oxide perform excellent electromagnetic interference shielding effectiveness. Compos. Part A Appl. Sci. Manuf. 2019, 123, 232–241. [Google Scholar] [CrossRef]

- Jia, Y.; Li, K.; Xue, L.; Ren, J.; Zhang, S.; Li, H. Mechanical and electromagnetic shielding performance of carbon fiber reinforced multilayered (PyC-SiC) n matrix composites. Carbon 2017, 111, 299–308. [Google Scholar] [CrossRef]

- Bheema, R.K.; Etika, K.C. The influence of hybrid decorated structures on the EMI shielding properties of epoxy composites over the X-Band. Mater. Today Proc. 2023, 76, 398–402. [Google Scholar] [CrossRef]

- David, D.A.; Jabeen Fatima, M.; Khan, A.; Joy, R.; Thakur, V.K.; Ruiz-Rosas, R.R.; Ozden, S.; Raghavan, P. Porous Carbon Materials and Their Composites for Electromagnetic Interference (EMI) Shielding: The State-of-the-Art of Technologies. In Handbook of Porous Carbon Materials; Springer: Berlin/Heidelberg, Germany, 2023; pp. 669–702. [Google Scholar]

- Gebrekrstos, A.; Ray, S.S. Superior electrical conductivity and mechanical properties of phase-separated polymer blend composites by tuning the localization of nanoparticles for electromagnetic interference shielding applications. J. Polym. Sci. 2023. [Google Scholar] [CrossRef]

- Voicu, V.; Pătru, I.; Dina, L.-A.; Nicolae, P.-M.; Smărăndescu, I.D. Shielding effectiveness evaluation using a non-standardized method. In Proceedings of the 2017 International Conference on Electromechanical and Power Systems (SIELMEN), Iasi, Romania, 11–13 October 2017; pp. 208–211. [Google Scholar]

- Kashi, S.; Gupta, R.K.; Baum, T.; Kao, N.; Bhattacharya, S.N. Morphology, electromagnetic properties and electromagnetic interference shielding performance of poly lactide/graphene nanoplatelet nanocomposites. Mater. Des. 2016, 95, 119–126. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.-J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Munalli, D.; Dimitrakis, G.; Chronopoulos, D.; Greedy, S.; Long, A. Electromagnetic shielding effectiveness of carbon fibre reinforced composites. Compos. Part B Eng. 2019, 173, 106906. [Google Scholar] [CrossRef]

- Khalid, T.; Albasha, L.; Qaddoumi, N.; Yehia, S. Feasibility study of using electrically conductive concrete for electromagnetic shielding applications as a substitute for carbon-laced polyurethane absorbers in anechoic chambers. IEEE Trans. Antennas Propag. 2017, 65, 2428–2435. [Google Scholar] [CrossRef]

- Kausar, A. Thermally conducting polymer/nanocarbon and polymer/inorganic nanoparticle nanocomposite: A review. Polym.-Plast. Technol. Mater. 2020, 59, 895–909. [Google Scholar] [CrossRef]

- Wiroonpochit, P.; Keawmaungkom, S.; Chisti, Y.; Hansupalak, N. A novel preparation of natural rubber films with a conducting nanocarbon network for antistatic applications. Mater. Today Commun. 2023, 34, 105349. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Electromagnetic interference shielding mechanisms of CNT/polymer composites. Carbon 2009, 47, 1738–1746. [Google Scholar] [CrossRef]

- Jalali, A.; Zhang, R.; Rahmati, R.; Nofar, M.; Sain, M.; Park, C.B. Recent progress and perspective in additive manufacturing of EMI shielding functional polymer nanocomposites. Nano Res. 2023, 16, 1–17. [Google Scholar] [CrossRef]

- Rayar, A.; Naveen, C.; Onkarappa, H.; Betageri, V.S.; Prasanna, G. EMI shielding applications of PANI-Ferrite nanocomposite materials: A review. Synth. Met. 2023, 295, 117338. [Google Scholar] [CrossRef]

- Idumah, C.I. Recent advancements in electromagnetic interference shielding of polymer and mxene nanocomposites. Polym.-Plast. Technol. Mater. 2023, 62, 19–53. [Google Scholar] [CrossRef]

- Kausar, A. Epitome of Fullerene in Conducting Polymeric Nanocomposite—Fundamentals and Beyond. Polym.-Plast. Technol. Mater. 2023, 62, 618–631. [Google Scholar] [CrossRef]

