1. Introduction

Solar energy is a widely distributed renewable energy and becoming increasingly popular for power generation. Photovoltaics (PV) is at present the most used and cost-effective technology of solar energy, which converts sunlight into electricity, directly based on the photovoltaic effect. In the last decade, PV production witnessed great growth. In 2021, solar PV capacity increased by 17% globally, accounting for ~60% of the total renewable power expansion [

1]. In order to meet the fast-growing solar PV demand, global production of PV-related products is expected to more than double by 2030 [

1]. Today, China dominates the global solar PV supply chains and contributes to an 80% decline in the price of solar panels, making solar PV an affordable electricity generation technology [

2,

3].

Crystalline silicon modules have dominated the current solar PV market at more than 95% of the installed capacity in the last five years [

4]. Solar PV manufacturing is energy-intensive and mostly powered by fossil fuels. Polysilicon production is the largest energy-consuming segment of the solar PV supply chain, accounting for up to ~40% of the total energy consumption [

4]. The first stage of polysilicon production is to extract metallurgical-grade silicon by melting quartz ore and reducing silica in a large electric arc furnace, which requires a great deal of heat at a high temperature (~2000 °C) and a lengthy time [

5,

6]. Metallurgical-grade silicon of 98% silicon purity is the fundamental material of subsequent silicon products [

2,

7]. Generally, 10 to 13 MWh of electricity is needed to produce one ton of metallurgical-grade silicon, but only ~30% of the total energy input is contained in the silicon product, whereas the rest of the energy is taken away as thermal energy by the off gas and the cooling water [

6,

8]. The temperature of the exhaust gas leaving the arc furnace mainly depends on the furnace load and air excess, at 500 to 700 °C. Therefore, there is great potential to utilize the waste heat in the exhaust gas, and a heat recovery steam generator (HRSG) with a steam turbine is a suitable and cost-effective method [

9]. Currently, many large-scale silicon arc furnaces are equipped with some sort of waste heat recovery system (WHRS), and the generated electricity can offset some of their power consumption. Metallurgical-grade silicon is subsequently purified into solar-grade polysilicon of 6–13 N purity [

7,

10].

Solar PV systems have obvious superiority to traditional power generation methods due to near-zero emission of atmospheric pollutants and greenhouse gases during operation, but the vast majority of their environmental burdens caused by solar PV are released during their manufacturing processes [

11,

12]. For instance, a lot of silica particles are formed in the silicon arc furnace and entrained by the exhaust gas, which needs to be gathered and removed before going into the atmosphere [

13,

14]. These particles are quite small in size, and their high specific surface area and volume result in easy contamination and difficult transportation. Emission or leakage of these fine particles aggravates atmospheric pollution and is hazardous to human health.

Due to good stability, silica cannot be easily tackled by common chemical methods, although melting followed by consolidation seems to be an effective way. Nowadays, plasma gasification is regarded as a superior and promising waste to energy (WTE) technique of solid waste [

15,

16,

17,

18].

Direct current (DC) plasma is widely considered due to its better stability and load adaptability than other types of plasma. In a DC plasma gasifier, strong DC electric arc is created by electrodes, resulting in thermal plasma and a high-temperature environment, which can destroy nearly all chemical bonds in the substances, releasing free electrons, ions, radicals, and molecules, allowing many reactions that cannot proceed in normal conditions to occur [

19,

20]. Consequently, the input organics are quickly decomposed into their component elements, which subsequently react to form a synthetic gas mostly consisting of H

2, CO, CH

4, and some other light hydrocarbons, and meanwhile, the inorganics are completely melted and transformed into inert and nontoxic glassy slags [

21,

22,

23]. Plasma gasification has two remarkable advantages: (1) producing combustible syngas of high calorific value, as a clean and valuable fuel for power generation; (2) disposing of a broad variety of solid wastes safely and harmlessly, especially some hazardous wastes, while consolidating solid residues [

18,

24,

25].

Plasma gasification has been widely considered in the treatment of municipal solid wastes (MSW) as an alternative to traditional incineration and landfill, due to its outstanding environmental benefits and flexibility [

16,

18,

26,

27,

28]. The disposal fee of wastes and electricity selling are the major sources of income for the power plant based on plasma gasification. However, at present, plasma gasification plants are quite scarce, owing to their high investments and operating costs, and therefore, energy conversion efficiency and economic viability are emphasized.

