Coherent Precipitation and Strengthening in Compositionally Complex Alloys: A Review

Abstract

:1. Introduction

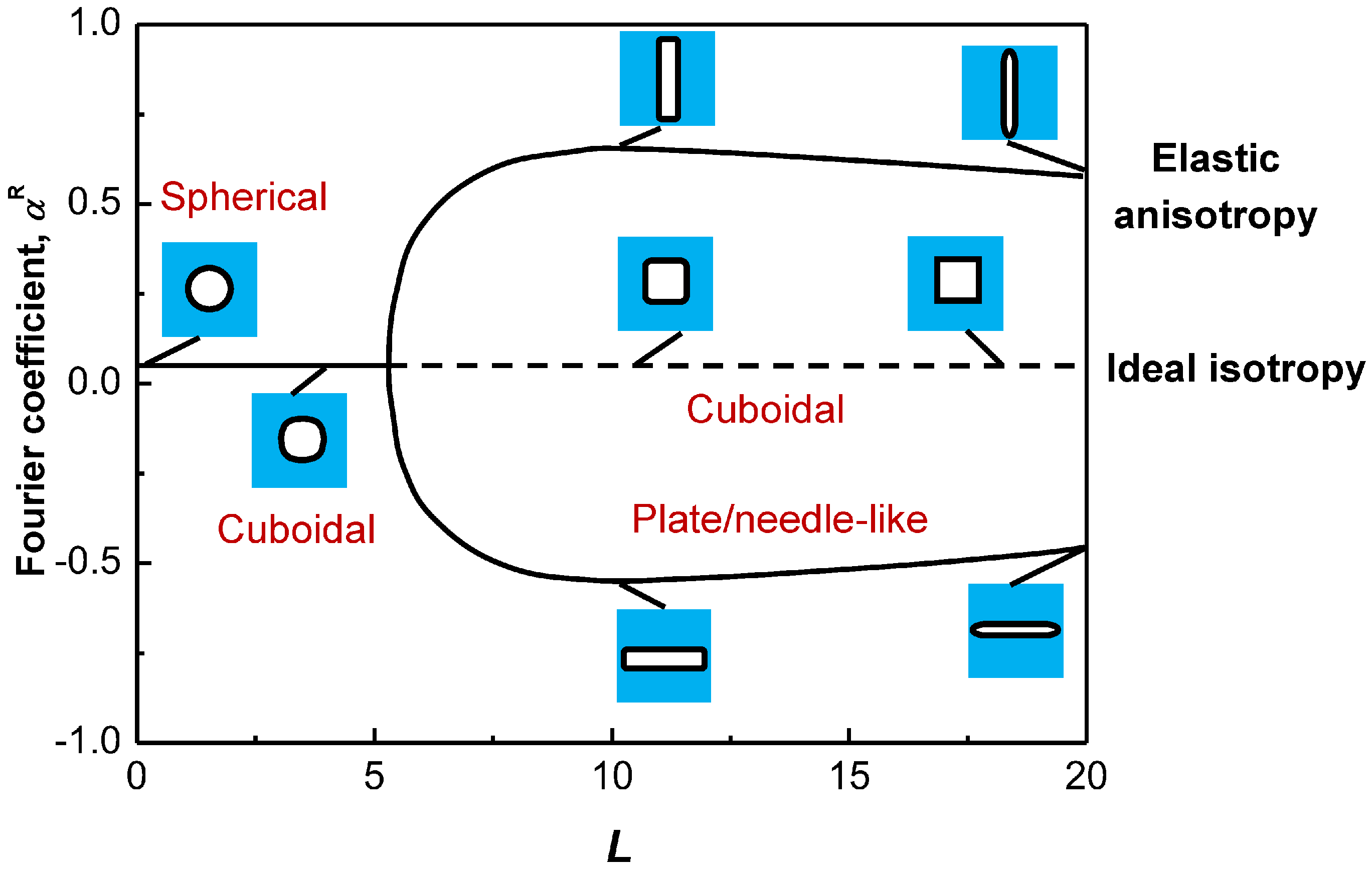

2. Equilibrium Morphology of a Misfitting Particle

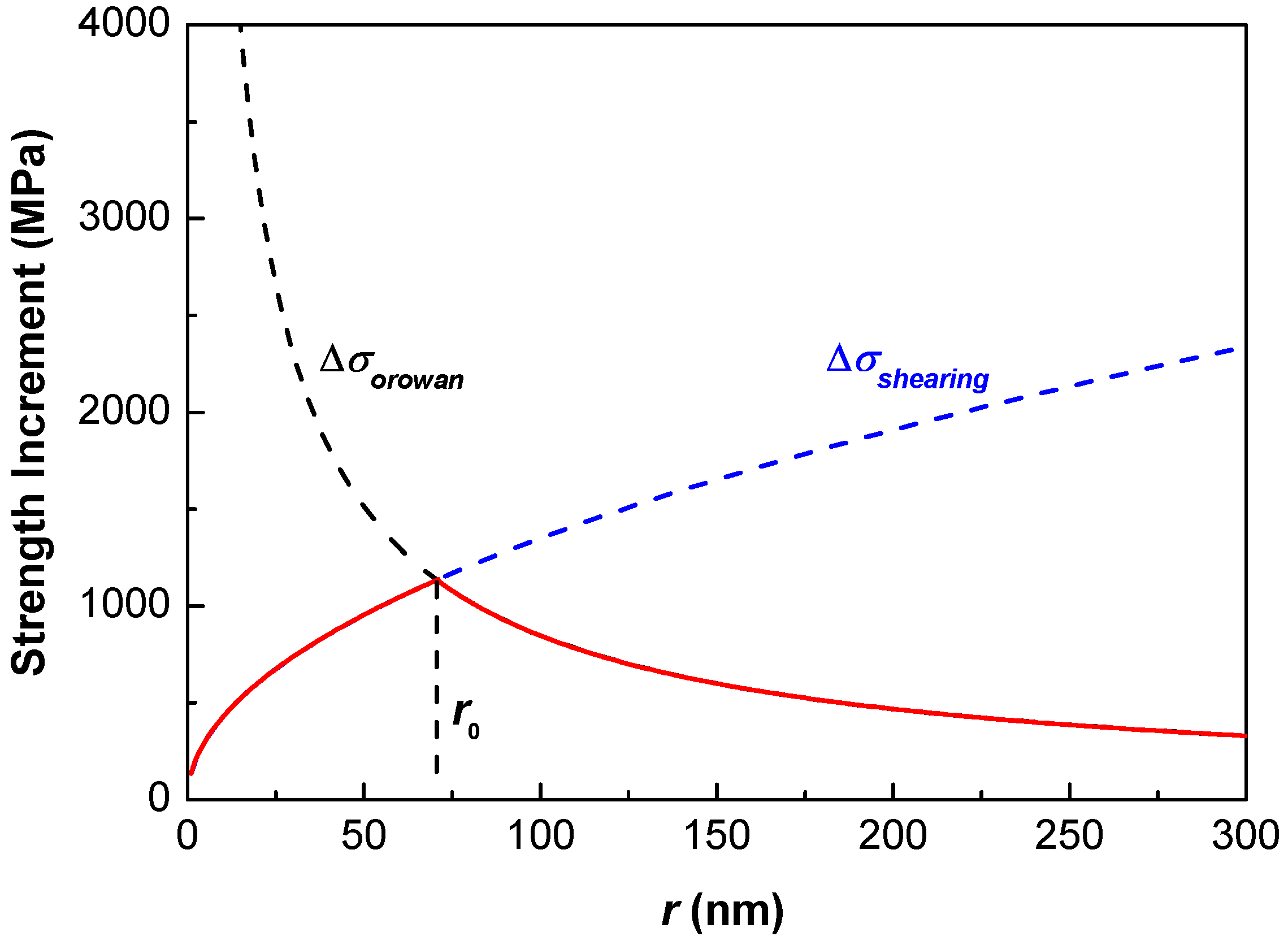

3. Precipitation Strengthening Mechanisms

4. Precipitate Morphology and Precipitation Strengthening in CCAs

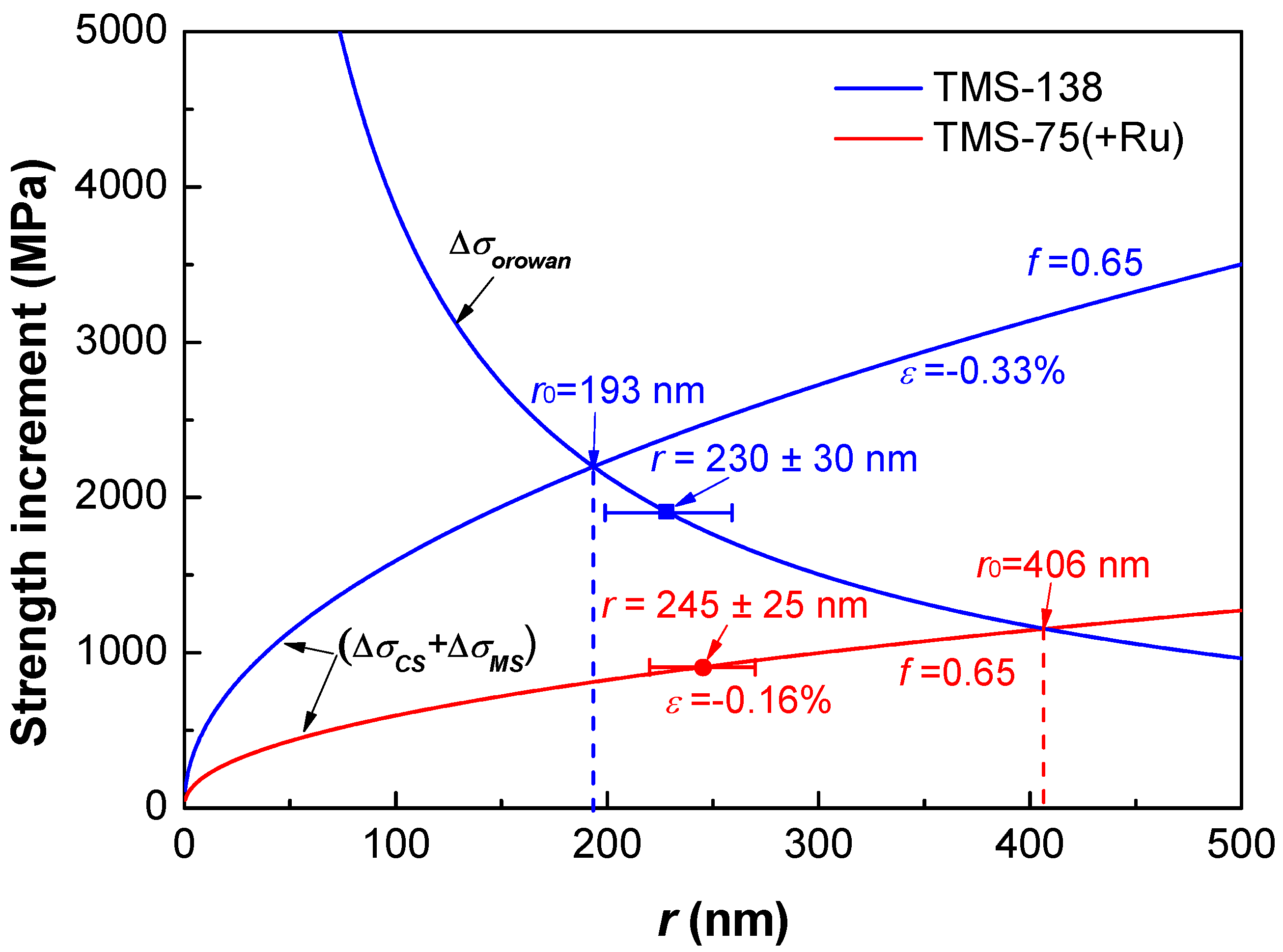

4.1. Ni-Based Superalloys

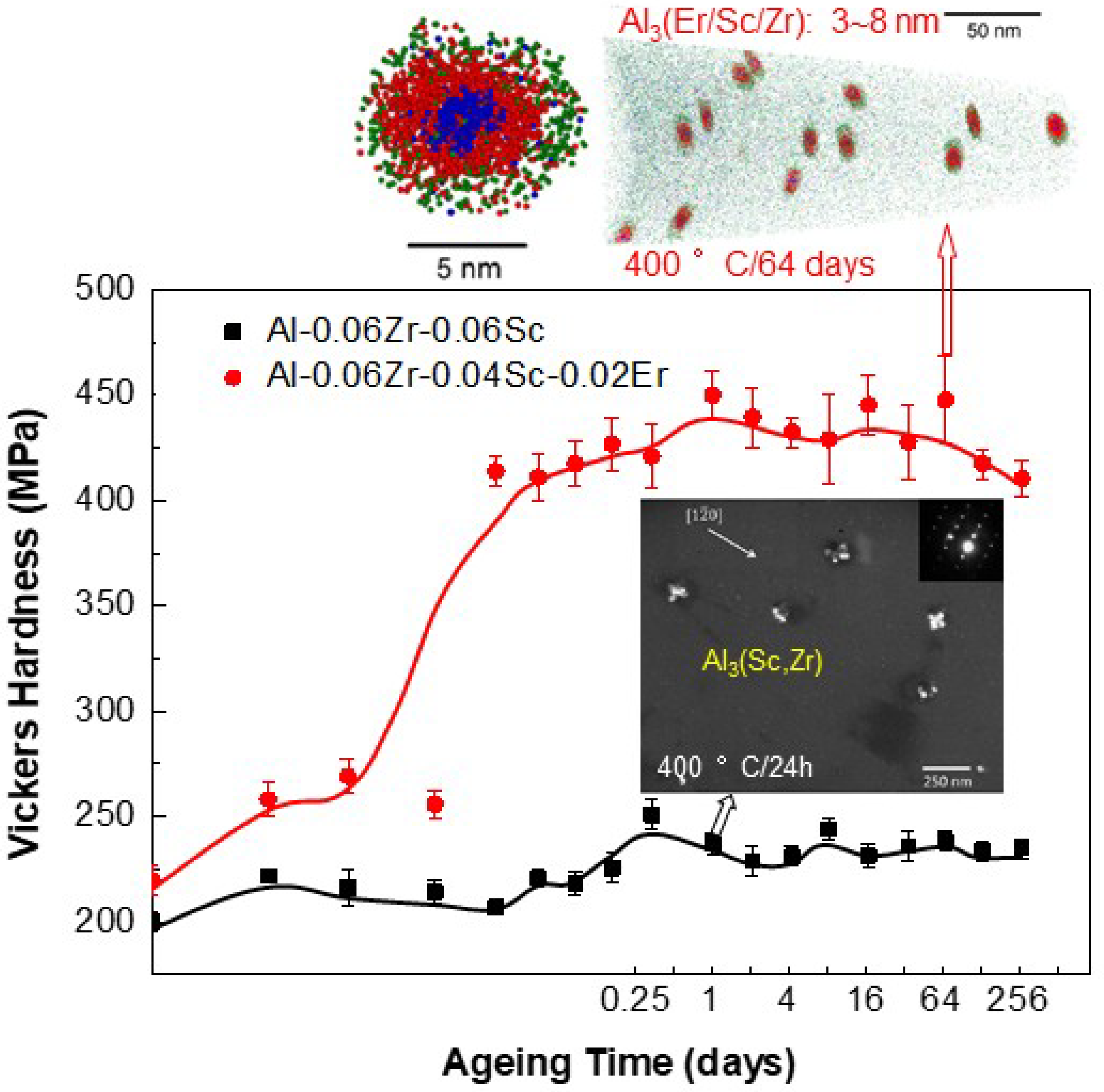

4.2. Al-Based Alloys

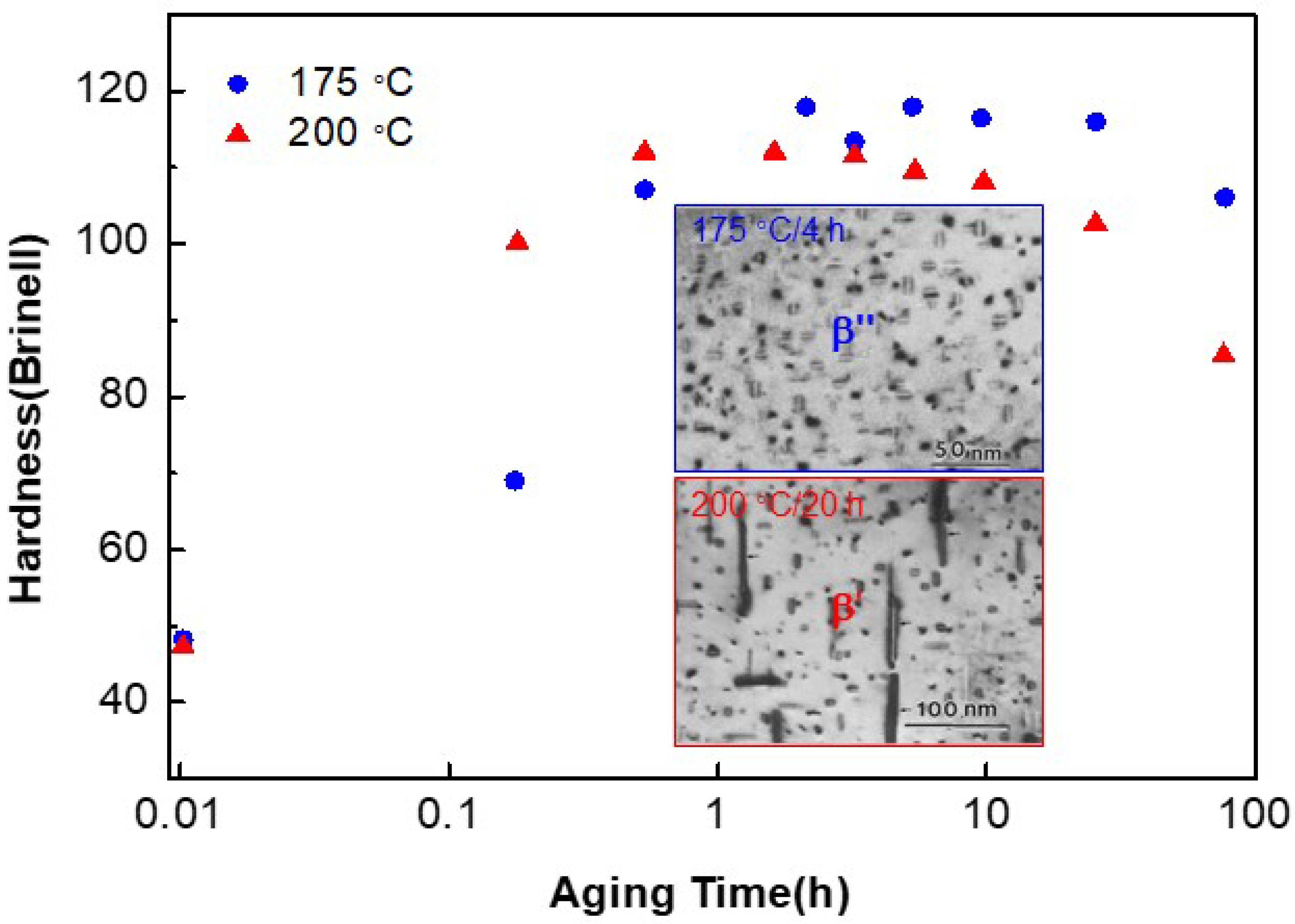

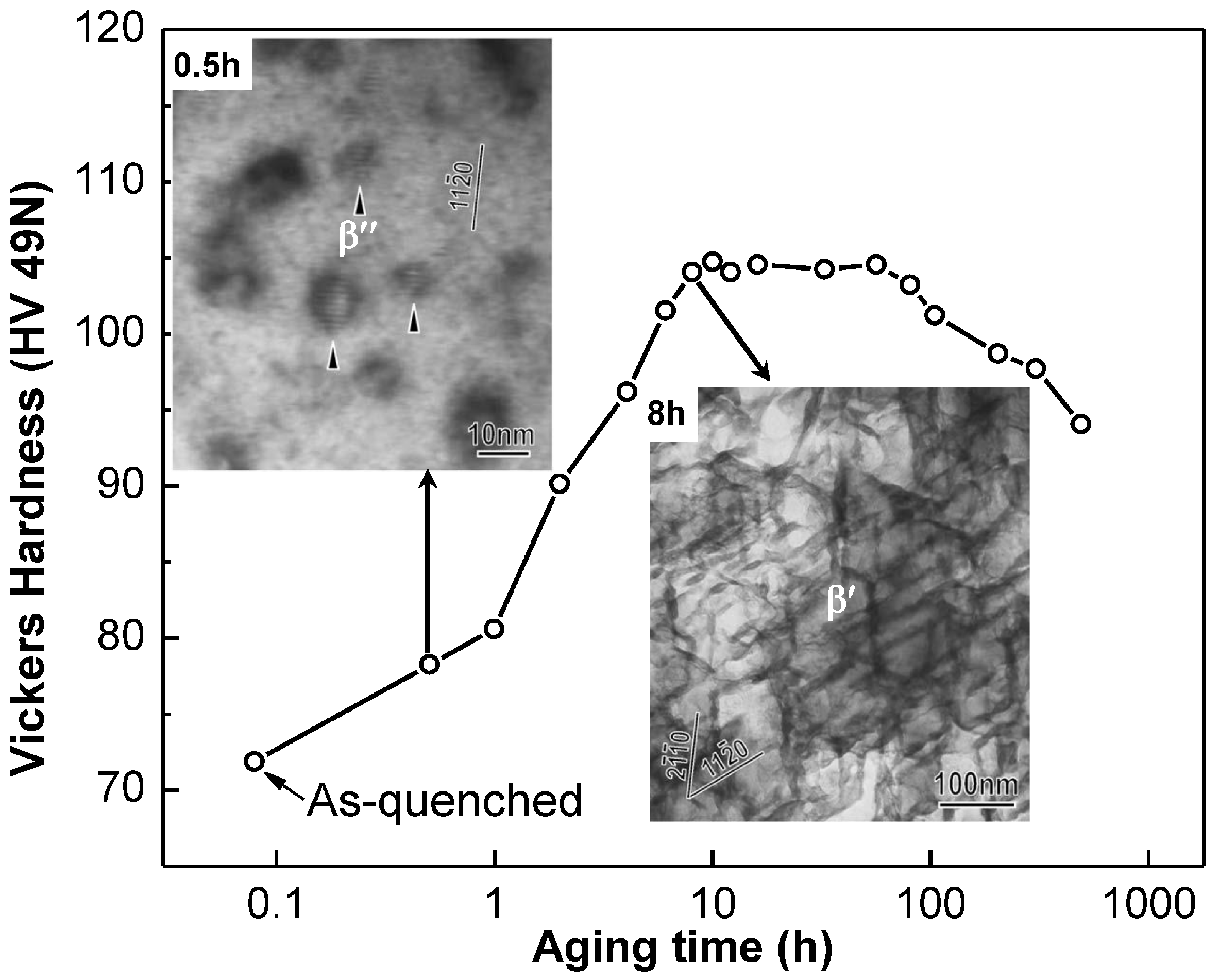

