An Entropy-Based Condition Monitoring Strategy for the Detection and Classification of Wear Levels in Gearboxes

Abstract

:1. Introduction

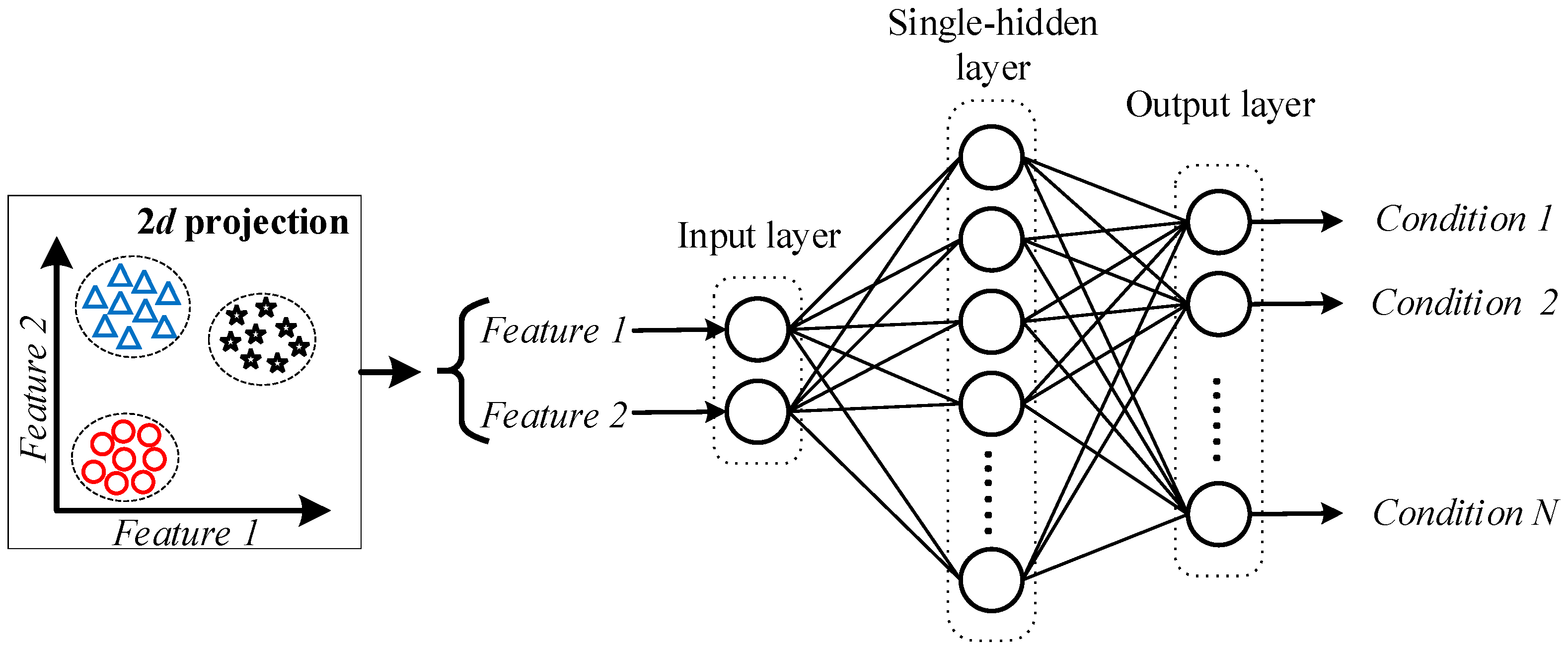

2. Materials and Methods

