1. Introduction

Electrical discharge coating (EDC) is a process used to improve and modify the surfaces of materials or workpieces in terms of mechanical, physical and biochemical properties. Researchers worldwide [

1] are using this technique to create protective coatings that can withstand extreme temperatures, pressures and hostile environments. By doing so, the properties of the base material, such as strength [

2], corrosion resistance [

3], wear resistance [

4], biocompatibility [

5], etc., are increased. Nowadays, surface modification is also important in the biomedical area [

6,

7], specifically in dentistry [

8] and orthopedic applications [

2,

9], to improve the biomechanical and morphological compatibilities between existing and newly introduced body tissues and to promote osteointegration [

10]. Plasma-based surface modification can improve adhesion and surface wettability, minimize tissue surface friction and reduce contaminants to a safe level [

11]. This is why previous research has consistently demonstrated the necessity of surface modification in the biomedical sector, particularly for modifying the surfaces of the outermost tissues and producing/fabricating a homogeneous implant surface [

12,

13].

In the past, there were many surface modification techniques, such as carburizing, electroplating, plasma spraying, etc., which are widely employed in today’s business [

14]. However, in recent years, the use of EDC to alter material surfaces using electrical discharge energy has received interest as a result of recent breakthroughs in the field of surface modification. EDC is a novel technology that is derived from electrical discharge machining (EDM) by changing the polarity of the electrodes [

15]. The electrode material is melted and deposited on the surface of the workpiece at an extremely high temperature (8000 °C to 12,000 °C) in EDC [

16]. EDC can also modify the surfaces of all types of electrically conductive materials, including those that are exceedingly difficult to process, such as tungsten carbide and silicon carbide [

17]. However, no literature is available on the thorough assessment of the fundamentals and applications of this extremely promising technology. Moreover, no comprehensive assessment has been reported on how the EDC process parameters will impact output process parameters such as the deposition rate, electrode wear rate, etc. To fill this gap, a systematic study was carried out to deposit copper on the titanium alloy (Ti6Al4V) surface and to then extract the strengths, weaknesses, opportunities and threats of EDC technology in the field of surface modification for high-function products [

18,

19,

20].

S. L. Li et al. [

21] developed an anti-wear coating deposited on H31 steel by considering the hierarchical aspects of TiC-enhanced cermet coating using different dielectric fluid mixing processes and evaluated micro-hardness (HV), wear and the coefficient of friction. A. F. Mansor et al. [

22], in their paper, reported the effects of input parameters of EDC coating on the recast layer, crater size and surface roughness (SR) of TiNi shape memory alloy. The recast layer formation discharge duration was the most influential factor, and the peak current affected SR and crater size. A researcher from IIT Dhanbad [

23] worked to improve the surface roughness and hardness of Ti6Al4V using brass electrodes by varying input parameters such as the powder concentration, voltage and duty factor of EDM. MoS

2 powder was mixed in deionized water to improve the above-mentioned parameters. They also reported that powder concentration was the most influential parameter for layer deposition, and SR decreased and HV increased with the powder concentration. In another paper [

24], it was reported that by modifying two input parameters, namely, electrode rotary speed and gas flow rate, cooling the electrode N

2 gas and rotating the electrode equipment setup, calcium and phosphorous were incorporated into the coating on a titanium workpiece for corrosion resistance application. A. Kumar et al. [

25] carried out their work by considering surface roughness, white layer thickness, micro-hardness and scatter crack density using an AlSI10 electrode on titanium alloy and AISI040. Their analysis concluded that surface characteristics were improved by using a rapid prototyping tool, whereas a low material removal rate was observed when using conventional electrodes, and the current was the most influential factor for micro-hardness. A. F. Mansor et al. [

26], in their paper, reported that they analyzed nickel-titanium shape memory alloy using titanium and copper materials to optimize the output parameters of the recast layer thickness, crater size and surface roughness. The input parameters considered were discharge duration, pulse interval, peak current and gap voltage, which were optimized using ANOVA. For the recast layer formation, the discharge duration was the most influential factor, and the peak current had an effect on surface roughness. D. Sharma et al. [

27] conducted a study to modify the surface of titanium alloy using hBN powder mixed in a dielectric on a micro-EDM machine. Input parameters such as voltage, duty factor and powder concentration were varied in their study to measure output parameters such as material deposition, surface roughness, hardness, wear coefficient and corrosion. V. D. Bui et al. [

28] investigated an antibacterial coating on a Ti6Al4V by mixing silver nanopowder at different concentrations in a dielectric fluid of micro-powder mixed electrical discharge machine (PMEDM). The analysis concluded that the deep coating contained a lower silver powder concentration. R. Tyagi et al. [

29] investigated the EDM-coated surface compared with an uncoated surface using a scanning electron microscope with energy-dispersive X-ray spectroscopy (EDX) characterization and conducted a wear test to analyze the wear. A paper authored by A. R. Siddique et al. [

30] reported on the difficulty in coating localized areas using powder electrodes with micro-EDM. Their study concluded that the brass electrode showed a better coating, whereas the WS

