Superstructure-Based Optimization of Vapor Compression-Absorption Cascade Refrigeration Systems

Abstract

:1. Introduction

2. Process Description

2.1. Vapor Absorption Refrigeration System (VARS)

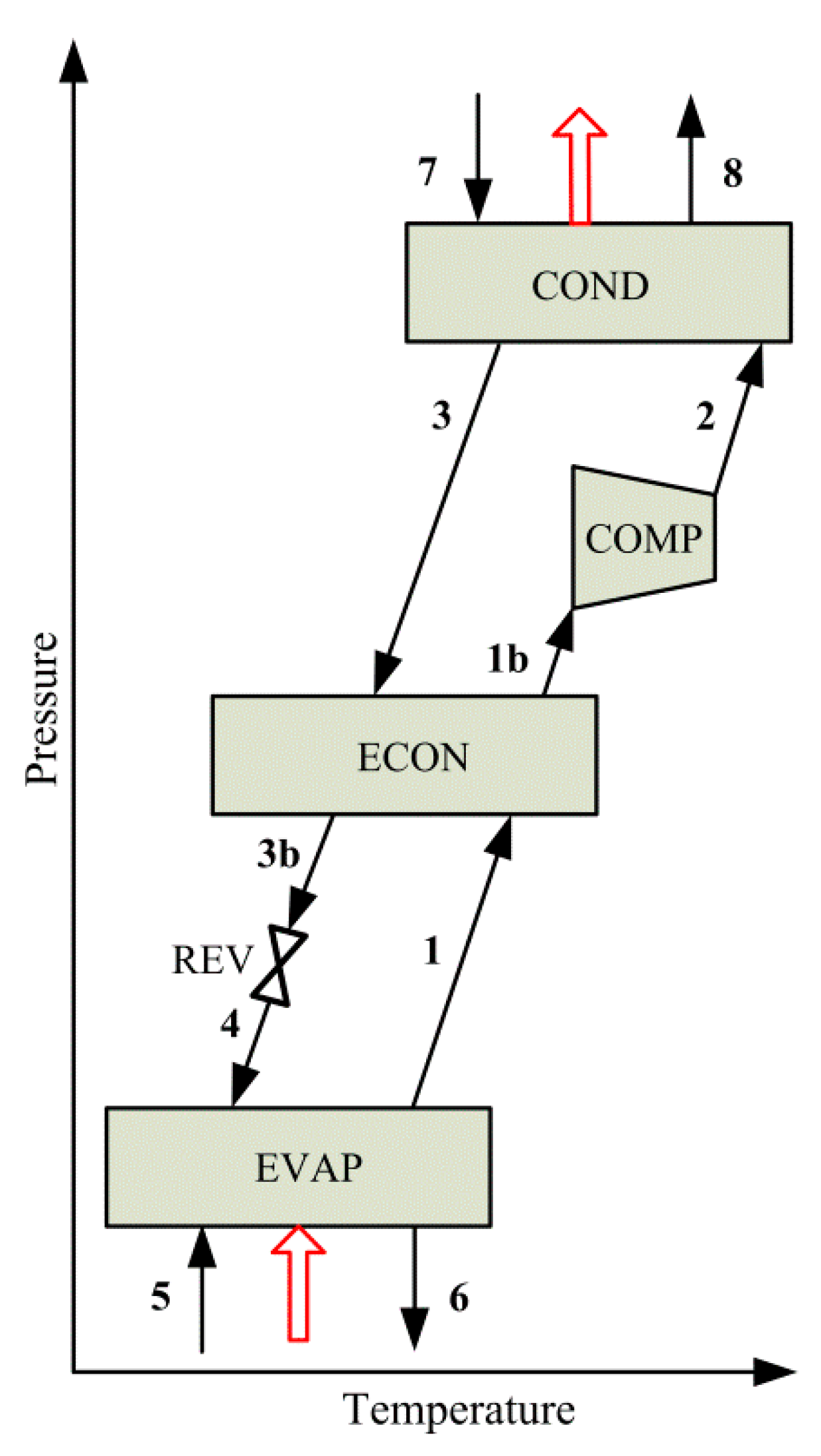

2.2. Vapor Compression Refrigeration System (VCRS)

3. Problem Statement

4. Modeling

4.1. Process Model

4.1.1. Definitions

4.1.2. Steady-State Balances for the k-th System Component

- Total mass balance:

- Mass balance of component j = LiBr:

- Energy balance (with negligible potential and kinetic energy changes):

4.1.3. Design Constraints

- Heat transfer area of a system component k (HTAk):where LMTDk is the logarithmic mean temperature difference, which is calculated as:and are the temperature differences at the hot and cold sides, respectively.