2.1. Shannon Entropy

Variants of Shannon Entropy

2.2. Dimensionality Reduction

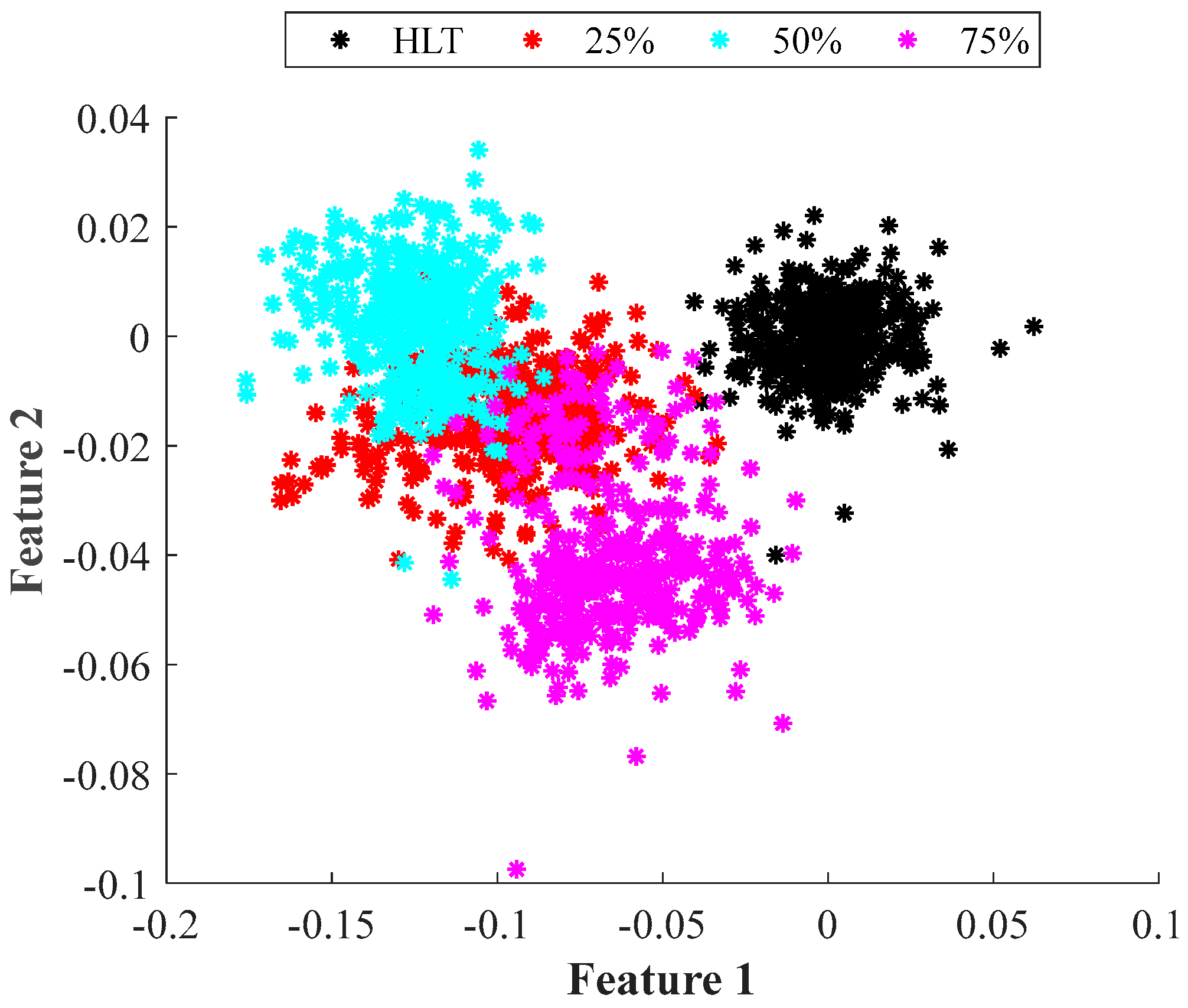

3. Methodology

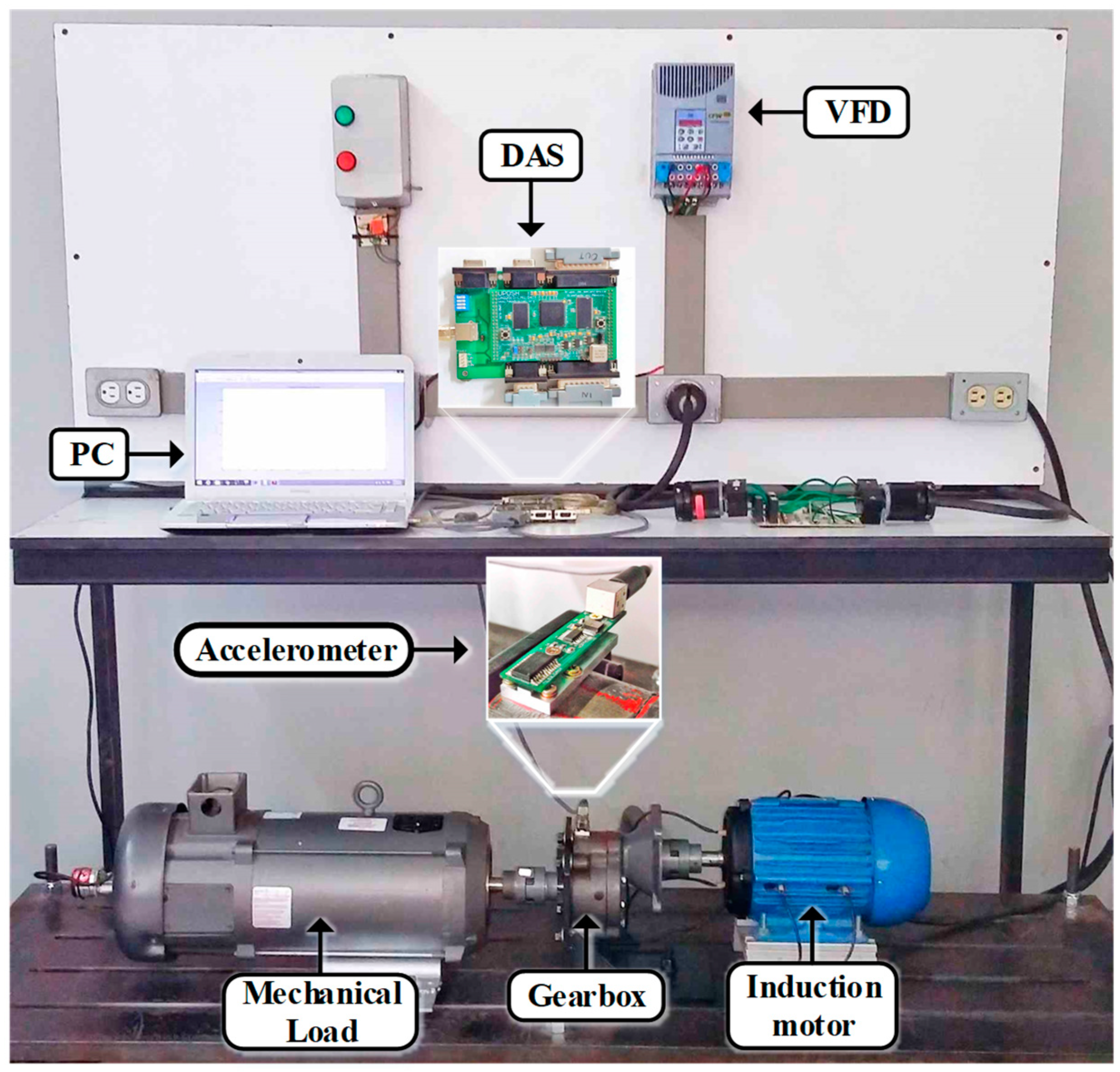

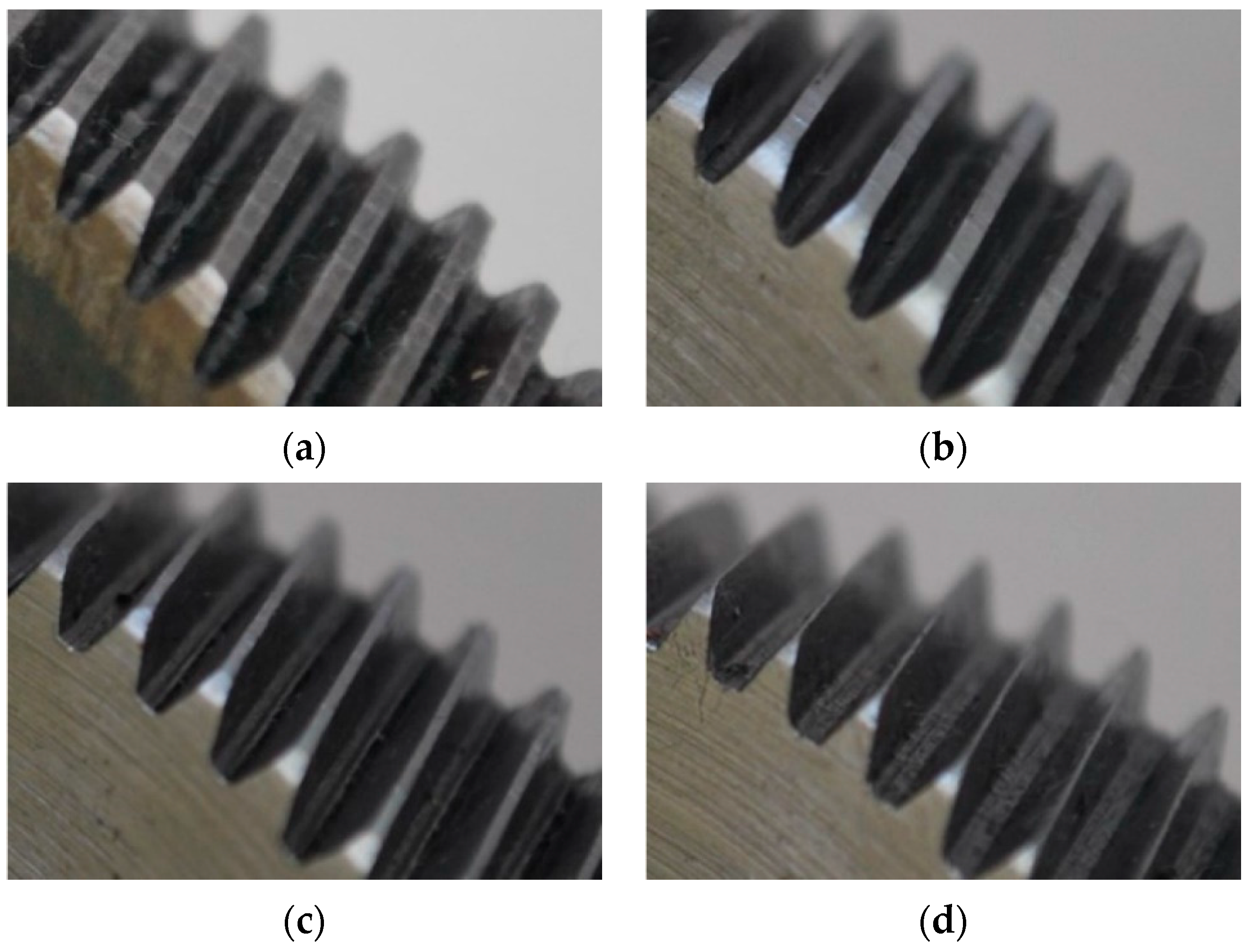