- Luo, J.; Wang, L.; Huang, X.; Li, B.; Guo, Z.; Song, X.; Lin, L.; Tang, L.-C.; Xue, H.; Gao, J. Mechanically durable, highly conductive, and anticorrosive composite fabrics with excellent self-cleaning performance for high-efficiency electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2019, 11, 10883–10894. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Jia, Z.; Feng, A.; Wang, X.; Liu, J.; Zhang, M.; Cao, H.; Wu, G. Synthesis of fish skin-derived 3D carbon foams with broadened bandwidth and excellent electromagnetic wave absorption performance. Carbon 2019, 152, 827–836. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, X.; Geng, L.; Liu, Z.; Zhang, X.; Li, C.; Zhang, D.; Wang, Z.; Zhao, G. Metallic Ni nanoparticles embedded in hierarchical mesoporous Ni(OH)2: A robust and magnetic recyclable catalyst for hydrogenation of 4-nitrophenol under mild conditions. Polyhedron 2019, 164, 7–12. [Google Scholar] [CrossRef]

- Banerjee, R.; Gebrekrstos, A.; Orasugh, J.T.; Ray, S.S. Nanocarbon-Containing Polymer Composite Foams: A Review of Systems for Applications in Electromagnetic Interference Shielding, Energy Storage, and Piezoresistive Sensors. Ind. Eng. Chem. Res. 2023, 62, 6807–6842. [Google Scholar] [CrossRef]

- Stunder, D.; Seckler, T.; Joosten, S.; Zink, M.D.; Driessen, S.; Kraus, T.; Marx, N.; Napp, A. In vivo study of electromagnetic interference with pacemakers caused by everyday electric and magnetic fields. Circulation 2017, 135, 907–909. [Google Scholar] [CrossRef]

- Lee, S.H.; Yu, S.; Shahzad, F.; Hong, J.; Noh, S.J.; Kim, W.N.; Hong, S.M.; Koo, C.M. Low percolation 3D Cu and Ag shell network composites for EMI shielding and thermal conduction. Compos. Sci. Technol. 2019, 182, 107778. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Gao, X.; Xu, D. A review of the interfacial characteristics of polymer nanocomposites containing carbon nanotubes. RSC Adv. 2018, 8, 28048–28085. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Peng, W.-J.; Fu, Z.-J.; Tang, X.-H.; Wu, H.; Guo, S.; Wang, M. Achieving high electrical conductivity and excellent electromagnetic interference shielding in poly (lactic acid)/silver nanocomposites by constructing large-area silver nanoplates in polymer matrix. Compos. Part B Eng. 2019, 171, 204–213. [Google Scholar] [CrossRef]

- Saini, M.; Shukla, R. Silver nanoparticles-decorated NiFe2O4/polyaniline ternary nanocomposite for electromagnetic interference shielding. J. Mater. Sci. Mater. Electron. 2020, 31, 5152–5164. [Google Scholar] [CrossRef]

- Singh, B.; Choudhary, V.; Saini, P.; Pande, S.; Singh, V.; Mathur, R. Enhanced microwave shielding and mechanical properties of high loading MWCNT–epoxy composites. J. Nanoparticle Res. 2013, 15, 1554. [Google Scholar] [CrossRef]

- Yu, F.; Deng, H.; Zhang, Q.; Wang, K.; Zhang, C.; Chen, F.; Fu, Q. Anisotropic multilayer conductive networks in carbon nanotubes filled polyethylene/polypropylene blends obtained through high speed thin wall injection molding. Polymer 2013, 54, 6425–6436. [Google Scholar] [CrossRef]

- He, Q.; Yuan, T.; Zhang, X.; Yan, X.; Guo, J.; Ding, D.; Khan, M.A.; Young, D.P.; Khasanov, A.; Luo, Z. Electromagnetic field absorbing polypropylene nanocomposites with tuned permittivity and permeability by nanoiron and carbon nanotubes. J. Phys. Chem. C 2014, 118, 24784–24796. [Google Scholar] [CrossRef]

- Jan, R.; Khan, M.B.; Khan, Z.M. Synthesis and electrical characterization of “carbon particles reinforced epoxy-nanocomposite” in Ku-band. Mater. Lett. 2012, 70, 155–159. [Google Scholar] [CrossRef]

- Wei, W.; Yue, X.; Zhou, Y.; Chen, Z.; Fang, J.; Gao, C.; Jiang, Z. New promising hybrid materials for electromagnetic interference shielding with improved stability and mechanical properties. Phys. Chem. Chem. Phys. 2013, 15, 21043–21050. [Google Scholar] [CrossRef]