- Total heat transfer area of VCACRS (THTA):

- Heat exchanger effectiveness factor (ε):The effectiveness factor ε of the solution LTSHE (Equation (8)) and HTSHE (Equation (9)) is based on the strong solution side:

- Inequality constraints on stream temperatures:Inequality constraints are added to avoid temperature crosses in the system components. For instance, Equations (10) and (11) are considered for LTC, where δ is a small (positive) value (in this case δ = 0.1). Similar inequality constraints are considered for the remaining system components.

- Other modeling considerations:The model also includes the mass balance corresponding to the splitter SPL (Equation (12)), which allows to optionally consider the heat integration between HTG and LTG in some candidate configurations.

4.2. Objective Function

5. Results and Discussion

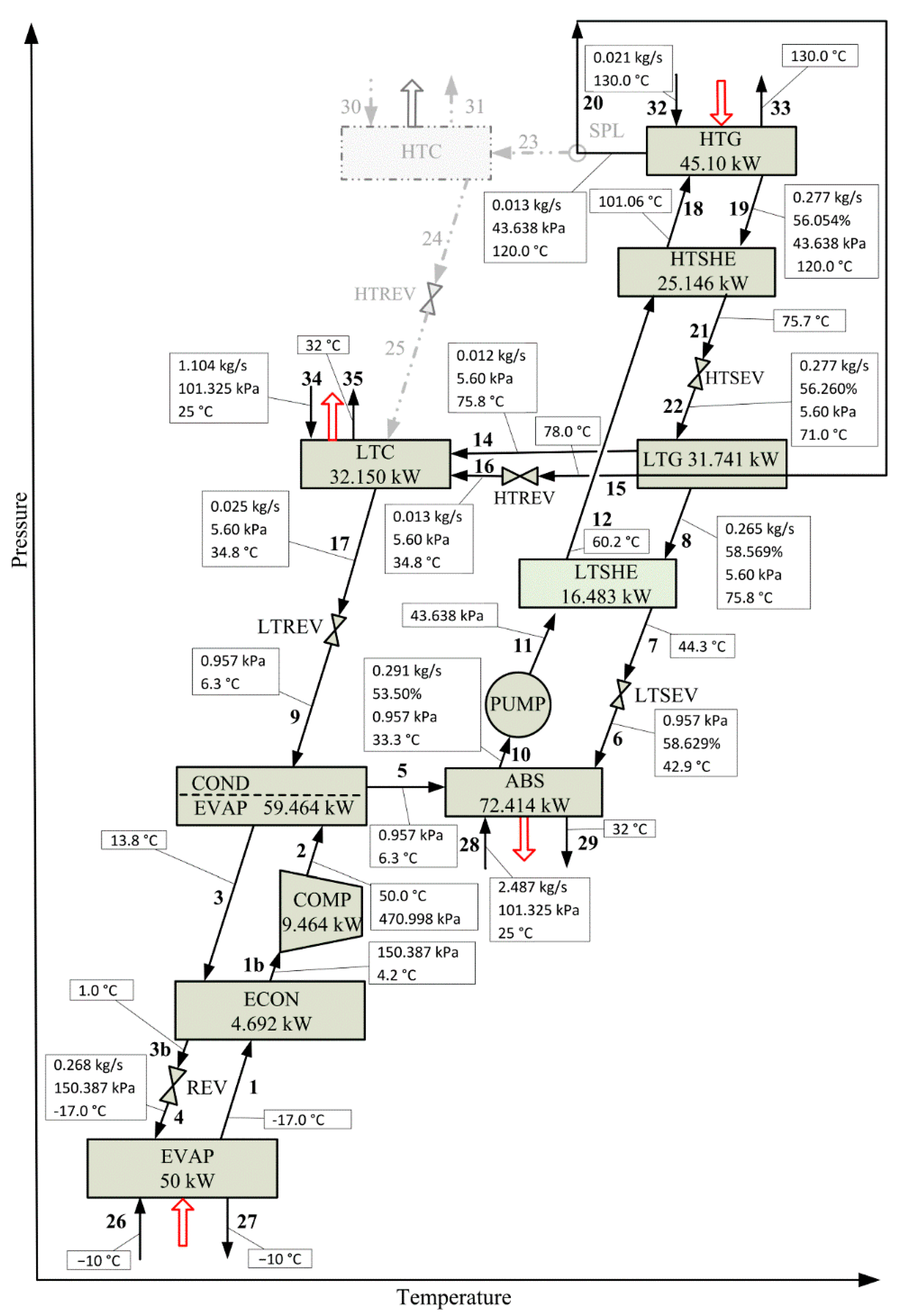

5.1. Model Verification

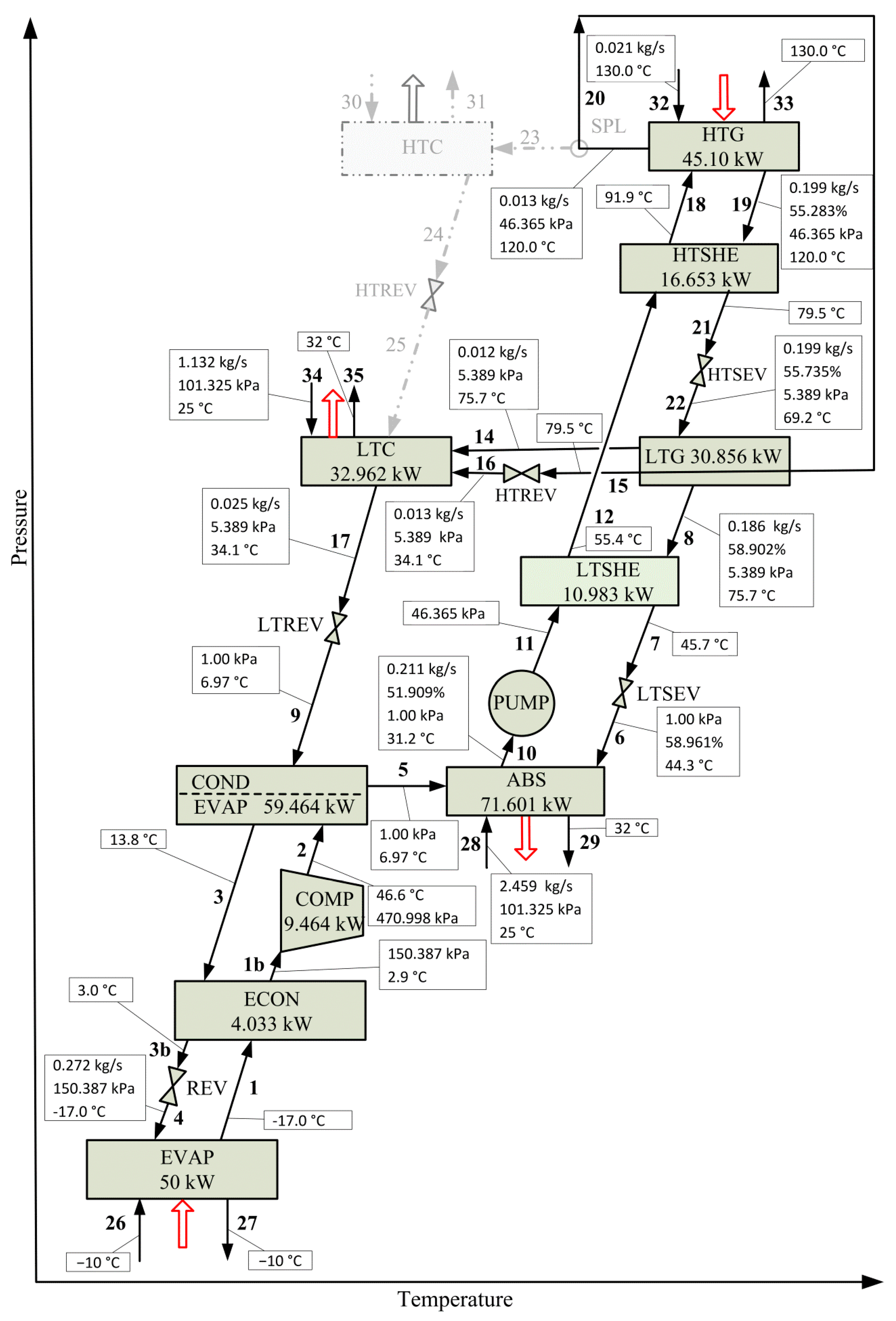

5.2. Optimization Results

Comparison between the Optimal Solution SubOS and the Reference Case CRS

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Coulomb, D. The Role of Refrigeration in the Global Economy. 29th Informatory Note on Refrigeration Technologies 2015. Available online: https://sainttrofee.nl/wp-content/uploads/2019/01/NoteTech_29-World-Statistics.pdf (accessed on 10 November 2019).

- Dincer, I. Refrigeration Systems and Applications, 3rd ed.; John Wiley & Sons, Inc.: Chichester, UK, 2017; ISBN 978-1-119-23075-5. [Google Scholar]

