Takt Production Monitoring and Control in Apartment Renovation Projects

Abstract

:1. Introduction

2. Theoretical Background

2.1. Construction Production Monitoring and Control

Digital Production Control

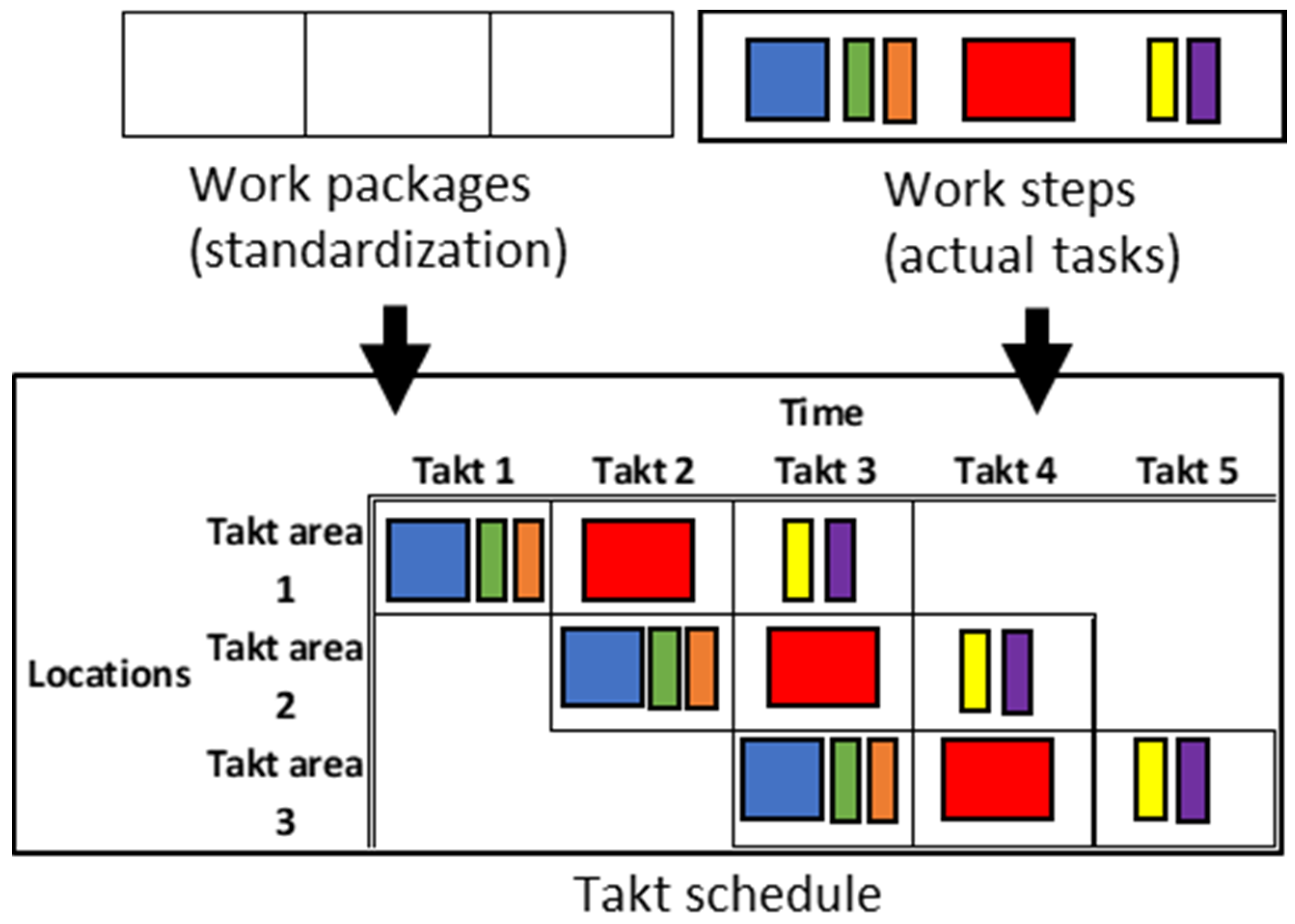

2.2. Takt Production Monitoring and Control

3. Materials and Methods

4. Results

4.1. Takt Production Monitoring—Monitoring Procedures in Paper and Digital Form

4.1.1. Paper Monitoring Form

4.1.2. Digital Monitoring Form

5. Discussion

5.1. The Takt Production Model Requires Systematic Production Monitoring

5.2. A Semi-Automatic Takt Production Monitoring Model

6. Limitations

7. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Haghsheno, S.; Binninger, M.; Dlouhy, J.; Sterlike, S. History and theoretical foundations of takt planning and takt control. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction (IGLC 24), Boston, MA, USA, 20–22 July 2016. [Google Scholar]

