Study on the Temperature and Smoke Movement in the Event of a Fire in a Semiclosed Tunnel under Water Spray

Abstract

:1. Introduction

1.1. Research Motivation

1.2. Related Work

1.3. Necessity of Research Based on Challenges in the Literature

- It is common to find semiclosed tunnels in engineering construction, but they pose a hidden fire risk. If a fire breaks out, there is only one rescue and escape route, which could lead to severe consequences. Previous studies on the fire characteristics of semiclosed tunnels have overlooked the ventilation system because these tunnels are not interconnected. A mine-driving roadway is an example of a semiclosed roadway that uses local press-in ventilation in the driving face. This type of ventilation produces a limited adherent jet airflow, which can mix smoke in the enclosed space and make the smoke migration more complex.

- As wet dedusting is usually carried out in the mine excavation face, it can be seen that it is feasible to add sprinkler facilities in the heading roadway. The research on spray fire prevention mainly focuses on highway tunnels and ground buildings, but there needs to be more research on spray fire prevention in semiclosed mine tunneling roadways.

- The research on traditional mine fires focuses on the movement of smoke in the air network. The laws of air volume and energy conservation are all aimed at the connected network, and they do not deal well with fire development in an independent tunneling system. Mine excavation roadway is a particular type of semiclosed boundary tunnel; its ventilation depends on the local fan but is also limited by the overall ventilation network of the mine. Mine excavation has more fire-hidden dangers than a ground tunnel, such as gas, rubber, diesel, and so on. The smoke generated by the fire can easily move along the ventilation network and enlarge the scope of the disaster.

1.4. Novelty and Main Contributions

- In this paper, a dynamic model of smoke movement under the action of water spray in heading roadways is established, the balanced relationship between water spray drag force and smoke buoyancy is discussed, and the prevention and control mechanism of water spray on fire smoke in heading roadway face is presented.

