Maximum Efficient Power Performance Analysis and Multi-Objective Optimization of Two-Stage Thermoelectric Generators

Abstract

:1. Introduction

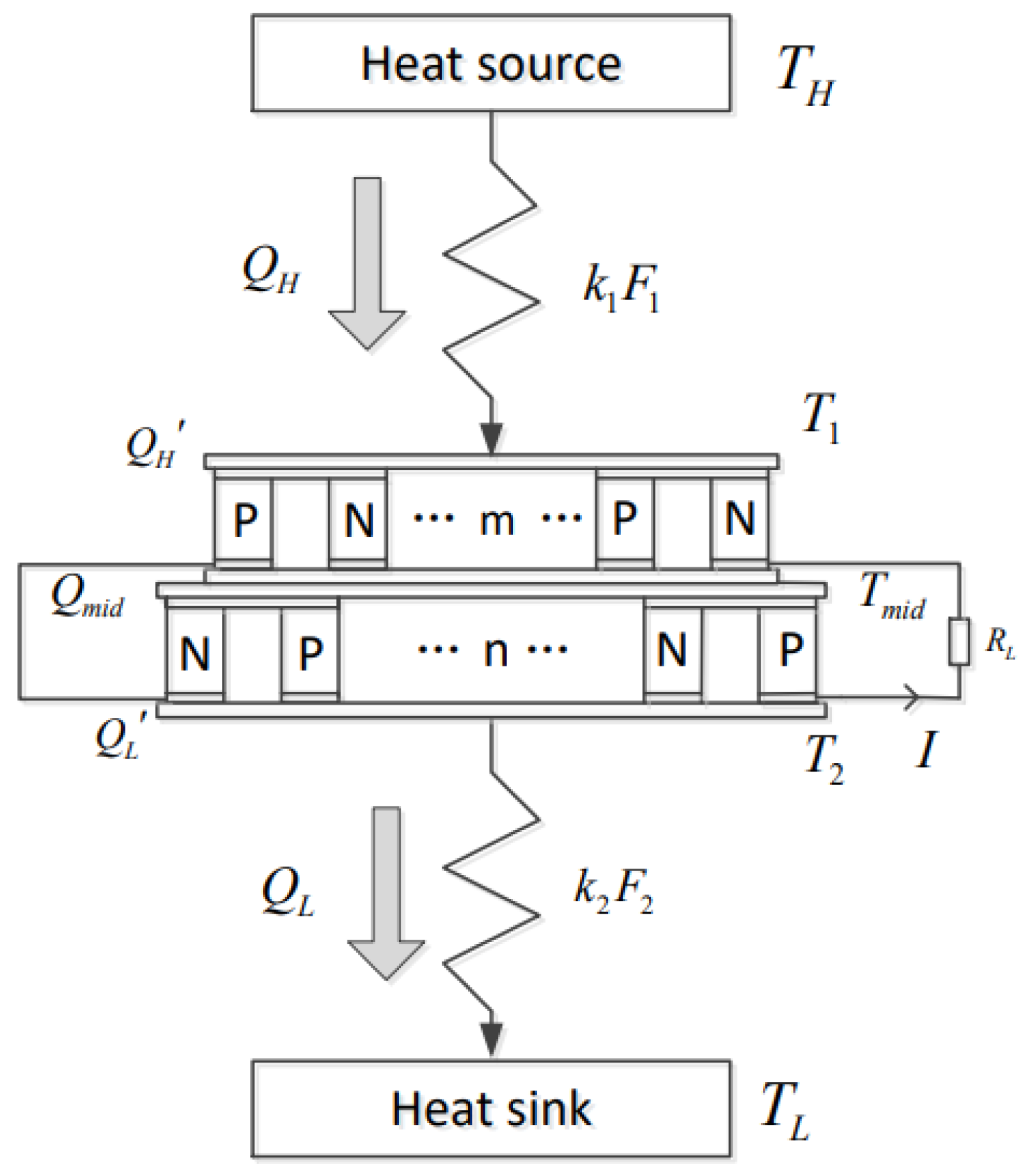

2. Model of TTEG

- (1)

- The effects of convective and radiative HT between and outside the TE element are ignored.

- (2)

- The effect of the Thomson effect is ignored.

- (3)

- The contact surface temperature difference and heat leakage losses between the first and second stages are ignored.

- (4)

- When the temperature difference at all stages is not large, the performance of the TE elements at all stages does not change with temperature.

