Luminous Transmittance and Color Rendering Characteristics of Evaporated Chalcopyrite Thin Films for Semitransparent Photovoltaics

Abstract

1. Introduction

2. Materials and Methods

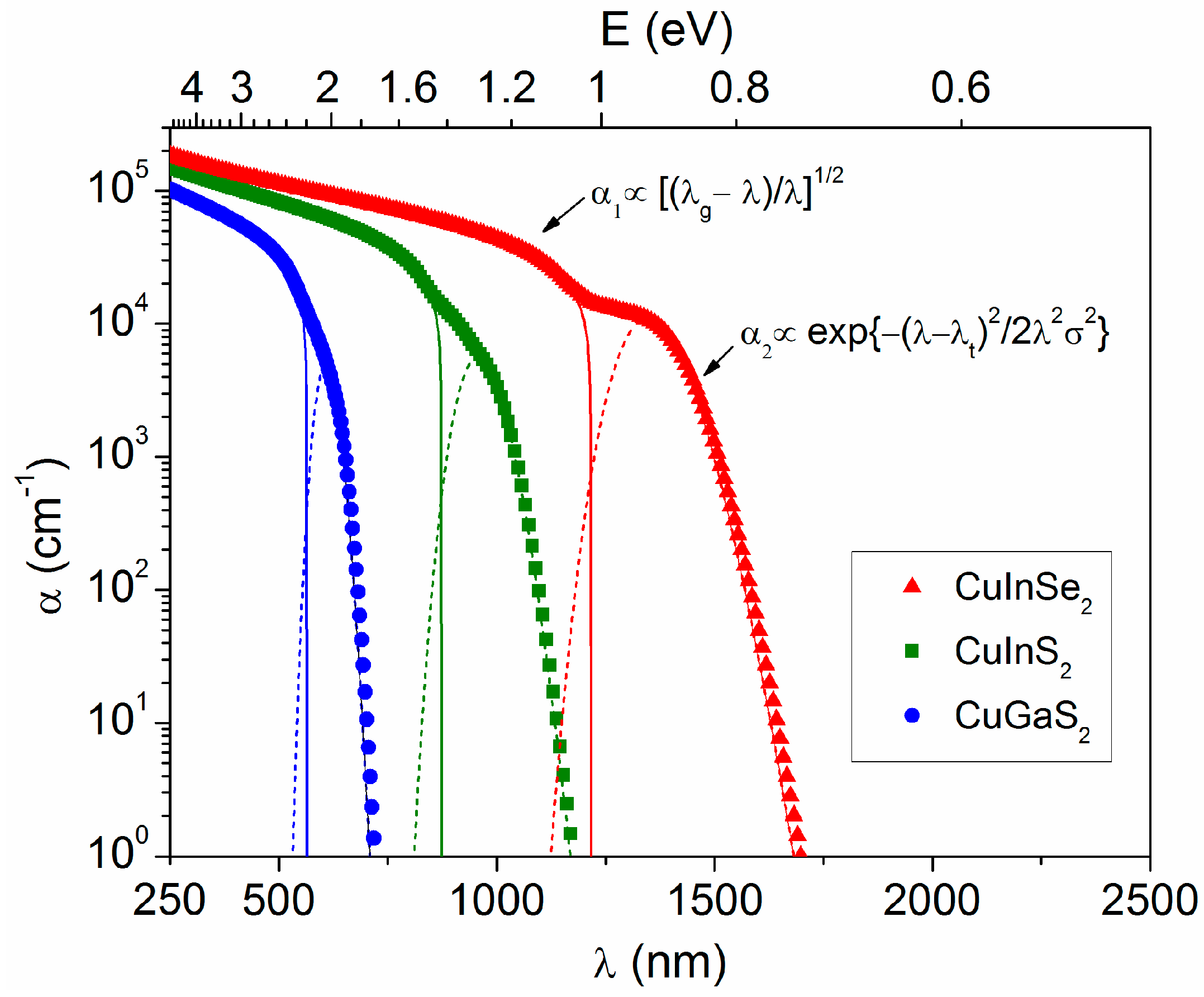

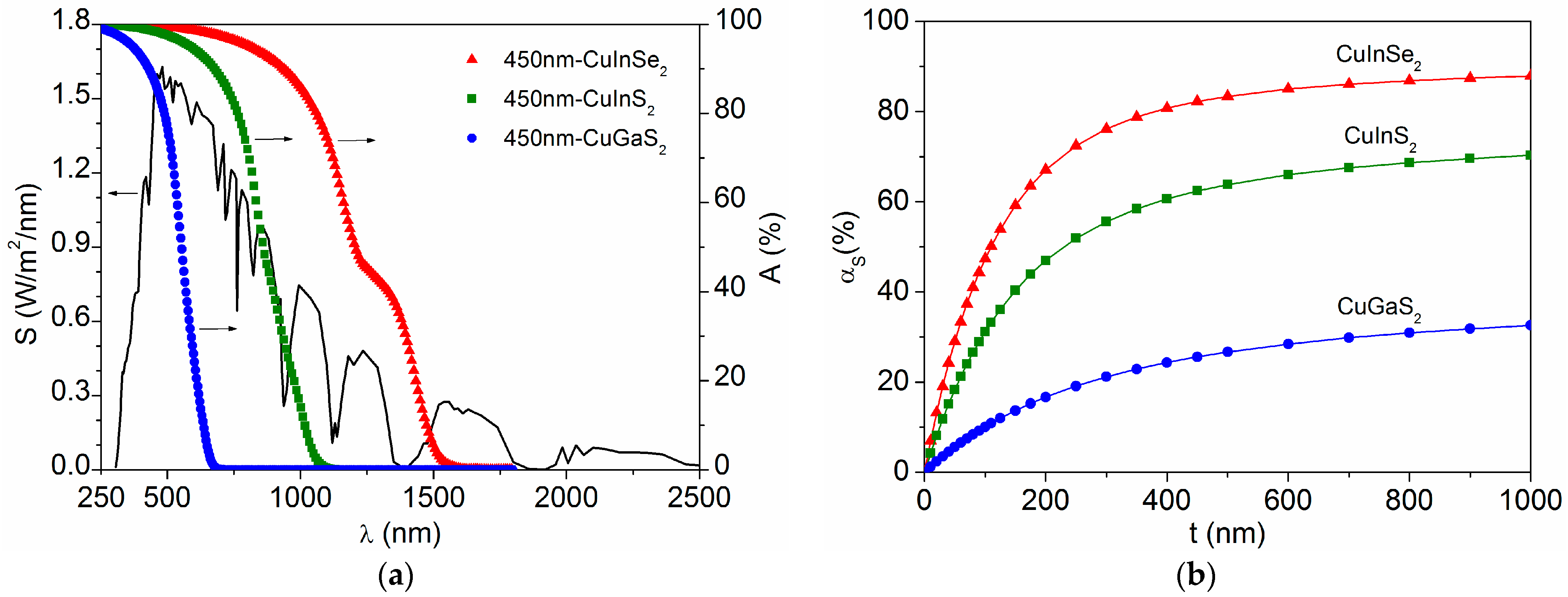

2.1. Determination of the Solar Absorptance and Luminous Transmittance

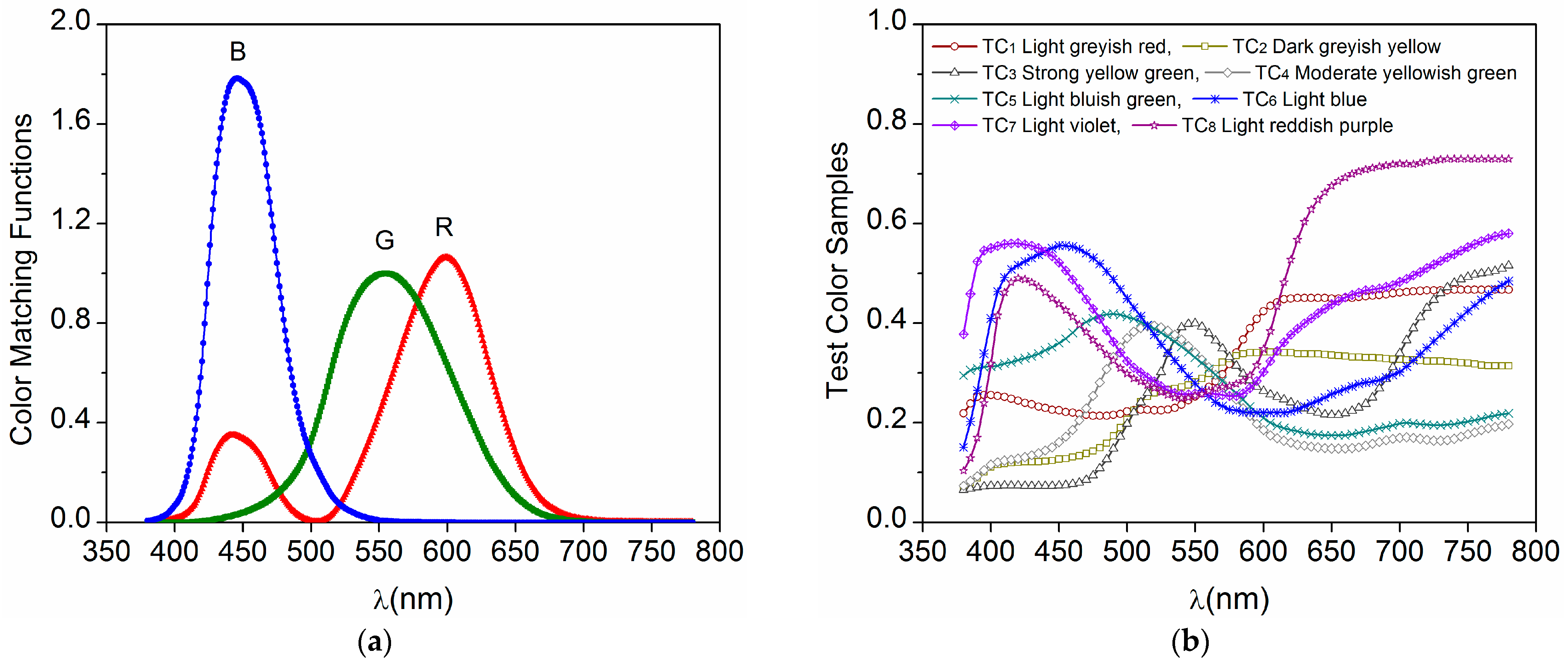

2.2. Determination of the Correlated Color Temperature

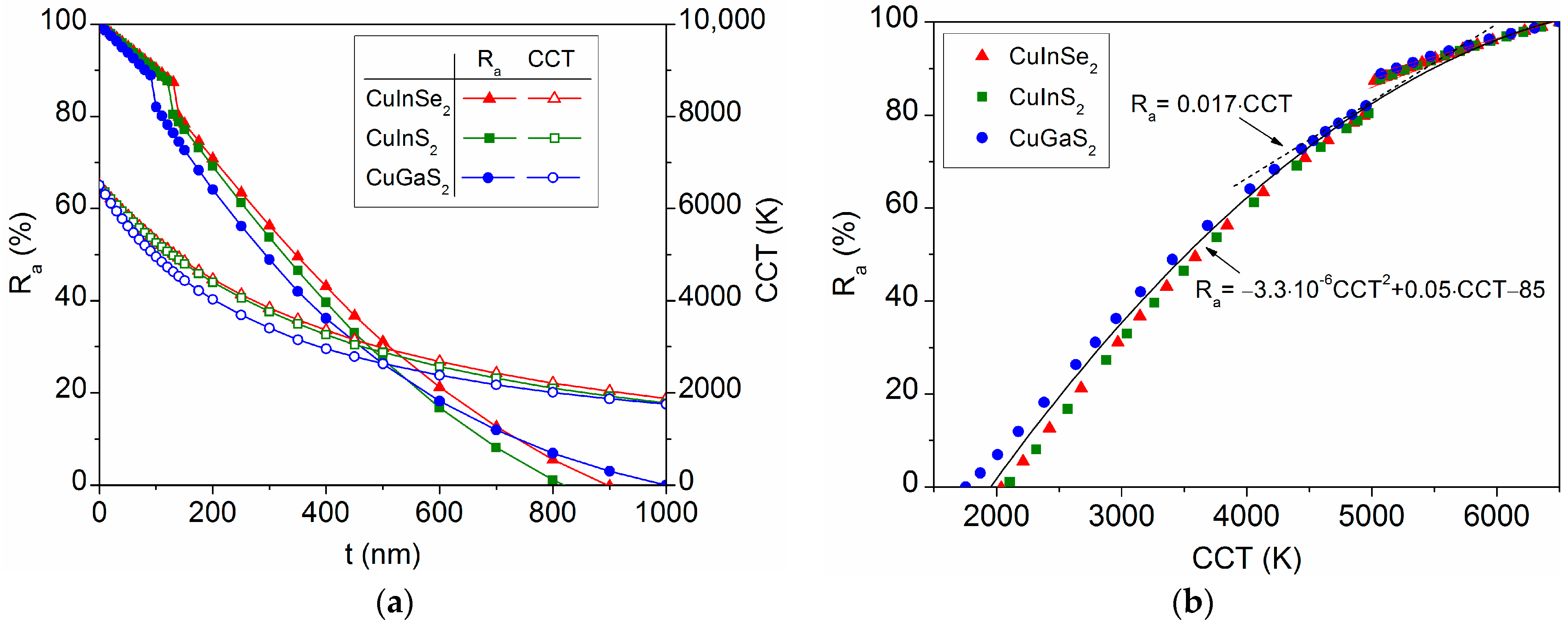

2.3. Determination of the Color Rendering Index

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, P.; You, S.; Vomiero, A. Recent progress in materials and device design for semitransparent photovoltaic technologies. Adv. Energy Mater. 2023, 13, 2301555. [Google Scholar] [CrossRef]

