An Evaluation of the Compressive Strength of Nanosilicate Hollow Crete Blocks †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement

2.1.2. Fine Aggregate

2.1.3. Water

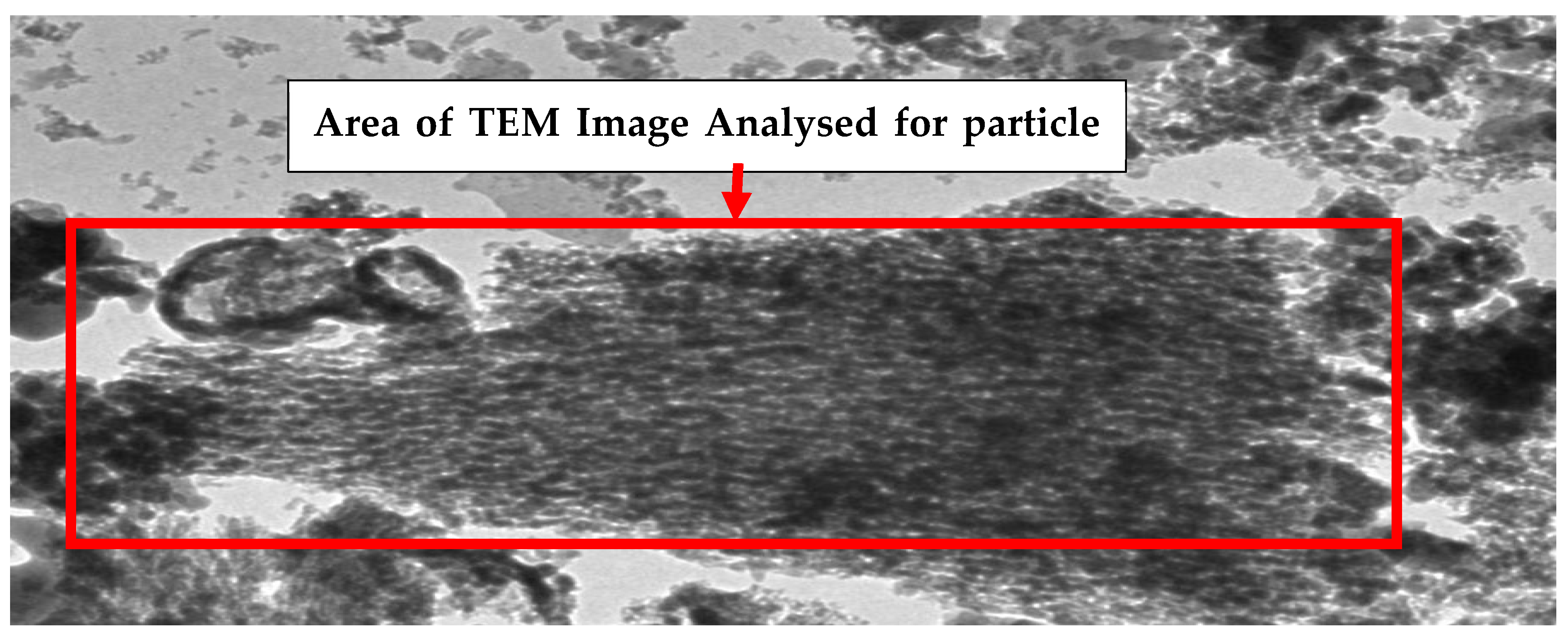

2.1.4. Nanosilica

2.2. Methods

2.2.1. Production of Nanosilicate Hollow Crete Blocks

2.2.2. Curing

2.2.3. Compressive Strength Test

3. Discussion of Results

3.1. Chemical Characterization of Nanosilca and Cement

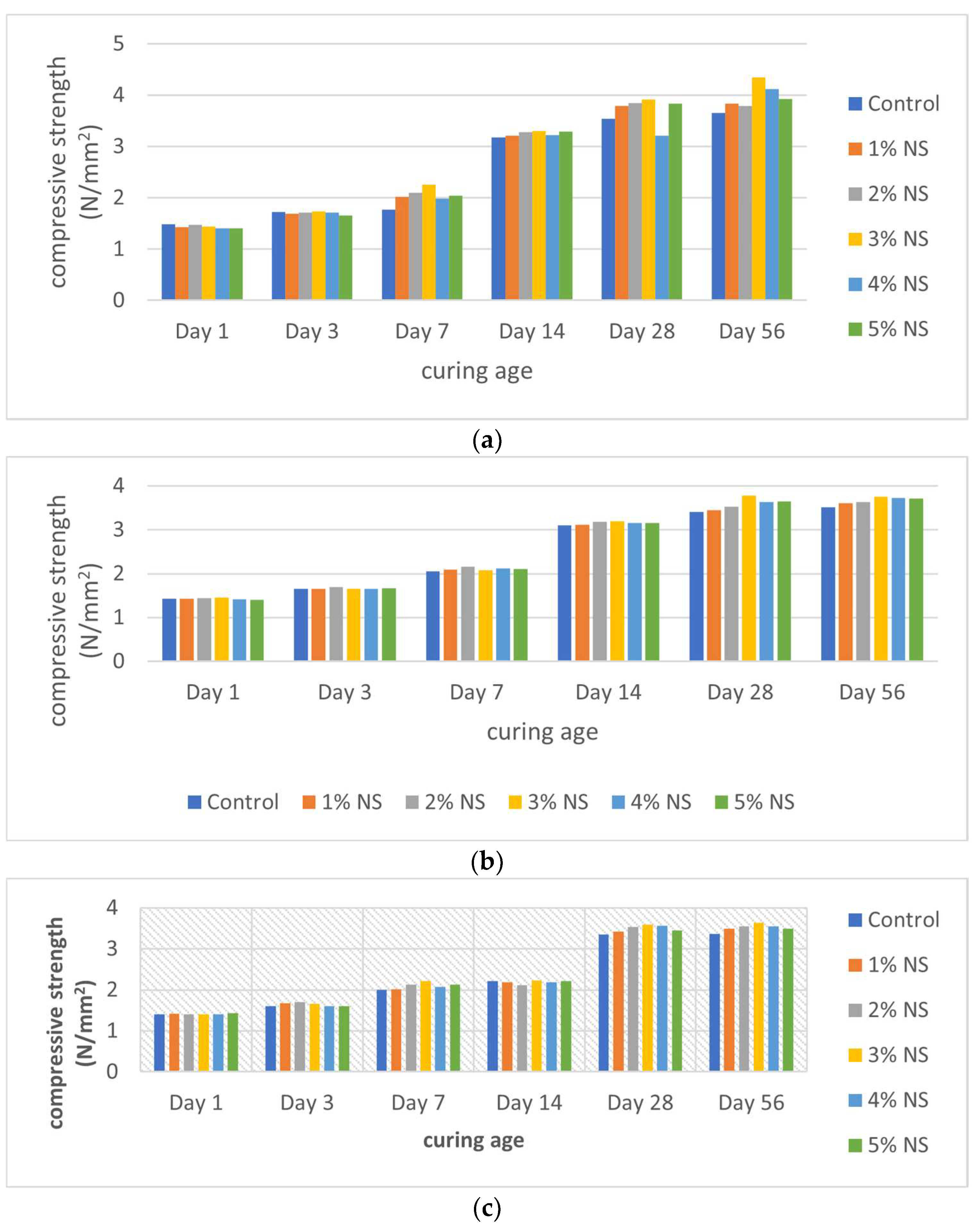

3.2. Compressive Strength

4. Conclusions

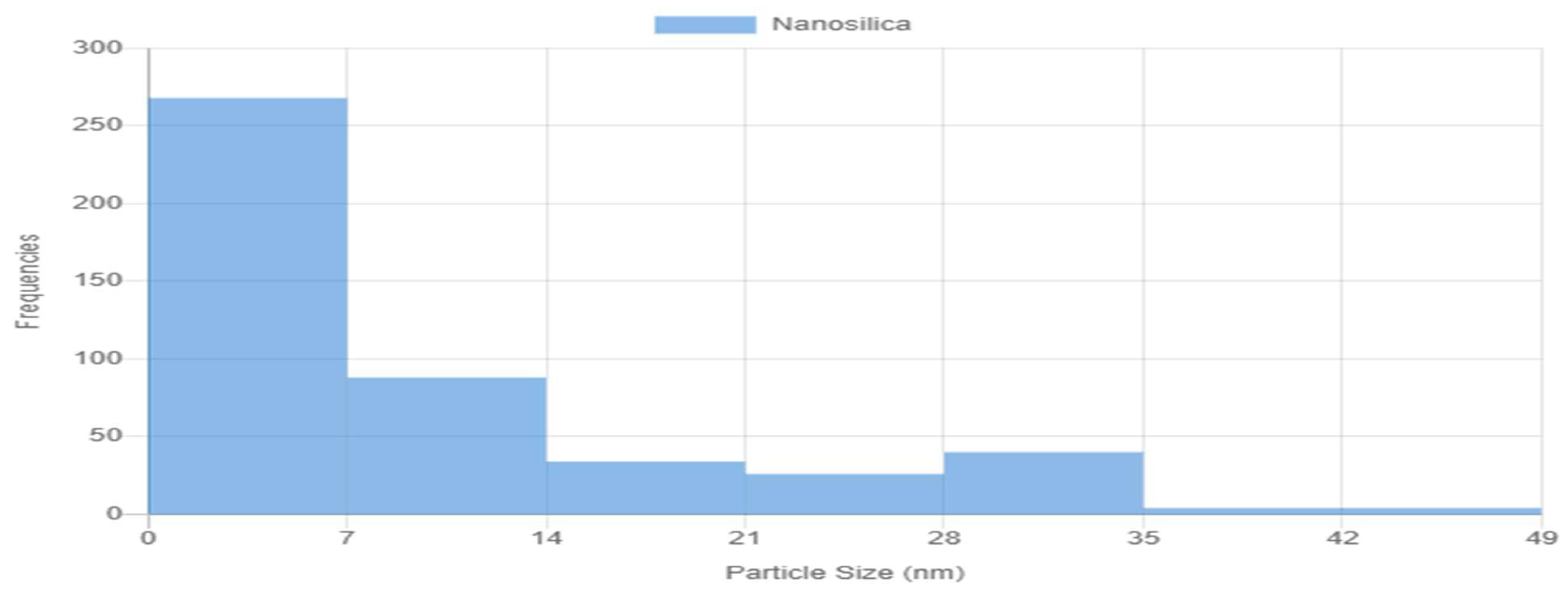

- The effect of nanosilica produced from rice husk ash on the compressive strength of hollow blocks (nanosilicate hollow crete blocks) mixed at different cement-to-sand-mix ratios, 1:4, 1:6, 1:8, and 1:10, and cured for 1, 3, 7, 14, 28, and 56 days were explored, and the compressive strength of the hollow blocks were tested. The results of this study showed that nanosilica produced from rice husk ash has a SiO2, Al2O3, and Fe2O3 combination of approximately 95.71%, which is greater than the minimum recommended of 70%. This is an indication that the nanosilica produced