- Yazdi, M.K.; Noorbakhsh, B.; Nazari, B.; Ranjbar, Z. Preparation and EMI shielding performance of epoxy/non-metallic conductive fillers nano-composites. Prog. Org. Coat. 2020, 145, 105674. [Google Scholar] [CrossRef]

- Tantawy, H.R.; Aston, D.E.; Smith, J.R.; Young, J.L. Comparison of electromagnetic shielding with polyaniline nanopowders produced in solvent-limited conditions. ACS Appl. Mater. Interfaces 2013, 5, 4648–4658. [Google Scholar] [CrossRef]

- Bhadra, S.; Singha, N.K.; Khastgir, D. Dielectric properties and EMI shielding efficiency of polyaniline and ethylene 1-octene based semi-conducting composites. Curr. Appl. Phys. 2009, 9, 396–403. [Google Scholar] [CrossRef]

- Mäkelä, T.; Pienimaa, S.; Taka, T.; Jussila, S.; Isotalo, H. Thin polyaniline films in EMI shielding. Synth. Met. 1997, 85, 1335–1336. [Google Scholar] [CrossRef]

- Wang, X.-X.; Zheng, Q.; Zheng, Y.-J.; Cao, M.-S. Green EMI shielding: Dielectric/magnetic “genes” and design philosophy. Carbon 2023, 206, 124–141. [Google Scholar] [CrossRef]

- Yao, L.; Wang, Y.; Zhao, J.; Zhu, Y.; Cao, M. Multifunctional Nanocrystalline-Assembled Porous Hierarchical Material and Device for Integrating Microwave Absorption, Electromagnetic Interference Shielding, and Energy Storage. Small 2023, 2208101. [Google Scholar] [CrossRef]

- He, W.; Li, J.; Tian, J.; Jing, H.; Li, Y. Characteristics and properties of wood/polyaniline electromagnetic shielding composites synthesized via in situ polymerization. Polym. Compos. 2018, 39, 537–543. [Google Scholar] [CrossRef]

- Kim, B.R.; Lee, H.-K.; Park, S.; Kim, H.-K. Electromagnetic interference shielding characteristics and shielding effectiveness of polyaniline-coated films. Thin Solid Film. 2011, 519, 3492–3496. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, T.; Yang, Z. Flexible polyethylene terephthalate/polyaniline composite paper with bending durability and effective electromagnetic shielding performance. Chem. Eng. J. 2020, 389, 124433. [Google Scholar] [CrossRef]

- Oh, H.-J.; Dao, V.-D.; Choi, H.-S. Electromagnetic shielding effectiveness of a thin silver layer deposited onto PET film via atmospheric pressure plasma reduction. Appl. Surf. Sci. 2018, 435, 7–15. [Google Scholar] [CrossRef]

- Bhardwaj, P.; Kaushik, S.; Gairola, P.; Gairola, S. Exceptional electromagnetic radiation shielding performance and dielectric properties of surfactant assisted polypyrrole-carbon allotropes composites. Radiat. Phys. Chem. 2018, 151, 156–163. [Google Scholar] [CrossRef]

- Raina, N.; Sharma, P.; Slathia, P.S.; Bhagat, D.; Pathak, A.K. Efficiency Enhancement of Renewable Energy Systems Using Nanotechnology. In Nanomaterials and Environmental Biotechnology; Springer: Berlin/Heidelberg, Germany, 2020; pp. 271–297. [Google Scholar]

- Sastry, D.N.; Revanasiddappa, M.; Suresh, T.; Kiran, Y.R.; Raghavendra, S. Electromagnetic shielding effectiveness studies on polyaniline/CSA-WO3 composites at KU band frequencies. AIP Conf. Proc. 2018, 1953, 090067. [Google Scholar]

- Vargas-Bernal, R. Mechanisms of Electrical Conductivity in Carbon Nanotubes and Graphene. In Encyclopedia of Information Science and Technology, 4th ed.; IGI Global: Hershey, PA, USA, 2018; pp. 2673–2684. [Google Scholar]

- Yao, Y.; Jin, S.; Zou, H.; Li, L.; Ma, X.; Lv, G.; Gao, F.; Lv, X.; Shu, Q. Polymer-based lightweight materials for electromagnetic interference shielding: A review. J. Mater. Sci. 2021, 56, 6549–6580. [Google Scholar] [CrossRef]

