Optimization of Performance and Emission Responses of Common Rail Direct Injection Engine by Taguchi-Grey Relational Analysis Technique †

Abstract

:1. Introduction

2. Methodology

- Experimental data’s normalization.

- Grey relation coefficient (GRC) estimation for each response.

- Grey relation grade calculation for each response.

- Choosing the best levels depending on the gray relation grade.

- Employing the signal to noise ratio (S/N ratio) to analyze the GRG.

- By using an ANOVA with the GRG, the importance of the engine control component is determined.

Employing the Signal to Noise Ratio to Analyze GRG

3. Experimental Setup

4. Results and Discussion

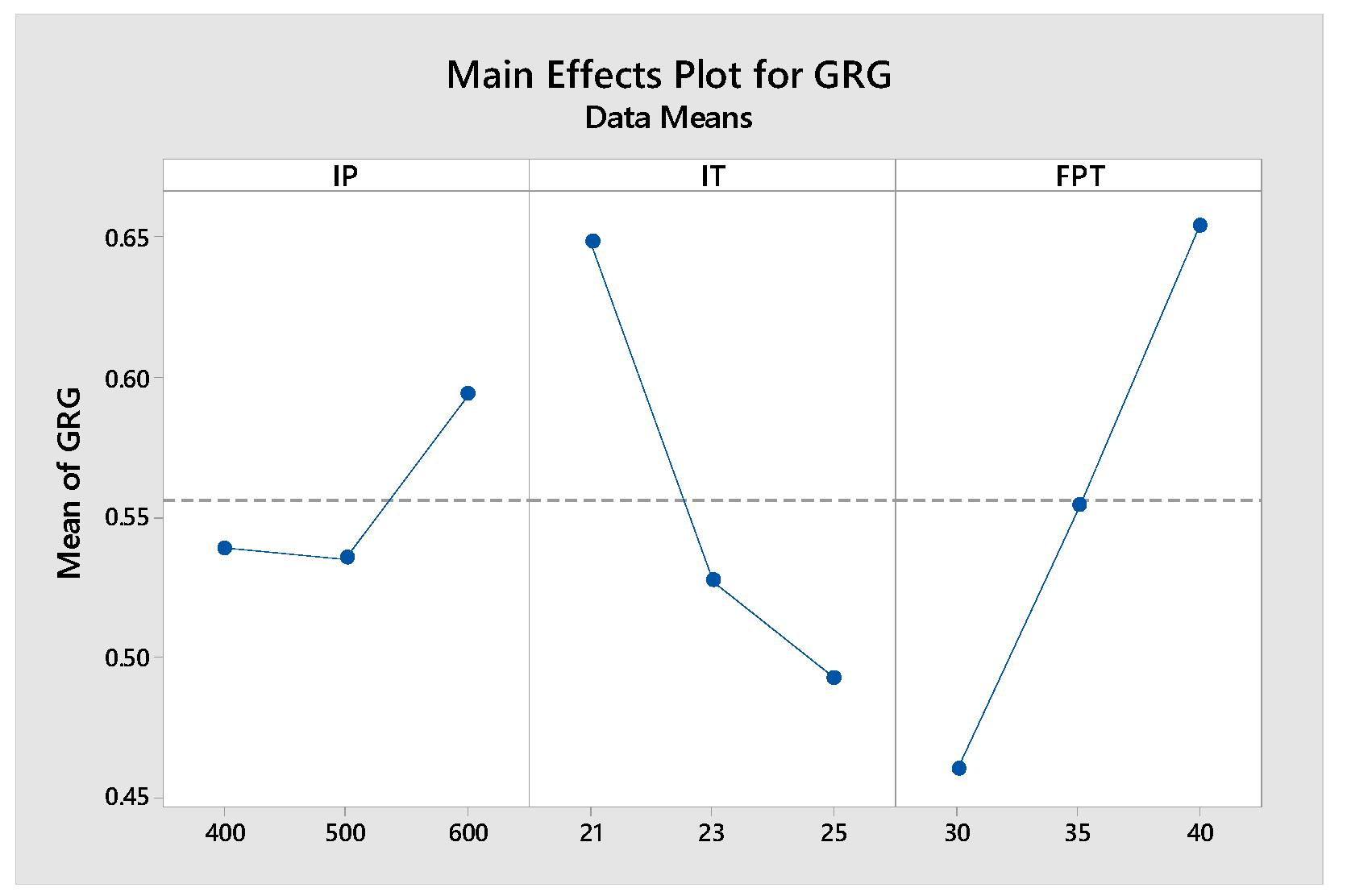

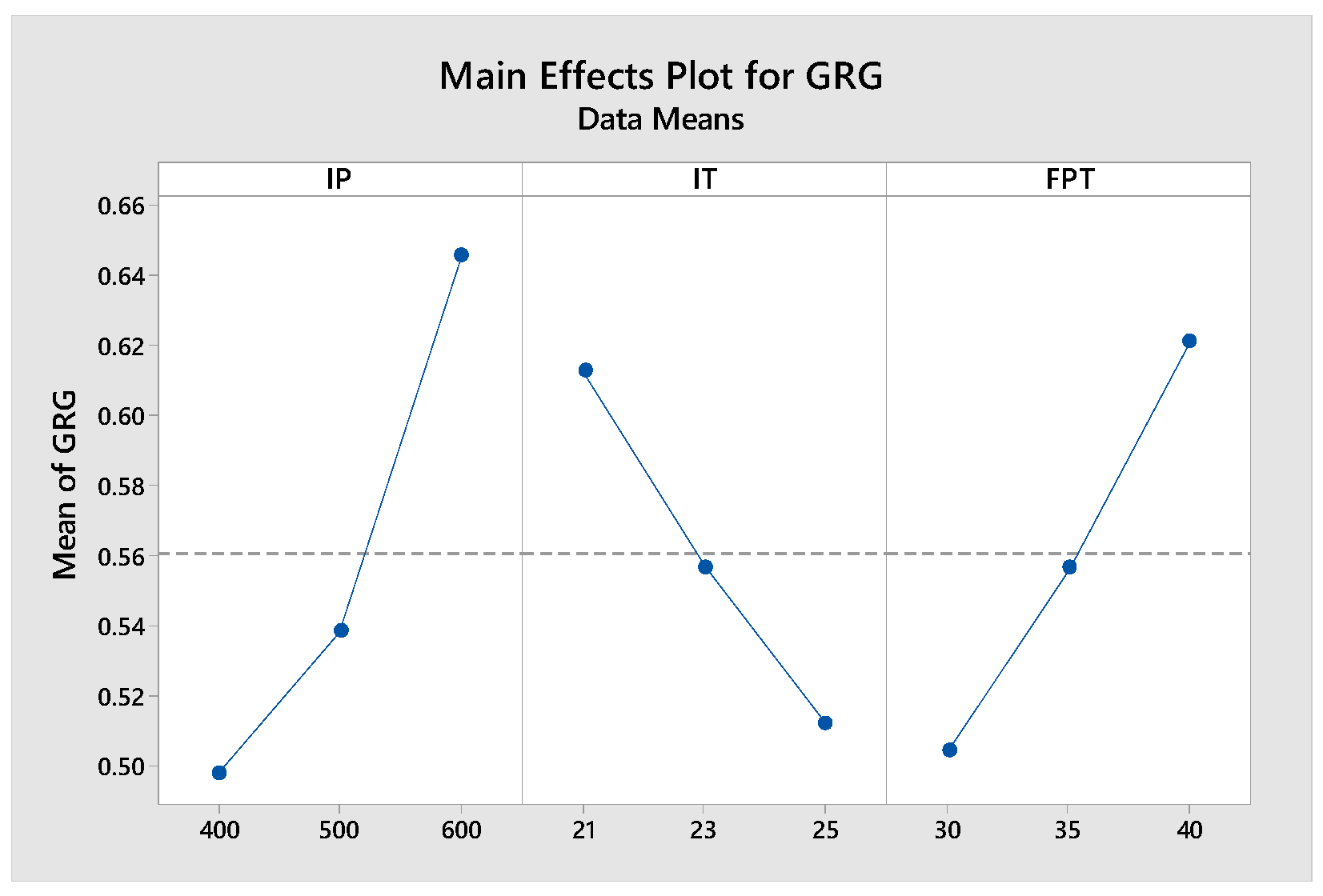

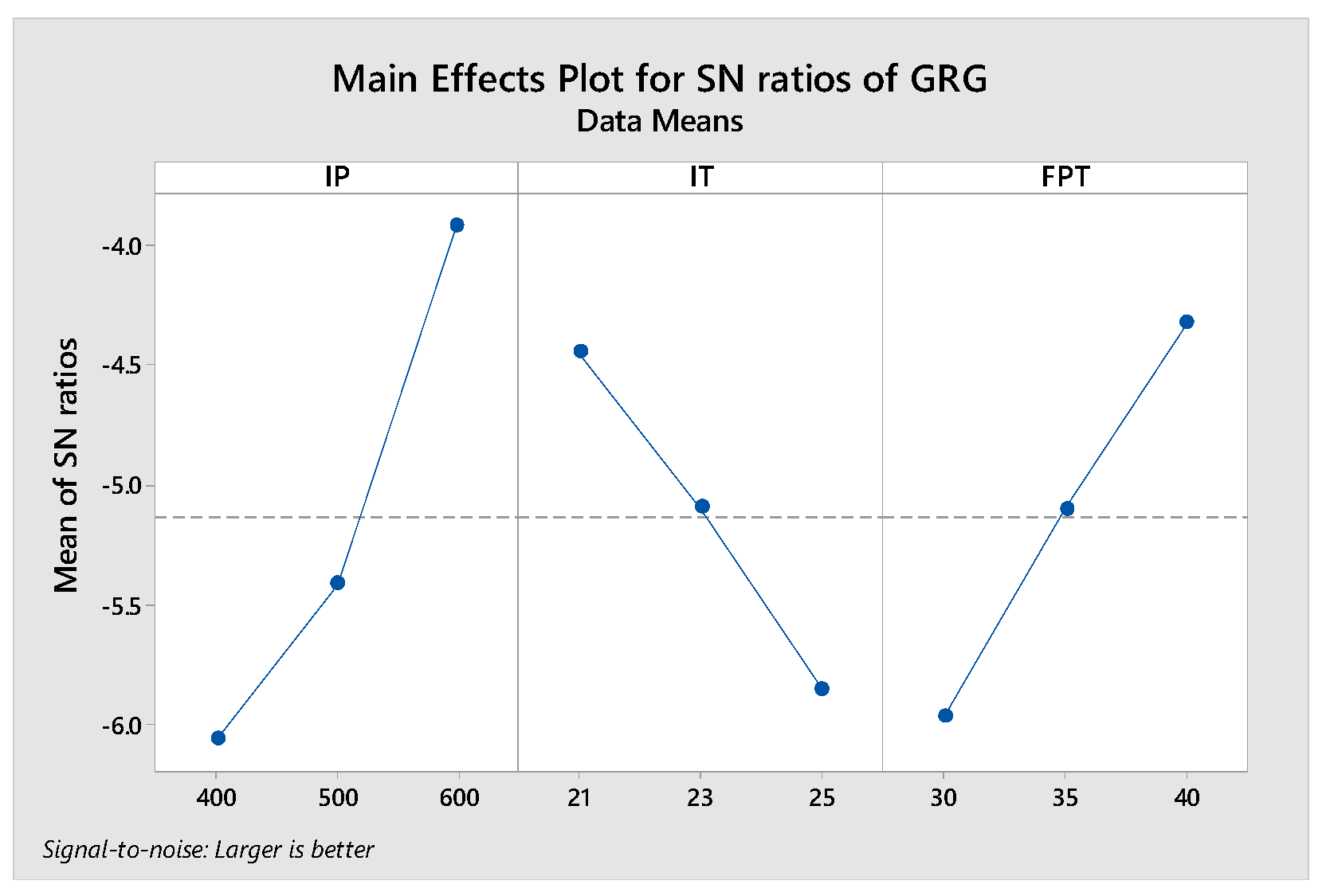

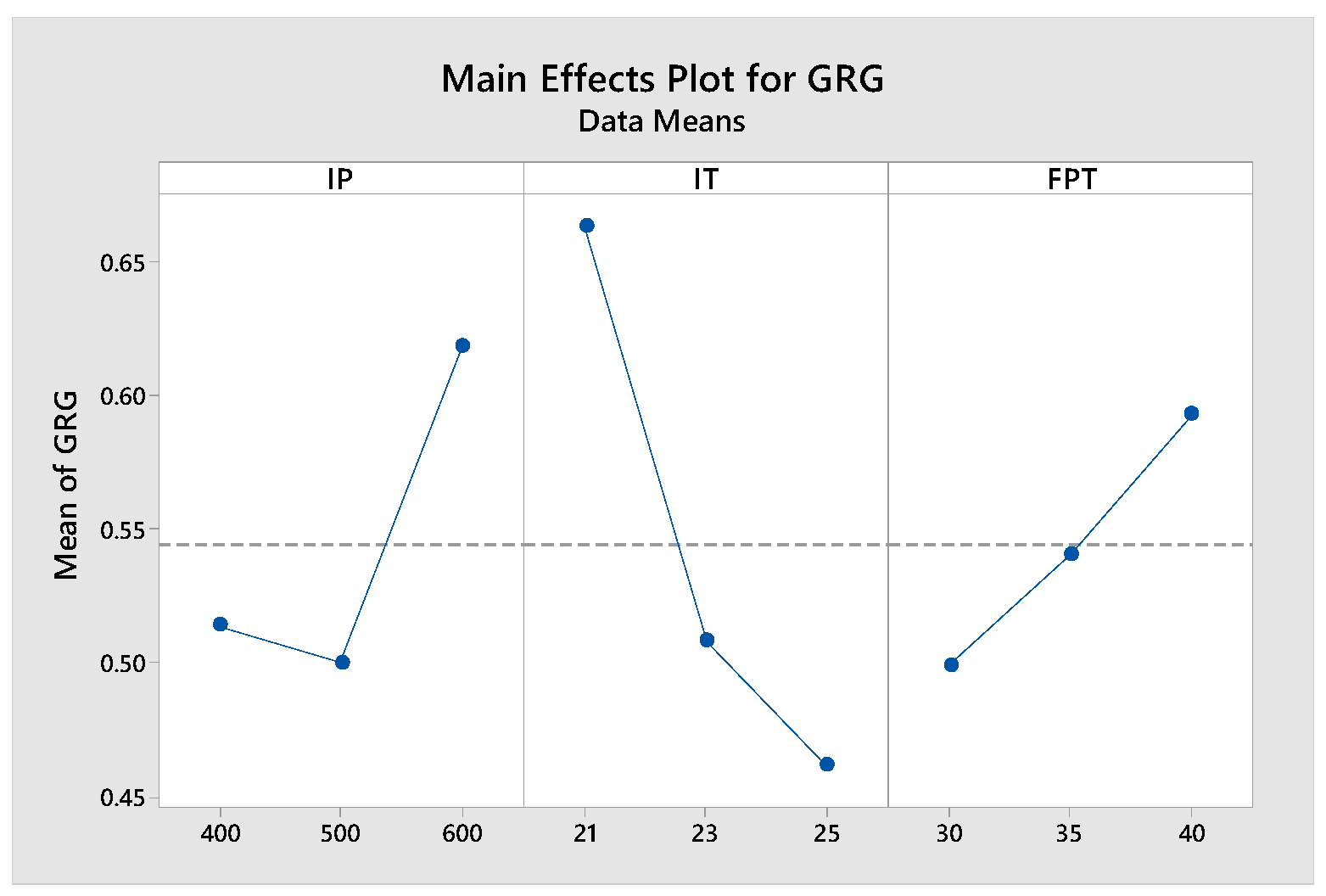

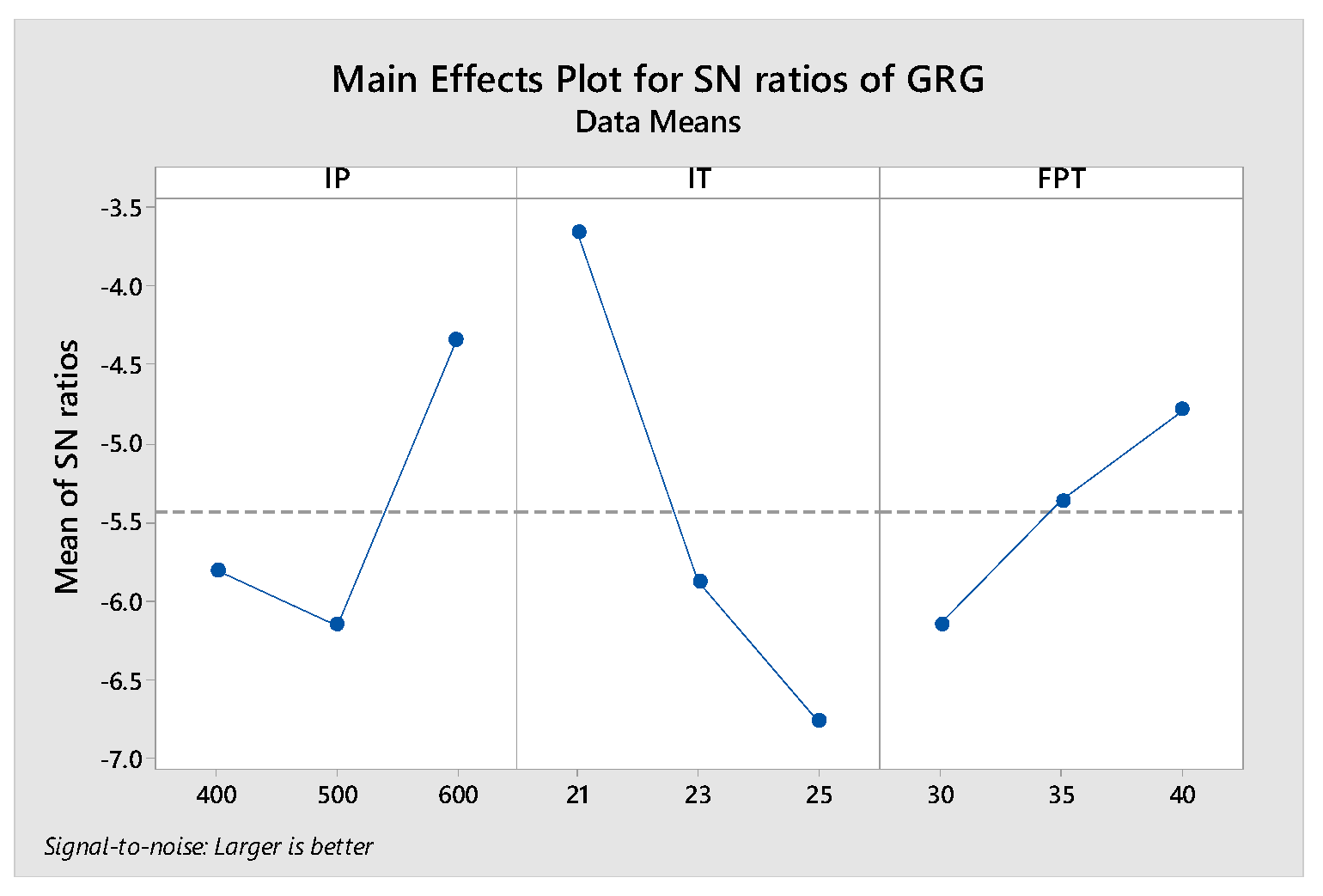