2–brass (70:30) electrode showed a uniform surface coating. V. D. Bui et al. [

31] conducted another work to study the elemental composition of surface-modified materials, i.e., silver layer coating on Ti6Al4V, for antibacterial application. Another research group [

32] reported their work on coating the SS304 surface by varying input parameters. A crack-free coating was obtained using different ceramics. Z. Y. Zeng et al. [

33] conducted a comparative study between physical vapor deposition and electrical discharge coating (EDC) for TiNC and concluded that EDC provided the required coating in terms of thickness and wear. P. J. Liew et al. [

34] conducted a review considering all of the previous research on electrical discharge coating techniques. Nuhaize et al. [

35] conducted a study on the formation of electrical discharge coatings on stainless steel with an electrode of stellite 31. They concluded in their study that particle sizes between 45 and 70 microns were obtained. The same group of researchers conducted a study to analyze residual stress in EDCs and concluded that residual stresses ranged between +6 and −140 MPa [

36]. Roshalliza et al. [

37], in their study on electrical discharge coating of NiTi alloy in deionized water, analyzed surface roughness and concluded that improving the surface roughness of Nitinol will have applications in the biomedical field. Ahmad et al. [

38] evaluated parameters for electrical discharge coatings on nickel–titanium shape memory alloy in deionized water and mentioned that the polarity of the electrode was found to have a significant influence on the recast layer.

This paper provides details on various issues and procedures involved in electrical discharge coatings; for example, reverse polarity (Tool + Workpiece−) is more effective than straight polarity (Tool – Workpiece+), adding a powder to a dielectric fluid can improve the coating deposition and reduce the formation of microcracks/holes, and the dry EDC process is the most eco-friendly process. The possibility of using powder metallurgy electrodes, etc., is also explored.

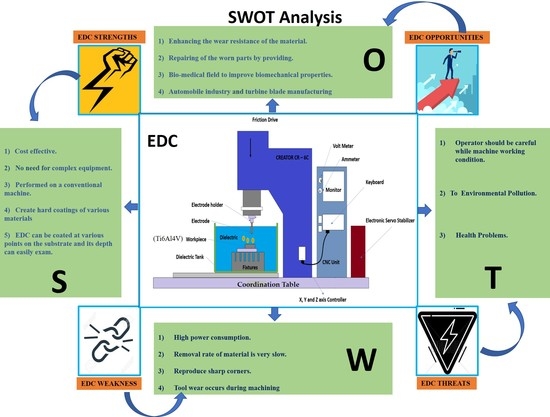

This work aimed to evaluate EDCs by SWOT (strengths, weaknesses, opportunities and threats) analysis. SWOT analysis is a cognitive process for studying the interrelations between the internal and external surroundings of processing. Based on the characterization of EDCs, an evaluation of strengths, weaknesses, opportunities and threats was performed. Combining these analysis strategies will serve to provide a solution for developing enhanced EDCs. Strengths in the SWOT analysis are internal capabilities and positive factors that are relevant to the objectives and applications [

20]. Weaknesses are internal factors or constraints that impede or hinder the performance of EDC. Therefore, the strengths and weaknesses are internal elements. Opportunities in the SWOT analysis are factors or features that facilitate the business establishment by connecting it with outside organizations. Threats deal with negative factors external to electrical discharge coating, which can hinder or delay achievable goals. The latter two are external factors, and EDC can exploit their differences. As such, opportunities and threats are viewed as environmental factors. In this work, firstly, a SWOT matrix was formed for the internal and external factors involved in electrical discharge coatings. To form a matrix, a case study was required, for which copper coating using an electrical discharge machine was chosen.

Reviewing the literature, it was observed that no SWOT analysis has been conducted on the electrical discharge coating process. SWOT analysis is used in most businesses to know the strengths, weaknesses, opportunities and threats of a system. In this work, a case study was conducted by depositing copper on a titanium alloy surface using different electrodes to understand the strengths, weaknesses, opportunities and threats of this process. Then, output parameters such as the material deposition rate, electrode wear, surface roughness, coating thickness and elemental composition were optimized. The main objectives of this study were to (1) conduct a case study by coating using an electrical discharge machine and (2) create a SWOT matrix showing the strengths, weaknesses, opportunities and threats of this coating.

5. Discussion

In this work, an electrical discharge machine was used for coating copper material on titanium alloy. To deposit the copper coating, an evaluation was carried out using three different electrodes, and it was observed that the brass electrode provided uniform and crack-free coatings. Taguchi’s design of experiments was implemented to conduct experiments at different levels in the L18 orthogonal array. Of these 18 experiments, 6 experiments resulted in uniform coatings, so these coatings were chosen for characterization and further optimization. Upon TOPIS optimization, one experiment was chosen that demonstrated the optimum coating (thickness of 20.43667 µs) and input parameters (current of 20 A, Ton of 600 µs, Toff of 120 µs, flushing pressure of 0.5 bar and brass as electrode material). An optimum coating was obtained with mid-level current and a high level of pulse-on time. The current in EDC was directly proportional to thermal energy, and a long time of exposure to thermal energy led to the melting and deposition of electrode material on the substrate.

