Ultrasonic Nondestructive Evaluation of Composite Bond Strength: Quantification through Bond Quality Index (BQI)

Abstract

:1. Introduction

2. Materials and Methods

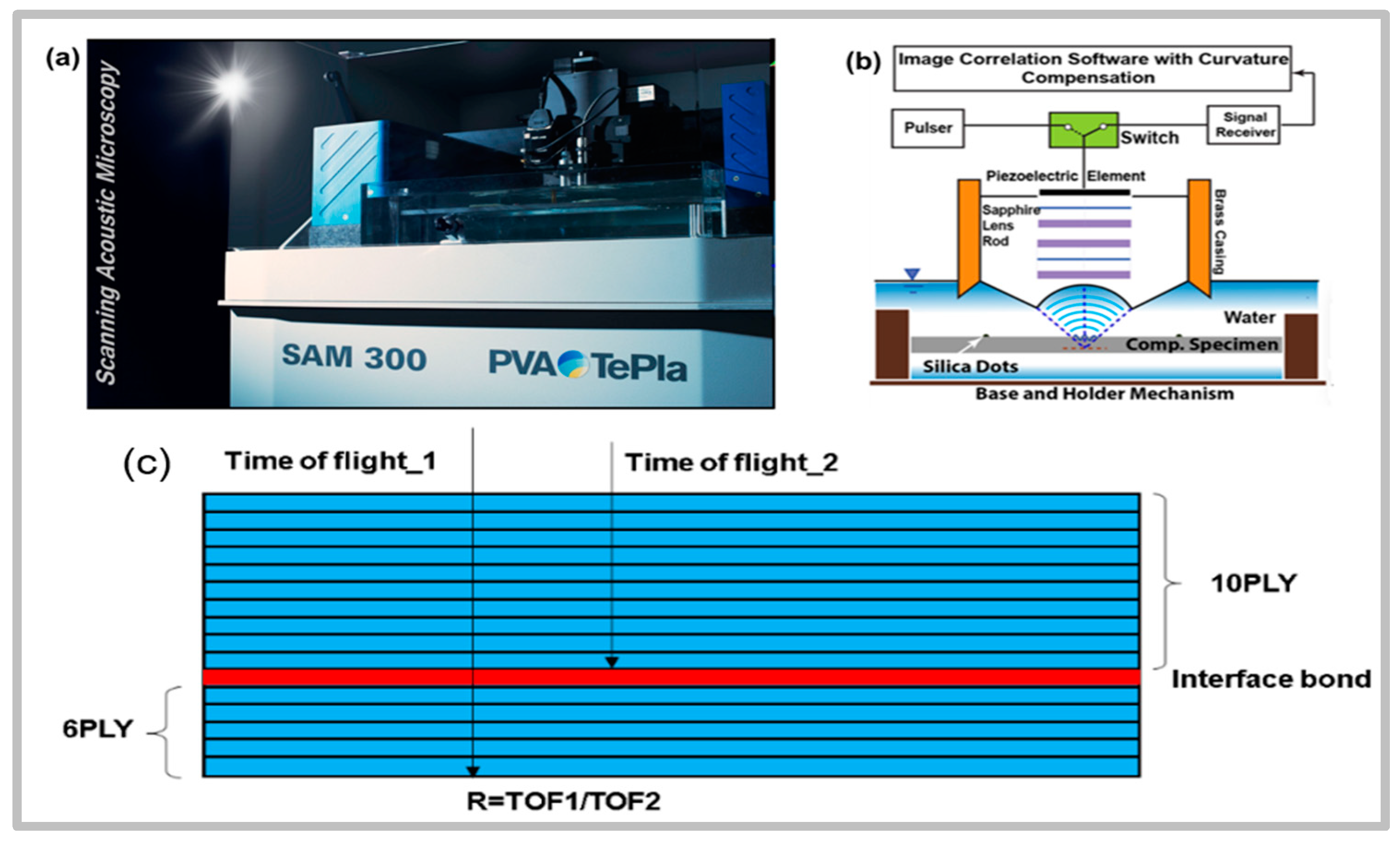

2.1. Sample Preparation and SAM

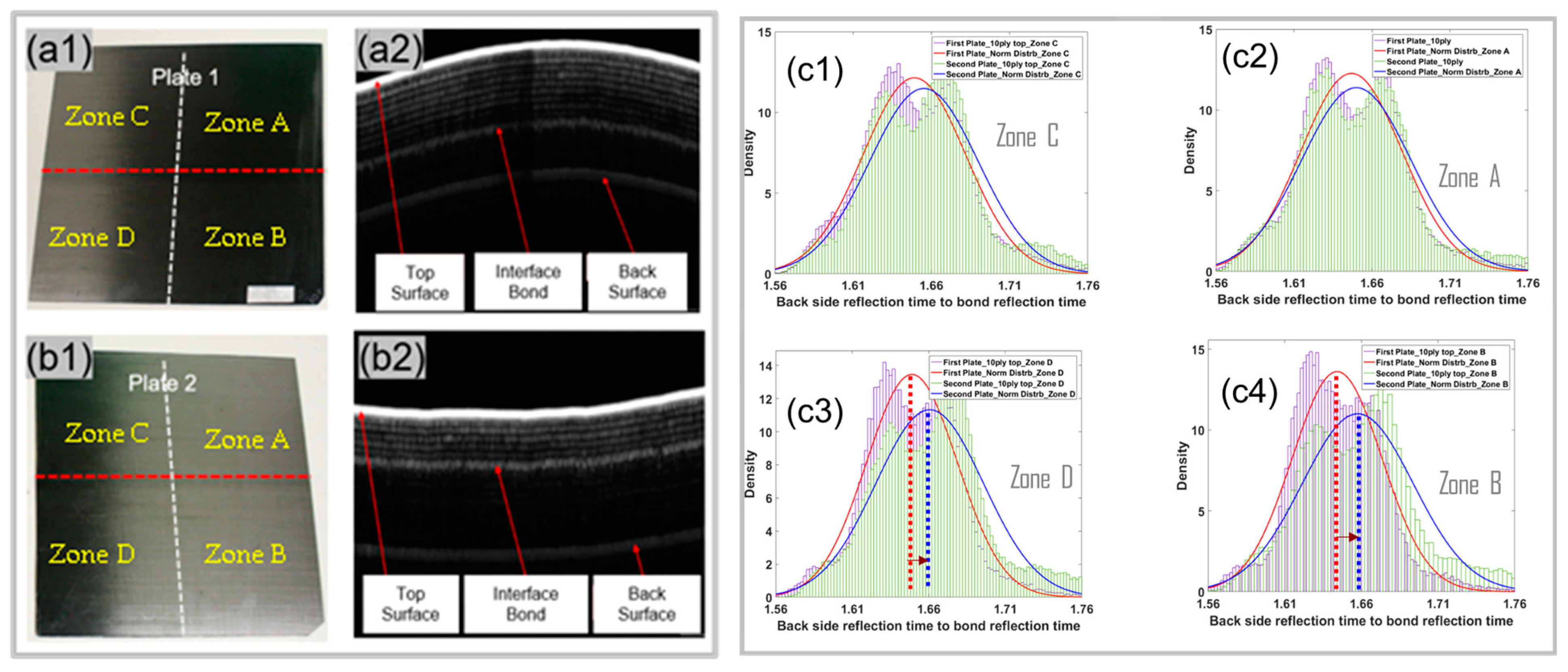

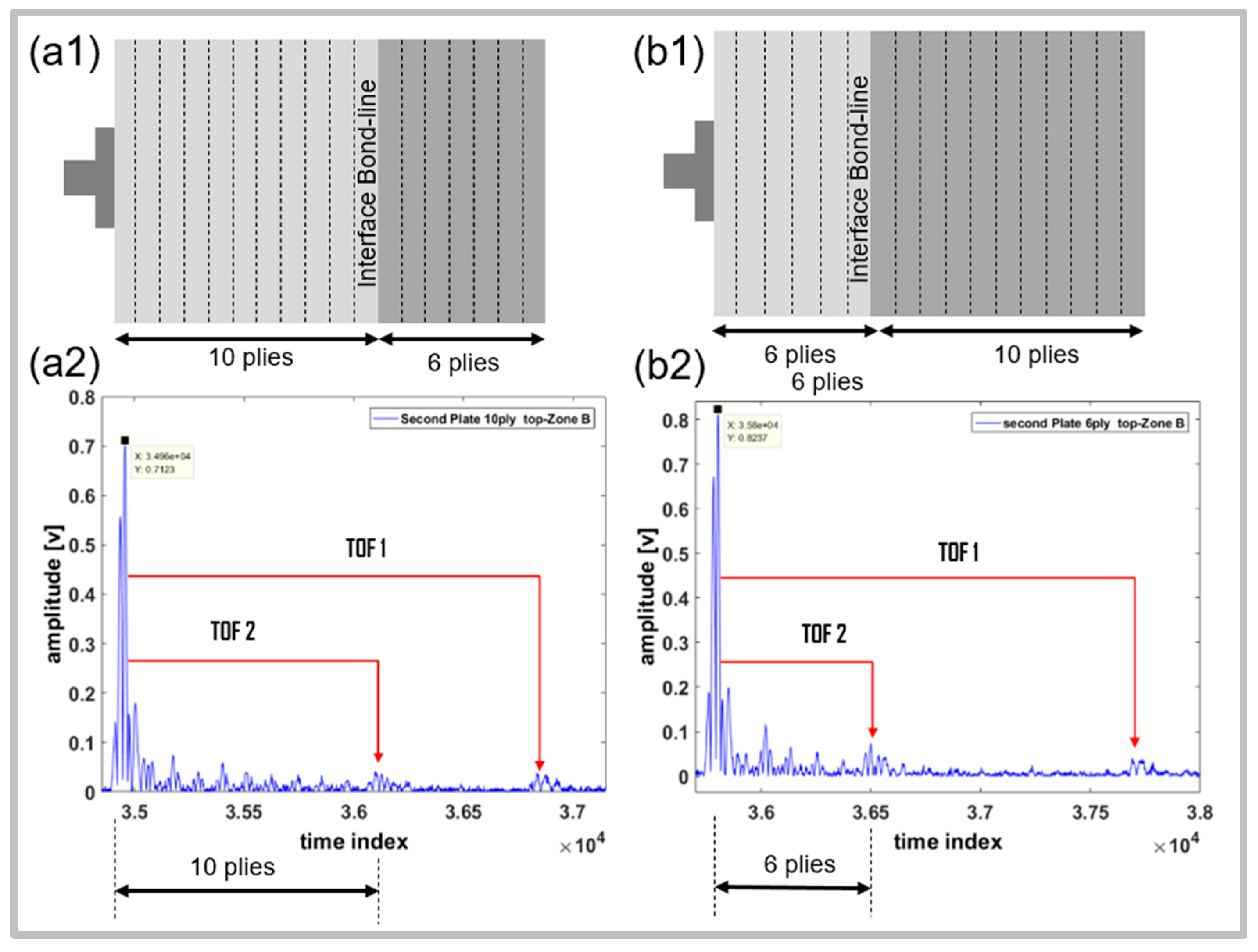

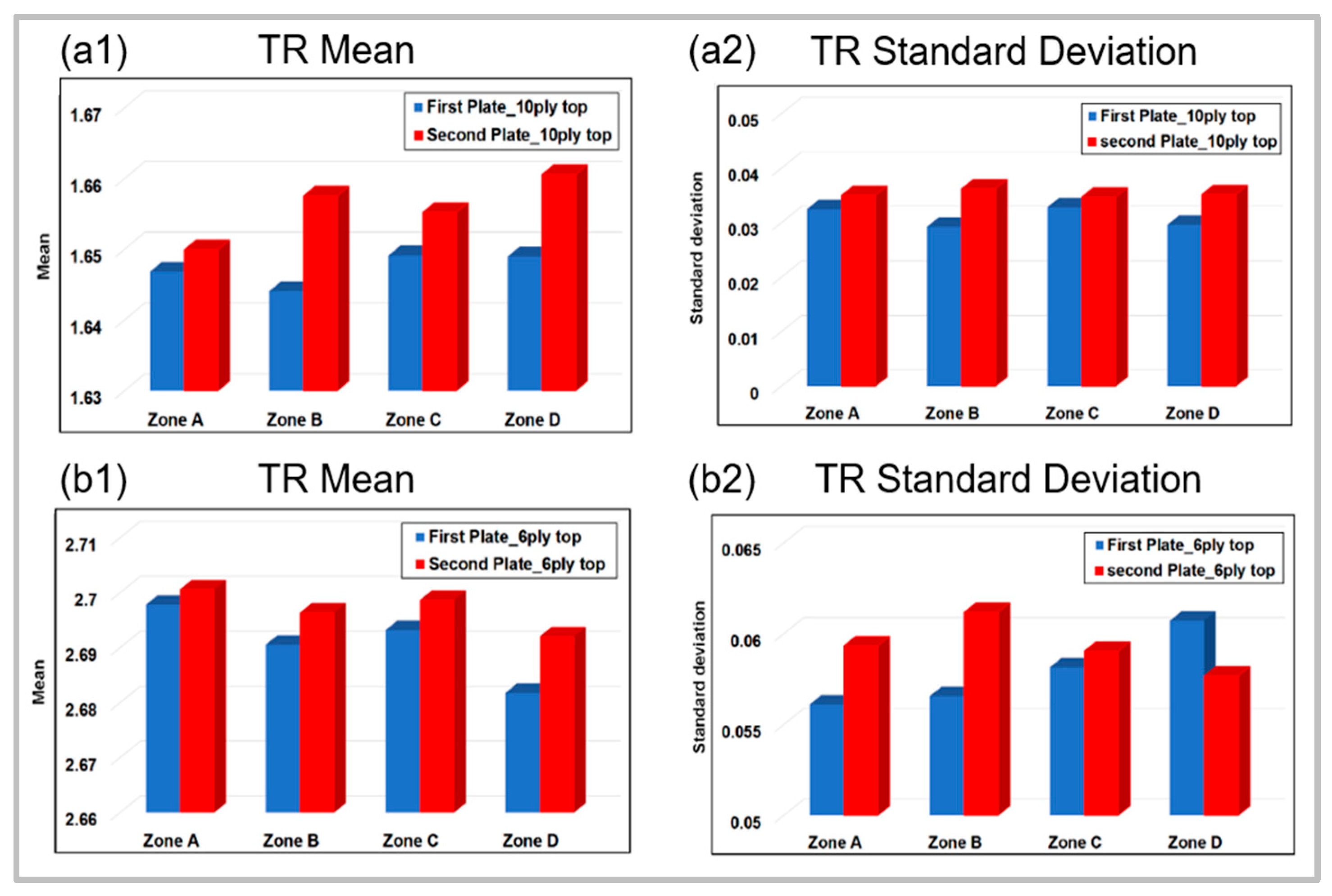

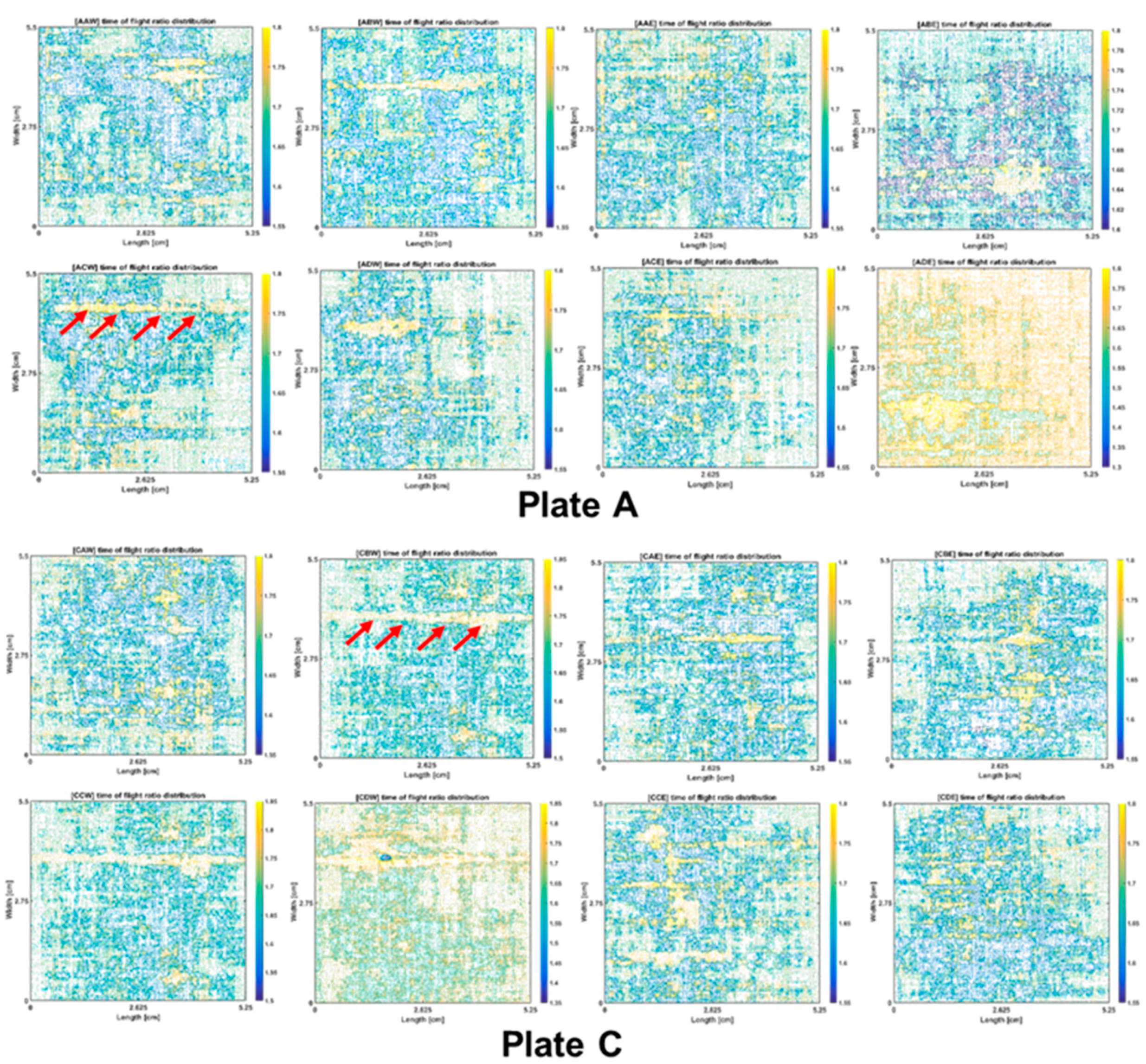

2.2. Analysis of SAM Data

2.3. Experimental Summary

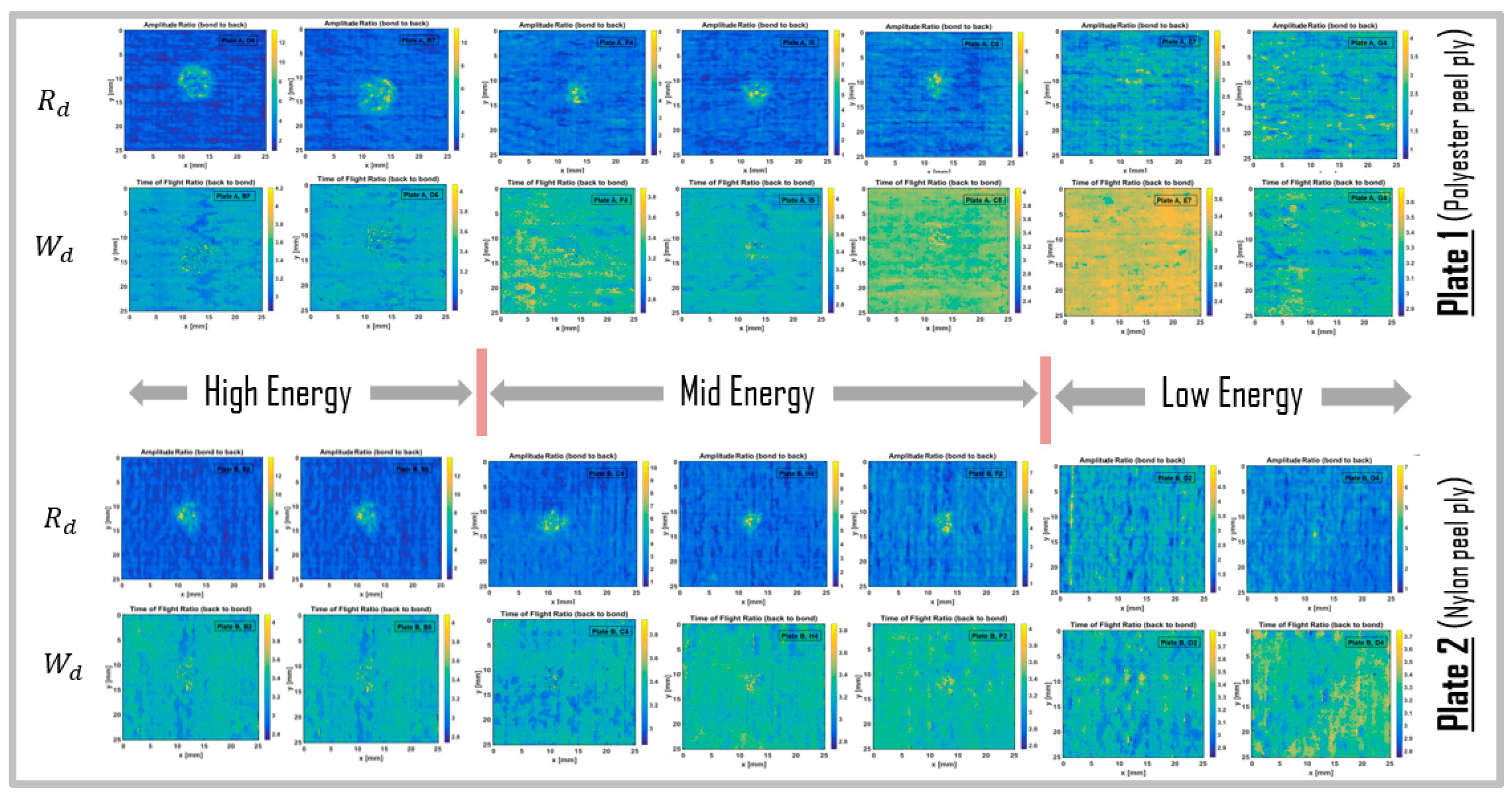