- Wan, Y.; Li, J.; Yang, Z.; Ao, H.; Xiong, L.; Luo, H. Simultaneously depositing polyaniline onto bacterial cellulose nanofibers and graphene nanosheets toward electrically conductive nanocomposites. Curr. Appl. Phys. 2018, 18, 933–940. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, E.; Yang, J.; Zhou, P.; Sun, D.; Tang, W. Bacterial cellulose nanofiber-supported polyaniline nanocomposites with flake-shaped morphology as supercapacitor electrodes. J. Phys. Chem. C 2012, 116, 13013–13019. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, P.; Gupta, R.; Verma, V. Electromagnetic interference shielding behaviors of in-situ polymerized ferrite-polyaniline nano-composites and ferrite-polyaniline deposited fabrics in X-band frequency range. J. Alloy. Compd. 2021, 862, 158331. [Google Scholar] [CrossRef]

- Lee, C.; Song, H.; Jang, K.; Oh, E.; Epstein, A.; Joo, J. Electromagnetic interference shielding efficiency of polyaniline mixtures and multilayer films. Synth. Met. 1999, 102, 1346–1349. [Google Scholar] [CrossRef]

- Pineda, E.G.; Azpeitia, L.; Presa, M.R.; Bolzán, A.; Gervasi, C. Benchmarking electrodes modified with bi-doped polypyrrole for sensing applications. Electrochim. Acta 2023, 444, 142011. [Google Scholar] [CrossRef]

- Gahlout, P.; Choudhary, V. Tailoring of polypyrrole backbone by optimizing synthesis parameters for efficient EMI shielding properties in X-band (8.2–12.4 GHz). Synth. Met. 2016, 222, 170–179. [Google Scholar] [CrossRef]

- Jani, R.K.; Patra, M.K.; Saini, L.; Shukla, A.; Singh, C.P.; Vadera, S.R. Tuning of Microwave Absorption Properties and Electromagnetic Interference (EMI) Shielding Effectiveness of Nanosize Conducting Black-Silicone Rubber Composites over 8–18 GHz. Prog. Electromagn. Res. 2017, 58, 193–204. [Google Scholar] [CrossRef] [Green Version]

- Kulkarni, G.; Kandesar, P.; Velhal, N.; Phadtare, V.; Jatratkar, A.; Shinde, S.; Kim, D.-Y.; Puri, V. Exceptional electromagnetic interference shielding and microwave absorption properties of room temperature synthesized polythiophene thin films with double negative characteristics (DNG) in the Ku-band region. Chem. Eng. J. 2019, 355, 196–207. [Google Scholar] [CrossRef]

- Ghosh, S.; Remanan, S.; Mondal, S.; Ganguly, S.; Das, P.; Singha, N.; Das, N.C. An approach to prepare mechanically robust full IPN strengthened conductive cotton fabric for high strain tolerant electromagnetic interference shielding. Chem. Eng. J. 2018, 344, 138–154. [Google Scholar] [CrossRef]

- Rawat, N.K.; Panda, P. Microwave Synthesized Conducting Polymer-Based Green Nanocomposites as Smart Promising Materials. In Integrating Green Chemistry and Sustainable Engineering; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2019; pp. 191–214. [Google Scholar]

- Rawat, N.K.; Khatoon, H.; Kahtun, S.; Ahmad, S. Conducting polyborozirconia (o-toluidine) nanostructures: Effect of boron and zirconia doping on synthesis, characterization and their corrosion protective performance. Compos. Commun. 2019, 16, 143–149. [Google Scholar] [CrossRef]

- Boroyevich, D.; Zhang, X.; Bishinoi, H.; Burgos, R.; Mattavelli, P.; Wang, F. Conducted EMI and systems integration. In Proceedings of the CIPS 2014, 8th International Conference on Integrated Power Electronics Systems, Nuremberg, Germany, 25–27 February 2014; pp. 1–14. [Google Scholar]

- Bhattacharjee, Y.; Arief, I.; Bose, S. Recent trends in multi-layered architectures towards screening electromagnetic radiation: Challenges and perspectives. J. Mater. Chem. C 2017, 5, 7390–7403. [Google Scholar] [CrossRef]

- Xu, W.; Wang, G.-S.; Yin, P.-G. Designed fabrication of reduced graphene oxides/Ni hybrids for effective electromagnetic absorption and shielding. Carbon 2018, 139, 759–767. [Google Scholar] [CrossRef]

- Marka, S.K.; Sindam, B.; Raju, K.J.; Srikanth, V.V. Flexible few-layered graphene/poly vinyl alcohol composite sheets: Synthesis, characterization and EMI shielding in X-band through the absorption mechanism. RSC Adv. 2015, 5, 36498–36506. [Google Scholar] [CrossRef]

- Patel, C.R.P.; Tripathi, P.; Singh, S.; Singh, A.P.; Dhawan, S.; Kotnala, R.; Gupta, B.K.; Srivastava, O. New emerging radially aligned carbon nano tubes comprised carbon hollow cylinder as an excellent absorber for electromagnetic environmental pollution. J. Mater. Chem. C 2016, 4, 5483–5490. [Google Scholar] [CrossRef]

