Abstract

A solar-aided coal-fired power plant realizes the integration of a fossil fuel (coal or gas) and clean energy (solar). In this paper, a conventional 600 MW coal-fired power plant and a 600 MW solar-aided coal-fired power plant have been taken as the study case to understand the merits of solar-aided power generation (SAPG) technology. The plants in the case study have been analyzed by using the First and Second Laws of Thermodynamics principles. The solar irradiation and load ratio have been considered in the analysis. We conclude that if the solar irradiation was 925 W/m2 and load ratio of the SAPG plant was 100%, the exergy efficiency would be 44.54% and the energy efficiency of the plant (46.35%). It was found that in the SAPG plant the largest exergy loss was from the boiler, which accounted for about 76.74% of the total loss. When the load ratio of the unit remains at 100%, and the solar irradiation varies from 500 W/m2 to 1,100 W/m2, the coal savings would be in the range of 8.6 g/kWh to 15.8 g/kWh. If the solar irradiation were kept at 925 W/m2 while the load ratio of the plant changed from 30% to 100%, the coal savings could be in the range of 11.99 g/kWh to 13.75 g/kWh.

1. Introduction

Coal is the main fuel used in the power industry in China. The dominant status of fossil fuel will not be displaced totally in a short term [1]. Solar energy is clean and renewable, but the utilization of solar energy usually requires a high investment, which is a major obstacle to its development. Solar-aided power generation (SAPG) would be able to integrate solar energy into a fossil fuel (coal or gas) fired power plant at a relatively low cost [2]. As the accumulated long term data from more than 700 weather stations shows that the total annual solar insolation in China varies from 831 kWh/m2 to 2,333 kWh/m2, with an average insolation of 1,628 kWh/m2, the strong development of China’s solar power technology is expected [3]. The first solar-aided coal fired power plant in China has been approved by the Chinese government and will be in operation in 2013. This project will couple the parabolic trough collector field of 1.5 MW to a 50 MW coal-fired power plant in Gansu Province [4].

There are several ways to use solar energy in existing conventional steam cycle power plants, such as feedwater heating, superheating/reheating of steam, and air preheating [5,6]. Solar thermal power generation attracts most attention, but an integrated solar combined cycle system seems promising since Gupta and Kaushik concluded that heating feedwater of a thermal power plant using solar energy is more efficient than using the same solar energy in a stand-alone solar thermal power plant [7,8]. It can be used to improve system costs and efficiency and to reduce coal consumption and CO2 emissions as a supplementary energy source in existing coal-fired thermal power plants. Pai presented an integration of solar energy into a 210 MWe coal-fired power plant [9]. Hu and Ying stated the thermodynamic advantages of using solar energy as an aided heat source in a regenerative Rankine power plant [10]. Price and Lupfert studied the techno-economic feasibility of a parabolic trough concentrator-based MW scale solar thermal power plant [11]. Eck and Zarza proved the feasibility of the direct steam generation process in a horizontal parabolic trough concentrator [12]. Zhao proposed a hybrid power system combining mid-temperature solar heat and a coal-fired power plant for CO2 capture [13]. The advantages of using exergy analysis as an efficient tool for pinpoint the location and magnitude of the process irreversibility in system have been presented by Kotas and Bejan [14,15]. Habib and Zubair reported an exergy analysis of regenerative Rankine power plants with reheating and concluded that maximum irreversible loss takes place in boiler [16]. Rosen and Dincer performed an exergoeconomic analysis of power plants which operate on various fuels [17]. Singh provided a computer simulation of a Kalina cycle coupled with a coal fired steam power plant with the aim of examining the possibility of exploiting low-temperature heat of exhaust gases for conversion into electricity [18]. Siva Reddy dealt with a comparative energy and exergetic analysis for evaluation of a natural gas fired combined cycle power plant and solar concentrator-aided natural gas fired combined cycle power plant [19].

Exergy analysis can provide the exergy efficiencies and exergy destructions of major plant components to assess their individual performances. However, there few energy studies on SAPG plants [20], and in previous SAPG-related exergy research, the solar irradiation and plant’s load ratio were not considered. In the present study, the simulation of a 600 MW solar-aided coal-fired power plant has been performed. The exergy analysis has been carried out based on the Second Law of Thermodynamics. Parameters such as the solar irradiation ratio and load ratio have been chosen to study their effects on the plant performance.

2. System Descriptions

In order to analyze the features of the solar aided coal-fired power plant, a coal-fired power plant of the same output as the solar-aided coal-fired power plant is introduced as the base plant for comparison. In the next section, the layout of the coal-fired power plant and solar-aided coal-fired power plants will be introduced.

2.1. Coal-fired Power Plant

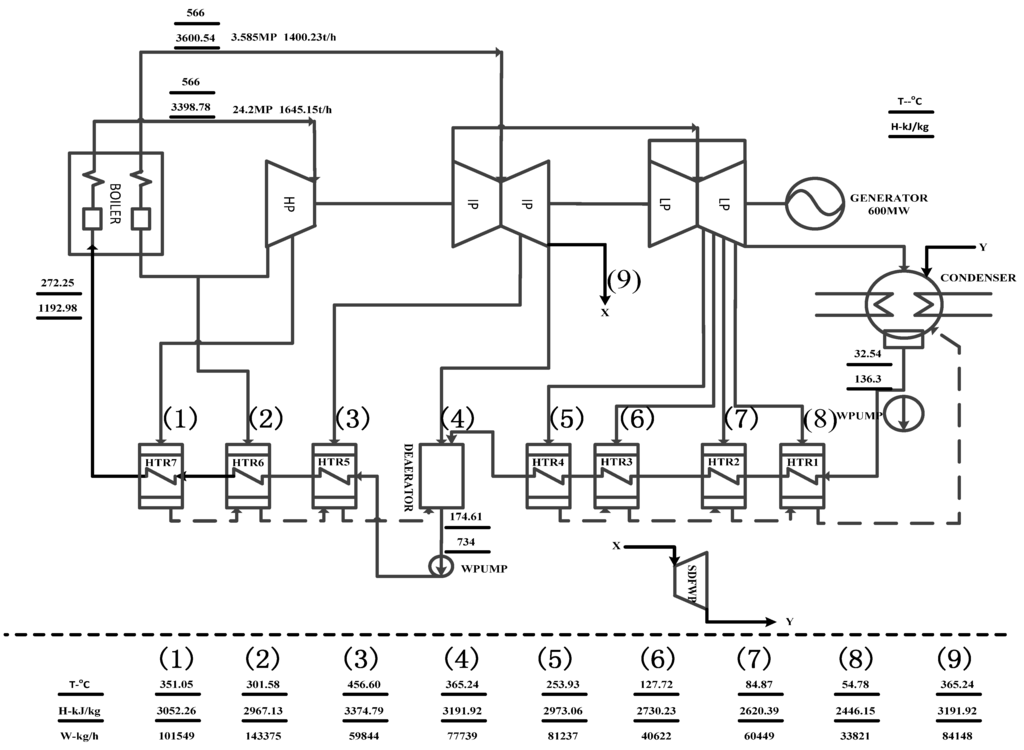

A typical widely used 600 MW reheat regenerative Rankine steam cycle system (called “base plant” in this paper) as shown in Figure 1 is selected in this study. The combustion of coal takes place in the boiler. The unsaturated boiler feed water from the condenser enters the boiler after going through four low-pressure feed-heaters (HTR1, HTR2, HTR3, and HTR4), a deaerator (Deaerator) and three high pressurere feed-heaters (HTR5, HTR6, and HTR7). The superheated steam from the boiler outlet travels to the high-pressure stage of the turbine and then the exhaust steam drives intermediate pressure and lower pressure cylinders after being reheated in the boiler. In the end, the final exhaust is condensed in the condenser. It can be seen from Figure 1 that the heat extractions from different positions of the turbine [(1)–(8)] are used to preheat the feed water in feedwater heaters.

Figure 1.

The layout of the coal-fired power plant.

