1. Introduction

Currently, preserving the environment is considered the main key in scientific and technical research throughout the world. The use of mineral and synthetic oils in slide bearing applications raises concerns about the environmental impact of these lubricants in cases of pollution [

1]. Slide bearing systems based on oil-free lubricants are considered the main direction for resolving our ecological problems. Bearing materials based on polymers are treated as the most promising materials, since polymers have several interesting properties, such as being lightweight and having a chemical inertness, low coefficient of friction, high wear resistance, and good impact toughness [

2,

3,

4]. Polymeric slide bearing products can be found in a wide range of industrial applications, such as in the automotive, aerospace, hydropower, and robotics sectors, and in medical applications, such as total replacements [

5,

6,

7].

Due to its excellent tribological and mechanical properties, self-lubricating characteristics, high chemical inertness, and biocompatible characteristics, ultra-high molecular weight polyethylene (UHMWPE) is one of the most widely utilized polymers in many industrial and medical applications [

3,

4,

8,

9]. However, UHMWPE, with an isotropic structural state, has a low elasticity modulus and yield strength and has exhibited a considerable creep under constant and high loads. UHMWPE outperforms nylon and polyformaldehyde, which are frequently used in applications requiring a low coefficient of friction, in terms of their tribological properties [

10,

11,

12,

13]. Polytetrafluoroethylene and UHMWPE are comparable in terms of their friction coefficient; however, UHMWPE outperforms in terms of wear resistance [

14]. Since using isotropic UHMWPE composites as antifriction bearing components for tribological purposes, improving the mechanical and tribological properties of UHMWPE composites using the process of orientation hardening, has attracted more attention from researchers [

10,

11,

15]. A further intriguing enhancement technique is to incorporate certain second-phase particles with good tribological characteristics into a UHMWPE matrix to create UHMWPE nanocomposites [

16]. In our previous work [

17], highly oriented UHMWPE films filled with 2 wt.% graphene nanoplates/polyaniline (GNP/PANI) were prepared (

Figure 1a), and they presented outstanding mechanical and tribological properties, such as a tensile strength of 836 MPa, Young’s modulus of 35.8 GPa, COF of 0.122, and a linear wear intensity of 1.92 µm/m·m

2, in comparison to isotropic UHMWPE (yield strength of ≥17 MPa, Young’s modulus of 720 MPa, COF of 0.269, and a linear wear intensity of 53.94 µm/m·m

2).

On the other hand, the main method used to bond UHMWPE with metals in the manufacture of a “polymer-metal” friction pair is thermal pressing, which leads to the loss of the unique mechanical and tribological properties of the highly oriented UHMWPE films due to applying high temperatures and pressures. Nevertheless, the best solution for bonding the oriented UHMWPE films to metals while preserving their unique properties is to glue them together. Bonding UHMWPE to each other or to metal materials is considered a very difficult task since the absence of polar groups in UHMWPE makes their surfaces very inert [

18]. Therefore, to manufacture antifriction sliding surfaces based on oriented UHMWPE films, it is necessary to develop a method for the pre-treatment of the surfaces prior to the gluing phase. The main mechanism of surface modification is to increase its roughness using chemical etching techniques; this leads to an increase in wettability and an improvement in adhesion properties compared to unmodified UHMWPE [

19,

20].

Numerous significant qualities exist in cellulose, including abundance, light weight, renewability, nontoxicity, biocompatibility, biodegradability, and high stability [

21,

22]. It can be utilized in binders and water-soluble adhesives [

23]. The cellulose carboxyl groups are crucial to the mechanisms involved in grafting techniques. For instance, a covalent grafting approach for the conjugation of benzophenone with cellulose has recently been developed for the UV-crosslinking of nanocellulose [

24].

A good opportunity to improve the UHMWPE’s adhesion properties exists thanks to chemical surface modification [

19,

25,

26]. UHMWPE surface’s characteristics have been enhanced using a variety of techniques [

27]. The primary method of surface modification relies on chemical etching, which is used to oxidize and roughen the surface. Such treatments produce superior wettability and increase adhesive properties more in comparison to unmodified UHMWPE. The polar groups on the UHMWPE surface are substituted for the hydrogen atoms in the polymer chains in this etching mechanism, increasing the surface’s wettability and providing potential locations for chemical interactions with other substances (

Figure 1b) [

28]. Ultraviolet (UV) irradiation, as a low-energy grafting technique for polymeric surfaces, is considered to be a promising method [

29,

30]. This is related to its low cost, effectiveness in functionalizing the substrate surface, quick reaction rate, and relatively small influence on the bulk polymers. In this article, and based on our previous work [

31], the oriented UHMWPE films are exposed to UV radiation after being placed in the initiator solution (benzophenone). To obtain the desired amount of dormant semi-pinacol groups (

Figure 1b), the initiator removes hydrogen from the UHMWPE chains [

30,

32]. The UHMWPE films, which were grafted with benzophenone, are then subjected to UV irradiation once more to cleave this bond again. The suggested reason for grafting cellulose chains onto the surface of the UHMWPE films is the reactivation of the dormant semi-pinacol groups (

Figure 1c) [

33].