- Ameli, A.; Jung, P.; Park, C. Electrical properties and electromagnetic interference shielding effectiveness of polypropylene/carbon fiber composite foams. Carbon 2013, 60, 379–391. [Google Scholar] [CrossRef]

- Xia, X.; Wang, Y.; Zhong, Z.; Weng, G.J. A theory of electrical conductivity, dielectric constant, and electromagnetic interference shielding for lightweight graphene composite foams. J. Appl. Phys. 2016, 120, 085102. [Google Scholar] [CrossRef]

- Chen, Y.-J.; Li, Y.; Chu, B.; Kuo, I.-T.; Yip, M.; Tai, N. Porous composites coated with hybrid nano carbon materials perform excellent electromagnetic interference shielding. Compos. Part B Eng. 2015, 70, 231–237. [Google Scholar] [CrossRef]

- Banerjee, S.; Sharma, R.; Kar, K.K. Nanocomposites Based on Carbon Nanomaterials and Electronically Nonconducting Polymers. In Composite Materials; Springer: Berlin/Heidelberg, Germany, 2017; pp. 251–280. [Google Scholar]

- Tofighy, M.A.; Mohammadi, T. Barrier, Diffusion, and Transport Properties of Rubber Nanocomposites Containing Carbon Nanofillers. In Carbon-Based Nanofiller and Their Rubber Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 253–285. [Google Scholar]

- Nagornaya, M.; Razdyakonova, G.; Khodakova, S.Y. The effect of functional groups of carbon black on rubber properties. Procedia Eng. 2016, 152, 563–569. [Google Scholar] [CrossRef] [Green Version]

- Marquis, D.M.; Guillaume, E.; Chivas-Joly, C. Properties of nanofillers in polymer. In Nanocomposites and Polymers with Analytical Methods; IntechOpen: London, UK, 2011. [Google Scholar]

- Jia, L.-C.; Zhang, G.; Xu, L.; Sun, W.-J.; Zhong, G.-J.; Lei, J.; Yan, D.-X.; Li, Z.-M. Robustly superhydrophobic conductive textile for efficient electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2018, 11, 1680–1688. [Google Scholar] [CrossRef]

- Yue, L.; Jayapal, M.; Cheng, X.; Zhang, T.; Chen, J.; Ma, X.; Dai, X.; Lu, H.; Guan, R.; Zhang, W. Highly dispersed ultra-small nano Sn-SnSb nanoparticles anchored on N-doped graphene sheets as high performance anode for sodium ion batteries. Appl. Surf. Sci. 2020, 512, 145686. [Google Scholar] [CrossRef]

- Zhang, L.; Bi, S.; Liu, M. Lightweight electromagnetic interference shielding materials and their mechanisms. In Electromagnetic Materials and Devices; IntechOpen: London, UK, 2018; pp. 1–10. [Google Scholar]

- Fang, Q.; Lafdi, K. Effect of nanofiller morphology on the electrical conductivity of polymer nanocomposites. Nano Express 2021, 2, 010019. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, S.; Salman, S.M. Effectiveness of polystyrene/carbon nanotube composite in electromagnetic interference shielding materials: A review. Polym.-Plast. Technol. Eng. 2017, 56, 1027–1042. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, J.; Haldolaarachchige, N.; Ryu, J.; Young, D.P.; Wei, S.; Guo, Z. Synthetic process engineered polyaniline nanostructures with tunable morphology and physical properties. Polymer 2012, 53, 2109–2120. [Google Scholar] [CrossRef]

- Youssef, A.; Mohamed, S.; Abdel-Aziz, M.; Abdel-Aziz, M.; Turky, G.; Kamel, S. Biological studies and electrical conductivity of paper sheet based on PANI/PS/Ag-NPs nanocomposite. Carbohydr. Polym. 2016, 147, 333–343. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, P.; Kaushik, S.; Gairola, P.; Gairola, S. Designing of nickel cobalt molybdate/multiwalled carbon nanotube composites for suppression of electromagnetic radiation. SN Appl. Sci. 2019, 1, 113. [Google Scholar] [CrossRef] [Green Version]

- Joshi, A.; Bajaj, A.; Singh, R.; Anand, A.; Alegaonkar, P.; Datar, S. Processing of graphene nanoribbon based hybrid composite for electromagnetic shielding. Compos. Part B Eng. 2015, 69, 472–477. [Google Scholar] [CrossRef]