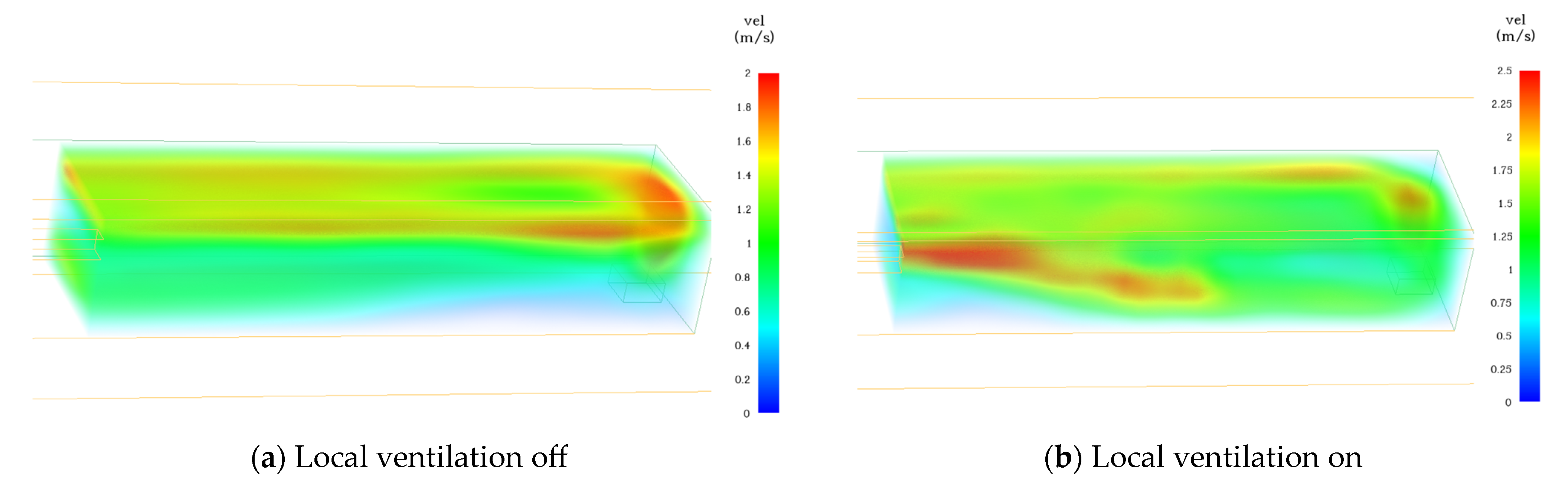

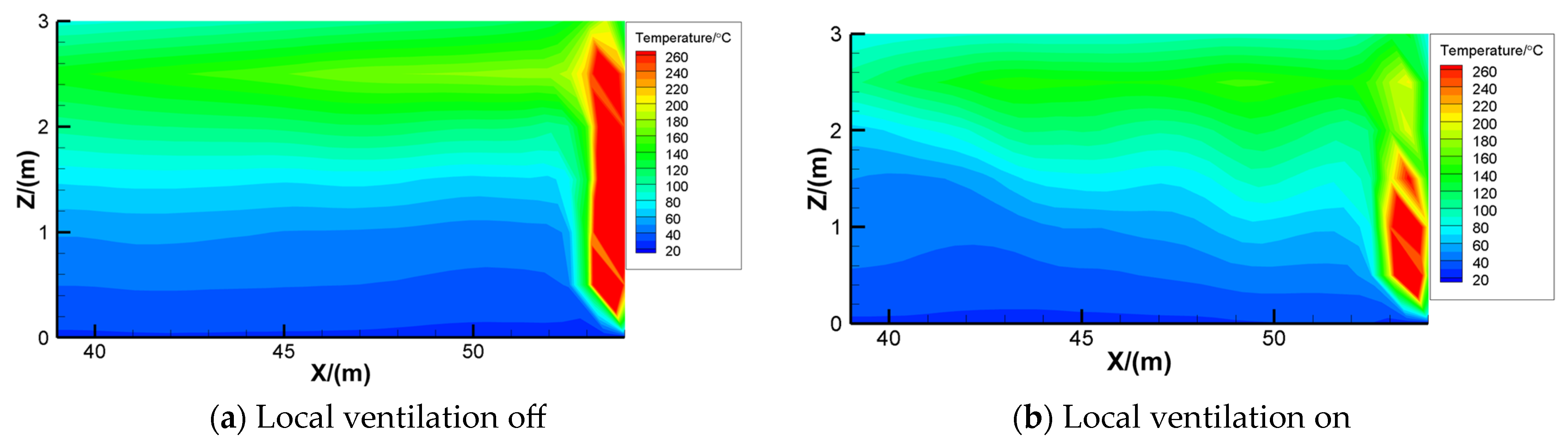

- The influence of local ventilation on the velocity and temperature fields of the heading face is explored by numerical simulation. It is discovered that local ventilation and smoke movement create circulating flow in the excavation face.