- She, X.; Cong, L.; Nie, B.; Leng, G.; Peng, H.; Chen, Y.; Zhang, X.; Wen, T.; Yang, H.; Luo, Y. Energy-efficient and -economic technologies for air conditioning with vapor compression refrigeration: A comprehensive review. Appl. Energy 2018, 232, 157–186. [Google Scholar] [CrossRef]

- Yang, S.; Deng, C.; Liu, Z. Optimal design and analysis of a cascade LiBr/H2O absorption refrigeration/transcritical CO2 process for low-grade waste heat recovery. Energy Convers. Manag. 2019, 192, 232–242. [Google Scholar] [CrossRef]

- Arshad, M.U.; Ghani, M.U.; Ullah, A.; Güngör, A.; Zaman, M. Thermodynamic analysis and optimization of double effect absorption refrigeration system using genetic algorithm. Energy Convers. Manag. 2019, 192, 292–307. [Google Scholar] [CrossRef]

- Mussati, S.F.; Gernaey, K.V.; Morosuk, T.; Mussati, M.C. NLP modeling for the optimization of LiBr-H2O absorption refrigeration systems with exergy loss rate, heat transfer area, and cost as single objective functions. Energy Convers. Manag. 2016, 127, 526–544. [Google Scholar] [CrossRef]

- Kaynakli, O.; Saka, K.; Kaynakli, F. Energy and exergy analysis of a double effect absorption refrigeration system based on different heat sources. Energy Convers. Manag. 2015, 106, 21–30. [Google Scholar] [CrossRef]

- Garousi Farshi, L.; Mahmoudi, S.M.S.; Rosen, M.A.; Yari, M.; Amidpour, M. Exergoeconomic analysis of double effect absorption refrigeration systems. Energy Convers. Manag. 2013, 65, 13–25. [Google Scholar] [CrossRef]

