Effect of Nanofillers on Tribological Properties of Polymer Nanocomposites: A Review on Recent Development

Abstract

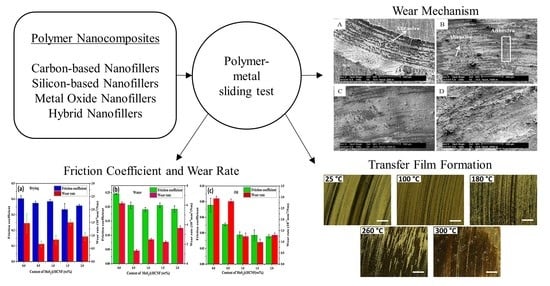

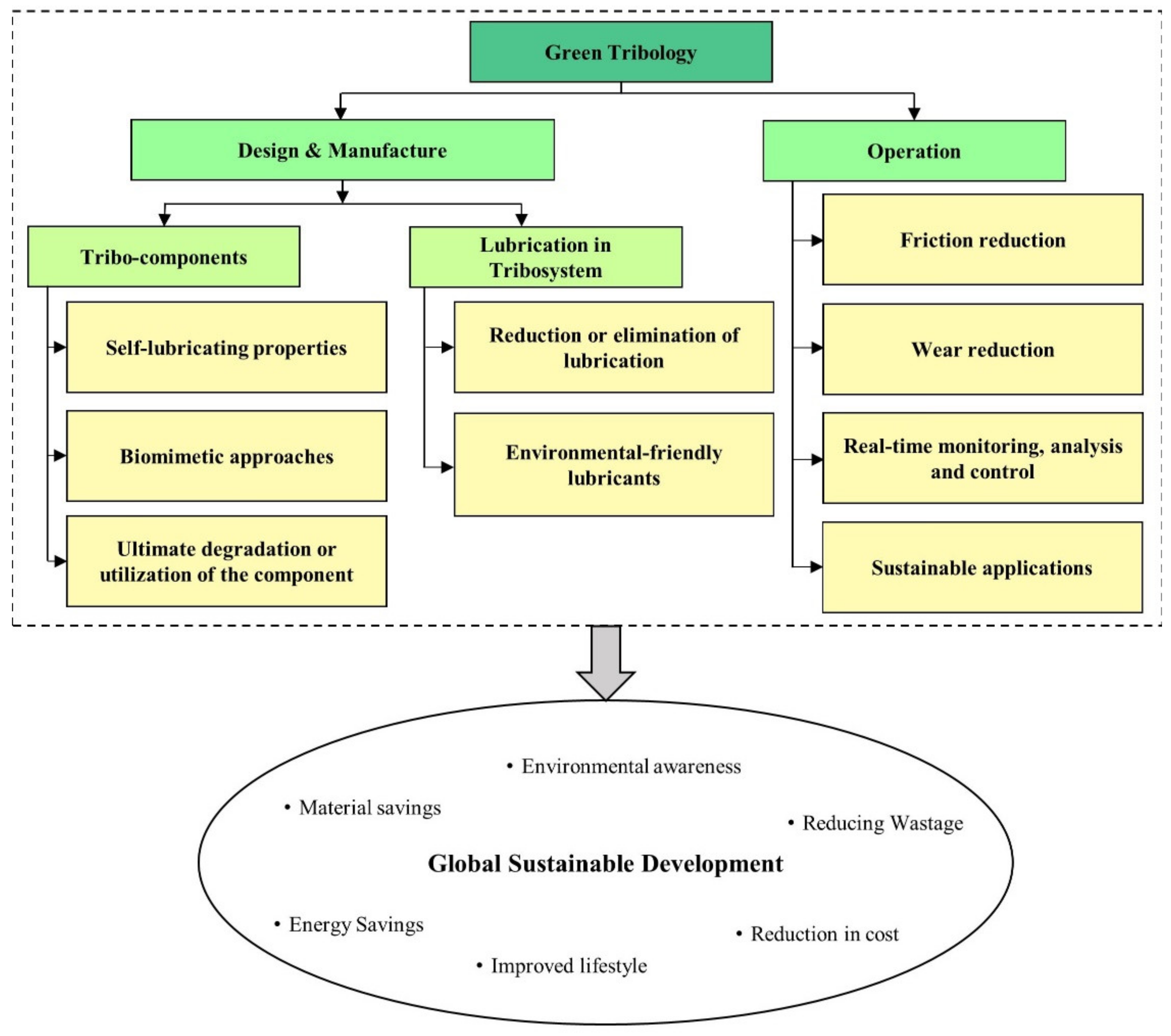

:1. Introduction

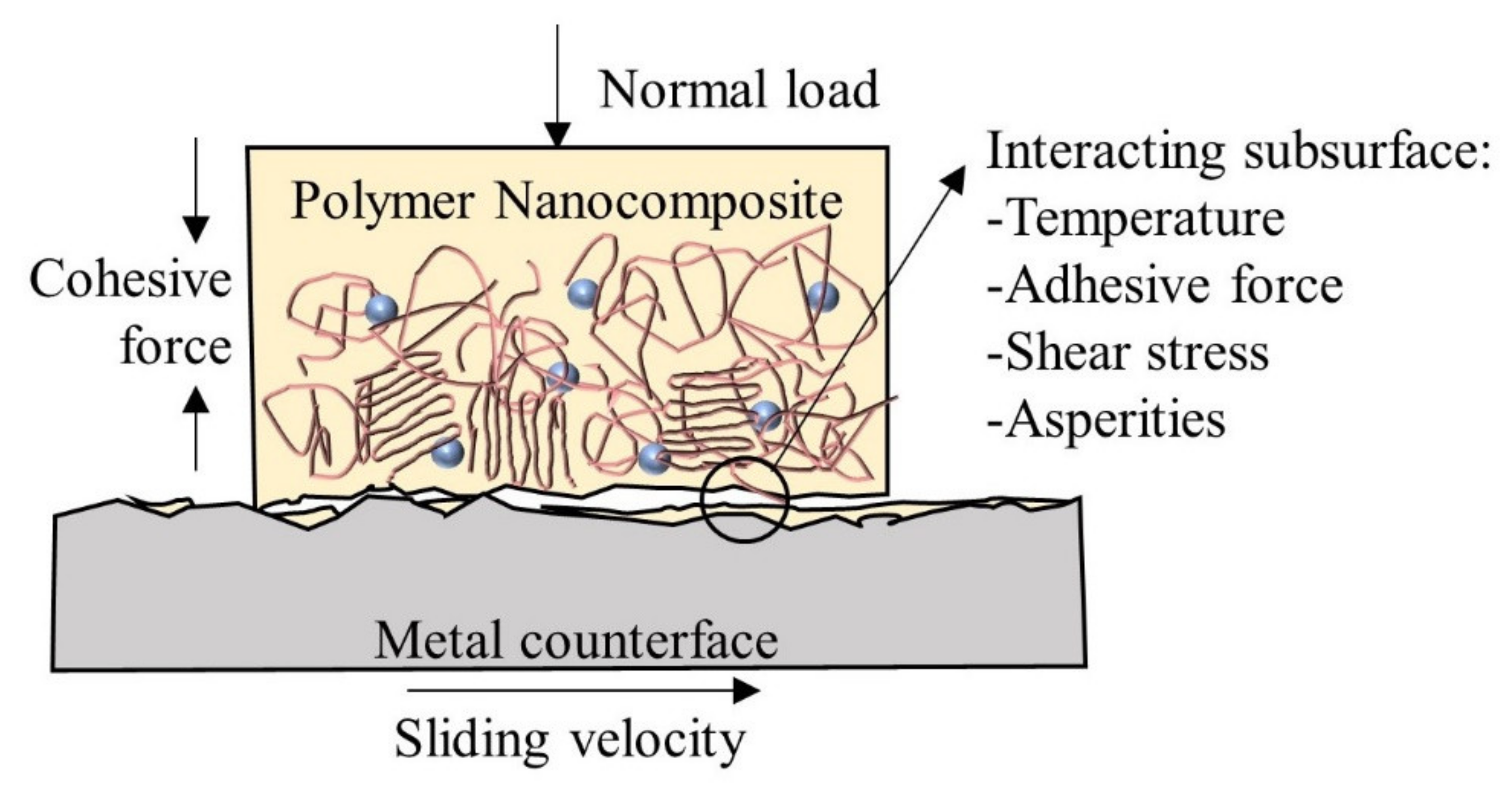

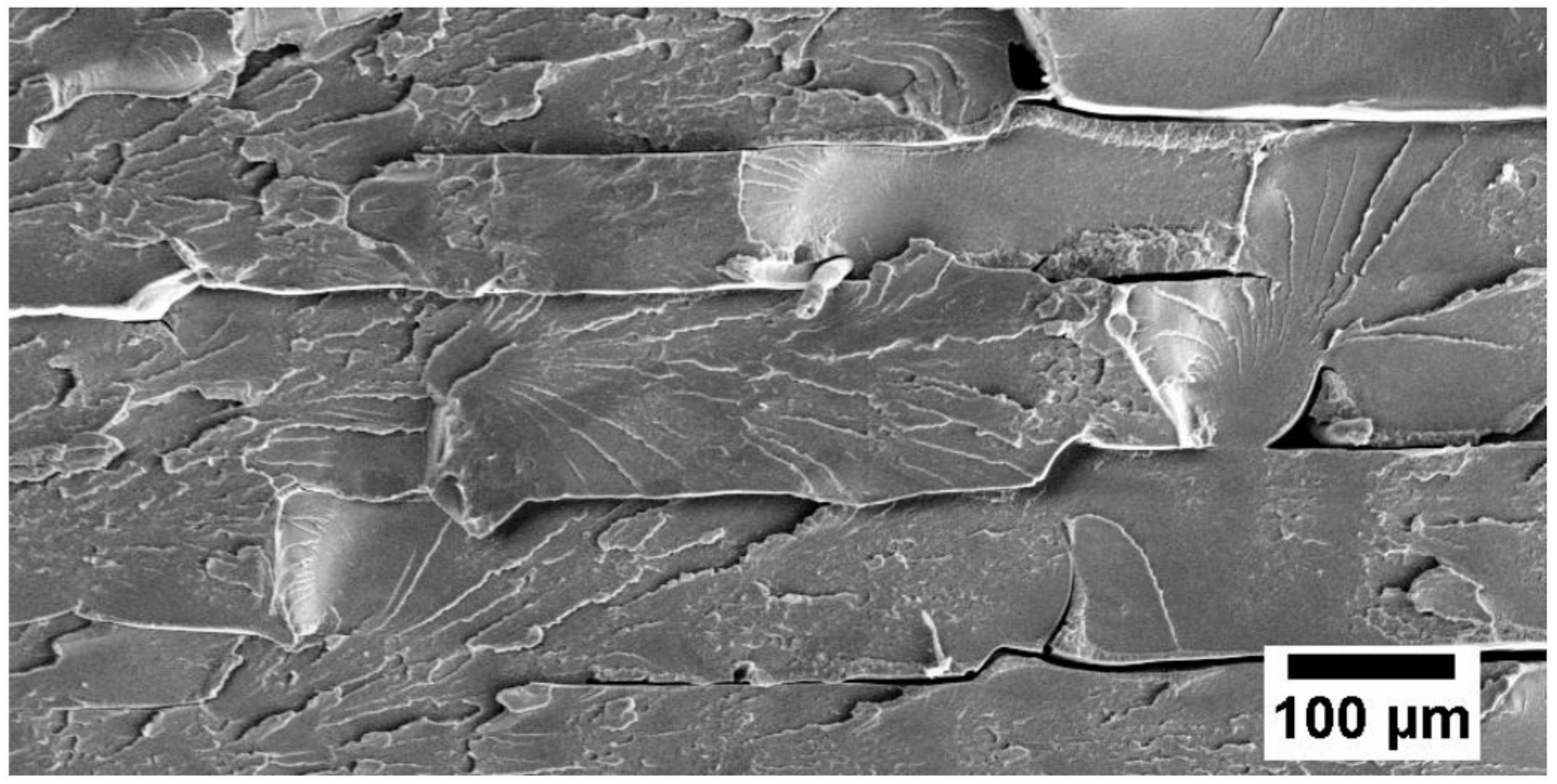

2. Tribological Performance of Polymer Nanocomposites

2.1. Carbon-Based Nanofillers

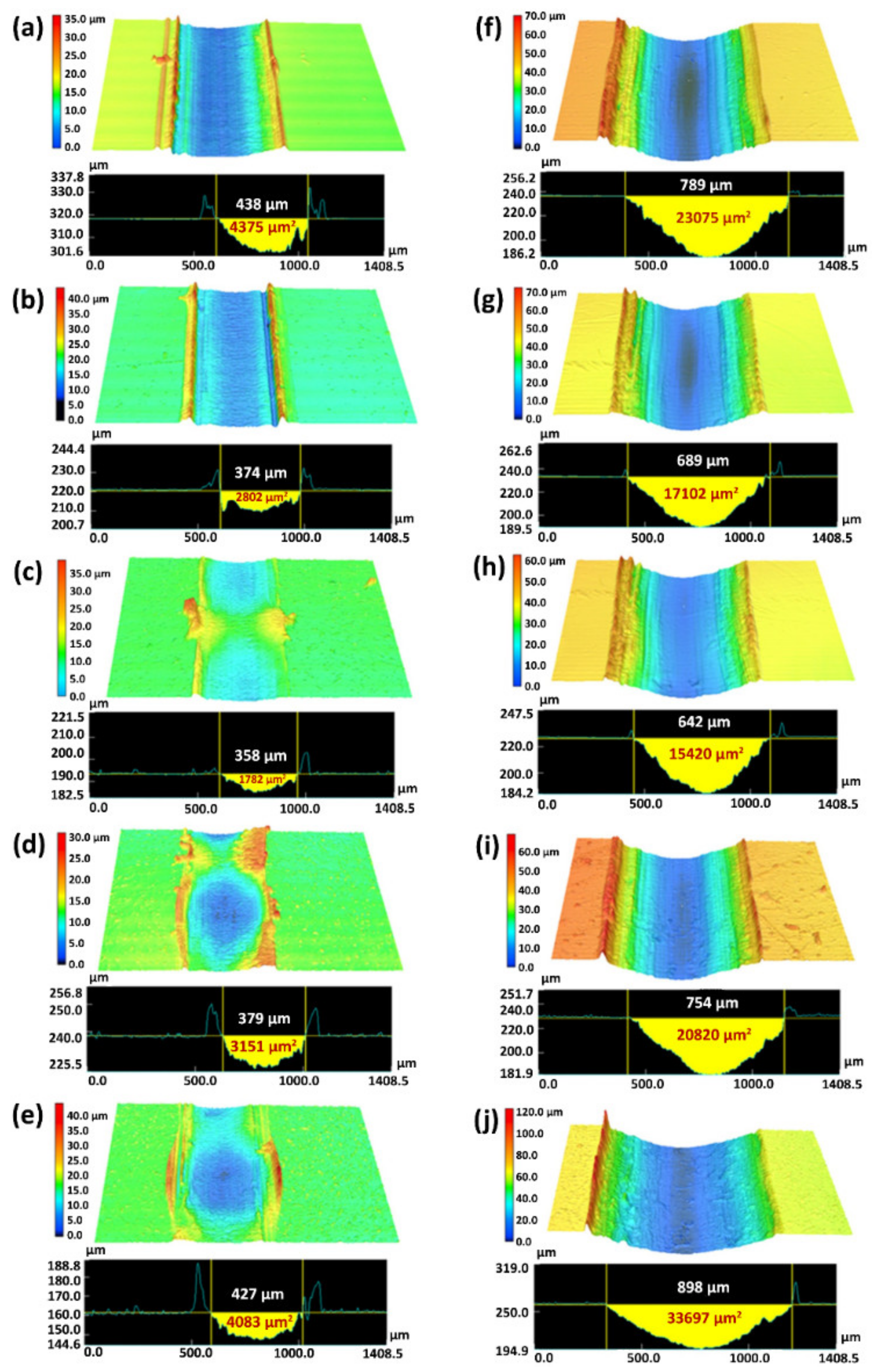

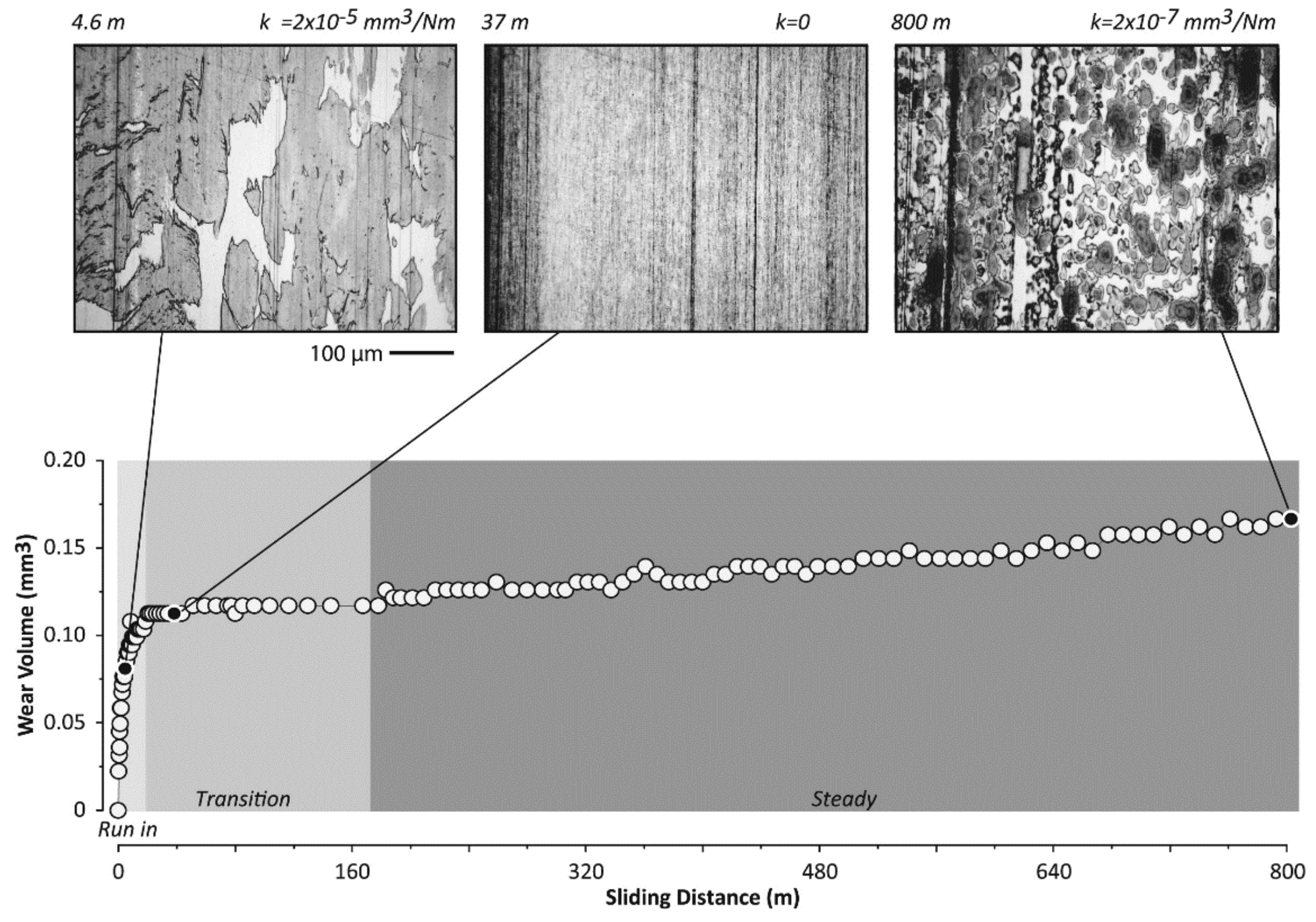

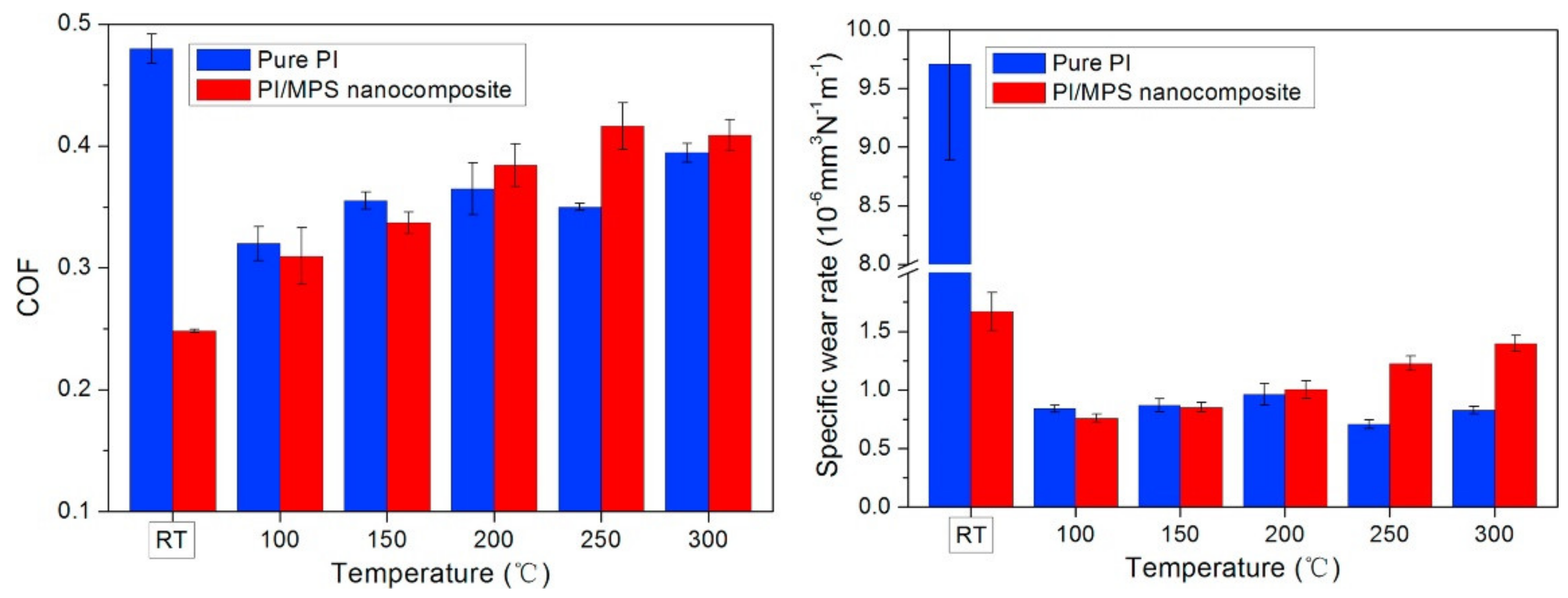

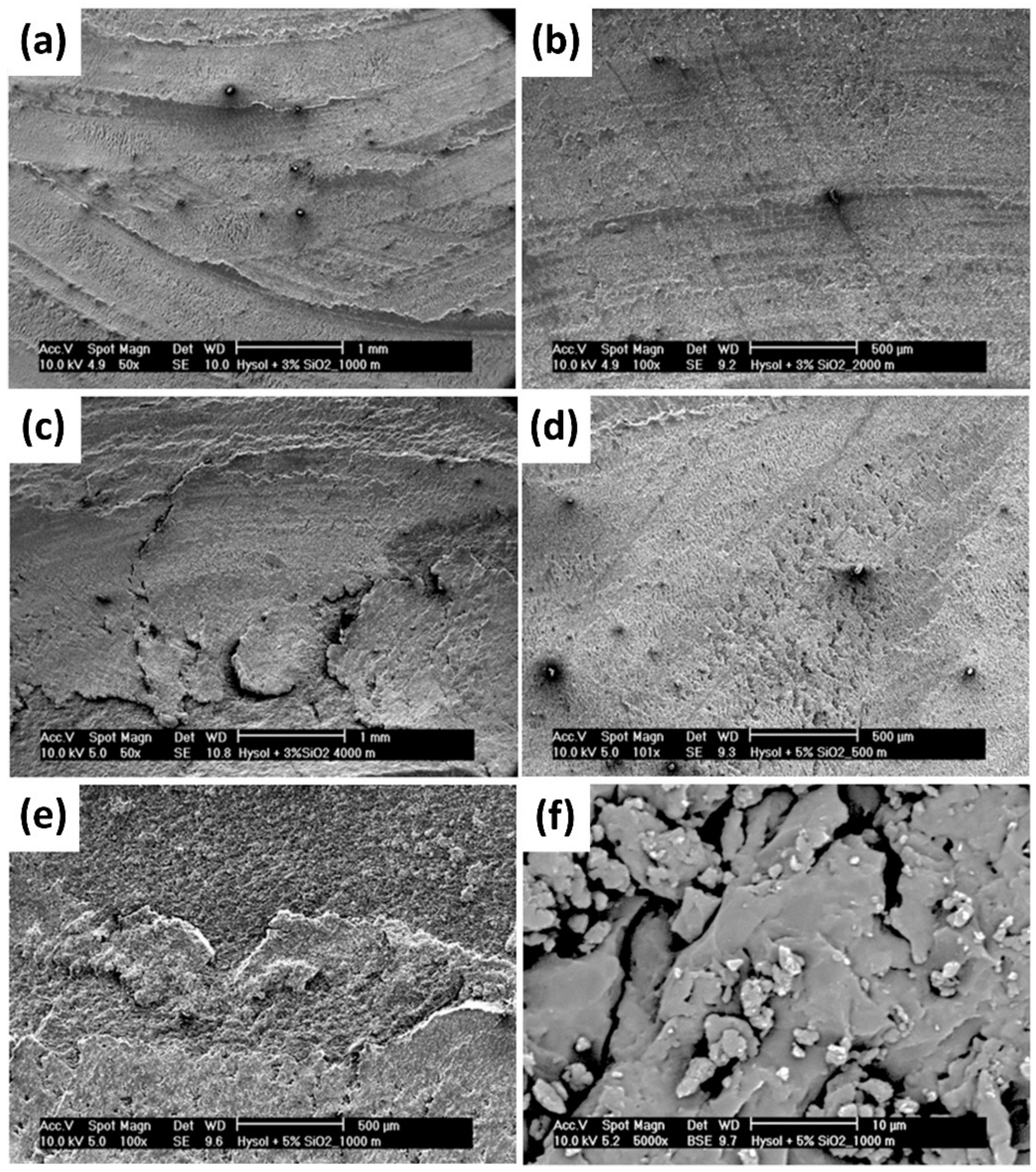

2.2. Silicon-Based Nanofillers

2.3. Metal Oxide Nanofillers

2.4. Miscellaneous Nanofillers

2.5. Hybrid Nanofillers

3. Summary of Tribological Performance of Polymer Nanocomposites

4. Challenges and Future Developments

- Increasing nanofiller content contributed to a positive effect on the tribological performance until agglomeration occurs. Not only that, nanofillers hybridization of different structures can improve dispersibility of nanofillers in the matrix, and different fabrication techniques also influence the dispersibility. Hence, more tribological studies should be conducted on the effects of the fabrication techniques of polymer nanocomposites, either in bulk, film or coating form.

- Owing to the viscoelasticity of polymer, high operating temperature and friction heat generation often limit the tribological applications of polymer nanocomposites. However, there is a lack of research on the contact temperature between tribo-pairs, the thermal conductivity and the stability of polymer nanocomposites at extreme operating conditions (applied load, sliding speed, temperature). Thus, more work in this field is suggested to widen the applications of polymer nanocomposites.

- Only few works have reported that the tribo-chemical reaction occurs during the sliding process. Different operating conditions and combinations of different tribo-pairs can result in distinct reactions. These reactions have a significant impact on tribological performance, and thus should be further explored.

- With the increasing concern in environmental sustainability, future works can focus on the tribological performance of polymer nanocomposites reinforced with greener nanofillers, such as natural nanofibers and wollastonite nanofibers derived from wastes.