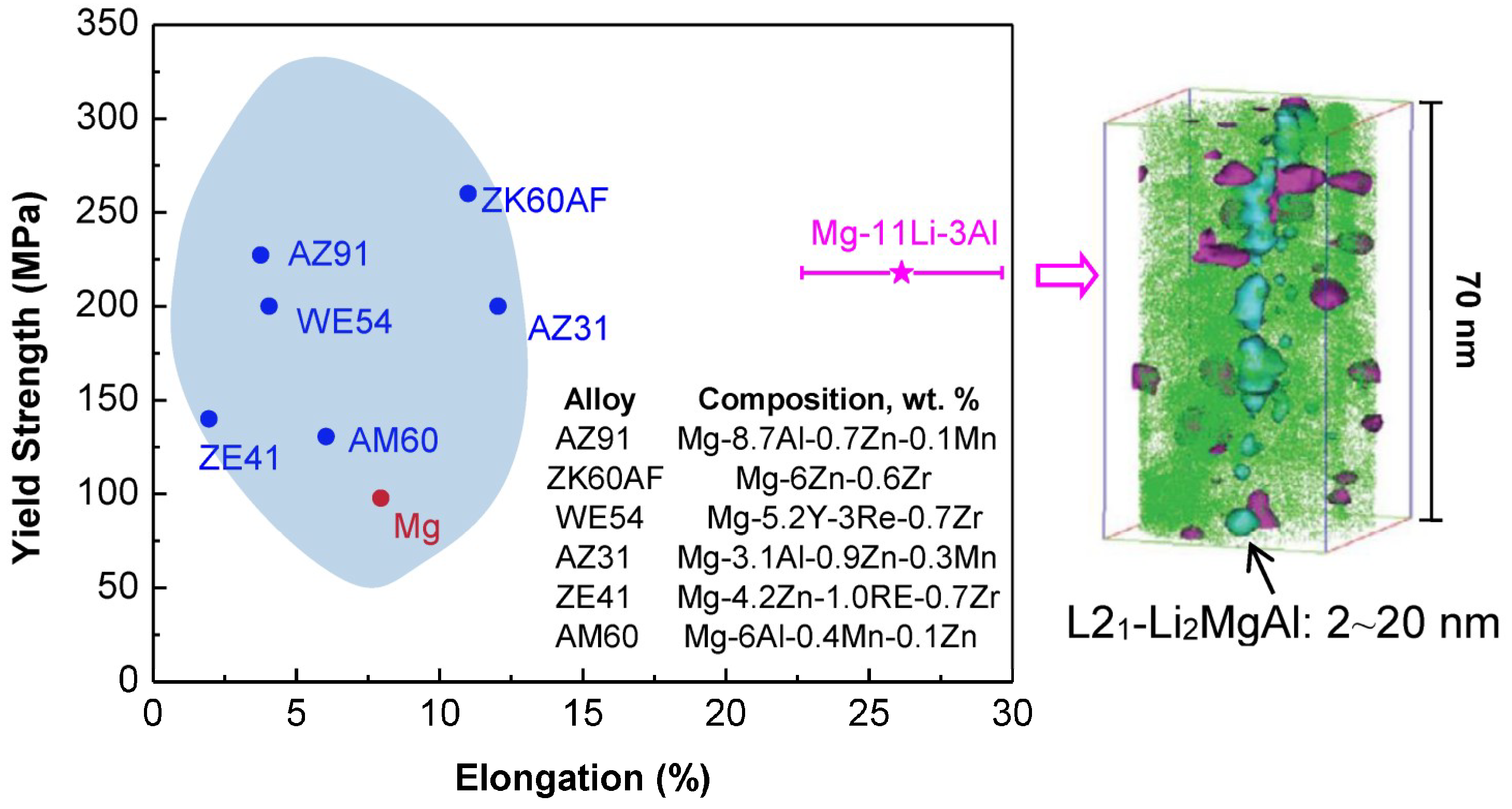

4.3. Mg-Based Alloys

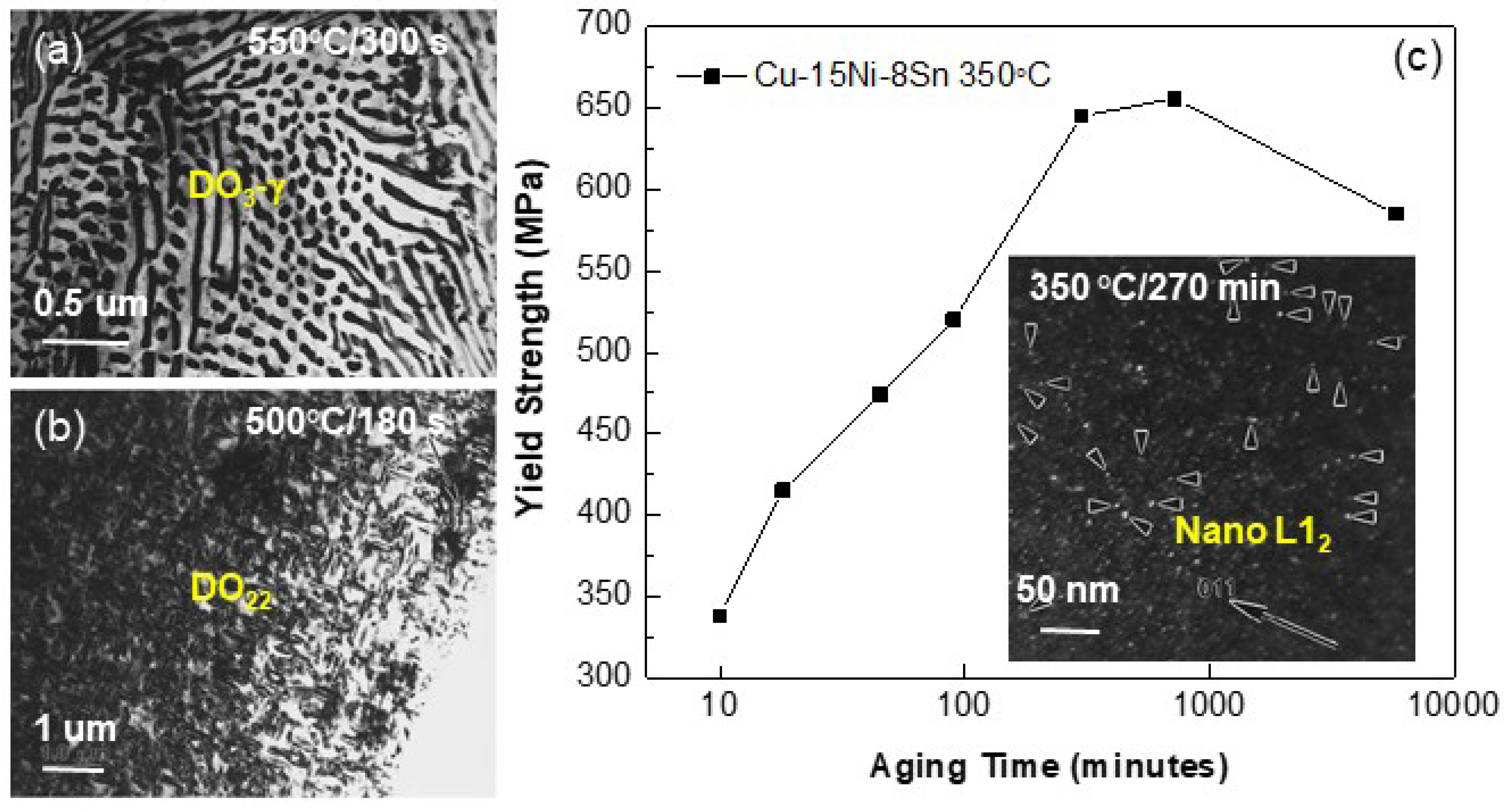

4.4. Cu-Based Alloys

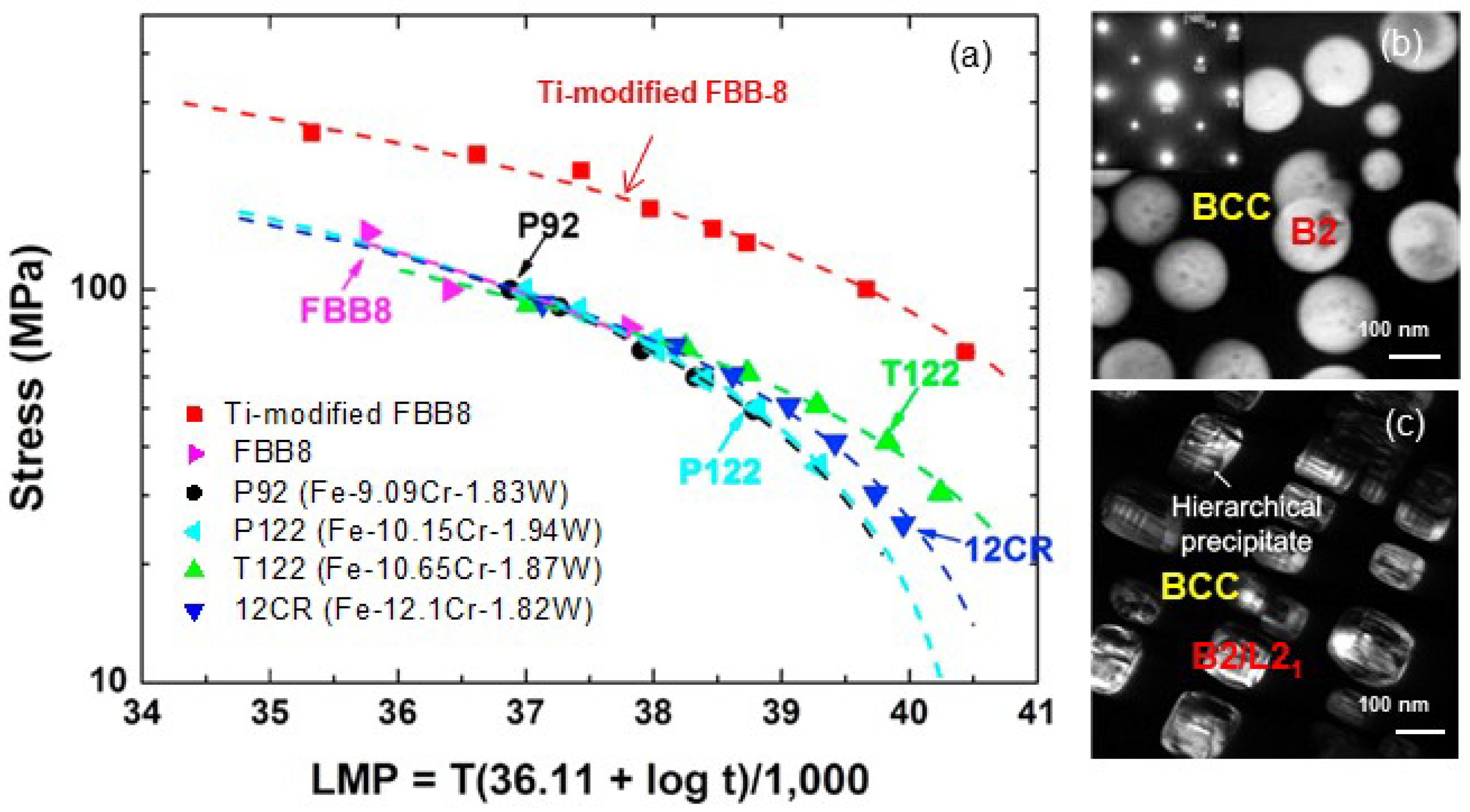

4.5. Fe-Based Stainless Steels

4.6. High-Entropy Alloys

5. Thoughts on the Coherent Precipitation Strengthening

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hosford, W.F. Mechanical Behavior of Materials, 1st ed.; Cambridge University Press: New York, NY, USA, 2005. [Google Scholar]

- Argon, A. Strengthening Mechanisms in Crystal Plasticity; Oxford University Press: Oxford, UK, 2007. [Google Scholar]

- Brown, L.M.; Ham, R.K. Dislocation-particle Interactions. In Strengthening Methods in Crystals; Kelly, A., Nicholson, R.B., Eds.; Elsevier: Amsterdam, The Netherlands, 1971. [Google Scholar]

- Giamei, A.F.; Anton, D.L. Rhenium additions to a Ni-base superalloy: Effects on microstructure. Metall. Trans. A 1985, 16, 1997–2005. [Google Scholar] [CrossRef]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: New York, NY, USA, 2006. [Google Scholar]

- Zhou, H.; Okada, I.; Ro, Y.; Koizumi, Y.; Kobayashi, K. Thermomechanical fatigue behavior of the third-generation, single-crystal superalloy TMS-75: Deformation structure. Metall. Mater. Trans. A 2004, 35, 1779–1787. [Google Scholar] [CrossRef]

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent developments in stainless steels. Mater. Sci. Eng. R 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Liu, Y.C.; Zhou, X.S.; Liu, C.X.; Yu, J.X.; Huang, Y.; Li, H.J.; Li, W.Y. Precipitation and hot deformation behavior of austenitic hear-resistant steels: A review. J. Mater. Sci. Technol. 2017, 33, 1448–1456. [Google Scholar] [CrossRef]