- Bereche, R.P.; Palomino, R.G.; Nebra, S. Thermoeconomic analysis of a single and double-effect LiBr/H2O absorption refrigeration system. Int. J. Thermodyn. 2009, 12, 89–96. [Google Scholar]

- Mohtaram, S.; Chen, W.; Lin, J. Investigation on the combined Rankine-absorption power and refrigeration cycles using the parametric analysis and genetic algorithm. Energy Convers. Manag. 2017, 150, 754–762. [Google Scholar] [CrossRef]

- Mussati, S.F.; Cignitti, S.; Mansouri, S.S.; Gernaey, K.V.; Morosuk, T.; Mussati, M.C. Configuration optimization of series flow double-effect water-lithium bromide absorption refrigeration systems by cost minimization. Energy Convers. Manag. 2018, 158, 359–372. [Google Scholar] [CrossRef]

- Gebreslassie, B.H.; Medrano, M.; Boer, D. Exergy analysis of multi-effect water–LiBr absorption systems: From half to triple effect. Renew. Energy 2010, 35, 1773–1782. [Google Scholar] [CrossRef]

- Chen, Q.; Zhou, L.; Yan, G.; Yu, J. Theoretical investigation on the performance of a modified refrigeration cycle with R170/R290 for freezers application. Int. J. Refrig. 2019, 104, 282–290. [Google Scholar] [CrossRef]

- Baakeem, S.S.; Orfi, J.; Alabdulkarem, A. Optimization of a multistage vapor-compression refrigeration system for various refrigerants. Appl. Therm. Eng. 2018, 136, 84–96. [Google Scholar] [CrossRef]