3. Assessment of Bond Quality Using Bond Quality Index (BQI)

4. Study and Results with Thickened Plates

4.1. Materials and Method

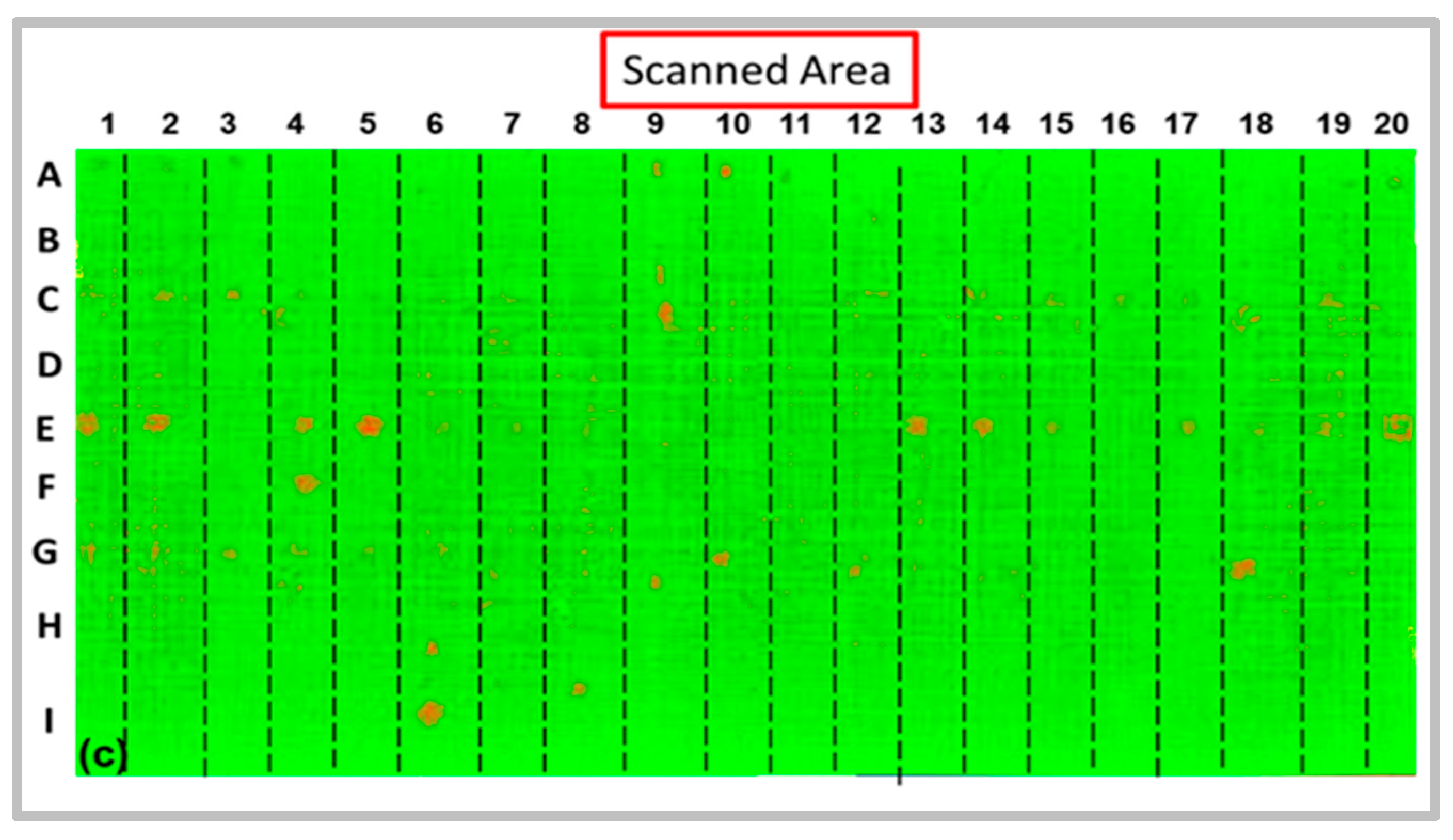

4.2. SAM Analysis before Imapct

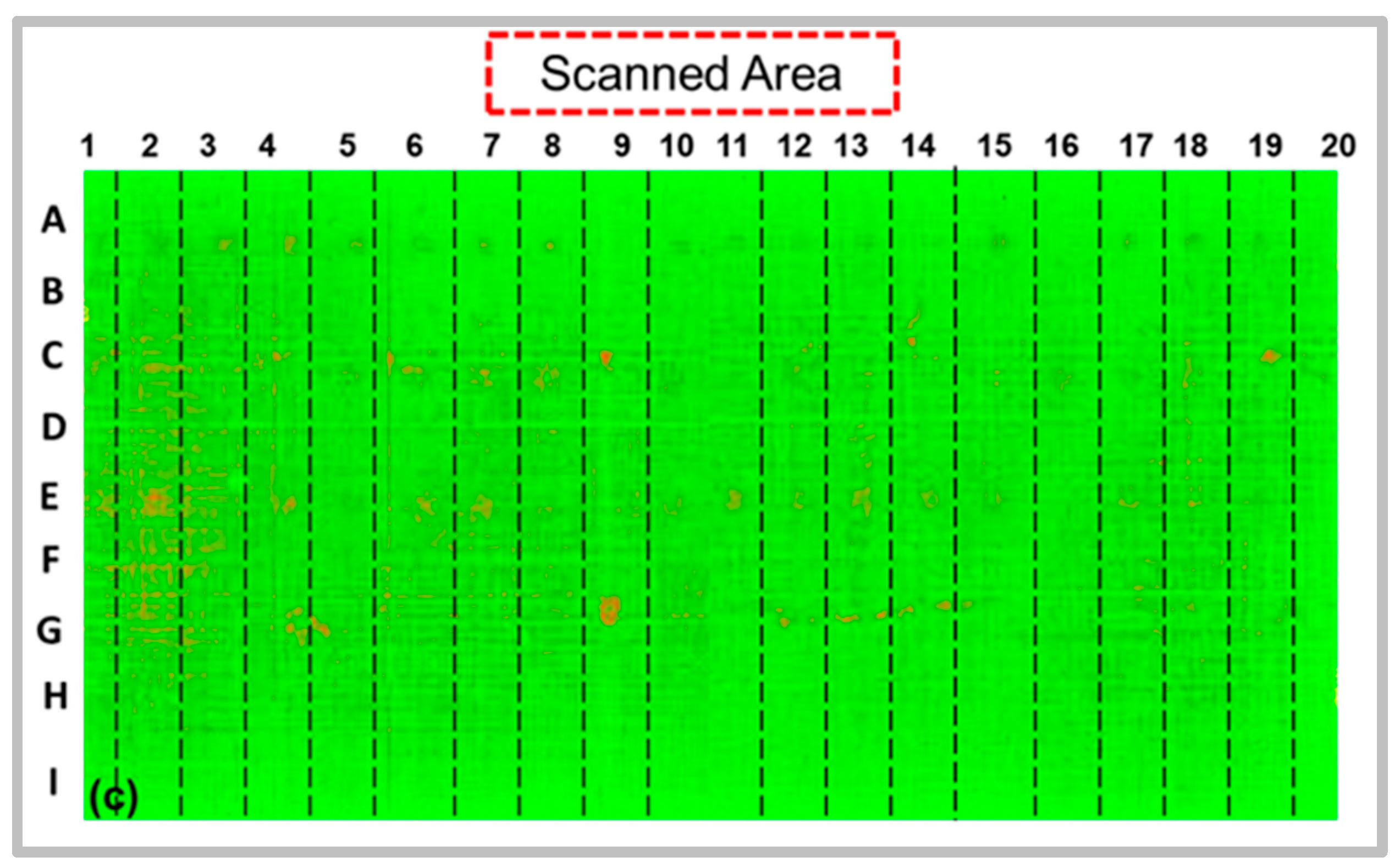

4.3. SAM Analysis after impact Tests

4.4. BQI Calculation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation Used in Text

| BQI | Bond Quality Index |

| NDE | Nondestructive Evaluation |

| NDI | Nondestructive Inspection |

| SAM | Scanning Acoustic Microscopy |

