Advances in Friction Stir Welding and Processing (2nd Edition)

A special issue of Metals (ISSN 2075-4701). This special issue belongs to the section "Additive Manufacturing".

Deadline for manuscript submissions: 15 September 2024 | Viewed by 2451

Special Issue Editor

Interests: metallurgy; magnesium alloys; amorphous alloys; friction stir welding and processing of Al, Cu, Mg and Ti alloys; high temperature mechanical properties; joining processes

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

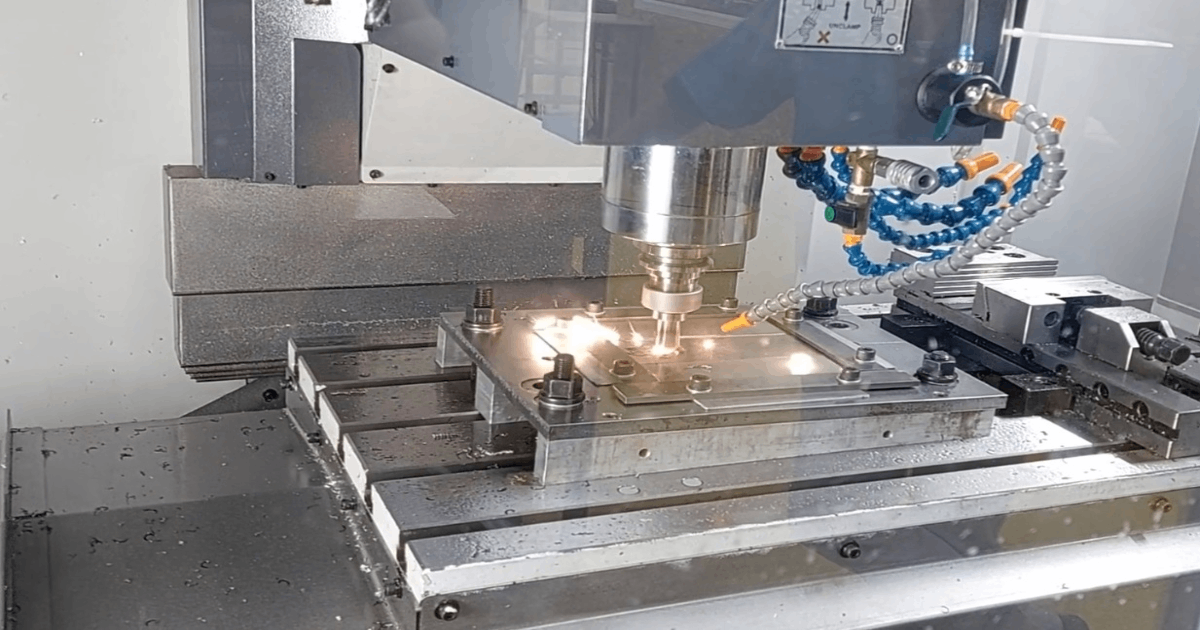

The friction stir welding process (FSW) was developed in the early 1990s. Over the years, FSW proved itself ideal for creating good-quality butt joints and lap joints in several materials, especially the family of nonferrous metallic materials, including even those that are extremely difficult to weld by conventional fusion-welding processes. During FSW, the generated frictional heat is effectively utilized to facilitate material consolidation and eventual joining with the aid of axial pressure. The process is, therefore, a non-fusion welding process. As of today, FSW is, due to its advantages, a common industrial welding process. Friction stir processing (FSP) was derived from FSW to use severe plastic deformation to obtain a stirred zone with a very fine grain size and hence, to improve the mechanical properties of the material. FSP is identical to FSW except that in FSP, the rotating tool does not weld the parts to one another. Thus, its operation may be referred to as a ‘‘bead on plate’’ process. It is my pleasure to invite you to submit a manuscript in the fields of FSW and FSP for this Special Issue. Full papers, communications, and reviews are all welcome.

Prof. Dr. Michael Regev

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Metals is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- friction stir welding

- friction stir processing

- mechanical properties

- microstructure