- Yang, S.; Ordonez, J.C. Integrative thermodynamic optimization of a vapor compression refrigeration system based on dynamic system responses. Appl. Therm. Eng. 2018, 135, 493–503. [Google Scholar] [CrossRef]

- Yang, S.; Ordonez, J.C.; Vargas, J. Constructal vapor compression refrigeration systems design. Int. J. Heat Mass Transf. 2017, 115, 754–768. [Google Scholar] [CrossRef]

- Ma, W.; Fang, S.; Su, B.; Xue, X.; Li, M. Second-law-based analysis of vapor compression refrigeration cycles: Analytical equations for COP and new insights into features of refrigerants. Energy Convers. Manag. 2017, 138, 426–434. [Google Scholar] [CrossRef]

- Zendehboudi, A.; Mota-Babiloni, A.; Makhnatch, P.; Saidur, R.; Sait, S.M. Modeling and multi-objective optimization of an R450A vapor compression refrigeration system. Int. J. Refrig. 2019, 100, 141–155. [Google Scholar] [CrossRef]

- Zhao, L.; Cai, W.; Ding, X.; Chang, W. Model-based optimization for vapor compression refrigeration cycle. Energy 2013, 55, 392–402. [Google Scholar] [CrossRef]

- Agarwal, S.; Arora, A.; Arora, B.B. Energy and exergy analysis of vapor compression–triple effect absorption cascade refrigeration system. Eng. Sci. Technol. 2019, in press. [Google Scholar] [CrossRef]

- Patel, B.; Kachhwaha, S.S.; Modi, B. Thermodynamic Modelling and Parametric Study of a Two Stage Compression-Absorption Refrigeration System for Ice Cream Hardening Plant. Energy Procedia 2017, 109, 190–202. [Google Scholar] [CrossRef]

- Jain, V.; Kachhwaha, S.S.; Sachdeva, G. Thermodynamic performance analysis of a vapor compression-absorption cascaded refrigeration system. Energy Convers. Manag. 2013, 75, 685–700. [Google Scholar] [CrossRef]

- Cimsit, C.; Ozturk, I.T. Analysis of compression—Absorption cascade refrigeration cycles. Appl. Therm. Eng. 2012, 40, 311–317. [Google Scholar] [CrossRef]

- Boyaghchi, F.A.; Mahmoodnezhad, M.; Sabeti, V. Exergoeconomic analysis and optimization of a solar driven dual-evaporator vapor compression-absorption cascade refrigeration system using water/CuO nanofluid. J. Clean. Prod. 2016, 139, 970–985. [Google Scholar] [CrossRef]

- Chen, W.; Li, Z.; Sun, Q.; Zhang, B. Energy and exergy analysis of proposed compression-absorption refrigeration assisted by a heat-driven turbine at low evaporating temperature. Energy Convers. Manag. 2019, 191, 55–70. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, N.; Pan, F.; Wang, Q.; Chen, G. Comparative study on two low-grade heat driven absorption-compression refrigeration cycles based on energy, exergy, economic and environmental (4E) analyses. Energy Convers. Manag. 2017, 133, 535–547. [Google Scholar] [CrossRef]

- Salhi, K.; Korichi, M.; Ramadan, K.M. Thermodynamic and thermo-economic analysis of compression–absorption cascade refrigeration system using low-GWP HFO refrigerant powered by geothermal energy. Int. J. Refrig. 2018, 94, 214–229. [Google Scholar] [CrossRef]

- Garousi Farshi, L.; Khalili, S.; Amirhossein, M. Thermodynamic analysis of a cascaded compression—Absorption heat pump and comparison with three classes of conventional heat pumps for the waste heat recovery. Appl. Therm. Eng. 2017, 128, 282–296. [Google Scholar] [CrossRef]

- Jain, V.; Sachdeva, G.; Kachhwaha, S.S. Comparative performance study and advanced exergy analysis of novel vapor compression-absorption integrated refrigeration system. Energy Convers. Manag. 2018, 172, 81–97. [Google Scholar] [CrossRef]

- Jing, Y.; Li, Z.; Chen, H.; Lu, S.; Lv, S. Exergoeconomic design criterion of solar absorption-subcooled compression hybrid cooling system based on the variable working conditions. Energy Convers. Manag. 2019, 180, 889–903. [Google Scholar] [CrossRef]