| PZT | Piezoelectric Transducer |

| TOF | Time of Flight |

| HHUT | Hand-held Ultrasonic Testing |

| FWT | Flat Wise Tension Test |

| TR | TOF Ratio |

References

- Talreja, R.; Varna, J. Modeling Damage, Fatigue and Failure of Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Reifsnider, K.L.; Case, S. Damage Tolerance and Durability of Material Systems; Wiley-VCH: Hoboken, NJ, USA, 2002; p. 435. ISBN 0-471-15299-4. [Google Scholar]

- Davies, P. 16—Adhesive bonding of composites. In Adhesive Bonding, 2nd ed.; Woodhead Publishing Series in Welding and Other Joining Technologies; Woodhead Publishing: Sawston, UK, 2021. [Google Scholar]

- Pantelakis, S.; Tserpes, K.I. Adhesive bonding of composite aircraft structures: Challenges and recent developments. Sci. China Phys. Mech. Astron. 2013, 57, 2–11. [Google Scholar] [CrossRef]

- Adams, R.D.; Comyn, J.; Wake, W.C. Structural Adhesive Joints in Engineering; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Banea, M.D.; da Silva, L.F. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Russell, J.D. Composites affordability initiative: Successes, failures—Where do we go from here? SAMPE J. 2007, 43, 26–36. [Google Scholar]

- Ji, G.; Ouyang, Z.; Li, G. Local interface shear fracture of bonded steel joints with various bondline thicknesses. Exp. Mech. 2012, 52, 481–491. [Google Scholar] [CrossRef]

- Crane, R.L.; Hart-Smith, J.; Newman, J. 8—Nondestructive inspection of adhesive bonded joints. In Adhesive Bonding, 2nd ed.; Woodhead Publishing Series in Welding and Other Joining Technologies; Woodhead Publishing: Sawston, UK, 2021; pp. 215–256. [Google Scholar]

- Crane, R.L.; Dillingham, G. Composite bond inspection. J. Mater. Sci. 2008, 43, 6682–6694. [Google Scholar] [CrossRef]

- Hart-Smith, L.J. An engineer asks: Is it really more important that paint stays stuck on the outside of an aircraft than that glue stays stuck on the inside? J. Adhes. 2006, 82, 181–214. [Google Scholar] [CrossRef]

- Adams, R.D.; Drinkwater, B.W. Non–destructive testing of adhesively–bonded joints. Int. J. Mater. Prod. Technol. 1999, 14, 385–398. [Google Scholar] [CrossRef]

- Munns, I.; Georgiou, G.J. Non-destructive testing methods for adhesively bonded joint inspection: A review. Insight 1995, 37, 941–952. [Google Scholar]

- Cawley, P.; Adams, R.D. Defect types and non-destructive testing techniques for composites and bonded joints. Mater. Sci. Technol. 1989, 5, 413–425. [Google Scholar] [CrossRef]

- Maldague, X. Theory and Practice of Infrared Technology for Nondestructive Testing; Wiley: Hoboken, NJ, USA, 2001. [Google Scholar]