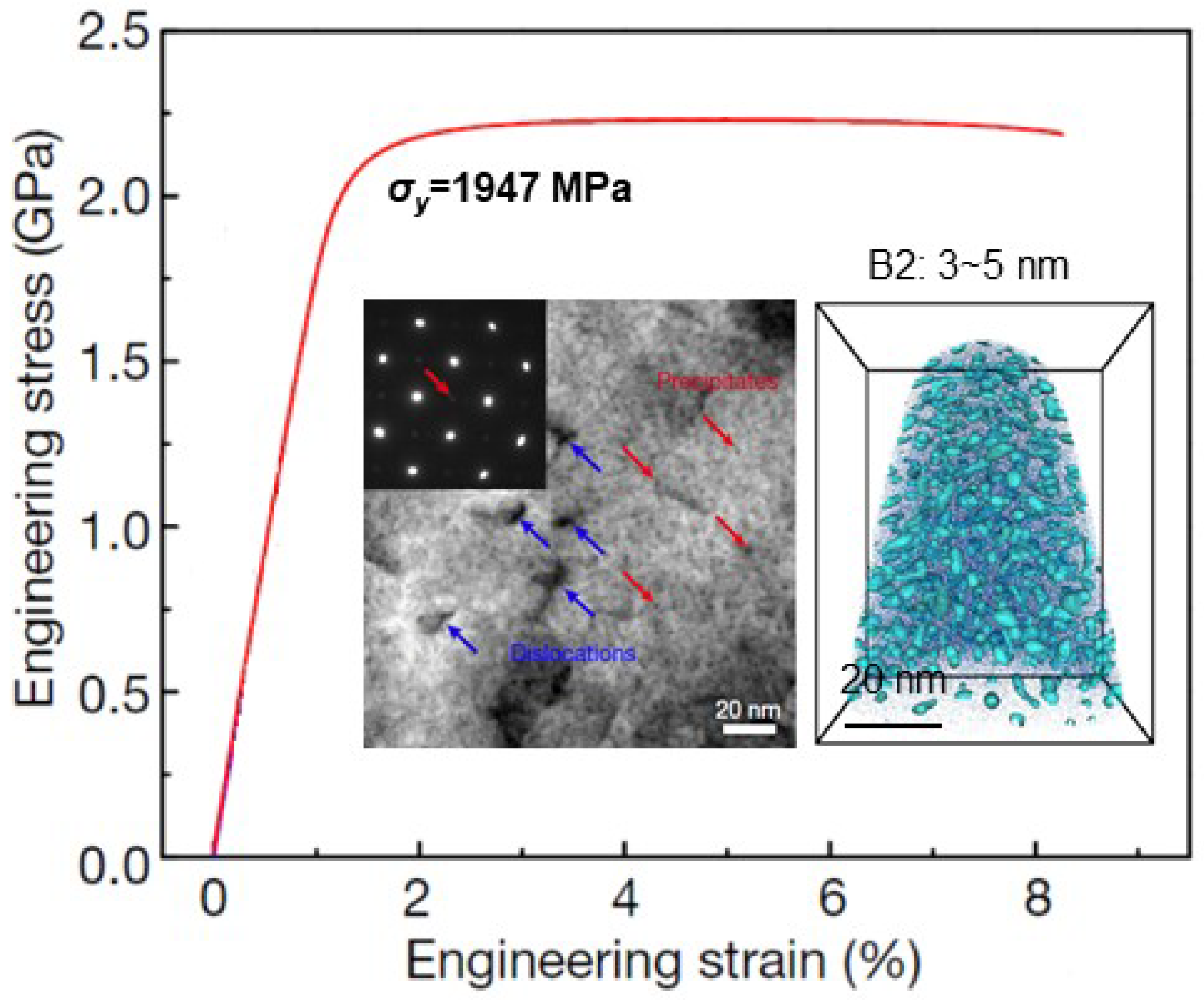

- Jiang, S.H.; Wang, H.; Wu, Y.; Liu, X.J.; Chen, H.H.; Yao, M.J.; Gault, B.; Ponge, D.; Raabe, D.; Hirata, A.; et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 2017, 544, 460–464. [Google Scholar] [CrossRef] [PubMed]

- Jiao, Z.B.; Luan, J.H.; Zhang, Z.W.; Liu, C.T. High-strength steels hardened mainly by nanoscale NiAl precipitates. Scr. Mater. 2014, 87, 45–48. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Miller, M.K.; Yu, C.Y.; Liu, C.T. Effects of Mn partitioning on nanoscale precipitation and mechanical properties of ferritic steels strengthened by NiAl nanoparticles. Acta Mater. 2015, 84, 283–291. [Google Scholar] [CrossRef] [Green Version]

- Teng, Z.K.; Miller, M.K.; Ghosh, G.; Liu, C.T.; Huang, S.; Russell, K.F.; Fine, M.E.; Liaw, P.K. Characterization of nanoscale NiAl-type precipitates in a ferritic steel by electron microscopy and atom probe tomography. Scr. Mater. 2010, 63, 61–64. [Google Scholar] [CrossRef]

- Vo, N.Q.; Liebscher, C.H.; Rawling, J.S.; Asta, M.; Dunand, D.C. Creep properties and microstructure of a precipitation-strengthened ferritic Fe-Al-Ni-Cr alloy. Acta Mater. 2014, 71, 89–99. [Google Scholar] [CrossRef]

- Aggen, G.; Allen, M. ASM Handbook Volume I, Properties and Selection: Irons, Steels, and High-Performance Alloys; The Materials Information Company: New York, NY, USA, 2018. [Google Scholar]

- Senkov, O.N.; Miller, J.D.; Miracle, D.B.; Woodward, C. Accelerated exploration of multi-principal element alloys with solid solution phases. Nat. Commun. 2015, 6, 6529–6535. [Google Scholar] [CrossRef] [PubMed]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2016, 122, 488–511. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Diao, H.; Xie, X.; Sun, F.; Dahmen, K.A.; Liaw, P.K. Mechanical Properties of High-Entropy Alloys. In High-Entropy Alloys: Fundamentals and Applications; Gao, M.C., Yeh, J.W., Liaw, P.K., Zhang, Y., Eds.; Springer International Publishing: Gewerbestrasse, Switzerland, 2016. [Google Scholar]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Youssef, K.M.; Zaddach, A.J.; Niu, C.; Irving, D.L.; Koch, C.C. A novel low-density, high-hardness, high-entropy alloy with close-packed single-phase nanocrystalline structures. Mater. Res. Lett. 2014, 2, 95–99. [Google Scholar] [CrossRef]

- Cahn, J.W.; Kalonji, G. Symmetry in Solid State Transformation Morphologies. In Proceedings of the International Conference on Solid-solid Phase Transformations, Whistler, BC, Canada, 28 June–3 July 1982. [Google Scholar]

- Khachaturyan, A.G. Theory of Structural Transformations in Solids; Wiley: New York, NY, USA, 1983. [Google Scholar]

- Ardell, A.J.; Nicholson, R.B. On the modulated structure of aged Ni-Al alloys: with an Appendix On the elastic interaction between inclusions by J. D. Eshelby. Acta Metall. 1966, 14, 1295–1309. [Google Scholar] [CrossRef]

- Doi, M.; Miyazaki, T.; Wakatsuki, T. The effects of elastic interaction energy on the γ′ precipitate morphology of continuously cooled nickel-base alloys. Mater. Sci. Eng. 1985, 74, 139–145. [Google Scholar] [CrossRef]

- Miyazaki, T.; Imamura, H.; Kozakai, T. The formation of “γ′ precipitate doublets” in Ni3Al alloys and their energetic stability. Mater. Sci. Eng. 1982, 54, 9–15. [Google Scholar] [CrossRef]

- Kaufman, M.J.; Voorhees, P.W.; Johnson, W.C.; Biancaniello, F.S. An elastically induced morphological instability of a misfitting precipitate. Metall. Trans. A 1989, 20, 2171–2175. [Google Scholar] [CrossRef]

- Glatzel, U.; Feller-Kniepmeier, M. Calculations of internal stresses in the γ/γ′ microstructure of a nickel-base superalloy with high volume fraction of γ′-phase. Scripta Metall. 1989, 23, 1839–1844. [Google Scholar] [CrossRef]

- Johnson, W.C.; Coorhees, P.W. Elastically-induced precipitate shape transitions in coherent solids. Solid State Phenom. 1992, 23, 87–103. [Google Scholar] [CrossRef]

- Khachaturyan, A.G.; Semenovskaya, S.V.; Morris, J.W., Jr. Theoretical analysis of strain-induced shape changes in cubic precipitates during coarsening. Acta Metall. 1988, 36, 1563–1572. [Google Scholar] [CrossRef] [Green Version]

- Voorhees, P.W.; Mcfadden, G.B.; Johnson, W.C. On the morphological development of second-phase particles in elastically-stressed solids. Acta Metall. Mater. 1992, 40, 2979–2992. [Google Scholar] [CrossRef]

- Thompson, M.E.; Su, C.S.; Voorhees, P.W. The equilibrium shape of a misfitting precipitate. Acta Metall. Mater. 1994, 42, 2107–2122. [Google Scholar] [CrossRef] [Green Version]

- Ardell, A.J. Precipitation hardening. Metall. Trans. A 1985, 16, 1985–2135. [Google Scholar] [CrossRef]

- Gerold, V.; Haberkorn, H. On the Critical Resolved Shear Stress of Solid Solutions Containing Coherent Precipitates. Phys. Stat. Sol. 1966, 16, 675–684. [Google Scholar] [CrossRef]

- Jansson, B.; Melander, A. On the critical resolved shear stress from misfitting particles. Scr. Metall. 1978, 12, 497–498. [Google Scholar] [CrossRef]

- Melander, A.; Persson, P.A. The strength of a precipitation hardened AlZnMg alloy. Acta Metall. 1978, 26, 267–278. [Google Scholar] [CrossRef]

- Nembach, E. Precipitation hardening caused by a difference in shear modulus between particle and matrix. Phys. Stat. Sol. 1983, 78, 571–581. [Google Scholar] [CrossRef]

- Gleiter, H.; Hornbogen, E. Theorie der wechselwirkung von versetzungen mit kohärenten geordneten zonen. Phys. Stat. Sol. 1965, 12, 235–250. [Google Scholar] [CrossRef]

- Zhang, J.X.; Wang, J.C.; Harada, H.; Koizumi, Y. The effect of lattice misfit on the dislocation motion in superalloys during high-temperature low-stress creep. Acta Mater. 2005, 53, 4623–4633. [Google Scholar] [CrossRef]

- Ding, Q.Q.; Li, S.X.; Chen, L.Q.; Han, X.D.; Zhang, Z.; Yu, Q.; Li, J.X. Re segregation at interfacial dislocation network in a nickel-based superalloy. Acta Mater. 2018, 154, 137–146. [Google Scholar] [CrossRef]

- Andersen, S.J.; Zandbergen, H.W.; Jansen, J.; Traeholt, C.; Tundal, U.; Reiso, O. The crystal structure of the β″ phase in Al-Mg-Si alloys. Acta Mater. 1998, 46, 3283–3298. [Google Scholar] [CrossRef]

- Murayama, M.; Hono, K. Pre-precipitate clusters and precipitation processes in Al-Mg-Si alloys. Acta Mater. 1999, 47, 1537–1548. [Google Scholar] [CrossRef]

- Fuller, C.B.; Murray, J.L.; Seidman, D.N. Temporal evolution of the nanostructure of Al(Sc,Zr) alloys: Part I-Chemical compositions of Al(ScxZrx) precipitates. Acta Mater. 2005, 53, 5401–5413. [Google Scholar] [CrossRef]

- Sha, G.; Cerezo, A. Early-stage precipitation in Al-Zn-Mg-Cu alloy (7050). Acta Mater. 2004, 52, 4503–4516. [Google Scholar] [CrossRef]

- Marlaud, T.; Deschamps, A.; Bley, F.; Lefebvre, W.; Baroux, B. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys. Acta Mater. 2010, 58, 248–260. [Google Scholar] [CrossRef]