- Colorado, D.; Rivera, W. Performance comparison between a conventional vapor compression and compression-absorption single-stage and double-stage systems used for refrigeration. Appl. Therm. Eng. 2015, 87, 273–285. [Google Scholar] [CrossRef]

- Sahoo, P.K. Exergoeconomic analysis and optimization of a cogeneration system using evolutionary programming. Appl. Therm. Eng. 2008, 28, 1580–1588. [Google Scholar] [CrossRef]

- Jain, V.; Surendra, G.S.; Kachhwaha, S.; Patel, B. Thermo-economic and environmental analyses based multi-objective optimization of vapor compression–absorption cascaded refrigeration system using NSGA-II technique. Energy Convers. Manag. 2016, 113, 230–242. [Google Scholar] [CrossRef]

- Lijuan, H.; Wang, S.; Suxia, L.; Xuan, W. Numerical and experimental evaluation of the performance of a coupled vapour absorption–compression refrigeration configuration. Int. J. Refrig. 2019, 99, 429–439. [Google Scholar] [CrossRef]

- Jianbo, L.; Shiming, X.; Xiangqiang, K.; Kai, L.; Fulin, C. Experimental study on absorption/compression hybrid refrigeration cycle. Energy 2019, 168, 1237–1245. [Google Scholar] [CrossRef]

- Jensen, J.K.; Markussen, W.B.; Reinholdt, L.; Elmegaard, B. On the development of high temperature ammonia–water hybrid absorption–compression heat pumps. Int. J. Refrig. 2015, 58, 79–89. [Google Scholar] [CrossRef] [Green Version]

- GAMS Development Corporation. General Algebraic Modeling System (GAMS) Release 23.6.5; GAMS Development Corporation: Washington, DC, USA, 2010. [Google Scholar]

- Drud, A. CONOPT 3 Solver Manual; ARKI Consulting and Development A/S: Bagsvaerd, Denmark, 2012. [Google Scholar]

| M (kg∙s−1) | T (°C) | P (kPa) | X (% p/p) | |||||

|---|---|---|---|---|---|---|---|---|

| Stream | Ref. [31] | This Work | Ref. [31] | This Work | Ref. [31] | This Work | Ref. [31] | This Work |