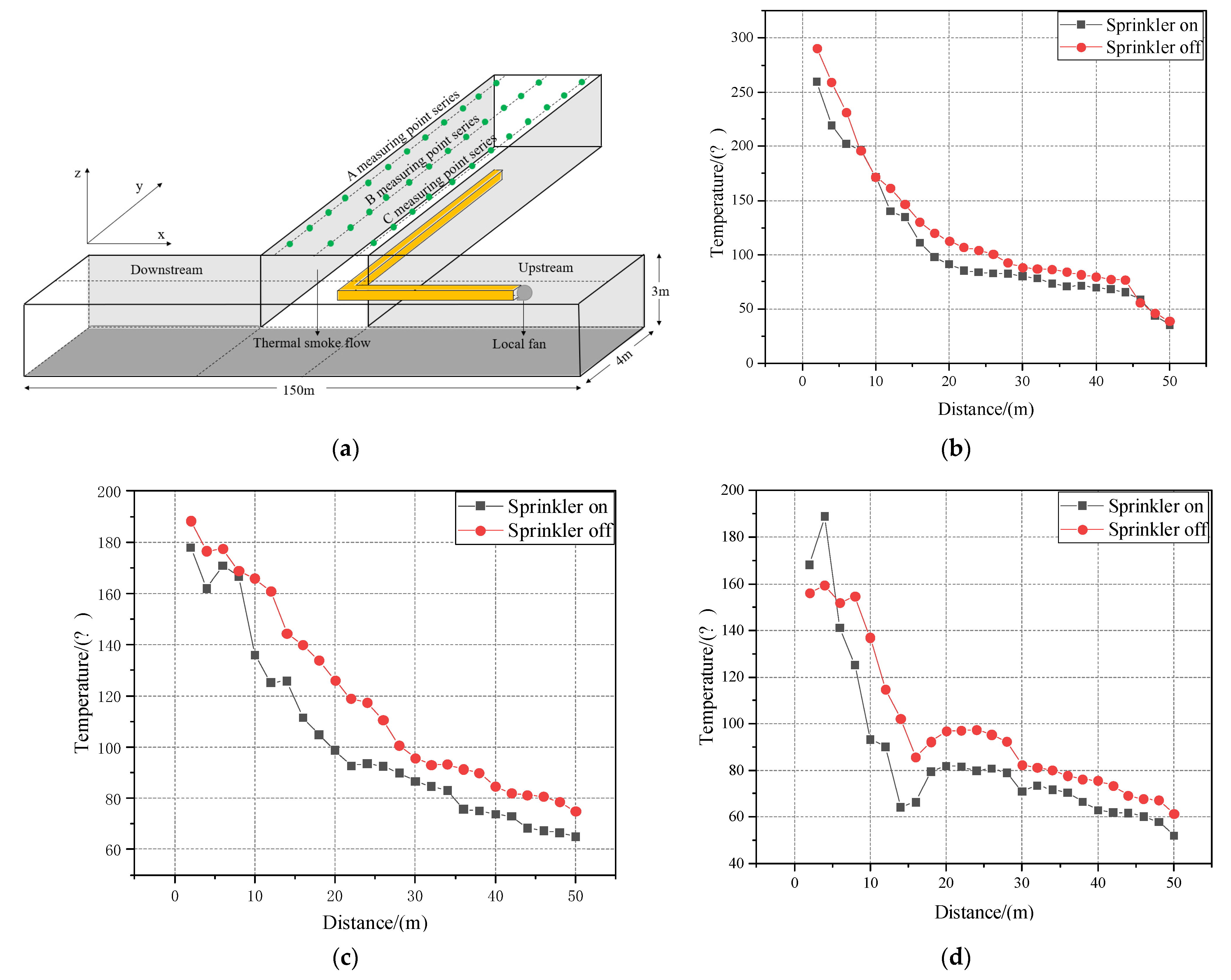

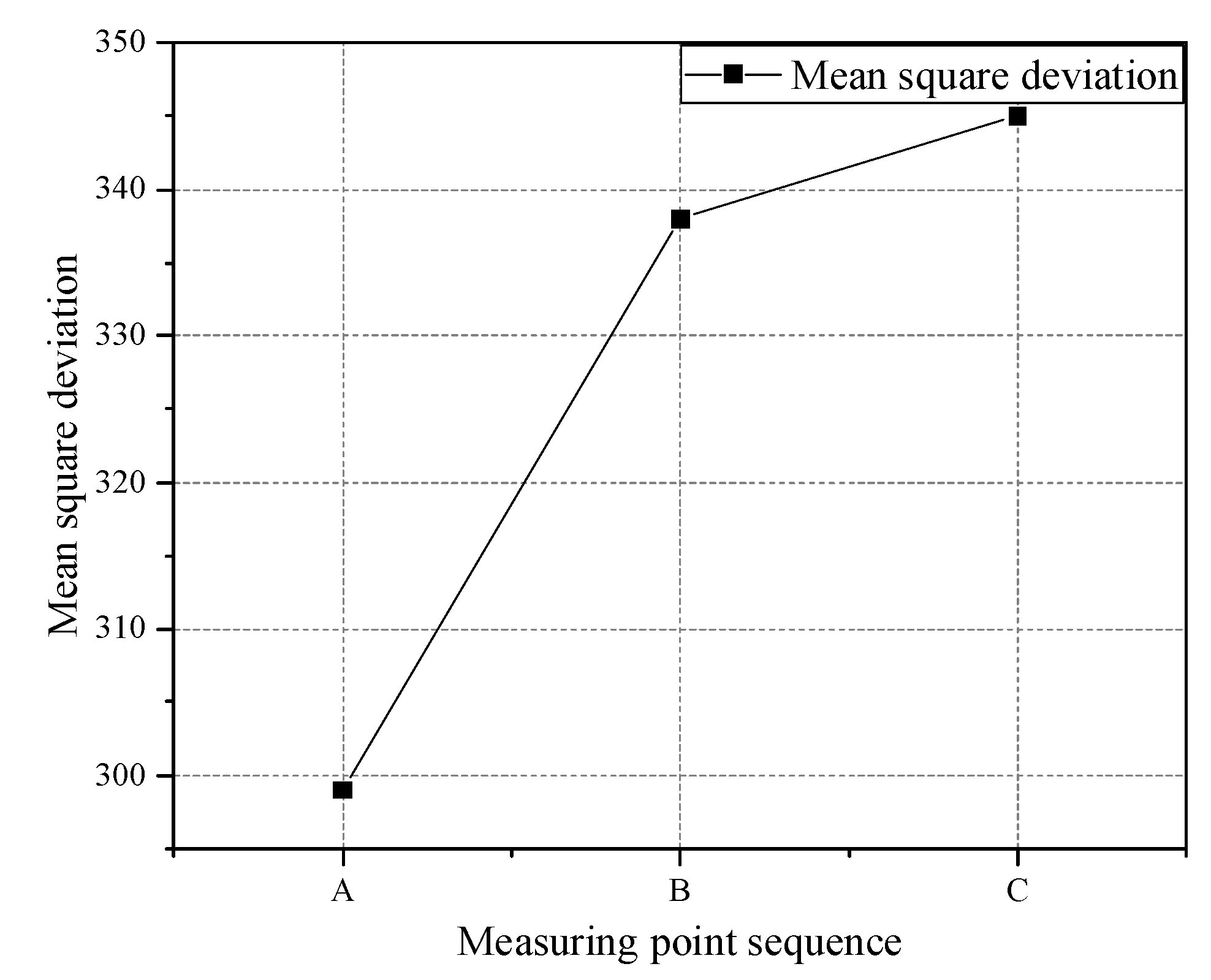

- This paper analyzes the temperature characteristics in the excavation face when the spray facilities are opened, analyzes the cooling effects of the liquid droplets and circulating airflow on the fire, and compares the liquid droplets’ cooling effects on different longitudinal roadway positions.

- The mine excavation roadway fire studied in this paper is a typical semiclosed tunnel end fire. This paper provides ideas and meaningful conclusions for studying semiclosed tunnel end fires.

