Coal and Rock Hardness Identification Based on EEMD and Multi-Scale Permutation Entropy

Abstract

:1. Introduction

- It was theoretically analyzed that the fluctuation in load torque not only produces an amplitude–frequency modulation of the stator current but also produces phase modulation, which provides a theoretical basis for stator current as a condition for coal hardness identification.

- The EEMD algorithm was used to decompose and reconstruct the stator current signal for highlighting the power frequency characteristics of the stator current. In addition, multi-scale permutation entropy was used to describe the weak changes of current from multiple scales. Finally, the multi-scale permutation entropy was identified by the Adaboost-BP network to improve the accuracy of coal rock hardness identification.

- An adaptive speed control strategy of the roadheader based on coal hardness was proposed to ensure efficient cutting of the roadheader by adjusting the rotational speed of the cutting head and swing speed of the cutting arm.

2. Relationship between Load and Current

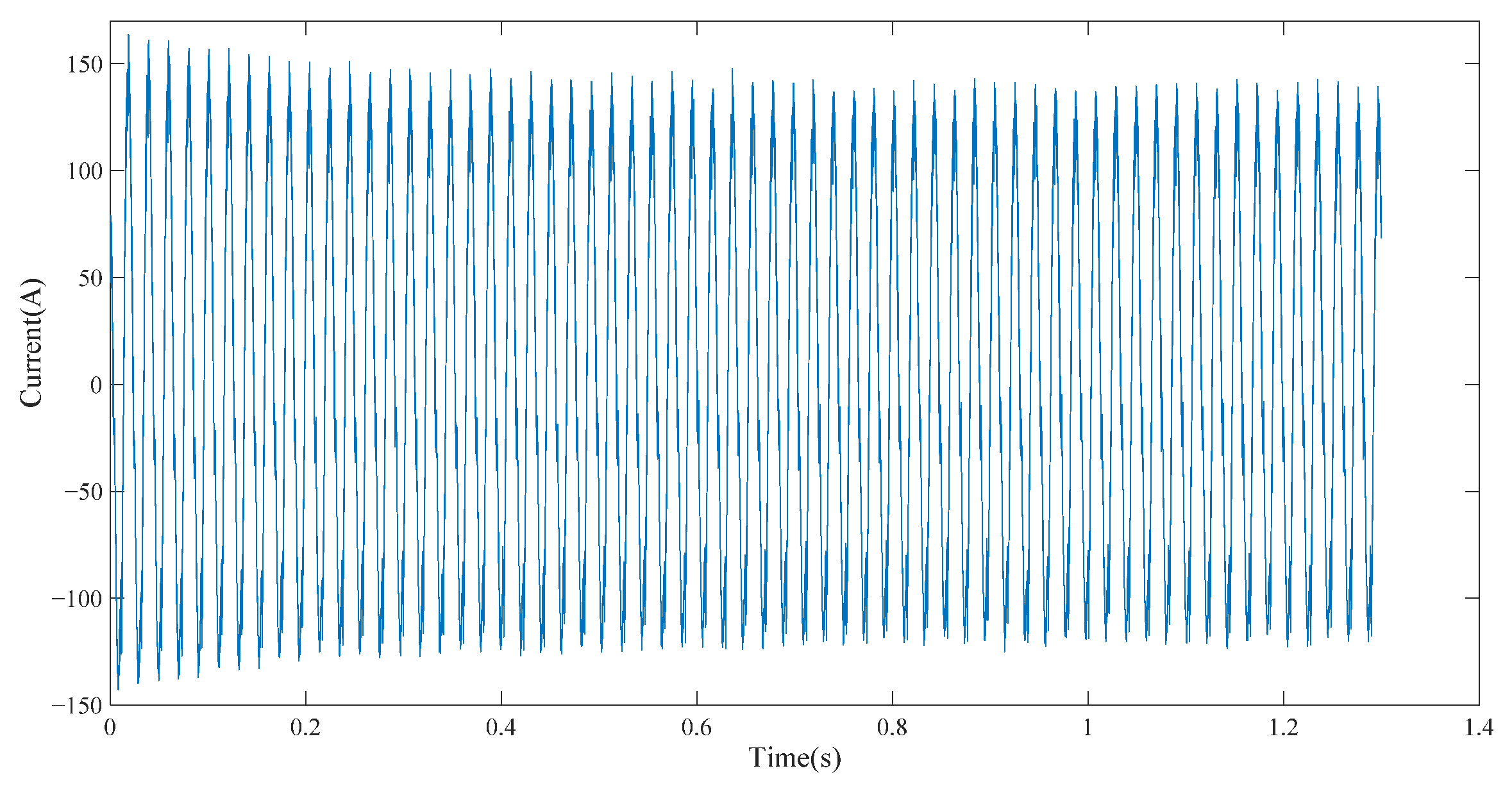

3. Decomposition and Reconstruction of Current Signal of Cutting Motor

3.1. EEMD Decomposition of Cutting Motor Current Signal

3.2. Signal Reconstruction Principle Based on Energy Density and Correlation Coefficient Criterion

4. Coal Hardness Identification

4.1. Calculation of Multi-Scale Permutation Entropy

4.2. Adaboost Improved BP Neural Network-Based Coal Hardness Estimation Algorithm

5. Control and Simulation

5.1. Adaptive Speed Control Based on Coal Rock Hardness Change

5.2. Adaptive Speed Control Simulation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, L.; Luo, C.; Hai, Y.; Fan, Q. Memory cutting of adjacent coal seams based on a hidden markov model. Arab. J. Geosci. 2014, 7, 5051–5060. [Google Scholar] [CrossRef]

