1. Introduction

The wear phenomena are induced by contact and by relative motion between two solids. They depend on the loading conditions and on the materials properties; they are essentially characterized by a matter loss.

Particles are detached from the solids in contact and a complex medium takes place between the two solids forming a thin layer. The conditions of friction are then affected and therefore the conditions of wear evolve simultaneously.

The interface is a complex medium made of detached particles and eventually of a lubricant fluid. The damaged zones belonging to the solids can be also considered as a part of the interface. All these zones constitute a layer where the materials lose their own cohesion.

The evolution of this layer is complex especially in the transient phase of the interface formation. However, for particular geometries and for steady states, with a constant flux of matter, the wear states can be studied experimentally and conceptually. This framework is a first step of comprehensive study for understand the parameters governing friction and wear.

Following the terminology introduced in [

1] the interface is called “third body” and must be considered as an aggregate thin layer of different particles with sometimes a lubricant fluid. This layer develops non-linear macroscopic rheology that must be characterized.

If macroscopic descriptions of such an interface are known in the literature [

1,

2], the connection with local mechanical quantities and discussion based on microscopic scale modelling are not currently developed, unless in some recent studies [

3,

4,

5,

6].

Some well known wear criteria, as Archard’s law [

7], are useful but such models cannot be predictive when the operating conditions are not sufficiently close to the experimental test conditions of their elaboration.

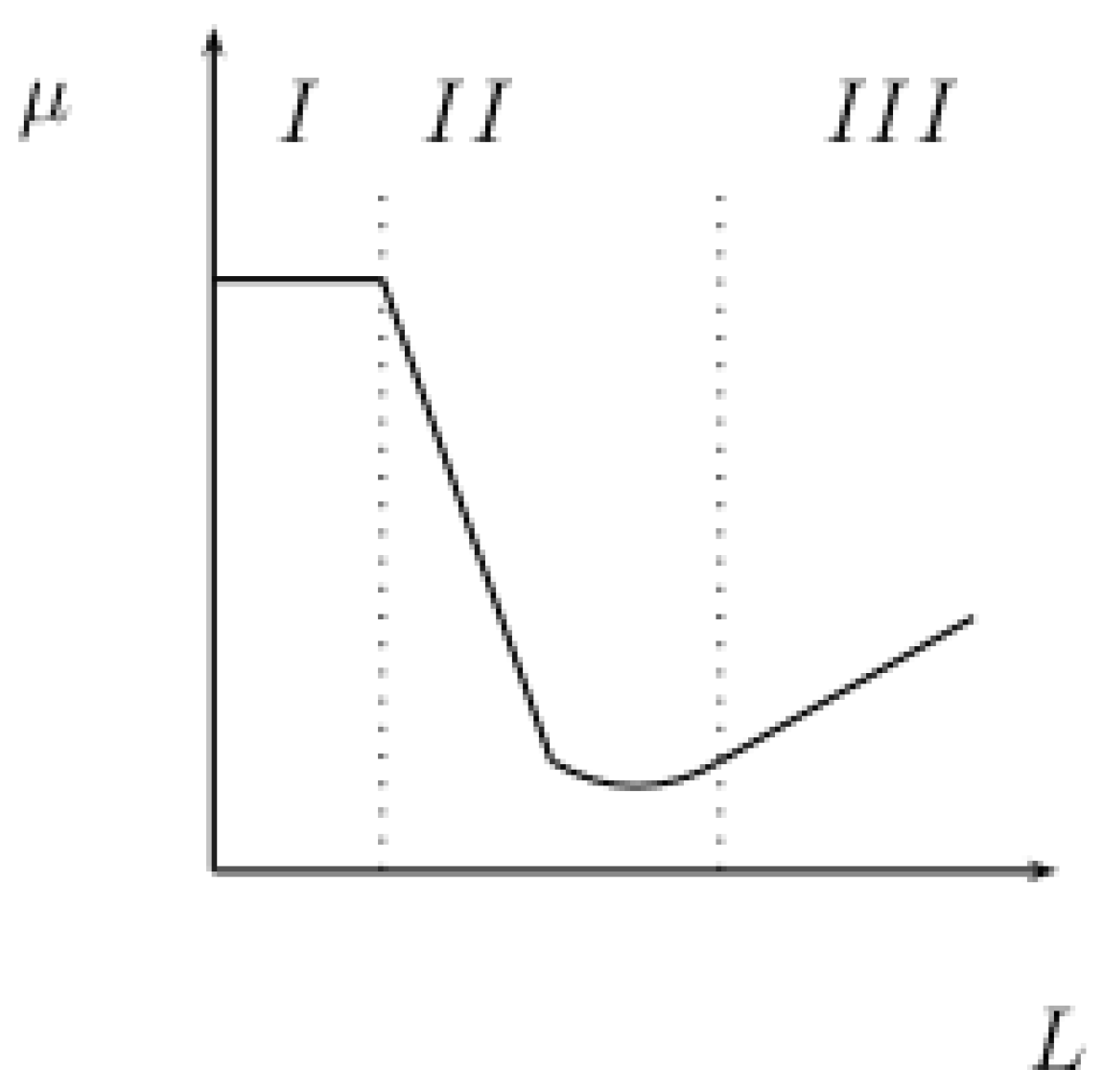

Experiments on wear and friction, as observed in Stribeck’s curve, can provide relations between the friction coefficient μ and the lubricant coefficient L : , where τ is the shear stress, p the pressure of contact, η the fluid viscosity and U the relative velocity.

