- Article

In-Situ Stress Manipulation by Hydraulic Fracturing for Safer Deep Open Stope Mining in the Canadian Shield

- Nikolas Dmitrovic and

- Shunde Yin

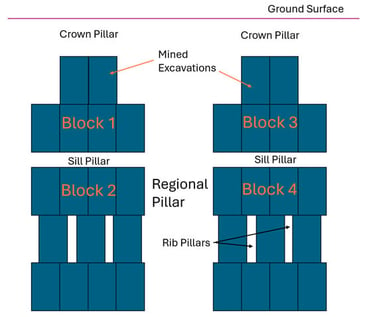

Hydraulic fracturing is a widely used technique in the oil and gas industry and, specifically, it is used in mining for fragmentation enhancement and rockburst risk mitigation. The technique is actively being applied to cave mining environments to induce caving and improve seismic response in deep high-strength rock masses. The method has great potential in Long Hole Open Stoping mines for large-scale stress management in high-risk environments. The use of hydraulic fracturing in deep mining was explored through the development of a conceptual design for the destressing of a mining pillar. Numerical modeling was conducted to understand the effects hydraulic fracture has on stress reduction, and how fractured geometries affect these results. The results of this analysis showed that there is a strong dependence on the geometry of hydraulic fractures on the stress reduction potential of the method. The developed conceptual design showed that hydraulic fracturing can be directly integrated into mine planning as a tool to strategically manage the hazards associated with highly stress pillars. The activities associated with treatment design directly identifies when treatment should occur in the mining sequence and provides a general assessment of risk reduction that can be used directly for operational decision-making.

18 February 2026

![(a) Location of the state of Minas Gerais; (b) location of the Iron Quadrangle (IQ) in the south-central region of Minas Gerais; (c) general geology of the IQ. Modified from [19].](https://mdpi-res.com/cdn-cgi/image/w=281,h=192/https://mdpi-res.com/mining/mining-06-00012/article_deploy/html/images/mining-06-00012-ag-550.jpg)