2.2. Solar-fired Coal-fired Power Plant

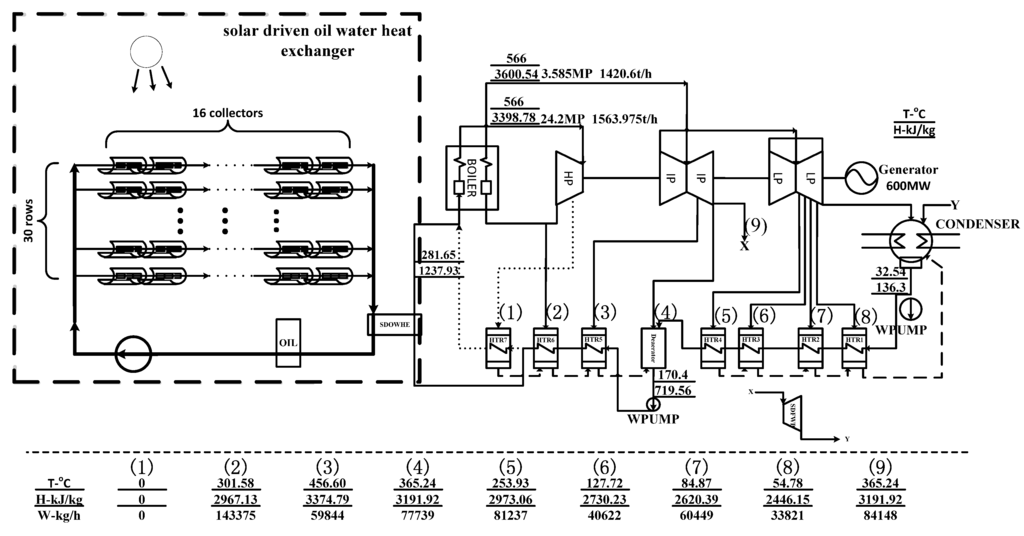

The purpose of the SAPG is basically to use the solar energy to replace the extraction steam to pre-heat the feed-water. A 600 MW SAPG plant is defined with reference to the base plant for this study. The main difference between the SAPG plant and the base plant lies in that a solar driven oil-water heat exchanger (SDOHE) has been added in parallel with the HTR7 (in the base plant). When the solar irradiation is sufficient (for example during the daytime), the steam extraction (1) is cut off and HTR7 would not be in operation, and the feedwater would be heated in the oil-heat exchanger. By integrating solar energy with the coal-fired power plant, the solar energy is still used for auxiliary purposes. To maintain the operation stability, solar energy utilization must be decided by the coal-fired part, which means the number of solar collector rows in use is decided by the heat demand of the boiler feedwater.

When the solar irradiation is weak or nil (for example at night), the oil-heat exchanger would not be in operation, but HTR 7 would be in operation and the (SAPG) plant would be operated the same as the base plant. Figure 2 shows the diagram of the solar-aided coal-fired power plant. In the solar field, several parabolic trough collectors are connected and the heat transfer medium is oil. The oil-heat exchanger is a tube-shell heat exchanger. The parabolic trough collectors and the oil-heat exchanger together is called the solar-driven oil-water heat exchanger (SDOHE) in this paper.

Figure 2.

The layout of the solar aided coal-fired power plant.

3. Methodology

Calculations have been made based on mass balance, energy balance and exergy balance, i.e., the First and Second Law of Thermodynamics. A simulation software named STAR-90 was applied in this paper, where it was used as a platform for building models and simulating the power plants. STAR-90 was developed by Baoding Sinosimu Technology Company (http://www.sinosimu.com), a subsidiary of North China Electric Power University, also one of the biggest power plant simulation software suppliers in China.

The facilities of the solar-aided coal-fired power plant would be divided into facilities in the power generation section and facilities in the solar collector field. Regarding the exergy efficiency, there are a couple of commonly accepted definitions in previous research that have been summarized [21]. In this paper, the exergy efficiency is defined as the ratio of the exergy obtained by the energy consumed to achieve the desired output.

3.1. Facilities in Power Generation Section

Facilities in the power generation section include the boiler, turbine, condenser, heat exchanger. According to different cooling media, the condenser can be divided into condenser cooled by water and condenser cooled by air. Based on different heat exchanging methods, the heat exchangers can be divided into two kinds: tube-shell heat exchangers and mixed heat exchangers.

(1) Boiler

Based on the First Law of Thermodynamics, the heat balance of the boiler can be described by:

where Qb is the heat supplied by the fuel (coal); ηb is the thermal efficiency of the boiler;

is the flowrate of feedwater;

,

denote the specific enthalpy of the inlet and outlet stream in the boiler.

Based on the Second Law of Thermodynamics, the exergy efficiency of the boiler can be described as:

where

denotes the exergy of the fuel (coal);

,

are the exergy of the inlet and outlet stream in the boiler. The exergy of coal () is composed of two parts: the chemical exergy () and the physical exergy ():

According to related reference [22], the specific exergy of the coal is calculated as:

where, lhv is the low heat value of the coal; [C], [H], [O], [N], [S], [Ash] are the weight percentages of each segment in the coal.

(2) Turbine

Base on the First Law of Thermodynamics, the output of the turbine can be expressed by:

where

is the flowrate of steam passing through the turbine;

,

are the specific enthalpy of the inlet and outlet steam;

is the isentropic efficiency of the turbine.

According to the Second Law of Thermodynamics, the exergy efficiency of the turbine can be described as:

where

,

are the exergy of the inlet and outlet steam.

(3) Condenser

Based on the First Law of Thermodynamics, the heat balance of the condenser can be written as:

where

is the flowrate of the condensed water;

,

are the specific enthalpy of the inlet and outlet steam;

is the thermal efficiency of the condenser.

Based on the Second Law of Thermodynamics, the exergy efficiency of the condenser can be written as:

where

,

are the exergy used and exergy consumed;

is the exergy efficiency of the condenser.

(4) Heat exchanger

Heat exchangers can be divided into tube-shell heat exchangers and mixed heat exchanger. For example, high pressure heat exchangers (shown as HTR5-7 in Figure 1) and low pressure heat exchangers (shown as HTR1-4 in Figure 1) are tube-shell heat exchangers, while the deareator is a mixed heat exchanger.

For the tube-shall heat exchanger, the heat balance can be obtained based on the First Law of Thermodynamics:

where

is the flowrate of the steam extraction;

is the specific enthalpy of the steam extraction;

is the flowrate of inlet water;

,

are the specific enthalpy of the inlet and outlet water;

is the flowrate of feedwater;

,

are the specific enthalpy of the inlet and outlet feedwater;

is the energy efficiency of the heat exchanger.

According to the Second Law of Thermodynamics, the exergy efficiency of the heat exchanger can be expressed as:

where

is the flowrate of the steam extraction;

is the specific exergy of the steam extraction;

is the inlet water flowrate;

,

; are the specific exergy of the inlet and outlet water;

is the flowrate of feedwater;

,

are the specific exergy of the inlet and outlet feedwater.

For the mixed heat exchanger, the heat balance based on the First Law of Thermodynamics can be written as:

where

is the specific enthalpy of the outlet water.

Based on the Second Law of Thermodynamics, the exergy balance of the mixed heat exchanger can be written as:

where

is the specific exergy of the outlet water.

3.2. Facilities in the Solar Field

Facilities in the solar field include the collector, oil-heat exchanger, the oil tank and so on. The exergy of solar energy can be calculated as [21]:

where

,

are the temperature of the environment and temperature of the solar surface.

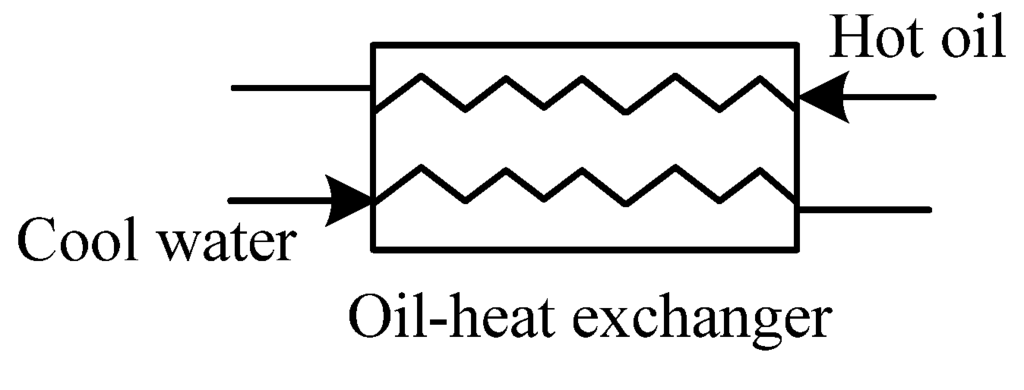

The oil-water heat exchanger is a typical non-phase change heat exchanger as shown in Figure 3. The heat exchange process can be divided into the heat release in the hot oil and heat absorption in the cool water. The hot oil used is THERMINOL VP-1 produced by Solutia (St. Louis, MO, USA), with an operation temperature ranging from 12 °C to 400 °C.

