Dynamic Measurements with the Bicone Interfacial Shear Rheometer: Numerical Bench-Marking of Flow Field-Based Data Processing

Abstract

:1. Introduction

- Solve the Navier–Stokes equations for the subphase flow field with no slip boundary conditions at the container and probe walls and the Boussinesq–Scriven boundary condition at the interface.

- Use the obtained flow field to compute the subphase and interface drags on the probe.

- Use the probe equations of motion to obtain a new prediction for the value of the complex interfacial viscosity.

- Go back to Step 1 till convergence is obtained for the value of the complex interfacial viscosity.

2. Hydrodynamic Model and Data Analysis Scheme

3. Results

3.1. Consistency of the Iterative Data Analysis Scheme

3.1.1. Consistency over the Frequency Range

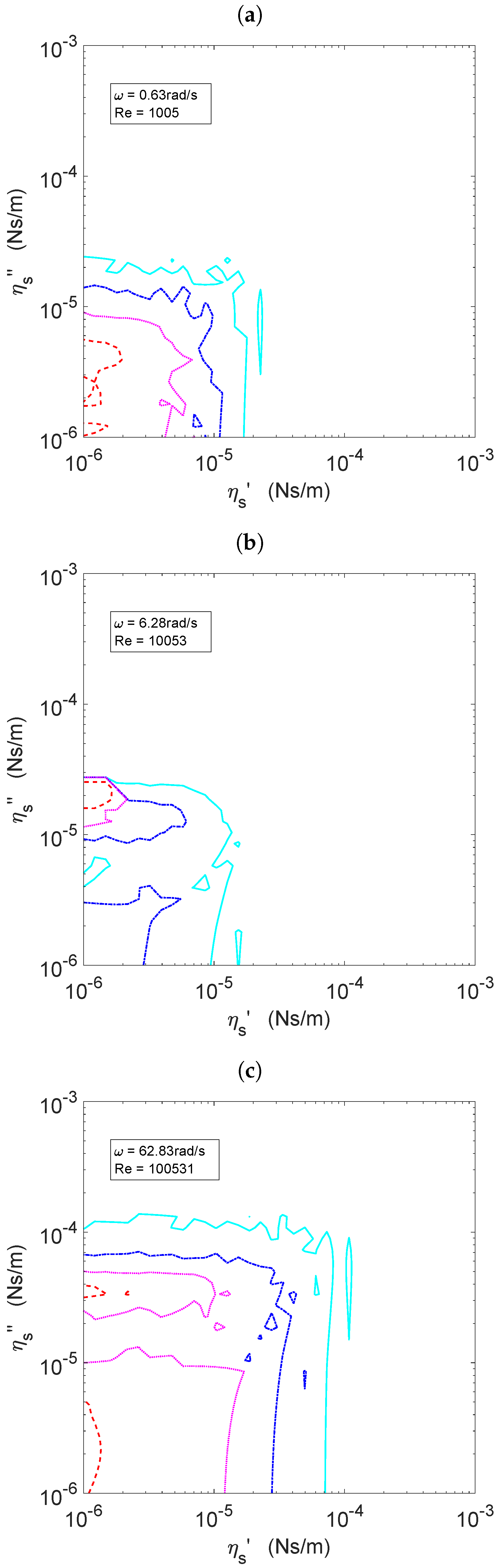

3.1.2. Consistency in the Complex Plane

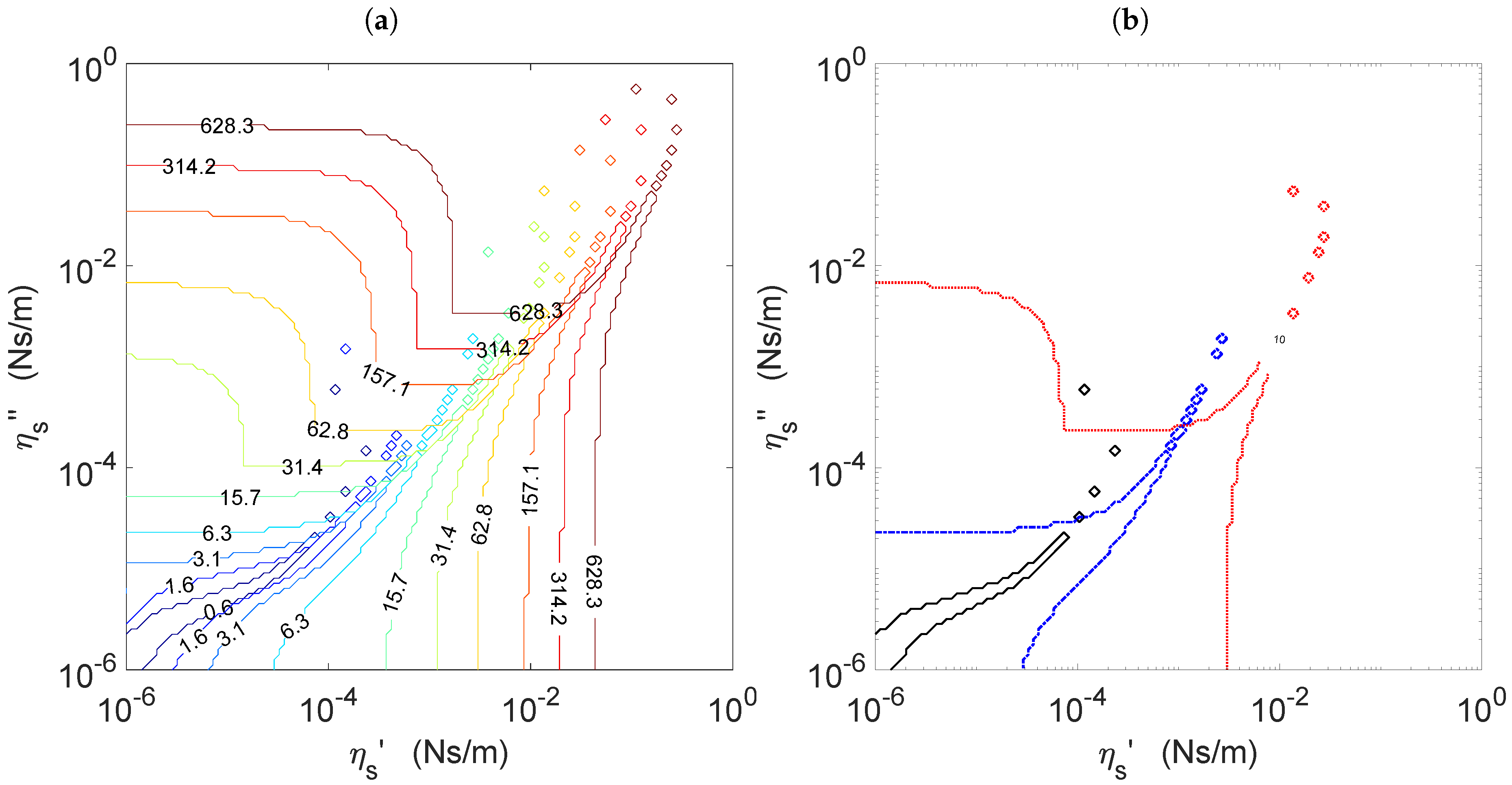

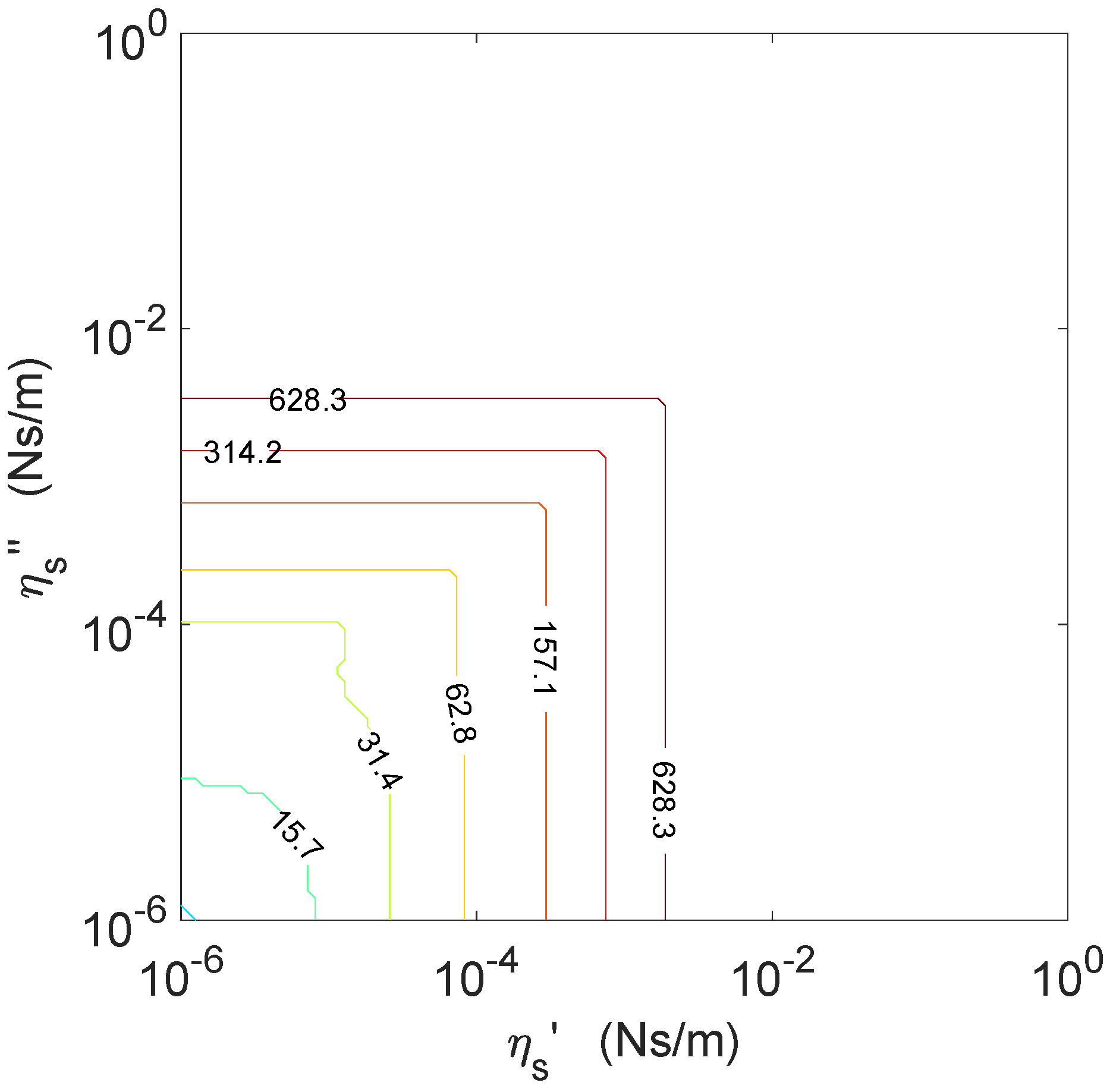

3.2. Estimation of the Achievable Measuring Range

3.3. Global Relative Errors

4. Discussion

5. Materials and Methods

5.1. Parameters for the Numerical Calculations

5.2. Definition of the Direct and Inverse Numerical Problems

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ISR | Interfacial shear rheometer |

| DWR | Double wall-ring |

References

- Fuller, G.G.; Vermant, J. Complex Fluid-Fluid Interfaces: Rheology and Structure. Annu. Rev. Chem. Biomol. Eng. 2012, 3, 519–543. [Google Scholar] [CrossRef] [PubMed]

