Multi-Source Coupling Based Analysis of the Acoustic Radiation Characteristics of the Wheel–Rail Region of High-Speed Railways

Abstract

:1. Introduction

2. Vibration Noise Combined Analysis Model of High-Speed Railways

2.1. Wheel–Rail Vibration Noise Combined Analysis Model

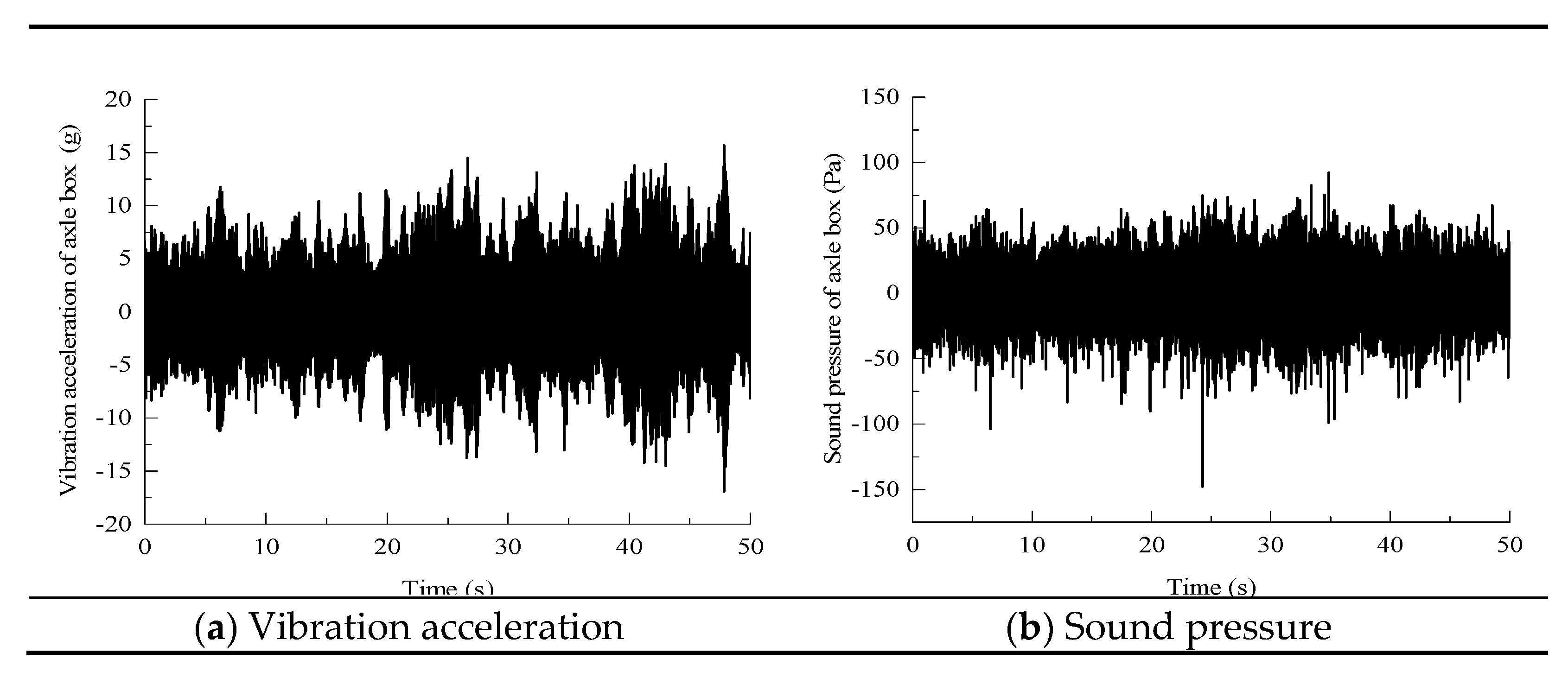

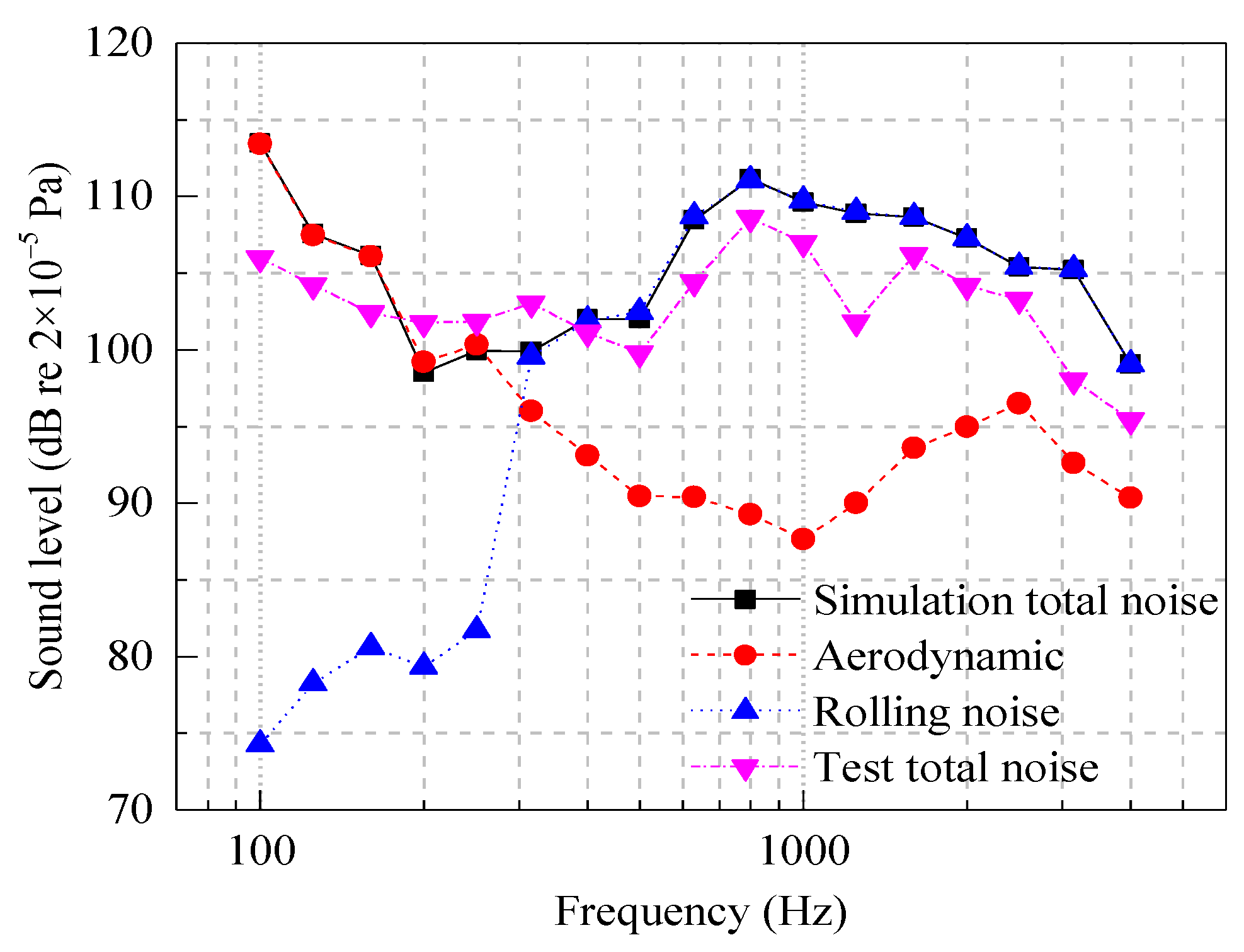

2.2. Model Validation

3. Subsystem Parameter of Vibration Noise Combined Analysis Model of High-Speed Railways

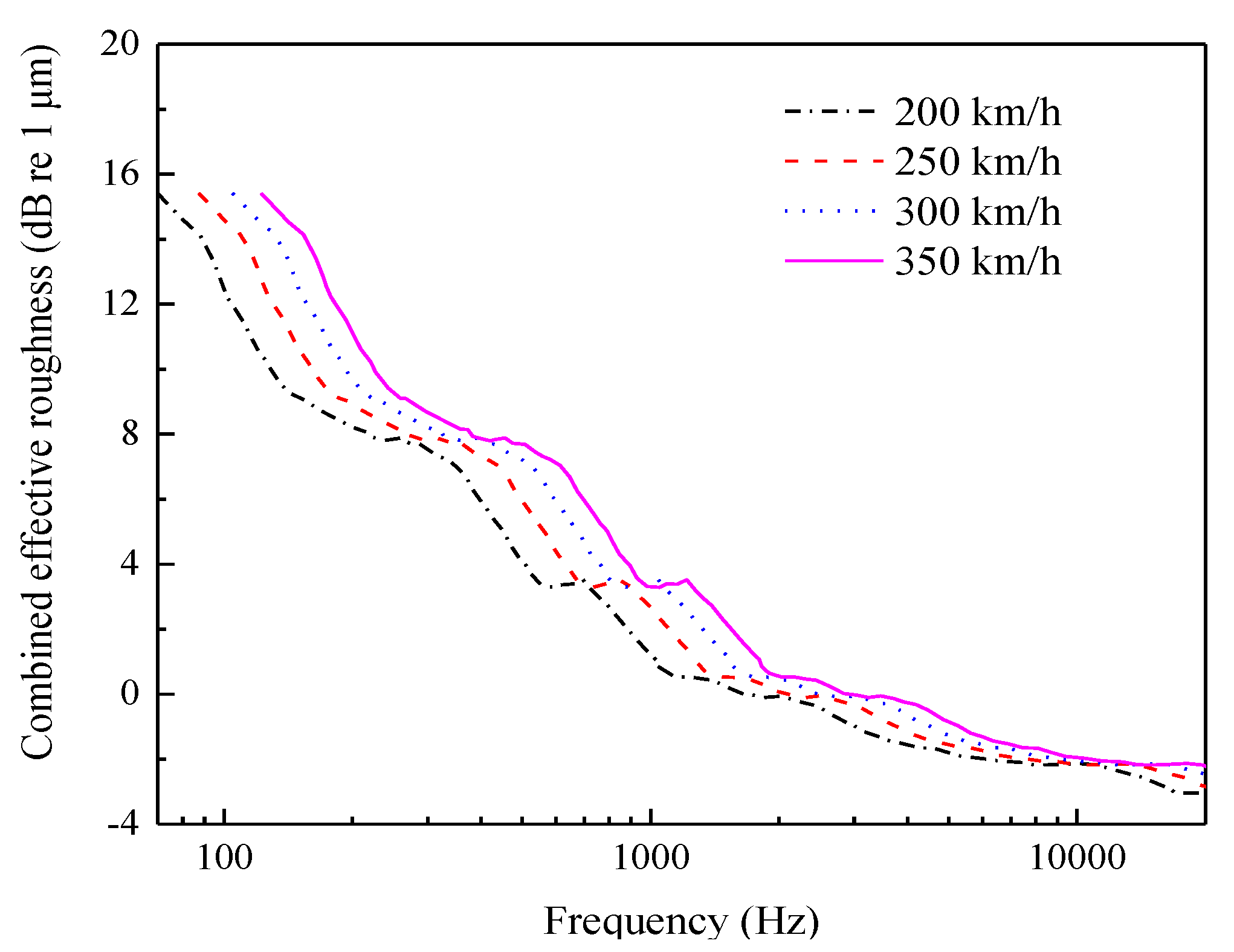

3.1. Analysis Model of the Wheel–Rail Rolling Noise

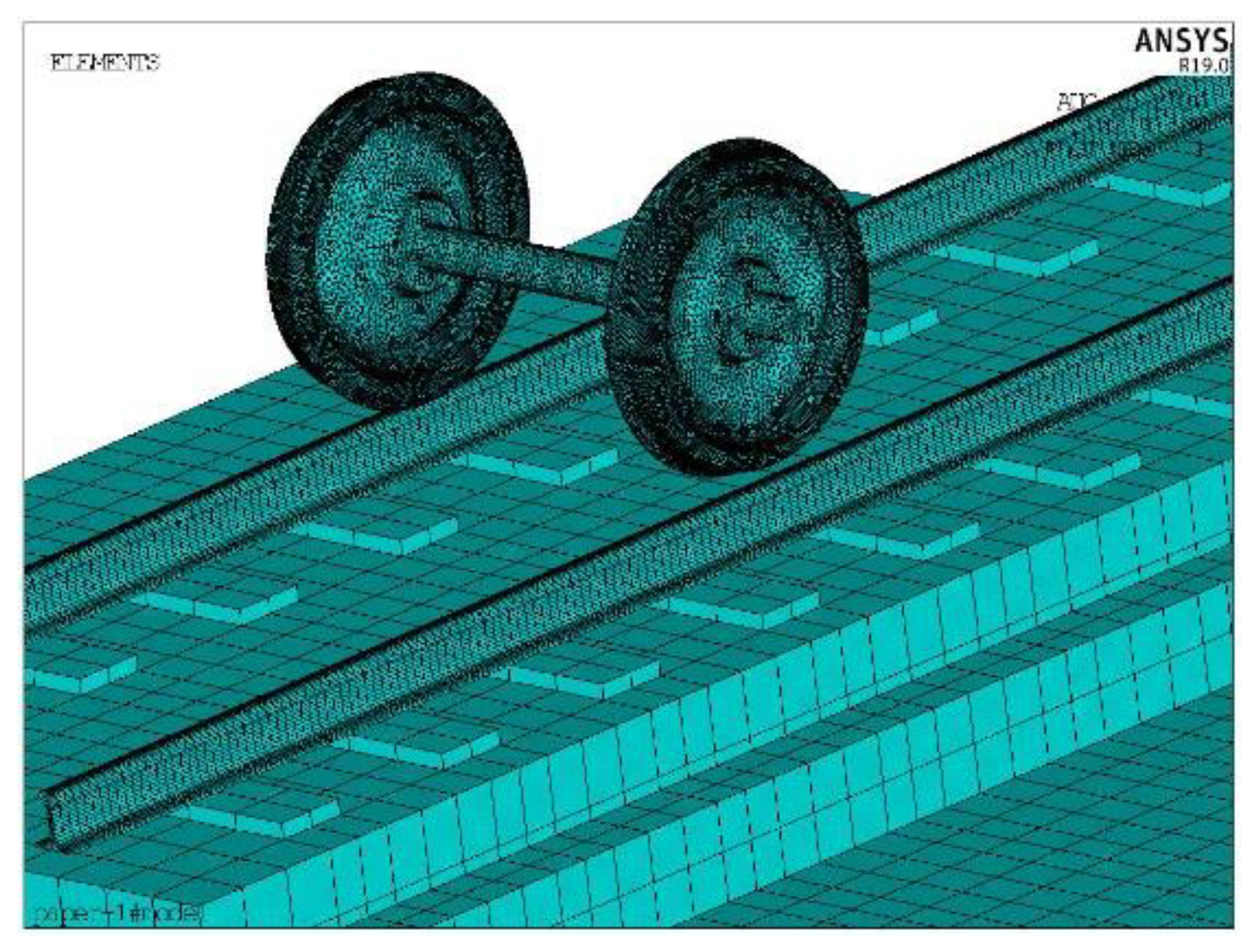

3.1.1. Wheel–Rail Coupling Dynamic Model

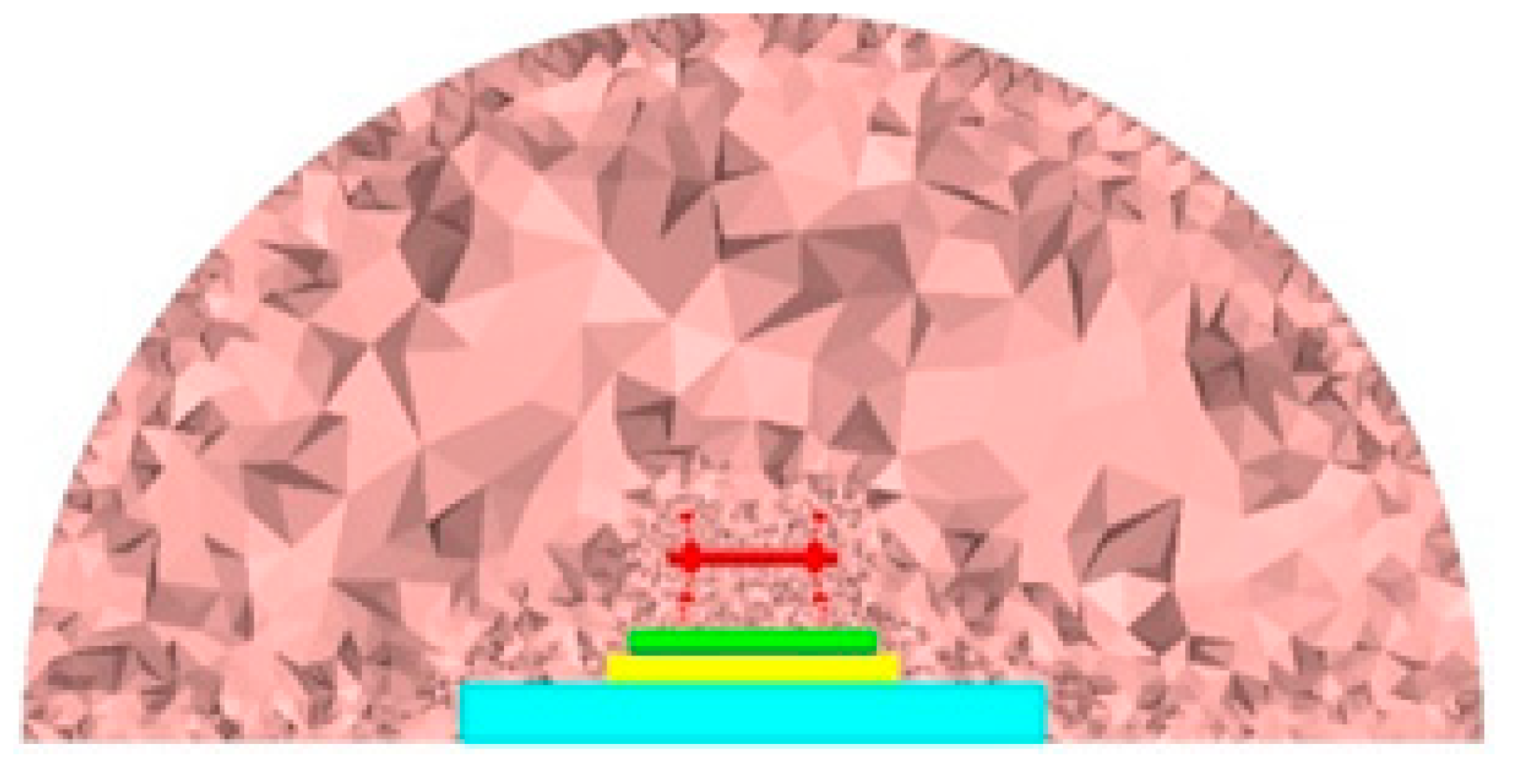

3.1.2. Sound Propagation Model of the Wheel–Rail Rolling Noise

3.2. Aerodynamic Noise Calculation

3.2.1. Near-Field Hydrodynamic Model of the Wheel–Rail Region

3.2.2. Modeling of the Aerodynamic Noise Propagation

4. Noise Radiation Characteristics of High-Speed Railways

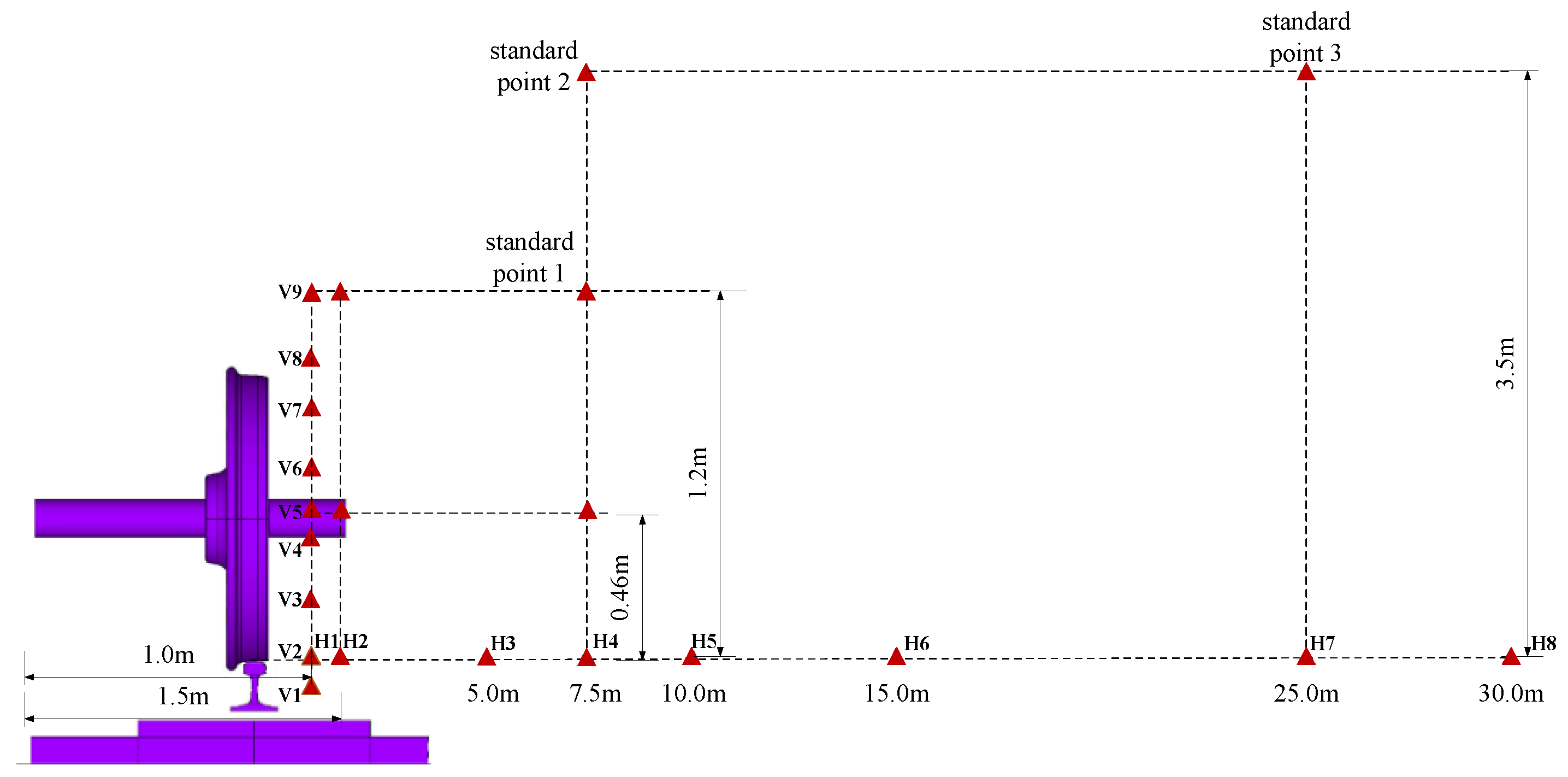

4.1. Location of the Noise Analysis Points for High-Speed Railways

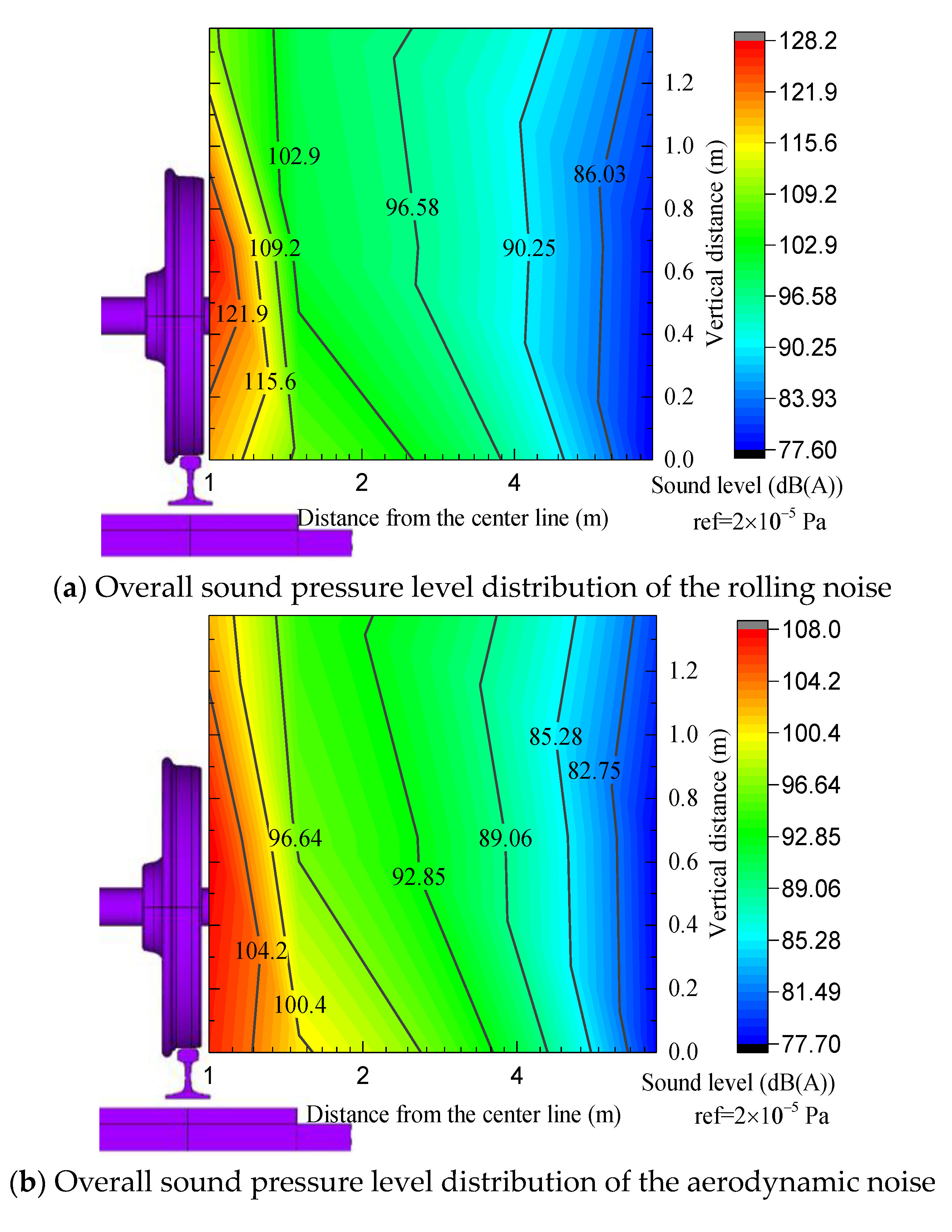