Figure 3.

The diagram of oil-water heat exchanger.

The pressure drop of the water is relevant to the flowrate of water. According to Reference [19], the pressure of water can be calculated as:

where

is the pressure of outlet water;

is the pressure of inlet water;

is the coefficient of the pressure drop;

is the mass flowrate of water;

is the specific enthalpy of outlet water.

Based on the energy balance, the heat exchanged from hot oil to water is:

where

is the enthalpy of inlet hot oil;

is the enthalpy of outlet hot oil;

is the mass flowrate of hot oil.

There are three indicators used to evaluate the base plant and new plant as: the (first law) energy efficiency, exergy efficiency and standard coal consumption rate.

For the SAPG power plant, the energy efficiency and exergy efficiency can be defined as:

Standard coal consumption rate (b) is defined as the coal consumed for per kWh electricity generation, with the unit of g/kWh.

The coal consumption rate (of standard coal) for coal fired power plant (b1) is:

The coal consumption rate for solar aided coal-fired power plant (b2) is:

4. Case Study

The plants described in Section 2 would be analyzed to compare the energy efficiencies and exergy efficiencies of the main facilities. The saved coal in SAPG is also discussed.

4.1. Fundamental Parameters

The main design parameters of the base plant are given in Table 1. Coal used as the fuel for the power plant has the following analysis: moisture = 9.9%, ash = 23.7%, hydrogen = 3.11%, nitrogen = 1.01%, sulphur = 2%, oxygen = 2.78%, carbon = 57.5%, LHV = 21,981 kJ/kg.

Table 1.

Main designed parameters of coal-fired power plant.

| Parameters | Values | Units |

|---|---|---|

| Capacity | 600 | MW |

| Parameters of main steam | 24.2/566/566 | MPa/°C/°C |

| Feedwater mass flowrate | 1645.15 | t/h |

| Condenser pressure | 4.9 | KPa |

| Feedwater temperature | 272.3 | °C |

| Coal consumption rate | 257.4 | g/kWh |

The SAPG plant has identical design parameters, except the mass flow of feed water passing through the boiler would be reduced. The data of the solar field is based on the real recorded data from the SEGS-VI station in USA [23,24,25], and some adjustments have been made to adapt it for the case in this paper. The collectors would be LS-2 parabolic trough collectors from the LUZ Company (San Francisco, NC, USA), the diagram and main parameters of the collectors are given in Table 2. The collector field is composed of 30 rows of 16 solar collectors installed in parallel. The heated heat transfer oil flows into the oil-water heat exchanger and the (cooled) heat transfer oil would be pumped back into the oil cycle.

Table 2.

Main parameters of the collector field.