- Gayle, F.W.; Goodway, M. Precipitation hardening in the first aerospace aluminum alloy: the wright flyer crankcase. Science 1994, 266, 1015–1507. [Google Scholar] [CrossRef] [PubMed]

- Biswas, A.; Siegel, D.J.; Wolverton, C.; Seidman, D.N. Precipitates in Al-Cu alloys revisited: Atom-probe tomographic experiments and first-principles calculations of compositional evolution and interfacial segregation. Acta Mater. 2011, 59, 6187–6204. [Google Scholar] [CrossRef]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The precipitation sequence in Al-Mg-Si alloys. Acta Mater. 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

- Booth-Morrison, C.; Dunand, D.C.; Seidman, D.N. Coarsening resistance at 400 °C of precipitation-strengthened Al-Zr-Sc-Er alloys. Acta Mater. 2011, 59, 7029–7042. [Google Scholar] [CrossRef]

- Wen, S.P.; Gao, K.Y.; Huang, H.; Nie, W.Z.R. Precipitation evolution in Al-Er-Zr alloys during aging at elevated temperature. J. Alloy. Compd. 2013, 574, 92–97. [Google Scholar] [CrossRef]

- Li, H.Y.; Bin, J.; Liu, J.J.; Gao, Z.H.; Lu, X.C. Precipitation evolution and coarsening resistance at 400 °C of Al microalloyed with Zr and Er. Scr. Mater. 2012, 67, 73–76. [Google Scholar] [CrossRef]

- Marquis, E.A.; Seidman, D.N. Nanoscale structural evolution of Al3Sc precipitates in Al(Sc) alloys. Acta Mater. 2001, 49, 1909–1919. [Google Scholar] [CrossRef]

- Seidman, D.N.; Marquis, E.A.; Dunand, D.C. Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys. Acta Mater. 2002, 50, 4021–4035. [Google Scholar] [CrossRef]

- Clouet, E.; Nastar, M.; Barbu, A.; Sigli, C.; Martin, G. An Atomic and Mesoscopic Study of Precipitation Kinetics in Al-Zr-Sc Alloys. Adv. Eng. Mater. 2006, 8, 1228–1231. [Google Scholar] [CrossRef]

- Avedesian, M.M.; Baker, H. ASM Specialty Handbook: Magnesium and Magnesium Alloys; ASM International: Headquarters, OH, USA, 1999. [Google Scholar]

- Nie, J.F. Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

- Wang, D.S.; Amsler, M.; Hegde, V.I.; Saal, J.E.; Issa, A.; Zhou, B.C.; Zeng, X.Q.; Wolverton, C. Crystal structure, energetics, and phase stability of strengthening precipitates in Mg alloys: A first-principles study. Acta Mater. 2018, 158, 65–78. [Google Scholar] [CrossRef]

- Duly, D.; Zhang, W.Z.; Audier, M. High-resolution electron microscopy observations of the interface structure of continuous precipitates in a Mg-Al alloy and interpretation with the O-lattice theory. Philos. Mag. A 1995, 71, 187–204. [Google Scholar] [CrossRef]

- Nie, J.F.; Xiao, X.L.; Luo, C.P.; Muddle, B.C. Characterisation of precipitate phases in magnesium alloys using electron microdiffraction. Micron 2001, 32, 857–863. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, W.Z.; Ye, F. Interpretation of precipitation crystallography of Mg17Al12 in a Mg-Al alloy in terms of singular interfacial structure. Metall. Mater. Trans. A 2005, 36, 1681–1688. [Google Scholar] [CrossRef]

- Geng, J.; Gao, X.; Fang, X.Y.; Nie, J.F. Enhanced age-hardening response of Mg-Zn alloys via Co additions. Scr. Mater. 2011, 64, 506–509. [Google Scholar] [CrossRef]

- Hono, K.; Mendis, C.L.; Sasaki, T.T.; Oh-Ishi, K. Towards the development of heat-treatable high-strength wrought Mg alloys. Scr. Mater. 2010, 63, 710–715. [Google Scholar] [CrossRef]

- Bettles, C.J.; Gibson, M.A.; Venkatesan, K. Enhanced age-hardening behaviour in Mg-4 wt.% Zn micro-alloyed with Ca. Scr. Mater. 2004, 51, 193–197. [Google Scholar] [CrossRef]

- Homma, T.; Nakawaki, S.; Oh-ishi, K.; Hono, K.; Kamado, S. Unexpected influence of Mn addition on the creep properties of a cast Mg-2Al-2Ca (mass%) alloy. Acta Mater. 2011, 59, 7662–7672. [Google Scholar] [CrossRef]

- Wilson, R.; Bettles, C.J.; Muddle, B.C.; Nie, J.F. Precipitation hardening in Mg-3 wt% Nd (-Zn) casting alloys. Mater. Sci. Forum 2003, 419, 267–272. [Google Scholar] [CrossRef]

- Nishijima, M.; Hiraga, K.; Yamasaki, M.; Kawamura, Y. Characterization of β′ Phase Precipitates in an Mg-5 at% Gd Alloy Aged in a Peak Hardness Condition, Studied by High-Angle Annular Detector Dark-Field Scanning Transmission Electron Microscopy. Mater. Trans. 2006, 47, 2109–2122. [Google Scholar] [CrossRef]

- Nie, J.F.; Muddle, B.C. Characterisation of strengthening precipitate phases in a M-Y-Nd alloy. Acta Mater. 2000, 48, 1691–1703. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P.M. Morphology and crystallography of Mg24Y5 precipitate in Mg-Y alloy. Scr. Mater. 2003, 48, 379–384. [Google Scholar] [CrossRef]

- Hilditch, T.; Nie, J.F.; Muddle, B.C. The Effect of Cold Work on Precipitation in Alloy WE54. In Magnesium Alloys and Their Applications; Mordike, B.L., Kainer, K.U., Eds.; Werkstoff-Informat: Frankfurt, Germany, 1998; pp. 339–344. [Google Scholar]

- Nie, J.F.; Oh-ishi, K.; Gao, X.; Hono, K. Solute segregation and precipitation in a creep-resistant Mg-Gd-Zn alloy. Acta Mater. 2008, 56, 6061–6076. [Google Scholar] [CrossRef]

- Gao, X.; He, S.M.; Zeng, X.Q.; Peng, L.M.; Ding, W.J.; Nie, J.F. Microstructure evolution in a Mg-15Gd-0.5Zr (wt.%) alloy during isothermal aging at 250 °C. Mater. Sci. Eng. A 2006, 431, 322–327. [Google Scholar] [CrossRef]

- Nishijima, M.; Hiraga, K. Structural changes of precipitates in an Mg-5at%Gd alloy studied by transmission electron microscopy. Mater. Trans. 2007, 48, 10–15. [Google Scholar] [CrossRef]

- Xu, W.Q.; Birbilis, N.; Sha, G.; Wang, Y.; Daniels, J.E.; Xiao, Y.; Ferry, M. A high-specific-strength and corrosion-resistant magnesium alloy. Nature 2015, 14, 1229–1236. [Google Scholar] [CrossRef] [PubMed]

- Carisa, J.; Li, D.Q.; Stephens, J.J., Jr.; Lewandowskia, J.J. Microstructural effects on tension behavior of Cu-15Ni-8Sn sheet. Mater. Sci. Eng. A 2010, 527, 769–781. [Google Scholar] [CrossRef]

- Spooner, S.; Lefevre, B.G. The effect of prior deformation on spinodal age hardening in Cu-15Ni-8Sn alloy. Metall. Trans. A 1980, 11, 1085–1093. [Google Scholar] [CrossRef]

- Zhao, J.C.; Notis, M.R. Spinodal decomposition, ordering transformation, and discontinuous precipitation in a Cu-15Ni-8Sn alloy. Acta Mater. 1998, 46, 4203–4218. [Google Scholar] [CrossRef]

- Lefevre, B.G.; D’annessa, A.T.; Kalish, D. Age hardening in Cu-15Ni-8Sn alloy. Metall. Trans. A 1978, 9, 577–586. [Google Scholar] [CrossRef]

- Hermann, P.; Morris, D.G. Relationship between microstructure and mechanical properties of a spinodally decomposing Cu-15Ni-8Sn alloy prepared by spray deposition. Metall. Mater. Trans. A 1994, 25, 1403–1412. [Google Scholar] [CrossRef]

- Sun, Z.Q.; Edmondson, P.D.; Yamamoto, Y. Effects of Laves phase particles on recovery and recrystallization behaviors of Nb-containing FeCrAl alloys. Acta Mater. 2018, 144, 716–727. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Brady, M.P.; Lu, Z.P.; Maziasz, P.J.; Liu, C.T.; Pint, B.A.; More, K.L.; Meyer, H.M.; Payzant, E.A. Creep-resistant, Al2O3-forming austenitic stainless steels. Science 2007, 316, 433–436. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.M.; Tjong, S.C.; Lai, K.L. Creep behavior of a β′(NiAl) precipitation strengthened ferritic Fe-Cr-Ni-Al alloy. Acta Mater. 1998, 46, 2969–2976. [Google Scholar] [CrossRef]

- Stallybrass, C.; Schneider, A.; Sauthoff, G. The strengthening effect of (Ni, Fe)Al precipitates on the mechanical properties at high temperatures of ferritic Fe-Al-Ni-Cr alloys. Intermetallics 2005, 13, 1263–1271. [Google Scholar] [CrossRef]

- Teng, Z.K.; Liu, C.T.; Ghosh, G.; Liaw, P.K.; Fine, M.E. Effects of Al on the microstructure and ductility of NiAl-strengthened ferritic steels at room temperature. Intermetallics 2010, 18, 1437–1443. [Google Scholar] [CrossRef]