3. Efficient Power Performance Analysis

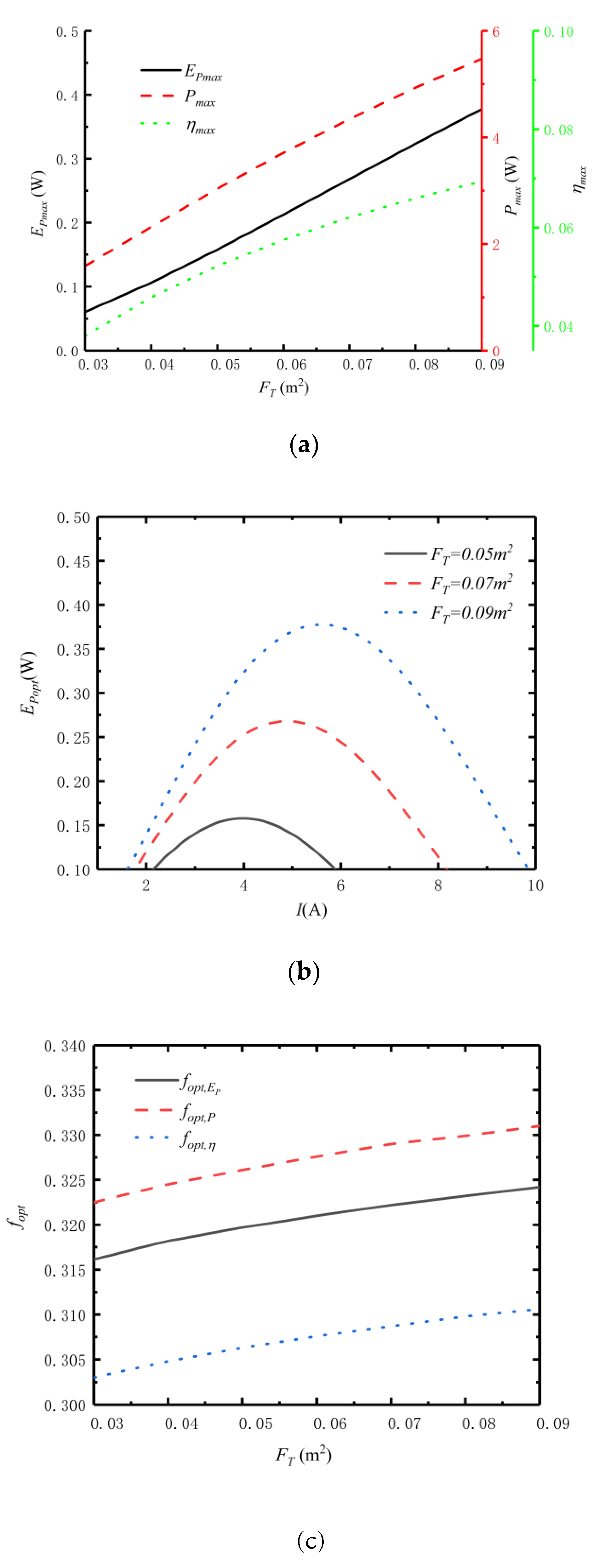

3.1. Optimal Distribution of Heat Exchangers Area

3.2. Effect of Number and Distribution of Thermoelectric Elements on Efficient Power

3.3. Effect of Total Heat Exchanger Area on Efficient Power

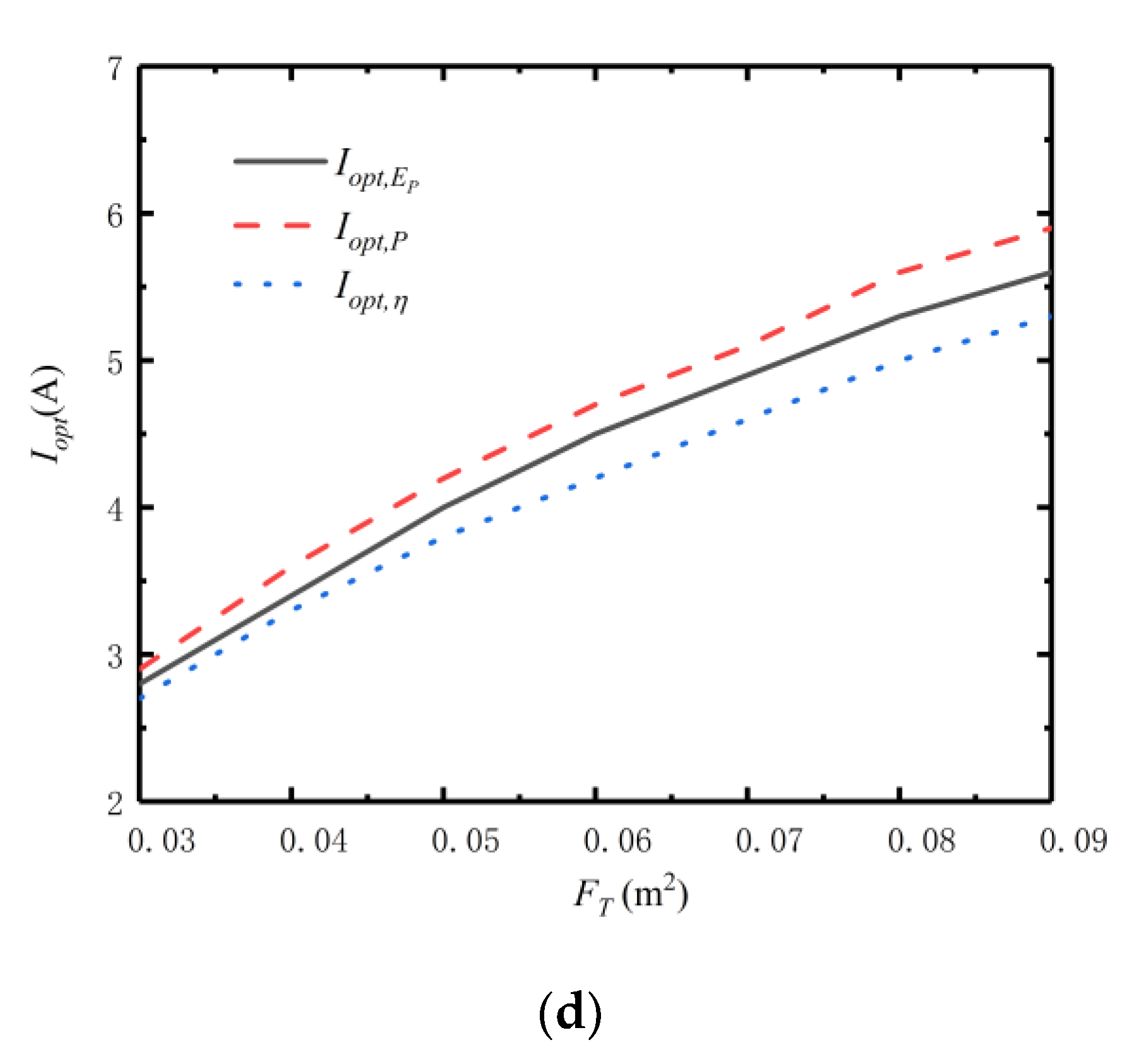

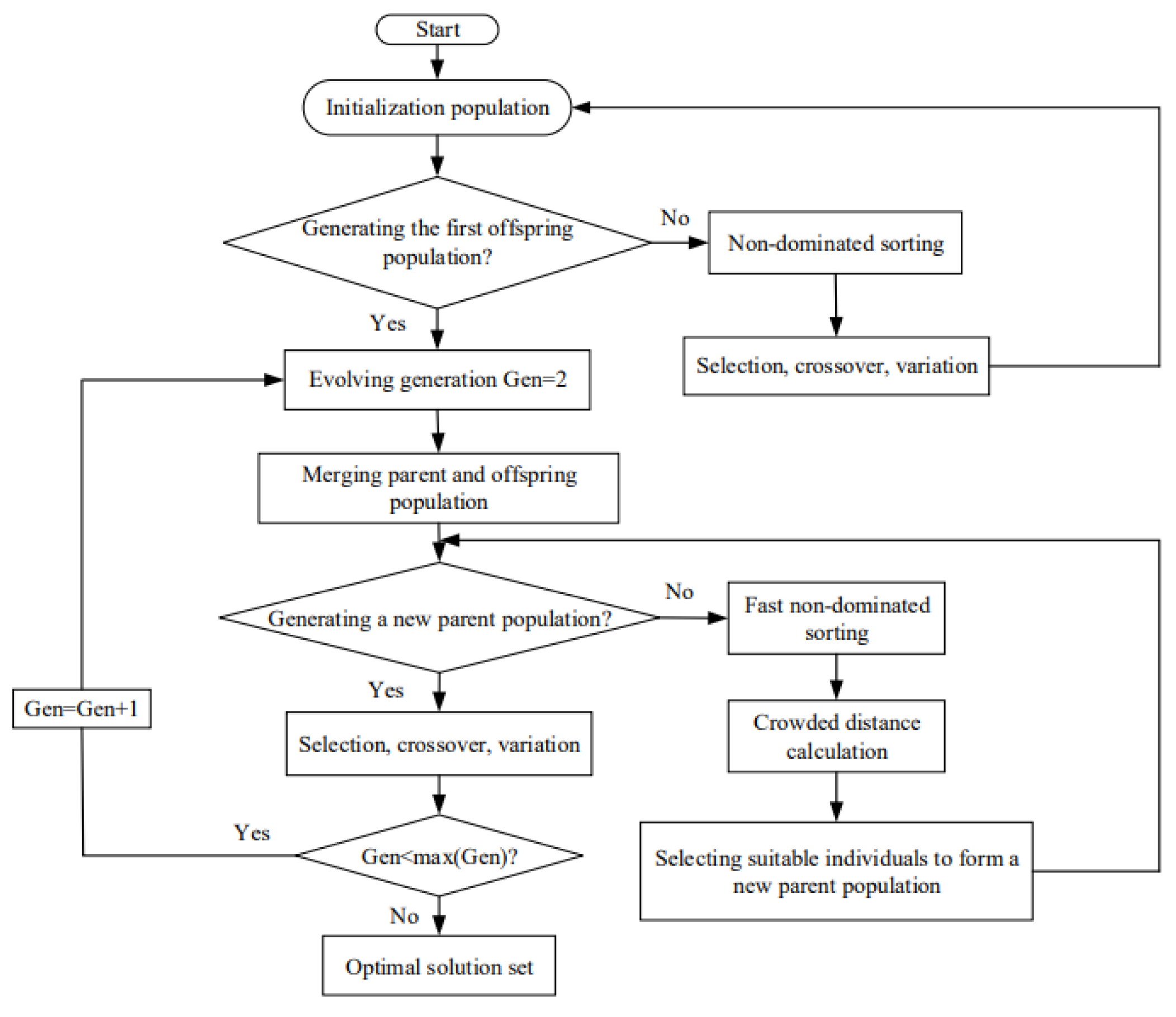

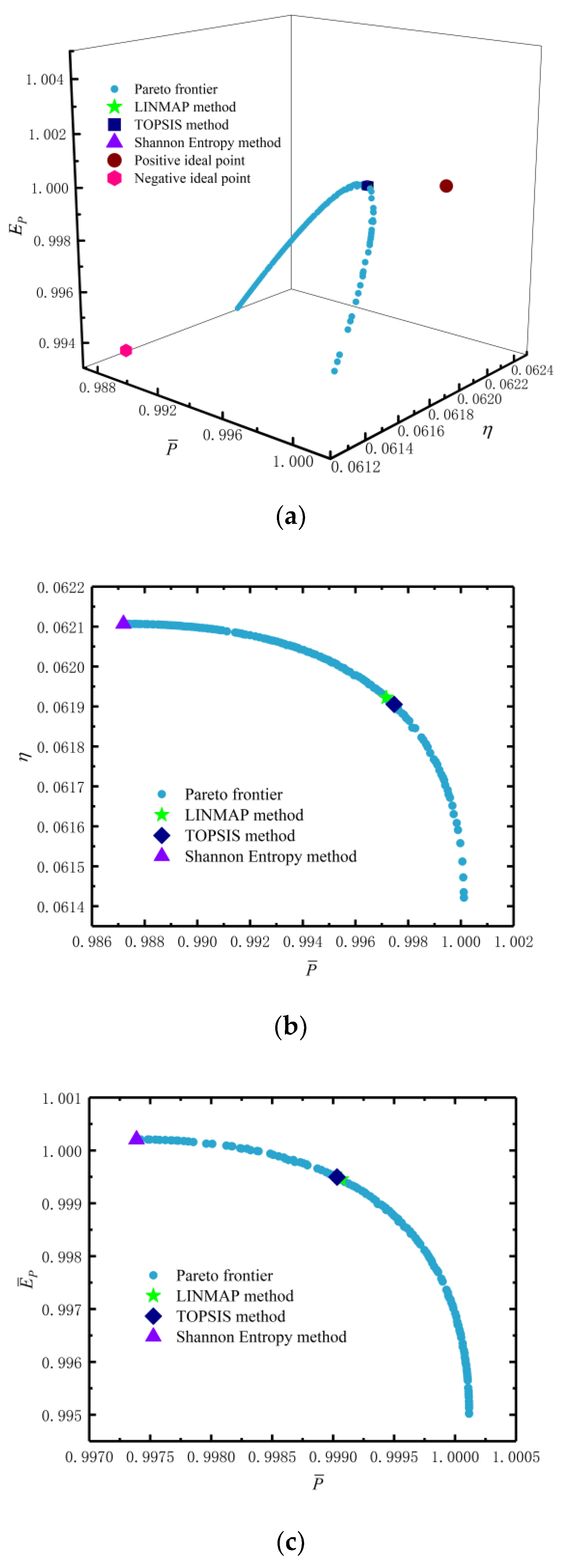

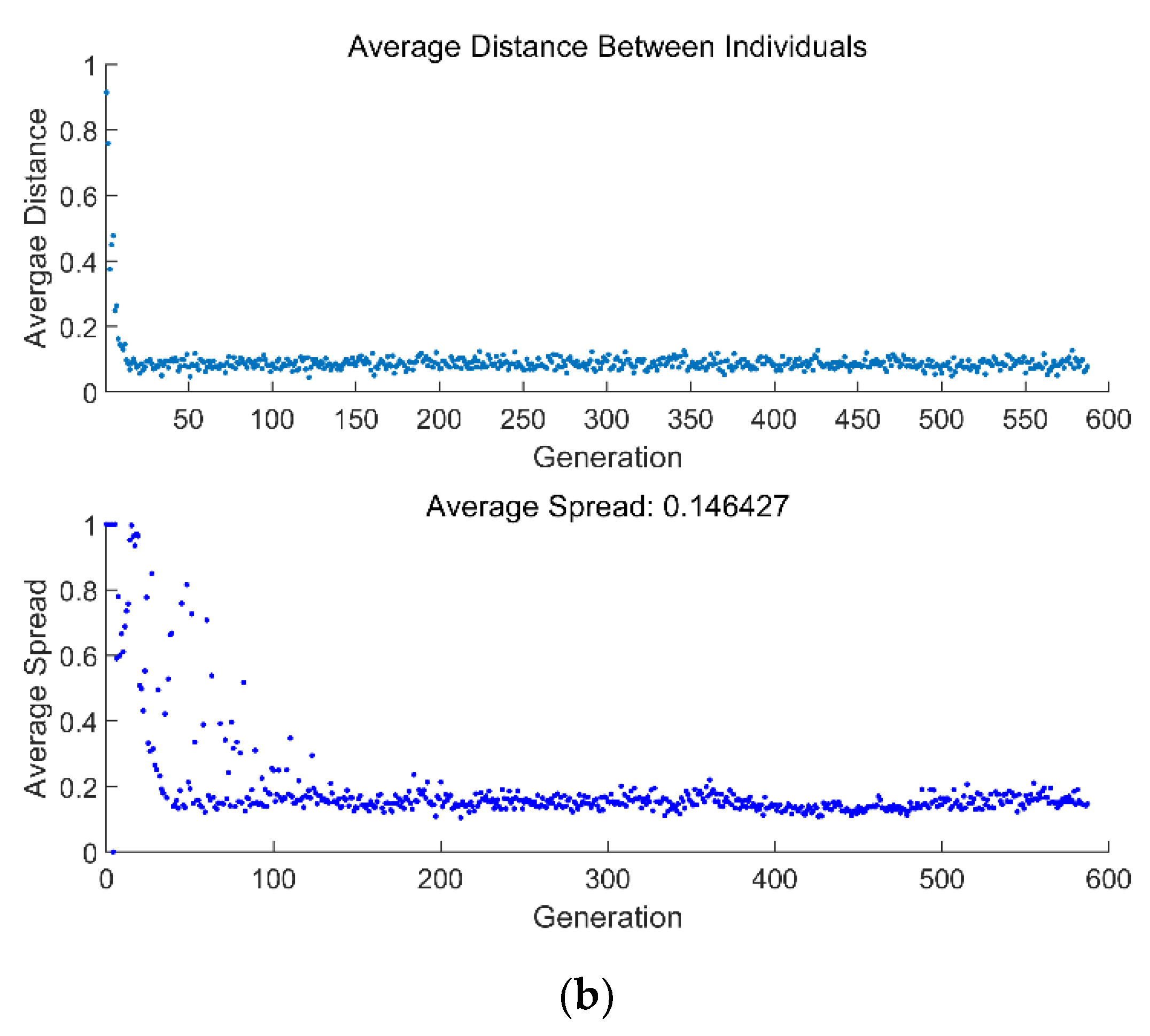

4. Multi-Objective Optimization

5. Conclusions

- The efficiency at maximum efficient power is significantly higher than the efficiency at maximum power. Under the same distribution of HEXs area, the efficiency at maximum efficient power and efficiency at maximum power both reach the maximum. The efficient power takes into account both the output power and thermal efficiency, and can provide new ideas for the design of practical TTEGs.

- It is found that reducing the total number of TE elements and increasing the total HEX area can not only obtain a higher output current, but also higher efficient power.

- By comparing the DIs of three-objective optimization and the DIs of single-objective optimization, it can be found that the former has a lower DI. Therefore, taking the three-objective optimization as the design scheme, the performance of the TTEG will be optimized.