As far as net electrical efficiency is concerned, a plasma gasification power plant containing only one single-stage steam turbine or gas turbine does not obviously perform better than conventional incineration plants. Using MSW as the feedstock, the net electrical efficiency of a plasma gasification power plant based on an individual steam cycle (Rankine cycle) is only about 14 to 21%, and utilization of a single gas turbine has the efficiency of 13 to 24%, compared to 20 to 30% of direct incineration [

24,

27,

29,

30,

31,

32,

33]. Therefore, an integrated plasma gasification combined cycle (IPGCC) is essential for efficiency improvement. In an IPGCC plant, the direct conversion of chemical energy of syngas into electricity is conducted by a gas turbine, and meanwhile, a steam cycle is established for heat recovery from the exhaust gas of the gas turbine, thereby promoting overall power generation and economic competitiveness. The net electrical efficiency of an IPGCC plant can be close to or even exceed 30% [

34,

35]. Minutillo et al. [

24] developed a thermochemical model of an IPGCC plant and pointed out that the system efficiency of power generation could be up to 31%. Montiel-Bohórquez et al. [

20] assessed the technical and economic performance of an IPGCC plant fueled with MSW, finding out its highest efficiency was 32.49%, and one-third of the total gross power output was from the steam turbine.

Recently, the development of healthcare facilities and the breaking COVID-19 pandemic made medical waste management a great environmental issue [

36,

37,

38]. Medical waste is mainly composed of plastics, paper, textiles, glass, and some organics, this means that they have similar characteristics to typical MSW [

39,

40,

41]. But due to the relatively low moisture content, high volatile content, and high lower calorific value (LHV) compared to MSW, medical waste is more worth exploiting in view of WTE [

37,

38]. Furthermore, because medical waste contains some infectious, pathological, chemical, pharmaceutical, or cytotoxic matters, there are potential risks of environmental pollution and infection, which lead to high disposal costs [

30,

42,

43].

In this study, medical waste rather than common MSW is taken as the major feedstock in the plasma gasifier [

36,

38]. The plasma gasifier is designed to be built close to the silicon arc furnace so that simultaneous disposal of medical waste and silica powder can be performed.

Over the past several decades, a WHRS for power generation based on the steam cycle has been extensively investigated and applied in many industrial processes. The concept of incorporating a conventional WHRS into the gasification system also has been proposed, because one of the HRSGs could be saved by sharing the equipment, thereby lowering the overall costs and land occupation. Chen et al. [

44] designed a novel medical WTE system based on plasma gasification integrated with an MSW incineration plant, using exhaust gas from the gas turbine to heat the live steam and feed water in the incineration plant, thereby increasing WTE efficiency up to 37.83%. Yang et al. [

45] proposed and techno-economically assessed a WTE process based on combined heat and power plant and intermediate pyrolysis technology, finding that the levelized cost of electricity was £0.063/kWh. In the authors’ previous work [

46], plasma waste gasification was integrated with a coal-fired power plant, promoting WTE efficiency by feeding the syngas directly into the coal-fired boiler. However, in the previous literature, the gasification system is usually integrated with large-scale power plants, so that the thermal energy contained by the syngas can be utilized at a high temperature, benefiting its efficiency. A WHRS for small-scale industrial boilers generating live steam of relatively low parameters is seldom considered. On the other hand, there is hardly any research on the treatment of the silica powder generated in polysilicon production by plasma gasification, because the melting of SiO

2 brings down the gasification efficiency. Therefore, the economic performance of integrating the WHRS of a silicon arc furnace with plasma gasification is still questionable.

In this work, in view of the expanding polysilicon production and increasing demand for medical waste treatment, a design that integrates the current WHRS of a silicon arc furnace with plasma gasification for medical waste is proposed. The advantage of this integration mainly includes: (1) The heat recovered in the plasma gasification system is exploited for extra heating of the steam and feed water in WHRS, thereby promoting WTE efficiency of the medical waste without affecting the power output by the exhaust gas from the silicon arc furnace. (2) The silica powder collected from the flue gas leaving the silicon furnace can be fed into the plasma gasifier and consolidated into vitrified slags, thereby avoiding pollution caused by the leakage of fine particles. (3) An HRSG system in a typical IPGCC scheme can be substituted by the existing equipment in a WHRS, so that investment, operational costs, and land occupation of the plasma gasification system can be significantly lowered.