4. Experimental Setup

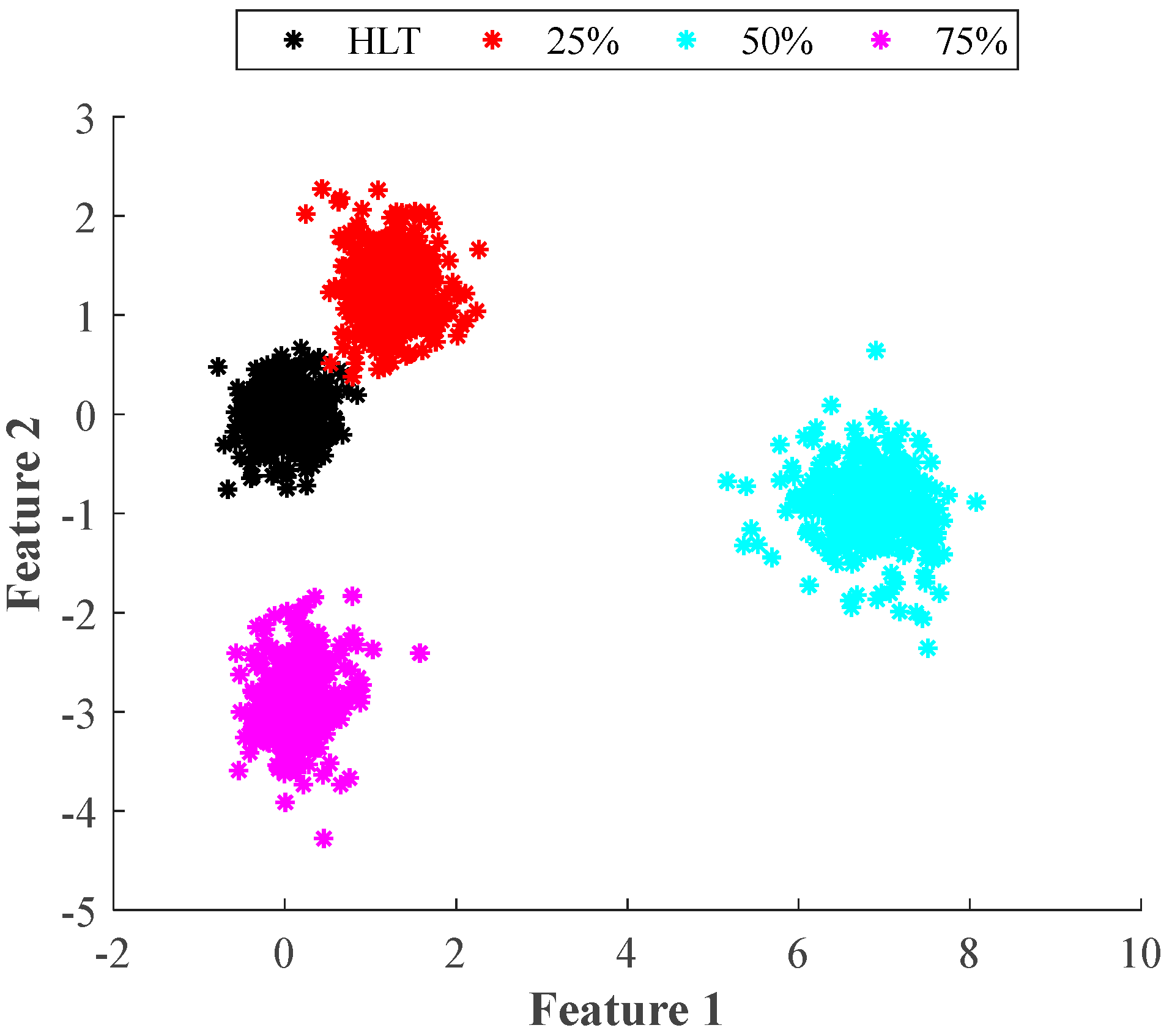

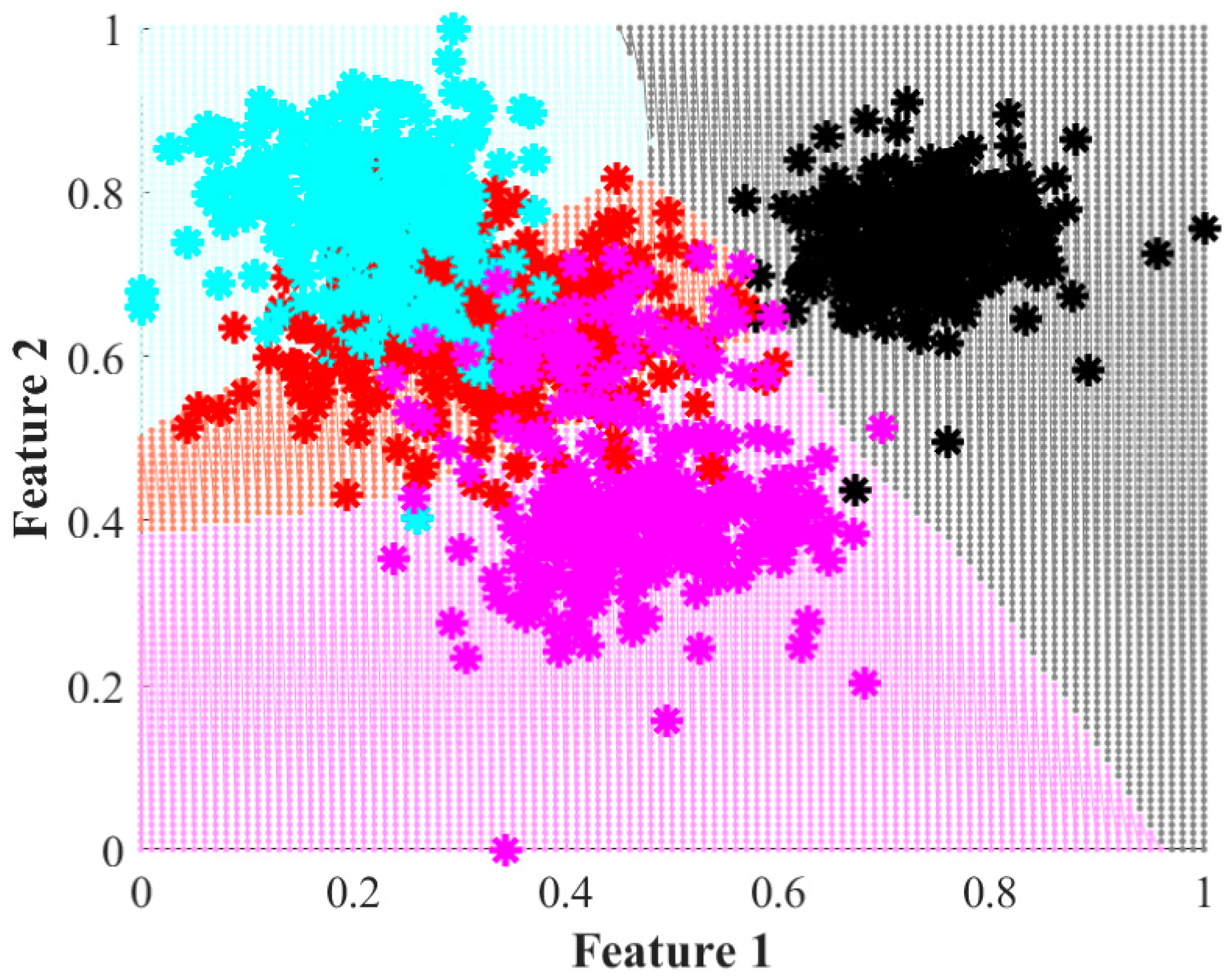

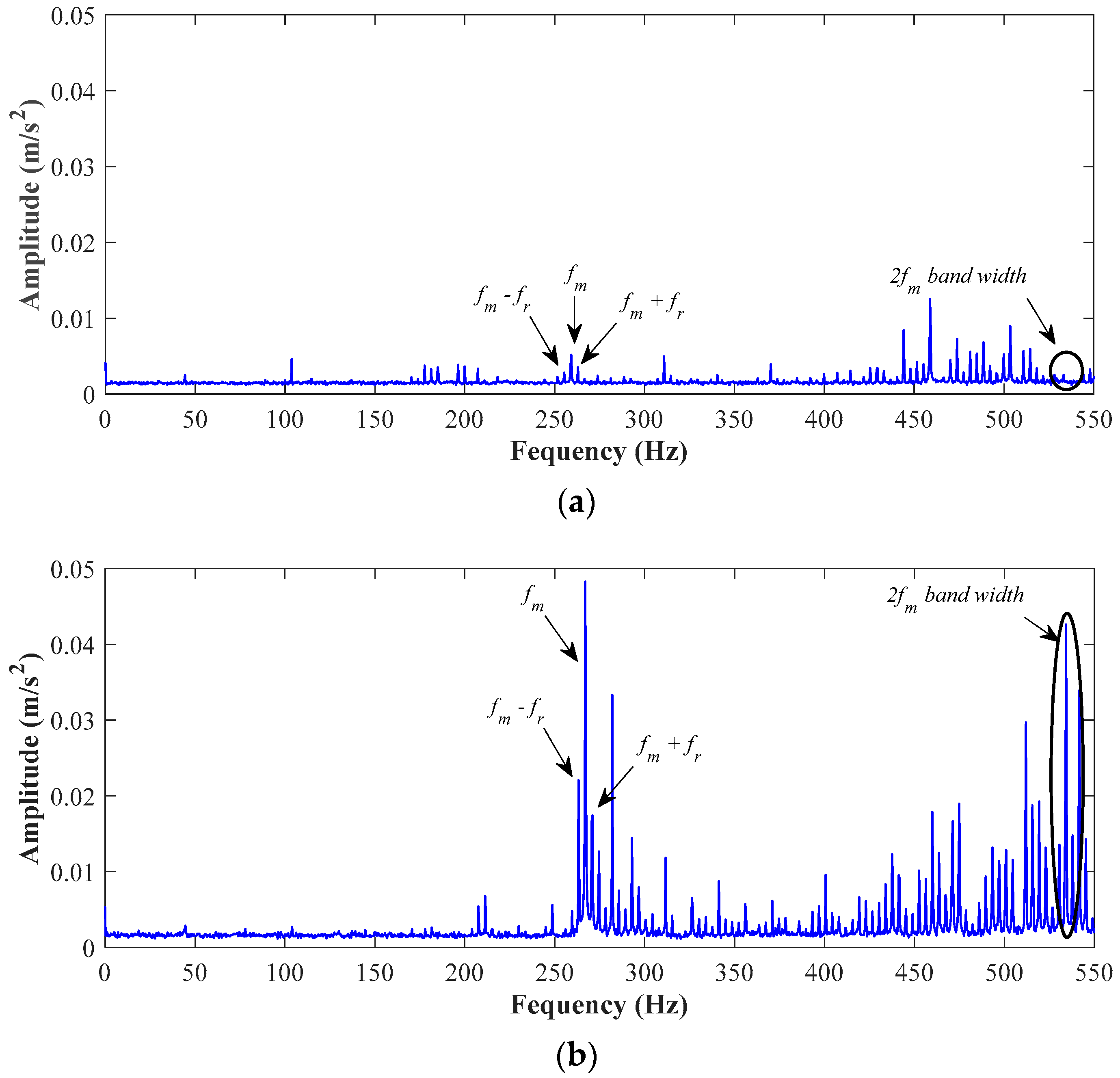

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Doğan, O.; Karpat, F. Crack Detection for Spur Gears with Asymmetric Teeth Based on the Dynamic Transmission Error. Mech. Mach. Theory 2019, 133, 417–431. [Google Scholar] [CrossRef]

- Ra, Y.; Oh, S.; Lee, J.; Yun, Y.; Cho, S.; Choi, J.H.; Jang, S.; Hwang, H.J.; Choi, D.; Kim, J.-G.; et al. Triboelectric Signal Generation and Its Versatile Utilization during Gear-Based Ordinary Power Transmission. Nano Energy 2020, 73, 104745. [Google Scholar] [CrossRef]

