2. Thermodynamic Analysis

A general feature typical of the process of cutting of hard to machine materials, such as Ti alloys, Ni-based super alloys and, in particular, the latest generation of super duplex stainless steels, is a very intensive adhesive interaction on the tool/chip interface leading to seizure and formation of built-up edge [

2]. This could be characterized as a catastrophic frictional condition [

2].

We have to stress that the tool/chip/workpiece tribo-system is a system where different parts (in our case tool, chip, workpiece) are interconnected or “functionally integrated”, so the failure of one part may cause the rest of the structure to fail [

6]. To control such complex engineering systems, an integrative approach is of critical need.

To understand a number of very complex and interconnected mechanisms that are taking place within the tool-buildup-workpiece tribo-system during cutting, a thermodynamic analysis of the frictional processes needs to be carried out. In our previous studies, thermodynamic analysis was conducted for one frictional body (cutting tool) [

2,

12]. In this research, we are analyzing a more complex system consisting of three frictional bodies: cutting tool/buildup/chips (work piece).

A seizure during friction is initiated by two major processes [

13]: formation of juvenile surfaces and plastic deformation, in other words, some activation of the surface is critically needed. A seizure leads to a decrease in the free energy of the system, since it decreases the surface energy by reducing the surface area. Hence, this is a spontaneous process with positive entropy production. On the other hand, to initiate a seizure it is necessary to create juvenile surfaces and this is a non-spontaneous process with the increase in surface energy, which is accompanied by a negative entropy production. Furthermore, during the plastic deformation process, localization of deformation and the consequent non-uniform distribution results in entropy decrease in the frictional body.

In this regard, let us try to analyze the entire process of the tool/chip interaction as follows.

The chips of austenitic steel tend to adhere to the surface of the uncoated coating tool. However, the surface layers of the uncoated tool have insufficient adaptability. Therefore, the energy released during cutting may not be enough to initiate self-organization on the tool surface. In this case, the system tends to initiate seizure and stop the friction (this leads to a decrease in entropy production, as there is no friction within the zone of seizure).

For the coated tool, the process looks different. The coating has the ability to adapt to external stimuli, i.e., to self-organize. A part of the cutting energy is spent on self-organization of the coating layer (by forming a nano-layer of thermal barrier/lubricating tribofilms [

2,

14,

15]). Thus, the tribo-system is able to reduce the entropy production by means of self-organization, instead of energy dissipation through surface damage. Thus, the intensity of seizure is much less in the coated tool.

A similar thing happens during the initial acceleration in cutting speed. However, a greater speed leads to a more intense release of energy, and respectively, a greater and more complete self-organization on the coated tool surface. In theory, this fully corresponds to the strategy of running-in on the edge of seizure during external friction [

16,

17,

18].

The flow of the material in front of the tool face and the structure of build-ups both resemble the formation of vortices within an impeded flow (

Figure 1). The corresponding torque generated by these vortices can tear off the built-ups from the tool. The torque associated with large vortices (built-ups) can even tear off some portions of the tool tip especially under intensive adhesion conditions. This situation was resembled to occurrence of a large avalanche previously. As discussed before, the goal of this study is to replace one big avalanche with several smaller avalanches through an application of adaptive coatings [

9,

10,

11]. Reducing adhesion and seizure, controlling the flow speed and consequently facilitating the material flow, through application of self protective/lubricating tribo-films in the contact zone, we replace large destructive vortices with smaller vortices.

An integrative analysis of the tribo-system, requires consideration of both contacting bodies (the tool and the workpiece material), as well as formed chips and the environment. Therefore, in this model, it is considered that the worn material remains within the system and does not leave the system with its entropy. In this way, the wear can be regarded as the formation of new surfaces.

Let us consider the balance of entropy change in the system:

The entropy change during tool wear (formation of new surfaces) dSw characterizes the tool wear. Due to the additivity of entropy, the greater the absolute value of dSw, the greater the wear of the tool.

The change in entropy during chip formation (and formation of new surfaces) dSch characterizes the intensity of the chip formation. Due to additivity of entropy the more absolute value dSch, the easier the chip formation process, which corresponds to higher chip velocity as well as shear angle and at the same time, smaller chip thickness (higher chip compression ratio, see below in Results).

The part of entropy production dSi1 is inherent in the tool without regard to physical and chemical transformations.