Figure 1.

Stribeck’s curve.

Figure 1.

Stribeck’s curve.

This curve shows three particular regimes: the first regime corresponds to a Coulomb’s friction law with constant coefficient, the second is an unstable regime with a strong decrease of the friction and the third is a linear regime corresponding to a state of mild wear.

These results suggest clearly a strong interaction between debris and the solids in relative motion. The modelization of this interaction can be explored through the evolution of specific internal state variables governing the third-body behaviour.

The simpler approach is made using of theory of mixtures, where the volume fraction of debris plays an important role.

The main purpose of this article is to propose a more general formulation using of thermodynamical considerations on wear phenomena studying the propagation of surfaces or layers inside sound bodies taking account of damage evolution and loss of sound matter. A thermodynamical approach of third body is then introduced and dissipation is analyzed.

For a macroscopic view point the behaviour of the interface is modelized by unit of surface of contact. The density of mass by surface unit is related to the volume fractions of detached particles and plays the role of an internal parameter. The driving force associated to wear is then deduced and criteria of wear are proposed.

Finally, particular situations are studied using some constitutive law of the interface. In each case the dissipation is analysed. The matter loss and the geometry change are determined according to specific criteria and associated laws. Analytical and semi-analytical solutions are presented.

2. General Features on Moving Surfaces and Moving Layers

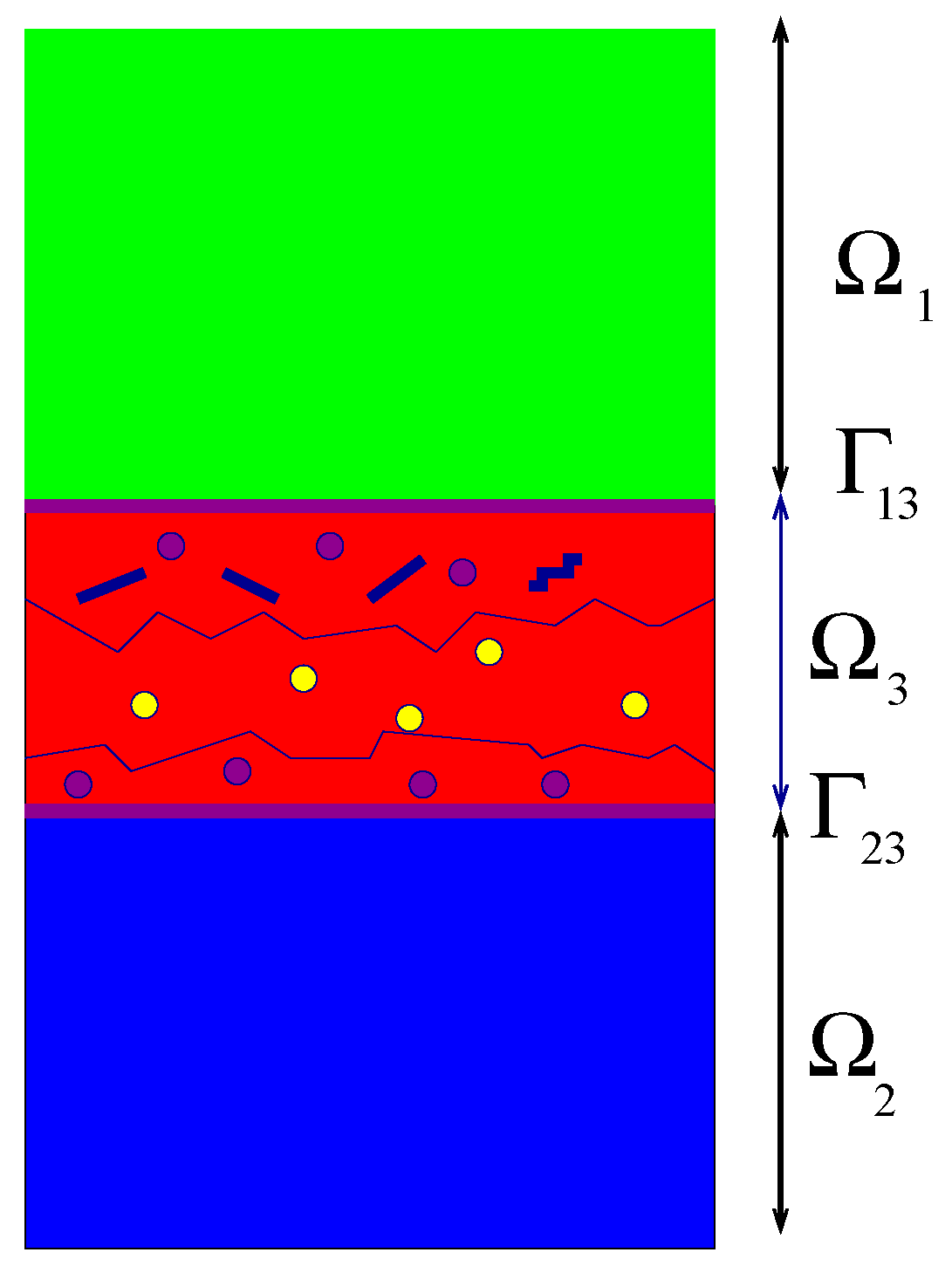

The wear phenomena due to contact and to relative motion between two solids , depend on loading conditions and on material mechanical constitutive laws of the solids in contact. Wear is essentially characterized by a matter loss. Each solid is decomposed into a undamaged part and a damaged zone . The boundary between and is .

Particles are moved from the solids when some criteria are satisfied at the boundaries between and a complex medium is generated called the interface or the third body.

The third body

is made of detached particles, damaged zone

of the two solids as depicted in

Figure 2.

Figure 2.

The microscopic description of wear process.

Figure 2.

The microscopic description of wear process.

The first step of modelization is to characterize the motion of the surface . The third body is then , where is a complex mixture of detached particles and eventually of a lubricant fluid.

Along the surface the displacement is continuous and the stress vector too. The local behaviour changes from those of the undamaged material to those of a damaged solid . The surface moves with the normal velocity in the reference state of the solid, is the outward unit normal vector to and then is positive. The value of is given by a constitutive law, this is a part of the wear description.

This transition can be brutal or diffuse. In the first situation, the transition is governed by the motion of a surface along which the material characteristics endure change by an irreversible process. Due to damage, the elastic moduli in domain are lower then those in , then during this brutal transformation the elastic moduli are discontinuous along . These discontinuities contribute to the dissipation by a surface term.