- Feng, K.; Ni, Q.; Beer, M.; Du, H.; Li, C. A Novel Similarity-Based Status Characterization Methodology for Gear Surface Wear Propagation Monitoring. Tribol. Int. 2022, 174, 107765. [Google Scholar] [CrossRef]

- Feng, K.; Borghesani, P.; Smith, W.A.; Randall, R.B.; Chin, Z.Y.; Ren, J.; Peng, Z. Vibration-Based Updating of Wear Prediction for Spur Gears. Wear 2019, 426–427, 1410–1415. [Google Scholar] [CrossRef]

- Raghav, M.S.; Sharma, R.B. A Review on Fault Diagnosis and Condition Monitoring of Gearboxes by Using AE Technique. Arch. Comput. Methods Eng. 2021, 28, 2845–2859. [Google Scholar] [CrossRef]

- Han, Q.; Wang, T.; Ding, Z.; Xu, X.; Chu, F. Magnetic Equivalent Modeling of Stator Currents for Localized Fault Detection of Planetary Gearboxes Coupled to Electric Motors. IEEE Trans. Ind. Electron. 2021, 68, 2575–2586. [Google Scholar] [CrossRef]

- Wang, T.; Han, Q.; Chu, F.; Feng, Z. Vibration Based Condition Monitoring and Fault Diagnosis of Wind Turbine Planetary Gearbox: A Review. Mech. Syst. Signal Process. 2019, 126, 662–685. [Google Scholar] [CrossRef]

- Li, Y.; Gu, J.X.; Zhen, D.; Xu, M.; Ball, A. An Evaluation of Gearbox Condition Monitoring Using Infrared Thermal Images Applied with Convolutional Neural Networks. Sensors 2019, 19, 2205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, L.; Chen, L.; Wang, Z.; Liu, D. Early Fault Detection of Planetary Gearbox Based on Acoustic Emission and Improved Variational Mode Decomposition. IEEE Sens. J. 2021, 21, 1735–1745. [Google Scholar] [CrossRef]

- Jiang, Z.; Han, Q.; Xu, X. Fault Diagnosis of Planetary Gearbox Based on Motor Current Signal Analysis. Shock Vib. 2020, 2020, e8854776. [Google Scholar] [CrossRef]

- Lu, D.; Qiao, W.; Gong, X. Current-Based Gear Fault Detection for Wind Turbine Gearboxes. IEEE Trans. Sustain. Energy 2017, 8, 1453–1462. [Google Scholar] [CrossRef]

- Bravo-Imaz, I.; Davari Ardakani, H.; Liu, Z.; García-Arribas, A.; Arnaiz, A.; Lee, J. Motor Current Signature Analysis for Gearbox Condition Monitoring under Transient Speeds Using Wavelet Analysis and Dual-Level Time Synchronous Averaging. Mech. Syst. Signal Process. 2017, 94, 73–84. [Google Scholar] [CrossRef]

- Merizalde, Y.; Hernández-Callejo, L.; Duque-Perez, O.; López-Meraz, R.A. Fault Detection of Wind Turbine Induction Generators through Current Signals and Various Signal Processing Techniques. Appl. Sci. 2020, 10, 7389. [Google Scholar] [CrossRef]

- Salameh, J.P.; Cauet, S.; Etien, E.; Sakout, A.; Rambault, L. Gearbox Condition Monitoring in Wind Turbines: A Review. Mech. Syst. Signal Process. 2018, 111, 251–264. [Google Scholar] [CrossRef]

- Azamfar, M.; Singh, J.; Bravo-Imaz, I.; Lee, J. Multisensor Data Fusion for Gearbox Fault Diagnosis Using 2-D Convolutional Neural Network and Motor Current Signature Analysis. Mech. Syst. Signal Process. 2020, 144, 106861. [Google Scholar] [CrossRef]

- Cheng, F.; Qu, L.; Qiao, W. Fault Prognosis and Remaining Useful Life Prediction of Wind Turbine Gearboxes Using Current Signal Analysis. IEEE Trans. Sustain. Energy 2018, 9, 157–167. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.C.; Ni, Q.; Beer, M. A Review of Vibration-Based Gear Wear Monitoring and Prediction Techniques. Mech. Syst. Signal Process. 2023, 182, 109605. [Google Scholar] [CrossRef]

- Qiu, G.; Gu, Y.; Cai, Q. A Deep Convolutional Neural Networks Model for Intelligent Fault Diagnosis of a Gearbox under Different Operational Conditions. Measurement 2019, 145, 94–107. [Google Scholar] [CrossRef]

- Suresh, S.; Naidu, V.P.S. Vibration Analysis of Heterogeneous Gearbox Faults Using EMD Features and SVM Classifier. IOP Conf. Ser. Mater. Sci. Eng. 2019, 624, 012032. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Cheng, H.; Han, C.; Liu, Y.; Mu, H. Compound Faults Diagnosis and Analysis for a Wind Turbine Gearbox via a Novel Vibration Model and Empirical Wavelet Transform. Renew. Energy 2019, 136, 393–402. [Google Scholar] [CrossRef]

- Brethee, K.F.; Ibrahim, G.R.; Mohammed, R.A.; Albarbar, A.-H. Diagnosis of Induced Gear Wear in Two-Stage Helical Gearbox Based on Vibration Analysis. In Proceedings of the 2020 13th International Conference on Developments in eSystems Engineering (DeSE), Liverpool, UK, 14–17 December 2020; pp. 233–238. [Google Scholar]