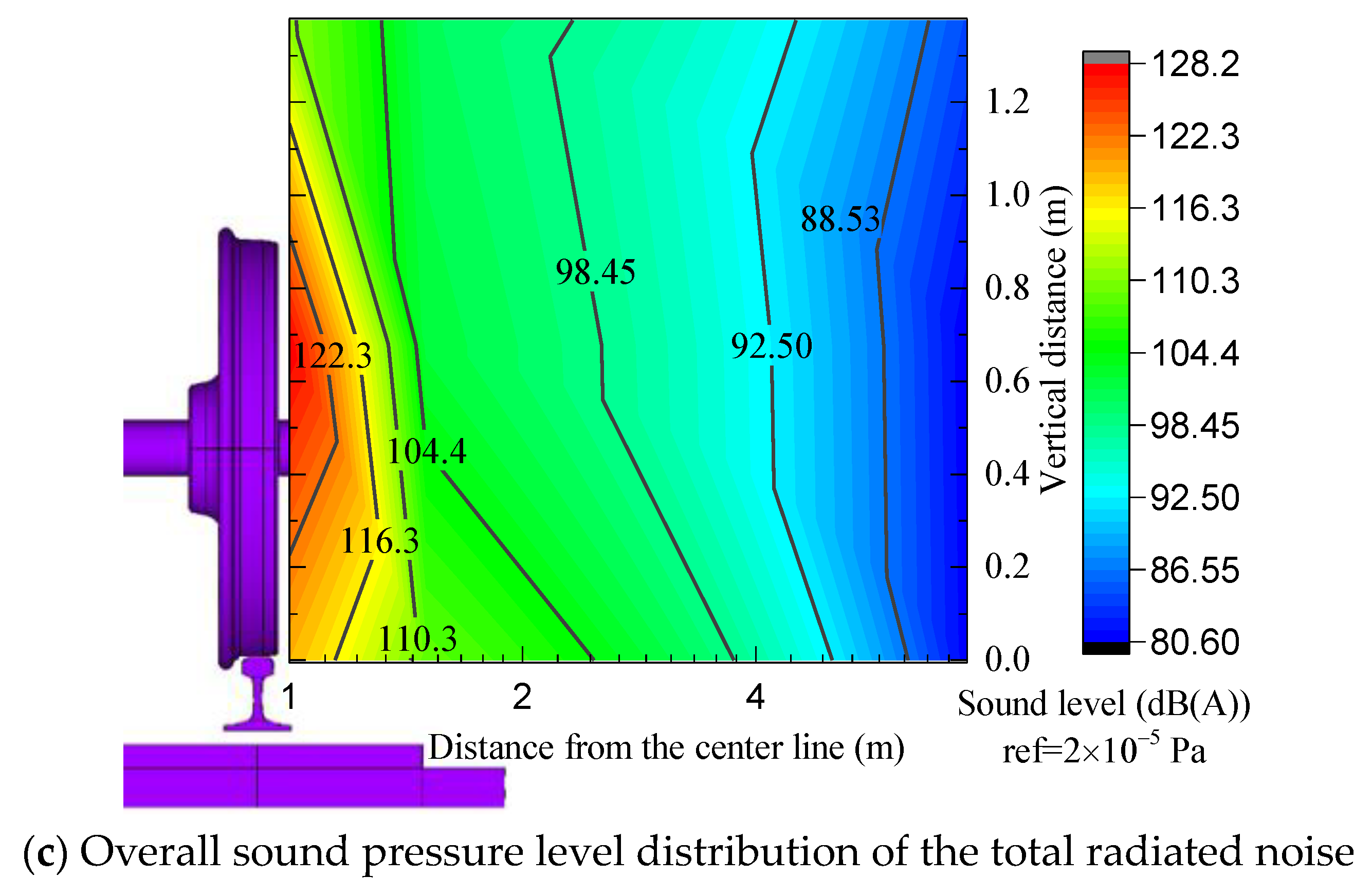

4.2. Analysis of the Noise Distribution Characteristics of High-Speed Railways

4.3. Sound Contribution of the Wheel–Rail Region

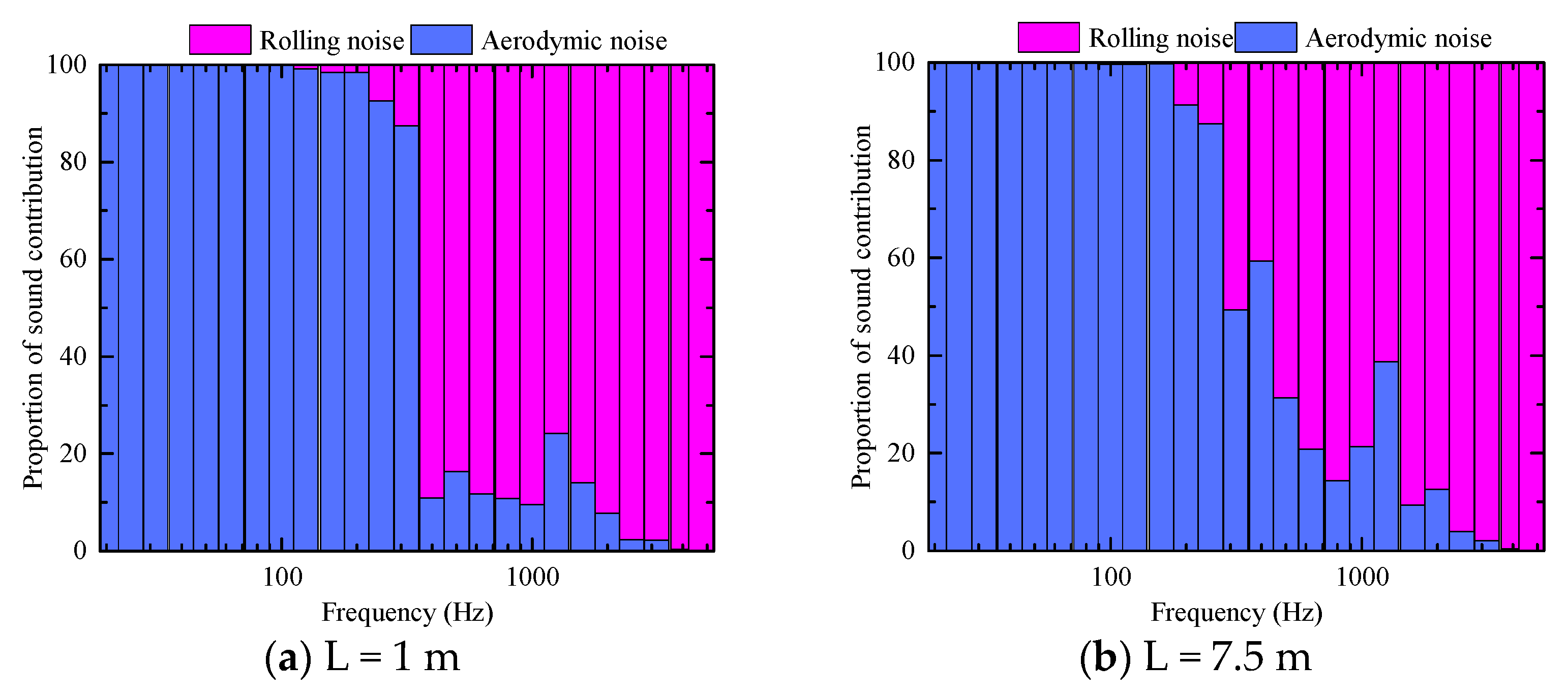

4.3.1. Acoustic Contribution of the Total Radiated Noise

4.3.2. Sound Contribution of the Wheel–Rail Rolling Noise of Various Components of the Track Structure

4.4. Sound Directivity in the Wheel–Rail Area

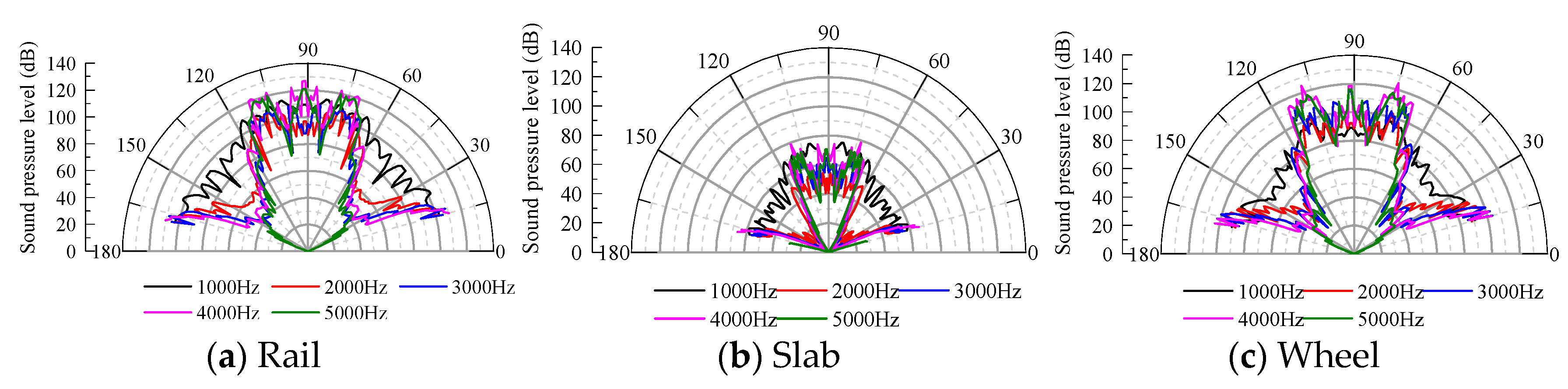

4.4.1. Directivity of the Main Radiated Noise Sources

4.4.2. Directivity of the Radiated Noise from Various Components of the System

5. Conclusions

- According to the wheel–rail combined roughness reported in the literature and the wheel–rail admittance calculated using the wheel–rail coupling model to obtain the wheel–rail force, which is applied to the wheel–rail vibration noise combined analysis model, the rolling noise is calculated according to the solid–gas interface coupling theory. Based on the Lighthill acoustic theory and the frequency domain acoustic wave equation, the aerodynamic noise is calculated to realize the wheel–rail area vibration noise combined simulation calculation.