| Parameters | Values | Units |

|---|---|---|

| Solar irradiation | 925 | W/m2 |

| Area of per collector | 235 | m2 |

| Number of collector in each row | 16 | |

| Rows of collectors | 30 | Rows |

| Inlet temperature of heat transfer oil | 250 | °C |

| Outlet temperature of heat transfer oil | 328 | °C |

4.2. Results and Discussions

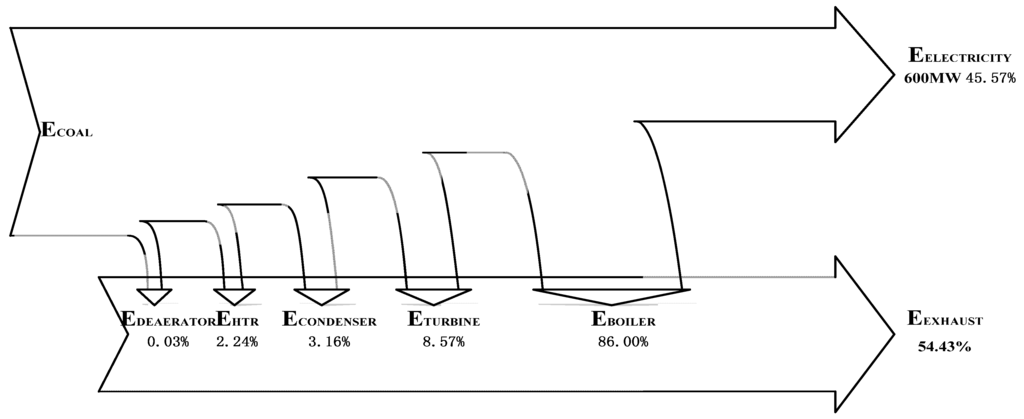

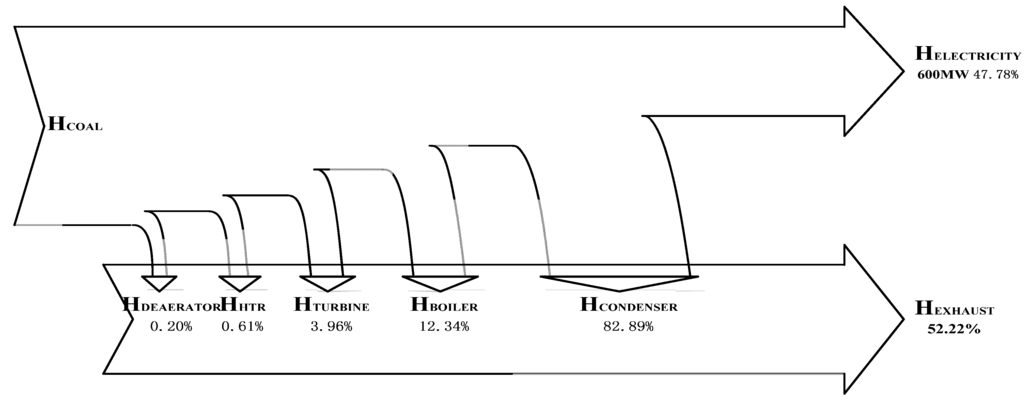

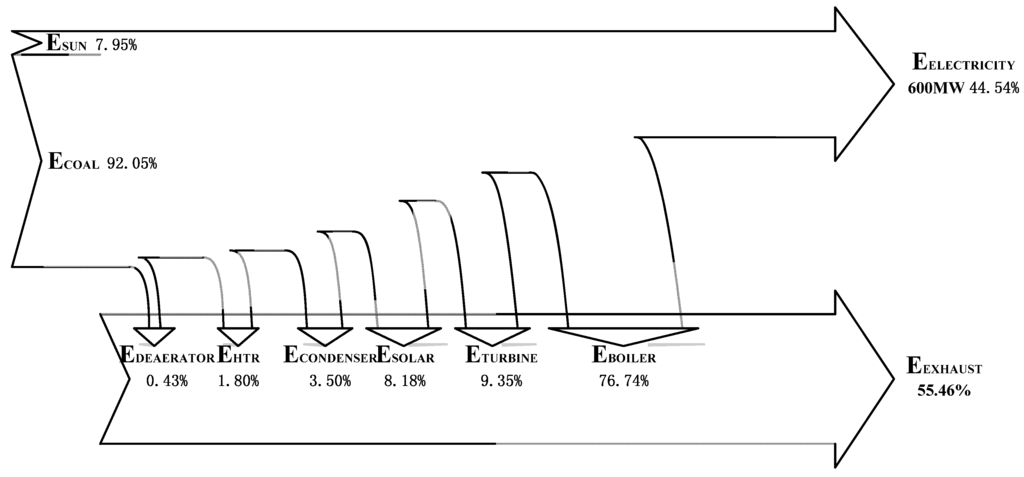

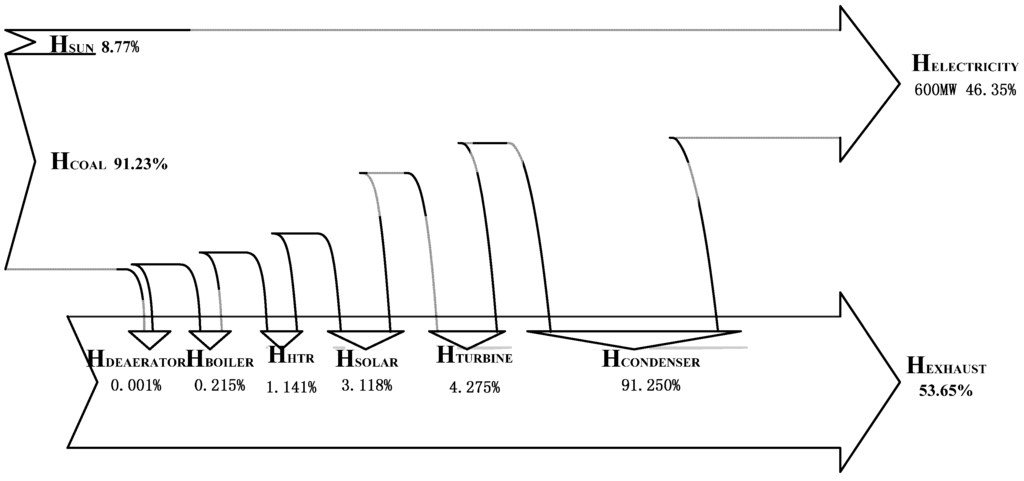

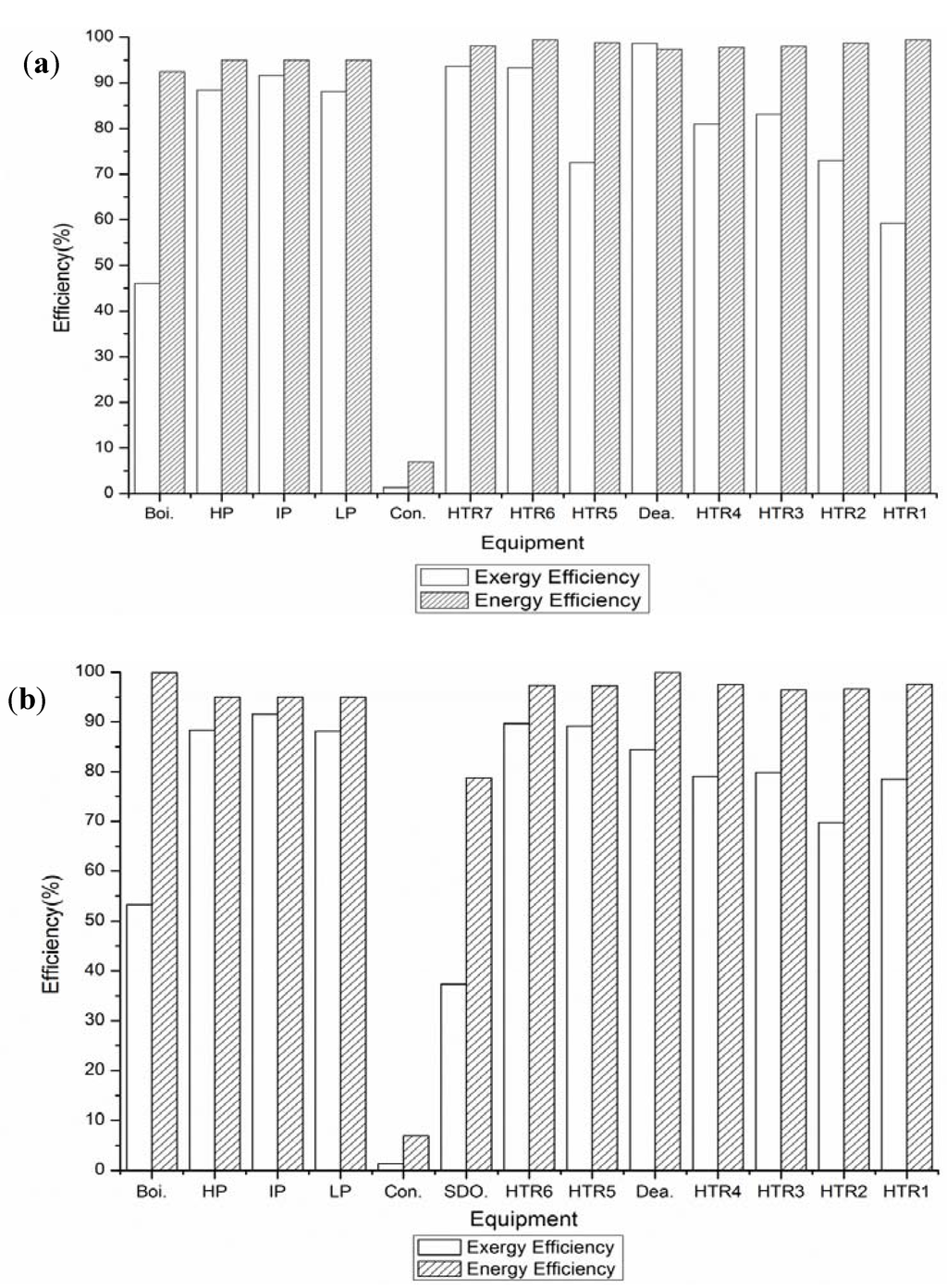

Simulation of the coal fired power plant has been performed on the STAR 90 simulation platform. Compared with the data from Table 1, the error of the simulation results is within a reasonable range. In the SAPG plant calculations, it is assumed that the flowrates of steam from the turbines are unchanged, except for the fact that one steam stream (i.e., the stream to HTR7 in base plant) is cut off. Figure 4, Figure 5, Figure 6, Figure 7 and Figure 8 show the exergy losses and energy losses distributions of the main facilities in the base plant and the SAPG plant.

Figure 4.

The distribution of exergy destructions in the base plant.

Figure 5.

The distribution of energy destructions in the base plant.

Figure 6.

The distribution of exergy destructions in the new plant (SAPG).

Figure 7.

The distribution of energy destructions in the new plant (SAPG).

Figure 8.

(a) The energy and exergy efficiency of the main facilities in the base plant; (b) The energy and exergy efficiency of the main facilities in the new plant.

Regarding the coal consumption rates, when the output of 600 MW is unchanged, the coal consumption rate of the SAPG is about 243.7 g/kWh, reduced by about 13.7 g/kWh, compared to that of the base plant 257.4 g/kWh. The input of the SAPG is solar and coal while that of the base plant is only coal. With the same outputs of the new plant and base plant, it is reasonable that the coal consumption of the new plant is lower than that of the base plant. If the new plant operates 3,000 h annually, the saved coal will be about 16,920 tons/year, with a high economic potential. The CO2 emissions of a traditional coal fired power plant are about 1 kg/kWh. However, with the new plant, about 66,327 tons of CO2 will be avoided annually, which makes the system quite environmentally friendly. As solar energy is added to the solar-aided system, with the coal-savings condition (with lower coal consumption rate), considering the solar energy is free, the cost of the electricity of a SAPG will be lower than that of the base power plant. However, compared to the pure solar power generation system, the coupled system uses the turbines, generators and other key equipment of the original thermal power system, and the work efficiency of the replaced high-temperature high-pressure high-grade steam is much higher than the pure solar thermal power generation. Therefore, the cost of electricity of the SAPG is less than the pure solar thermal power generation system.

The overall exergy efficiency of the base plant is about 45.57% and the overall energy efficiency is about 47.78%; while the overall exergy efficiency of the new plant is about 44.54% and the overall energy efficiency is about 46.35%. The exergy efficiency of the base plant is 45.57%, lower than the energy efficiency of the plant (47.78%). For the base plant, the electricity output is of high quality and its enthalpy and exergy are equal to the electricity output. In the calculation of exergy efficiency, the denominator is the fuel exergy, but it is the fuel supplied heat in the calculation of energy efficiency. According to the coal fuel equation, it is calculated that the fuel exergy is about 1.05 times higher than the fuel supplied heat for the type of coal in the study. Therefore, the energy efficiency is about 1.05 times higher than the exergy efficiency. The exergy efficiency of the new plant is 44.54%, lower than the energy efficiency of the plant (46.35%). For the new plant, the enthalpy and exergy are still the electricity output. In the calculation of exergy efficiency, the denominator is the fuel exergy and solar exergy, but it is solar supplied heat and the fuel supplied heat. The fuel exergy is about 1.05 times higher than the fuel supplied heat for the type of coal in the study but the solar exergy is about 0.95 times of the solar supplied heat. The heat supplied by solar is relatively less than that from the fuel, therefore the exergy efficiency of the new plant is still lower than the energy efficiency.