3. Results

Table 2 presents the FT-IR spectrum peaks for all chemical groups, and

Figure 3 shows the FT-IT measurements for the virgin UHMWPE films, oriented UHMWPE/PE-wax/GNP/PANI films, and treated oriented UHMWPE/PE-wax/GNP/PANI by cellulose grafting. As can be seen in

Table 2 and

Figure 3, the presence of GNP/PANI in the oriented UHMWPE films is related to the peaks at 803, 1115, 1261, and 1295 cm

−1. Peaks at 808 and 1629 cm

−1 are related to the presence of benzophenone, whereas the peaks at 1031, 1099, and 1261 cm

−1 are related to the grafted cellulose. As can be noted in

Figure 3, the -OH groups of the cellulose, which have an intensity range between 3100 and 3600 cm

−1, disappeared in the treated UHMWPE/PE-wax/GNP/PANI films. This can be related to the reactions that took place between the -OH groups of the cellulose and both of the ketones groups of the benzophenone and C–H groups of the UHMWPE, which had led to the formation of the C-O-C (ethers) (peaks in the range of 1150–1200 cm

−1) [

40].

Table 2.

The FT-IR spectrum peaks for all components.

Table 2.

The FT-IR spectrum peaks for all components.

| UHMWPE [41,42] | GNP/PANI [43,44] | Benzophenone [45] | Cellulose [46,47] |

|---|

| Wave Number, cm−1 | Functional Group | Wave Number, cm−1 | Functional Group | Wave Number, cm−1 | Functional Group | Wave Number, cm−1 | Functional Group |

|---|

| 717 | rocking vibration peak due to the high degree of polymerization and long molecular chain of UHMWPE | 803 | aromatic C–H out-of-plane bending vibration (GNP) | 808 | C–CO–C sym. str. | 1031 | C–O stretching group of 3,6-anhydrogalactose |

| 730 | 800–1115 | C–H stretching (PANI) |

| 1261 | N–Q–N–Q stretch of the quinoid ring | 1099 |

| 1460 | in-plane bending vibration peak of C–H | 1295 | C–N stretching (GNP) |

| 1471 | 1627 | C=O stretch | 1261 | C–OH bending at C6 |

| 2848 | sym. stretching vibration peak of C–H |

| 2912 | asym. stretching vibration peak of C–H |

The presence of the cellulose on the treated UHMWPE/PE-wax/GNP/PANI films was also demonstrated in the SEM images (

Figure 4 and

Figure 5). As it can be seen in

Figure 4, the acid pre-treatment led to the formation of micro-pores and grooves on the surface of the UHMWPE films, and to the increase in the surface roughness. These changes in surface morphology can improve the effective contact area between the surface and the adhesive materials that are in contact with it.

Figure 5 illustrates the distribution of the adhered cellulose on the treated surface of the UHMWPE/PE-wax/GNP/PANI films. The distribution densities indicate the cellulose’s high adherence to the treated UHMWPE films.

Figure 6 demonstrates the changes in the surface morphology of the treated UHMWPE films and how grafting cellulose improves the adhesion properties of the treated UHMWPE films in comparison to the untreated ones.

The processes of the acid pre-treatment and cellulose grafting have led to an enhancement in the UHMWPE’s hydrophilicity (

Table 3 and

Figure 7). However, the GNP/PANI filler contains some functional groups, such as ethers, carboxyls, or hydroxyls. As can be seen in

Table 2 and

Figure 3, the untreated UHMWPE/PE-wax/GNP/PANI film had a lower water contact angle in comparison to the untreated virgin UHMWPE film The water contact angle value of the treated UHMWPE/PE-wax/GNP/PANI film was decreased to 91° in comparison to the untreated virgin UHMWPE film’s value, which was 120°. Since the water contact angle of 90° is considered the boarder value between the hydrophilic and hydrophobic materials, the value of the water contact angle of the treated UHMWPE/PE-wax/GNP/PANI film is also considered a boarder value [

48,

49,

50]. This increase in the hydrophilicity indicates an increase in the free energy of the UHMWPE material’s surface [

51], which led to an improvement of its adhesion properties.

Table 4 shows the tensile mechanical properties of the treated UHMWPE/PE-wax/GNP/PANI film after acid pre-treatment and cellulose grafting. As can be seen in

Table 4, its tensile strength was decreased a little by about 6% as a result of the acid pre-treatment process. Moreover, the values of Young’s modulus, elongation, and work of fracture were almost the same after the treatment by cellulose grafting. This small decrease in the mechanical tensile properties in the UHMWPE/PE-wax/GNP/PANI film is related to the semi-crystalline structure of the UHMWPE. In other words, in the acid pre-treatment process, the mixed acids attack the polymer macromolecules in the amorphous regions (weak zones), leading to an etching process in the UHMWPE structure that led to a small decrease in the mechanical properties of the oriented films [

52].