from rice husk ash and used in this study is a good reactive pozzolana. Also, the produced nanosilica consists of particle sizes ranging from 1 to 49 nm, with the majority of the particle size within 1–7 nm, which is an indication that the produced nanosilica contains nanoparticles. Hollow blocks produced at 1, 2, 3, 4, and 5% replacement by weight of cement (nanosilica-crete) proved stronger than hollow blocks produced at 0% cement replacement (sandcrete).

- In conclusion, the compressive strength results showed that the best percentage of nanosilica replacement by weight of cement was 3%. It is therefore recommended that, in order to produce nanosilicate hollow crete blocks with satisfactory compressive strength, nanosilica should replace cement by not more than 3% by weight.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mulki, S.; Hinge, A. Green Investment Horizons: Effects of Policy on the Market for Building Energy Efficiency Technologies; World Resources Institute: Washington, DC, USA, 2010. [Google Scholar]

- Joseph, P.; Nally, S.M. Sustainable Non-Metallic Building Materials. Sustainability 2010, 2, 400–427. [Google Scholar] [CrossRef]

- Milne, G.; Reardon, C. Embodied Energy, in Your Technical Manual. 2008. Available online: http://www.yourhome.gov.au/technical/fs52.html (accessed on 12 December 2009).

- Mehta, P.K.; Monteiro, J.M. Concrete Microstructure Properties and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Kaura, J.M.; Amartey, Y.D.; Shuaibu, A.A.; Rabiu, A. Strength microstructure of Cement mortar Containing Metakaolin. In Proceedings of the NBRRI International Conference, Abuja, Nigeria, 24–26 May 2016. [Google Scholar]

- van Oss, H.G.; Padovani, A.C. Cement Manufacture and the Environment, Part I: Chemistry and Technology. J. Ind. Ecol. 2002, 6, 89–105. [Google Scholar] [CrossRef]

- Suhendro, B. Toward Green Concrete for Better Sustainable Environment. Procedia Eng. 2014, 95, 305–320. [Google Scholar] [CrossRef]

- Aitcin, P.-C.; Mindess, S. Sustainability of Concrete (Modern Concrete Technology Series); CRC Press: London, UK, 2011. [Google Scholar]

- NIS 2000; NIS 87: Nigeria Industrial Standard: Standard for Sandcrete Blocks. Standards Organization of Nigeria: Lagos, Nigeria, 2004.