- Modak, P.; Kondawar, S.B.; Nandanwar, D. Synthesis and characterization of conducting polyaniline/graphene nanocomposites for electromagnetic interference shielding. Procedia Mater. Sci. 2015, 10, 588–594. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.; Wang, T.; Wen, B.; Lu, M.; Xu, Z.; Zhu, C.; Chen, Y.; Xue, X.; Sun, C.; Cao, M. Graphene/polyaniline nanorod arrays: Synthesis and excellent electromagnetic absorption properties. J. Mater. Chem. 2012, 22, 21679–21685. [Google Scholar] [CrossRef]

- Gyergyek, S.; Pahovnik, D.; Žagar, E.; Mertelj, A.; Beković, M.; Jagodič, M.; Hofmann, H.; Makovec, D. Nanocomposites comprised of homogeneously dispersed magnetic iron-oxide nanoparticles and poly (methyl methacrylate). Beilstein J. Nanotechnol. 2018, 9, 1613–1622. [Google Scholar] [CrossRef]

- Biswas, S.; Panja, S.S.; Bose, S. Tailored distribution of nanoparticles in bi-phasic polymeric blends as emerging materials for suppressing electromagnetic radiation: Challenges and prospects. J. Mater. Chem. C 2018, 6, 3120–3142. [Google Scholar] [CrossRef]

- Pal, R.; Goyal, S.L.; Rawal, I. Lightweight graphene encapsulated with polyaniline for excellent electromagnetic shielding performance in X-band (8.2–12.4 GHz). Mater. Sci. Eng. B 2021, 270, 115227. [Google Scholar] [CrossRef]

- Khasim, S. Polyaniline-Graphene nanoplatelet composite films with improved conductivity for high performance X-band microwave shielding applications. Results Phys. 2019, 12, 1073–1081. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiu, M.; Yu, Y.; Wen, B.; Cheng, L. A novel polyaniline-coated bagasse fiber composite with core–shell heterostructure provides effective electromagnetic shielding performance. ACS Appl. Mater. Interfaces 2017, 9, 809–818. [Google Scholar] [CrossRef] [PubMed]

- Saini, P.; Choudhary, V.; Singh, B.; Mathur, R.; Dhawan, S. Polyaniline–MWCNT nanocomposites for microwave absorption and EMI shielding. Mater. Chem. Phys. 2009, 113, 919–926. [Google Scholar] [CrossRef]

- Sundara, R.; Srinivasan, S.K. Nerve Guide Conduit Containing Carbon Nanotubes. U.S. Patent US9327054B2, 3 May 2016. [Google Scholar]

- Mei, J.F.; Jia, X.Y.; Lai, J.C.; Sun, Y.; Li, C.H.; Wu, J.H.; Cao, Y.; You, X.Z.; Bao, Z. A highly stretchable and autonomous self-healing polymer based on combination of Pt··· Pt and π–π interactions. Macromol. Rapid Commun. 2016, 37, 1667–1675. [Google Scholar] [CrossRef] [PubMed]

- Gu, H.; Guo, J.; He, Q.; Jiang, Y.; Huang, Y.; Haldolaarachige, N.; Luo, Z.; Young, D.P.; Wei, S.; Guo, Z. Magnetoresistive polyaniline/multi-walled carbon nanotube nanocomposites with negative permittivity. Nanoscale 2014, 6, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Hu, W. The physics of polymer chain-folding. Phys. Rep. 2018, 747, 1–50. [Google Scholar] [CrossRef]

- Yun, J.; Kim, H.-I. Electromagnetic interference shielding effects of polyaniline-coated multi-wall carbon nanotubes/maghemite nanocomposites. Polym. Bull. 2012, 68, 561–573. [Google Scholar] [CrossRef]

- Fagbayigbo, B.; Opeolu, B.; Fatoki, O. Adsorption of perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS) from water using leaf biomass (Vitis vinifera) in a fixed-bed column study. J. Environ. Health Sci. Eng. 2020, 18, 221–233. [Google Scholar] [CrossRef]

- Saini, P.; Choudhary, V.; Singh, B.; Mathur, R.; Dhawan, S. Enhanced microwave absorption behavior of polyaniline-CNT/polystyrene blend in 12.4–18.0 GHz range. Synth. Met. 2011, 161, 1522–1526. [Google Scholar] [CrossRef]

- Duan, Y.; Liu, W.; Song, L.; Wang, T. A discrete structure: FeSiAl/carbon black composite absorption coatings. Mater. Res. Bull. 2017, 88, 41–48. [Google Scholar] [CrossRef]