4.1. S/N Ratio Study

4.2. Analysis of Variance (ANOVA)

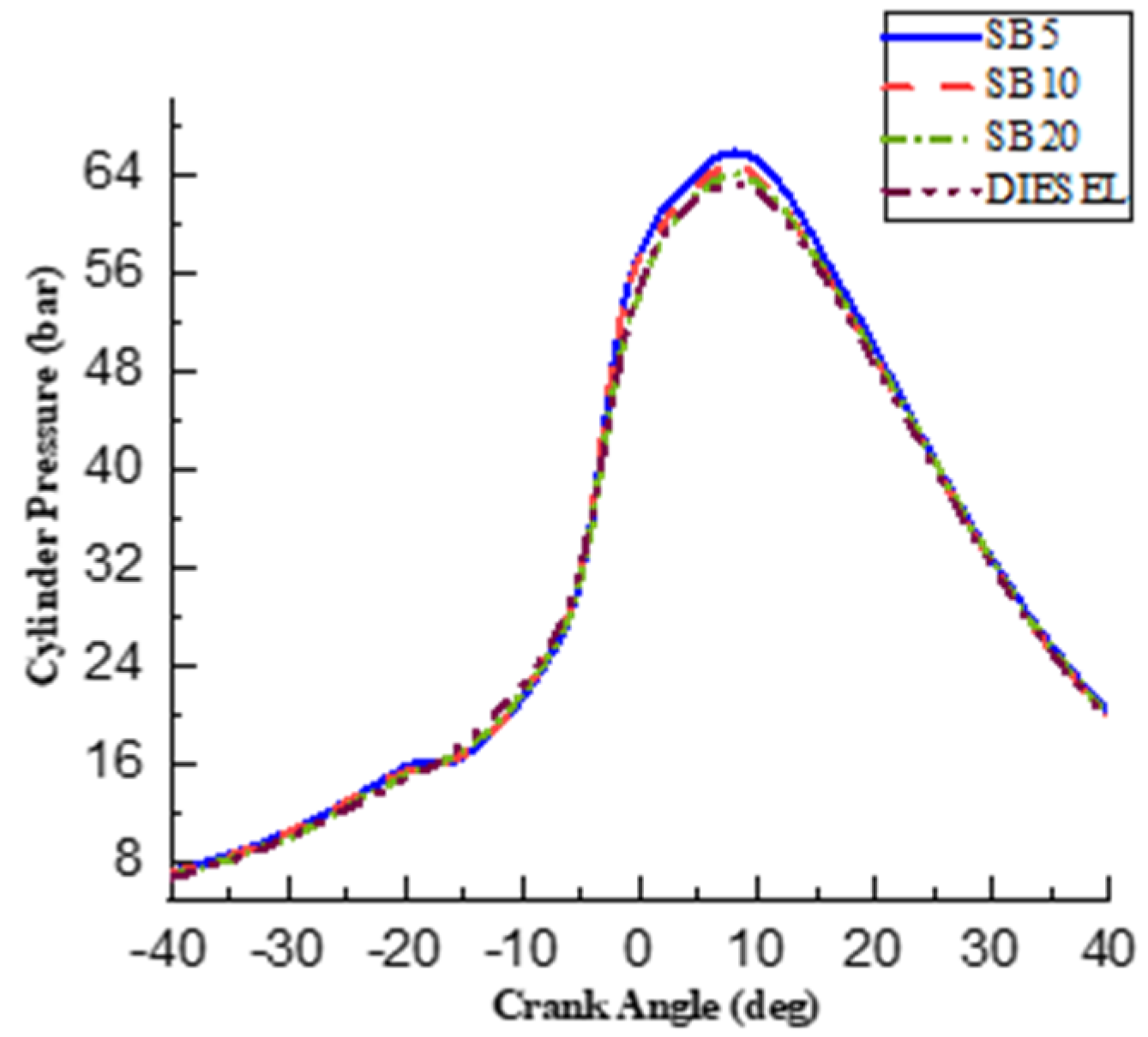

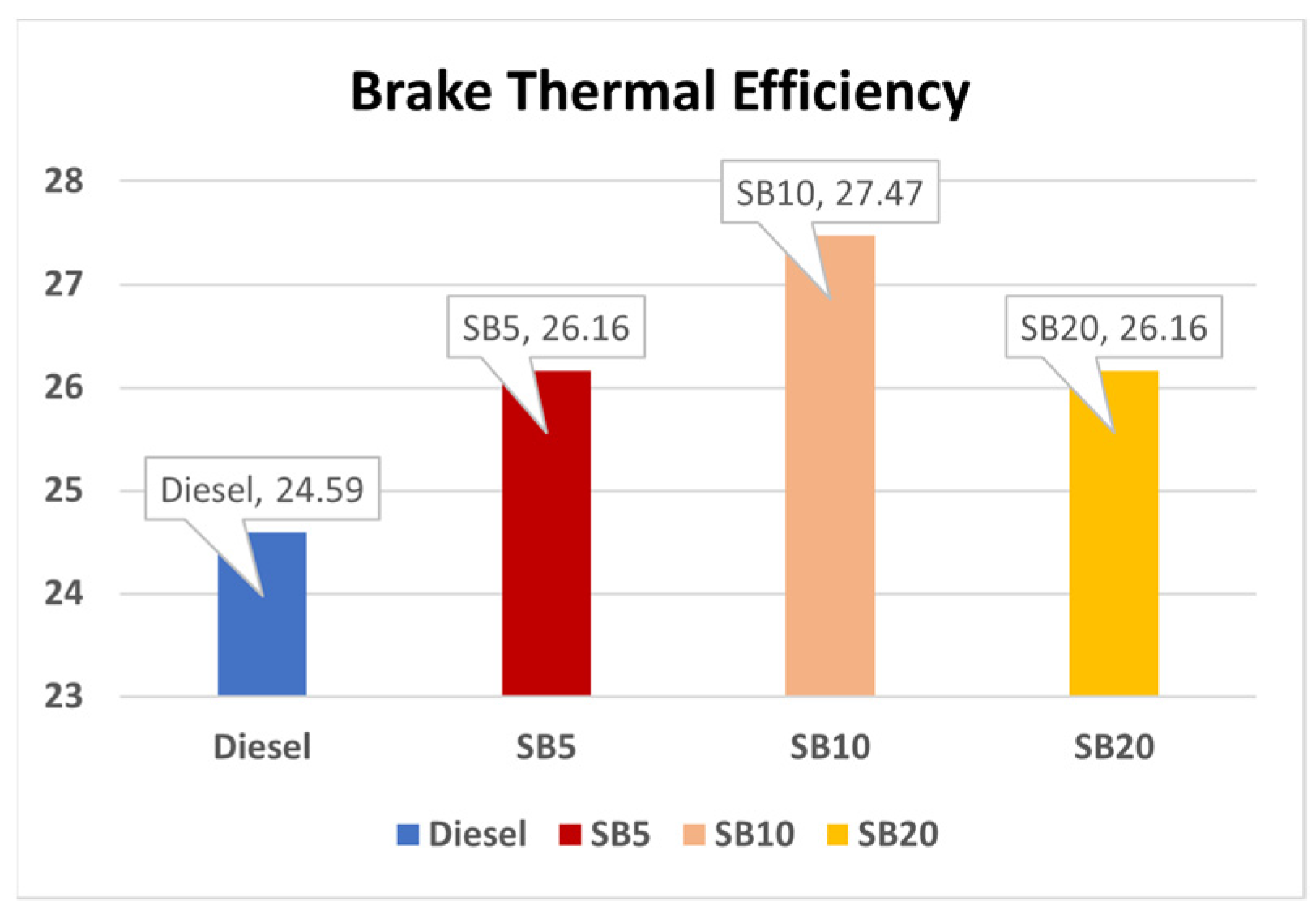

4.3. Performance Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Perez, T.C. A Mini-Review of the Environmental Footprint of Lithium-Ion Batteries for Electric Vehicles. J. Comput. Mech. Manag. 2023, 2, 43–52. [Google Scholar] [CrossRef]