- Shin, M.J.; Jo, J.H.; Cho, A.; Gwak, J.; Yun, J.H.; Kim, K.; Ahn, S.K.; Park, J.H.; Yoo, J.; Jeong, I.; et al. Semi-transparent photovoltaics using ultra-thin Cu(In,Ga)Se2 absorber layers prepared by single-stage co-evaporation. Sol. Energy 2019, 181, 276–284. [Google Scholar] [CrossRef]

- Chae, Y.T.; Kim, J.; Park, H.; Shin, B. Building energy performance evaluation of building integrated photovoltaic (BIPV) window with semi-transparent solar cells. Appl. Energy 2014, 129, 217–227. [Google Scholar] [CrossRef]

- Chee, A.K.W. On current technology for light absorber materials used in highly efficient industrial solar cells. Renew. Sustain. Energy Rev. 2023, 173, 113027. [Google Scholar] [CrossRef]

- Sivaraj, S.; Rathanasamy, R.; Kaliyannan, G.V.; Panchal, H.; Jawad Alrubaie, A.; Musa Jaber, M.; Said, Z.; Memon, S. A comprehensive review on current performance, challenges and progress in thin-film solar cells. Energies 2022, 15, 8688. [Google Scholar] [CrossRef]

- Siebentritt, S.; Lomuscio, A.; Adeleye, D.; Sood, M.; Dwivedi, A. Sulfide chalcopyrite solar cells—Are they the same as selenides with a wider bandgap? Phys. Status Solidi Rapid Res. Lett. 2022, 16, 2200126. [Google Scholar] [CrossRef]

- Kim, S.; Nagai, T.; Tampo, H.; Ishizuka, S.; Shibata, H. Large open-circuit voltage boosting of pure sulfide chalcopyrite Cu(In,Ga)S2 prepared using Cu-deficient metal precursors. Prog. Photovoltaics Res. Appl. 2020, 28, 816–822. [Google Scholar] [CrossRef]

- Klenk, R.; Klaer, J.; Scheer, R.; Lux-Steiner, M.C.; Luck, I.; Meyer, N.; Rühle, U. Solar cells based on CuInS2—An overview. Thin Solid Films 2005, 480–481, 509–514. [Google Scholar] [CrossRef]

- Qi, Y.; Liu, Q.; Tang, K.; Liang, Z.; Ren, Z.; Liu, X. Synthesis and characterization of nanostructured wurtzite CuInS2: A new cation disordered polymorph of CuInS2. J. Phys. Chem. C 2009, 113, 3939–3944. [Google Scholar] [CrossRef]

- Gogova, D.; Olsen, V.S.; Bazioti, C.; Lee, I.H.; Prytz, Ø.; Vines, L.; Kuznetsov, A.Y. High electron mobility single-crystalline ZnSnN2 on ZnO (0001) substrates. CrystEngComm 2020, 22, 6268–6274. [Google Scholar] [CrossRef]