- It is also found that in the MOO, there are optimal intervals for the distribution of the TE elements, output current and distribution of HEX area. Values in these ranges will significantly improve the various performances of the TTEGs.

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Efficient power (W) | |

| Heat transfer area of heat exchangers () | |

| Output current () | |

| Thermal conductance () | |

| Coefficient of heat transfer () | |

| Total number of thermoelectric elements | |

| Number of first-stage thermoelectric elements | |

| Number of second-stage thermoelectric elements | |

| Output power () | |

| Heat flux () | |

| Electric resistance () | |

| Temperature () | |

| Greek symbols | |

| Total Seebeck coefficient () | |

| Thermal efficiency | |

| Subscripts | |

| 1 | High temperature side of thermoelectric device |

| 2 | Low temperature side of thermoelectric device |

| Maximum efficient power point | |

| High-temperature heat source | |

| Low-temperature heat sink | |

| max | Maximum value |

| mid | Middle connection layer |

| Optimal | |

| Maximum power point | |

| Total | |

| Maximum thermal efficiency point | |

| Superscript | |

| Dimensionless | |

| Abbreviations | |

| DI | Deviation index |

| FTT | Finite-time thermodynamics |

| HEX | Heat exchanger |

| HT | Heat transfer |

| MOO | Multi-objective optimization |

| NET | Non-equilibrium thermodynamics |

| TE | Thermoelectric |

| TTEG | Two-stage thermoelectric generator |

Appendix A. Coefficients in Equation (12)

References

- DiSalvo, F.J. Thermoelectric cooling and power generation. Science 1999, 285, 703–706. [Google Scholar] [CrossRef]

- Zoui, M.A.; Bentou-ba, S.; Stocholm, J.G.; Bourouis, M. A review on thermoelectric generators: Progress and applications. Energies 2020, 13, 3606. [Google Scholar] [CrossRef]

- Tohidi, F.; Holagh, S.G.; Chitsaz, A. Thermoelectric generators: A comprehensive review of characteristics and applications. Appl. Therm. Eng. 2022, 201, 117793. [Google Scholar] [CrossRef]

- Atouei, S.A.; Ranjbar, A.A.; Rezania, A. Experimental investigation of two-stage thermoelectric generator system integrated with phase change materials. Appl. Energy 2017, 208, 332–343. [Google Scholar] [CrossRef]

- Pei, J.; Li, L.L.; Liu, D.W.; Zhang, B.P.; Xiao, Y.; Li, J.F. Development of integrated two-stage thermoelectric generators for large temperature difference. Sci. China Technol. Sci. 2019, 62, 1596–1604. [Google Scholar] [CrossRef]