If the new plant is compared with the base plant, the exergy and energy efficiency of the new plant are lower than those of the base plant. According to Equation (17), the output of the two plants is 600 MW, in the calculation of the base plant, solar supplied heat input is zero (i.e., Qsolar equals 0). In the calculation of the new plant, Qsolar is positive and with the supply of solar the energy supplied reduced from coal is lower than the heat supplied increased from solar. Therefore, the energy efficiency of the new plant is lower than that of the base plant. According to Equation (18), the outputs of the two plants is 600 MW, and in the calculation of the base plant, solar exergy input is zero (i.e., Esolar equals 0). In the calculation of the new plant, Esolar is positive and the exergy efficiency of the new plant is lower than that of the base plant, therefore, the exergy efficiency of the new plant is still lower than that of the base plant.

The exergy and energy destruction distributions in the new plant and base plant have been shown in Figure 4, Figure 5, Figure 6 and Figure 7. It can be seen from Figure 4 and Figure 5 that the main exergy losses in the base plant from high to low are the boiler, turbines, condenser, reheaters and deareator, while the main energy losses in the base plant from high to low are the condenser, boiler, turbines, reheaters and deareator. It can be seen from Figure 6 and Figure 7 that the main exergy losses in the new plant from high to low are the boiler, turbines, oil-water heat exchanger, condenser, reheater and deareator, while the main energy losses in the new plant from high to low are the condenser, turbines, oil-water heat exchanger, reheaters, deareator and boiler. From the aspect of exergy losses, in the base plant, the largest exergy loss is from the boiler accounting for about 86%, the next largest exergy loss is from the turbines, while in the new plant, the largest exergy loss is still from the boiler accounting for about 76.74%, the next largest exergy loss is from the turbines. From the aspect of energy losses, in the base plant, the largest energy loss is in the condenser accounting for about 82.89%, the next energy loss is in the boiler; while in the new plant, the largest energy loss is still in the condenser accounting for about 91.25%, the next largest loss is in the turbines. In the new plant, the SDOHE takes the third largest share of exergy and energy losses, therefore the reasonable modification of the SDOHE to improve the energy and exergy efficiency for the system is of interest.

Figure 8 shows the energy efficiencies and exergy efficiencies of the main facilities in the base plant and the new plant. It can be seen that the energy efficiency is higher than the exergy efficiency for each facility both in the base plant and new plant. Any real process is irreversible, and the lower exergy efficiency is due to the irreversibility of each facility. If Figure 8a and Figure 8b are compared, it can be found that the exergy efficiencies of the boiler in the new plant are higher than those in the base plant, while that of the turbines are almost unchanged and that of the HTR6 is lower. The energy efficiencies of boiler in the new plant are higher than that in the base plant while that of the turbines are almost unchanged and those of the HTR5 and HTR6 are lower.