- Nezhdanov, A.; Skrylev, A.; Shestakov, D.; Usanov, D.; Fukina, D.; Malyshev, A.; De Filpo, G.; Mashin, A. Mixed phase ZnSnN2 thin films for solar energy applications: Insight into optical and electrical properties. Opt. Mater. 2023, 144, 114335. [Google Scholar] [CrossRef]

- Massiot, I.; Cattoni, A.; Collin, S. Progress and prospects for ultrathin solar cells. Nat. Energy 2020, 5, 959–972. [Google Scholar] [CrossRef]

- Shin, M.J.; Lee, A.; Park, J.H.; Cho, A.; Ahn, S.K.; Shin, D.; Gwak, J.; Yun, J.H.; Yoo, J.; Cho, J.S. Ultrathin Cu(In,Ga)Se2 transparent photovoltaics: An alternative to conventional solar energy-harvesting windows. Nano Energy 2022, 92, 106711. [Google Scholar] [CrossRef]

- EN 410:2011; Glass in Building. Determination of Luminous and Solar Characteristics of Glazing. European Committee for Standardization: Bruxelles, Belgium, 2011.

- CIE 13.3:1995; Method of Measuring and Specifying Colour Rendering Properties of Light Sources. International Commission on Illumination: Vienna, Austria, 1995.

- Gueymard, C.A.; duPont, W.C. Spectral effects on the transmittance, solar heat gain, and performance rating of glazing systems. Sol. Energy 2009, 83, 940–953. [Google Scholar] [CrossRef]

- Li, D.H.W.; Lam, T.N.T.; Chan, W.W.H.; Mak, A.H.L. Energy and cost analysis of semi-transparent photovoltaic in office buildings. Appl. Energy 2009, 86, 722–729. [Google Scholar] [CrossRef]

- Traverse, C.J.; Pandey, R.; Barr, M.C.; Lunt, R.R. Emergence of highly transparent photovoltaics for distributed applications. Nat. Energy 2017, 2, 849–860. [Google Scholar] [CrossRef]

- Ghosh, A.; Selvaraj, P.; Sundaram, S.; Mallick, T.K. The colour rendering index and correlated colour temperature of dye-sensitized solar cell for adaptive glazing application. Sol. Energy 2018, 163, 537–544. [Google Scholar] [CrossRef]

- Lynn, N.; Mohanty, L.; Wittkopf, S. Color rendering properties of semi-transparent thin-film PV modules. Build. Environ. 2012, 54, 148–158. [Google Scholar] [CrossRef]

- Martín-Chivelet, N.; Guillén, C.; Trigo, J.F.; Herrero, J.; Pérez, J.J.; Chenlo, F. Comparative performance of semi-transparent PV modules and electrochromic windows for improving energy efficiency in buildings. Energies 2018, 11, 1526. [Google Scholar] [CrossRef]

- Guillén, C.; Herrero, J. CuInS2 and CuGaS2 thin films grown by modulated flux deposition with various Cu contents. Phys. Status Solidi 2006, 203, 2438–2443. [Google Scholar] [CrossRef]

- Guillén, C. Evaporated chalcopyrite thin films for indoor photovoltaic applications. Adv. Energy Convers. Mater. 2024, 5, 31–39. [Google Scholar] [CrossRef]

- Woods-Robinson, R.; Han, Y.; Zhang, H.; Ablekim, T.; Khan, I.; Persson, K.A.; Zakutayev, A. Wide band gap chalcogenide semiconductors. Chem. Rev. 2020, 120, 4007–4055. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Yoo, J.; Lee, M.; Jung, J.; Jang, J. CuInSe2-based near-infrared photodetector. Appl. Sci. 2021, 12, 92. [Google Scholar] [CrossRef]

- Dolgonos, A.; Mason, T.O.; Poeppelmeier, K.R. Direct optical band gap measurement in polycrystalline semiconductors: A critical look at the Tauc method. J. Solid State Chem. 2016, 240, 43–48. [Google Scholar] [CrossRef]