2. System Description

A 33 MVA submerged arc furnace producing metallurgical-grade silicon with its current WHRS was selected as the reference plant, which is now operational at a large-scale manufacturing base of silicon PV in northwestern China. The manufacturing base has 32 silicon arc furnaces and dozens of polysilicon purification and monocrystalline silicon production lines. At present, each arc furnace has already been equipped with WHRS for power generation. The furnaces and WHRS have both been operating reliably for the past five years, and the operating parameters collected online coincided well with design values. In this study, the design diagrams and data provided by the manufacturers were used for analysis. The existing WHRS and the proposed WHRS integrated with plasma gasification for medical waste are respectively described in

Section 2.1 and

Section 2.2.

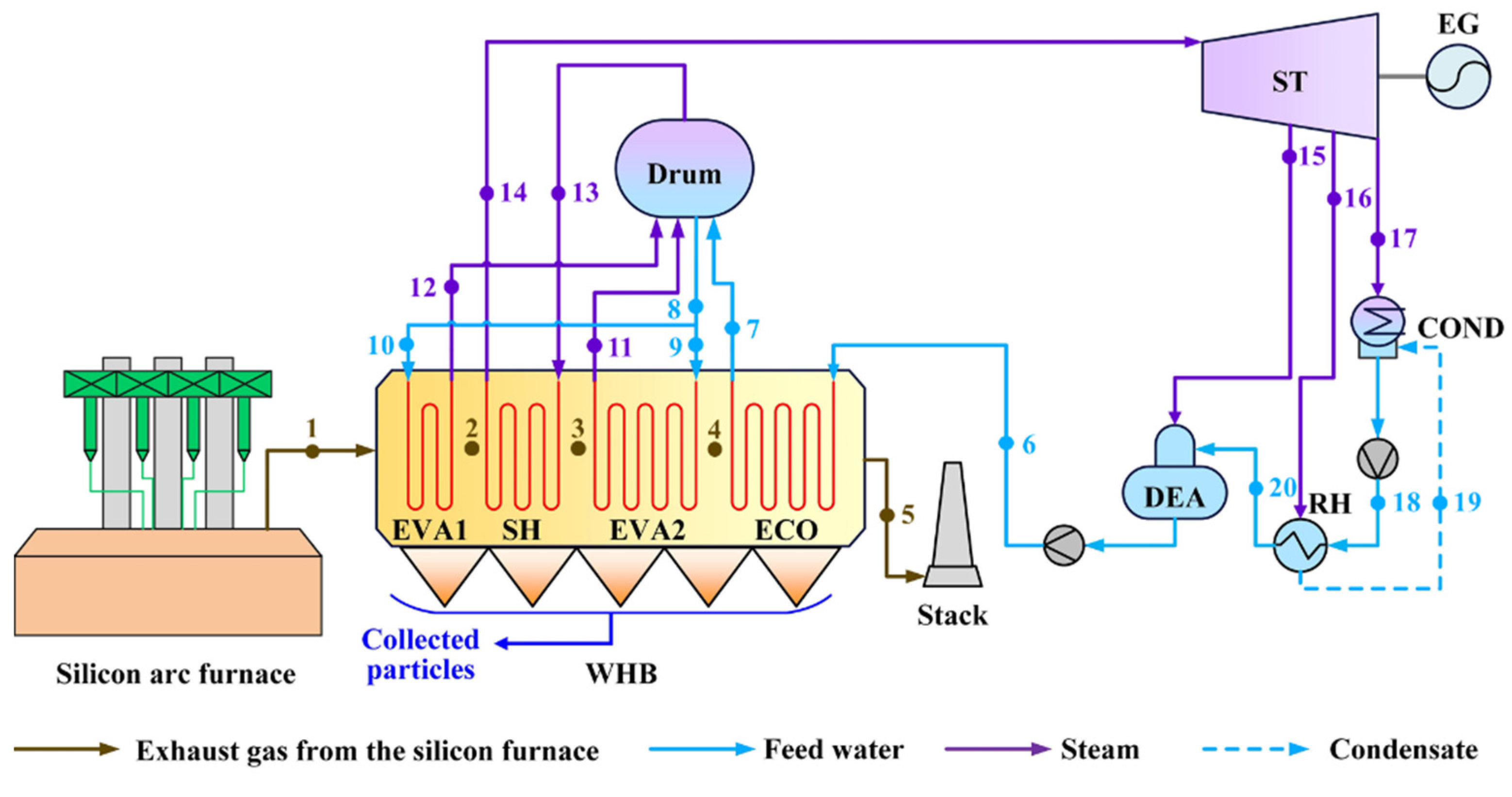

2.1. Current WHRS for the Silicon Arc Furnace

Figure 1 shows the current WHRS for the silicon arc furnace. Quartz ore that mainly consists of SiO