In the second situation, the variation of the quantities is smooth and the quantities remain continuous. The damaged zone constitutes a thin layer where the damage and the internal variables vary continuously. The boundary between the undamaged material and the damaged zone is moving but all the mechanical quantities are continuous, the surface term in the dissipation disappears.

Each situation implies different type of dissipation and for each case a driving force associated to the wear process is proposed.

The conditions of loading are chosen such that the inertia effects are small. Extension to dynamical problems uses dynamical concept for the driving force applied for defects motion [

8], interface or surface motion [

9,

10,

11,

12].

The local constitutive law The state of each body is characterized by the displacement

, from which the strain field

ε is derived. The other parameters are the temperature

θ and a set of internal parameters

α. The behaviour of

is defined by the free energy density

ψ as a function of strain

ε, the temperature

θ and the set of internal parameters

α. The mass density of each phase (undamaged and damaged) is the same

ρ. The state equations of each phase are

The boundary , between and , is a perfect interface. The external boundary is decomposed into and on which the displacement and the loading are prescribed respectively.

The internal state of stresses satisfies the conservation of the momentum

This state σ is decomposed in the reversible part and an irreversible part . The irreversible stresses are essentially due to viscosity. In non linear mechanics, the internal state is generally associated with irreversibility. The evolution of internal state must satisfy the second law of thermodynamics. Such requirement is fulfilled by the existence of a potential of dissipation.

Analysis of the dissipation and potential of dissipation The fundamental inequality of thermodynamics implies that the internal production of entropy must be non negative. The equations of state do not provide all the constitutive equations; some complementary laws are necessary to describe the irreversibility. In the total dissipation

the contribution of the conduction and those of internal forces must be distinguished.

The two parts are assumed to be separately non-negative. The mechanical part has the form:

and using of equations of state, the thermodynamical forces associated to irreversibility are obtained

and we recognize the role of the irreversible stresses

.

To determine the evolution of the internal state, relation between velocity and driving forces must be given. These relations must be compatible with the positivity of the internal production of entropy .

Let us assume that the local behaviour belongs to the class of the so-called “generalized standard” materials [

13]. For this class, a potential of dissipation

defines the local irreversibility. The potential

d is a convex function of these arguments with a minimum value at the origin. The evolution of the internal state is given by the normality rule:

this means that the subdifferential

of

d is the set of state

such that:

for all admissible fields

. The existence of such a potential for the dissipation ensures the positivity of the entropy production:

2.1. The conservation laws

Classical laws of conservation are written, taking discontinuities into account:

Energy balance

where

e is the internal energy

,

s is the entropy,

the heat flux

Continuity of displacement Continuity of temperature 2.2. On moving interface

To study this problem, the analysis is made on one body . The solid is decomposed into and . Along the boundary , is the outward unit normal vector to , c is the normal velocity and is the magnitude of c.