- As tribological properties of polymer nanocomposites are not innate, the advancement of polymer nanocomposites for tribological applications is limited by the lack of a model that is capable of relating mechanical, thermal and tribological properties of polymer nanocomposites. Such model would be very useful in supporting product development with lower cost and time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Friedrich, K.; Reinicke, P. Friction and wear of polymer-based composites. Mech. Compos. Mater. 1998, 34, 503–514. [Google Scholar] [CrossRef]

- Myshkin, N.K.; Kovalev, A. Polymer mechanics and tribology. Ind. Lubr. Tribol. 2018, 70, 764–772. [Google Scholar] [CrossRef] [Green Version]

- Aldousiri, B.; Shalwan, A.; Chin, C.W. A Review on Tribological Behaviour of Polymeric Composites and Future Reinforce-ments. Adv. Mater. Sci. Eng. 2013, 2013, 645923. [Google Scholar]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Oliveira, J.D.; Rocha, R.C.; Galdino, A.G.D.S. Effect of Al2O3 particles on the adhesion, wear, and corrosion performance of epoxy coatings for protection of umbilical cables accessories for subsea oil and gas production systems. J. Mater. Res. Technol. 2019, 8, 1729–1736. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Girijappa, Y.G.T.; Puttegowda, M.; Rangappa, S.M.; Siengchin, S. Effect of natural filler materials on fiber re-inforced hybrid polymer composites: An Overview. J. Nat. Fibers 2020, 1–16. [Google Scholar] [CrossRef]

- Praveenkumara, J.; Madhu, P.; Gowda, T.G.Y.; Sanjay, M.R.; Siengchin, S. A comprehensive review on the effect of synthetic filler materials on fiber-reinforced hybrid polymer composites. J. Text. Inst. 2021, 1–9. [Google Scholar] [CrossRef]

- Sazali, N.; Ngadiman, N.H.A. Materials for Tribology’s Application: A Mini Analysis. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 68, 177–185. [Google Scholar] [CrossRef]

- Lan, P.; Nunez, E.E.; Polycarpou, A.A. Advanced Polymeric Coatings and Their Applications: Green Tribology. In Encyclopedia of Renewable and Sustainable Materials; Hashmi, S., Choudhury, I.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 345–358. ISBN 9780128035818. [Google Scholar]

- Alajmi, A.E.; Alotaibi, J.G.; Yousif, B.F.; Nirmal, U. Tribological Studies of Bamboo Fibre Reinforced Epoxy Composites Using a BOD Technique. Polymers 2021, 13, 1–17. [Google Scholar]

- Jost, H.P. The Presidential address. In Proceedings of the World Tribology Congress 2009, Kyoto, Japan, 6–11 September 2009. Unpublished data. [Google Scholar]