- The comparison of the simulation results with the vibration and noise signals measured near the axle box in a high-speed railway commissioning test indicates that the test and simulation results exhibit relatively small errors, and the rail vibration exhibits a notable resonance peak at 40 Hz. When the frequency exceeds 100 Hz, the vibration level of the rail increases significantly. The contribution of the aerodynamic noise is dominant in the low frequency range below 300 Hz. As the frequency increases, the rolling noise continues to increase, and the proportion in the high frequency range increases significantly.

- The distribution of the total radiation noise from V1 to V9 at the measurement point first increases and later decreases along the vertical direction of the track structure in the wheel–track area of the high-speed railway. The total radiation noise at the axle position is the largest, with an intensity of 128.1 dB, and the smallest value is observed at the top of the wheel. The sound pressure level of the monitoring point decays exponentially within the range of 7.5 m from the center line and is approximately linear in the range beyond 7.5 m.

- The contribution of each component of the track structure to the rolling noise in the wheel–rail area varies considerably. In terms of the contribution of each structural vibration to the sound source, the energy contributed by the rail is the largest, accounting for 73% to 74% of the total value, followed by that contributed by the wheel, accounting for 25 to 26% of the total value. The track slab contributions (0.1%) can be ignored. In terms of the proportion of each sound source to the total sound source, the energy contributed by the rolling noise is the largest, accounting for 78% to 87% of the energy, and the energy contributed by the aerodynamic noise is 13–21% the total value. According to the acoustic contribution map, in the low frequency range, the wheel–track area is mainly dominated by the aerodynamic noise, whereas the rolling noise is dominant at a frequency above 300 Hz.

- According to the analysis of the acoustic directivity of the noise in the wheel–track area of the high-speed railway, the directivity of the different sources of noise fluctuates around the