When the surface

is moving, a mechanical quantity

f can suffer a discontinuity

. The volume

is decomposed in two domains, separated by a moving boundary

. The volume average of

f has a rate defined by

Entropy production Using the definition of the entropy of the system

the second law of thermodynamic is written as

and after integration by part, the value of the volume dissipation

is recovered and a surface contribution appears

Taking the balance equation of energy and the continuity of temperature into account, the dissipation by unit of surface is obtained

This dissipation is a linear function of the normal velocity

of

. The quantity

is the driving force associated to the movement of

. The displacement is continuous along

then the discontinuity

satisfies the Hadamard’s relation

and the release rate of energy

becomes

The condition , which explains that there is no loss of matter, induces that then there is no discontinuity , so there is no dissipation along the surface , because this surface does not move.

Interface propagation law To control the matter loss, a criterion based on

can be formulated. For example, we can considered a Griffith’s type law for the propagation of the moving interface

When the interface moves hence

, this quantity must be conserved during the motion.

Convected differentiation To study the evolution of the mechanical state around the moving surface

a convected derivative of any mechanical quantity

f is needed. A point

is on

if its coordinates satisfy the scalar equation:

It is well known that the gradient

is normal to the surface. At time

the point

comes in

and

For any function

, the convected derivative of

f in the movement of

is

In particular, the evolution of the middle surface satisfies

and the convected derivatives of

and

are

The convected derivative is useful for write the Hadamard’s equation of compatibility: for any continuous function

f along

For the displacement, we have

The convected derivative of

and of

are given by

the classical relation on discontinuity is recovered as

Consistency condition The law of propagation shows that the condition

implies

, that relation is conserved during the propagation. The consistency condition associated with the Griffith’s propagation law is then written at point

where

in the form

this ensures that

if

. This condition determines the velocity

; the surface equation is then implicitly defined by the condition

.

This description is based on the fact that the transition between the initial solid and the damaged material is brutal, that transition induces discontinuities.

2.3. On moving layer

The situation of diffuse damage is now considered. For example, a damage constitutive law governed by a continuous scalar function

d is assumed and a free energy is taken as

the damage parameter varies from 0 (no damage) to 1 (totally damaged). Over

,

and

d varies continuously from 0 to 1 over

.

In this description along the surface , between sound material and damaged zone, . The stress vector (), the displacement and the elastic moduli are continuous quantities. These properties induce that is continuous and so the energy release rates is zero along the surface . The previous results on dissipation must be revisited. The loss of matter is governed by the motion of the surface .

The volume

is decomposed as previously, but now the displacement and the internal parameters are continuous along the surface

. Inside the domain

, the evolution of a mechanical quantity

function of the strain

ε and of the set of internal parameters

α must be characterized. The volume average of

f is decomposed as

and has a time-derivative expressed in term of a classical time derivative in

and a convected derivative on

. Convective derivative is useful to describe hypothesis of self-similarity process in the damaged zone during the wear.

The domain evolves simultaneously with two surfaces: one is associated with the boundary and the other is along which .

A point

in

is locally defined by it’s normal projection

on the surface

and the normal coordinate

z along the unit normal vector

. The thickness of the layer is

and

.

When the surface

moves with the normal velocity

, the local frame

moves simultaneously. For example a 2D motion of a curve satisfies the geometric relations

where

is the curvature of the surface

at point

S,

the normal unit vector et

the tangent unit vector to the curve. It can be noticed that

the elementary length is function of the curvature

in the reference coordinates

. Similar relations exist for a surface motion.

The point

has a convected derivative

During the motion, the thickness evolves and the velocity of the point

is

The evolution of each term of

F can now be given.

In these expressions, .

The function

f is continuous along Γ, then there is no contribution of discontinuities on the time derivative of

F, then

The only surface contribution is due to the flux of matter along the surface . Along , the loss matter occurs simultaneously with the full damage .

Over

, the convected derivative of

f is used

and we have

then the rate of

F is finally

The global dissipation is expressed using these expressions.

Analysis of dissipation The dissipation has the classical expression

as previously we have

The dissipation contains to terms, one in the volume and the last one defined on the surface. In the transient phase this terms is zero, because the material in

is only partially damaged

, then

. When rupture occurs, this term contributes to the dissipation, the value of energy at point

is lost.

Some others expressions for dissipation can be formulated.

Others expressions of dissipation Introducing the local Eshelby momentum tensor

P

This tensor satisfies the relations

And using the convected frame with

with the velocity

, the dissipation is rewritten as

This expression has a great interest when local conditions of the stationarity of the steady state is realized. If the damage

d is a function of the distance

z to the curve

the local stationarity is expressed as

and for local stationarity,

.

Comments on local stationarity If

Y is the driving force associated to

d, then the contribution of damage to dissipation is

Therefore, if the distribution of

is known inside the layer, the average value

is the driving force associated to the velocity

,

The quantity

takes the shape of the layer into account and it defines the measure of area at

with respect to the measure of area at

so that

Assuming now that the profile

is a given function, the propagation law is generalized as

Combining the hypothesis of stationarity and an imposed profile for d, the thickness H is given, the interface is moving with the normal velocity of , when .