- Ma, L.Y.; Zhao, Q.; Zhang, H.C. Performance analysis of a new hybrid system composed of a concentrated photovoltaic cell and a two-stage thermoelectric generator. Sustain. Energy Grids Netw. 2021, 27, 100481. [Google Scholar] [CrossRef]

- Andresen, B. Finite-Time Thermodynamics; University of Copenhagen: Copenhagen, Denmark, 1983. [Google Scholar]

- Chen, L.G.; Wu, C.; Sun, F.R. Finite time thermodynamic optimization or entropy generation minimization of energy systems. J. Non-Equilib. Thermodyn. 1999, 24, 327–359. [Google Scholar]

- Andresen, B. Current trends in finite-time thermodynamics. Angew. Chem. Int. Ed. 2011, 50, 2690–2704. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.G.; Meng, F.K.; Sun, F.R. Thermodynamic analyses and optimizations for thermoelectric devices: The state of the arts. Sci. China Tech. Sci. 2016, 59, 442–455. [Google Scholar] [CrossRef]

- Feidt, M. The history and perspectives of efficiency at maximum power of the Carnot engine. Entropy 2017, 19, 369. [Google Scholar] [CrossRef] [Green Version]

- Junior, O.H.A.; Calderon, N.H.; De Souza, S.S. Characterization of a thermoelectric generator (TEG) system for waste heat recovery. Energies 2018, 11, 1555. [Google Scholar] [CrossRef]