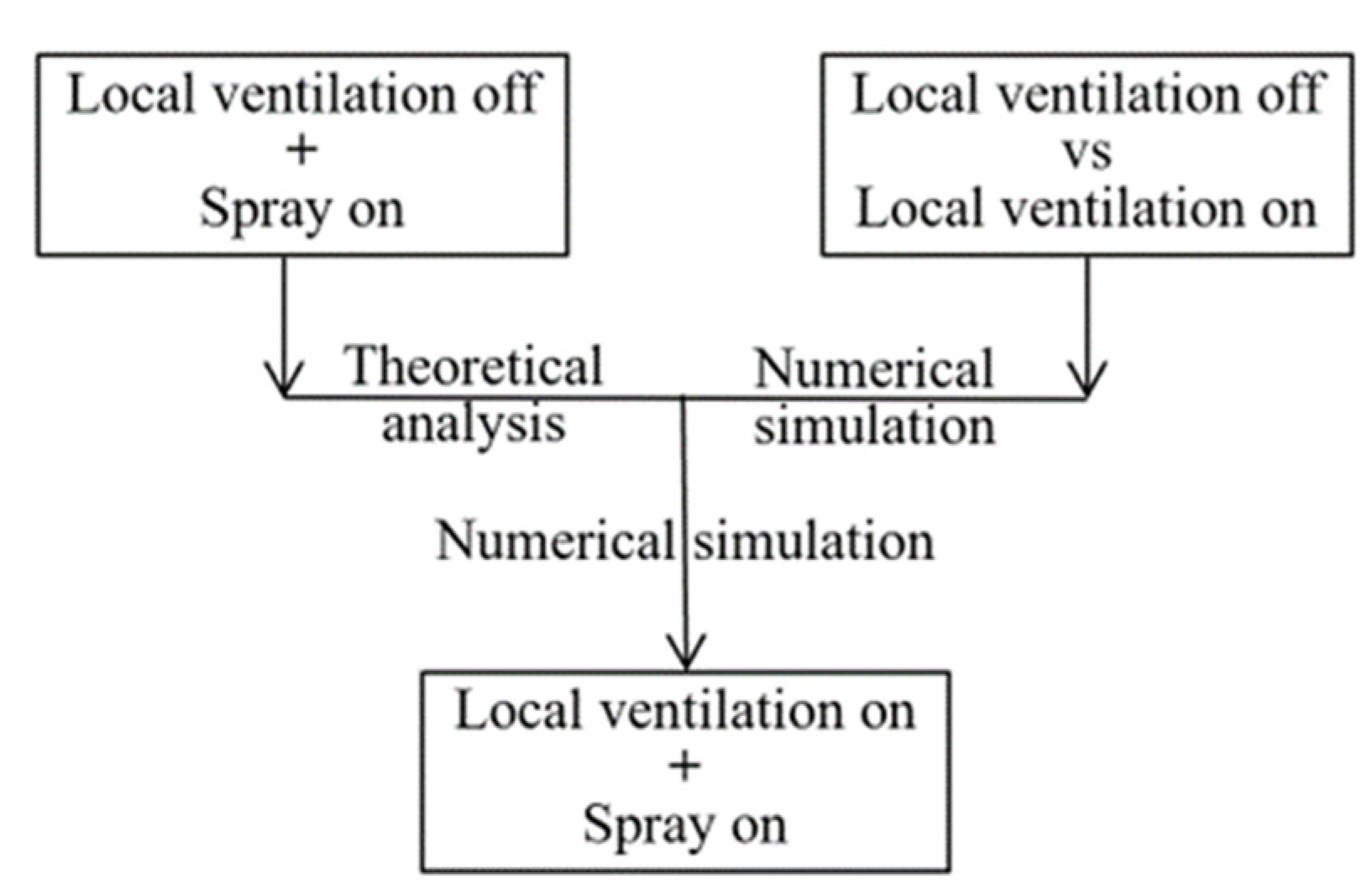

1.5. Research Methods

2. Introduction of Numerical Simulation

2.1. Model Structure

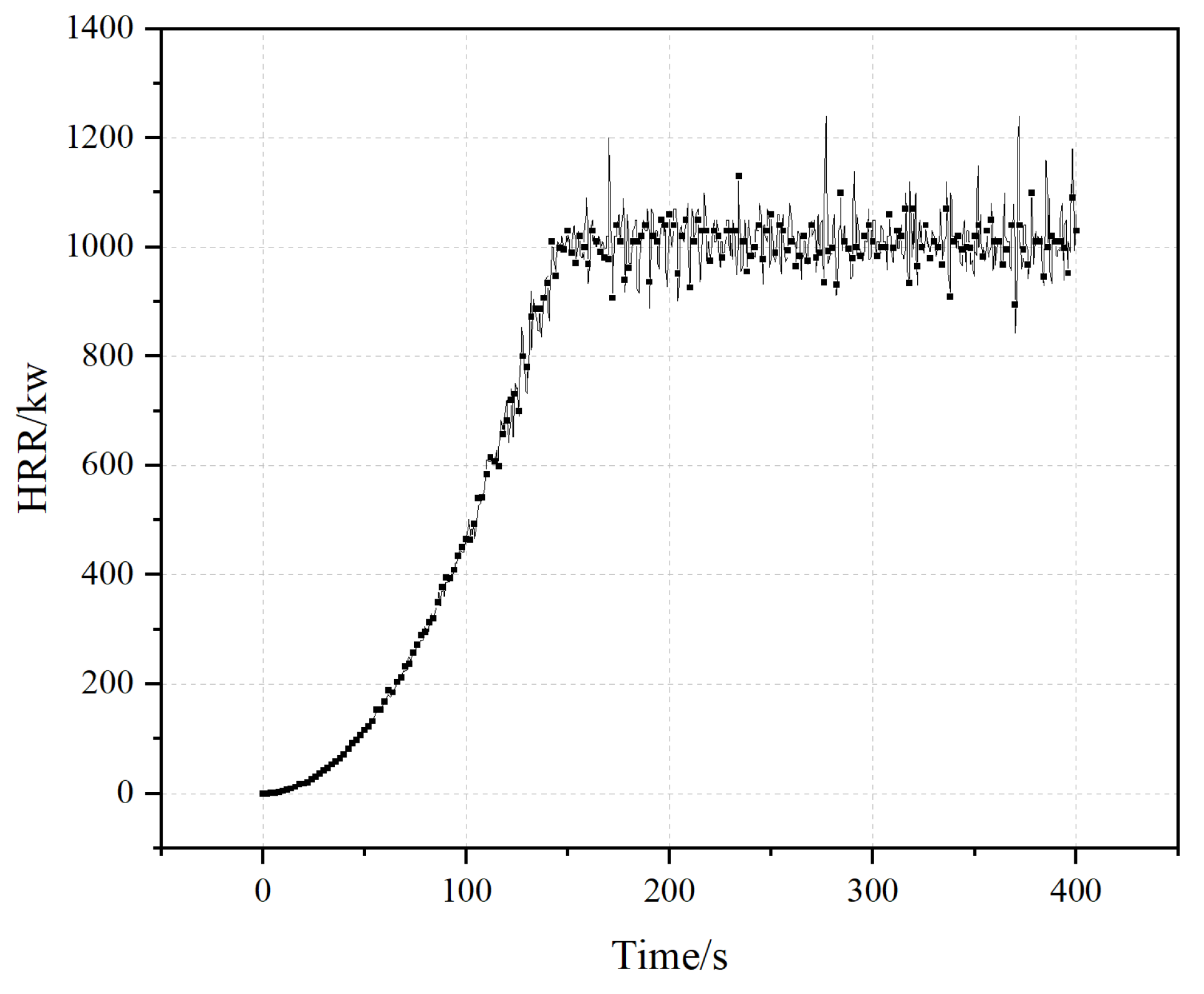

2.2. Fire Source Setting

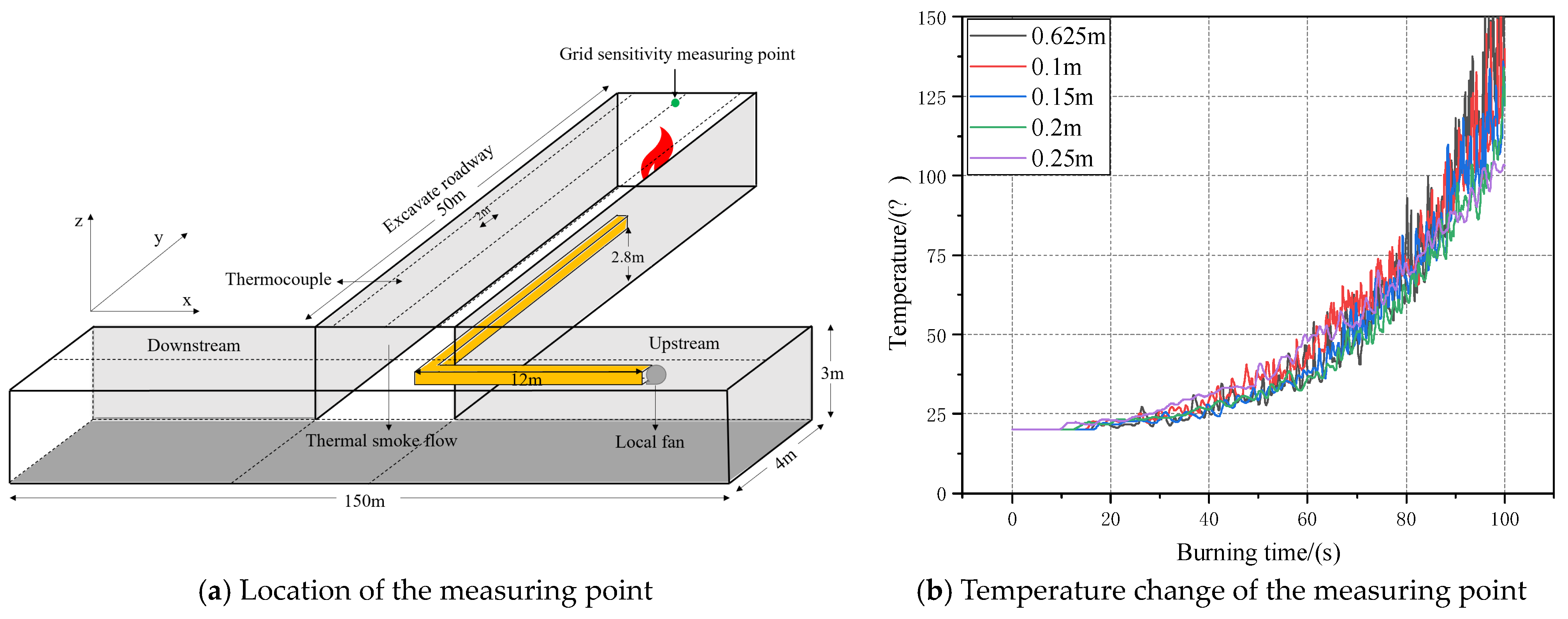

2.3. Grid Sensitivity Analysis

2.4. Design of the Working Conditions

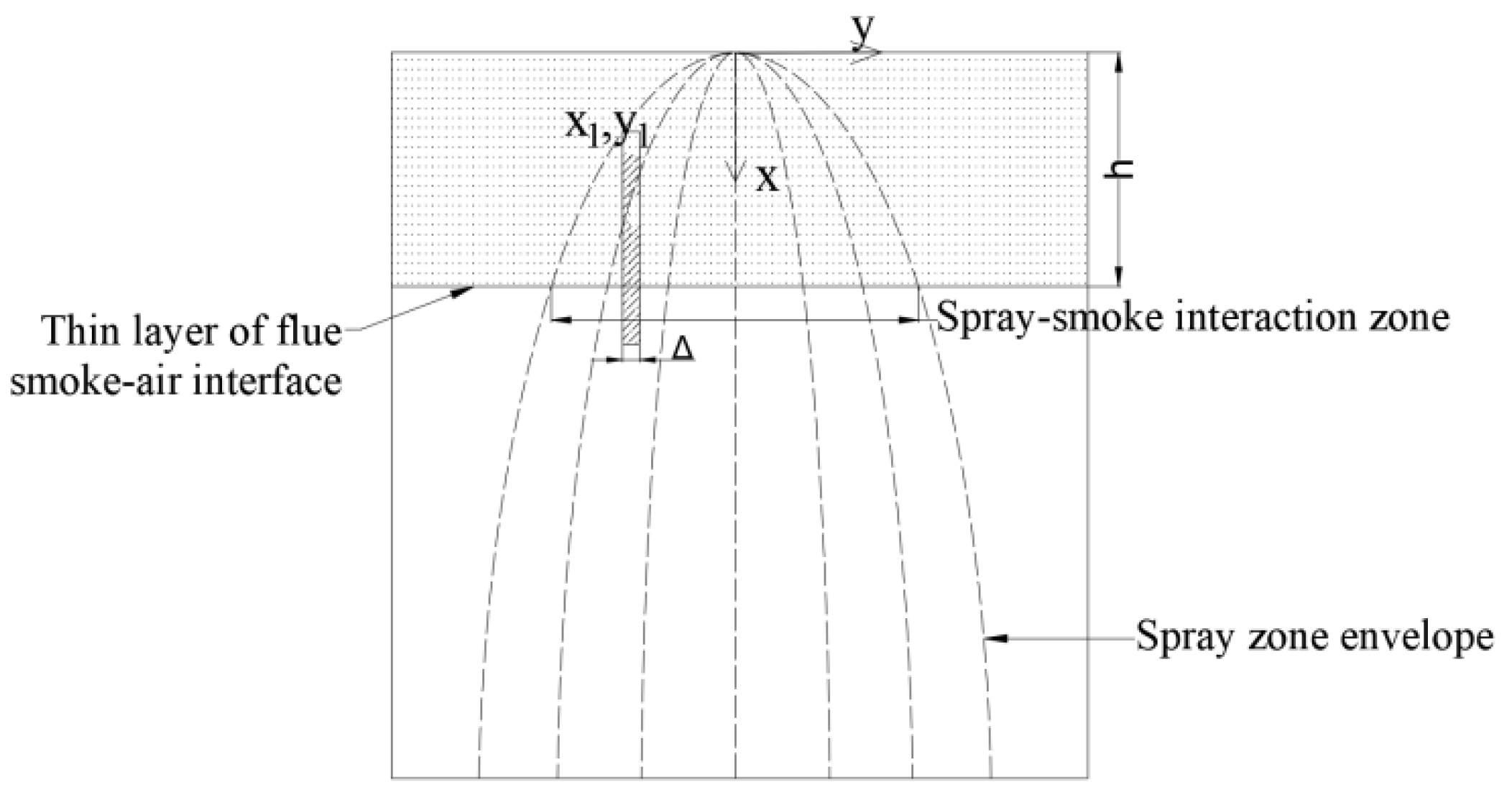

3. Dynamic Model of Smoke Movement under Spray

3.1. Drag Force of Liquid Droplets per Unit Area under Steady State

3.2. Total Buoyancy of Smoke per Unit Area in Steady State

3.3. Calculation of Blocking Smoke under the Action of Spray in Excavation Roadway

4. Numerical Simulation of the Influence of Local Ventilation on the Temperature Characteristics of Smoke in the Excavation Face

4.1. Characteristics of Three-Dimensional Velocity Field in the Heading Face

4.2. Analysis of Two-Dimensional Temperature Field Characteristics of a Specific Cross Section

5. Analysis of the Influence of Spray on Temperature Field in the Excavation Roadway

5.1. Distribution of Temperature Field around Spray

5.2. Temperature Distribution in the Excavation Roadway

6. Discussion

7. Conclusions

7.1. Conclusions and Contribution

- From the point of view of dynamics, the equilibrium relationship between droplet drag force and smoke buoyancy is presented. The smoke control mechanism of water spraying in semiclosed tunnels is explained. According to the ratio of congestion thickness to initial thickness, the equation for calculating the blocking smoke volume of a semiclosed tunnel under the action of spray is presented.