- Ehrhart, B.; Ecault, R.; Touchard, F.; Boustie, M.; Berthe, L.; Bockenheimer, C.; Valeske, B. Development of a laser shock adhesion test for the assessment of weak adhesive bonded CFRP structures. Int. J. Adhes. Adhes. 2014, 52, 57–65. [Google Scholar] [CrossRef]

- Maeva, E.; Severina, I.; Bondarenko, S.; Chapman, G.; O’Neill, B.; Severin, F.; Maev, R.G. Acoustical methods for the investigation of adhesively bonded structures: A review. Can. J. Phys. 2004, 82, 981–1025. [Google Scholar] [CrossRef]

- Marty, P.N.; Desai, N.; Andersson, J. NDT of kissing bond in aeronautical structures. In Proceedings of the 16th World Conference on NDT, Montreal, QC, Canada, 30 August–3 September 2004. [Google Scholar]

- Drewry, M.A.; Smith, R.A.; Phang, A.P.; Yan, D.; Wilcox, P.; Roach, D.P. Ultrasonic techniques for detection of weak adhesion. Mater. Eval. 2009, 67, 1048–1058. [Google Scholar]

- Lévesque, D.; Legros, A.; Michel, A.; Piché, L. High resolution ultrasonic interferometry for quantitative nondestructive characterization of interfacial adhesion in multilayer (metal/polymer/metal) composites. J. Adhes. Sci. Technol. 1993, 7, 719–741. [Google Scholar] [CrossRef]

- Lissenden, C.J.; Rose, J.L. Structural Health Monitoring of Composite Laminates through Ultrasonic Guided Wave Beam Forming; NATO Applied Vehicle Technology: Båstad, Sweden, 2008; pp. 1–14. [Google Scholar]

- Cawley, P. The impedance method of non-destructive inspection. NDT Int. 1984, 17, 59–65. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Redmond, J.M.; Roach, D.P.; Rackow, K. Active sensors for health monitoring of aging aerospace structures. In Smart Structures and Materials 2000: Smart Structures and Integrated Systems; International Society for Optics and Photonics: Bellingham, WA, USA, 2000. [Google Scholar]

- Roth, W.W. Nondestructive Evaluation and Health Monitoring of Adhesively Bonded Composite Structures. Doctoral Dissertation, University of South Carolina, Columbia, SC, USA, 2017. [Google Scholar]

- Light, G.; Kwun, H. Nondestructive Evaluation of Adhesive Bond Quality: State of the Art Review; Nondestructive Testing Information Analysis Center: San Antonio, TX, USA, 1989. [Google Scholar]

- Cawley, P. Low frequency NDT techniques for the detection of disbonds and delaminations. Br. J. Non-Destr. Test. 1990, 32, 454–461. [Google Scholar] [CrossRef]

- Heslehurst, R.B. Optical NDT of adhesively bonded joints. Mater. Eval. 2009, 67, 837–842. [Google Scholar]

- Bossi, R.; Housen, K.; Walters, C.T.; Sokol, D. Laser bond testing. Mater. Eval. 2009, 67, 819–827. [Google Scholar]

- Perton, M.; Blouin, A.; Monchalin, J.P. Laser shock waves for adhesive bond testing. J. Phys. D Appl. Phys. 2010, 44, 034012. [Google Scholar] [CrossRef]

- Bossi, R. NDE for Adhesive Bond Strength. In Spring Conference 2011; Springer: New York, NY, USA, 2011. [Google Scholar]

- Bossi, R.; Lahrman, D.; Sokol, D.; Walters, C. Laser Bond Inspection for adhesive bond strength. In Proceedings of the International SAMPE Technical Conference, Paris, France, 28–29 March 2011. [Google Scholar]

- Bossi, R.; Giurgiutiu, V. Nondestructive testing of damage in aerospace composites. In Polymer Composites in the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2015; pp. 413–448. [Google Scholar]

- Gardiner, G.J. Certification of bonded composite primary structures. In High-Performance Composites; Composite World: Cincinnati, OH, USA, 2014; pp. 50–57. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banerjee, S.; Tavaf, V.; Indaleeb, M.M. Ultrasonic Nondestructive Evaluation of Composite Bond Strength: Quantification through Bond Quality Index (BQI). J. Compos. Sci. 2024, 8, 107. https://doi.org/10.3390/jcs8030107

Banerjee S, Tavaf V, Indaleeb MM. Ultrasonic Nondestructive Evaluation of Composite Bond Strength: Quantification through Bond Quality Index (BQI). Journal of Composites Science. 2024; 8(3):107. https://doi.org/10.3390/jcs8030107

Chicago/Turabian StyleBanerjee, Sourav, Vahid Tavaf, and Mustahseen M. Indaleeb. 2024. "Ultrasonic Nondestructive Evaluation of Composite Bond Strength: Quantification through Bond Quality Index (BQI)" Journal of Composites Science 8, no. 3: 107. https://doi.org/10.3390/jcs8030107