- Feidt, M.; Costea, M. Progress in Carnot and Chambadal modeling of thermomechnical engine by considering entropy and heat transfer entropy. Entropy 2019, 21, 1232. [Google Scholar] [CrossRef] [Green Version]

- Pourkiaei, S.M.; Ahmadi, M.H.; Sadeghzadeh, M.; Moosavi, S.; Pourfayaz, F.; Chen, L.G.; Yazdi, M.A.; Kumar, R. Thermoelectric cooler and thermoelectric generator devices: A review of present and potential applications, modeling and materials. Energy 2019, 186, 115849. [Google Scholar] [CrossRef]

- Cotfas, P.A.; Cotfas, D.T. Comprehensive review of methods and instruments for photovoltaic–thermoelectric generator hybrid system characterization. Energies 2020, 13, 6045. [Google Scholar] [CrossRef]

- Neska, M.; Mrozek, M.; Zurek-Mortka, M.; Majcher, A. Analysis of the parameters of the two-sections hot side heat exchanger of the module with thermoelectric generators. Energies 2021, 14, 5196. [Google Scholar] [CrossRef]

- Attar, A.; Rady, M.; Abuhabaya, A.; Albatati, F.; Hegab, A.A.; Almatrafi, E. Performance assessment of using thermoelectric generators for waste heat recovery from vapor compression refrigeration systems. Energies 2021, 14, 8192. [Google Scholar] [CrossRef]

- Araiz, M.; Casi, Á.; Catalán, L.; Aranguren, P.; Astrain, D. Thermoelectric generator with passive biphasic thermosyphon heat exchanger for waste heat recovery: Design and experimentation. Energies 2021, 14, 5815. [Google Scholar] [CrossRef]

- Pfeiffelmann, B.; Benim, A.C.; Joos, F. Water-cooled thermoelectric generators for improved net output power: A review. Energies 2021, 14, 8329. [Google Scholar] [CrossRef]

- Yang, W.L.; Zhu, W.C.; Yang, Y.; Huang, L.; Shi, Y.; Xie, C.J. Thermoelectric performance evaluation and optimization in a concentric annular thermoelectric generator under different cooling methods. Energies 2022, 15, 2231. [Google Scholar] [CrossRef]

- Andresen, B.; Salamon, P. Future perspectives of finite-time thermodynamics. Entropy 2022, 24, 690. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.G.; Li, J.; Sun, F.R.; Wu, C. Performance optimization of a two-stage semiconductor thermoelectric-generator. Appl. Energy 2005, 82, 300–312. [Google Scholar] [CrossRef]

- Hans, R.; Manikandan, S.; Kaushik, S.C. Performance optimization of two-stage exoreversible thermoelectric converter in electrically series and parallel configuration. J. Electron. Mater. 2015, 44, 3571–3580. [Google Scholar] [CrossRef]

- Asaadi, S.; Khalilarya, S.; Jafarmadar, S. A thermodynamic and exergoeconomic numerical study of two-stage annular thermoelectric generator. Appl. Therm. Eng. 2019, 156, 371–381. [Google Scholar] [CrossRef]

- Zhang, F.; Cheng, L.; Wu, M.Y.; Xu, X.Y.; Wang, P.C.; Liu, Z.B. Performance analysis of two-stage thermoelectric generator model based on Latin hypercube sampling. Energy Convers. Manag. 2020, 221, 113159. [Google Scholar] [CrossRef]

- Yan, Z.J. η and P of a Carnot engine at maximum ηP. Chin. J. Nat. 1984, 7, 475. (In Chinese) [Google Scholar]

- Yilmaz, T. A new performance criterion for heat engines: Efficient power. J. Energy Inst. 2006, 79, 38–41. [Google Scholar] [CrossRef]

- Yilmaz, T. Performance optimization of a Joule-Brayton engine based on the efficient power criterion. Proc. IMechE Part A J. Power Energy 2007, 221, 603–608. [Google Scholar] [CrossRef]

- Kumar, R.; Kaushik, S.C.; Kumar, R. Efficient power of Brayton heat engine with friction. Int. J. Eng. Res. Technol. 2013, 6, 643–650. [Google Scholar]

- Kumar, R.; Kaushik, S.C.; Kumar, R. Performance analysis and optimization of Brayton heat engine at maximum efficient power using temperature dependent specific heat of working fluid. J. Therm. Eng. 2015, 1, 345–354. [Google Scholar] [CrossRef]

- Nilavarasi, K.; Ponmurugan, M. Optimized efficiency at maximum figure of merit and efficient power of power law dissipative Carnot like heat engines. J. Stat. Mech. Theory Exp. 2021, 043208. [Google Scholar] [CrossRef]

- Gong, Q.R.; Ge, Y.L.; Chen, L.G.; Shi, S.S.; Feng, H.J. Performance analyses and four-objective optimizations of an irreversible rectangular cycle. Entropy 2021, 23, 1203. [Google Scholar] [CrossRef] [PubMed]

- Tian, L.; Chen, L.G.; Ren, T.T.; Ge, Y.L.; Feng, H.J. Optimal distribution of heat exchanger area for maximum efficient power of thermoelectric generators. Energy Rep. 2022, 8, 10492–10500. [Google Scholar] [CrossRef]