- In the excavation face, local ventilation will provide a circulating airflow. The circulating airflow causes the temperature in the upper right corner of the temperature cloud image on the cross section of Z = 2.8 m to be the highest, while on the cross section of Y = 22 m, it causes a difference in the size of the high-temperature area and the shape of the temperature stratification. The smoke blocking model that operates under the influence of water spray on a moving roadway is inapplicable due to this type of circulating airflow.

- When the volume of the smoke is small, the circulation flow helps the smoke avoid the majority of the water spraying effect; however, when the volume of the smoke is large, the effect of the circulation flow is reduced and the smoke accumulates near the nozzle, so the blocking effect of the water spray is substantial. The mean square error analysis revealed that activating the sprinkler has the biggest cooling impact on the wall on one side of the air duct.

7.2. Limitations and Prospects of the Study

- This study only analyzed the temperature characteristics of a two-dimensional plane at a height of 2.8 m in the heading face. The entire three-dimensional space was not taken into consideration.

- The smoke movement model under the coupling of local ventilation and water spray was not derived in this study; it only derived the kinematic model without local ventilation. A follow-up study must conclusively support the mathematical simulation-based theoretical model.

- This paper used numerical simulation as the research method. In subsequent studies, similar experiments should be designed to verify and supplement the relevant conclusions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, Y.; Li, Y.; Dong, B.; Li, J.; Liang, Q. Numerical investigation on the maximum ceiling temperature and longitudinal decay in a sealing tunnel fire. Tunn. Undergr. Space Technol. 2018, 72, 120–130. [Google Scholar] [CrossRef]

- Yao, Y.; Li, Y.Z.; Lönnermark, A.; Ingason, H.; Cheng, X. Study of tunnel fires during construction using a model scale tunnel. Tunn. Undergr. Space Technol. 2019, 89, 50–67. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y. Study on Underground Utility Tunnel Fire Characteristics under Sealing and Ventilation Conditions. Adv. Civ. Eng. 2020, 2020, 9128704. [Google Scholar] [CrossRef]

- Liu, X.; Chang, P.; Wang, E.; Zhang, Z.; Yang, S. Numerical Study of the Respirable Coal Dust Removal Performance of a Vortex Ventilation System at an Excavation Face. Energies 2018, 11, 2449. [Google Scholar] [CrossRef]