- Nosonovsky, M.; Bhushan, B. Green tribology: Principles, research areas and challenges. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4677–4694. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nirmal, U.; Hashim, J.; Ahmad, M.M. A review on tribological performance of natural fibre polymeric composites. Tribol. Int. 2015, 83, 77–104. [Google Scholar] [CrossRef]

- Tzanakis, I.; Hadfield, M.; Thomas, B.; Noya, S.M.; Henshaw, I.; Austen, S. Future Perspectives on Sustainable Tribology. Renew. Sustain. Energy Rev. 2012, 4126–4140. [Google Scholar] [CrossRef] [Green Version]

- Franek, F.; Vorlaufer, G.; Stadler, A.; Jech, M.; Wopelka, T. Modeling and Simulation Assisted Tribometrology. Tribol. Ind. 2008, 30, 37–47. [Google Scholar]

- Wood, R. Green Tribology. nCATS Newsletter, 6th ed.; (October 2011). Available online: https://issuu.com/university_of_southampton/docs/singlepage_3884_uos_ncats_newsletter_6pp_a2_0_2710 (accessed on 16 August 2021).

- Myshkin, N.; Kovalev, A. Adhesion and surface forces in polymer tribology—A review. Friction 2018, 6, 143–155. [Google Scholar] [CrossRef]

- Bahadur, S. The development of transfer layers and their role in polymer tribology. Wear 2000, 245, 92–99. [Google Scholar] [CrossRef]

- Pogosian, A.; Hovhannisyan, K.; Isajanyan, A. Polymer Friction Transfer (FT). In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.-W., Eds.; Springer: Boston, MA, USA, 2013; pp. 2585–2592. ISBN 978-0-387-92896-8. [Google Scholar]

- Nunez, E.E.; Gheisari, R.; Polycarpou, A.A. Tribology review of blended bulk polymers and their coatings for high-load bearing applications. Tribol. Int. 2019, 129, 92–111. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Sun, Z.; Huang, P.; Li, Y.-Q.; Hu, N. Some basic aspects of polymer nanocomposites: A critical review. Nano Mater. Sci. 2019, 1, 2–30. [Google Scholar] [CrossRef]

- Shameem, M.M.; Sasikanth, S.M.; Annamalai, R.; Raman, R.G. A brief review on polymer nanocomposites and its applications. Mater. Today Proc. 2021, 45, 2536–2539. [Google Scholar] [CrossRef]

- Puggal, S.; Dhall, N.; Singh, N.; Litt, M.S. A Review on Polymer Nanocomposites: Synthesis, Characterization and Mechanical Properties. Indian J. Sci. Technol. 2016, 9, 1–6. [Google Scholar] [CrossRef]

- Kausar, A. A review of high performance polymer nanocomposites for packaging applications in electronics and food indus-tries. J. Plast. Film Sheeting 2020, 36, 94–112. [Google Scholar] [CrossRef]

- Chen, W.; Weimin, H.; Li, D.; Chen, S.; Dai, Z. A critical review on the development and performance of polymer/graphene nanocomposites. Sci. Eng. Compos. Mater. 2018, 25, 1059–1073. [Google Scholar] [CrossRef]