SWOT analysis was conducted to understand the strengths, weaknesses, opportunities and threats. A SWOT matrix is presented in

Section 4, and a discussion of the SWOT matrix is provided in the following.

5.1. EDC Strengths

Electrical discharge coatings have proven strengths, and researchers worldwide are still working to extend the applications of EDC in various fields. The optimization of coating according to input parameters is still under development to further improve this coating technique. Standards for controlling input parameters to obtain certain coating thickness are lacking, but in comparison with weaknesses, this technique has several strengths, which are as follows:

- (1)

Electrical discharge coating is a cost-effective technique in comparison with other coating methods [

43]. The cost of the machine is the major cost of this process.

- (2)

Electrical discharge coating is carried out on a well-established machine, the ‘Electrical Discharge Machine’, which is mostly used for drilling, machining complex shapes and hard materials, etc. [

29,

44]. Since this machine is available in most universities, further research on electrical discharge coating is possible, and it could lead to the standardization of the procedure.

- (3)

In addition, the coating can be deposited conventionally without power metallurgy electrodes/powder mixed in a dielectric fluid, etc., just by using conventional electrodes readily available in the market [

45]. Though many researchers have coated material using powder metallurgy/powder mixed in a dielectric medium, the case study presented in this paper proved that it can be coated using conventional electrodes.

- (4)

In comparison with other coating methods, it is possible to coat hard materials. Liew et al. [

46], in their paper, commented that the electrical discharge coating process can coat hard materials, which is also described in the Introduction section.

- (5)

Depth can be administered using the numerical controls available on an electrical discharge machine, whereas for other coating methods, such as physical vapor deposition (PVD), chemical vapor deposition (CVD), etc., a special apparatus is required for control. For example, PVD coating needs a vacuum setup to control the machine surface [

42,

44].

5.2. EDC Opportunities

Various opportunities are available when an electrical discharge machine is used for coating purposes.

- (1)

This technique can be used for surface modifications both without coating and with coating. It has the exceptional characteristic that it can be carried on any hard material [

47].

- (2)

The wear resistance of the hard material can also be improved, or if the surface is already worn out, it can be repaired [

48].

- (3)

This coating has applications in various fields, such as biomedicine [

12], aerospace [

49] and turbine blades [

12]. The surface adjustment was carried out by modifying the center to obtain a thick and permeable oxide layer on the surface of restorative Ti inserts to improve tissue development and quicken recuperation. In some cases, due to cleaning, handling and grinding, the oxide coatings can disintegrate over time. In such situations, electrical discharge coatings have the awesome potential of utilizing oxide layers to functionalize the surface [

50]. Additionally, EDC has the potential to make strides in improving the biocompatibility of Ti6Al4V with human bones and teeth by depositing a layer of perovskite Ti (CaTiO

3) [

14].

5.3. EDC Weaknesses

Though electrical discharge coating is useful in various applications, it also has some weaknesses that can be overcome. Some of them are listed here as follows:

- (1)

In the modern world, most coating equipment requires power. Similarly, this technique is completely based on power, without which coating cannot be deposited.

- (2)

When coating the substrate, material removal from the substrate is negligible. In any coating technique, such as PVD [

45], CVD [

6], electroless [

51], etc., when depositing a material, it causes a difference in the surface of the material.

- (3)

This technique cannot reproduce sharp corners of a substrate for complex shapes. Thus, complex shapes with sharp corners cannot be coated using this technique.

- (4)

There will be a high loss in the deposition of electrode material. Most of the material remains in the dielectric fluid, as observed in our case study.

- (5)

Due to the mixture of electrode and workpiece materials remaining in the dielectric fluid, the filtration time is longer in comparison with other processes, such as drilling, machining, etc., on electrical discharge machines. The filtration time increases from 2 to 3 h when depositing a copper coating on titanium alloy.

- (6)

The complete process should be carried out in one run, or else it will lead to defects when re-running. Defects will be cracks, irregular surfaces, etc., Moreover, it is not possible to continue from an earlier stopping point.

5.4. EDC Threats

There are not many threats connected with electrical discharge coating. Some of them are as follows:

- (1)

Technicians working with this machine have to be careful by using the necessary gloves, etc. A fire can erupt in a conventional EDC operation, damaging the building and equipment, interrupting business and delaying deliveries to customers. Operators should be warned of the potential of fires in the machine to spread when blowing the burning dielectric fluid in the tank with an extinguisher. Sometimes, extreme care is also necessary to prevent blasting the flame in the direction of anyone assisting with the fire.

- (2)

Technicians have to be skilled to code the program for the computer numerically controlled electrical discharge machine. EDM operators need to be trained adequately beforehand concerning safe procedures for setup and operation, the maintenance of the integrity of fire protection systems and the need to monitor operations.

- (3)

Environmental pollution is another threat with any kind of machinery. This technique will pollute the environment when dielectric fluid is disposed of, and while working with the machines, it will cause air pollution. An EDM machine usually generates flammable gases during machining. The quantities and types of gases produced vary depending upon the material being machined, dielectric fluid, operating temperature, current and voltage.

- (4)

There are possible health issues for people working with this machine.