- Stetten, A.Z.; Iasella, S.V.; Corcoran, T.E.; Garoff, S.; Przybycien, T.M.; Tilton, R.D. Current Opinion in Colloid & Interface Science Surfactant-induced Marangoni transport of lipids and therapeutics within the lung. Curr. Opin. Colloid Interface Sci. 2018, 36, 58–69. [Google Scholar] [CrossRef] [PubMed]

- Ezuddin, N.S.; Alawa, K.A.; Galor, A. Therapeutic Strategies to Treat Dry Eye in an Aging Population. Drugs Aging 2015, 32, 505–513. [Google Scholar] [CrossRef] [PubMed]

- Yang, N.; Lv, R.; Jia, J.; Nishinari, K.; Fang, Y. Application of Microrheology in Food Science. Annu. Rev. Food Sci. Technol. 2017, 8, 493–521. [Google Scholar] [CrossRef] [PubMed]

- Sharipova, A.; Aidarova, S.; Mutaliyeva, B.; Babayev, A.; Issakhov, M.; Issayeva, A.; Madybekova, G.; Grigoriev, D.; Miller, R. The Use of Polymer and Surfactants for the Microencapsulation and Emulsion Stabilization. Colloids Interfaces 2017, 1, 3. [Google Scholar] [CrossRef]

- Berton-Carabin, C.C.; Sagis, L.; Schroën, K. Formation, Structure, and Functionality of Interfacial Layers in Food Emulsions. Annu. Rev. Food Sci. Technol. 2018, 9, 551–587. [Google Scholar] [CrossRef] [PubMed]

- Langevin, D.; Argillier, J.F. Interfacial behavior of asphaltenes. Adv. Colloid Interface Sci. 2016, 233, 83–93. [Google Scholar] [CrossRef] [PubMed]

- Erni, P. Deformation modes of complex fluid interfaces. Soft Matter 2011, 7, 7586–7600. [Google Scholar] [CrossRef]

- Guzmán, E.; Tajuelo, J.; Pastor, J.M.; Rubio, M.A.; Ortega, F.; Rubio, R.G. Shear rheology of fluid interfaces: Closing the gap between macro- and micro-rheology. Curr. Opin. Colloid Interface Sci. 2018, 37, 33–48. [Google Scholar] [CrossRef]

- Jaensson, N.; Vermant, J. Tensiometry and rheology of complex interfaces. Curr. Opin. Colloid Interface Sci. 2018. [Google Scholar] [CrossRef]

- Liggieri, R.; Miller, L. Interfacial Rheology; Brill Academic Publishers: Leiden, The Netherlands, 2009. [Google Scholar]

- Erni, P.; Fischer, P.; Windhab, E.J.; Kusnezov, V.; Stettin, H.; Läuger, J. Stress- and strain-controlled measurements of interfacial shear viscosity and viscoelasticity at liquid/liquid and gas/liquid interfaces. Rev. Sci. Instrum. 2003, 74, 4916–4924. [Google Scholar] [CrossRef]

- Vandebril, S.; Franck, A.; Fuller, G.G.; Moldenaers, P.; Vermant, J. A double wall-ring geometry for interfacial shear rheometry. Rheol. Acta 2010, 49, 131–144. [Google Scholar] [CrossRef]

- Brooks, C.F.; Fuller, G.G.; Frank, C.W.; Robertson, C.R. Interfacial stress rheometer to study rheological transitions in monolayers at the air-water interface. Langmuir 1999, 15, 2450–2459. [Google Scholar] [CrossRef]

- Tajuelo, J.; Pastor, J.M.; Rubio, M.A. A magnetic rod interfacial shear rheometer driven by a mobile magnetic trap. J. Rheol. 2016, 60, 1095–1113. [Google Scholar] [CrossRef]