- Sorrentino, A. Tribology of Self-Lubricating Polymer Nanocomposites. In Self-Lubricating Composites; Menezes, P.L., Rohatgi, P.K., Omrani, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 105–131. ISBN 9783662565285. [Google Scholar]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Bahramnia, H.; Semnani, H.M.; Habibolahzadeh, A.; Abdoos, H. Epoxy/polyurethane nanocomposite coatings for an-ti-erosion/wear applications: A review. J. Compos. Mater. 2020, 3189–3203. [Google Scholar] [CrossRef]

- Padhan, M.; Marathe, U.; Bijwe, J. Tribology of Poly(etherketone) composites based on nano-particles of solid lubricants. Compos. Part B Eng. 2020, 201, 108323. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Sinha, S.K. Tribological applications of polymers and their composites—past, present and future prospects. In Tribology of Polymeric Nanocomposites; Friedrich, K., Schlarb, A.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1–22. ISBN 9780444594556. [Google Scholar]

- Aly, A.A.; Zeidan, E.-S.B.; Alshennawy, A.A.; El-Masry, A.A.; Wasel, W.A. Friction and Wear of Polymer Composites Filled by Nano-Particles: A Review. World J. Nano Sci. Eng. 2012, 2, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Cao, Z.; Shi, G.; Yan, X.; Wang, Q. In situ fabrication of CuO/UHMWPE nanocomposites and their tribological performance. J. Appl. Polym. Sci. 2019, 136, 47925. [Google Scholar] [CrossRef]

- Rothon, R. Fillers for Polymer Applications; Springer: Berlin, Germany, 2017; p. 489. [Google Scholar] [CrossRef]

- Mamidi, N.; Gamero, M.R.M.; Villela-Castrejón, J.; Elías-Zúníga, A. Development of ultra-high molecular weight polyeth-ylene-functionalized carbon nano-onions composites for biomedical applications. Diam. Relat. Mater. 2019, 97, 107435. [Google Scholar] [CrossRef]

- Zavala, J.M.D.; Gutiérrez, H.M.L.; Segura-Cárdenas, E.; Mamidi, N.; Morales-Avalos, R.; Villela-Castrejón, J.; Elías-Zúñiga, A. Manufacture and mechanical properties of knee implants using SWCNTs/UHMWPE composites. J. Mech. Behav. Biomed. Mater. 2021, 120, 104554. [Google Scholar] [CrossRef]

- Mamidi, N.; Leija, H.M.; Diabb, J.M.; Romo, I.L.; Hernandez, D.; Villela-Castrejón, J.; Romero, O.M.; Barrera, E.V.; Eli-as-Zúñiga, A. Cytotoxicity evaluation of unfunctionalized multiwall carbon nanotubes-ultrahigh molecular weight polyeth-ylene nanocomposites. J. Biomed. Mater. Res. Part A 2017, 105, 3042–3049. [Google Scholar] [CrossRef]

- Tiwari, J.N.; Tiwari, R.N.; Kim, K.S. Zero-dimensional, one-dimensional, two-dimensional and three-dimensional nanostruc-tured materials for advanced electrochemical energy devices. Prog. Mater. Sci. 2012, 57, 724–803. [Google Scholar] [CrossRef]

- Ren, G.; Zhang, Z.; Song, Y.; Li, X.; Yan, J.; Wang, Y.; Zhu, X. Effect of MWCNTs-GO hybrids on tribological performance of hybrid PTFE/Nomex fabric/phenolic composite. Compos. Sci. Technol. 2017, 146, 155–160. [Google Scholar] [CrossRef]

- Song, J.; Lei, H.; Zhao, G. Improved mechanical and tribological properties of polytetrafluoroethylene reinforced by carbon nanotubes: A molecular dynamics study. Comput. Mater. Sci. 2019, 168, 131–136. [Google Scholar] [CrossRef]

- Dabees, S.; Tirth, V.; Mohamed, A.; Kamel, B.M. Wear performance and mechanical properties of MWCNT/HDPE nano-composites for gearing applications. J. Mater. Res. Technol. 2021, 12, 2476–2488. [Google Scholar] [CrossRef]

- Arif, M.F.; Alhashmi, H.; Varadarajan, K.M.; Koo, J.H.; Hart, A.J.; Kumar, S. Multifunctional performance of carbon nanotubes and graphene nanoplatelets reinforced PEEK composites enabled via FFF additive manufacturing. Compos. Part B Eng. 2020, 184, 107625. [Google Scholar] [CrossRef]

- Atlukhanova, L.B.; Kozlov, G.V.; Dolbin, I.V. Structural Model of Frictional Processes for Polymer/Carbon Nanotube Nano-composites. J. Frict. Wear 2019, 40, 475–479. [Google Scholar] [CrossRef]

- Clavería, I.; Gimeno, S.; Miguel, I.; Mendoza, G.; Lostalé, A.; Fernández, Á.; Castell, P.; Elduque, D. Tribological Performance of Nylon Composites with Nanoadditives for Self-Lubrication Purposes. Polymers 2020, 12, 2253. [Google Scholar] [CrossRef] [PubMed]

- Remanan, M.; Kannan, M.; Rao, R.S.; Bhowmik, S.; Varshney, L.; Abraham, M.; Jayanarayanan, K. Microstructure Devel-opment, Wear Characteristics and Kinetics of Thermal Decomposition of Hybrid Nanocomposites Based on Poly Aryl Ether Ketone, Boron Carbide and Multi Walled Carbon Nanotubes. J. Inorg. Organomet. Polym. Mater. 2017, 27, 1649–1663. [Google Scholar] [CrossRef]

- Xin, Y.; Xu, F.; Wang, M.; Li, T. Synergistic Effects of Carbon Nanotube/Nano-MoS2 Hybrid on Tribological Performance of Polyimide Nanocomposite Films. Tribol. Lett. 2018, 66, 25. [Google Scholar] [CrossRef]

- Goriparthi, B.K.; Naveen, P.N.E.; Sankar, H.R.; Ghosh, S. Effect of functionalization and concentration of carbon nanotubes on mechanical, wear and fatigue behaviours of polyoxymethylene/carbon nanotube nanocomposites. Bull. Mater. Sci. 2019, 42, 98. [Google Scholar] [CrossRef] [Green Version]

- Maksimkin, A.V.; Nematulloev, S.G.; Chukov, D.I.; Danilov, V.D.; Senatov, F.S. Bulk oriented UHMWPE/FMWCNT films for tribological applications. Polymers 2017, 9, 629. [Google Scholar] [CrossRef] [Green Version]

- Chen, B.; Chen, J.; Li, J.-Y.; Tong, X.; Zhao, H.-C.; Wang, L.-P. Oligoaniline assisted dispersion of carbon nanotubes in epoxy matrix for achieving the nanocomposites with enhanced mechanical, thermal and tribological properties. Chin. J. Polym. Sci. 2017, 35, 446–454. [Google Scholar] [CrossRef]

- Goriparthi, B.K.; Naveen, P.N.E.; Shankar, H.R.; Ghosh, S. Mechanical, wear and fatigue behavior of functionalized CNTs reinforced POM/PTFE composites. Mater. Res. Express 2019, 6, 065051. [Google Scholar] [CrossRef]

- Ali, M.; Khalil, A.; Osman, T.A. Enhanced mechanical and tribological properties of polyamide using carbon nanotube. Int. J. Adv. Manuf. Technol. 2020, 106, 243–252. [Google Scholar] [CrossRef]

- Upadhyay, R.K.; Kumar, A. A novel approach to minimize dry sliding friction and wear behavior of epoxy by infusing fullerene C70 and multiwalled carbon nanotubes. Tribol. Int. 2018, 120, 455–464. [Google Scholar] [CrossRef]

- Baduruthamal, Z.A.; Mohammed, A.S.; Kumar, A.M.; Hussein, M.A.; Al-Aqeeli, N. Tribological and Electrochemical Char-acterization of UHMWPE Hybrid Nanocomposite Coating for Biomedical Applications. Materials 2019, 12, 3665. [Google Scholar] [CrossRef] [Green Version]

- Azam, M.U.; Samad, M.A. A novel organoclay reinforced UHMWPE nanocomposite coating for tribological applications. Prog. Org. Coat. 2018, 118, 97–107. [Google Scholar] [CrossRef]

- Azam, M.U.; Samad, M.A. Tribological Evaluation of a UHMWPE Hybrid Nanocomposite Coating Reinforced With Nanoclay and Carbon Nanotubes Under Dry Conditions. J. Tribol. 2018, 140, 051304. [Google Scholar] [CrossRef]

- Vadivel, H.S.; Bek, M.; Šebenik, U.; Perše, L.S.; Kádár, R.; Emami, N.; Kalin, M. Do the particle size, molecular weight, and processing of UHMWPE affect its thermomechanical and tribological performance? J. Mater. Res. Technol. 2021, 12, 1728–1737. [Google Scholar] [CrossRef]

- Cotet, A.; Bastiurea, M.; Andrei, G.; Cantaragiu, A.; Hadar, A. Dry Sliding Friction Analysis and Wear Behavior of Carbon Nanotubes / Vinylester Nanocomposites, Using Pin-on-Disc Test. Rev. Chim. 2019, 70, 3592–3596. [Google Scholar]

- Zhang, M.; Chen, B.; Dong, Z.; Wang, S.; Li, X.; Jia, Y.; Yan, F. Enhancement on the tribological properties of poly(phthalazinone ether sulfone ketone) by carbon nanotube-supported graphitic carbon nitride hybrid. Polym. Compos. 2020, 41, 3768–3777. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.; Jia, Y.; Xu, L.; Liang, H.; Li, X.; Yang, J.; Li, C.; Yan, F. Fabrication of ternary hybrid of carbon nano-tubes/graphene oxide/MoS2 and its enhancement on the tribological properties of epoxy composite coatings. Compos. Part A Appl. Sci. Manuf. 2018, 115, 157–165. [Google Scholar] [CrossRef]

- Li, X.; Chen, B.; Jia, Y.; Li, X.; Yang, J.; Li, C.; Yan, F. Enhanced tribological properties of epoxy-based lubricating coatings using carbon nanotubes-ZnS hybrid. Surf. Coat. Technol. 2018, 344, 154–162. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Aleksenko, V.O.; Ivanova, L.R.; Shil’ko, S.V.; Pleskachevsky, Y.M. Extrudable UHMWPE-Based Composites: Prospects of Application in Additive Technologies. Nanosci. Technol. Int. J. 2017, 8, 85–94. [Google Scholar] [CrossRef]

- Chen, B.; Jia, Y.; Zhang, M.; Liang, H.; Li, X.; Yang, J.; Yan, F.; Li, C. Tribological properties of epoxy lubricating composite coatings reinforced with core-shell structure of CNF/MoS2 hybrid. Compos. Part A Appl. Sci. Manuf. 2019, 122, 85–95. [Google Scholar] [CrossRef]

- Thakur, A.; Manna, A.; Samir, S.; Jindal, P. Polymer nanocomposite reinforced with selectively synthesized coiled carbon nanofibers. Compos. Interfaces 2020, 27, 215–226. [Google Scholar] [CrossRef]