- Dlouhy, J.; Binninger, M.; Oprach, S.; Haghsheno, S. Three-level method of Takt planning and Takt control—A new approach for designing production systems in construction. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016. [Google Scholar]

- Binninger, M.; Dlouhy, J.; Haghsheno, S. Technical takt planning and takt control in construction. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017. [Google Scholar]

- Mubarak, S.A. Schedule Updating and Project Control. In Construction Project Scheduling and Control, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Pierce, D.R., Jr. Monitoring and Controlling the project. In Project Scheduling and Management for Construction; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Lehtovaara, J.; Mustonen, I.; Peuronen, P.; Seppänen, O.; Peltokorpi, A. Implementing Takt Planning and Takt Control into Residential Construction. In Proceedings of the Annual Conference of the International Group for Lean Construction, Dublin, Ireland, 3–5 July 2019. [Google Scholar]

- Dlouhy, J.; Oprach, S.; Binninger, M.; Richter, T.; Haghsheno, S. Using takt planning and takt control in production projects–comparision of construction and equipment phases. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 18–20 July 2018. [Google Scholar]

- Keskiniva, K.; Saari, A.; Junnonen, J.-M.J. Takt planning in apartment building renovation projects. Buildings 2020, 10, 226. [Google Scholar] [CrossRef]

- Toimiva Työmaa—Hyvät Käytännöt. Available online: https://www.rakennusteollisuus.fi/globalassets/julkaisuja/toimiva_tyomaa_2014.pdf (accessed on 22 August 2020).

- Frandson, A.G.; Seppänen, O.; Tommelein, I.D. Comparison between location based management and takt time planning. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 29–31 July 2015. [Google Scholar]

- Frandson, A.; Berghede, K.; Tommelein, I.D. Takt time planning for construction of exterior cladding. In Proceedings of the 21st Annual Conference of the International Group for Lean Construction (IGLC 21), Fortaleza, Brazil, 31 July–2 August 2013. [Google Scholar]

- Harris, F.; McCaffer, R. Modern Construction Management, 7th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Project Management Institute. A Guide to the Project Management Body of Knowledge (PMBOK® Guide), 5th ed.; Project Management Institute: Newton Square, PA, USA, 2013. [Google Scholar]

- Hegazy, T.; Abdel-Monem, M.; Saad, D.A. Framework for enhanced progress tracking and control of linear projects. Eng. Constr. Arch. Manag. 2014, 21, 94–110. [Google Scholar] [CrossRef]

- Sears, S.K.; Sears, G.A.; Clough, R.H.; Rounds, J.L.; Segner, R.O. Project scheduling applications. In Construction Project Management—A Practical Guide to Field Construction Management, 6th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Baldwin, A.; Bordoli, D. Planning and Scheduling Practices. In Handbook for Construction Planning and Scheduling; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Eriksson, P.E.; Westerberg, M. Effects of cooperative procurement procedures on construction project performance: A conceptual framework. Int. J. Proj. Manag. 2011, 29, 197–208. [Google Scholar] [CrossRef]

- Chan, A.P.; Chan, A.P. Key performance indicators for measuring construction success. Benchmarking Int. J. 2004, 11, 203–221. [Google Scholar] [CrossRef]

- Kenley, R.; Seppänen, O. Location-Based Management for Construction: Planning, Scheduling and Control; Routledge: London, UK, 2010. [Google Scholar]

- Navon, R.; Sacks, R. Assessing research issues in automated project performance control (APPC). Autom. Constr. 2007, 16, 474–484. [Google Scholar] [CrossRef]

- Deng, H.; Hong, H.; Luo, D.; Deng, Y.; Su, C. Automatic Indoor Construction Process Monitoring for Tiles Based on BIM and Computer Vision. J. Constr. Eng. Manag. 2020, 146, 04019095. [Google Scholar] [CrossRef]

- Fang, Y.; Cho, Y.K.; Zhang, S.; Perez, E. Case study of BIM and cloud–enabled real-time RFID indoor localization for construction management applications. J. Constr. Eng. Manag. 2016, 142, 05016003. [Google Scholar] [CrossRef]