In this case, the iso-d curves are orthogonal to the normal and each iso-d curve has the same velocity .

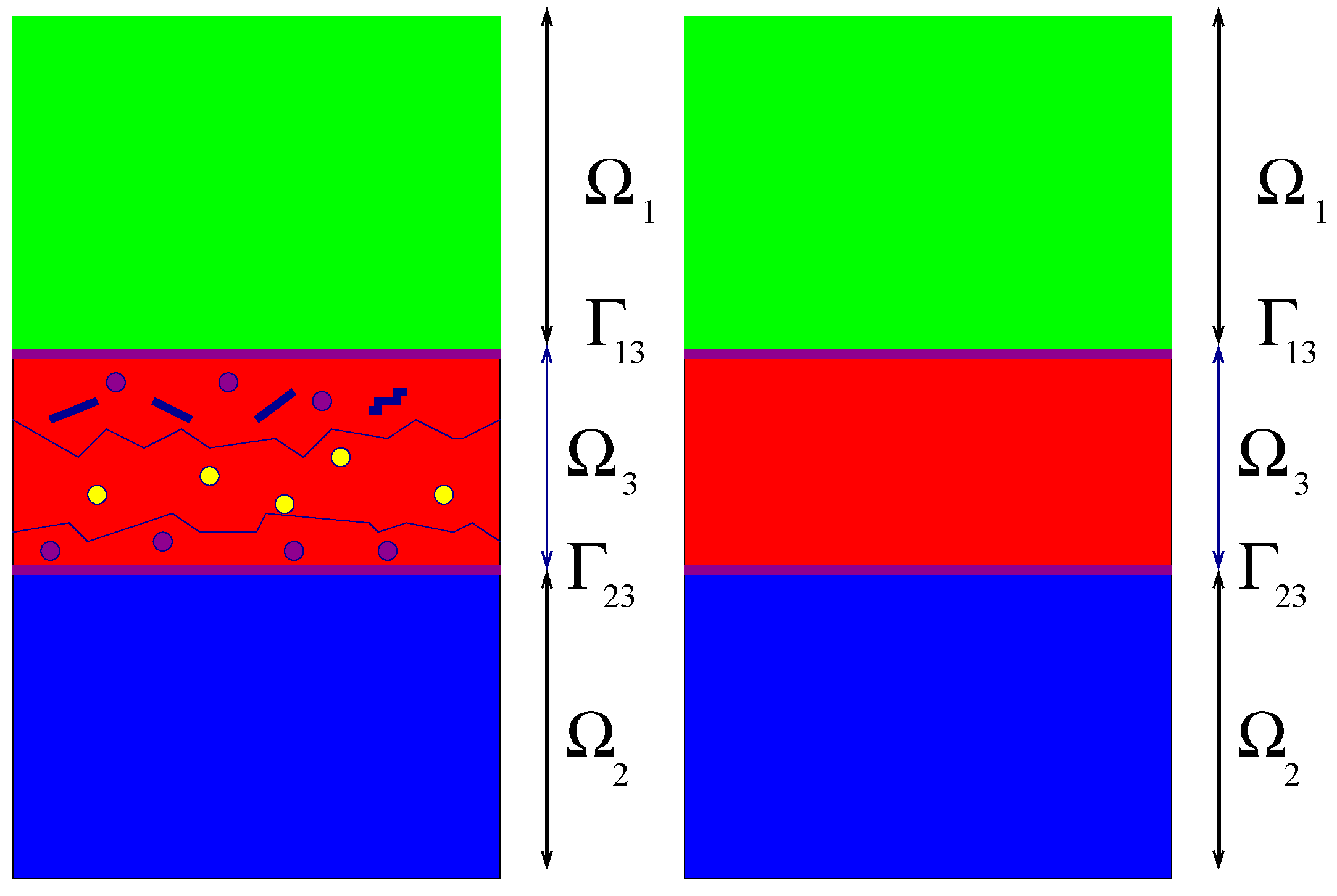

3. The Macroscopic Interface Study

From a macroscopic point of view, it is not necessary to model the microscopic behaviour which occurs in

. Micromechanical considerations can be useful in order to describe in a realistic manner the behaviour of the interface. This type of analysis can provide a relevant interface law at the mesoscopic level and at macroscopic scale too. The multi scale approach of the interface is based on fundamental characteristics at three different scales:

Some other studies are founded on cyclic loading taking account of cyclic asymptotic behaviour of elastoplastic materials generalised to the theory of damage in mechanics [

17].

The system of two bodies in relative motion separated by the third body is considered. As previously in each domain the local behaviour is described by a free energy ψ and a potential d of dissipation. The dissipation is considered only for domain . So the behaviour in and is reversible. Therefore dissipation is concentrate into the interface.

The proposed description is depicted in

Figure 3.

Figure 3.

The transition from microscopic to mesoscopic description of wear process.

Figure 3.