| 1 | 0.267 | 0.268 | −17.0 | −17.0 a | 150.8 | 150.387 | – | – |

| 1b | 0.267 | 0.268 | 4.7 | 4.4 | 150.8 | 150.387 | – | – |

| 2 | 0.267 | 0.268 | 49.9 | 50.1 | 472.9 | 470.998 | – | – |

| 3 | 0.267 | 0.268 | 14.0 | 14.0 a | 472.9 | 470.998 | – | – |

| 3b | 0.267 | 0.268 | 1.0 | 1.0 a | 472.9 | 470.998 | – | – |

| 5 | 0.025 | 0.025 | 7.0 | 6.4 | 1.0 | 0.957 | – | – |

| 6 | 0.266 | 0.255 | 47.6 | 44.4 | 1.0 | 0.957 | 58.9 | 58.569 |

| 8 | 0.266 | 0.255 | 77.1 | 76.4 | 5.6 | 5.600 a | 58.9 | 58.569 |

| 10 | 0.291 | 0.280 | 35.0 | 34.1 | 1.0 | 0.958 | 53.8 | 53.498 |

| 14 | 0.011 | 0.011 a | 77.1 | 76.4 | 5.6 | 5.600 a | – | – |

| 18 | 0.291 | 0.280 | 99.0 | 102.3 | 42.1 | 43.638 | 53.8 | 53.498 |

| 19 | 0.278 | 0.266 | 120.0 | 120.0 a | 42.1 | 43.638 | 56.3 | 56.054 |

| Item | Ref. [31] | This Work |

|---|---|---|

| Heat load (kW) | ||

| – High-temperature generator, HTG | 45.80 | 45.10 |

| – Absorber, ABS | 72.63 | 72.414 |

| – Condenser, COND | 32.27 | 32.150 |

| – Evaporator, EVAP | 50.00 | 50.00 a |

| Work (kW) | ||

| – Compressor, COMP | 9.10 | 9.464 |

| COP (dimensionless) | ||

| – VARS cycle | 1.29 | 1.312 |

| – VCRS cycle | 5.49 | 5.283 |

| – VCRS-VARS cascade cycle | 0.91 | 0.916 |

| Parameter | Value |

|---|---|

| Cooling capacity (kW) | 50.00 |

| Utility inlet/outlet temperature (°C): | |

| – Cooling water in condensers and absorbers | 25.0/32.0 |

| – Steam in generators | 130.0 |

| Overall heat transfer coefficient (kW∙m−2∙°C−1): | |

| – Evaporator, UEVAP | 1.50 |

| – Absorber, UABS | 0.70 |

| – Condenser, UCOND | 2.50 |

| – Generator, UGEN | 1.50 |

| – Cascade condenser | 0.55 |

| – Solution heat exchanger, USHE | 1.00 |

| Component | HTA (m2) | Q (kW) | LMTD (K) |

|---|---|---|---|

| ABS | 10.339 | 77.353 | 10.7 |

| COND/EVAP | 0.277 a/4.948 b 5.225 c | 7.068 a/51.070 b 58.138 c | 16.9 a/6.9 b |

| LTC | 2.959 | 44.080 | 6.0 |

| EVAP | 2.331 | 50.00 | 7.1 |

| LTG | 2.190 | 17.912 | 5.4 |

| HTG | 1.288 | 63.296 | 32.7 |

| LTSHE | 0.457 | 10.699 (ε = 40.3%) | 23.4 |

| ECON | 0.191 | 4.033 | 16.2 |

| HTSHE | 1.53 × 10−24 | 1.060 × 10−22 (ε = 0) | 69.0 |

| HTC | – | – | – |

| Total | 24.980 (THTA) |

| Ref. [31] | SubOS (This Work) | |||||

|---|---|---|---|---|---|---|

| Component | Q (kW) | HTA (m2) | DF (K) | Q (kW) | HTA (m2) | DF (K) |

| EVAP | 50.00 | 2.331 | 7.150 | 50.00 | 2.331 | 7.150 |

| COND/EVAP | 9.127 a/50.336 b 59.463 c | 0.299 a/4.469 b 4.768 c | 20.3 a/7.5 b | 8.396 a/51.068 b 59.464 c | 0.302 a/4.948 b 5.25 c | 18.5 a/6.8 b |

| ABS | 72.414 | 10.828 | 9.5 | 71.601 | 11.438 | 8.9 |

| LTSHE | 16.483 | 1.247 | 13.2 | 10.983 (ε = 54.348%) | 0.637 | 17.2 |

| LTG | 31.741 | 5.120 | 4.1 | 30.856 | 3.164 | 6.5 |

| HTSHE | 25.146 | 1.463 | 17.2 | 16.653 (ε = 56.542%) | 0.64 | 26.0 |

| HTG | 45.10 | 1.690 | 17.8 | 45.100 | 1.438 | 20.9 |

| LTC | 32.150 | 2.285 | 5.629 | 32.962 | 2.735 | 4.8 |

| ECON | 4.692 | 0.269 | 13.4 | 4.033 | 0.191 | 16.2 |

| HTC | - | - | - | – | – | – |

| Total | 30.000 (THTA) | 27.824 (THTA) | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mussati, S.F.; Morosuk, T.; Mussati, M.C. Superstructure-Based Optimization of Vapor Compression-Absorption Cascade Refrigeration Systems. Entropy 2020, 22, 428. https://doi.org/10.3390/e22040428

Mussati SF, Morosuk T, Mussati MC. Superstructure-Based Optimization of Vapor Compression-Absorption Cascade Refrigeration Systems. Entropy. 2020; 22(4):428. https://doi.org/10.3390/e22040428

Chicago/Turabian StyleMussati, Sergio F., Tatiana Morosuk, and Miguel C. Mussati. 2020. "Superstructure-Based Optimization of Vapor Compression-Absorption Cascade Refrigeration Systems" Entropy 22, no. 4: 428. https://doi.org/10.3390/e22040428

APA StyleMussati, S. F., Morosuk, T., & Mussati, M. C. (2020). Superstructure-Based Optimization of Vapor Compression-Absorption Cascade Refrigeration Systems. Entropy, 22(4), 428. https://doi.org/10.3390/e22040428