- Cheng, L.H.; Ueng, T.H.; Liu, C.W. Simulation of ventilation and fire in the underground facilities. Fire Saf. J. 2001, 36, 597–619. [Google Scholar] [CrossRef]

- Yuan, L.; Zhou, L.; Smith, A.C. Modeling carbon monoxide spread in underground mine fires. Appl. Therm. Eng. 2016, 100, 1319–1326. [Google Scholar] [CrossRef]

- Tang, Z.; Gao, K.; Shan, Y.; Zhu, C.; Liu, Z.; Liu, Z. Study of the Fire Behavior of Multilayer Cables in a Mine Tunnel. Energies 2022, 15, 2059. [Google Scholar] [CrossRef]

- Pach, G.; Różański, Z.; Wrona, P.; Niewiadomski, A.; Zapletal, P.; Zubíček, V. Reversal Ventilation as a Method of Fire Hazard Mitigation in the Mines. Energies 2020, 13, 1755. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Z.; Hu, Z.; Cui, X.; Peng, X.; Zhang, J. Effects of Fire Location and Forced Air Volume on Fire Development for Single-Ended Tunnel Fire with Forced Ventilation. Fire 2023, 6, 111. [Google Scholar] [CrossRef]

- Chen, C.K.; Zhu, C.X.; Liu, X.Y.; Yu, N.H. Experimental investigation on the effect of asymmetrical sealing on tunnel fire behavior. Int. J. Heat Mass Transf. 2016, 92, 55–65. [Google Scholar] [CrossRef]

- Han, J.; Liu, F.; Wang, F.; Weng, M.; Wang, J. Study on the smoke movement and downstream temperature distribution in a sloping tunnel with one closed portal. Int. J. Therm. Sci. 2019, 149, 106165. [Google Scholar] [CrossRef]

- Wang, Z.; Han, J.; Wang, J.; Geng, P.; Weng, M.; Liu, F. Temperature distribution in a blocked tunnel with one closed portal under natural ventilation. Tunn. Undergr. Space Technol. 2021, 109, 103752. [Google Scholar] [CrossRef]

- Cooper, L.Y. The interaction of an isolated sprinkler spray and a two-layer compartment fire environment. Phenom. Model Simul. Fire Saf. J. 1995, 38, 679–690. [Google Scholar] [CrossRef]

- Chen, C.K.; Zhu, C.X.; Liu, X.Y.; Yu, N.H. Flow fields induced by longitudinal ventilation and water spray system in reduced-scale tunnel fires. Tunn. Undergr. Space Technol. 2020, 104, 103543. [Google Scholar]

- Chen, C.F.; Shu, C.M.; Ho, S.P.; Kung, H.C.; Chien, S.W. Effects of Ventilation and Water Spray in a Model-Scale Tunnel Fire. Fire Technol. 2018, 54, 75–96. [Google Scholar] [CrossRef]

- Qin, J.; Chow, W.K. Experimental data on water mist suppression. In Proceedings of the Asia-Oceania Symposium on Fire Science and Technology, Tsukuba, Japan, 5–7 October 2015. [Google Scholar]

- Blanchard, E.; Boulet, P.; Fromy, P.; Desanghere, S.; Carlotti, P.; Vantelon, J.P.; Garo, J.P. Experimental and Numerical Study of the Interaction Between Water Mist and Fire in an Intermediate Test Tunnel. Fire Technol. 2014, 50, 565–587. [Google Scholar] [CrossRef]

- Caliendo, C.; Genovese, G.; Russo, I. A Numerical Study for Assessing the Risk Reduction Using an Emergency Vehicle Equipped with a Micronized Water System for Contrasting the Fire Growth Phase in Road Tunnels. Appl. Sci. 2021, 11, 5248. [Google Scholar] [CrossRef]

- Wang, K.; Hao, H.; Jiang, S.; Wu, Z.; Cai, W.; Wang, Z. Study on fire smoke flow characteristics in the ventilation network and linkage control system in coal mines. Fire Mater. 2020, 44, 989–1003. [Google Scholar] [CrossRef]

- Fan, C.G.; Li, X.Y.; Mu, Y.; Guo, F.Y.; Ji, J. Smoke movement characteristics under stack effect in a mine laneway fire. Appl. Therm. Eng. 2017, 110, 70–79. [Google Scholar] [CrossRef]

- Liu, C.; Zhong, M.; Shi, C.; Zhang, P.; Tian, X. Temperature profile of fire-induced smoke in node area of a full-scale mine shaft tunnel under natural ventilation. Appl. Therm. Eng. 2017, 110, 382–389. [Google Scholar] [CrossRef]

- Lee, C.W.; Nguyen, V.D. A Study on the Optimal Installation of Ducted Fan Ventilation System in Long Mine Airways: Focused on the Wall Separation Distance and the Gap Length between Ducts. Tunn. Undergr. Spaces 2017, 27, 12–25. [Google Scholar] [CrossRef]

- Grekhneva, N.N.P.V. Adaptation of Main Mine Fan Aerodynamics to Vent Mode Changes. J. Min. Sci. 2013, 49, 779–784. [Google Scholar]

- GB51251-2017; Technical standard for smoke management systems in buildings. China Planning Press: Beijing, China, 2017.