- Mohammed, O.D.; Rantatalo, M. Gear Fault Models and Dynamics-Based Modelling for Gear Fault Detection—A Review. Eng. Fail. Anal. 2020, 117, 104798. [Google Scholar] [CrossRef]

- Cao, W.; Han, Z.; Yang, Z.Z.; Wang, N.; Qu, J.X.; Wang, D. Deterioration State Diagnosis and Wear Evolution Evaluation of Planetary Gearbox Using Vibration and Wear Debris Analysis. Measurement 2022, 193, 110978. [Google Scholar] [CrossRef]

- Maraş, S.; Arslan, H.; Birgören, B. Detection of Gear Wear and Faults in Spur Gear Systems Using Statistical Parameters and Univariate Statistical Process Control Charts. Arab. J. Sci. Eng. 2021, 46, 12221–12234. [Google Scholar] [CrossRef]

- Kumar, A.; Parey, A.; Kankar, P.K. Supervised Machine Learning Based Approach for Early Fault Detection in Polymer Gears Using Vibration Signals. MAPAN 2023, 1–12. [Google Scholar] [CrossRef]

- Inturi, V.; Sabareesh, G.R.; Supradeepan, K.; Penumakala, P.K. Principal Component Analysis Based Gear Fault Diagnostics in Different Stages of a Multi-Stage Gearbox Subjected to Extensive Fluctuating Speeds. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2021, 4, 031005. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, H.; Zhang, Y.; Li, Z.; Wang, Y.; Zhou, J.; Mei, J.; Wei, Y. A Fault Diagnosis Scheme for Gearbox Based on Improved Entropy and Optimized Regularized Extreme Learning Machine. Mathematics 2022, 10, 4585. [Google Scholar] [CrossRef]

- Zhang, F.; Sun, W.; Wang, H.; Xu, T. Fault Diagnosis of a Wind Turbine Gearbox Based on Improved Variational Mode Algorithm and Information Entropy. Entropy 2021, 23, 794. [Google Scholar] [CrossRef]

- Liu, L.; Zhi, Z.; Zhang, H.; Guo, Q.; Peng, Y.; Liu, D. Related Entropy Theories Application in Condition Monitoring of Rotating Machineries. Entropy 2019, 21, 1061. [Google Scholar] [CrossRef] [Green Version]

- Ramteke, D.S.; Pachori, R.B.; Parey, A. Automated Gearbox Fault Diagnosis Using Entropy-Based Features in Flexible Analytic Wavelet Transform (FAWT) Domain. J. Vib. Eng. Technol. 2021, 9, 1703–1713. [Google Scholar] [CrossRef]

- Syed, S.H.; Muralidharan, V.; Kumar, P. Effect of K-Nearest Neighbours (k-NN) in Classifying Planetary Gearbox Faults Using Statistical Features; SAE International: Warrendale, PA, USA, 2022. [Google Scholar]

- Li, H.; Huang, J.; Yang, X.; Luo, J.; Zhang, L.; Pang, Y. Fault Diagnosis for Rotating Machinery Using Multiscale Permutation Entropy and Convolutional Neural Networks. Entropy 2020, 22, 851. [Google Scholar] [CrossRef]

- Liao, J.; Zheng, J.; Chen, Z. Research on the Fault Diagnosis Method of an Internal Gear Pump Based on a Convolutional Auto-Encoder and PSO-LSSVM. Sensors 2022, 22, 9841. [Google Scholar] [CrossRef]

- Heidari Bafroui, H.; Ohadi, A. Application of Wavelet Energy and Shannon Entropy for Feature Extraction in Gearbox Fault Detection under Varying Speed Conditions. Neurocomputing 2014, 133, 437–445. [Google Scholar] [CrossRef]

- Bai, L.; Han, Z.; Ren, J.; Qin, X. Research on Feature Selection for Rotating Machinery Based on Supervision Kernel Entropy Component Analysis with Whale Optimization Algorithm. Appl. Soft Comput. 2020, 92, 106245. [Google Scholar] [CrossRef]

- Chen, X.; Yang, Y.; Cui, Z.; Shen, J. Vibration Fault Diagnosis of Wind Turbines Based on Variational Mode Decomposition and Energy Entropy. Energy 2019, 174, 1100–1109. [Google Scholar] [CrossRef]

- Fu, L.; Zhu, T.; Zhu, K.; Yang, Y. Condition Monitoring for the Roller Bearings of Wind Turbines under Variable Working Conditions Based on the Fisher Score and Permutation Entropy. Energies 2019, 12, 3085. [Google Scholar] [CrossRef] [Green Version]

- Huo, Z.; Martínez-García, M.; Zhang, Y.; Yan, R.; Shu, L. Entropy Measures in Machine Fault Diagnosis: Insights and Applications. IEEE Trans. Instrum. Meas. 2020, 69, 2607–2620. [Google Scholar] [CrossRef]

- Li, X.; Dai, K.; Wang, Z.; Han, W. Lithium-Ion Batteries Fault Diagnostic for Electric Vehicles Using Sample Entropy Analysis Method. J. Energy Storage 2020, 27, 101121. [Google Scholar] [CrossRef]

- Wang, D.; Zhong, J.; Shen, C.; Pan, E.; Peng, Z.; Li, C. Correlation Dimension and Approximate Entropy for Machine Condition Monitoring: Revisited. Mech. Syst. Signal Process. 2021, 152, 107497. [Google Scholar] [CrossRef]

- Multi-Fault Diagnosis of Rolling Bearing Using Fuzzy Entropy of Empirical Mode Decomposition, Principal Component Analysis, and SOM Neural Network—Mohamed Zair, Chemseddine Rahmoune, Djamel Benazzouz. 2019. Available online: https://journals.sagepub.com/doi/abs/10.1177/0954406218805510 (accessed on 16 January 2023).