- van Oss, H.G.; Padovani, A.C. Cement Manufacture and the Environment, Part II: Chemistry and Technology. J. Ind. Ecol. 2003, 7, 93–126. [Google Scholar] [CrossRef]

- Köksal, F.; Altun, F.; Yiğit, İ.; Şahin, Y. Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater. 2008, 22, 1874–1880. [Google Scholar] [CrossRef]

- Ejeh, S.P.; Abubakar, I. Sandcrete Hollow Blocks in Zamfara State. Int. J. Sci. Technol. Res. 2008, 5, 135–143. [Google Scholar]

- British Standard Institutions. BS 3148: Method of Test for Water for Making Concrete; British Standard Institutions: London, UK, 1980. [Google Scholar]

- BS 812; Method for Determination of Water Absorption in Concrete. Part 2; British Standard Institution: London, UK, 1995.

- BS 1881; Method for Determination of Compressive strength of Concrete Cubes. Part 116; British Standard Institution: London, UK, 1983.

- ASTM C618; Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolanas for Use as Mineral Admixtures in Ordinary Portland Cement of Concrete. Annual Books of ASTM Standards vol 4; ASTM international (ASTM): West Conshecken, PA, USA, 2008.

- BS EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. British Standard Institution: London, UK, 2011.

- Fadi, A.; Osama, Z.; Rebeca, M.G.; Fahad, A.; Mohd, A.; Mohammed, M.A. Impact of Nanosilica on the hydration, strength, durability and Microstructural properties of concrete: A state-of-the-art review. J. Build. Eng. 2023, 18, e01997. [Google Scholar]

| Element | Content (%) | Element | Content (%) |

|---|---|---|---|

| SiO2 | 93.611 | CaO | 0.463 |

| V2O5 | 0.021 | MgO | 0.000 |

| Cr2O3 | 0.023 | K2O | 1.183 |

| MnO | 0.105 | BaO | 0.006 |

| Fe2O3 | 0.700 | Al2O3 | 1.339 |

| Co3O4 | 0.002 | Ta2O5 | 0.006 |

| NiO | 0.001 | TiO2 | 0.291 |

| CuO | 0.050 | ZnO | 0.011 |

| Nb2O3 | 0.006 | Ag2O | 0.003 |

| WO3 | 0.002 | Cl | 0.992 |

| P2O5 | 1.018 | ZrO2 | 0.011 |

| SO3 | 0.156 | SnO2 | 0.000 |

| Oxide Composition | Percentage (%) of Oxide Composition | BS EN 197-1 (2011) |

|---|---|---|

| CaO | 64.45 | Limit not specified |

| SiO2 | 21.55 | Max. 35.5% |

| Al2O3 | 5.28 | Max. 6.3% |

| Fe2O3 | 3.95 | Max. 6.5% |

| MgO | 1.85 | Max. 4.0% |

| SO3 | 1.50 | Max. 3.0% |

| Loss of ignition | 1.44 | Max. 5.0% |

| Insoluble residue | 0.65 | Max. 1.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tyoden, J.N.; Lawan, A.; Ejeh, S. An Evaluation of the Compressive Strength of Nanosilicate Hollow Crete Blocks. Eng. Proc. 2023, 56, 40. https://doi.org/10.3390/ASEC2023-15316

Tyoden JN, Lawan A, Ejeh S. An Evaluation of the Compressive Strength of Nanosilicate Hollow Crete Blocks. Engineering Proceedings. 2023; 56(1):40. https://doi.org/10.3390/ASEC2023-15316

Chicago/Turabian StyleTyoden, Juliana N., Adamu Lawan, and Sp Ejeh. 2023. "An Evaluation of the Compressive Strength of Nanosilicate Hollow Crete Blocks" Engineering Proceedings 56, no. 1: 40. https://doi.org/10.3390/ASEC2023-15316