- Ma, Q.; Chen, J.; Zhang, H. Heat release rate determination of pool fire at different pressure conditions. Fire Mater. 2018, 42, 620–626. [Google Scholar] [CrossRef]

- Li, J.; Prétrel, H.; Beji, T.; Merci, B. Influence of fire heat release rate (HRR) evolutions on fire-induced pressure variations in air-tight compartments. Fire Saf. J. 2021, 126, 103450. [Google Scholar] [CrossRef]

- Tang, F.; Cao, Z.; Palacios, A.; Wang, Q. A study on the maximum temperature of ceiling jet induced by rectangular source fires in a tunnel using ceiling smoke extraction. Int. J. Therm. Sci. 2018, 127, 329–334. [Google Scholar] [CrossRef]

- Lin, C.H.; Ferng, Y.M.; Hsu, W.S. Investigating the effect of computational grid sizes on the predicted characteristics of thermal radiation for a fire. Appl. Therm. Eng. 2009, 29, 2243–2250. [Google Scholar] [CrossRef]

- Carvel, R.; Beard, A.; Jowitt, P.; Drysdale, D. The Influence of Tunnel Geometry and Ventilation on the Heat Release Rate of a Fire. Fire Technol. 2004, 40, 5–26. [Google Scholar] [CrossRef]

- Arya, J. Development of a flooded-bed scrubber for removing coal dust at a longwall mining section. Saf. Sci. 2018, 110, 204–213. [Google Scholar] [CrossRef]

- Liu, Z.; Nie, W.; Peng, H.; Yang, S.; Chen, D.; Liu, Q. The effects of the spraying pressure and nozzle orifice diameter on the atomizing rules and dust suppression performances of an external spraying system in a fully-mechanized excavation face. Powder Technol. 2019, 350, 62–80. [Google Scholar] [CrossRef]

- Tianshui, L.; Mengjie, L.; Xinli, W.; Wei, Z. An Experimental Study on the Interaction of Water Mist with Vertical/Horizontal Spray Flame. Procedia Eng. 2014, 84, 543–552. [Google Scholar] [CrossRef]

- Link, E.; Myers, T.; Trouvé, A.; Marshall, A. Measurements of spray-plume interactions for model validation. Fire Saf. J. 2017, 91, 714–722. [Google Scholar] [CrossRef]

- Li, K.Y.; Sun, X.Q.; Huo, R.; Wang, P. A New Criterion for Stability of Smoke Layer under Sprinkler Spray. Univ. Canterb. Civ. Nat. Resour. Eng. 2007. [Google Scholar]

- Kai-Yuan, L.I.; Zhang, C.F.; Si-Cheng, L.I.; Ran, H.; Xiao-Qian, S.; Yu-Hang, Y. Criterion for Stability of Smoke Layer Under Sprinkler Spray and Experimental Validation. J. Combust. Sci. Technol. 2008, 14, 6. [Google Scholar]

- Sheppard, D.T. Spray Characteristics of Fire Sprinklers; Northwestern University: Evanston, IL, USA, 2002. [Google Scholar]

- Editor, C.D. Automatic Sprinkler Systems Handbook; National Fire Protection Association: Quincy, MA, USA, 2002. [Google Scholar]

- Xiaojia, H.; Wenyuan, J. Design Manual of Automatic Sprinkler System; China Construction Industry Press: Beijing, China, 2002. [Google Scholar]

- Chow, W.K.; Shek, L.C. Physical properties of a sprinkler water spray. Fire Mater. 2010, 17, 279–292. [Google Scholar] [CrossRef]

- Xi, Y.; Dong, X.; Chow, W. Numerical simulation on temperature in wood crib fires. Therm. Sci. 2020, 25, 2621–2636. [Google Scholar] [CrossRef]

- Lee, Y.P.; Tsai, K. Effect of vehicular blockage on critical ventilation velocity and tunnel fire behavior in longitudinally ventilated tunnels. Fire Saf. J. 2012, 53, 35–42. [Google Scholar] [CrossRef]

- Zhong, W.; Lv, J.; Li, Z.; Liang, T. A study of bifurcation flow of fire smoke in tunnel with longitudinal ventilation. Int. J. Heat Mass Transf. 2013, 67, 829–835. [Google Scholar] [CrossRef]

| HRR | Characteristic Diameter of Fire Source | Mesh Diameter | Mesh Size |

|---|---|---|---|

| 1 MW | 0.94 m | 0.25 m | |

| 0.2 m | |||

| 0.15 m | |||

| 0.1 m | |||

| 0.0625 |

| No. | Comparison of Working Conditions | Heat Release Rate/kw | Fire Growth Law | Ventilation Condition | Spray Equipment | Wind/(m/s) |

|---|---|---|---|---|---|---|

| 1 | Local ventilation | 1000 | t2 | On | Off | 6.5 |

| 2 | 1000 | t2 | Off | Off | 0 | |

| 3 | Sprinkler | 1500 | Constant | On | Off | 6.5 |

| 4 | 1500 | Constant | On | On | 6.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Zhang, W.; Li, Y.; Zhang, Z.; Dong, J.; Cui, Y. Study on the Temperature and Smoke Movement in the Event of a Fire in a Semiclosed Tunnel under Water Spray. Fire 2023, 6, 324. https://doi.org/10.3390/fire6080324

Li B, Zhang W, Li Y, Zhang Z, Dong J, Cui Y. Study on the Temperature and Smoke Movement in the Event of a Fire in a Semiclosed Tunnel under Water Spray. Fire. 2023; 6(8):324. https://doi.org/10.3390/fire6080324

Chicago/Turabian StyleLi, Bolun, Wei Zhang, Yucheng Li, Zhitao Zhang, Jinyang Dong, and Yunan Cui. 2023. "Study on the Temperature and Smoke Movement in the Event of a Fire in a Semiclosed Tunnel under Water Spray" Fire 6, no. 8: 324. https://doi.org/10.3390/fire6080324