cylindrical surface for the frequency band below 1000 Hz, and the overall directivity is not significant. In the 1000–3000 Hz frequency band, which corresponds to the most significant pure tone perception, the directivity of the total radiated noise is significant in the directions of 20–30° and 70–90°. When evaluating the intensity of rail traffic noise sources, the measurement points can likely be arranged in this range. Moreover, the direction of propagation must be considered in the design of the sound barrier.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jin, X.S. Key problems faced in high-speed train operation. In China’s High-Speed Rail Technology: An International Perspective; Fang, Y., Zhang, Y.H., Eds.; Springer: Singapore, 2018; pp. 27–45. [Google Scholar]

- Yokoshima, S.; Morihara, T.; Sato, T.; Yano, T. Combined effects of high-speed railway noise and ground vibrations on annoyance. Int. J. Environ. Res. Public Health 2017, 14, 845. [Google Scholar] [CrossRef]

- Jang, K.S.; Kim, Y.C.; Seo, H.S.; Choi, C.Y.; Park, J.H. A study on the device installed on the barrier for the environmental noise reduction in 400 km/h high speed railway. J. Korean Soc. Environ. Eng. 2017, 39, 679–684. [Google Scholar] [CrossRef]

- Yuan, C.Y.; Li, M.Q. Multi-objective optimization for the aerodynamic noise of the high-speed train in the near and far field based on the improved NSGA-II algorithm. J. Vibroengineering 2017, 19, 4759–4782. [Google Scholar] [CrossRef]

- Deivasigamani, A.; White, A. Comparison of rail noise prediction methodologies for elevated rail designs. In Proceedings of the ACOUSTICS 2016, Brisbane, Australia, 9–11 November 2016; pp. 1–10. [Google Scholar]

- Zhang, J.; Zhu, C. Far field noise contribution radiated from aerodynamic noise source of high-speed train. China Railw. Sci. 2019, 40, 115–121. [Google Scholar]

- Noh, H.-M. Noise-source identification of a high-speed train by noise source level analysis. Proc. Inst. Mech. Eng. F J. Rail Rapid Transit 2016, 231, 717–728. [Google Scholar] [CrossRef]

- Wu, X.Y. A study on the prediction methods of railway environmental noise. Railw. Transp. Econ. 2018, 40, 98–103. [Google Scholar]

- Yang, X.W. Characteristics of wheel–rail rolling noise of ballastless track in high-speed railway. J. Tongji Univ. (Nat. Sci.) 2014, 42, 421–428. [Google Scholar]

- Liu, L.Y.; Lei, X.Y.; Lian, S.L. Research on non-linear vibration characteristics of contact system for switching electrical apparatus used in aerospace. J. Vib. Shock 2007, 26, 146–150+178. [Google Scholar] [CrossRef]

- Thompson, D.; Squicciarini, G.; Zhang, J.; Lopez Arteaga, I.; Zea, E.; Dittrich, M.; Jansen, E.; Arcas, K.; Cierco, E.; Magrans, F.X.; et al. Assessment of measurement-based methods for separating wheel and track contributions to railway rolling noise. Appl. Acoust. 2018, 140, 48–62. [Google Scholar] [CrossRef] [Green Version]

- Jang, S.; Ryue, J. Study on the rolling noise model using an analysis of wheel and rail vibration characteristics. J. Korean Soc. Railw. 2013, 16, 175–182. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Wu, S.P. Numerical analysis of aerodynamic noise of a new high-speed train. Appl. Mech. Mater. 2013, 275–277, 681–686. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Jing, J.H. Research and control of aerodynamic noise in high speed trains. Foreign Roll. Stock 2011, 48, 1–8. [Google Scholar]