- Research and Development Report on Tree Born Oilseeds, National Oilseeds and Vegetable Oils Development Board; Government of India: New Delhi, India, 2009.

- Naik, N.; Kowshik, S.; Bhat, R.; Bawa, M. Failure analysis of governor in diesel engine using Shainin System™. Eng. Fail. Anal. 2019, 101, 456–463. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Tandale, M.S. Multi-objective performance optimization of compression ignition engine operated on mangifera indica biodiesel by applying taguchi grey relational analysis. Waste Biomass Valorization 2016, 7, 1309–1325. [Google Scholar] [CrossRef]

- Pohit, G.; Misra, D. Optimization of performance and emission characteristics of diesel engine with biodiesel using grey-taguchi method. J. Eng. 2013, 2013, 915357. [Google Scholar] [CrossRef]

- Rao, N.D.; Sudheer Prem Kumar, B.; Srinath, C.; Patil, C. Optimization of engine operating parameters. Int. J. Mech. Eng. Technol. (IJMET) 2014, 5, 1–7. [Google Scholar]

- Geetha, N.K.; Sekar, P. Optimization of operating parameters on a diesel engine using grey relational analysis. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 701–707. [Google Scholar]

- Hussain, M.; Peethambaran, K.M.; Ushakumari, E.R. Performance optimization of diesel engine with chicken waste bio-diesel blend using grey relational analysis. Int. J. Eng. Res. Dev. 2014, 10, 9–15. [Google Scholar]