- Bangolla, H.K.; Nallapureddy, R.R. MCSK Cu-rich copper indium sulfide thin films deposited by co-evaporation for photovoltaic applications. J. Mater. Sci. Mater. Electron. 2023, 34, 341. [Google Scholar] [CrossRef]

- Wang, L.; Yuan, X.; Wang, Y.; Yao, W.; Zhu, J.; Jing, W. Preparation and characterization of CuGaS2 thin films as a promising parent material for intermediate band solar cells. Mater. Sci. Semicond. Process. 2015, 30, 267–270. [Google Scholar] [CrossRef]

- Nishiwaki, M.; Nagaya, K.; Kato, M.; Fujimoto, S.; Tampo, H.; Miyadera, T.; Chikamatsu, M.; Shibata, H.; Fujiwara, H. Tail state formation in solar cell materials: First principles analyses of zincblende, chalcopyrite, kesterite, and hybrid perovskite crystals. Phys. Rev. Mater. 2018, 2, 1–28. [Google Scholar] [CrossRef]

- Katahara, J.K.; Hillhouse, H.W. Quasi-Fermi level splitting and sub-bandgap absorptivity from semiconductor photoluminescence. J. Appl. Phys. 2014, 116, 173504. [Google Scholar] [CrossRef]

- Sritrakool, W.; Sa-yakanit, V.; Glyde, H.R. Band tails in disordered systems. Phys. Rev. B 1986, 33, 1199–1202. [Google Scholar] [CrossRef]

- Rey, G.; Larramona, G.; Bourdais, S.; Choné, C.; Delatouche, B.; Jacob, A.; Dennler, G.; Siebentritt, S. On the origin of band-tails in kesterite. Sol. Energy Mater. Sol. Cells 2018, 179, 142–151. [Google Scholar] [CrossRef]

- Kruse, O.; Rupprecht, J.; Mussgnug, J.H.; Dismukes, G.C.; Hankamer, B. Photosynthesis: A blueprint for solar energy capture and biohydrogen production technologies. Photochem. Photobiol. Sci. 2005, 4, 957–970. [Google Scholar] [CrossRef]

- Venkateswararao, A.; Ho, J.K.W.; So, S.K.; Liu, S.W.; Wong, K.T. Device characteristics and material developments of indoor photovoltaic devices. Mater. Sci. Eng. R Rep. 2020, 139, 100517. [Google Scholar] [CrossRef]

- Meddeb, H.; Götz-Köhler, M.; Neugebohrn, N.; Banik, U.; Osterthun, N.; Sergeev, O.; Berends, D.; Lattyak, C.; Gehrke, K.; Vehse, M. Tunable photovoltaics: Adapting solar cell technologies to versatile applications. Adv. Energy Mater. 2022, 12, 2200713. [Google Scholar] [CrossRef]

- Nundy, S.; Mesloub, A.; Alsolami, B.M.; Ghosh, A. Electrically actuated visible and near-infrared regulating switchable smart window for energy positive building: A review. J. Clean. Prod. 2021, 301, 126854. [Google Scholar] [CrossRef]

- Ghosh, A.; Mesloub, A.; Touahmia, M.; Ajmi, M. Visual comfort analysis of semi-transparent perovskite based building integrated photovoltaic window for hot desert climate (Riyadh, Saudi Arabia). Energies 2021, 14, 1043. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guillén, C. Luminous Transmittance and Color Rendering Characteristics of Evaporated Chalcopyrite Thin Films for Semitransparent Photovoltaics. Solids 2024, 5, 98-109. https://doi.org/10.3390/solids5010007

Guillén C. Luminous Transmittance and Color Rendering Characteristics of Evaporated Chalcopyrite Thin Films for Semitransparent Photovoltaics. Solids. 2024; 5(1):98-109. https://doi.org/10.3390/solids5010007

Chicago/Turabian StyleGuillén, Cecilia. 2024. "Luminous Transmittance and Color Rendering Characteristics of Evaporated Chalcopyrite Thin Films for Semitransparent Photovoltaics" Solids 5, no. 1: 98-109. https://doi.org/10.3390/solids5010007

APA StyleGuillén, C. (2024). Luminous Transmittance and Color Rendering Characteristics of Evaporated Chalcopyrite Thin Films for Semitransparent Photovoltaics. Solids, 5(1), 98-109. https://doi.org/10.3390/solids5010007