2 is intermittently fed into the submerged arc furnace and reduced by carbon reductants (coke) at ~2000 °C to produce polysilicon. The major chemical reactions are as follows [

6]:

These reactions occur in the packed bed and the required heat is provided by the arc created by three AC electrodes that are half submerged in the raw material. Molten silicon is taken out through the tapping at the bottom, while the hot exhaust gas continuously flows upward and leaves the furnace through the top hole.

Table 1 lists the main gaseous components of the exhaust gas. The average temperature of the exhaust gas is ~650 °C, making its heat worth recovering. Meanwhile, the exhaust gas has 4 to 10 g/m

3 of fly ash, and the main components of the fly ash are listed in

Table 2. Fine amorphous silica particles dominate in the fly ash, and have an average particle size of less than 1 μm.

As depicted in

Figure 1, current WHRS is composed of a waste heat boiler (WHB) for waste heat recovery and steam generation, a steam turbine (ST) driven by the live steam, an electricity generator (EG) for power generation, and heat regeneration equipment. Their basic parameters are referred by the values in

Table A1 and

Table A2 in

Appendix A. The exhaust gas leaving the silicon arc furnace flows through WHB and is cooled from 650 °C to 187.3 °C, and meanwhile, the feed water from the outlet of the deaerator (DEA) at 104.8 °C/4.02 MPa is heated to a superheated steam at 450 °C/3.82 MPa. Due to the high content and small particle size of the fly ash in the gas flow, efficient and uninterrupted ash removal from heat transfer surfaces is necessary in WHB. Mechanical striking using steel balls is applied and the falling ash is collected by the ash hoppers at the bottom.

The feed water delivered to WHB is first heated in the economizer (ECO) to approximate saturated water. Water/steam separation is performed in the drum. Some of the saturated water from the drum flows into the evaporator 2 (EVA2) between the superheater (SH) and ECO, and the rest of the saturated water is sent to EVA1 at the inlet of WHB. The purpose of EVA1 is to cool the high-temperature gas rapidly in view of slagging prevention. The saturated steam separated by the drum is sent into SH for final heating and then flows into ST.

2.2. Proposed WHRS Integrated with Plasma Gasification

The current WHRS can be integrated with a plasma gasification system fueled with medical waste, exploiting the heat recovered from syngas treating processes to further raise its power output. The combustible syngas generated by gasification is used for power generation through the gas turbine (GT). In the meantime, the collected silica powder is fed into the gasifier together with medical waste and ends up in vitrified slags that are harmless and transportable.

This proposed hybrid scheme is illustrated in

Figure 2. From the perspective of power generation based on plasma gasification, a combination with WHRS is an alternative to conventional IPGCC, making full use of the syngas and combustion gas and requiring lower capital investment.

The plasma gasification system can be roughly divided into two parts, the plasma gasifier subsystem, and the gas turbine subsystem.

The plasma gasifier subsystem includes the DC plasma gasifier and syngas conditioning equipment [

20]. The medical waste and the collected silica powders are fed from the top of the gasifier, and the organic components quickly decompose when being heated, generating volatiles. O

2 separated from the air is injected into the bottom of the gasifier as the oxidizing agent of the gasification process, and the extremely high temperature environment (~4000 °C) created by plasma torches transforms the residual carbon, hydrogen, and other combustible elements into micro-molecular gases. The remaining inorganic solids, including the fine silica particles in the feedstock, are completely melted, and the effluent slags are cooled and solidified.

The syngas formed in the gasifier contains various high calorific value components, making it a good fuel. However, the formation of contaminants, such as particulates, condensable hydrocarbons, sulfur compounds, nitrogen compounds, halides, and trace heavy metals, is inevitable in gasification, and thus the raw syngas needs to be cleaned to meet stringent emission regulations and protect the downstream equipment from fouling, corrosion, and erosion [

47,

48]. There is a multitude of technologies for syngas purification. Conventional syngas cleaning equipment includes the cyclone separator (CS), wet scrubber, carbonyl sulfide (COS) hydrolysis, acid gas removal (AGR), and filters [

47,

49]. Syngas needs to be properly cooled and heated in order to meet the temperature requirements of different cleaning processes [

48].