- Liu, Z.C.; Zhu, S.P.; Ge, Y.; Shan, F.; Zeng, L.P.; Liu, W. Geometry optimization of two-stage thermoelectric generators using simplified conjugate-gradient method. Appl. Energy 2017, 190, 540–552. [Google Scholar] [CrossRef]

- Sun, H.N.; Ge, Y.; Liu, W.; Zhi, C. Geometric optimization of two-stage thermoelectric generator using genetic algorithms and thermodynamic analysis. Energy 2019, 171, 37–48. [Google Scholar] [CrossRef]

- Arora, R.; Kaushikb, S.C.; Arora, R. Multi-objective and multi-parameter optimization of two-stage thermoelectric generator in electrically series and parallel configurations through NSGA-II. Energy 2015, 91, 242–254. [Google Scholar] [CrossRef]

- Arora, R.; Kaushikb, S.C.; Arora, R. Thermodynamic modeling and multi-objective optimization of two stage thermoelectric generator in electrically series and parallel configuration. Appl. Therm. Eng. 2016, 103, 1312–1323. [Google Scholar] [CrossRef]

- Arora, R.; Arora, R. Multi-objective optimization and analytical comparison of single- and 2-stage (series/parallel) thermoelectric heat pumps. Int. J. Energy Res. 2018, 42, 1760–1778. [Google Scholar] [CrossRef]

- Sun, H.N.; Gil, S.U.; Liu, W.; Zhi, C. Structure optimization and exergy analysis of a two-stage TEC with two different connections. Energy 2019, 180, 175–191. [Google Scholar] [CrossRef]

- Arora, R.; Kaushik, S.C.; Kumar, R.; Arora, R. Soft computing based multi-objective optimization of Brayton cycle power plant with isothermal heat addition using evolutionary algorithm and decision making. Appl. Soft Comput. 2016, 46, 267–283. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ahmadi, M.A.; Pourfayaz, F.; Hosseinzade, H.; Acıkkalp, E.; Tlili, I.; Feidt, M. Designing a powered combined Otto and Stirling cycle power plant through multi-objective optimization approach. Renew. Sustain. Energy Rev. 2016, 62, 585–595. [Google Scholar] [CrossRef]

- Fergani, Z.; Morosuk, T.; Touil, D. Exergy-based multi-objective optimization of an organic Rankine cycle with a zeotropic mixture. Entropy 2021, 23, 954. [Google Scholar] [CrossRef] [PubMed]

- Rostami, M.; Assareh, E.; Moltames, R.; Jafarinejad, T. Thermo-economic analysis and multi-objective optimization of a solar dish Stirling engine. Energy Sources Part A 2021, 43, 2861–2877. [Google Scholar] [CrossRef]

- Ahmed, F.; Zhu, S.M.; Yu, G.Y.; Luo, E.C. A potent numerical model coupled with multi-objective NSGA-II algorithm for the optimal design of Stirling engine. Energy 2022, 247, 123468. [Google Scholar] [CrossRef]

- Yu, J.L.; Zhao, H.; Xie, K.S. Analysis of optimum configuration of two-stage thermoelectric modules. Cryogenics 2007, 47, 89–93. [Google Scholar] [CrossRef]

- Yu, J.; Wang, B. Enhancing the maximum coefficient of performance of thermoelectric cooling modules using internally cascaded thermoelectric couples. Int. J. Refrig. 2009, 32, 32–39. [Google Scholar] [CrossRef]

- Du, C.Y.; Wen, C.D. Experimental investigation and numerical analysis for one- stage thermoelectric cooler considering Thomson effect. Int. J. Heat Mass Transfer 2011, 54, 4875–4884. [Google Scholar] [CrossRef]

- He, W.; Su, Y.; Riffat, S.B.; Hou, J.X.; Ji, J. Parametrical analysis of the design and performance of a solar heat pipe thermoelectric generator unit. Appl. Energy 2011, 88, 5083–5089. [Google Scholar] [CrossRef]

- Miguel, G.; Rachel, R.; Brandon, O.; Lee, H. Influence of electrical current variance and thermal resistances on optimum working conditions and geometry for thermoelectric energy harvesting. Jpn. J. Appl. Phys. 2013, 113, 174908. [Google Scholar]

- Siyi, Z.; Sammakia, B.G.; White, B.; Borgesen, P. Multiscale modeling of thermoelectric generators for the optimized conversion performance. Int. J. Heat Mass Transfer 2013, 62, 435–444. [Google Scholar]

- Lam, T.T.; Yuan, S.W.K.; Fong, E.; Fischer, W.D. Analytical study of transient performance of thermoelectric coolers considering the Thomson effect. Int. J. Therm. Sci. 2018, 130, 435–448. [Google Scholar] [CrossRef]

- Chen, L.G.; Meng, F.K.; Ge, Y.L.; Feng, H.J.; Xia, S.J. Performance optimization of a class of combined thermoelectric heating devices. Sci. China: Tech. Sci. 2020, 63, 2640–2648. [Google Scholar] [CrossRef]

- Shen, L.M.; Zhang, W.S.; Liu, G.Y.; Tu, Z.L.; Lu, Q.Q.; Chen, H.X.; Huang, Q.L. Performance enhancement investigation of thermoelectric cooler with segmented configuration. Appl. Therm. Eng. 2020, 168, 114852. [Google Scholar] [CrossRef]

- Rowe, D.M. CRC Handbook of Thermoelectrics, 1st ed.; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef] [Green Version]