- Chao, T.; Xu, R.; Wang, Z.; Lei, S.; Liu, X. An improved genetic fuzzy logic control method to reduce the enlargement of coal floor deformation in shearer memory cutting process. Comput. Intell. Neurosci. 2016, 2016, 3973627. [Google Scholar] [CrossRef] [Green Version]

- Cheluszka, P. Optimization of the Cutting Process Parameters to Ensure High Efficiency of Drilling Tunnels and Use the Technical Potential of the Boom-Type Roadheader. Energies 2020, 13, 6597. [Google Scholar] [CrossRef]

- Zheng, Z.; Chen, D.; Huang, T.; Zhang, G. Coordinated Speed Control Strategy for Minimizing Energy Consumption of a Shearer in Fully Mechanized Mining. Energies 2021, 14, 1224. [Google Scholar] [CrossRef]

- Miao, S.; Liu, X. Free radical characteristics and classification of coals and rocks using electron spin resonance spectroscopy. J. Appl. Spectrosc. 2019, 86, 345–352. [Google Scholar] [CrossRef]

- Wang, X.; Hu, K.X.; Zhang, L.; Yu, X.; Ding, E.J. Characterization and classification of coals and rocks using terahertz time-domain spectroscopy. J. Infrared. Millim. Terahertz Waves 2017, 38, 248–260. [Google Scholar] [CrossRef]

- Si, L.; Wang, Z.; Tan, C.; Liu, X. A novel approach for coal seam terrain prediction through information fusion of improved D–S evidence theory and neural network. Measurement 2014, 54, 140–151. [Google Scholar] [CrossRef]

- Ren, F.; Liu, Z.Y.; Yang, Z.J. Weighted algorithm of multi-sensor data conflict in coal-rock interface recognition. Appl. Mech. Mater. 2011, 58–60, 1908–1913. [Google Scholar] [CrossRef]

- Yong, L.; Gang, C.; Chen, X.; Chang, L. Coal–rock interface recognition based on permutation entropy of LMD and supervised Kohonen neural network. Curr. Sci. 2019, 116, 96–103. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Z.; Zhao, L.; Qi, Y.; Wang, J. Coal-rock recognition in top coal caving using bimodal deep learning and Hilbert-Huang transform. Shock Vib. 2017, 2017, 3809525. [Google Scholar] [CrossRef]