- King, W.F. On the role of aerodynamically generated sound in determining wayside noise levels from high speed trains. J. Sound Vib. 1977, 54, 361–378. [Google Scholar] [CrossRef]

- Cui, J.; Yuan, T.C.; Yang, J. Analysis on far field aerodynamic noise of train based on simulation and actual measurement. Meas. Control Technol. 2018, 37, 67–71. [Google Scholar]

- Thompson, D.J.; Iglesias, E.L.; Liu, X.; Zhu, J.; Hu, Z. Recent developments in the prediction and control of aerodynamic noise from high-speed trains. Int. J. Rail Transp. 2015, 3, 119–150. [Google Scholar] [CrossRef]

- Ju, L.H.; Ge, J.N.; Guo, Y.J. Model of high-speed railway noise prediction based on multi-source mode. J. Tongji Univ. (Nat. Sci.) 2017, 45, 58–63. [Google Scholar]

- Thompson, D.J.; Hemsworth, B.; Vincent, N. Experimental validation of the twins prediction program for rolling noise, part 1: Description of the model and method. J. Sound Vib. 1996, 193, 123–135. [Google Scholar] [CrossRef]

- Oregui, M.; Li, Z.; Dollevoet, R. An investigation into the modeling of railway fastening. Int. J. Mech. Sci. 2015, 92, 1–11. [Google Scholar] [CrossRef]

- Cui, R.; Gao, L.; Cai, X. Study on vibration and noise reduction properties of damping rail for high-speed railway. J. China Railw. Soc. 2015, 37, 78–84. [Google Scholar]

- Thompson, D.J. Wheel–rail noise generation, part i: Introduction and interaction model. J. Sound Vib. 1993, 161, 387–400. [Google Scholar] [CrossRef]

- Janssens, M.H.A.; Dittrich, M.G.; de Beer, F.G.; Jones, C.J.C. Railway noise measurement method for pass-by noise, total effective roughness, transfer functions and track spatial decay. J. Sound Vib. 2006, 293, 1007–1028. [Google Scholar] [CrossRef]

- Su, N.; Pang, F.; Yao, X.L. Variable order mapped wave envelope element of outer structural sound field. J. Sh. Mech. 2014, 18, 856–863. [Google Scholar] [CrossRef]

- Sun, Z.X.; Yao, Y.F.; Yang, Y. Overview of the research progress on aerodynamic noise of high speed trains in China. Acta Aerodyn. Sin. 2018, 36, 385–397. [Google Scholar] [CrossRef]

- Ma, D.Y. Theoretical Basis of Modern Acoustics; Science Press: Beijing, China, 2004. [Google Scholar]

- Luo, L.; Zheng, X.; Lv, Y.; Hao, Z.Y. Aerodynamic noise analysis of high-speed train with pantograph system. J. Zhejiang Univ. (Eng. Sci.) 2015, 49, 2179–2185. [Google Scholar]

- Meng, C.X.; Yang, S.E.; Li, G.J. Spatial directivity of ship radiated noise at far field. J. Harbin Inst. Technol. 2010, 42, 824–826+831. [Google Scholar]

- Gao, Y.; Li, Q.L.; Chen, Y.; Wang, Y.G.; Qian, K. Prediction of near field and far field noise for high-speed train head shape. J. Tongji Univ. (Nat. Sci.) 2019, 47, 124–129. [Google Scholar]

- Yang, Y.; Zhang, J.; He, B.; Fan, J. Analysis on exterior noise characteristics of high-speed trains in bridges and embankments section based on experiment. J. Mech. Eng. 2019, 55, 188–197. [Google Scholar]

- Yang, X.W.; Wang, J.; Lian, S.L. Review on wheel/rail noise in rail transit. J. China Railw. Soc. 2017, 39, 100–108. [Google Scholar]

- Zhang, Y.; Zhang, J.; Li, T.; Zhang, L. Investigation of the aeroacoustic behavior and aerodynamic noise of a high-speed train pantograph. Sci. China Technol. Sci. 2017, 60, 561–575. [Google Scholar] [CrossRef]

| Track Structure Component | Parameter | Value | Unit |

|---|---|---|---|

| Wheel | Elastic modulus | N/m2 | |

| Density | 7830 | kg/m3 | |

| Poisson’s ratio | 0.3 | - | |

| Rail | Cross-sectional area | 7745 | mm2 |

| Elastic modulus | N/m2 | ||

| Density | 7850 | kg/m3 | |

| Poisson’s ratio | 0.3 | - | |

| Fastener | Vertical stiffness | N/m | |

| Vertical damping | 10 | kN·s/m | |

| Support spacing | 0.65 | m | |

| Slab | Elastic modulus | N/m2 | |

| Density | 2500 | kg/m3 | |

| Poisson’s ratio | 0.2 | - | |

| CA mortar | Elastic modulus | N/m2 | |

| Density | 1800 | kg/m3 | |

| Poisson’s ratio | 0.2 | - | |

| Base plate | Elastic modulus | N/m2 | |

| Density | 2500 | kg/m3 | |

| Poisson’s ratio | 0.2 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, B.; Li, J.; Gao, L.; Wang, D. Multi-Source Coupling Based Analysis of the Acoustic Radiation Characteristics of the Wheel–Rail Region of High-Speed Railways. Entropy 2021, 23, 1328. https://doi.org/10.3390/e23101328

Hou B, Li J, Gao L, Wang D. Multi-Source Coupling Based Analysis of the Acoustic Radiation Characteristics of the Wheel–Rail Region of High-Speed Railways. Entropy. 2021; 23(10):1328. https://doi.org/10.3390/e23101328

Chicago/Turabian StyleHou, Bowen, Jiajing Li, Liang Gao, and Di Wang. 2021. "Multi-Source Coupling Based Analysis of the Acoustic Radiation Characteristics of the Wheel–Rail Region of High-Speed Railways" Entropy 23, no. 10: 1328. https://doi.org/10.3390/e23101328