The transition from microscopic to mesoscopic description of wear process.

Sharp transition At the mesoscopic level, the dissipation is given by

where

, and

is the volume dissipation due to the irreversibility processes inside

:

Comments If matter loss occurs,

or

is positive, then the corresponding discontinuity

exists too and the local quantity

) is positive. There is a dissipation due to the loss of material: that is a characterization of wear.

The volume dissipation

contains two contributions, one is due to heat conduction, the other is associated to mechanical irreversibility. This contribution can be associated with the viscosity of the fluid which carry the detached particle. When the shear reaches a critical value

the velocity field inside the interface is reduced to a gliding motion

and the dissipation in the mesoscopic scale is evaluated as

The second term is due to the viscoplasticity governed by the yield stress

, it plays the role of friction [

18,

19].

The control of the wear dissipation obeys to the normality rule

This simple description is based on the brutal transition on the mechanical characteristic from initial material to a damaged one. The interface moves according to this normality rule.

Diffuse damage Consider now that

is a zone of diffuse damage. The description of damage can be made with a smooth transition governed by a damage parameter

d in

, a set of internal parameters

α, which contains the plastic strain

. For example a free energy of the form

is considered. In this case, the damage parameter governs continuously the change of moduli of elasticity and it describes the degradation of the stiffness.

As previously, the state equations are given by

and a potential of dissipation

is given so that

The thickness of the interface is . At this stage all possible choice for the local constitutive behaviour can be used. And literature provide many papers on this subject with computational results. But the main difficulty is to determine the physical characteristics of the behaviour at this scale.

A macro level approach based on this local description can be tempted to understand the specific structure of the thin layer and to estimate some necessary parameters to a relevant description of the mechanisms inside the interface.

4. A Macrolevel Approach

The preceding sections emphasise the fact that in a more general global approach, we can tempt to characterize the thin layer behaviour by considering it is in a state of equilibrium under given conditions applied to

. Then the behaviour of the thin layer can be considered as affected to a surface Γ, by considering that the thickness is an infinitesimal quantity compared to a characteristic length of the bodies in interaction. Time derivatives of integral of varying surface or volume domains are studied in [

20]. Some such results are used here to express the dissipation.

The interface is a thin layer composed by . The geometry of the layer is described by its middle surface Γ and the thickness at each point of this surface.

The free energy

per unit of area of the middle surface Γ of the layer is defined by

,

is the position of the middle surface,

z is the normal coordinate

, the middle surface has a curvature

κ, and

is the variation of area surface due to curvature with respect to the middle surface coordinates. The local volume is then

.

The mass

by unit of area is defined by

The mass of the overall system is not conserved. The mass loss

from

is added to

hence we obtain

with

. But in the same time, a flux of matter is present in the tangent plane of Γ with the velocity

Then the rate of the surface density is given by

This contributes locally to the matter flux. Assuming that the conservation is locally true, we have

The local problem The layer is in equilibrium with external loading and contact conditions. The displacement is continuous on

, the surface energy

depends upon the given displacements along

. The other parameters are a set of internal parameters

, the thickness

and the temperature. The local strain

ε derives from the displacement

. The displacement is continuous along the interfaces

then

Then, it is obvious that the surface free energy is a function of

and of the thickness

H.

Time derivatives of integral of varying surface or volume domains are studied in [

20]. Some such results are used here to express the dissipation.

The strain is rate is

, where

. The dissipative function

associated to the local potential

is defined by the average

We consider that the behaviour inside

is reversible. The steady state equations over

are then

For the interface, we have

where

is the reversible tension along the interface. The balance momentum equations using of the local behaviour is given by

