Advances in Low-Temperature Nitriding and Carburizing of Stainless Steels and Metallic Materials: Formation and Properties (Volume II)

A special issue of Metals (ISSN 2075-4701). This special issue belongs to the section "Metal Casting, Forming and Heat Treatment".

Deadline for manuscript submissions: 20 May 2024 | Viewed by 6924

Special Issue Editors

Interests: surface modification of metals and alloys; low-temperature nitriding of stainless steels; oxynitriding of titanium alloys; material characterization

Special Issues, Collections and Topics in MDPI journals

Interests: plasma nitriding; plasma carburizing; thermal spraying; laser metal deposition

Special Issues, Collections and Topics in MDPI journals

Interests: thermal spraying; thermochemical treatment; heat treatment; Spark Plasma Sintering; laser cladding; high-entropy alloys; stainless-steel; Wear; corrosion; Microstructure

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

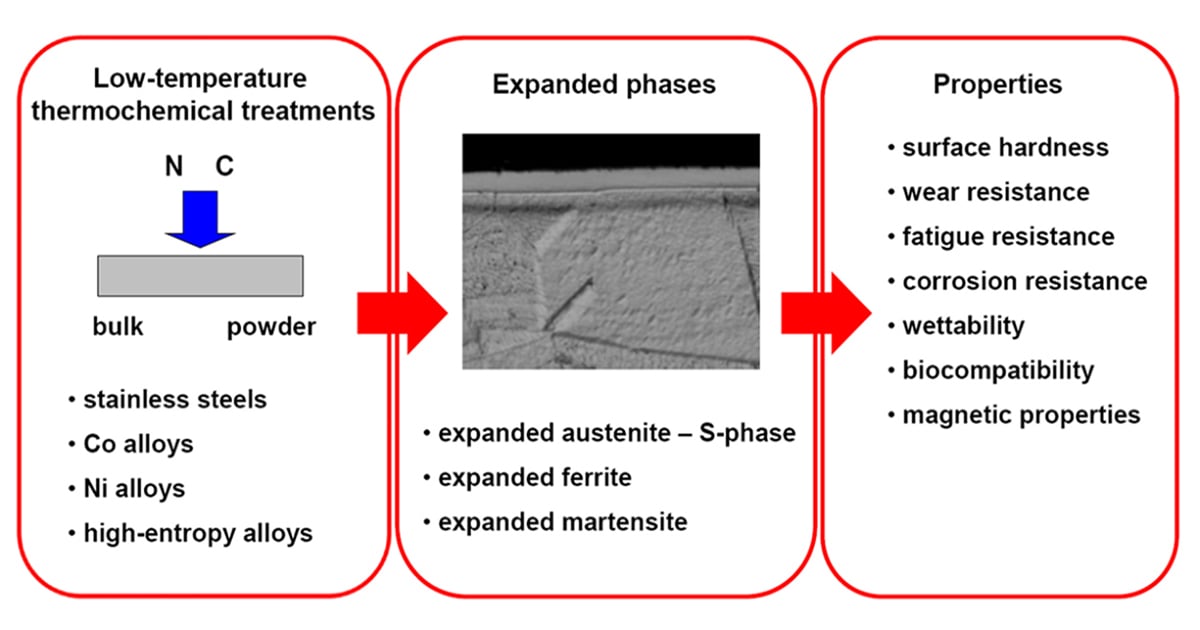

The formation of an expanded austenite phase (S-phase) by low-temperature thermochemical treatments using nitrogen and/or carbon (nitriding, carburizing and nitrocarburizing) of stainless steels has been studied since the 1980s. Initially, this method was applied to austenitic stainless steels, but it has proved to be suitable to produce expanded phases not only on the different grades of stainless steels (duplex, martensitic, precipitation-hardening and ferritic), but also on cobalt- and nickel-based alloys, and, recently, on high entropy alloys. The discovery of important scientific findings and their practical applications in industry have been achieved. In recent years, it has been combined with new processes such as thermal spray coating and additive manufacturing techniques, and it is expected to contribute to the manufacturing of the next generation.

This Special Issue on “Advances in Low-Temperature Nitriding and Carburizing of Stainless Steels and Metallic Materials: Formation and Properties” intends to cover original research and critical review articles on recent advances in all aspects of low-temperature thermochemical treatments using nitrogen and/or carbon.

In particular, the topics of interest include, but are not limited to, the following:

- Fundamentals and new concepts;

- Characteristics and properties of the expanded phases;

- Characteristics and properties of the modified layers;

- Application to novel alloys;

- Combination with other manufacturing processes;

- Industrial applications.

Prof. Dr. Francesca Borgioli

Dr. Shinichiro Adachi

Dr. Thomas Lindner

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Metals is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- low-temperature nitriding

- low-temperature carburizing

- low-temperature nitrocarburizing

- expanded austenite (S-phase)

- expanded phases

- material properties

- material characterization