The part of entropy production dSi2 entropy is inherent in the workpiece material without regard to physical and chemical transformations. The part of entropy production dSi11 is associated with the tool, which takes into account the physical-chemical transformations on the surface. The part of entropy production dSi21 is associated with the workpiece material and takes into account the physical and chemical transformations on the surface. The part of the entropy production dSs is associated with build-up formation. The part of entropy production dSa is associated with build-up tearing off.

The entropy flow is associated with the exchange of energy with the environment

dSe. The change in entropy of such tribo-system similar to Reference [

2] will be as follows:

The terms in Equation (1) are combined by an identical type of process. The first term (

dSe) is the entropy flux. We will consider it as an independent variable and unchanged, i.e., its intensity is independent of the state of the system and is determined only by the intensity of the friction process (in our case is chiefly related to the increase in cutting speed). The latter two terms united in brackets, (

dSi1 +

dSi2), represent the entropy production and are positive because they are related to the propagation of heat by frictional bodies. The third pair of terms are combined in absolute terms and have a “minus” sign, because during the formation of new surfaces, the surface energy increases. The fourth pair of terms (

dSi11 +

dSi21) describe the physical and chemical processes on the surfaces. This sum, as are the single terms, could be either positive or negative. For example, the surface oxidation of the steel chips is a spontaneous process with positive entropy production. The formation of protective surface tribo-films on the surface of the cutting tool is a non-spontaneous process, especially after self-organization, as shown in Reference [

2]. The fifth term (

dSs) is visibly positive because seizure reduces the surface energy. The sixth term (

dSa) is visibly negative, as the build-up tears off, new surfaces form, and, respectively, the surface energy increases. In differentiating Equation (1) with respect to time, and considering the stationary process we get:

or:

The amount of the left part of Equation (3) represents the entropy rate change due to tool wear and chip formation. It should be noted that both of the terms in the left part of Equation (3) have the same sign (negative), therefore:

The change in this sum could yield simultaneous change in either term or could result in different changes in each term. For example, reduction of this sum could lead to a simultaneous reduction in the both tool wear rate and the intensity of the chip formation (decrease in both terms); reduction in the tool wear rate (a decrease in the first term) and increase in the chip formation rate (increase in the second term); increase in tool wear rate (increase in the first term) and reduction of chip formation rate (reduction of the second term).

Substituting Equation (4) into Equation (3) we obtain:

It follows from Equation (5) that the more intensive the chip formation, the lower the intensity of the tool wear, and vice versa.

With the decrease of tool wear, due to lower friction, chip formation becomes easier. By ease of chip formation, we mean a higher shear angle and consequently thinner chips with higher chip velocities.

From Equations (3) and (4), it follows that with increasing and the wear rate of the cutting tool and/or the intensity of the chip formation will increase. Considering that is highly affected by cutting speed, this is quite natural because the sum of these terms describes the intensity of the cutting process in general.

From Equations (3) and (4), it follows that with increasing the rate of tool wear and/or intensity of the chip formation will increase. This is due to the fact that, during adhesion, additional energy is released that is associated with the decrease in the surface energy. It is well known that very high seizure and a consequent high built up edge will result in high tool wear. Higher seizure also adversely affects chip formation and reduces its intensity. From Equations (3) and (4), it follows that with the increase of the tool wear rate and/or the rate of the chip formation will decrease, because the formation of new surface requires energy to form these surfaces. In the following section, it will be shown how, through controlling this term, significant enhancements can be obtained in terms of tool life and chip formation.

The influence of fourth terms (

dSi11/

dt and

dSi21/dt) on the wear rate of the tool and/or the intensity of the chip formation depend on the signs in front of the terms in parentheses. During regular oxidation of the processed material, energy is released, therefore, it is a spontaneous process and

is positive. For example, if the cutting tool material were to also undergo regular thermal oxidation, without self-organization, then the energy would be released, i.e., it would be a spontaneous process and

would be positive. Usually, spontaneous processes on surfaces prevail with a relatively small

, i.e., during cutting at low intensity when the power of cutting is not enough to initiate self-organization. Spontaneous processes at surfaces may prevail when there is no opportunity for self-organization to be initiated, such as a lack of complexity of the cutting material [

19], which is possible for an uncoated tool.