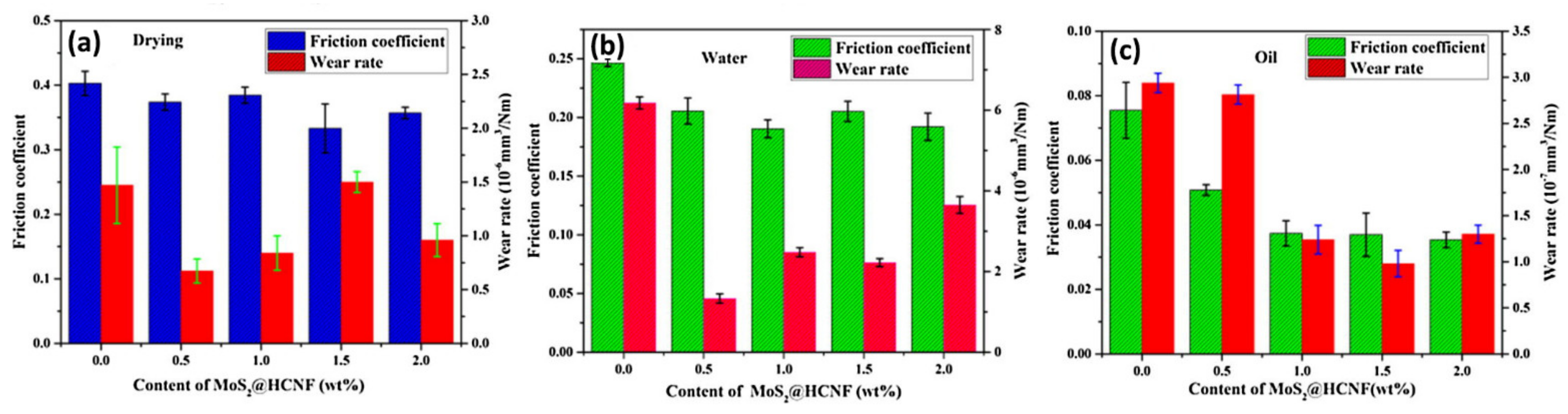

- Yuan, H.; Yang, S.; Liu, X.; Wang, Z.; Ma, L.; Hou, K.; Yang, Z.; Wang, J. Polyimide-based lubricating coatings synergistically enhanced by MoS2@HCNF hybrid. Compos. Part A Appl. Sci. Manuf. 2017, 102, 9–17. [Google Scholar] [CrossRef]

- Tóth, L.F.; De Baets, P.; Szebényi, G. Thermal, Viscoelastic, Mechanical and Wear Behaviour of Nanoparticle Filled Polytetra-fluoroethylene: A Comparison. Polymers 2020, 12, 1940. [Google Scholar] [CrossRef]

- Bashandeh, K.; Lan, P.; Meyer, J.L.; Polycarpou, A.A. Tribological Performance of Graphene and PTFE Solid Lubricants for Polymer Coatings at Elevated Temperatures. Tribol. Lett. 2019, 67, 99. [Google Scholar] [CrossRef]

- Aliyu, I.K.; Mohammed, A.S.; Al-Qutub, A. Tribological performance of ultra high molecular weight polyethylene nanocom-posites reinforced with graphene nanoplatelets. Polym. Compos. 2019, 40, E1301–E1311. [Google Scholar] [CrossRef]

- Aliyu, I.K.; Mohammed, A.S.; Al-Qutub, A. Tribological Performance of UHMWPE/GNPs Nanocomposite Coatings for Solid Lubrication in Bearing Applications. Tribol. Lett. 2018, 66, 144. [Google Scholar] [CrossRef]

- Aliyu, I.K.; Samad, M.A.; Al-Qutub, A. Tribological characterization of a bearing coated with UHMWPE/GNPs nanocomposite coating. Surf. Eng. 2020, 844, 60–69. [Google Scholar] [CrossRef]

- Puértolas, J.A.; Castro, M.; Morris, J.A.; Ríos, R.; Ansón-Casaos, A. Tribological and mechanical properties of graphene na-noplatelet/PEEK composites. Carbon 2019, 141, 107–122. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Qiu, S.; Cui, M.; Qin, S.; Yan, G.; Zhao, H.; Wang, L.; Xue, Q. Achieving high performance corrosion and wear resistant epoxy coatings via incorporation of noncovalent functionalized graphene. Carbon 2017, 114, 356–366. [Google Scholar] [CrossRef]

- Kazemi-Khasragh, E.; Bahari-Sambran, F.; Platzer, C.; Eslami-Farsani, R. The synergistic effect of graphene nanoplatelets–montmorillonite hybrid system on tribological behavior of epoxy-based nanocomposites. Tribol. Int. 2020, 151, 106472. [Google Scholar] [CrossRef]

- Amirbeygi, H.; Khosravi, H.; Tohidlou, E. Reinforcing effects of aminosilane-functionalized graphene on the tribological and mechanical behaviors of epoxy nanocomposites. J. Appl. Polym. Sci. 2019, 136, 47410. [Google Scholar] [CrossRef]

- Feng, J.; Wang, X.; Guo, P.; Wang, Y.; Luo, X. Mechanical Properties and Wear Resistance of Sulfonated Graphene/Waterborne Polyurethane Composites Prepared by In Situ Method. Polymers 2018, 10, 75. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.; Li, W.; Zhao, W.; Liu, C.; Fang, Z.; Gao, X. Tribological behaviors of polyimide composite films enhanced with fluo-rographene. Colloids Surf. A Physicochem. Eng. Asp. 2019, 580, 123707. [Google Scholar] [CrossRef]

- Song, J.; Dai, Z.; Nan, F.; Li, J.; Zhao, H.; Wang, L. Dopamine-modified nanographite as reinforcing filler for epoxy nano-composite. J. Compos. Mater. 2019, 53, 1671–1679. [Google Scholar] [CrossRef]

- Ray, S.C. Application and Uses of Graphene Oxide. In Applications of Graphene and Gra-phene-Oxide Based Nanomaterials; Ray, S.C., Ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 39–55. ISBN 978-0-323-37521-4. [Google Scholar]

- Yetgin, S.H. Tribological properties of compatabilizer and graphene oxide-filled polypropylene nanocomposites. Bull. Mater. Sci. 2020, 43, 4–11. [Google Scholar]

- Yuan, R.; Ji, L.; Wu, Y.; Li, H.; Ju, P.; Chen, L.; Zhou, H.; Chen, J. “Plate-anchor” shaped POSS-functionalized graphene oxide with self-fixing effect in polyimide matrix: Molecular dynamic simulations and experimental analysis. Compos. Sci. Technol. 2019, 176, 103–110. [Google Scholar] [CrossRef]

- Myalski, J.; Godzierz, M.; Olesik, P. Effect of carbon fillers on the wear resistance of pa6 thermoplastic composites. Polymers 2020, 12, 2264. [Google Scholar] [CrossRef]

- Suñer, S.; Gowland, N.; Craven, R.; Joffe, R.; Emami, N.; Tipper, J.L. Ultrahigh molecular weight polyethylene/graphene oxide nanocomposites: Wear characterization and biological response to wear particles. J. Biomed. Mater. Res. Part B Appl. Biomater. 2018, 106, 183–190. [Google Scholar] [CrossRef]

- Min, C.; Shen, C.; Zeng, M.; Nie, P.; Song, H.J.; Li, S. Influence of graphene oxide as filler on tribological behaviors of polyi-mide/graphene oxide nanocomposites under seawater lubrication. Monatshefte fur Chem.-Chem. Mon. 2017, 148, 1301–1309. [Google Scholar] [CrossRef]

- Pelto, J.; Verho, T.; Ronkainen, H.; Kaunisto, K.; Metsäjoki, J.; Seitsonen, J.; Karttunen, M. Matrix morphology and the particle dispersion in HDPE nanocomposites with enhanced wear resistance. Polym. Test. 2019, 77, 105897. [Google Scholar] [CrossRef]

- Pelto, J.; Heino, V.; Karttunen, M.; Rytöluoto, I.; Ronkainen, H. Tribological performance of high density polyethylene (HDPE) composites with low nanofiller loading. Wear 2020, 460, 203451. [Google Scholar] [CrossRef]

- Bao, T.; Wang, Z.; Zhao, Y.; Wang, Y.; Yi, X. Friction and mechanical properties of amino-treated graphene-filled epoxy composites: Modification conditions and filler content. RSC Adv. 2020, 10, 26646–26657. [Google Scholar] [CrossRef]

- Bao, T.; Wang, Z.; Zhao, Y.; Wang, Y.; Yi, X. Improving tribological performance of epoxy composite by reinforcing with pol-yetheramine-functionalized graphene oxide. J. Mater. Res. Technol. 2021, 12, 1516–1529. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, J.; Chen, B.; Guo, S.; Li, J.; Li, C. One-step hydrothermal synthesis of reduced graphene oxide/zinc sulfide hybrids for enhanced tribological properties of epoxy coatings. Surf. Coat. Technol. 2017, 326, 87–95. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, H.; Lyu, Q.; Niu, S.; Tang, C. Ternary hybrid nanoparticles of reduced graphene oxide/graphene-like MoS2/zirconia as lubricant additives for bismaleimide composites with improved mechanical and tribological properties. Compos. Part A Appl. Sci. Manuf. 2017, 101, 98–107. [Google Scholar] [CrossRef]

- Liu, C.; Dong, Y.; Lin, Y.; Yan, H.; Zhang, W.; Bao, Y.; Ma, J. Enhanced mechanical and tribological properties of gra-phene/bismaleimide composites by using reduced graphene oxide with non-covalent functionalization. Compos. Part B Eng. 2019, 165, 491–499. [Google Scholar] [CrossRef]

- Zhao, B.; Bai, T. Improving the tribological performance of epoxy coatings by the synergistic effect between dehydrated eth-ylenediamine modified graphene and polytetrafluoroethylene. Carbon 2019, 144, 481–491. [Google Scholar] [CrossRef]

- Haddadi, S.A.; Ahmad, A.R.; Amini, M.; Kheradmand, A. In-situ preparation and characterization of ultra-high molecular weight polyethylene/diamond nanocomposites using Bi-supported Ziegler-Natta catalyst: Effect of nanodiamond silanization. Mater. Today Commun. 2018, 14, 53–64. [Google Scholar] [CrossRef]

- Shettar, M.; Kowshik, C.S.S.; Manjunath, M.; Hiremath, P. Experimental investigation on mechanical and wear properties of nanoclay-epoxy composites. J. Mater. Res. Technol. 2020, 9, 9108–9116. [Google Scholar] [CrossRef]

- bin Ali, A.; Mohammed, A.S.; Merah, N. Tribological investigations of UHMWPE nanocomposites reinforced with three dif-ferent organo-modified clays. Polym. Compos. 2018, 39, 2224–2231. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Bin Ali, A.; Nesar, M. Evaluation of Tribological Properties of Organoclay Reinforced UHMWPE Nano-composites. J. Tribol. 2017, 139, 012001. [Google Scholar] [CrossRef]

- Gaur, A.; Rana, D.; Maiti, P. Mechanical and wear behaviour of poly(vinylidene fluoride)/clay nanocomposite. J. Mater. Res. Technol. 2019, 8, 5874–5881. [Google Scholar] [CrossRef]

- Cheng, Z.-L.; Chang, X.-Y.; Liu, Z.; Qin, D.-Z.; Zhu, A.-P. High-performance PTFE nanocomposites based on halloysite nanotubes. Clay Miner. 2017, 52, 427–438. [Google Scholar] [CrossRef]