5. Effects of Solar Irradiations and Load Ratios

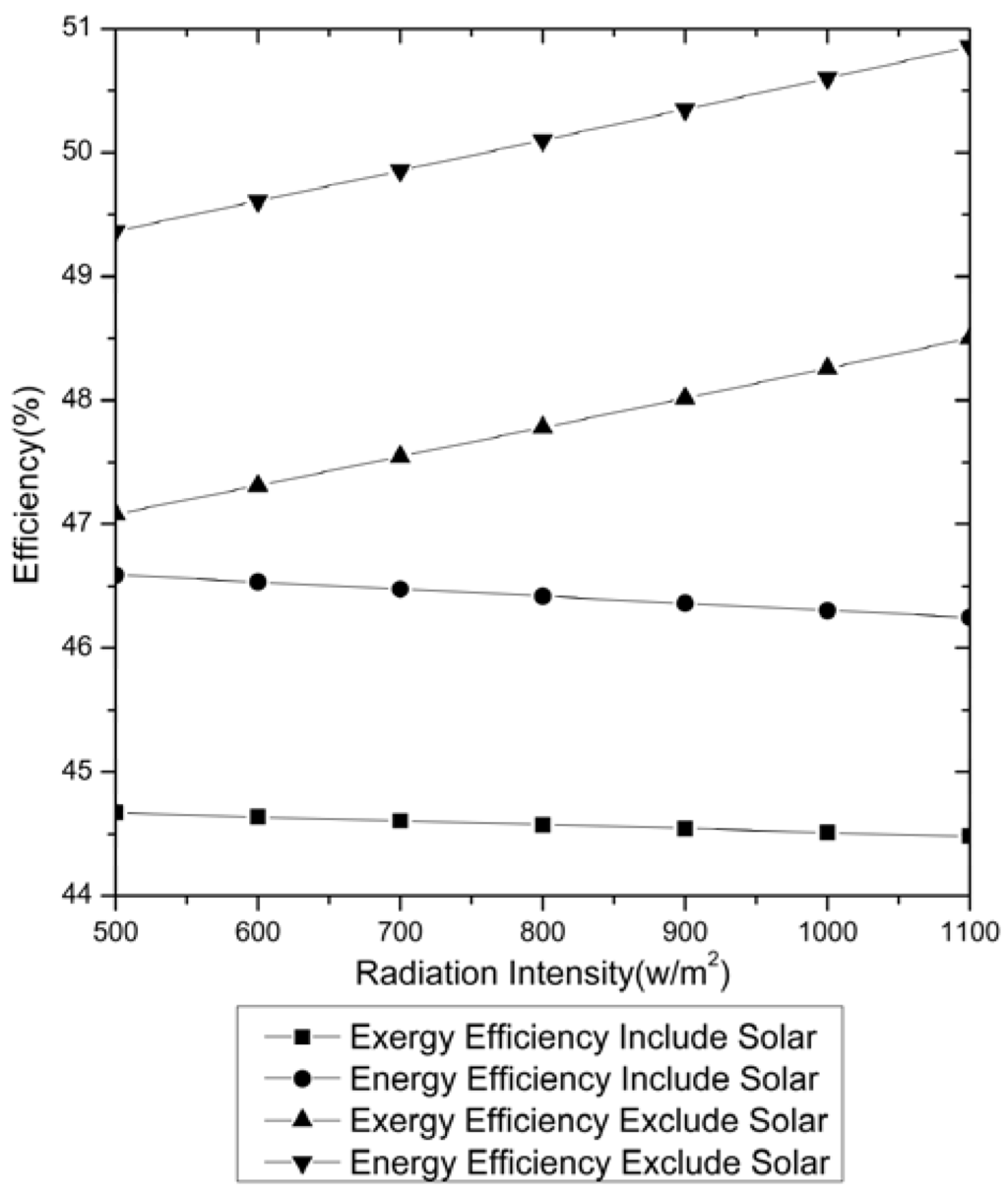

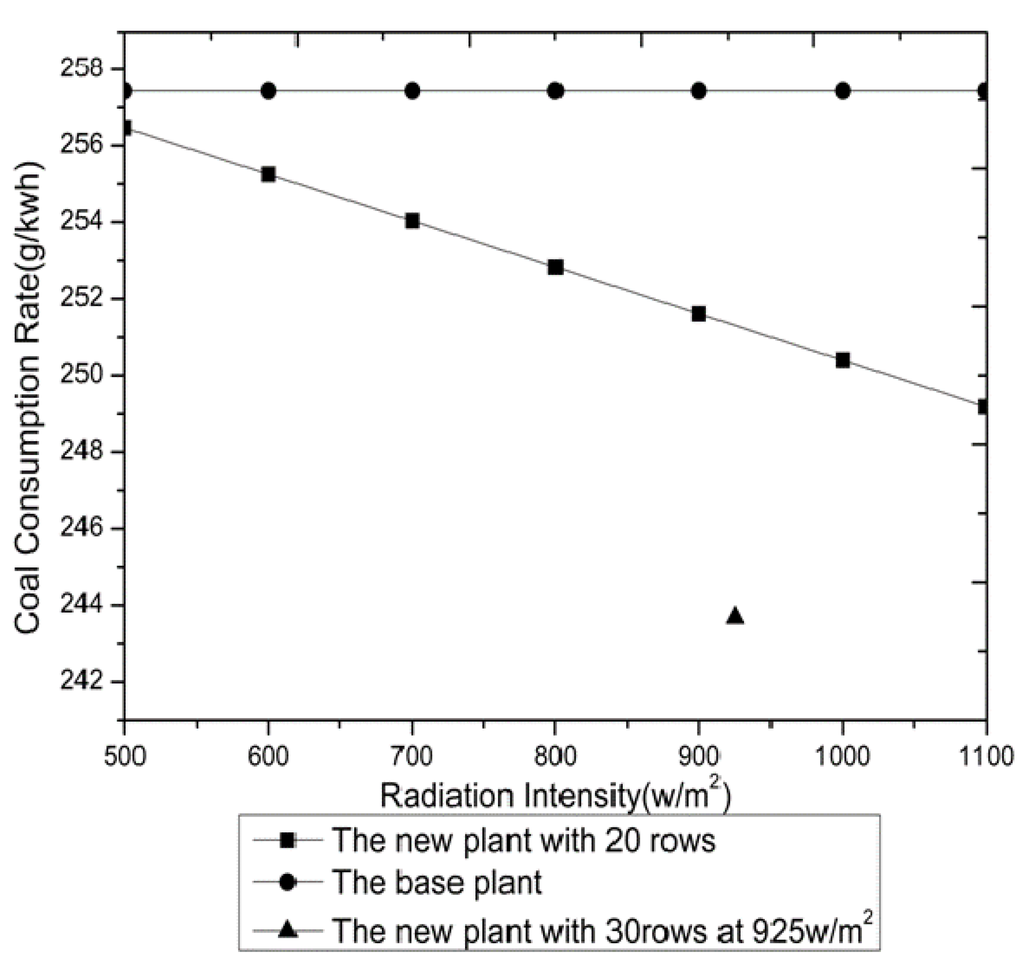

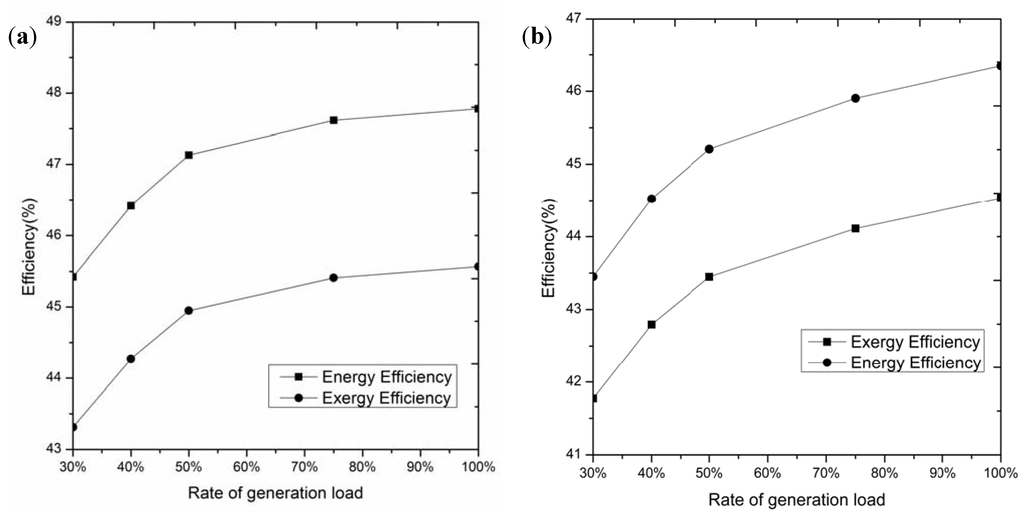

Solar irradiation differs due to different seasons, positions, weather conditions and so on. For example, solar irradiation in summer is usually higher than that in winter and solar irradiation at noon is normally higher than that in the morning in China. The solar irradiation conditions will directly affect the utilization of solar energy in the solar field, thus the performance of the new plant is highly dependent on the solar irradiation conditions. In addition, the outputs of both the new plant and base plant are based on the load needed by the customers. The energy and exergy efficiencies differ for different outputs. In the calculations above, the output of the unit is kept unchanged at 600 MW and the solar irradiation is 925 W/m2. In the solar field design, 30 row collectors have been used. However, how many rows are used depends on the utilization of solar energy in the operation. In this part, the solar irradiation and power output will be taken as two parameters to study their effects to the plants. When the load ratio of the unit is 100%, (i.e., with output of 600 MW), and the solar irradiation differs from 500 W/m2 to 1,100 W/m2, the energy efficiencies, exergy efficiencies and coal consumption rates with 20 rows of collectors in use are shown in Figure 9, Figure 10 and Figure 11. When the solar irradiation is kept unchanged at 925 W/m2, and the load ratio of the unit changes from 30% to 100% with different rows of collectors in use, the energy efficiencies, exergy efficiencies and coal consumption rates as shown in Figure 12.

5.1. Effects of the Solar Irradiations

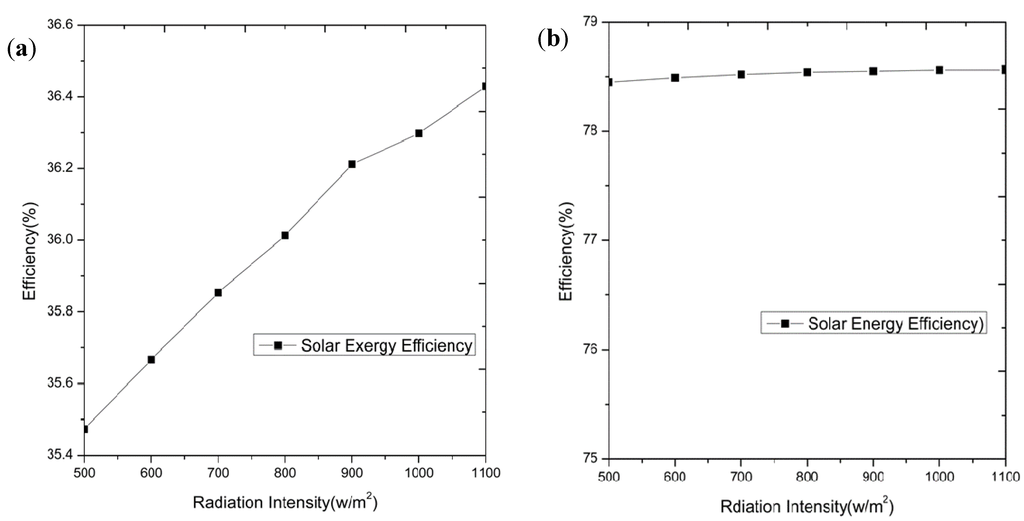

It can be seen from Figure 9 that with the solar irradiation increasing from 500 W/m2 to 1,100 W/m2, the exergy efficiency of solar field increases from 35.5% to 36.4%. This implies that from the aspect of energy quality, with the increase of solar irradiation, the solar field uses the energy more reasonably. However, the energy efficiency of the solar field is almost unchanged with the increment of solar irradiation. This is because the energy efficiency of the solar field is dependent on the optical efficiency of the solar collector and the factors affecting the optical efficiency are kept unchanged in our study. Based on the calculations, the energy and exergy utilizations become better with higher irradiation.

Figure 9.

(a) The exergy efficiency of the solar aided oil-water heat exchanger; (b) The energy efficiency of the solar aided oil-water heat exchanger.

Figure 10.

The energy efficiency and exergy efficiency with the change of solar irradiation (500 W/m2–1,100 W/m2) in SAPG.

Figure 11.

The coal consumption rate with the change of solar irradiation in SAPG.

Figure 12.