Once the self-organization on the surface of the cutting tool is initiated, the value of

term can be negative or positive, but it is much less than it would be without self-organization. Let us consider the last two terms on the right side of Equation (3). During the formation of a built-up edge, the chips adhere to the cutting tool surface. The formation of build-up takes place due to the progressive, multilayer adherence of the chips to the tool surface, i.e., the first scales of the chips adhere to the tool surface and subsequent scales adhere to the previous scales. Let us suppose the buildup consists of n layers of the scales. In this case:

where

B is the average size of a scale and τ is surface energy of scales. At a certain period of a cycle that includes the build-up formation and build-up tearing off, with an increase in the thickness of the build-up (increasing of n), the

increases as well. After reaching a certain thickness of build-up, the formed build-up will be fractured and torn away, i.e.,

where

τm is surface energy of the material where the tearing has occurred. It is difficult to compare the values of

and

due to the different time of formation and separation of the build-up. Let us try to compare the integrated value (integrated over time):

It should be noted that during the formation of build-up:

Separation typically occurs on the material with a lower surface energy, therefore, typically:

Using Equations (10) and (11):

The greater the difference, Equation (11), the higher the tool wear rate can be. If, by analogy with avalanches (self-organized critical process [

6]), we replace thick built-ups (

n layers) with thinner ones (

m layers where 1 ≤

m ≤

n), then Equations (8) and (9) will become:

Taking into account Equations (13) and (14), ceteris paribus:

Taking into account that the period duration of adhesion and separation will be close for thin (probably mono-layered or consisting of a few layers) build-ups, it can be assumed that:

Accordingly, by replacing these terms in Equation (3), the sum of the right side of Equation (3) will be reduced and, therefore, wear rate will likely be lower as well. Thus, through non-spontaneous processes inside tribo-system (self-organization), as well as the formation of thinner layered build-ups, rather than a thick build-up, the value

decreases. Thus, it can be demonstrated that, by replacing a thick built-up with several smaller ones, the intensity of tool wear will be reduced, whereas the chip formation will be improved. Improvement of chip formation is accompanied by less cutting forces and power consumption. The tribo-films, which are also known in the literature as secondary (i.e., formed during friction) structures [

18], are formed on the surface to protect the tooling material from direct interaction with the counter-body (in our case chips and workpiece). The physical and chemical processes of secondary structure formation can be non-spontaneous, and be accompanied by a negative entropy production [

2]. In this case, it leads to reduced wear rate and entropy production.

If tribo-materials in contact cannot initiate self-organization and the formation of secondary structures required by friction, (for instance if the tribo-materials do not possess sufficient complexity [

19]) then the system tries to reduce the wear rate by terminating the friction process through seizure. Presumably this occurs on the surface of the uncoated tool (see Experimental Section below). The nano-multilayer coating on the surface of cutting tool has a fairly complex structure and a non-equilibrium state [

15,

19,

20,

21]. This increases the probability of self-organization initiating along with spontaneous processes of secondary structure formation. Most of the friction energy has been spent on non-spontaneous processes on the coating surface, so less energy is available for adhesive interaction with the workpiece material. With an increase in the initial cutting speed, the intensified non-spontaneous processes are initiated [

22], respectively, and even less energy remains on the surface to cause damage to processes. This strategy is somewhat similar to the earlier-developed approach for external friction conditions [

16,

17].

3. Experimental Section

Two nano-multilayered Ti

0.2Al

0.55Cr

0.2Si

0.03Y

0.02N/Ti

0.25Al

0.65Cr

0.1N and Ti

0.15Al

0.6Cr

0.2Si

0.03Y

0.02N/Ti

0.25Al

0.65Cr

0.1N coatings were deposited using Ti

0.2Al

0.55Cr

0.2Si

0.03Y

0.02, Ti

0.15Al

0.6Cr

0.2Si

0.03Y

0.02N, and Ti

0.25Al

0.65Cr

0.1 targets fabricated by powder metallurgical process. The cemented carbide K 313 Kennametal inserts (CNGG432FS) were used for cutting tool life studies. Coatings were deposited in an R&D-type hybrid PVD coater (Kobe Steel Ltd., Kobe, Japan) using a plasma-enhanced arc source. Samples were heated up to about 500 °C and cleaned through an Ar ion etching process. Ar-N

2 mixture gas was fed to the chamber at a pressure of 2.7 Pa with a N

2 partial pressure of 1.3 Pa. The arc source was operated at 100 A for a 100 mm diameter × 16 mm thick target. Other deposition parameters were: Bias voltage 100 V and substrate rotation of 5 rpm. The thickness of the coatings studied was around 3 micrometres for film characterization and cutting test work. The characteristics of the TiAlCrSiYN/TiAlCrN coatings are presented in

Table 1 [

20].