- Sahnoune, M.; Kaci, M.; Taguet, A.; Delbé, K.; Mouffok, S.; Abdi, S.; Lopez-Cuesta, J.M.; Focke, W.W. Tribological and me-chanical properties of polyamide-11/halloysite nanotube nanocomposites. J. Polym. Eng. 2019, 39, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Z.-L.; Chang, X.-Y.; Liu, Z.; Qin, D.-Z. Surface-modified halloysite nanotubes as fillers applied in reinforcing the per-formance of polytetrafluoroethylene. Clay Miner. 2018, 53, 643–656. [Google Scholar] [CrossRef]

- Vuluga, Z.; Corobea, M.C.; Elizetxea, C.; Ordonez, M.; Ghiurea, M.; Raditoiu, V.; Nicolae, C.A.; Florea, D.; Iorga, M.; Somoghi, R.; et al. Morphological and Tribological Properties of PMMA/Halloysite Nanocomposites. Polymers 2018, 10, 816. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Danilova, S.N.; Yarusova, S.B.; Kulchin, Y.N.; Zhevtun, I.G.; Buravlev, I.Y.; Okhlopkova, A.A.; Gordienko, P.S.; Subbotin, E.P. UHMWPE/CaSiO3 Nanocomposite: Mechanical and Tribological Properties. Polymers 2021, 13, 570. [Google Scholar] [CrossRef] [PubMed]

- Serenko, O.A.; Muzafarov, A.M. Polymer composites with surface modified SiO2 nanoparticles: Structures, properties, and promising applications. Polym. Sci. Ser. C 2016, 58, 93–101. [Google Scholar] [CrossRef]

- Shi, G.; Wang, Q.; Sun, T.; Yan, X. In situ filling of SiO2 nanospheres into PTFE by sol-gel as a highly wear-resistant nano-composite. J. Appl. Polym. Sci. 2020, 137, 49096. [Google Scholar] [CrossRef]

- Shi, G.; Cao, Z.; Yan, X.; Wang, Q. In-situ fabrication of a UHMWPE nanocomposite reinforced by SiO2 nanospheres and its tribological performance. Mater. Chem. Phys. 2019, 236, 121778. [Google Scholar] [CrossRef]

- Ma, J.; Qi, X.; Zhao, Y.; Zhang, Q.; Yang, Y. Effects of elevated temperature on tribological behavior of polyimide and polyi-mide/mesoporous silica nanocomposite in dry sliding against GCr15 steel. Wear 2017, 374–375, 142–151. [Google Scholar] [CrossRef]

- Ma, J.; Qi, X.; Dong, Y.; Zhao, Y.; Zhang, Q.; Fan, B.; Yang, Y. Transfer film formation mechanism and tribochemistry evolution of a low-wear polyimide/mesoporous silica nanocomposite in dry sliding against bearing steel. Tribol. Int. 2018, 120, 233–242. [Google Scholar] [CrossRef] [Green Version]

- Ye, J.; Khare, H.S.; Burris, D.L. Transfer film evolution and its role in promoting ultra-low wear of a PTFE nanocomposite. Wear 2013, 297, 1095–1102. [Google Scholar] [CrossRef]

- Abenojar, J.; Tutor, J.; Ballesteros, Y.; del Real, J.C.; Martínez, M.A. Erosion-wear, mechanical and thermal properties of silica filled epoxy nanocomposites. Compos. Part B Eng. 2017, 120, 42–53. [Google Scholar] [CrossRef]

- Mohammed, A.S. UHMWPE nanocomposite coatings reinforced with alumina (Al2O3) nanoparticles for tribological applica-tions. Coatings 2018, 8, 280. [Google Scholar] [CrossRef] [Green Version]

- Guo, L.; Zhang, Y.; Zhang, G.; Wang, Q.; Wang, T. MXene-Al2O3 synergize to reduce friction and wear on epoxy-steel contacts lubricated with ultra-low sulfur diesel. Tribol. Int. 2021, 153, 106588. [Google Scholar] [CrossRef]

- Llorente, A.; Serrano, B.; Baselga, J.; Gedler, G.; Ozisik, R. Nanoindentation and wear behavior of thermally stable biocom-patible polysulfone-alumina nanocomposites. RSC Adv. 2016, 6, 100239–100247. [Google Scholar] [CrossRef] [Green Version]

- Derazkola, H.; Simchi, A. Effects of alumina nanoparticles on the microstructure, strength and wear resistance of poly(methyl methacrylate)-based nanocomposites prepared by friction stir processing. J. Mech. Behav. Biomed. Mater. 2018, 79, 246–253. [Google Scholar] [CrossRef] [PubMed]

- Dass, K.; Chauhan, S.R.; Gaur, B. Study on the effects of nanoparticulates of SiC, Al2O3, and ZnO on the mechanical and tribological performance of epoxy-based nanocomposites. Part. Sci. Technol. 2017, 35, 589–606. [Google Scholar] [CrossRef]

- Botlhoko, O.J.; Letwaba, L.; Bandyopadhyay, J.; Ray, S.S. UV-protection, tribology, and mechanical properties of ZnO-containing polyamide composites. J. Appl. Polym. Sci. 2020, 137, 48418. [Google Scholar] [CrossRef]

- Sharma, R.K.; Nisar, A.; Balani, K. Mechanics of ZnO morphological dependence on wear resistance of ultra high molecular weigh polyethylene. Eur. J. Mech. A/Solids 2017, 65, 149–158. [Google Scholar] [CrossRef]

- Zhang, D.; Li, Z.; Gao, F.; Wei, X.; Ni, Y. Tribological performance of polymer composite coatings modified with La2O3 and MoS2 nanoparticles. J. Tribol. 2019, 141, 111601. [Google Scholar] [CrossRef]

- Wu, J.; Huang, X.; Berglund, K.; Lu, X.; Feng, X.; Larsson, R.; Shi, Y. CuO nanosheets produced in graphene oxide solution: An excellent anti-wear additive for self-lubricating polymer composites. Compos. Sci. Technol. 2018, 162, 86–92. [Google Scholar] [CrossRef]

- Xu, Q.; Hu, P.; Wu, D.; Li, X.; Zhang, Z. Studies on the mechanical and friction properties of polyamide 6-Cu/Si nanocompo-sites. J. Macromol. Sci. Part A 2017, 54, 323–327. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, W.; Wu, Y.; Wang, D.; Feng, R. Tribological properties of epoxy composite coatings reinforced with functionalized C-BN and H-BN nanofillers. Appl. Surf. Sci. 2018, 434, 1311–1320. [Google Scholar] [CrossRef]

- Joshi, M.D.; Goyal, A.; Patil, S.M.; Goyal, R.K. Tribological and thermal properties of hexagonal boron nitride filled high-performance polymer nanocomposites. J. Appl. Polym. Sci. 2017, 134, 1–9. [Google Scholar] [CrossRef]

- Gao, C.; Guo, G.; Zhang, G.; Wang, Q.; Wang, T.; Wang, H. Formation mechanisms and functionality of boundary films derived from water lubricated polyoxymethylene/hexagonal boron nitride nanocomposites. Mater. Des. 2017, 115, 276–286. [Google Scholar] [CrossRef]

- Chen, J.; Chen, B.; Li, J.; Tong, X.; Zhao, H.; Wang, L. Enhancement of mechanical and wear resistance performance in hex-agonal boron nitride-reinforced epoxy nanocomposites. Polym. Int. 2017, 66, 659–664. [Google Scholar] [CrossRef]

- Zhang, H.; Li, X.; Qian, W.; Zhu, J.; Chen, B.; Yang, J.; Xia, Y. Characterization of mechanical properties of epoxy/nanohybrid composites by nanoindentation. Nanotechnol. Rev. 2020, 9, 28–40. [Google Scholar] [CrossRef] [Green Version]

- Chen, B.; Li, X.; Jia, Y.; Li, X.; Yang, J.; Yan, F.; Li, C. MoS2 nanosheets-decorated carbon fiber hybrid for improving the friction and wear properties of polyimide composite. Compos. Part A Appl. Sci. Manuf. 2018, 109, 232–238. [Google Scholar] [CrossRef]

- Hazarika, S.J.; Mohanta, D. Revealing mechanical, tribological, and surface-wettability features of nanoscale inorganic full-erene-type tungsten disulfide dispersed in a polymer. J. Mater. Res. 2019, 34, 3666–3677. [Google Scholar] [CrossRef]

- Zhu, L.; You, L.; Shi, Z.; Song, H.; Li, S. An investigation on the graphitic carbon nitride reinforced polyimide composite and evaluation of its tribological properties. J. Appl. Polym. Sci. 2017, 134, 45403. [Google Scholar] [CrossRef]

- Zhang, L.; Li, G.; Guo, Y.; Qi, H.; Che, Q.; Zhang, G. PEEK reinforced with low-loading 2D graphitic carbon nitride nanosheets: High wear resistance under harsh lubrication conditions. Compos. Part A Appl. Sci. Manuf. 2018, 109, 507–516. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, Z.; Yang, M.; Yuan, J.; Li, P.; Guo, F.; Men, X. One-step synthesis of g-C3N4 nanosheets to improve tribological properties of phenolic coating. Tribol. Int. 2019, 132, 221–227. [Google Scholar] [CrossRef]

- Fiołek, A.; Zimowski, S.; Kopia, A.; Moskalewicz, T. The Influence of Electrophoretic Deposition Parameters and Heat Treat-ment on the Microstructure and Tribological Properties of Nanocomposite Si3N4/PEEK 708 Coatings on Titanium Alloy. Coatings 2019, 9, 530. [Google Scholar] [CrossRef] [Green Version]

- Aliyu, I.K.; Azam, M.U.; Lawal, D.U.; Samad, M.A. Optimization of SiC Concentration and Process Parameters for a Wear-Resistant UHMWPE Nancocomposite. Arab. J. Sci. Eng. 2020, 45, 849–860. [Google Scholar] [CrossRef]

- Qian, M.; Song, P.; Qin, Z.; Yan, S.; Zhang, L. Mechanically robust and abrasion-resistant polymer nanocomposites for potential applications as advanced clearance joints. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105607. [Google Scholar] [CrossRef]

- Hattab, A.K.; Yusr, H.A.; Farhan, F.K. Mechanical properties of (PMMA/CaTiZrO5) the biocompatible. J. Phys. Conf. Ser. 2019, 1362. [Google Scholar] [CrossRef]

- Iyer, S.B.; Dube, A.; Dube, N.M.; Roy, P.; Sailaja, R.R.N. Sliding wear and friction characteristics of polymer nanocomposite PAEK-PDMS with nano-hydroxyapatite and nano-carbon fibres as fillers. J. Mech. Behav. Biomed. Mater. 2018, 86, 23–32. [Google Scholar] [CrossRef] [PubMed]

- Fouly, A.; Ibrahim, A.M.M.; Sherif, E.-S.M.; FathEl-Bab, A.M.R.; Badran, A.H. Effect of Low Hydroxyapatite Loading Fraction on the Mechanical and Tribological Characteristics of Poly(Methyl Methacrylate) Nanocomposites for Dentures. Polymers 2021, 13, 857. [Google Scholar] [CrossRef] [PubMed]

- Hadi, N.J.; Al-Kawaz, A.; Hamza, A.F.; Mohamed, D.J. New Approach to Predict Mechanical and Tribological Behaviour Through Rheological Properties of Polypropylene Composites. In Proceeding of 2018 9th International Conference on Me-chanical and Aerospace Engineering (ICMAE), Hungary, Budapest, 10–13 July 2018; pp. 556–560. [Google Scholar] [CrossRef]