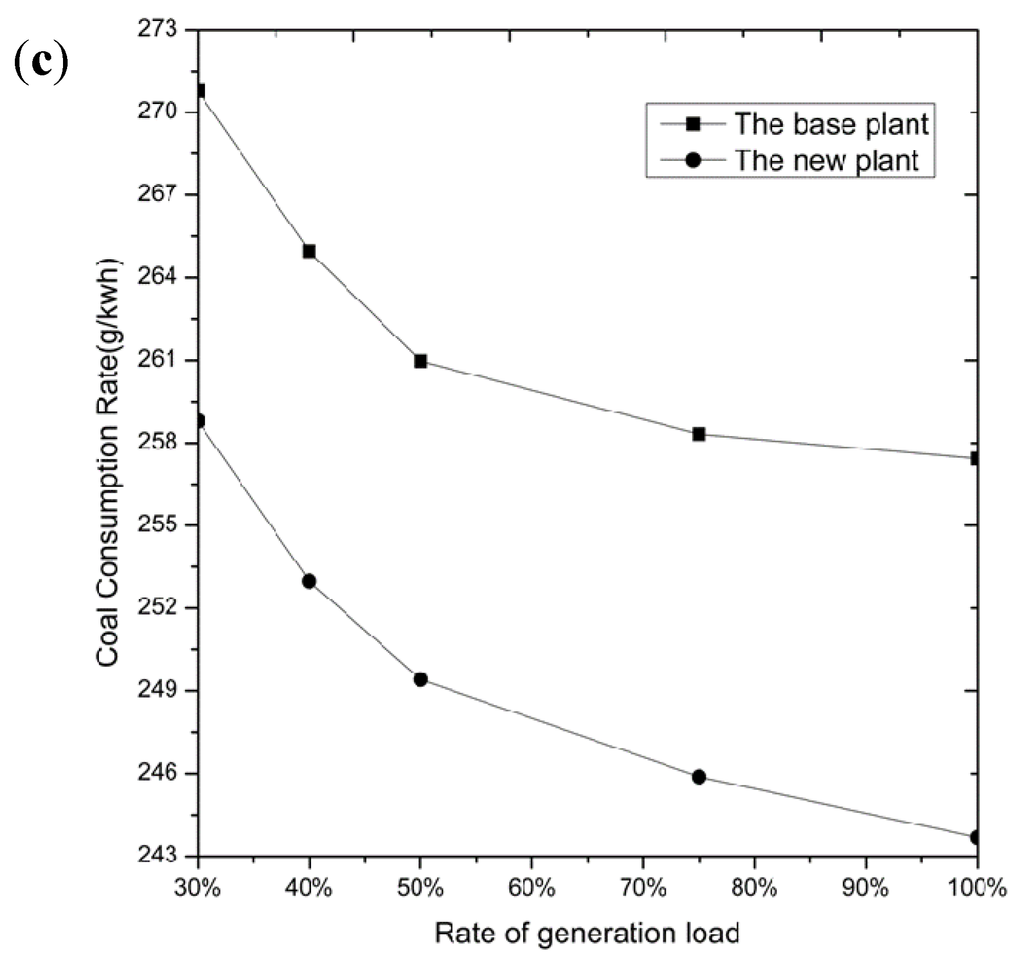

(a) The energy and exergy efficiency with the change of load ratio in the base plant (30%–100%); (b) The energy and exergy efficiency with the change of load ratio in the new plant (30%–100%); (c) The coal consumption rate with the change of load ratio.

It can be seen from Figure 10 and Figure 11 that the energy efficiency, exergy efficiency and coal consumption decrease with the increase of solar irradiation. Based on Equation (17), the power output is kept unchanged and the

increases while

decreases with the increase of solar irradiation, but the decrease of coal supplied heat is less than the increase of solar supplied heat, therefore the energy efficiency of the new plant is reduced. The coal consumption rate reduces with the increase of solar irradiation. When the solar irradiation increases from 500 W/m2 to 1,100 W/m2, the coal consumption rate reduces from 248.8 g/kWh to 241.6 g/kWh, saving coal from 8.6 g/kWh to 15.8 g/kWh. However, if the solar energy is taken as free, thus the equation of energy efficiency can be changed into Equation (19). Therefore, the energy efficiency of the new plant increases with the increase of solar irradiation as shown in Figure 10. No matter which equation is used to calculate the energy efficiency, the coal consumption rate will not be affected, because it is objective and denotes the coal consumed by the unit when per kWh power is produced. With the increase of solar irradiation from 500 W/m2 to 1,100 W/m2, there is a small decrease in the exergy efficiency of the new plant, from 44.67% to 44.48%. If the solar energy is taken as free, there will be an increase in the exergy efficiency as shown in Figure 10. The number of rows of collectors is dependent on the operation conditions, for example solar irradiations and load ratios. When the solar irradiation is very good, if the same number of rows as 30 is taken, the inlet temperature of the feedwater to the boiler will be quite high. Theoretically, if inlet temperature of the feedwater temperature is higher, the coal consumption rates will be less, but a high inlet temperature will increase the risk of damage to the pipes and is not reasonable in real operation, therefore, the numbers of rows are changed due to different conditions to make the inlet temperature of feedwater similar to that used in the base case.

5.2. Effects of the Load Ratio

As has been discussed before, in the operation of the solar-driven oil-water heat exchanger, the number of rows of collectors in use is dependent on the solar irradiation and load ratio. In the analysis of load ratio, different numbers of rows of collectors are used. When the load ratio are 30%, 40%, 50%, 75% and 100%, the numbers of rows are 6, 7, 9, 17 and 30, respectively. For the base case (as shown in Figure 12a), with the increase of load ratio from 30% to 100%, the exergy and energy efficiency increases from 43.3% to 45.6%, from 45.4% to 47.8%.

It can be seen from Figure 12b that with the increase of load ratio, the energy and exergy efficiencies of the new plant increase, which is in the same trend of that seen in the base plant. It can be seen from Figure 12c that when the load ratio of the base plant increases from 30% to 100%, the coal consumption rate of the base plant decreases from 270.8 g/kWh to 257.4 g/kWh. When the load ratio of the new plant increases from 30% to 100%, the coal consumption rate of the new plant decreases from 258.8 g/kWh to 243.7 g/kWh. For the new plant and base plant, there are no electricity reservation facilities, thus the better prediction of the demand of load from the customers can make the unit work more effective.

6. Conclusions

In this paper, the First and Second Laws of Thermodynamics have been used to study the performance of a solar-aided power plant. The main parameters such as the solar irradiation and power output have also been varied to analyze their effects to the plants. The main conclusions are as follows:

- (1)

- When the solar irradiation is 925 W/m2 and load ratio of the unit is 100%, the exergy efficiency of the base plant is 45.57%, lower than the energy efficiency of the plant (47.78%); the exergy efficiency of the new plant is 44.54%, lower than the energy efficiency of the plant (46.35%). If the new plant is compared with the base plant, the exergy and energy efficiencies of the new plant are lower than those of the base plant compared to the base plant, and the new plant saves about 13.7 g/kWh of coal.

- (2)

- When the solar irradiation is 925 W/m2 and load ratio of the unit is 100%, from the aspect of exergy losses, in the base plant, the largest exergy loss is from the boiler, accounting for about 86%, and the next largest exergy loss is from the turbines, while in the new plant, the largest exergy loss is still from the boiler, accounting for about 76.74%, and the next largest exergy loss is from the turbines. From the aspect of energy losses, in the base plant, the largest energy loss is in the condenser, accounting for about 82.89%, and the next energy loss is in the boiler; while in the new plant, the largest energy loss is still in the condenser accounting for about 91.25%, the next largest loss is in the turbines.

- (3)

- When the load ratio of the unit is 100%, (i.e., with output of 600 MW), the solar irradiation differs from 500 W/m2 to 1,100 W/m2, the coal consumption rate reduces from 248.8 g/kWh to 241.6 g/kWh, saving coal from 8.6 g/kWh to 15.8 g/kWh.

- (4)

- When the solar irradiation is kept 925 W/m2 unchanged, the load ratio of the unit changes from 30% to 100%, the coal consumption rate of the base plant decreases from 270.8 g/kWh to 257.4 g/kWh. When the load ratio of the new plant increases from 30% to 100%, the coal consumption rate of the new plant decreases from 258.8 g/kWh to 243.7 g/kWh.

Based on the above analysis, in order to improve the energy and exergy efficiencies of a solar-aided coal-fired power plant, modifications can be made to the boiler, condenser and solar-aided oil-water heat exchanger. In the design of a new plant, the solar irradiation should be taken into consideration for the choice of solar collectors; in the plant operation, solar irradiation and load demand from the customers should be considered. The effective predictions of solar irradiation and load demands can make the unit work in a high efficiency range, which is useful to improve the performance of the plant. There are two parameters in the parameter study in this paper; discussions have been made based on keeping one parameter unchanged while the other changed. In future research, the analysis based on the change of both the solar irradiation and load demand will be made to obtain an optimal operating strategy for the system.

Acknowledgments

The research work is supported by China National Natural Science Foundation (No. 51106048); State 863 Project (2012AA050604); the Fundamental Research Funds for the Central Universities and the 111 Project.