- Teng, Z.K.; Ghosh, G.; Miller, M.K.; Huang, S.; Clausen, B.; Brown, D.W.; Liaw, P.K. Neutron-diffraction study and modeling of the lattice parameters of a NiAl-precipitate-strengthened Fe-based alloy. Acta Mater. 2012, 60, 5362–5369. [Google Scholar] [CrossRef]

- Teng, Z.K.; Zhang, F.; Miller, M.K.; Liu, C.T.; Huang, S.; Chou, Y.T.; Tien, R.H.; Chang, Y.A.; Liaw, P.K. New NiAl-strengthened ferritic steels with balanced creep resistance and ductility designed by coupling thermodynamic calculations with focused experiments. Intermetallics 2012, 29, 110–115. [Google Scholar] [CrossRef]

- Huang, S.; Gao, Y.; An, K.; Zheng, L.; Wu, W.; Teng, Z.; Liaw, P.K. Deformation mechanisms in a precipitation-strengthened ferritic superalloy revealed by in situ neutron diffraction studies at elevated temperatures. Acta Mater. 2015, 83, 137–148. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.; Song, G.; Ilavsky, J.; Liaw, P.K. Nano-sized precipitate stability and its controlling factors in a NiAl-strengthened ferritic alloy. Sci. Rep. 2015, 5, 16081. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, G.; Sun, Z.Q.; Poplawsky, J.D.; Xu, X.D.; Chen, M.W.; Liaw, P.K. Primary and secondary precipitates in a hierarchical-precipitate-strengthened ferritic alloy. J. Alloy. Compd. 2017, 706, 584. [Google Scholar] [CrossRef]

- Song, G.; Sun, Z.Q.; Poplawsky, J.D.; Gao, Y.; Liaw, P.K. Microstructural evolution of single Ni2TiAl or hierarchical NiAl/Ni2TiAl precipitates in Fe-Ni-Al-Cr-Ti ferritic alloys during thermal treatment for elevated-temperature applications. Acta Mater. 2017, 127, 1–16. [Google Scholar] [CrossRef]

- Hattestrand, M.; Nilsson, J.O.; Stiller, K.; Liu, P.; Andersson, M. Precipitation hardening in a 12%Cr-9%Ni-4%Mo-2% Cu stainless steel. Acta Mater. 2004, 52, 1023–1037. [Google Scholar] [CrossRef]

- Schober, M.; Schnitzer, R.; Leitner, H. Precipitation evolution in a Ti-free and Ti-containing stainless maraging steel. Ultramicroscopy 2009, 109, 553–562. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Rivera-Diaz-del-Castillo, P.E.J.; Yan, W.; Yang, K.; Martin, D.S.; Kestens, L.A.I.; Zwaag, S. A new ultrahigh-strength stainless steel strengthened by various coexisting nanoprecipitates. Acta Mater. 2010, 58, 4067–4075. [Google Scholar] [CrossRef] [Green Version]

- Ifergane, S.; Sabatani, E.; Carmeli, B.; Barkay, Z.; Ezersky, V.; Beeri, O.; Eliaz, N. Hydrogen diffusivity measurement and microstructural characterization of Custom 465 stainless steel. Electrochim. Acta 2015, 178, 494–503. [Google Scholar] [CrossRef]

- Liu, W.H.; Wu, Y.; He, J.Y.; Nieh, T.G.; Lu, Z.P. Grain growth and the Hall-Petch relationship in a high entropy alloy FeCrNiCoMn. Scr. Mater. 2013, 68, 526–529. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Raabe, D.; Tasan, C.C.; Springer, H.; Bausch, M. From High-entropy alloys to high-entropy steels. Steel Res. Int. 2015, 86, 1127–1138. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schuh, B.; Mendez-Martin, F.; Volker, B.; George, E.P.; Clemens, H.; Pippan, R.; Hohenwarter, A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015, 96, 258–268. [Google Scholar] [CrossRef] [Green Version]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Owen, L.R.; Pickering, E.J.; Playford, H.Y.; Stone, H.J.; Yucker, M.G.; Jones, N.G. An assessment of the lattice strain in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2017, 122, 11–18. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef] [Green Version]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Mao, M.M.; Wang, J.; Gludovatz, B.; Zhang, Z.; Mao, S.X.; George, E.P.; Yu, Q.; Ritchie, R.O. Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2015, 6, 10143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Na, Y.S.; Lim, K.R.; Chang, H.J.; Kim, J. Effect of trace additions of Ti on the microstructure of AlCoCrFeNi-based high entropy alloy. Sci. Adv. Mater. 2016, 8, 1984–1988. [Google Scholar] [CrossRef]

- Li, D.Y.; Li, C.X.; Feng, T.; Zhang, Y.D.; Shang, G.; Lewandowski, J.J.; Liaw, P.K.; Zhang, Y. High-entropy Al0.3CoCrFeNi alloy fibers with high tensile strength and ductility at ambient and cryogenic temperatures. Acta Mater. 2017, 123, 285–294. [Google Scholar] [CrossRef]

- Li, C.L.; Ma, Y.; Hao, J.M.; Wang, Q.; Pang, S.J.; Dong, C.; Liaw, P.K. Effect of Ti substitution for Al on the cuboidal nanoprecipitates in Al0.7NiCoFeCr2 high-entropy alloys. J. Mater. Res. 2018, 33, 3266–3275. [Google Scholar] [CrossRef]

- Li, C.L.; Ma, Y.; Hao, J.M.; Yan, Y.; Wang, Q.; Dong, C.; Liaw, P.K. Microstructures and mechanical properties of body-centered-cubic (Al,Ti)0.7(Ni,Co,Fe,Cr)5 high entropy alloys with coherent B2/L21 nanoprecipitation. Mater. Sci. Eng. A 2018, 737, 286–296. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Tikhonovsky, M.A.; Zherebtsov, S.V. Structure and high temperature mechanical properties of novel nonequiatomic Fe-(Co,Mn)-Cr-Ni-Al-(Ti) high entropy alloys. Intermetallics 2018, 102, 140–151. [Google Scholar] [CrossRef]

- Niu, S.Z.; Kou, H.C.; Guo, T.; Zhang, Y.; Wang, J.; Li, J.S. Strengthening of nanoprecipitations in an annealed Al0.5CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 2016, 671, 82–86. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C. Effect of aluminum on the microstructure and properties of two refractory high-entropy alloys. Acta Mater. 2014, 68, 214–228. [Google Scholar] [CrossRef]

- Singh, S.; Wanderka, N.; Murty, B.S.; Glatzel, U.; Banhart, J. Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater. 2011, 59, 182–190. [Google Scholar] [CrossRef]

- Hemphill, M.A.; Yuan, T.; Wang, G.Y.; Yeh, J.W.; Tsai, C.W.; Chuang, A.; Liaw, P.K. Fatigue behavior of high entropy alloys. Acta Mater. 2012, 60, 5723–5734. [Google Scholar] [CrossRef]

- Wang, Y.P.; Li, B.S.; Ren, M.X.; Yang, C.; Fu, H.Z. Microstructure and compressive properties of AlCrFeCoNi high entropy alloy. Mater. Sci. Eng. A 2008, 491, 154–158. [Google Scholar] [CrossRef]

- Kao, Y.F.; Chen, T.J.; Chen, S.K.; Yeh, J.W. Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. J. Alloy. Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Wang, W.R.; Wang, W.L.; Yeh, J.W. Phases, microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures. J. Alloy. Compd. 2014, 589, 143–152. [Google Scholar] [CrossRef]

- Shun, T.T.; Du, Y.C. Microstructure and tensile behaviors of FCC Al0.3CoCrFeNi high entropy alloy. J. Alloy. Compd. 2009, 479, 157–160. [Google Scholar] [CrossRef]

- Ma, Y.; Jiang, B.B.; Li, C.L.; Wang, Q.; Dong, C.; Liaw, P.K.; Xu, F.; Sun, L. The BCC/B2 morphologies in AlxNiCoFeCr high-entropy alloys. Metals 2017, 7, 57. [Google Scholar] [CrossRef]

- Wang, Q.; Ma, Y.; Jiang, B.B.; Li, X.N.; Shi, Y.; Dong, C.; Liaw, P.K. A cuboidal B2 nanoprecipitation-enhanced body-centered-cubic alloy Al0.7CoCrFe2Ni with prominent tensile properties. Scr. Mater. 2016, 120, 85–89. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, Q.; Jiang, B.B.; Li, C.L.; Hao, J.M.; Li, X.N.; Dong, C.; Nieh, T.G. Controlled formation of coherent cuboidal nanoprecipitates in body-centered cubic high-entropy alloys based on Al2(Ni,Co,Fe,Cr)14 compositions. Acta Mater. 2018, 147, 213–225. [Google Scholar] [CrossRef]

- Zhou, Y.; Jin, X.; Zhang, L.; Du, X.Y.; Li, B.S. A hierarchical nanostructured Fe34Cr34Ni14Al14Co4 high-entropy alloy with good compressive mechanical properties. Mater. Sci. Eng. A 2018, 716, 235–239. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, D.; Li, B.S. Anomalous microstructure and excellent mechanical properties of Ni35Al21.67Cr21.67Fe21.67 high-entropy alloy with BCC and B2 structure. Mater. Lett. 2018, 216, 252–255. [Google Scholar] [CrossRef]

- Shaysultanov, D.G.; Salishchev, G.A.; Ivanisenko, Y.V.; Zherebtsov, S.V.; Tikhonovsky, M.A.; Stepanov, N.D. Novel Fe36Mn21Cr18Ni15Al10 high entropy alloy with bcc/B2 dual-phase structure. J. Alloy. Compd. 2017, 705, 756–763. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Chernichenko, R.S.; Tikhonovsky, M.A.; Zherebtsov, S.V. Effect of Al on structure and mechanical properties of Fe-Mn-Cr-Ni-Al non-equiatomic high entropy alloys with high Fe content. J. Alloy. Compd. 2019, 770, 194–203. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef] [Green Version]