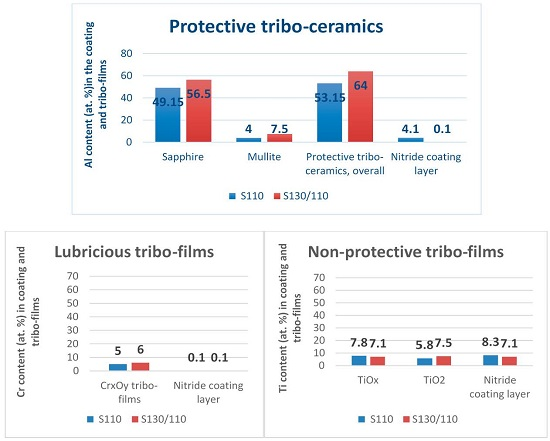

To reveal the microstructure of the SDSSUNS32750 workpiece, samples of this material were metallographic prepared by polishing and etching in Aqua regia 1:3 HNO3:HCl solution. The microstructure of SDSS workpiece and microstructure of chip cross section generated during cutting process, as well as the worn tool surface, were characterized using both an Optical (Olympus BX60 equipped with UC30 camera, Center Valley, PA, USA) and Scanning Electron Microscopy (SEM) facilities (Vega 3-TESCAN, Brno, Czech Republic).

Two sets of turning tests were performed: Semi-roughing tests to accelerate build up formation and perform progressive SEM studies (

Figure 1). For the semi-roughing operation, cutting conditions were the following: Speed, m/min-60; feed rate, 3.3 mm/rev; depth of cut, 1 mm. For finishing, machining conditions that are widely used in practice were used (

Figure 2). The experiments were performed at speeds of 110 m/min, 130 m/min and on accelerated test conditions (130 m/min at the beginning of machining followed by slowing down to 110 m/min for the remainder of the tool’s life), which were designated as S110, S130 and S130/110 respectively. A cutting speed of 110 m/min can be characterized as usual in industrial practice. Other machining parameters were the following: Feed rate of 0.125 mm/rev and depth of cut of 0.25 mm under wet cutting condition. The tool life criterion was set to flank wear of 0.1 mm. Tool wear rate was characterized by its cutting length. The machining experiments were performed in a Boehringer VDF 180CM turning machining center (FFG Werke GmbH, Uhingen, Germany). The force measurements were performed with a Kistler dynamometer (type 9121, Kistler Instrument Corp., Amherst, NY, USA). The sampling rate was 200 data points per second. Wear resistance data for the schematic presentation of buildup edge avalanche-like behavior (

Figure 1) was collected under the following aggressive conditions used in practice: Speed 60 m/min; depth of cut: 1 mm; feed rate of 0.3 mm. At least three tests per sample were performed.

During the cutting test, tool flank wear was measured using an optical microscope (Mitutoyo-model™, Aurora, IL, USA). The covered area (build up) on the tool rake surface was measured at a cutting length of 8000 m. For this analysis the digital microscope model VHX 5000 series by Keyence (Keyence Corp., Osaka, Japan) was employed.

The chip compression ratio was determined according to the standard methods [

17]. The shear angle and the cutting force were determined by the conventional methods [

17]. In addition, the hardness on the chip cross-section was evaluated using Shimadzu Micro-hardness Tester using Vickers indenter. In these tests the applied load was 0.05 kg for 10 s.

The structural and phase transformation at the cutting tool/workpiece interface, as well as the chemical nature of the tribo-films formed, were determined by X-ray Photoelectron Spectroscopy (XPS) on a Physical Electronics (PHI) Quantera II (Physical Electronics Inc., Chanhassen, MN, USA) equipped with a hemispherical energy analyzer and an Al anode source for X-ray generation and a quartz crystal monochromator for focusing the generated X-rays. A monochromatic Al K-α X-ray (1486.7 eV) source was operated at 50 W–15 kV. The system base pressure was as low as 1.0 × 10−9 Torr, with an operating pressure that did not exceed 2.0 × 10−8 Torr. Before any spectra were collected from the samples, the samples were sputter-cleaned for four minutes using a 4 kV Ar+ beam. A pass energy of 280 eV was used to obtain all survey spectra, while a pass energy of 69 eV was used to collect all high-resolution data. All spectra were obtained at a 45° take off angle and utilized a dual beam charge compensation system to ensure the neutralization of all samples. The instrument was calibrated using a freshly cleaned Ag reference foil, where the Ag 3d5/2 peak was set to 368 eV. All data analyses were performed using PHI Multipak version 9.4.0.7 software. Spots for the high resolution (HR) HR analysis were selected based on careful preliminary investigation of general photoelectron spectra of the worn surface close to the buildup edge area.