Nomenclature

heat supplied by the fuel (coal) | |

thermal efficiency of the boiler | |

flowrate of feedwater | |

the specific enthalpy of the inlet stream in the boiler | |

the specific enthalpy of the outlet stream in the boiler | |

the exergy efficiency of the boiler | |

the exergy of the fuel (coal) | |

the exergy of the inlet stream in the boiler | |

the exergy of the outlet stream in the boiler | |

he chemical exergy | |

the physical exergy | |

the output of the turbine | |

the flowrate of steam passing through the turbine | |

the specific enthalpy of the inlet steam | |

the specific enthalpy of the outlet steam | |

the isentropic efficiency of the turbine | |

the exergy efficiency of the turbine | |

the exergy of the inlet steam for the turbine | |

the exergy of the outlet steam for the turbine | |

The heat transferred from the condenser | |

the flowrate of the condensed water | |

the specific enthalpy of the inlet steam | |

the specific enthalpy of outlet steam | |

the thermal efficiency of the condenser | |

the exergy efficiency of the condenser | |

the inlet exergy of condenser | |

the outlet exergy of condenser | |

the flowrate of the steam extraction | |

the specific enthalpy of the steam extraction | |

the flowrate of inlet water for the heat exchanger | |

the specific enthalpy of the inlet water for the heat exchanger | |

the specific enthalpy of the outlet water for the heat exchanger | |

the flowrate of feedwater for the heat exchanger | |

the specific enthalpy of the outlet feedwater for the heat exchanger | |

the specific enthalpy of the outlet feedwater for the heat exchanger | |

the energy efficiency of the heat exchanger | |

the flowrate of the steam extraction for the heat exchanger | |

the specific exergy of the steam extraction for the heat exchanger | |

the inlet water flowrate for the heat exchanger | |

the specific exergy of the inlet water for the heat exchanger | |

the specific exergy of the outlet water for the heat exchanger | |

the flowrate of feedwater for the heat exchanger | |

the specific exergy of the inlet feedwater for the heat exchanger | |

the specific exergy of the outlet feedwater for the heat exchanger | |

the specific enthalpy of the outlet water for mixed heat exchanger | |

the specific exergy of the outlet water for mixed heat exchanger | |

the exergy of solar energy | |

the temperature of the environment | |

the temperature of the solar surface | |

the pressure of outlet water in oil-water heat exchanger | |

the pressure of inlet water in oil-water heat exchanger | |

the coefficient of the pressure drop | |

the mass flowrate of water | |

the enthalpy of outlet water | |

the enthalpy of inlet hot oil | |

the enthalpy of outlet hot oil | |

the mass flowrate of hot oil | |

the energy efficiency for the solar aided coal-fired power plant | |

the output power by the solar aided coal-fired power plant | |

the coal heat consumed by the solar aided coal-fired power plant | |

the input solar heat of the solar aided coal-fired power plant | |

the exergy efficiency for the solar aided coal-fired power plant | |

the coal exergy consumed by the solar aided coal-fired power plant | |

the input solar exergy of the solar aided coal-fired power plant | |

The coal consumption rate for coal fired power plant | |

The energy efficiency of the plant | |

The coal consumption rate for solar aided coal-fired power plant | |

Heat supplied by solar | |

Work output |

References

- Yang, Y.P.; Guo, X.Y.; Wang, N.L. Power generation from pulverized coal in China. Energy 2010, 35, 4336–4348. [Google Scholar] [CrossRef]

- Eric, H.; Yang, Y.P.; Nishimura, A.; Yilmaz, F. Solar-aided power generation. Appl. Energy 2010, 87, 2881–2885. [Google Scholar]

- Wang, Z.; Li, X.; Yao, Z. Concentrating solar power development in China. Renew. Energy 2010, 35, 981–988. [Google Scholar] [CrossRef]

- Report of China Energy Chamber of Commerce. Available online: http://www.cnecc.org.cn/dispArticle.asp?id=7838/ (accessed on 28 December 2010).

- Zoschak, R.J.; Wu, S.F. Studies of the direct input of solar energy to a fossil-fueled central station steam power plant. Sol. Energy 1975, 17, 297–305. [Google Scholar] [CrossRef]

- Jamel, M.S.; Abd Rahman, A.; Shamsuddin, A.H. Advances in the integration of solar thermal energy with conventional and non-conventional power plants. Renew. Sustain. Energy Rev. 2013, 20, 71–81. [Google Scholar] [CrossRef]

- Gupta, M.K.; Kaushik, S.C. Exergetic utilization of solar energy for feedwater preheating in a conventional thermal power plant. Int. J. Energy Res. 2009, 33, 593–604. [Google Scholar] [CrossRef]

- Yang, Y.P.; Yan, Q.; Zhai, R.R.; Eric, H. An efficient way to use medium-or-low temperature solar heat for power generation—Integration into conventional power plant. Appl. Therm. Eng. 2011, 31, 157–162. [Google Scholar] [CrossRef]

- Pai, B.R. Augmentation of thermal power stations with solar energy. Sadhana 1991, 16, 59–74. [Google Scholar] [CrossRef]

- Ying, Y.; Hu, E.J. Thermodynamic advantages of using solar energy in the regenerative Rankine power plant. Appl. Therm. Eng. 1999, 19, 1173–1180. [Google Scholar] [CrossRef]

- Price, H.; Lupfert, E.; Kearney, D.; Zarza, E.; Cohen, G.; Gee, R. Advances in parabolic trough solar power technology. J. Sol. Energy Eng. 2002, 124, 109–125. [Google Scholar] [CrossRef]

- Eck, M.; Zarza, E.; Eickhoff, M.; Rheinlander, J.; Valenzuela, L. Applied research concerning the direct steam generation in parabolic troughs. Sol. Energy 2003, 74, 341–351. [Google Scholar] [CrossRef]

- Zhao, Y.; Hong, H.; Zhang, X.; Jin, H. Integrating mid-temperature solar heat and post-combustion CO2-capture in a coal-fired power plant. Sol. Energy 2012, 86, 3196–3204. [Google Scholar] [CrossRef]

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis; Butterworths: London, UK, 1985. [Google Scholar]

- Bejan, A. Advanced Engineering Thermodynamics; Wiley Interscience: Durham, UK, 1988. [Google Scholar]

- Habib, M.A.; Zubair, S.M. Second-law-based thermodynamic analysis of regenerative-reheat Rankine-cycle power plants. Energy 1992, 17, 295–301. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I. Exergoeconomic analysis of power plants operating on various fuels. Appl. Therm. Eng. 2003, 23, 643–658. [Google Scholar] [CrossRef]

- Singh, O.K.; Kaushik, S.C. Energy and exergy analysis and optimization of Kalina cycle coupled with a coal fired steam power plant. Appl. Therm. Eng. 2013, 51, 787–800. [Google Scholar] [CrossRef]

- Siva Reddy, V.; Kaushik, S.C.; Tyagi, S.K. Exergetic analysis of solar concentrator aided natural gas fired combined cycle power plant. Renew. Energy 2012, 39, 114–125. [Google Scholar] [CrossRef]

- Yan, Q.; Eric, H.; Yang, Y.P.; Zhai, R.R. Evaluation of Solar Aided Thermal Power Generation with Various Power Plants. Int. J. Energy Res. 2011, 35, 909–922. [Google Scholar] [CrossRef]

- Baghernejad, A.; Yaghoubi, M. Exergy analysis of an integrated solar combined cycle system. Renew. Energy 2010, 35, 2157–2164. [Google Scholar] [CrossRef]

- Qian, S.; Yang, D. The calculation model and equations of chemical exergy for complex substance. J. East China Inst. Chem. Technol. 1986, 12, 95–104. [Google Scholar]

- Patnode, A.M. Simulation and Performance Evaluation of Parabolic Trough Solar Power Plants. M.Sc. Thesis, University of Wisconsin-Madison, Madison, WI, USA, 2006. [Google Scholar]

- Thorsten, A.S. Automatic Control of the 30 MWe SEGS VI Parabolic Trough Plant. M.Sc. Thesis, The University of Wisconsin-Madison, Madison, WI, USA, 2002. [Google Scholar]

- Thorsten, A.S.; Nathan, B.; John, W.M.; William, A.B. Automatic control of a 30MWe SEGD VI parabolic trough plant. Sol. Energy 2004, 76, 187–193. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).