- Sayyaadi, H.; Mehrabipour, R. Efficiency enhancement of a gas turbine cycle using an optimized tubular recuperative heat exchanger. Energy 2012, 38, 362–375. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making-Methods and Applications a State of the Art Survey; Springer: New York, NY, USA, 1981. [Google Scholar]

- Etghani, M.M.; Shojaeefard, M.H.; Khalkhali, A.; Akbari, M. A hybrid method of modified NSGA-II and Topsis to optimize performance and emissions of a diesel engine using biodiesel. Appl. Therm. Eng. 2013, 59, 309–315. [Google Scholar] [CrossRef]

- Guisado, J.; Morales, F.J.; Guerra, J. Application of shannon’s entropy to classify emergent behaviors in a simulation of laser dynamics. Math. Comput. Modell. 2005, 42, 847–854. [Google Scholar] [CrossRef]

- Kumar, R.; Kaushik, S.C.; Kumar, R.; Hans, R. Multi-objective thermodynamic optimization of an irreversible regenerative Brayton cycle using evolutionary algorithm and decision making. Ain Shams Eng. J. 2016, 7, 741–753. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Xu, F. Finite-time thermodynamic modeling and a comparative performance analysis for irreversible Otto, Miller and Atkinson Cycles. Entropy 2018, 20, 75. [Google Scholar] [CrossRef]

| 40 | 19 | 21 | 0.308 | 0.475 |

| 50 | 24 | 26 | 0.3059 | 0.48 |

| 60 | 29 | 31 | 0.2964 | 0.4833 |

| 70 | 34 | 36 | 0.2832 | 0.4857 |

| 80 | 39 | 41 | 0.2683 | 0.4875 |

| 90 | 44 | 46 | 0.2531 | 0.4889 |

| 100 | 49 | 51 | 0.2381 | 0.49 |

| Optimization Objectives | Decision-Making Approach | Optimization Variables | Performance Indicators | Deviation Index | ||||

|---|---|---|---|---|---|---|---|---|

| , and | LINMAP | 4.9 | 0.3221 | 39/80 | 0.9973 | 0.0619 | 1.0000 | 0.1866 |

| TOPSIS | 4.9 | 0.3221 | 39/80 | 0.9973 | 0.0619 | 1.0000 | 0.1866 | |

| Shannon entropy | 4.9 | 0.3222 | 39/80 | 0.9974 | 0.0619 | 1.0000 | 0.1815 | |

| and | LINMAP | 4.9 | 0.3221 | 39/80 | 0.9972 | 0.0619 | 1.0000 | 0.1943 |

| TOPSIS | 4.9 | 0.3217 | 39/80 | 0.9975 | 0.0619 | 1.0000 | 0.1751 | |

| Shannon entropy | 4.6 | 0.3087 | 38/80 | 0.9872 | 0.0621 | 0.9937 | 0.9421 | |

| and | LINMAP | 5.0 | 0.3257 | 39/80 | 0.9991 | 0.0617 | 0.9995 | 0.0757 |

| TOPSIS | 5.0 | 0.3247 | 39/80 | 0.9990 | 0.0617 | 0.9995 | 0.0934 | |

| Shannon entropy | 5.0 | 0.3223 | 39/80 | 0.9974 | 0.0618 | 1.0000 | 0.1821 | |

| and | LINMAP | 4.8 | 0.3183 | 39/80 | 0.9951 | 0.0620 | 0.9993 | 0.3366 |

| TOPSIS | 4.8 | 0.3185 | 39/80 | 0.9951 | 0.0620 | 0.9994 | 0.3345 | |

| Shannon entropy | 4.6 | 0.3087 | 38/80 | 0.9872 | 0.0621 | 0.9931 | 0.9548 | |

| —— | 5.1 | 0.3290 | 39/80 | 1.0000 | 0.0615 | 0.9966 | 0.2140 | |

| —— | 4.6 | 0.3087 | 39/80 | 0.9872 | 0.0621 | 0.9925 | 0.9429 | |

| —— | 4.9 | 0.3222 | 39/80 | 0.9974 | 0.0619 | 1.0000 | 0.1815 | |

| Positive ideal point | —— | 1.0000 | 0.0621 | 1.0000 | —— | |||

| Negative ideal point | —— | 0.9872 | 0.0614 | 0.9931 | —— | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, L.; Chen, L.; Ge, Y.; Shi, S. Maximum Efficient Power Performance Analysis and Multi-Objective Optimization of Two-Stage Thermoelectric Generators. Entropy 2022, 24, 1443. https://doi.org/10.3390/e24101443

Tian L, Chen L, Ge Y, Shi S. Maximum Efficient Power Performance Analysis and Multi-Objective Optimization of Two-Stage Thermoelectric Generators. Entropy. 2022; 24(10):1443. https://doi.org/10.3390/e24101443

Chicago/Turabian StyleTian, Lei, Lingen Chen, Yanlin Ge, and Shuangshuang Shi. 2022. "Maximum Efficient Power Performance Analysis and Multi-Objective Optimization of Two-Stage Thermoelectric Generators" Entropy 24, no. 10: 1443. https://doi.org/10.3390/e24101443

APA StyleTian, L., Chen, L., Ge, Y., & Shi, S. (2022). Maximum Efficient Power Performance Analysis and Multi-Objective Optimization of Two-Stage Thermoelectric Generators. Entropy, 24(10), 1443. https://doi.org/10.3390/e24101443