- Ali, S.; Hassan, M.; Kim, J.Y.; Farid, M.I.; Sanaullah, M.; Mufti, H. FF-PCA-LDA: Intelligent Feature Fusion Based PCA-LDA Classification System for Plant Leaf Diseases. Appl. Sci. 2022, 12, 3514. [Google Scholar] [CrossRef]

- Capelli, L.; Massaccesi, G.; Molano, J.C.C.; Campo, F.; Borghi, D.; Rubini, R.; Cocconcelli, M. A Structured Approach to Machine Learning Condition Monitoring. In Smart Monitoring of Rotating Machinery for Industry 4.0; Chaari, F., Chiementin, X., Zimroz, R., Bolaers, F., Haddar, M., Eds.; Applied Condition Monitoring; Springer International Publishing: Cham, Switzerland, 2022; pp. 33–54. ISBN 978-3-030-79519-1. [Google Scholar]

- Rezamand, M.; Kordestani, M.; Carriveau, R.; Ting, D.S.-K.; Saif, M. A New Hybrid Fault Detection Method for Wind Turbine Blades Using Recursive PCA and Wavelet-Based PDF. IEEE Sens. J. 2020, 20, 2023–2033. [Google Scholar] [CrossRef]

- Song, B.; Suh, Y. Identifying Convergence Fields and Technologies for Industrial Safety: LDA-Based Network Analysis. Technol. Forecast. Soc. Change 2019, 138, 115–126. [Google Scholar] [CrossRef]

- SpringerLink. Vibration Region Analysis for Condition Monitoring of Gearboxes Using Image Processing and Neural Networks. Available online: https://link.springer.com/article/10.1007/s40799-019-00329-9 (accessed on 17 January 2023).

- Duda, R.O.; Stork, D.G.; Hart, P.E. Pattern Classification, 2nd ed.; Wiley-Interscience: New York, NY, USA, 2000. [Google Scholar]

| Statistical Time Domain Feature | Mathematical Equation |

|---|---|

| Maximum value | |

| Root mean square | |

| Standard deviation | |

| RMS shape factor | |

| Crest factor |

| Actual | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Training | Validation | ||||||||

| Condition | HLT | 25% | 50% | 75% | HLT | 25% | 50% | 75% | |

| Estimation | HLT | 318 | 0 | 0 | 2 | 80 | 1 | 0 | 0 |

| 25% | 1 | 272 | 50 | 67 | 0 | 56 | 9 | 44 | |

| 50% | 0 | 38 | 268 | 0 | 0 | 16 | 71 | 0 | |

| 75% | 1 | 10 | 2 | 251 | 0 | 7 | 0 | 66 | |

| Actual | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Training | Validation | ||||||||

| Condition | HLT | 25% | 50% | 75% | HLT | 25% | 50% | 75% | |

| Estimation | HLT | 319 | 0 | 0 | 0 | 80 | 1 | 0 | 0 |

| 25% | 1 | 320 | 0 | 0 | 0 | 79 | 0 | 0 | |

| 50% | 0 | 0 | 320 | 0 | 0 | 0 | 80 | 0 | |

| 75% | 0 | 0 | 0 | 320 | 0 | 0 | 0 | 80 | |

| Rotational Speed (rpm) | Frequencies of Interest (Hz) | |||

|---|---|---|---|---|

| 293.4 | 88.02 | 176.04 | 4.89 | 1.22 |

| 889.28 | 266.79 | 533.58 | 14.82 | 3.70 |

| 2984.4 | 895.32 | 1790.65 | 49.74 | 12.43 |

| Training | Test | ||

|---|---|---|---|

| Other approaches | EF + NN | 74.7% | 75.0% |

| SF + NN | 66.2% | 66.6% | |

| FFT + NN | 60.5% | 61.7% | |

| SF + LDA + NN | 86.6% | 85.3% | |

| Proposed method | EF + LDA + NN | 99.7% | 99.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elvira-Ortiz, D.A.; Saucedo-Dorantes, J.J.; Osornio-Rios, R.A.; Romero-Troncoso, R.d.J. An Entropy-Based Condition Monitoring Strategy for the Detection and Classification of Wear Levels in Gearboxes. Entropy 2023, 25, 424. https://doi.org/10.3390/e25030424

Elvira-Ortiz DA, Saucedo-Dorantes JJ, Osornio-Rios RA, Romero-Troncoso RdJ. An Entropy-Based Condition Monitoring Strategy for the Detection and Classification of Wear Levels in Gearboxes. Entropy. 2023; 25(3):424. https://doi.org/10.3390/e25030424

Chicago/Turabian StyleElvira-Ortiz, David A., Juan J. Saucedo-Dorantes, Roque A. Osornio-Rios, and Rene de J. Romero-Troncoso. 2023. "An Entropy-Based Condition Monitoring Strategy for the Detection and Classification of Wear Levels in Gearboxes" Entropy 25, no. 3: 424. https://doi.org/10.3390/e25030424

APA StyleElvira-Ortiz, D. A., Saucedo-Dorantes, J. J., Osornio-Rios, R. A., & Romero-Troncoso, R. d. J. (2023). An Entropy-Based Condition Monitoring Strategy for the Detection and Classification of Wear Levels in Gearboxes. Entropy, 25(3), 424. https://doi.org/10.3390/e25030424