- Edwards, D.A.; Brenner, H.; Wasan, D.T. Interfacial Transport Processeses and Rheology; Butterworth-Heinemann: Boston, MA, USA, 1991. [Google Scholar]

- Reynaert, S.; Brooks, C.F.; Moldenaers, P.; Vermant, J.; Fuller, G.G. Analysis of the magnetic rod interfacial stress rheometer. J. Rheol. 2008, 52, 261–285. [Google Scholar] [CrossRef]

- Verwijlen, T.; Imperiali, L.; Vermant, J. Separating viscoelastic and compressibility contributions in pressure-area isotherm measurements. Adv. Colloid Interface Sci. 2014, 206, 428–436. [Google Scholar] [CrossRef] [PubMed]

- Tajuelo, J.; Pastor, J.M.; Martínez-Pedrero, F.; Vázquez, M.; Ortega, F.; Rubio, R.G.; Rubio, M.A. Magnetic microwire probes for the magnetic rod interfacial stress rheometer. Langmuir 2015, 31, 1410–1420. [Google Scholar] [CrossRef] [PubMed]

- Tajuelo, J.; Rubio, M.A.; Pastor, J.M. Flow field based data processing for the oscillating conical bob interfacial shear rheometer. J. Rheol. 2018, 62, 295–311. [Google Scholar] [CrossRef]

- Raghunandan, A.; Lopez, J.M.; Hirsa, A.H. Bulk flow driven by a viscous monolayer. J. Fluid Mech. 2015, 785, 283–300. [Google Scholar] [CrossRef]

- Rasheed, F.; Raghunandan, A.; Hirsa, A.H.; Lopez, J.M. Oscillatory shear rheology measurements and Newtonian modeling of insoluble monolayers. Phys. Rev. Fluids 2017, 2, 044002. [Google Scholar] [CrossRef]

- Sánchez-Puga, P.; Tajuelo, J.; Pastor, J.M.; Rubio, M.A. BiconeDrag—A data processing application for the oscillating conical bob interfacial shear rheometer. arXiv, 2018; arXiv:1810.01696. [Google Scholar]

- Sanchez-Puga, P.; Tajuelo, J.; Pastor, J.M.; Rubio, M.A. BiconeDrag—A Data Processing Application for the Oscillating Conical Bob Interfacial Shear Rheometer (Software Package). 2018. Available online: https://data.mendeley.com/datasets/4tmy9k4ys3/1 (accessed on 7 December 2018). [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Puga, P.; Tajuelo, J.; Pastor, J.M.; Rubio, M.A. Dynamic Measurements with the Bicone Interfacial Shear Rheometer: Numerical Bench-Marking of Flow Field-Based Data Processing. Colloids Interfaces 2018, 2, 69. https://doi.org/10.3390/colloids2040069

Sánchez-Puga P, Tajuelo J, Pastor JM, Rubio MA. Dynamic Measurements with the Bicone Interfacial Shear Rheometer: Numerical Bench-Marking of Flow Field-Based Data Processing. Colloids and Interfaces. 2018; 2(4):69. https://doi.org/10.3390/colloids2040069

Chicago/Turabian StyleSánchez-Puga, Pablo, Javier Tajuelo, Juan Manuel Pastor, and Miguel A. Rubio. 2018. "Dynamic Measurements with the Bicone Interfacial Shear Rheometer: Numerical Bench-Marking of Flow Field-Based Data Processing" Colloids and Interfaces 2, no. 4: 69. https://doi.org/10.3390/colloids2040069

APA StyleSánchez-Puga, P., Tajuelo, J., Pastor, J. M., & Rubio, M. A. (2018). Dynamic Measurements with the Bicone Interfacial Shear Rheometer: Numerical Bench-Marking of Flow Field-Based Data Processing. Colloids and Interfaces, 2(4), 69. https://doi.org/10.3390/colloids2040069