- Zhang, Q.; Gu, J.; Liu, J. Research on coal and rock type recognition based on mechanical vision. Shock Vib. 2021, 2021, 6617717. [Google Scholar] [CrossRef]

- Dong, L.H.; Zhao, P.B. Application of improved canny edge detection algorithm in coal-rock interface recognition. Appl. Mech. Mater. 2012, 220–223, 1279–1283. [Google Scholar] [CrossRef]

- Xue, G.H.; Hu, B.H.; Zhao, X.Y.; Liu, E.M.; Ding, W.J. Study on characteristic extraction of coal and rock at mechanized top coal caving face based on image gray scale. Appl. Mech. Mater. 2014, 678, 193–196. [Google Scholar] [CrossRef]

- Sun, J.; Bo, S. Coal–rock interface detection on the basis of image texture features. Int. J. Min. Sci. Technol. 2013, 23, 681–687. [Google Scholar] [CrossRef]

- Si, L.; Xiong, X.; Wang, Z.; Tan, C. A deep convolutional neural network model for intelligent discrimination between coal and rocks in coal mining face. Math. Probl. Eng. 2020, 2020, 2616510. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Q. Dynamic identification of coal-rock interface based on adaptive weight optimization and multi-sensor information fusion. Inf. Fusion 2018, 51, 114–128. [Google Scholar] [CrossRef]

- Liu, Y.; Dhakal, S.; Hao, B. Coal and rock interface identification based on wavelet packet decomposition and fuzzy neural network. J. Intell. Fuzzy Syst. 2020, 38, 3949–3959. [Google Scholar] [CrossRef]

- Liu, W.; He, K.; Liu, C.Y.; Gao, Q.; Yan, Y.H. Coal-gangue interface detection based on hilbert spectral analysis of vibrations due to rock impacts on a longwall mining machine. Proc. Inst. Mech. Eng. C Mech. Eng. Sci. 2014, 229, 1523–1531. [Google Scholar] [CrossRef]

- Deshmukh, S.; Raina, A.K.; Murthy, V.M.S.R.; Trivedi, R.; Vajre, R. Roadheader—A comprehensive review. Tunn. Undergr. Sptech. 2020, 95, 103148. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Z.; Wang, J.; Tan, C.; Zhang, L.; Liu, X. Acoustic-Based Cutting Pattern Recognition for Shearer through Fuzzy C-Means and a Hybrid Optimization Algorithm. Appl. Sci. 2016, 6, 294. [Google Scholar] [CrossRef] [Green Version]

- Xue, G.H.; Liu, E.M.; Zhao, X.Y.; Hu, B.H.; Ding, W.J. Coal-rock character recognition in fully mechanized caving faces based on acoustic pressure data time domain analysis. Appl. Mech. Mater. 2015, 789–790, 566–570. [Google Scholar] [CrossRef]

- Wang, B.P.; Wang, Z.C.; Li, Y.X. Application of Wavelet Packet Energy Spectrum in Coal-rock Interface Recognition. Key. Eng. Mater. 2011, 474–476, 1103–1106. [Google Scholar] [CrossRef]

- Li, N.; Huang, B.; Zhang, X.; Tan, Y.; Li, B. Characteristics of microseismic waveforms induced by hydraulic fracturing in coal seam for coal rock dynamic disasters prevention. Saf. Sci. 2019, 115, 188–198. [Google Scholar] [CrossRef]

- Nan, W.; Qin, Q.; Li, C.; Zhao, S.; Jian, H. Direct interpretation of petroleum reservoirs using electromagnetic radiation anomalies. J. Petrol. Sci. Eng. 2017, 146, 84–95. [Google Scholar] [CrossRef]

- Gilles, J.; Heal, K. A parameterless scale-space approach to find meaningful modes in histograms—Application to image and spectrum segmentation. Int. J. Wavelets Multiresolut. Inf. Process. 2014, 12, 1450044. [Google Scholar] [CrossRef]