- Peymanfar, R.; Rahmanisaghieh, M. Preparation of neat and capped BaFe2O4 nanoparticles and investigation of morphology, magnetic, and polarization effects on its microwave and optical performance. Mater. Res. Express 2018, 5, 105012. [Google Scholar] [CrossRef]

- Zhao, J.; Lu, Y.; Ye, W.; Wang, L.; Liu, B.; Lv, S.; Chen, L.; Gu, J. Enhanced wave-absorbing performances of silicone rubber composites by incorporating C-SnO2-MWCNT absorbent with ternary heterostructure. Ceram. Int. 2019, 45, 20282–20289. [Google Scholar] [CrossRef]

- Mondal, S.; Das, P.; Ganguly, S.; Ravindren, R.; Remanan, S.; Bhawal, P.; Das, T.K.; Das, N.C. Thermal-air ageing treatment on mechanical, electrical, and electromagnetic interference shielding properties of lightweight carbon nanotube based polymer nanocomposites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 447–460. [Google Scholar] [CrossRef]

- Kaur, A.; Dhawan, S. Tuning of EMI shielding properties of polypyrrole nanoparticles with surfactant concentration. Synth. Met. 2012, 162, 1471–1477. [Google Scholar] [CrossRef]

- Ebrahimi, I.; Gashti, M.P. Chemically reduced versus photo-reduced clay-Ag-polypyrrole ternary nanocomposites: Comparing thermal, optical, electrical and electromagnetic shielding properties. Mater. Res. Bull. 2016, 83, 96–107. [Google Scholar] [CrossRef]

- Ebrahimi, I.; Gashti, M.P. Polypyrrole-MWCNT-Ag composites for electromagnetic shielding: Comparison between chemical deposition and UV-reduction approaches. J. Phys. Chem. Solids 2018, 118, 80–87. [Google Scholar] [CrossRef]

- Aghvami-Panah, M.; Wang, A.; Panahi-Sarmad, M.; Esfahani, S.A.S.; Seraji, A.A.; Shahbazi, M.; Ghaffarian, R.; Jamalpour, S.; Xiao, X. A comparison study on polymeric nanocomposite foams with various carbon nanoparticles: Adjusting radiation time and effect on electrical behavior and microcellular structure. Int. J. Smart Nano Mater. 2022, 13, 504–528. [Google Scholar] [CrossRef]

- Yu, D.; Wang, Y.; Hao, T.; Wang, W.; Liu, B. Preparation of silver-plated polyimide fabric initiated by polyaniline with electromagnetic shielding properties. J. Ind. Text. 2018, 47, 1392–1406. [Google Scholar] [CrossRef]

- Fang, F.; Li, Y.-Q.; Xiao, H.-M.; Hu, N.; Fu, S.-Y. Layer-structured silver nanowire/polyaniline composite film as a high performance X-band EMI shielding material. J. Mater. Chem. C 2016, 4, 4193–4203. [Google Scholar] [CrossRef]

- Yu, L.; Yang, Q.; Liao, J.; Zhu, Y.; Li, X.; Yang, W.; Fu, Y. A novel 3D silver nanowires@ polypyrrole sponge loaded with water giving excellent microwave absorption properties. Chem. Eng. J. 2018, 352, 490–500. [Google Scholar] [CrossRef]

- Chen, J.-J.; Liu, S.-L.; Wu, H.-B.; Sowade, E.; Baumann, R.R.; Wang, Y.; Gu, F.-Q.; Feng, Z.-S. Structural regulation of silver nanowires and their application in flexible electronic thin films. Mater. Des. 2018, 154, 266–274. [Google Scholar] [CrossRef]

- Mindemark, J.; Lacey, M.J.; Bowden, T.; Brandell, D. Beyond PEO—Alternative host materials for Li+-conducting solid polymer electrolytes. Prog. Polym. Sci. 2018, 81, 114–143. [Google Scholar] [CrossRef]

- Bora, P.J.; Vinoy, K.; Ramamurthy, P.C.; Madras, G. Electromagnetic interference shielding efficiency of MnO2 nanorod doped polyaniline film. Mater. Res. Express 2017, 4, 025013. [Google Scholar] [CrossRef]

- Bora, P.J.; Vinoy, K.; Ramamurthy, P.C.; Madras, G. Electromagnetic interference shielding effectiveness of polyaniline-nickel oxide coated cenosphere composite film. Compos. Commun. 2017, 4, 37–42. [Google Scholar] [CrossRef]

- Raicheff, R.; Mladenov, M.; Stoyanov, L.; Boshkov, N.; Bachvarov, V. Novel current collector and active mass carrier of the zinc electrode for alkaline nickel-zinc batteries. Bulg. Chem. Commun. 2016, 48, 61–65. [Google Scholar]