- Karthikayan, S.; Sankaranarayanan, G. Optimisation of engine performance variables using taguchi and grey relational analysis. Natl. J. Adv. Build. Sci. Mech. 2013, 4, 11–19. [Google Scholar]

- Ganesan, S.; Kumar, J.S.; Hemanandh, J. Optimisation of CI engine parameter using blends of biodiesel by the Taguchi method. Int. J. Ambient. Energy 2008, 41, 205–208. [Google Scholar] [CrossRef]

- Avinash, K.B.A. Gowreesh, Optimization of diesel engine parameters with blend of pongamia biodiesel and diesel using taguchi method. Int. J. Appl. Eng. Res. Dev. (IJAERD) 2015, 5, 13–20. [Google Scholar]

- Nayee, N.R.; Patel, T.M.; Patel, P.R.; Rathod, G.P. Parametric optimization of single cylinder diesel engine for karanja biodiesel & diesel blend for specific fuel consumption using taguchi method. IOSR J. Mech. Civ. Eng. (IOSR-JMCE) 2017, 14, 41–46. [Google Scholar]

- Modi, M.A.; Patel, T.M.; Rathod, G.P. Parametric optimization of single cylinder diesel engine for palm seed oil & diesel blend for brake thermal efficiency using taguchi method. IOSR J. Eng. (IOSRJEN) 2014, 4, 49–54. [Google Scholar]

- Sivaramakrishnan, K.; Ravikumar, P. Performance optimization of karanja biodiesel engine using taguchi approach and multiple regressions. ARPN J. Eng. Appl. Sci. 2012, 7, 506–516. [Google Scholar]

- Kökkülünk, G.; Parlak, A.; Bağci, E.; Aydin, Z. Application of taguchi methods for the optimization of factors affecting engine performance and emission of exhaust gas recirculation in steam-injected diesel engines. Acta Polytech. Hung. 2014, 11, 95–107. [Google Scholar]

- Kumar, S.; Navaneetha Krishnan, P.; Senthil Kumar, T.; Kumaragurubaran, B. Performance optimization of diesel engine with watermelon seed oil blend using taguchi-grey relational analysis. Int. J. Eng. Sci. Comput. 2016, 6, 5231–5234. [Google Scholar]

- Shailaja, M.; Sitarama Raju, A.V. Optimization of diesel engine parameters for performance, combustion and emission parameters using taguchi and grey relational analysis. Glob. J. Res. Eng. A Mech. Mech. Eng. 2016, 16, 37–50. [Google Scholar]

- Joshi, D.H.; Patel, T.M. Parametric optimization of single cylinder diesel engine for pyrolysis oil & diesel blend for mechanical efficiency using taguchi method. Int. J. Eng. Res. Technol. (IJERT) 2012, 1, 1–6. [Google Scholar]

- Kumar, R.S.; Sureshkumar, K. Data set of multi-objective optimization of diesel engine parameters. Data Brief 2019, 25, 104184. [Google Scholar] [CrossRef] [PubMed]

- Sukhdeve, V.; Ganguly, S.K. Utility of taguchi based grey relational analysis to optimize any process or system. Int. J. Adv. Eng. Res. Stud. 2015, 4, 242–250. [Google Scholar]

- Tandale, M.S.; Garjepatil, G.V.; Jadhav, S.D. Optimization of performance & emission characteristics of compressed ignition engine operated on mahua biodiesel using taguchi and multiple regression analysis. In Proceedings of the World Congress on Engineering, London, UK, 29 June–1 July 2016; Volume II. [Google Scholar]

- Karnwal, A.; Hasan, M.M.; Kumar, N.; Siddiquee, A.N.; Khan, Z.A. Multi-response optimization of diesel engine performance parameters using thumba biodiesel-diesel blends by applying the taguchi method and grey relational analysis. Int. J. Automot. Technol. 2011, 12, 599–610. [Google Scholar] [CrossRef]

| Trials | IP (A) | IT (B) | FPT (C) |

|---|---|---|---|

| 1. | 400 | 21 | 30 |

| 2. | 400 | 23 | 35 |

| 3. | 400 | 25 | 40 |

| 4. | 500 | 21 | 35 |

| 5. | 500 | 23 | 40 |

| 6. | 500 | 25 | 30 |

| 7. | 600 | 21 | 40 |

| 8. | 600 | 23 | 30 |

| 9. | 600 | 25 | 35 |

| Responses | BTE | BSFC | CO | NOx | UHC | CO2 |

| Weight factor | 0.25 | 0.25 | 0.1 | 0.2 | 0.1 | 0.1 |

| Properties | Al 6061 |

|---|---|

| Product | CRDI VCR Engine |

| Type | 1-cylinder 4-stroke Kirloskar make |

| Model | 244 |

| Cooling | Water cooled |

| Power | 3.5 kW |

| Compression ratio | 12:1 to 18:1 |

| Standard IT | 23° bTDC |

| Bore | 87.5 mm |

| Capacity | 661 cc |

| Run | Bsfc | BTE | CO | NOx | UHC | CO2 | GRG | Rank. |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.333 | 0.371 | 0.333 | 1.000 | 0.333 | 0.920 | 0.535 | 6 |