- Feng, G.; Wei, H.; Qi, T.; Pei, X.; Wang, H. A Transient Electromagnetic Signal Denoising Method Based on An Improved Variational Mode Decomposition Algorithm. Measurement 2021, 184, 109815. [Google Scholar] [CrossRef]

- Wei, W.; Li, L.; Shi, W.F.; Liu, J.P. Ultrasonic imaging recognition of coal-rock interface based on the improved variational mode decomposition. Measurement 2020, 170, 108728. [Google Scholar] [CrossRef]

- Yang, Y.; Li, G.; Yuan, A. Performance analysis of a hybrid power cutting system for roadheader. Math. Probl. Eng. 2017, 2017, 1359592. [Google Scholar] [CrossRef]

- Shi., H.; Dong, X.; Zhang, N.; Ding, N. Research of Dynamic Load Identification for Rock Roadheader. In Proceedings of the 2018 IEEE International Conference on Progress in Informatics and Computing (PIC), Suzhou, China, 14–16 December 2018; pp. 158–162. [Google Scholar] [CrossRef]

- Gao, B.; Woo, W.L.; Dlay, S.S. Single-channel source separation using emd-subband variable regularized sparse features. IEEE Trans. Audio Speech Lang. Process. 2011, 19, 961–976. [Google Scholar] [CrossRef]

- Jin, Y.; Duan, Y. Identification of Unstable Subsurface Rock Structure Using Ground Penetrating Radar: An EEMD-Based Processing Method. Appl. Sci. 2020, 10, 8499. [Google Scholar] [CrossRef]

- Liu, X.; Liu, L.; Zhou, X.; Li, W. A combined denoising approach based on EEMD and sparse-constrained curvelet transform. In Proceedings of the International Geophysical Conference, Beijing, China, 24–27 April 2018. [Google Scholar]

- Kumar, R.; Kaur, P.; Singh, D.; Sharma, M.; Singh, M.; Meng, J. Online monitoring technology of power transformer based on vibration analysis. Int. J. Intell. Syst. 2021, 30, 554–563. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, X.; Yuan, J.; Wang, X.; Zeng, Y. The extraction method of laser ultrasonic defect signal based on EEMD. Opt. Commun. 2021, 484, 126570. [Google Scholar] [CrossRef]

- Gao, Y.; Villecco, F.; Li, M.; Song, W. Multi-Scale Permutation Entropy Based on Improved LMD and HMM for Rolling Bearing Diagnosis. Entropy 2017, 19, 176. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Si, S.; Wei, Y.; Li, Y. The Optimized Multi-Scale Permutation Entropy and Its Application in Compound Fault Diagnosis of Rotating Machinery. Entropy 2019, 21, 170. [Google Scholar] [CrossRef] [Green Version]

- Dávalos, A.; Jabloun, M.; Ravier, P.; Buttelli, O. The Impact of Linear Filter Preprocessing in the Interpretation of Permutation Entropy. Entropy 2021, 23, 787. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Zhang, M.; Liu, T.; Wang, C. Control Strategy for Upper Limb Rehabilitation Robot Based on Muscle Strength Estimation. In Proceedings of the 2020 International Conference on Artificial Intelligence and Computer Engineering (ICAICE), Beijing, China, 23–25 October 2020; pp. 54–60. [Google Scholar] [CrossRef]

- Liu, H.; Tian, H.Q.; Li, Y.F.; Zhang, L. Comparison of four Adaboost algorithm based artificial neural networks in wind speed predictions. Energy Convers. Manag. 2015, 92, 67–81. [Google Scholar] [CrossRef]

- Liu, Q.; Lu, C.; Liu, T.; Xu, Z. Adaptive Cutting Control for Roadheaders Based on Performance Optimization. Machines 2021, 9, 46. [Google Scholar] [CrossRef]

- Liang, Q.W.; Yang, C.; Lin, S.; Hao, X.Y. Multi-source information grey fusion method of torpedo loading reliability. Ocean Eng. 2021, 234, 109303. [Google Scholar] [CrossRef]