- Tian, Z.; Zhao, Z.; Yang, K.; Peng, K.; Zong, C.; Lai, Y. Communication—Solvothermal Synthesis of Bi2O3@ ZnO Spheres for High-Performance Rechargeable Zn-Ni Battery. J. Electrochem. Soc. 2019, 166, A208–A210. [Google Scholar] [CrossRef]

- Phang, S.W.; Tadokoro, M.; Watanabe, J.; Kuramoto, N. Synthesis, characterization and microwave absorption property of doped polyaniline nanocomposites containing TiO2 nanoparticles and carbon nanotubes. Synth. Met. 2008, 158, 251–258. [Google Scholar] [CrossRef]

- Petrovski, S.; Bouchet, F.; Petrovski, A. Data-driven modelling of electromagnetic interferences in motor vehicles using intelligent system approaches. In Proceedings of the 2013 IEEE INISTA, Albena, Bulgaria, 19–21 June 2013; pp. 1–7. [Google Scholar]

- Ram, R.; Rahaman, M.; Khastgir, D. Electromagnetic interference (EMI) shielding effectiveness (SE) of polymer-carbon composites. In Carbon-Containing Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2019; pp. 339–368. [Google Scholar]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, S.; Ganguly, S.; Das, P.; Das, T.K.; Bose, M.; Singha, N.K.; Das, A.K.; Das, N.C. Fabrication of reduced graphene oxide/silver nanoparticles decorated conductive cotton fabric for high performing electromagnetic interference shielding and antibacterial application. Fibers Polym. 2019, 20, 1161–1171. [Google Scholar] [CrossRef]

- Mondal, S.; Ganguly, S.; Das, P.; Khastgir, D.; Das, N.C. Low percolation threshold and electromagnetic shielding effectiveness of nano-structured carbon based ethylene methyl acrylate nanocomposites. Compos. Part B Eng. 2017, 119, 41–56. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding. Prog. Mater. Sci. 2019, 103, 319–373. [Google Scholar] [CrossRef]

- Wu, G.; Jia, Z.; Zhou, X.; Nie, G.; Lv, H. Interlayer controllable of hierarchical MWCNTs@ C@ FexOy cross-linked composite with wideband electromagnetic absorption performance. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105687. [Google Scholar] [CrossRef]

- Yu, L.; Lan, X.; Wei, C.; Li, X.; Qi, X.; Xu, T.; Li, C.; Li, C.; Wang, Z. MWCNT/NiO-Fe3O4 hybrid nanotubes for efficient electromagnetic wave absorption. J. Alloy. Compd. 2018, 748, 111–116. [Google Scholar] [CrossRef]

| Sample | Radiation Duration (s) | Filler Content (wt. %) | Electrical Conductivity (S/cm) | EMI SE (dB) | Dielectric Constant at Frequency of 100 Hz |

|---|---|---|---|---|---|

| Polystyrene/carbon nanotube | 45 | 1 | 3.29 × 10−6 | 4.4 | 11.1 |

| 60 | 1 | 3.05 × 10−7 | 2.9 | 19.2 | |

| 90 | 1 | 8.31 × 10−7 | 3.3 | 14.5 | |

| Polystyrene/graphene | 120 | 1 | 9.23 × 10−8 | 2.2 | 14.1 |

| 150 | 1 | 5.31 × 10−8 | 2.0 | 12.3 | |

| 180 | 1 | 4.31 × 10−8 | 1.9 | 10.8 | |

| Polystyrene/carbon black | 120 | 1 | 4.42 × 10−9 | 0.9 | 10.3 |

| 150 | 1 | 6.34 × 10−9 | 1.0 | 8.7 | |

| 180 | 1 | 8.13 × 10−9 | 1.0 | 8.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, A.; Ahmad, I. Conducting Polymer Nanocomposites for Electromagnetic Interference Shielding—Radical Developments. J. Compos. Sci. 2023, 7, 240. https://doi.org/10.3390/jcs7060240

Kausar A, Ahmad I. Conducting Polymer Nanocomposites for Electromagnetic Interference Shielding—Radical Developments. Journal of Composites Science. 2023; 7(6):240. https://doi.org/10.3390/jcs7060240

Chicago/Turabian StyleKausar, Ayesha, and Ishaq Ahmad. 2023. "Conducting Polymer Nanocomposites for Electromagnetic Interference Shielding—Radical Developments" Journal of Composites Science 7, no. 6: 240. https://doi.org/10.3390/jcs7060240