Heat recovery in syngas conditioning is essential for attaining system efficiency, and thus heat exchangers are required. As shown in

Figure 2, the raw syngas is first cooled in a gas-gas heat exchanger, named syngas cooler 1 (SGC1). O

2 entering the plasma gasifier needs to be well-preheated to facilitate gasification. In this scheme, O

2 has two-stage preheating, and SGC1 is used for the second stage. SGC2 heats a steam flow from WHRS and supplies superheated steam to ST directly. Syngas from SGC2 flows through CS and a filter to remove bulk particles. CS is a widely used inertial separation device and is able to operate in a wide temperature range while requiring low energy [

48,

50]. In view of syngas, a temperature of 300 to 500 °C benefits the operation of CS and filters because particulate matters can stay in the solid state, avoiding problems caused by melting or moisture absorption.

The filtered syngas is then used for the first-stage preheating of O

2 in SGC3. SGC4 is placed downstream of SGC3, cooling the syngas further to ~130 °C, while reheating the syngas at the outlet of the wet scrubber to 250.0 °C. Water scrubbing is an easily-operated and effective method for syngas decontamination, removing NH

3 compounds, halides, fine particles, some H

2S, and other trace contaminants simultaneously [

47,

49]. However, a large flow of scrubbing water is required so that the syngas is rapidly cooled to its dew point temperature, ensuring the finest particles can be removed by acting as the nuclei for condensation [

51].

Sulfur compounds are the main residual contaminants in the scrubbed syngas. Although most sulfur in the feedstock is converted to H

2S in gasification, about 3 to 10% of the sulfur is converted to carbonyl sulfide, which is the main organic sulfur component and cannot be efficiently removed by the downstream AGR due to its low solubility in most solvents. Therefore, a catalytic hydrolysis reactor is set up to convert over 99% of COS in the syngas to H

2S, according to the flowing reaction [

47,

52].

The scrubbed syngas needs to be reheated to ~250 °C in view of the efficiency of alumina-based catalysts used in COS hydrolysis [

53,

54]. The conversion of COS to H

2S is an exothermic reaction, technically, but the passing of the syngas through COS hydrolysis can be regarded as an isothermal process in heat calculation due to the low concentration of COS.

AGR is the endmost syngas cleaning process, using regenerative solvents in an absorber column to remove various sulfur-bearing gases, including H

2S and SO

2 surviving from the wet scrubbing, H

2S converted from COS by hydrolysis, and some organic sulfur compounds [

55,

56]. Most of the common chemical solvents, such as piperazine-activated methyl diethanolamine (MDEA) and aqueous alkaline salt solutions, are effective over a wide range of acid gas concentrations at near-room temperatures, and thus AGR is typically designed to operate at slightly above the ambient temperature [

56]. In order to minimize the heat loss due to AGR, the syngas from COS hydrolysis is used to heat the low-temperature condensate from condenser (COND) of WHRS in SGC5.

In the gas turbine subsystem, the cleaned syngas is sent to compressor 1 (CP1) for compression, and meanwhile, the feeding air is compressed in CP2. Syngas is burned in the combustion chamber (CC), and the formed high-temperature and -pressure combustion gas enters GT, generating power by electric generator 1 (EG1).

The exhaust gas of GT still has a high temperature and is delivered to the WHRS of the silicon arc furnace for heat exploitation, so as to save HRSG equipment in the conventional IPGCC scheme. The combustion gas leaving GT flows through gas coolers HX1 to HX5 successively.

The live steam supplied by WHB is further heated in HX1 before entering ST. HX2 is to heat a saturated steam flow from the drum, which is subsequently sent to SGC2 for final heating. HX4 and HX5 are used for additional heating of the feed water in the heat regeneration subsystem so as to save the extracted steam from ST. The condensate from COND flows through SGC5, HX5, RH, and HX4 successively before entering DEA. At last, the temperature of the feed water into WHB is promoted by HX3.

Via integration with plasma gasification, the steam cycle in WHRS is largely assisted by the heat recovered from the syngas and combustion gas, and thus its power generation capacity is improved. Meanwhile, the combination with WHRS makes it possible for the plasma gasification power generation system to save some high-cost components compared to conventional IPGCC systems. Furthermore, with a view to waste management, the troublesome silica fines generated by polysilicon production can be handled by the plasma gasifier harmlessly.