- Tsao, T.K.; Yeh, A.C.; Kuo, C.M.; Murakami, H. On the superior high temperature hardness of precipitation strengthened high entropy Ni-based alloys. Adv. Eng. Mater. 2017, 19, 1600475. [Google Scholar] [CrossRef]

- Daoud, H.M.; Manzoni, A.; Volkl, R.; Wanderka, N.; Glatzel, U. Microstructure and tensile behavior of Al8Co17Cr17Cu8Fe17Ni33 (at. %) high-entropy alloy. JOM 2013, 65, 1805–1814. [Google Scholar] [CrossRef]

- Senkov, O.N.; Isheim, D.; Seidman, D.N.; Pilchak, A.L. Development of a refractory high entropy superalloy. Entropy 2016, 18, 102. [Google Scholar] [CrossRef]

- Soni, V.; Senkov, O.N.; Gwalani, B.; Miracle, D.B.; Banerjee, R. Microstructural design for improving ductility of an initially brittle refractory high entropy alloy. Sci. Rep. 2018, 8, 8816. [Google Scholar] [CrossRef] [PubMed]

- Tsai, C.W.; Tsai, M.H.; Yeh, J.W.; Yang, C.C. Effect of temperature on mechanical properties of Al0.5CoCrCuFeNi wrought alloy. J. Alloy. Compd. 2010, 490, 160–165. [Google Scholar] [CrossRef]

- Zhang, W.R.; Liaw, P.K.; Zhang, Y. Science and technology in high-entropy alloys. Sci. China Mater. 2018, 61, 2–22. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.G.; Liu, J.L.; Jin, T.; Sun, X.F. The effects of ruthenium additions on tensile deformation mechanisms of single crystal superalloys at different temperatures. Mater. Des. 2014, 63, 286–293. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.D.; Cheng, S.C. Microstructure Evolution and Mechanical Porperties of HR3C Steel during Long term Aging at High Temperature. J. Iron Steel Res. Int. 2014, 21, 765–773. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, Z.F.; Tu, H.Y. Microstructure evolution in HR3C austenitic steel during long-term creep at 650 °C. Mater. Sci. Eng. A 2017, 681, 74–84. [Google Scholar] [CrossRef]

- Physical Constants and Thermal Properties. Available online: http://www.specialmetals.com/assets/smc/documents/alloys/inconel/inconel-alloy-718.pdf (accessed on 14 November 2018).

- Chaturvedi, M.C.; Han, Y. Effect of particle size on the creep rate of superalloy Inconel 718. Mater. Sci. Eng. 1987, 89, L7–L10. [Google Scholar] [CrossRef]

- Ma, Y.; Hao, J.M.; Wang, Q.; Zhang, C.; Li, C.L.; Dong, C. Microstructural stability of coherent cuboidal B2 particles in precipitation-strengthened body-centered-cubic Al0.7NiCoFeCr2 high-entropy alloy. J. Mater. Sci 2018. submitted. [Google Scholar]

- Cowley, J.M. Short- and long-range order parameters in disordered solid solutions. Phys. Rev. 1960, 120, 1648–1657. [Google Scholar] [CrossRef]

- Reinhard, L.; Schönfeld, B.; Kostorz, G.; Bührer, W. Short-range order in α-brass. Phys. Rev. B 1990, 41, 1727–1734. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, Q.; Li, C.L.; Santodonato, L.J.; Feygenson, M.; Dong, C.; Liaw, P.K. Chemical short-range orders and the induced structural transition in high-entropy alloys. Scr. Mater. 2018, 144, 64–68. [Google Scholar] [CrossRef]

- Hong, H.L.; Wang, Q.; Dong, C.; Liaw, P.K. Understanding the Cu-Zn brass alloys using a short-range-order cluster model: significance of specific compositions of industrial alloys. Sci. Rep. 2014, 4, 7065. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, Y.P.; Dong, D.D.; Dong, C.; Luo, L.J.; Wang, Q.; Qiang, J.B.; Wang, Y.M. Composition formulas of binary eutectics. Sci. Rep. 2015, 5, 17880. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Alloys | Matrix Phase | Particle Size (nm) and Morphology of Precipitated Phase at RT | Mechanical Properties | ||

|---|---|---|---|---|---|

| Temp. (°C) | σy (MPa) | δ (%) | |||

| (NiCoFeCr)94Ti2Al4 (at.%) [125] (tensile test) | FCC | 25 Spherical L12 | RT | 1005 | 17 |

| Ni48.6Al10.3Co17Cr7.5Fe9.0Ti5.8Ta0.6Mo0.8W0.4 (at.%) [126] (microhardness test) | FCC | 287 Spherical L12 | RT | 1230 | - |

| 500 | 1128 | - | |||

| 700 | 1056 | - | |||

| 900 | 918 | - | |||

| Fe36Co21Cr18Ni15Al10 (at.%) [123] (compressive test) | FCC | 90 plate-like B2/BCC | RT | 250 | >50 |

| 400 | 155 | >50 | |||

| 600 | 150 | >50 | |||

| Al0.3FeCoNiCr [117] (tensile test) | FCC | 35 Spherical L12 | RT | 160 | 60.8 |

| Al0.5CoCuCrFeNi [113,131] (tensile test) | FCC | 200~400 Spherical L12 | RT | 1290 | 5.7 |

| 600 | 425 | 2.8 | |||

| 700 | 186 | 5.4 | |||

| Al8Co17Cr17Cu8Fe17Ni33 (at.%) [127] (tensile test) | FCC | <20 Spherical L12 | RT | 357 | 9 |

| 500 | 315 | 0.7 | |||

| Fe36Mn21Cr18Ni15Al10 (at.%) [123] (tensile test) | BCC | 160 Cuboidal B2 | RT | 750 | 2.5 |

| 400 | 640 | 20 | |||

| 500 | 515 | 42 | |||

| 600 | 310 | 55 | |||

| Fe35Mn20Cr17Ni12Al12Ti4 (at.%) [109] (compressive test) | BCC | 190 Cuboidal L21 | RT | 1280 | 31 |

| 400 | 1100 | >50 | |||

| 600 | 355 | >50 | |||

| Fe35Co20Cr17Ni12Al12Ti4 (at.%) [109] (compressive test) | BCC | 65 Plate-like L21 | RT | 1420 | 18 |

| 400 | 1285 | 24 | |||

| 600 | 795 | >50 | |||

| 800 | 285 | >50 | |||

| Al0.7NiCoFe2Cr [119] (tensile test) | BCC | 50~90 Cuboidal B2 | RT | 1085 | 8.2 |

| 650 | 454 | 6.4 | |||

| 700 | 108 | 5.5 | |||

| Al0.7NiCoFeCr2 [120] (compressive test) | BCC | 80~120 Cuboidal B2 | RT | 1718 | 26.5 |

| (Al2Ti)0.7NiCoFeCr2 [107] (compressive test) | BCC | 50~60 Cuboidal L21 | RT | 1808 | 35 |

| AlMo0.5NbTa0.5TiZr [128] (compressive test) | B2 | 10~55 Cuboidal & plate-like BCC | RT | 2000 | 10 |

| 600 | 1870 | 10 | |||

| 800 | 1597 | 11 | |||

| 1000 | 745 | >50 | |||

| 1200 | 250 | >50 | |||

| Al0.5NbTa0.8Ti1.5V0.2Zr [129] (compressive test) | BCC | 50 Spherical B2 | RT | 1345 | 38 |

| 600 | 1423 | 16.2 | |||

| HR3C Fe54.73Cr24.01Ni20.6C0.05Nb0.37N0.24 (wt.%) [132,133] (tensile test) | FCC | 25~30 Spherical Z-NbCrN phase | RT | 368 | 48 |

| 650 | 180 | 46 | |||

| Ti-modified FBB8 Fe67.85Al6.5Ni10Cr10Mo3.4Ti2Zr0.25B0.005 (wt.%) [89,90] (In-situ tensile test) | BCC | 84~138 Cuboidal L21 | RT | 1138 MPa, converted from HV value | |

| 700 | 230 | 7.5 | |||

| Inonel 718 Ni53Fe18.5Cr19Nb5.1Mo3.0Ti0.9Al0.5 (wt.%) [134,135] (tensile test) | FCC | 15~25 Spherical γ′-L12 and γ′′-Ni3Nb | RT | 1206 | 17.8 |

| 600 | 1048 | 17.1 | |||

| 700 | 979 | 20.5 | |||

| 800 | 629 | 28.0 | |||

| 900 | 262 | 83.0 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Li, Z.; Pang, S.; Li, X.; Dong, C.; Liaw, P.K. Coherent Precipitation and Strengthening in Compositionally Complex Alloys: A Review. Entropy 2018, 20, 878. https://doi.org/10.3390/e20110878

Wang Q, Li Z, Pang S, Li X, Dong C, Liaw PK. Coherent Precipitation and Strengthening in Compositionally Complex Alloys: A Review. Entropy. 2018; 20(11):878. https://doi.org/10.3390/e20110878

Chicago/Turabian StyleWang, Qing, Zhen Li, Shujie Pang, Xiaona Li, Chuang Dong, and Peter K. Liaw. 2018. "Coherent Precipitation and Strengthening in Compositionally Complex Alloys: A Review" Entropy 20, no. 11: 878. https://doi.org/10.3390/e20110878

APA StyleWang, Q., Li, Z., Pang, S., Li, X., Dong, C., & Liaw, P. K. (2018). Coherent Precipitation and Strengthening in Compositionally Complex Alloys: A Review. Entropy, 20(11), 878. https://doi.org/10.3390/e20110878