- Uflyand, I.E.; Drogan, E.G.; Burlakova, V.E.; Kydralieva, K.A.; Shershneva, I.N.; Dzhardimalieva, G.I. Testing the mechanical and tribological properties of new metal-polymer nanocomposite materials based on linear low-density polyethylene and Al65Cu22Fe13 quasicrystals. Polym. Test. 2019, 74, 178–186. [Google Scholar] [CrossRef]

- Rajamani, G.; Paulraj, J.; Krishnan, K. Analysis of Wear Behavior of Graphene Oxide-Polyamide Gears for Engineering Applications. Surf. Rev. Lett. 2017, 24, 1850018. [Google Scholar] [CrossRef]

- Bellairu, P.K.; Bhat, S.; Madhyastha, K. A study on wear properties of SWCNT reinforced polymer nanocomposite. In Emerging Trends in Mechanical Engineering 2018, Proceedings of the International Conference on Emerging Trends in Mechanical Engineering eTIME-2018, India, 10–11 August 2018; Gopalakrishna, B.K., Mudradi, S., Eds.; AIP Conference Proceedings: Karnataka, India, 2019; Volume 2080, p. 020013. [Google Scholar]

- Kobykhno, I.; Honcharenko, D.; Li, H.; Steshenkov, A.; Xu, J.; Yadykin, V. Friction and wear characteristics of UD thermo-plastic tape based nanocomposites with fullerene soot. Key Eng. Mater. 2019, 822, 215–223. [Google Scholar] [CrossRef]

- Liu, L.; Yan, F.; Gai, F.; Xiao, L.; Shang, L.; Li, M.; Ao, Y. Enhanced tribological performance of PEEK/SCF/PTFE hybrid composites by graphene. RSC Adv. 2017, 7, 33450–33458. [Google Scholar] [CrossRef] [Green Version]

- Gbadeyan, O.J.; Kanny, K. Tribological Behaviors of Polymer-Based Hybrid Nanocomposite Brake Pad. J. Tribol. 2018, 140, 032003. [Google Scholar] [CrossRef]

- Bin Ali, A.; Samad, M.A.; Merah, N. UHMWPE Hybrid Nanocomposites for Improved Tribological Performance Under Dry and Water-Lubricated Sliding Conditions. Tribol. Lett. 2017, 65, 102. [Google Scholar]

- Guo, L.; Zhang, G.; Wang, D.; Zhao, F.; Wang, T.; Wang, Q. Significance of combined functional nanoparticles for enhancing tribological performance of PEEK reinforced with carbon fibers. Compos. Part A Appl. Sci. Manuf. 2017, 102, 400–413. [Google Scholar] [CrossRef]

- Guo, L.; Qi, H.; Zhang, G.; Wang, T.; Wang, Q. Distinct tribological mechanisms of various oxide nanoparticles added in PEEK composite reinforced with carbon fibers. Compos. Part A Appl. Sci. Manuf. 2017, 97, 19–30. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Su, X.; Tao, J.; Fu, R.; You, C.; Chen, X. Effect of SiO2 nanoparticles-decorated SCF on mechanical and tribological properties of cenosphere/SCF/PEEK composites. J. Appl. Polym. Sci. 2020, 137, 48749. [Google Scholar]

- Liu, G.; Zhang, L.; Li, G.; Zhao, F.; Che, Q.; Wang, C.; Zhang, G. Tuning the tribofilm nanostructures of polymer-on-metal joint replacements for simultaneously enhancing anti-wear performance and corrosion resistance. Acta Biomater. 2019, 87, 285–295. [Google Scholar] [CrossRef]

- Uyor, U.O.; Popoola, A.P.I.; Popoola, O.M.; Aigbodion, V.S. Effects of titania on tribological and thermal properties of poly-mer/graphene nanocomposites. J. Thermoplast. Compos. Mater. 2020, 33, 1030–1047. [Google Scholar] [CrossRef]

- Zheng, X.; Fei, J.; Li, M.; Huang, J.; Wang, N. Sodium citrate-assisted synthesis of nano-manganese oxide on carbon fiber for enhancing the mechanical and frictional performances of carbon fiber-reinforced resin matrix composites. J. Appl. Polym. Sci. 2021, 138, 50322. [Google Scholar] [CrossRef]

- He, Y.; Chen, Q.; Liu, H.; Zhang, L.; Wu, D.; Lu, C.; OuYang, W.; Jiang, D.; Wu, M.; Zhang, J.; et al. Friction and Wear of MoO3/Graphene Oxide Modified Glass Fiber Reinforced Epoxy Nanocomposites. Macromol. Mater. Eng. 2019, 304, 1900166. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Qi, H.; Li, G.; Guo, X.; Wan, Y.; Zhang, G. Significance of an in-situ generated boundary film on tribocorrosion behavior of polymer-metal sliding pair. J. Colloid Interface Sci. 2018, 518, 263–276. [Google Scholar] [CrossRef]

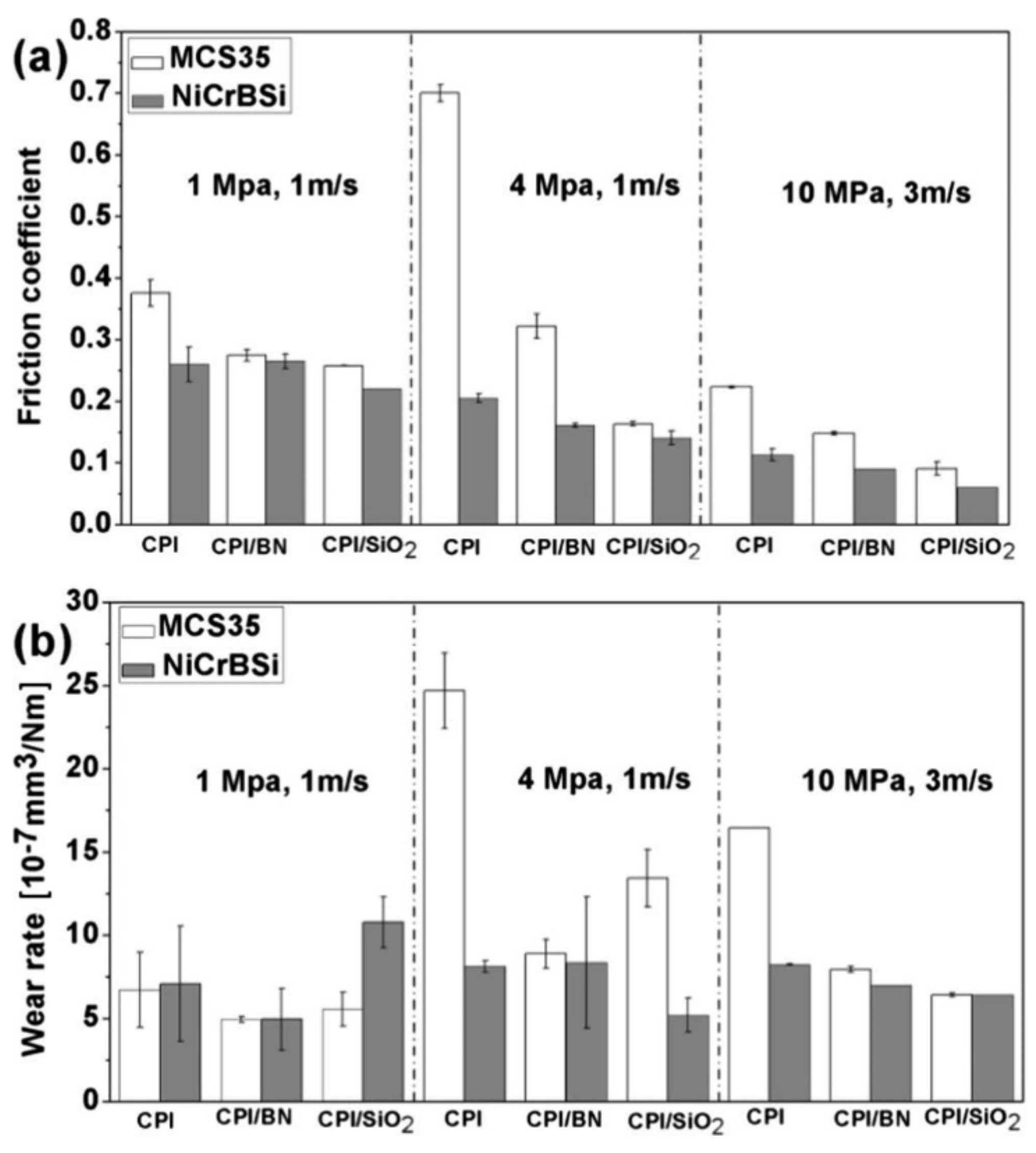

- Qi, H.; Li, G.; Liu, G.; Zhang, C.; Zhang, G.; Wang, T.; Wang, Q. Comparative study on tribological mechanisms of polyimide composites when sliding against medium carbon steel and NiCrBSi. J. Colloid Interface Sci. 2017, 506, 415–428. [Google Scholar] [CrossRef]

- Kazemi-Khasragh, E.; Bahari-Sambran, F.; Siadati, S.M.H.; Eslami-Farsani, R.; Chirani, S.A. The effects of surface-modified graphene nanoplatelets on the sliding wear properties of basalt fibers-reinforced epoxy composites. J. Appl. Polym. Sci. 2019, 136, 47986. [Google Scholar] [CrossRef]

- Wani, T.P.; Raja, R.; Sampathkumaran, P.; Seetharamu, S. Investigation on Wear and Friction Characteristics of Bi-Directional Silk Fiber Reinforced Nanoclay Added HDPE Composites. Mater. Today Proc. 2018, 5, 25713–25719. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Tribological Studies of Nanoclay Filled Epoxy Hybrid Laminates. Tribol. Trans. 2017, 60, 681–692. [Google Scholar] [CrossRef]

- Yi, H.; Hu, M.; Yao, D.; Lin, H.; Zheng, B. Tribological and thermomechanical properties of epoxy-matrix nanocomposites containing montmorillonite nanoclay intercalated with polybutadiene-based quaternary ammonium salt. Plast. Rubber Compos. 2020, 49, 389–399. [Google Scholar] [CrossRef]

- Patil, N.A.; Njuguna, J.; Kandasubramanian, B. UHMWPE for biomedical applications: Performance and functionalization. Eur. Polym. J. 2020, 125, 109529. [Google Scholar] [CrossRef]

- Kadhim, M.O.; Farhan, F.K.; Sabar, D.A.; Abood, O.N. Friction coefficient and biophysical properties for UPE-PMMA blend reinforced by nano-zinc oxide. EurAsian J. Biosci. 2018, 12, 481–486. [Google Scholar]