Table 5 and

Figure 8 show the tribological properties of the untreated and treated UHMWPE/PE-wax/GNP/PANI films in comparison to the isotropic UHMWPE films. As can be seen, the cellulose grafting processes led to an increase in the COF of the treated UHMWPE films up to 0.172 in comparison to the untreated UHMWPE films with a COF of 0.122. Moreover, the linear wear intensity increased from 1.92 µm/m·m

2 for the untreated UHMWPE films and up to 15.43 µm/m·m

2 for the treated UHMWPE films. Here, it can be noted that the applied tribological conditions are considered very harsh (a load of 30 N “about 4 MPa”, and dry friction), and the decrease in the tribological properties is related to the presence of the cellulose on the UHWMPE surface of the treated films causing a change in surface morphology. Under the tribological tests and due to high surface roughness, the presence of the cellulose led to an increase in the deformation component of the friction coefficient (increasing the penetration of the counter-body into the surface of the material), and the friction between the counter-body and treated UHMWPE films caused cellulose erosion in the beginning of this process [

53,

54]. Afterwards, the COF stabilized at a value of 0.172.

Table 6 and

Table 7 show the results of the T-peel tests for the treated UHMWPE/PE-wax/GNP/PANI films. In order to investigate the adhesion strength for the treated UHMWPE films, two T-peel tests were carried out using two different types of adhesive tapes. The first T-peel test was carried out for the adhesion strength between the treated UHMWPE films and adhesive tapes, whereas the second one was carried out between two treated films bonded by two adhesive tapes (

Table 6 and

Table 7). As can be seen in

Table 6, by using the acrylic foam-based tape, the peel strength between the UHMWPE films and adhesive tape was increased from 0.9 kg/cm up to 1.8 kg/cm (100%) for the untreated films. Oppositely, when using the synthetic rubber fabric double-sided tape, the peel strength between the UHMWPE films and adhesive tape increased from 0.6 kg/cm up to 1.9 kg/cm (217%) for the untreated films.

Table 7 shows the adhesion strength between two treated UHMWPE films using two adhesive tapes. As can be seen, the peel strength was increased from 0.8 kg/cm up to 2.8 kg/cm (250%) for the untreated films, whereas the peel strength between the UHMWPE films and adhesive tape increased from 0.4 kg/cm, for the untreated films, up to 1.5 kg/cm (275%) using synthetic rubber fabric double-sided tape.

It should be noted that T-peel tests were also carried out to investigate the adhesion strength between the treated UHMEPE films and metals (stainless steel 316L), and the occurrence of the bonding separation between the UHMWPE films and the adhesive tapes was observed, which meant that the adhesion strength between the metals and adhesive tapes was higher than the one that between the treated UHMWPE films and the adhesive tapes.

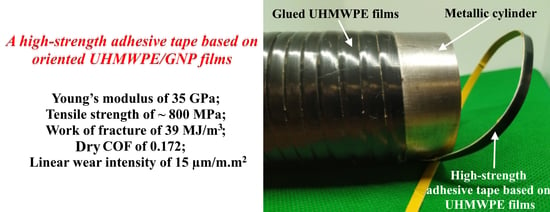

The main aim of this work was to develop a product in the form of a high-strength adhesive tape based on UHMWPE films, which has a low coefficient of friction, high wear resistance, and high strength (

Figure 9). These adhesive tapes are considered promising materials for creating plain bearings, various guides, etc.

4. Conclusions

UHMWPE is recognized worldwide as the polymer of the future, as a result of the possibility of creating various composite materials with unique mechanical, tribological, and functional properties. In this work, using ultraviolet initiation after a pre-treatment process with mixed acids, the surface of the oriented UHMWPE films was grafted by cellulose. Using Fourier transform infrared spectroscopy (FT-IR), the presence of GNP/PANI, cellulose, and benzophenone on the treated UHMWPE films was demonstrated. Using scanning electron microscopy (SEM), the presence of cellulose on the treated UHMWPE films was also demonstrated. The contact angle measurements showed that its value decreased from 120° to 91° after the treatment procedure. Mechanical T-peel tests showed that the peel strength for the treated UHMWPE films increased from 0.6 up to 1.8 kg/cm in comparison to the untreated films. However, it was found that the treatment procedure led to a slight decrease in the tensile strength of the treated UHMWPE films by about 6% to 788 MPa. Tribological tests showed that the values of both the friction coefficient and wear intensity were insignificantly increased up to 0.172 and 15.43 µm/m·m2, respectively, for the treated UHMWPE films. The use of high-strength-oriented UHMWPE films instead of isotropic thermally pressed UHMWPE films could significantly increase the performance and service life of various anti-friction sliding surfaces for industrial and medical slide bearing applications, such as bearings, rollers, various guides, and as a lining. The proposed method for modifying the surface of UHMWPE films allows us to increase the adhesion properties of these films by more than 200%, while the mechanical and tribological properties can only be insignificantly reduced. It should be noted that because of carrying out chemical modifications on both UHMWPE surfaces, a reduction in the coefficient of friction and wear was recognized. Therefore, to preserve tribological properties, it is better to apply chemical modifications on one polymer surface that will be adhered to the metals being used.