- Koh, B.H.D.; Lim, C.L.P.; Rahimi, H.; Woo, W.L.; Gao, B. Deep Temporal Convolution Network for Time Series Classification. Sensors 2021, 21, 603. [Google Scholar] [CrossRef]

| Mean Energy | IMF2 | IMF3 | IMF4 | IMF5 | IMF6 | IMF7 | IMF8 | IMF9 |

|---|---|---|---|---|---|---|---|---|

| E(10−2) | 0.6615 | 0.1529 | 0.0097 | 0.1855 | 20.49 | 13.11 | 0.1281 | 0.0038 |

| Average Correlation Coefficient | IMF2 | IMF3 | IMF4 | IMF5 | IMF6 | IMF7 | IMF8 | IMF9 |

|---|---|---|---|---|---|---|---|---|

| R | 0.0602 | 0.0279 | 0.0387 | 0.1396 | 0.9455 | 0.9079 | 0.0389 | 0.0005 |

| s | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Pk = 350 | 0.5198 | 0.6122 | 0.6862 | 0.7483 | 0.8011 | 0.85 | 0.8896 | 0.9225 | 0.9504 | 0.9708 |

| Pk = 490 | 0.5175 | 0.6078 | 0.6817 | 0.7448 | 0.7985 | 0.8451 | 0.8848 | 0.918 | 0.9434 | 0.9678 |

| Pk = 650 | 0.5045 | 0.587 | 0.6556 | 0.7143 | 0.7656 | 0.8107 | 0.8502 | 0.884 | 0.9139 | 0.9388 |

| Pk = 800 | 0.4993 | 0.5785 | 0.6443 | 0.7009 | 0.7508 | 0.7951 | 0.8343 | 0.8683 | 0.8988 | 0.9235 |

| Pk = 1000 | 0.4945 | 0.5708 | 0.6343 | 0.6898 | 0.7389 | 0.7823 | 0.821 | 0.8556 | 0.8861 | 0.9122 |

| Pk = 1300 | 0.4909 | 0.5652 | 0.6275 | 0.6818 | 0.7299 | 0.7721 | 0.8105 | 0.8441 | 0.875 | 0.9013 |

| Pk (MPa) | 350 | 490 | 650 | 800 | 1000 | 1300 |

| BP | 0.2864 | 0.1275 | 0.1545 | 0.0734 | 0.0486 | 0.0585 |

| Adaboost-BP | 0.0707 | 0.102 | 0.0955 | 0.0532 | 0.0299 | 0.0285 |

| Pk = 350 (MPa) | n (r/min) | v (m/min) | |||||

|---|---|---|---|---|---|---|---|

| Before optimization | 50 | 2.5 | 0.0117 | 0.0612 | 0.0236 | 0.0106 | 1.017 |

| After optimization | 48.28 | 2.43 | 0.011 | 0.0583 | 0.0215 | 0.0102 | 0.9136 |

| Pk(MPa) | 350 | 490 | 650 | 800 | 1000 | 1300 |

| n(r/min) | 48.28 | 43.96 | 40.15 | 38 | 36.91 | 34.17 |

| v(m/min) | 2.43 | 2.18 | 1.92 | 1.7 | 1.508 | 1.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Lu, C.; Liu, Q.; Zha, Y. Coal and Rock Hardness Identification Based on EEMD and Multi-Scale Permutation Entropy. Entropy 2021, 23, 1113. https://doi.org/10.3390/e23091113

Liu T, Lu C, Liu Q, Zha Y. Coal and Rock Hardness Identification Based on EEMD and Multi-Scale Permutation Entropy. Entropy. 2021; 23(9):1113. https://doi.org/10.3390/e23091113

Chicago/Turabian StyleLiu, Tao, Chao Lu, Qingyun Liu, and Yiwen Zha. 2021. "Coal and Rock Hardness Identification Based on EEMD and Multi-Scale Permutation Entropy" Entropy 23, no. 9: 1113. https://doi.org/10.3390/e23091113