- Shi, S.-C.; Chen, T.-H.; Mandal, P.K. Enhancing the Mechanical and Tribological Properties of Cellulose Nanocomposites with Aluminum Nanoadditives. Polymers 2020, 12, 1246. [Google Scholar] [CrossRef]

| Polymer | Nanofiller | Test Conditions | Wear Rate | Friction Coefficient | Reference |

|---|---|---|---|---|---|

| Carbon-Based Nanofillers | |||||

| PTFE | CNT | Dry; AL: 101 kPa | N/A | −25% | [40] |

| PEEK | MWCNT OD: 10–15 nm; L: 0.1–10 µm | BOD (R); AISI E52100 stainless-steel ball; Dry; AL: 10 N; SV: 5 Hz; SD: 10,000 cycles | +142% | −67% | [42] |

| Graphene Thickness: 0.34–100 nm | +121% | −56% | |||

| POM copolymer | Pure MWCNT | POD; Steel; Dry; AL: 15, 25, 35 N; SV: 1 m/s; ST: 30 min; Ra: 0.25 µm | −9% | −20% | [47] |

| Acid-treated MWCNT | −19% | −19% | |||

| Silanized MWCNT | −45% | −27% | |||

| Carbonylated MWCNT | −28% | −21% | |||

| Aminated MWCNT | −31% | −22% | |||

| UHMWPE | Fluorinated MWCNT L: 2 mm; OD: 8–15 nm; ID: 4–8 nm | POD; Steel; Dry; AL: 32 N; SV: 2.6 m/s; SD: 2355 m | −95% | −27% | [48] |

| Epoxy resin | MWCNT D: 10–50 nm | POD; 316L steel ball; Dry; AL: 5 N; SV: 2 Hz; SD: 5 mm | −83% | −31% | [49] |

| POM copolymer/PTFE blend | Silanized MWCNT | POD; Steel; Dry; AL: 15, 25, 35 N; SV: 1 m/s; ST: 30 min; Ra: 0.25 µm | −35% | +23% | [50] |

| PA11 | MWCNT D: 10–12 nm | POD; Steel disk; Dry; AL: 5, 10 N; SV: 150 rpm; ST: 10 min | −11% | N/A | [51] |

| Epoxy resin | MWCNT L: 1–10 µm; Number of walls: 3–15 | BOD; Bearing steel SAE 52,100 balls, Dry; AL: 2 and 4 N; SV: 0.28 m/s (1000 rpm) | −36% | −78% | [52] |

| C70 | −71% | −39% | |||

| Vinyl ester resin | MWCNT L: 10–20 µm; OD: 8–15 nm; ID: 3–5 nm | POD; Steel 42CrMo4 disc; Dry; AL: 10–20 N; SV: 0.5–1.5 m/s; SD: 1600 m | +167% | −43% | [57] |

| SWCNT L: 5–30 µm; OD: 1–2 nm; ID: 0.8–1.6 nm | −33% | +11% | |||

| UHMWPE/PP-b-LLDPE blend | Taunit CNF D: 60 nm | POD; ShKh15 steel; Dry; AL: 160 N; SV: 0.3 m/s | −80% | −46% | [61] |

| TPU | CNF | POD; Metal; Dry; AL: 1 kg; SV: 0.5 m/s; SD: 1000 m; ST: 33.3 min | −94% | −72% | [63] |

| ATSP | Graphene D: 25 µm; Surface area: 120–150 m2/g | POD; E52100 bearing steel pin; Dry; T: 25–300 °C; AL: 135 N (4 MPa); SV: 1 m/s (530 rpm); SD: 3603 m; ST: 60 min | N/A | −52% | [66] |

| UHMWPE | Graphene D: 10 µm; Thickness: 180 nm | POD; Hardened tool steel pin; Dry; AL: 39.0–97.5 N; SV: 0.1–0.75 m/s; SD: 1000 m; Ra: 0.43 µm | −31% | +27% | [67] |

| POD; Hardened tool steel pin; Dry; AL: 2–8 MPa; SV: 0.1–1 m/s; SD: 377 m; Ra: 0.37 µm | −52% | −12% | [68] | ||

| Ring on Disc; AISI4140 steel; Dry and base oil lubrication; AL: 0.1–3.1 MPa; SV: 1–2 m/s; SD: 750–1000 m; Ra: 0.341 µm | −46% (Dry) −83% (Base oil) | −40% (Dry) +40% (Base oil) | [69] | ||

| PEEK | Graphene Lateral size: 40 µm; Thickness: 10 nm; Number of layers ≤ 30 | BOD; Alumina ball; Deionized water lubrication; T: 37 °C; AL: 5 N; SV: 0.05 m/s; SD: 4520 m; ST: 48 h; Ra: 0.05 µm | −83% | −38% | [70] |

| Epoxy/poly(2-butylaniline) | Graphene | BOD (R); 316L steel ball; Dry; AL: 2 N; SV: 1 Hz; ST: 20 min | −68% | −16% | [71] |

| PI | FG | BOD; GCr15 steel ball; Dry and seawater lubrication; AL: 10 N; SV: 5 Hz; ST: 30 min | −51% (Dry) −40.5% (Seawater) | −10% (Dry) −12.2% (Seawater) | [75] |

| Epoxy | Dopamine-coating nanographite | (R), Dry; AL: 5 N; ST: 30 min | −52% | −2% | [76] |

| PP/PP-g-MA | GO | POD; ASIS 1040 steel; Dry; AL: 10 −40 N; SV: 0.4–1.6 m/s; Ra: 0.2–0.32 µm | −78% | −44% | [78] |

| PA6 | GO | POD (R); Cast iron; Dry; AL: 40 N; SV: 0.1 m/s; SD: 250 m | −18% | −53% | [80] |

| UHMWPE | GO monolayer sheets L: 3–5 µm; Thickness: 0.7–1.2 nm | POD; High carbon cobalt chromium alloy plate; Serum solution lubrication; AL: 160N; SV: 1 Hz; ST: 4 weeks; Ra: 0.01 µm | −30% | N/A | [81] |

| PI | GO | BOD; Dry and seawater lubrication; AL: 5 N; SV: 0.1569 m/s; ST: 30 min | −22% (Seawater) | −28% (Seawater) | [82] |

| Epoxy | Amino-treated GO | BOD (R); GCr15 steel; Dry; AL: 5 N; SV: 0.1 m/s SD: 5 mm; ST: 60 min | −92% | −58% | [85] |

| BMI resin | RGO | POD; Steel; Dry; AL: 196 N; SV: 200 rpm | −74% | −26% | [89] |

| Epoxy resin | EDA-RGO | BOD (R); GCr15 steel ball; Dry; AL: 5 N; SV: 4.2 Hz; SD: 5 mm; ST: 30 min | −30% | −75% | [90] |

| Epoxy/PTFE blend | −33% | −80% | |||

| UHMWPE | ND particle size: 4 to 6 nm | POD; Steel; Dry; AL: 5 N; SV: 0.3 m/s; SD: 1000 m; ST: 1 h | −14% | −25% | [91] |

| MTS-modified ND Particle size: 4–6 nm | −50% | −42% | |||

| Silicon-based nanofillers | |||||

| UHMWPE | C15A modified with quaternary dimethyl dihydrogenated ammonium Platelet size: 8–15 µm | BOD; Stainless-steel ball; Dry; AL: 30 N; SV: 6.82 cm/s (300 rpm); SD: 68.2 m | −41% | −38% | [93] |

| Nanomer I30E clay modified with primary octadecyl ammonium ion Platelet size: 15–20 µm | −30% | −31% | |||

| Nanomer I28E clay modified with quaternary octadecyl ammonium Platelet size: 15–20 µm, | −29% | −31% | |||

| UHMWPE | C15A modified with quaternary dimethyl dehydrogenated ammonium | BOD; 100Cr6 steel; Dry; AL: 30, 60, 90 N; SV: 6.82 m/s; SD: 68.2 m | −43% | −36% | [94] |

| PA11 | HNT OD: 30–70 nm; L: 1.3 μm | POD; Hardened steel; Dry; AL: 10 N; SV: 0.3 m/s; SD: 800 m | −38% | −14% | [97] |

| PTFE | HNT OD: 40 nm | ROR; 45 carbon steel ring; Dry; AL: 200 N; SV: 200 rpm; ST: 60 min | −98% | +40% | [96] |

| HNT-PMMA | −95% | N/A | [98] | ||

| HNT-SDS | −96% | N/A | |||

| HNT-COOH | −98% | N/A | |||

| UHMWPE | Wollastonite nanoneedle | POD; Carbon steel; Dry; AL:1.9 MPa; SV: 0.5 m/s; ST: 3 h | −84% | +5% | [100] |

| PTFE | SNS | BOR; Steel; Dry; AL: 200 N; SV: 200 rpm; SD: 3500 m; ST: 2 h | −97% | −15% | [102] |

| UHMWPE | SNS | BOR; Steel ring; Dry; AL: 200 N; SV: 200 rpm; ST: 2 h | −73% | −54% | [103] |

| PI | MPS | BOD (R); GCr15 steel; Dry; T: 25 −300 °C; AL: 5, 10, 15 N; SV: 0.08 m/s | −83% | −48% | [104] |

| Epoxy | Amorphous SiO2 Particle size: 10–20 nm | POD; Al2O3 ball; Dry; AL: 15 N; SV: 120 rpm; SD: 500–4000 m | +1150% (Bulk) +213% (Coating) | +61% (Bulk) +100% (Coating) | [107] |

| Metal oxide nanofillers | |||||

| UHMWPE | CuO | BOR; Steel friction ring; Dry; AL: 200 N; SV: 200 rpm; ST: 2 h | Wear scar width: −33% | −34% | [33] |

| PTFE | Graphene | POD; Steel; Dry; AL: 151 N; SV: 0.1 m/s; SD: 1000 m | −98% | N/A | [65] |

| Alumina Particle size: 27–43 nm | −99% | N/A | |||

| PSU | PSU-grafted 𝛾-Al2O3 | POD; Dry; AL: 5 N; SV: 75 rpm; SD: 50 m | −14% | −12% | [110] |

| PMMA | Al2O3 Particle size: 50 nm | POD; AISI 4140 steel disk; Dry; AL: 3, 6, 9N; SV: 1.5 m/s; SD: 450 m | −94% (5 vol% as basis, compared to 20 vol%) | −62% | [111] |

| PA | Hexagonal ZnO | BOD; WC steel ball; Dry; AL: 5N; SD: 90.9 m | −57% | −85% | [113] |

| UHMWPE | ZnO nanoparticles | BOD; stainless-steel ball; Dry; AL: 20N; SV: 300 rpm; ST: 90 min | −52% | +40% | [114] |

| Unsaturated polyester/PMMA blend | ZnO Particle size: 72 nm | POD; Stainless-steel; Dry; AL: 20N; SV: 1.58 m/s; SD: 1582.6 m; ST: 30 min; Ra: 0.5 µm | −63% | −36% | [156] |

| Miscellaneous nanofillers | |||||

| HDPE | GO Thickness: 2–3 nm; Lateral dimensions: 6–8 μm | POD; 100Cr6 steel; Dry; AL: 10 N; SV: 0.2 m/s; SD: 16,000 m | Wear volume: −56% | +29% | [83] |

| γ-Al2O3 Particle size: 20 nm | Wear volume: −95% | +33% | |||

| Fumed Al2O3 Surface area: 100 m2/g | Wear volume: −89% | +75% | |||

| TiN Particle size: 20 nm; L: 200–300 nm | Wear volume: +6% | −13% | |||

| HDPE | VTMS-treated GO Thickness: 2–3 nm; Lateral dimensions: 6–8 μm | POD; 100Cr6 steel; Dry; AL: 10 N; SV: 0.2 m/s; SD: 16,000 m | −79% | +3% | [84] |

| VTMS-treated HNT OD: 50–70 nm; L: 200–2000 nm | −38% | +18% | |||

| VTMS-treated TiN Particle size: 20 nm; L: 200–300 nm | −49% | −8% | |||

| VTMS-treated fumed SiO2 Particle size: 12–15 nm | −72% | +15% | |||

| Epoxy/PVDF blend | La2O3 D: 50 nm | BOD (R); