Ignition of Carbon Black during Nanosecond Diffuse and Spark Discharges in Air at Atmospheric Pressure

Abstract

:1. Introduction

2. Materials and Methods

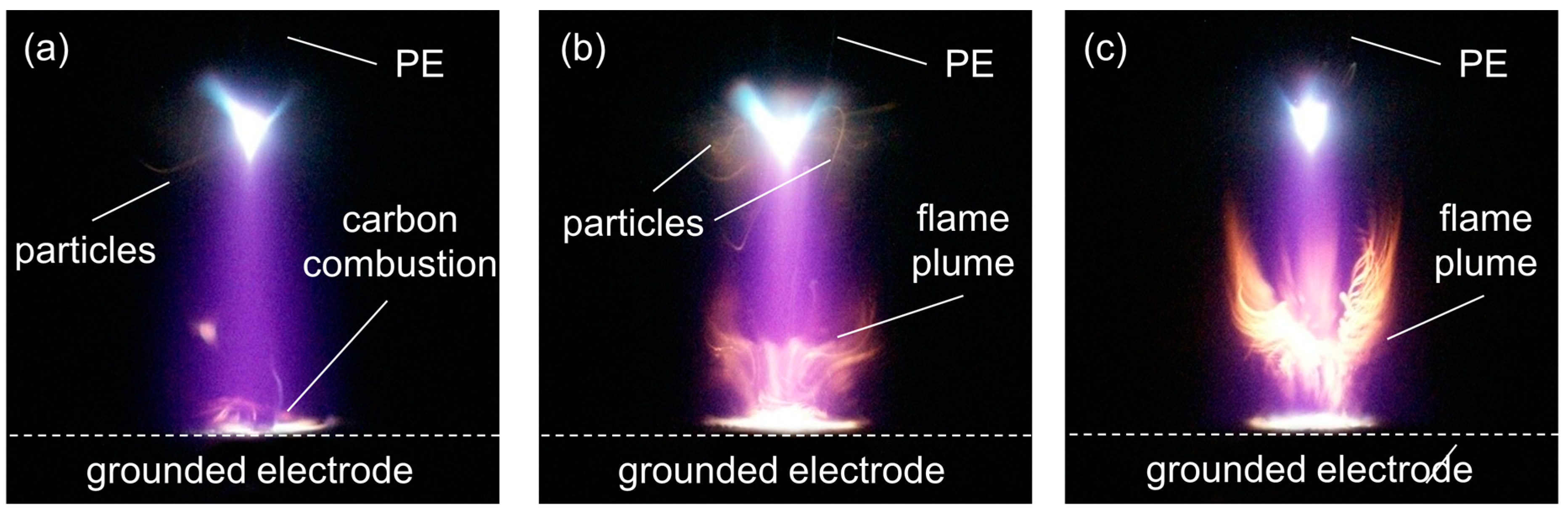

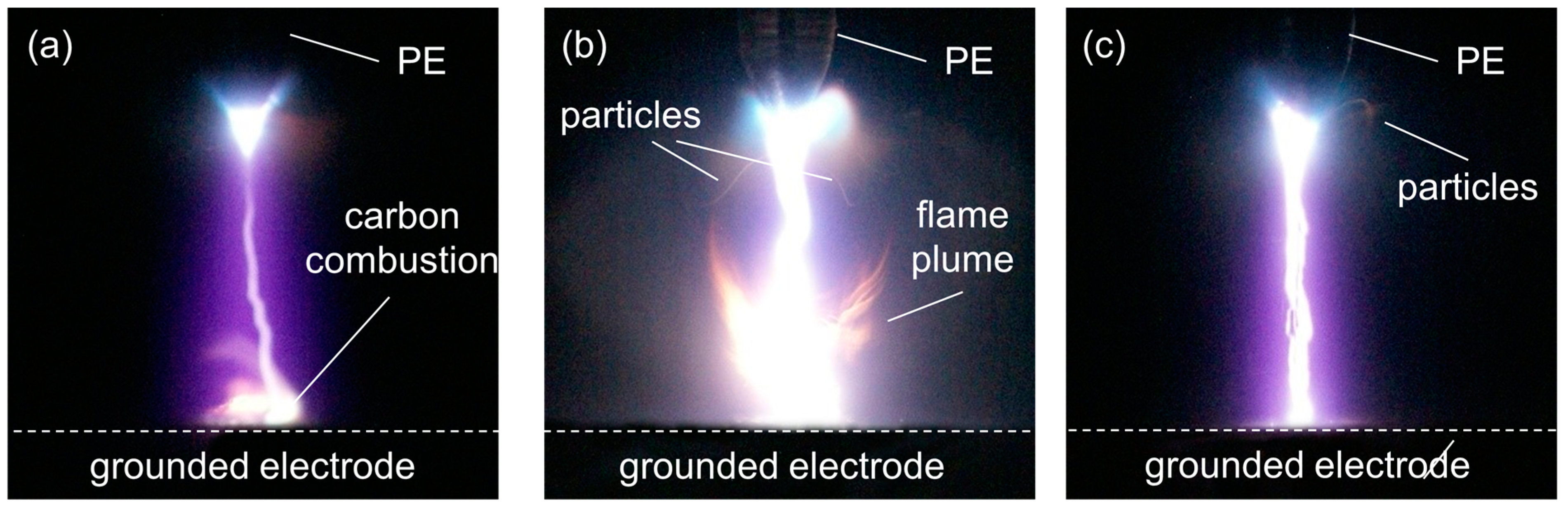

3. Results

3.1. Excitation Conditions

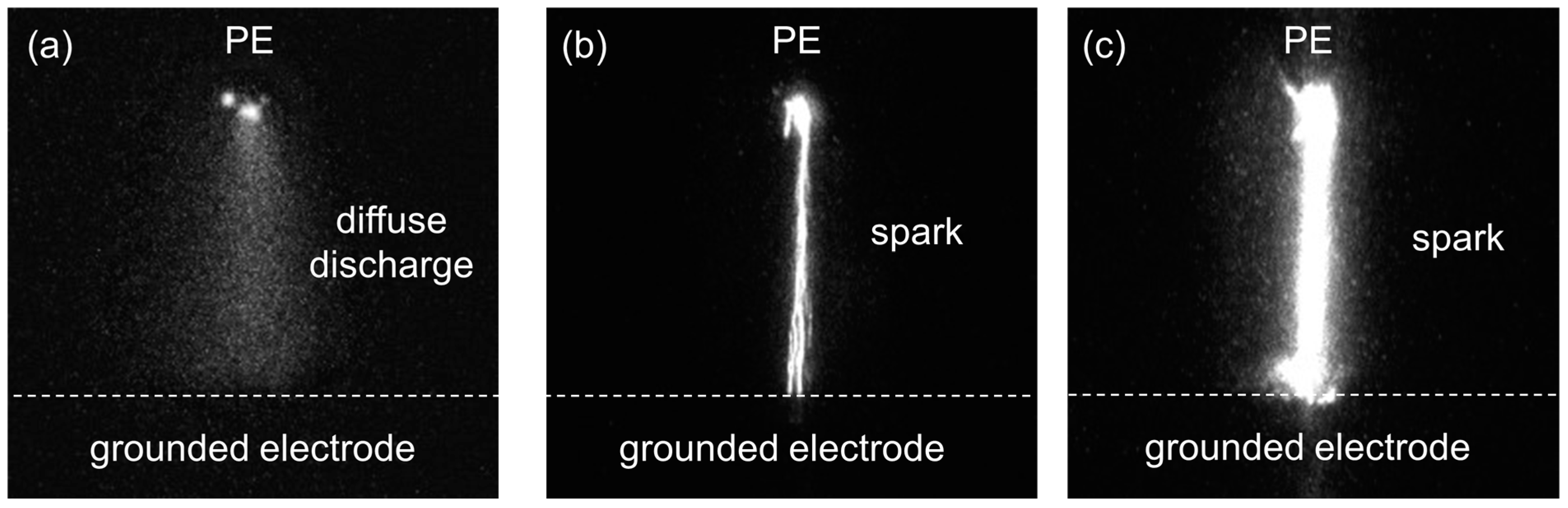

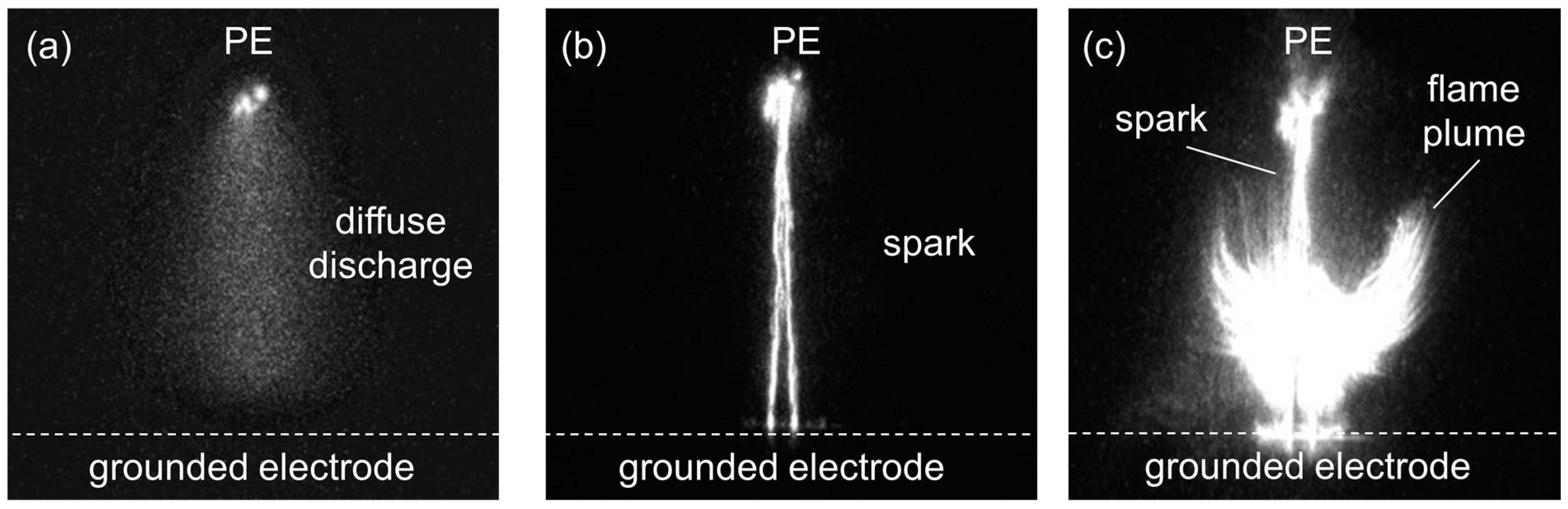

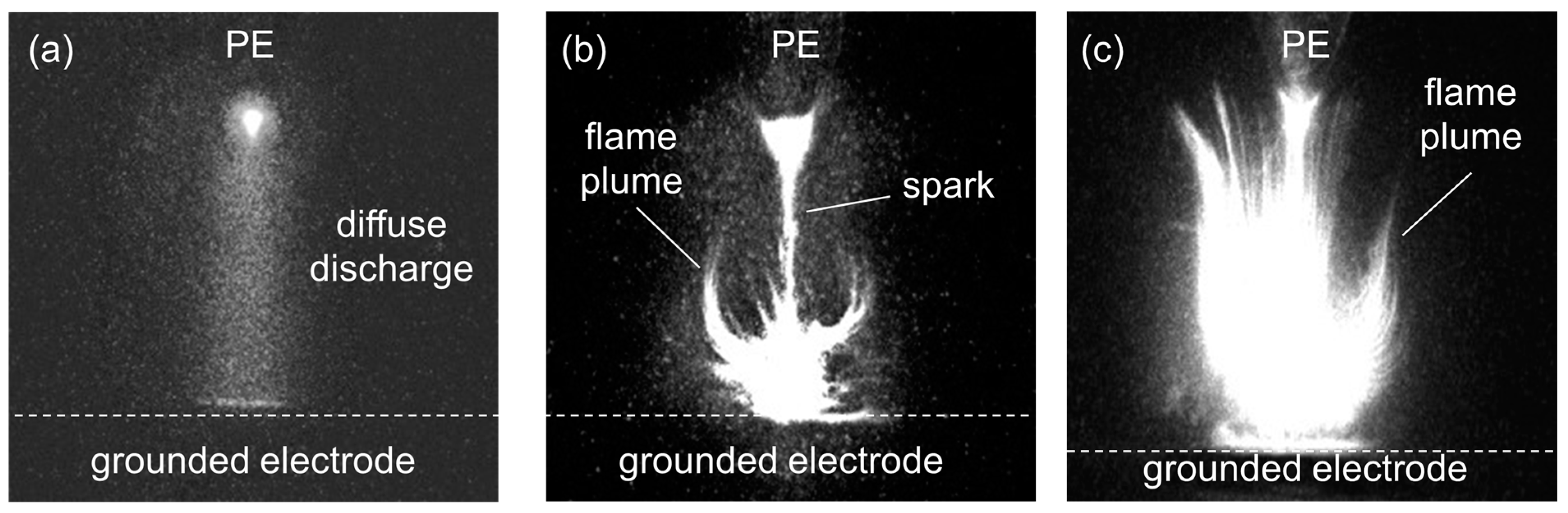

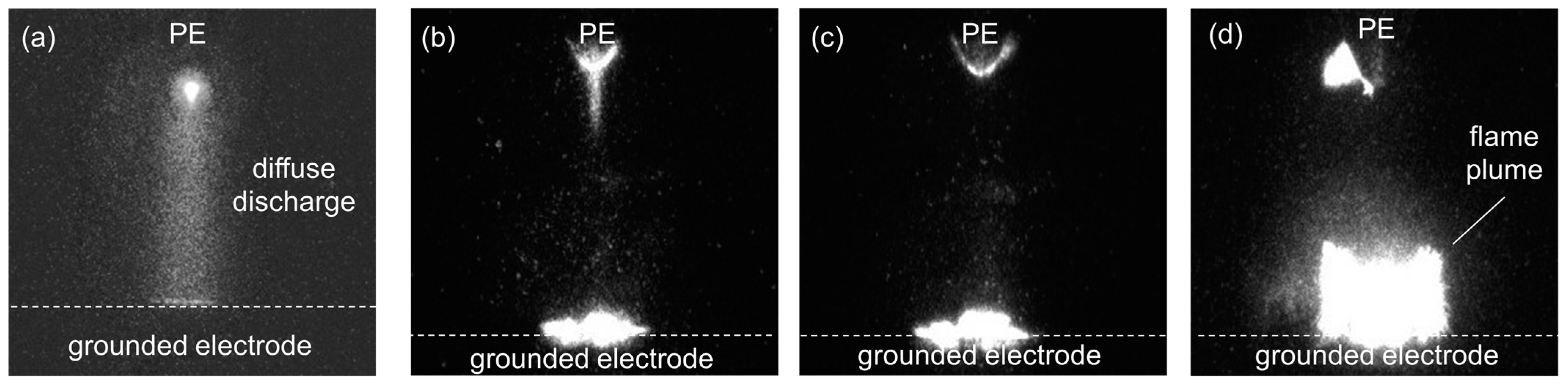

3.2. Time-Integrated Discharge Plasma Glow

3.3. Discharge Glow Dynamics with and without Carbon Black on the Anode Surface

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kefeng, S.; Wang, M.; Peng, B.; Li, J.; Lu, N.; Jiang, N.; Wu, Y. Characterization of a novel volume-surface DBD reactor: Discharge characteristics, ozone production and benzene degradation. J. Phys. D Appl. Phys. 2019, 53, 065201. [Google Scholar] [CrossRef]

- Pang, W.; Li, Y.; DeLuca, L.T.; Liang, D.; Qin, Z.; Liu, X.; Xu, H.; Fan, X. Effect of Metal Nanopowders on the Performance of Solid Rocket Propellants: A Review. Nanomaterials 2021, 11, 2749. [Google Scholar] [CrossRef] [PubMed]

- Adamovich, I.; Agarwal, S.; Ahedo, E.; Alves, L.L.; Baalrud, S.; Babaeva, N.; Bogaerts, A.; Bourdon, A.; Bruggeman, P.J.; Canal, C.; et al. The 2022 Plasma Roadmap: Low temperature plasma science and technology. J. Phys. D Appl. Phys. 2022, 55, 373001. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, Y.; Guo, S.; Guo, L.; Yu, W.; Akram, S.; Zhu, X.; Cui, X.; Fang, Z. Surface treatment of large-area epoxy resin by water-perforated metal plate electrodes dielectric barrier discharge: Hydrophobic modification and uniformity improvement. Appl. Surf. Sci. 2023, 639, 158166. [Google Scholar] [CrossRef]

- Dieringa, H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 2011, 46, 289–306. [Google Scholar] [CrossRef]

- Mehrizi, M.K.; Mortazavi, S.M.; Mallakpour, S.; Bidoki, S.M.; Vik, M.; Vikova, M. The effect of carbon black nanoparticles on some properties of air plasma printed cotton/polyamide 6 fabrics. Fibers Polym. 2013, 14, 1620–1626. [Google Scholar] [CrossRef]

- Kalered, E.; Brenning, N.; Pilch, I.; Caillault, L.; Minéa, T.; Ojamäe, L. On the work function and the charging of small (r ≤ 5 nm) nanoparticles in plasmas. Phys. Plasmas 2017, 24, 013702. [Google Scholar] [CrossRef]

- Andronov, A.; Budylina, E.; Shkitun, P.; Gabdullin, P.; Gnuchev, N.; Kvashenkina, O.; Arkhipov, A. Characterization of thin carbon films capable of low-field electron emission. J. Vac. Sci. Technol. B 2018, 36, 02C108. [Google Scholar] [CrossRef]

- Slobodian, O.M.; Okholin, P.N.; Lytvyn, P.M.; Malyuta, S.V.; Khyzhun, O.Y.; Vasin, A.V.; Rusavsky, A.V.; Gomeniuk, Y.V.; Glotov, V.I.; Nazarova, T.M.; et al. Plasma treatment as a versatile tool for tuning of sorption properties of thin nanoporous carbon films. Appl. Surf. Sci. 2021, 544, 148876. [Google Scholar] [CrossRef]

- Tardiveau, P.; Moreau, N.; Bentaleb, S.; Postel, C.; Pasquiers, S. Diffuse mode and diffuse-to-filamentary transition in a high pressure nanosecond scale corona discharge under high voltage. J. Phys. D Appl. Phys. 2009, 42, 175202. [Google Scholar] [CrossRef]

- Babich, L.P. High-Energy Phenomena in Electric Discharges in Dense Gases: Theory, Experiment and Natural Phenomena; Futurepast: Arlington, VA, USA, 2003; p. 358. [Google Scholar]

- Tarasenko, V.F. (Ed.) Generation of Runaway Electron Beams and X-rays in High Pressure Gases, Volume 1: Techniques and Measurements; Nova Science Publishers: New York, NY, USA, 2016; p. 405. [Google Scholar]

- Tarasenko, V.F. (Ed.) Generation of Runaway Electron Beams and X-rays in High Pressure Gases, Volume 2: Processes and Applications; Nova Science Publishers: New York, NY, USA, 2016; p. 315. [Google Scholar]

- Shao, T.; Zhang, C. (Eds.) Pulsed Discharge Plasmas: Characteristics and Applications; Springer Nature: Singapore, 2023; p. 1034. [Google Scholar] [CrossRef]

- Erofeev, M.; Lomaev, M.; Ripenko, V.; Shulepov, M.; Sorokin, D.; Tarasenko, V. Generators of Atmospheric Pressure Diffuse Discharge Plasma and Their Use for Surface Modification. Plasma 2019, 2, 27–38. [Google Scholar] [CrossRef]

- Almazova, K.I.; Belonogov, A.N.; Borovkov, V.V.; Gorelov, E.V.; Morozov, I.V.; Tren’kin, A.A.; Kharitonov, S.Y. Microstructure of a Spark Discharge in Air in a Point-Plane Gap. Tech. Phys. 2018, 63, 801–805. [Google Scholar] [CrossRef]

- Parkevich, E.V.; Ivanenkov, G.V.; Medvedev, M.A.; Khirianova, A.I.; Selyukov, A.S.; Agafonov, A.V.; Mingaleev, A.R.; Shelkovenko, T.A.; Pikuz, S.A. Mechanisms responsible for the initiation of a fast breakdown in an atmospheric discharge. Plasma Sources Sci. Technol. 2018, 27, 11LT01. [Google Scholar] [CrossRef]

- Parkevich, E.V.; Medvedev, M.A.; Khirianova, A.I.; Ivanenkov, G.V.; Selyukov, A.S.; Agafonov, A.V.; Shpakov, K.V.; Oginov, A.V. Extremely fast formation of anode spots in an atmospheric discharge points to a fundamental ultrafast breakdown mechanism. Plasma Sources Sci. Technol. 2019, 28, 125007. [Google Scholar] [CrossRef]

- Tren’kin, A.A.; Almazova, K.I.; Belonogov, A.N.; Borovkov, V.V.; Gorelov, E.V.; Morozov, I.V.; Kharitonov, S.Y. Dynamics of the initial stage of the spark and diffuse discharges in air in a point–plane gap at different parameters of the tip electrode. Tech. Phys. 2019, 64, 470–474. [Google Scholar] [CrossRef]

- Almazova, K.I.; Belonogov, A.N.; Borovkov, V.V.; Kurbanismailov, V.S.; Khalikova, Z.R.; Omarova, P.K.; Ragimkhanov, G.B.; Tereshonok, D.V.; Trenkin, A.A. Investigation of the microchannel structure in the initial phase of the discharge in air at atmospheric pressure in the “pin (anode)-plane” gap. Phys. Plasmas 2020, 27, 123507. [Google Scholar] [CrossRef]

- Almazova, K.I.; Belonogov, A.N.; Borovkov, V.V.; Kurbanismailov, V.S.; Ragimkhanov, G.B.; Tren’kin, A.A.; Tereshonok, D.V.; Khalikova, Z.R. Plasma and Gas-Dynamic Near-Electrode Processes in the Initial Phase of a Microstructured Spark Discharge in Air. Tech. Phys. Lett. 2020, 46, 737–740. [Google Scholar] [CrossRef]

- Almazova, K.I.; Belonogov, A.N.; Borovkov, V.V.; Khalikova, Z.R.; Ragimkhanov, G.B.; Tereshonok, D.; Trenkin, A.A. Investigation of plasma properties in the phase of the radial expansion of spark channel in the pin-to-plate geometry. Plasma Sources Sci. Technol. 2021, 30, 095020. [Google Scholar] [CrossRef]

- Rep’ev, A.G.; Repin, P.B.; Pokrovskiĭ, V.S. Microstructure of the current channel of an atmospheric-pressure diffuse discharge in a rod-plane air gap. Tech. Phys. 2007, 52, 52–58. [Google Scholar] [CrossRef]

- Lomaev, M.; Tarasenko, V.; Shulepov, M.; Beloplotov, D.; Sorokin, D. Nano-and Microparticles of Carbon as a Tool for Determining the Uniformity of a Diffuse Discharge Exposure. Surfaces 2023, 6, 40–52. [Google Scholar] [CrossRef]

- Efanov, V.M.; Efanov, M.V.; Komashko, A.V.; Kriklenko, A.V.; Yarin, P.M.; Zazoulin, S.V. Ultra-Wideband, Short Pulse Electromagnetics; Springer: New York, NY, USA, 2010; pp. 301–305. [Google Scholar]

- Tarasenko, V.F.; Beloplotov, D.V.; Panchenko, A.N.; Sorokin, D.A. Thin Luminous Tracks of Particles Released from Electrodes with A Small Radius of Curvature in Pulsed Nanosecond Discharges in Air and Argon. Surfaces 2023, 6, 214–226. [Google Scholar] [CrossRef]

- Korolev, I.D.; Kuzmin, V.A.; Mesiats, G.A. Nanosecond Gas Discharge in an Inhomogeneous Field with Explosive Processes on the Electrodes. Sov. Phys. Technol. Phys. 1980, 25, 418–420. [Google Scholar]

- Janda, M.; Machala, Z.; Niklová, A.; Martišovitš, V. The streamer-to-spark transition in a transient spark: A dc-driven nanosecond-pulsed discharge in atmospheric air. Plasma Sources Sci. Technol. 2012, 21, 045006. [Google Scholar] [CrossRef]

- Shao, T.; Tarasenko, V.F.; Zhang, C.; Lomaev, M.I.; Sorokin, D.A.; Yan, P.; Kozyrev, A.V.; Baksht, E.K. Spark discharge formation in an inhomogeneous electric field under conditions of runaway electron generation. J. Appl. Phys. 2012, 111, 023304. [Google Scholar] [CrossRef]

- Starikovskiy, A.; Aleksandrov, N. Plasma-assisted ignition and combustion. Prog. Energy Combust. Sci. 2013, 39, 61–110. [Google Scholar] [CrossRef]

- Riaza, J.; Gibbins, J.; Chalmers, H. Ignition and combustion of single particles of coal and biomass. Fuel 2017, 202, 650–655. [Google Scholar] [CrossRef]

- Watson, A.Y.; Valberg, P.A. Carbon black and soot: Two different substances. AIHAJ-Am. Ind. Hyg. Assoc. 2001, 62, 218–228. [Google Scholar] [CrossRef] [PubMed]

- Long, C.M.; Nascarella, M.A.; Valberg, P.A. Carbon black vs. black carbon and other airborne materials containing elemental carbon: Physical and chemical distinctions. Environ. Pollut. 2013, 181, 271–286. [Google Scholar] [CrossRef] [PubMed]

- Misyura, S.Y. Comparing the dissociation kinetics of various gas hydrates during combustion: Assessment of key factors to improve combustion efficiency. Appl. Energy 2020, 270, 115042. [Google Scholar] [CrossRef]

- Michelsen, H.A.; Colket, M.B.; Bengtsson, P.E.; D’anna, A.; Desgroux, P.; Haynes, B.S.; Miller, J.H.; Nathan, G.J.; Pitsch, H.; Wang, H. A review of terminology used to describe soot formation and evolution under combustion and pyrolytic conditions. ACS Nano 2020, 14, 12470–12490. [Google Scholar] [CrossRef]

- Pal, Y.; Palateerdham, S.K.; Mahottamananda, S.N.; Sivakumar, S.; Ingenito, A. Combustion performance of hybrid rocket fuels loaded with MgB2 and carbon black additives. Propuls. Power Res. 2023, 12, 212–226. [Google Scholar] [CrossRef]

- Weiser, V.; Eisenreich, N. Fast emission spectroscopy for a better understanding of pyrotechnic combustion behavior. Propellants Explos. Pyrotech. Int. J. Deal. Sci. Technol. Asp. Energetic Mater. 2005, 30, 67–78. [Google Scholar] [CrossRef]

| Model | Amplitude, kV | Duration **, ns | Rise Time, ns |

|---|---|---|---|

| NGP-18/3500N | 18 | 8.0 | 4.0 |

| GIN-100-1 | 20 | 4.5 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lomaev, M.; Tarasenko, V.; Sorokin, D.; Beloplotov, D. Ignition of Carbon Black during Nanosecond Diffuse and Spark Discharges in Air at Atmospheric Pressure. Surfaces 2024, 7, 44-53. https://doi.org/10.3390/surfaces7010004

Lomaev M, Tarasenko V, Sorokin D, Beloplotov D. Ignition of Carbon Black during Nanosecond Diffuse and Spark Discharges in Air at Atmospheric Pressure. Surfaces. 2024; 7(1):44-53. https://doi.org/10.3390/surfaces7010004

Chicago/Turabian StyleLomaev, Mikhail, Victor Tarasenko, Dmitry Sorokin, and Dmitry Beloplotov. 2024. "Ignition of Carbon Black during Nanosecond Diffuse and Spark Discharges in Air at Atmospheric Pressure" Surfaces 7, no. 1: 44-53. https://doi.org/10.3390/surfaces7010004