- Omar, T.; Nehdi, M.L. Data acquisition technologies for construction progress tracking. Autom. Constr. 2016, 70, 143–155. [Google Scholar] [CrossRef]

- Binninger, M.; Dlouhy, J.; Oprach, S.; Haghsheno, S. Methods for production leveling–transfer from Lean Production to Lean Construction. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016. [Google Scholar]

- Kenley, R.; Harfield, T. Location Breakdown Structure (LBS): A solution for construction project management data redundancy. In Proceedings of the International Conference on Construction in a Changing World, Kandalama, Sri Lanka, 4–7 May 2014; pp. 4–7. [Google Scholar]

- Lehtovaara, J.; Seppänen, O.; Peltokorpi, A.; Kujansuu, P.; Grönvall, M. How takt production contributes to construction production flow: A theoretical model. Constr. Manag. Econ. 2021, 39, 73–95. [Google Scholar] [CrossRef]

- Dlouhy, J.; Binninger, M.; Oprach, S.; Haghsheno, S. Mastering complexity in takt planning and takt control—Using the three level model to increase efficiency and performance in construction projects. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction, Chennai, India, 18–20 July 2018. [Google Scholar]

- Lewin, K. Action Research and Minority Problems. J. Soc. Issues 1946, 2, 34–46. [Google Scholar] [CrossRef]

- Ottosson, S. Participation action research—A key to improved knowledge of management. Technovation 2003, 23, 87–94. [Google Scholar] [CrossRef]

- Stephens, J.; Barton, J.; Haslett, T. Action Research: Its History and Relationship to Scientific Methodology. Syst. Pract. Action Res. 2009, 22, 463–474. [Google Scholar] [CrossRef]

- Customized Takt Production Monitoring Software for the Case Project; Alpha Version of the Mobile Application Software; Not Available Publicly; Mestamaster, Inc.: Turku, Finland, 2019.

- Alhava, O.; Rinne, V.; Laine, E.; Koskela, L. Can a Takt Plan Ever Survive Beyond the First Contact with the Trades On-Site? In Proceedings of the Annual Conference of the International Group for Lean Construction, Dublin, Ireland, 3–5 July 2019. [Google Scholar]

- Andersen, L.; Fyhn, H. Organisational and cultural preconditions for extending the use of takt time planning. In Proceedings of the Annual Conference of the International Group for Lean Construction, Dublin, Ireland, 3–5 July 2019. [Google Scholar]

| Inside Apartments: Wet Room Renovation | Inside Apartments: Dry Room Renovation |

| Demolition | Demolition |

| Diamond drilling & cutting | Diamond drilling & cutting |

| Floor drain installation | Kitchen-living room plumbing, ventilation |

| Mesh reinforcement, floor heating & floor cast | Rough concrete wall repair |

| Wall leveling | Leveling |

| Bathroom riser duct encasement | Painting |

| Water proofing & tiling | Lowered ceiling installation |

| Exposed water pipes installation | Floor surface installation |

| (plumbing & ventilation) | Door frames & doors installation |

| Suspended ceiling paneling | Baseboard installation |

| Fitting & fixtures | Fittings & fixtures installation |

| Inside Apartments: Building Services Systems | |

| Electrical casing & wiring (surface installation) | |

| Electrical fixtures | |

| Horizontal water pipes | |

| Drainage: riser & horizontal installations (kitchen & bathroom) | |

| Ventilation riser & horizontal installations (kitchen & bathroom) | |

| Original radiators: detachment, flushing, painting, reattachment | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keskiniva, K.; Saari, A.; Junnonen, J.-M. Takt Production Monitoring and Control in Apartment Renovation Projects. Buildings 2021, 11, 92. https://doi.org/10.3390/buildings11030092

Keskiniva K, Saari A, Junnonen J-M. Takt Production Monitoring and Control in Apartment Renovation Projects. Buildings. 2021; 11(3):92. https://doi.org/10.3390/buildings11030092

Chicago/Turabian StyleKeskiniva, Kimmo, Arto Saari, and Juha-Matti Junnonen. 2021. "Takt Production Monitoring and Control in Apartment Renovation Projects" Buildings 11, no. 3: 92. https://doi.org/10.3390/buildings11030092

APA StyleKeskiniva, K., Saari, A., & Junnonen, J.-M. (2021). Takt Production Monitoring and Control in Apartment Renovation Projects. Buildings, 11(3), 92. https://doi.org/10.3390/buildings11030092