and the complementary laws are

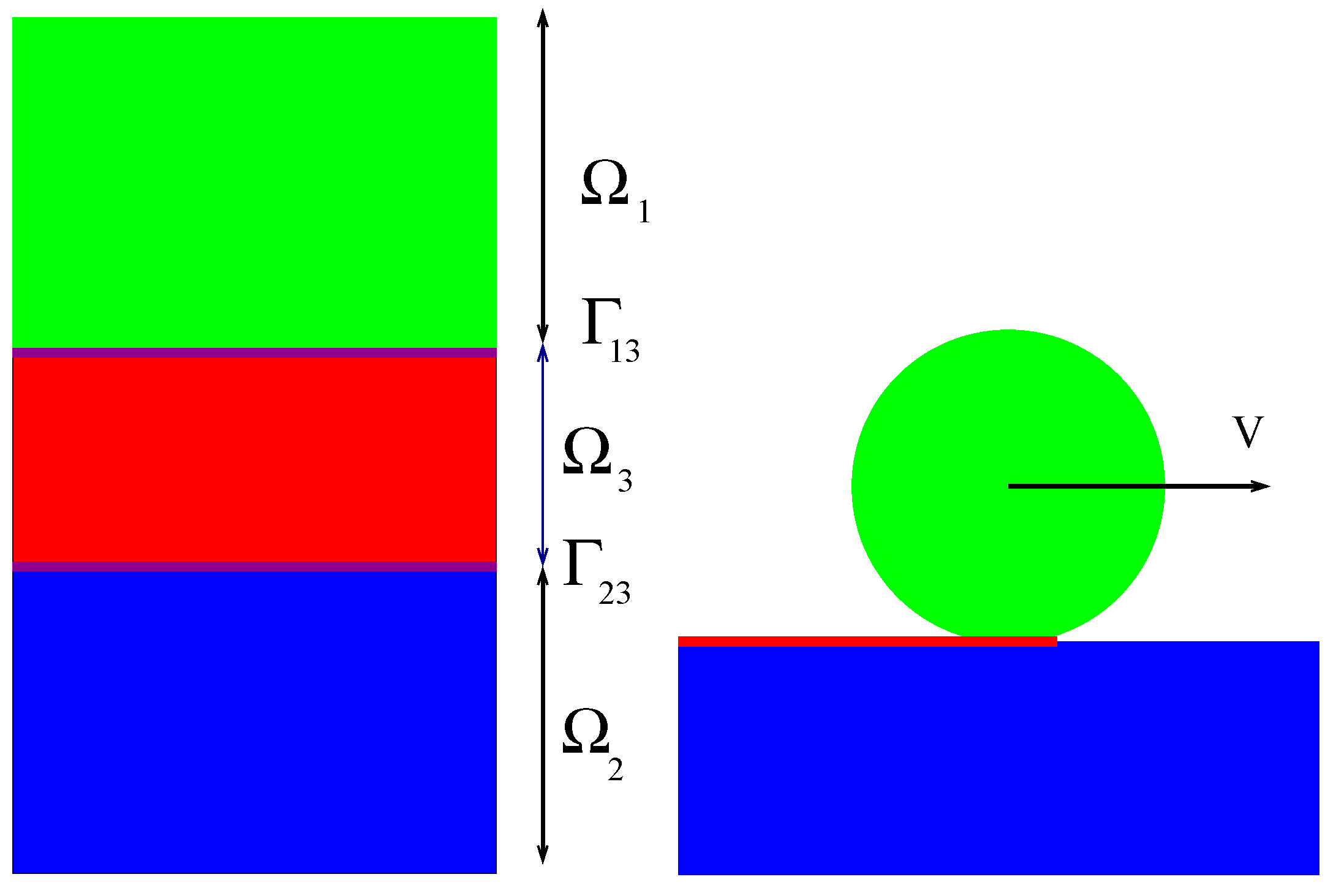

Figure 4.

The transition from mesoscopic description to macroscopic description of wear process.

Figure 4.

The transition from mesoscopic description to macroscopic description of wear process.

The normal along the interface is not the normal to the middle surface because h depends on .

The macroscopic description as depicted on 4 ignores the details at the microscopic level.

The local thickness is obviously the relevant parameter geometrically associated with the interface, while the internal parameters govern the physical properties of the layer. For example, the set of volume fraction of debris from materials 1 and 2 are such parameters.

Analysis of dissipation The global dissipation is derived from the macroscopic description. It is useful to introduce the global free energy

of the tribologic system

The rate of the free energy is then

which becomes after rearrangements

where

γ is the mean curvature of the middle surface and

ϕ the normal velocity of the mean surface.

Taking account of equilibrium and conservation of mass, we have

The displacement is continuous along the interfaces

then

where

The total dissipation

is

hence

where

. A term due to the variation of the thickness appears

But

are dependent. The velocities of propagation are linked

then

And the dissipation is equivalent to

the second term is due to

and it is very small because

H is small, and

Expansion of displacement with respect to z This macroscopic point of view suggests to develop the internal state over

as an asymptotic expansion of the coordinate

z The relative displacement

is then a function of the gradient of

on the middle surface

at the first order in

z.

The free energy is expanded with to

z and the expression is given by

where

at first order. In the same way, the potential of dissipation is

Under this approximation

so the energy depends on the value of

and on the gradient of the displacement along Γ.

Many studies concerning interface behaviour are based on such approximation [

21,

22,

23].

In this case, the global state of equilibrium is revisited to take into account of the dependance of the energy with gradient of displacement

. The variations of

with respect to

are then

by integration by parts we obtain

Hence the equilibrium of the interface is now given by

if there is no viscosity, if not the right part contains new terms

This approximation shows that the conditions of continuity of the displacement given by the asymptotic expansion and the displacement of the undamaged bodies implies that the imposed shear is related to the discontinuity of the two bodies in contact. These expressions show that global approach based on relative displacement or relative rate of displacement can be justified by micromechanical considerations, but they emphasise the role plays by the mass density by unit of area. This quantity is an important internal parameter which is governed by the mass conservation and the wear criterion.