| 2 | 0.333 | 0.508 | 0.407 | 0.712 | 0.440 | 1.000 | 0.537 | 5 |

| 3 | 0.500 | 0.621 | 0.536 | 0.451 | 0.647 | 0.561 | 0.545 | 4 |

| 4 | 0.500 | 0.677 | 0.597 | 0.581 | 0.524 | 0.742 | 0.597 | 3 |

| 5 | 0.500 | 0.791 | 0.683 | 0.408 | 0.733 | 0.590 | 0.605 | 2 |

| 6 | 0.333 | 0.333 | 0.664 | 0.392 | 0.579 | 0.354 | 0.405 | 9 |

| 7 | 1.000 | 1.000 | 0.738 | 0.468 | 0.846 | 0.622 | 0.814 | 1 |

| 8 | 0.333 | 0.349 | 0.775 | 0.402 | 0.733 | 0.377 | 0.440 | 8 |

| 9 | 0.500 | 0.411 | 1.000 | 0.333 | 1.000 | 0.333 | 0.528 | 7 |

| Run | Bsfc | BTE | CO | NOx | UHC | CO2 | GRG | Rank. |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.333 | 0.333 | 0.333 | 1.000 | 0.333 | 0.529 | 0.486 | 7 |

| 2 | 0.400 | 0.343 | 0.473 | 0.688 | 0.538 | 1.000 | 0.525 | 6 |

| 3 | 0.400 | 0.470 | 0.545 | 0.518 | 0.412 | 0.659 | 0.482 | 8 |

| 4 | 0.500 | 0.522 | 0.470 | 0.731 | 0.500 | 0.600 | 0.559 | 4 |

| 5 | 0.500 | 0.538 | 0.841 | 0.485 | 0.700 | 0.771 | 0.588 | 2 |

| 6 | 0.400 | 0.409 | 0.647 | 0.399 | 0.778 | 0.443 | 0.469 | 9 |

| 7 | 1.000 | 1.000 | 1.000 | 0.435 | 0.583 | 0.474 | 0.793 | 1 |

| 8 | 0.500 | 0.473 | 0.914 | 0.409 | 1.000 | 0.415 | 0.558 | 5 |

| 9 | 0.667 | 0.509 | 0.920 | 0.333 | 1.000 | 0.333 | 0.586 | 3 |

| Run | Bsfc | BTE | CO | NOx | UHC | CO2 | GRG | Rank. |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.429 | 0.411 | 0.407 | 1.000 | 0.333 | 0.926 | 0.576 | 3 |

| 2 | 0.429 | 0.417 | 0.373 | 0.668 | 0.385 | 0.714 | 0.492 | 7 |

| 3 | 0.429 | 0.426 | 0.333 | 0.532 | 0.405 | 0.806 | 0.474 | 8 |

| 4 | 0.600 | 0.417 | 0.783 | 0.608 | 0.556 | 1.000 | 0.610 | 2 |

| 5 | 0.600 | 0.498 | 0.484 | 0.446 | 0.484 | 0.410 | 0.501 | 6 |

| 6 | 0.333 | 0.333 | 0.562 | 0.402 | 0.484 | 0.385 | 0.390 | 9 |

| 7 | 1.000 | 1.000 | 0.811 | 0.475 | 0.714 | 0.556 | 0.803 | 1 |

| 8 | 0.429 | 0.491 | 1.000 | 0.401 | 0.882 | 0.333 | 0.532 | 4 |

| 9 | 0.429 | 0.458 | 0.859 | 0.333 | 1.000 | 0.472 | 0.521 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nithyananda, B.S.; Naveen Prakash, G.V.; Ankegowda, N.; Vinay, K.B.; Anand, A. Optimization of Performance and Emission Responses of Common Rail Direct Injection Engine by Taguchi-Grey Relational Analysis Technique. Eng. Proc. 2023, 59, 140. https://doi.org/10.3390/engproc2023059140

Nithyananda BS, Naveen Prakash GV, Ankegowda N, Vinay KB, Anand A. Optimization of Performance and Emission Responses of Common Rail Direct Injection Engine by Taguchi-Grey Relational Analysis Technique. Engineering Proceedings. 2023; 59(1):140. https://doi.org/10.3390/engproc2023059140

Chicago/Turabian StyleNithyananda, B. S., G. V. Naveen Prakash, Naveen Ankegowda, K. B. Vinay, and A. Anand. 2023. "Optimization of Performance and Emission Responses of Common Rail Direct Injection Engine by Taguchi-Grey Relational Analysis Technique" Engineering Proceedings 59, no. 1: 140. https://doi.org/10.3390/engproc2023059140