An important task is to develop models of the layer based on micromechanical hypotheses. Using homogenization theory for thin layer under global shear loading, taking account of the mass flux, must be investigated. This process will provide different models of interface behaviour depending on the dissipative mechanisms evolving inside the third body. These models must be derived taking account of conditions of sliding contact, in particular in the presence of viscous fluid, the flow between the bodies must be characterized. This shows the emergence of specific time scales according to each models of interface depending on loading conditions. The mechanisms of degradation can also be modified during the loading history. This approach should be useful for determination of the domains described by the Stribeck’s curve or also to study the transition from a regular state of low rate of wear to a state of abrasive wear.

5. Examples and Applications

A linear elastic half-plane in plane strain is considered. The purpose of the study is to analyse the contact wear under a rigid punch. The studies are made in two cases of loading:

the sliding wear under steady relative motion [

3],

the sliding wear under cyclic loading [

17].

In order to obtain displacements, stresses and strains at the surface of the half-space, which is covered in the contact area by the interface model, it is useful to consider integral equations.

The displacement (

) of the upper boundary of an linear elastic half-space with elasticity characteristics Young modulus

E, Poisson’s ratio

ν, satisfies the integral equations [

24], for which the contact area is (

):

where the constants

are

and the principal value

is defined as

5.1. Sliding contact in steady relative motion

The rigid punch has a vertical displacement and we assume that wear occurs only in the half space. Ahead the punch there is no debris, then the volume fraction of debris . The thickness of the interface is , which corresponds to the sum of rugosities of the solids and contains the thickness of the incompressible fluid. Due to wear, the thickness evolves. The mass conservation and the fluid incompressibility give the relations between the wear rate , the fraction of debris and the thickness of the thin layer .

All the equations of conservation are written in the moving frame with the punch at the velocity

and

by integration over the thickness

H we have

and because the layer is submitted to a local shear

we obtain

The mass of fluid is also conserved then

The constitutive law The free energy of the mixture is given by

A potential of dissipation is given to determine the irreversible contribution, essentially due to viscosity

This constitutive law generalizes the law use in [

3] in which

. For (

) we have an interfacial behaviour given by

and

are chosen from typical homogenized value of the phases.

that the homogenized Reuss’s model for the stiffness, and the Einstein’s law for the viscosity.

Introducing these equations in the equilibrium equation for a given profile

the answer of the half-space will be determined. The wear rate

ϕ must satisfy a complementary law, as proposed before. For the sake of simplicity we take

This relation determines the velocity

ϕ. The solution is obtained analytically by an asymptotic expansion in series of the volume fraction

f of particles.

This analytical solution is studied in paper [

3] and discussed in [

26].

5.2. Cyclic loading

The matter loss is determined with respect a criterion of wear in the case of cyclic loading. For this the results of cyclic plasticity are generalized for elastic brittle materials.

The vertical displacement δ of the punch is prescribed and a periodic horizontal displacement of the punch is imposed.

The wear rate is related to the Griffith’s law:

During the loading, wear occurs, the surface evolves and reaches an asymptotic shape Γ.

The loss of matter is determined by the surface shape of the half space such that the volume of loss matter is the smaller volume compatible with the criterion of wear: during the motion of the punch the criterion ( is fulfilled all time.

Assume that

is small. During the motion, the applied loading is cyclic and is convected by the motion to the surface. Using of derivative

, on the initial configuration the loading is given by

and is now convected along the moving interface with the velocity

ϕ, then

then

The rate solution is determined on the initial geometry, with components of stress and displacement rate given by these relations.

and

Since the variation of the geometry is small, the kernel

of the integral equation

must be developed at least at first order in

ϕ [

17].

For an isotropic material, the solution for displacement is found to be:

where

.

The problem of asymptotic solution for wear is given by the optimisation problem

This problem is solved using for the driving force

where

is the normal vector to the surface

. In the considered case, the indenter is rigid so there is no contribution of the indenter to the driving force.

The stabilized answer is obtained numerically, using an iterative algorithm [

17]. The conditions of contact include Signorini’s condition with friction and comparisons are made with experiments [

27].

6. Conclusions

In this article, a review of different descriptions of wear is presented. The approach emphasise the role of micromechanics on the elaboration of a relevant modelisation of wear by introducing the most important parameters in the description of the third body. The modelization shows that the mass density by unit of surface plays an crucial role, especially in transient phase.

The thermodynamical analysis suggests also to consider local criterion for wear based on driving forces associated with the local phenomena involving the final rupture. At different scale the relations between local driving forces and global driving forces to describe the behaviour of the thin layer must be established solving a complex boundary value problem. This problem is a problem of equilibrium of a thin layer under macroscopic shear deformation with non-linear behaviour including damage and viscoplasticity. According to non-linear behaviour and to presence of fluid, different time scales must appear determining domains of validity of each model of interface.

This multi-scale approach has been shortly discussed. According to different choice of modelisation, different expressions for dissipation are obtained. The driving force associated to wear process have been expressed and wear laws have been proposed.

Simpler formulations have been achieved, taking account of the most important features of the wear process and semi-explicit answers are obtained. These results show the ability of such an approach.

Some of the ideas and techniques used here (like integral equations) could be of some interest for solving other problems on wear.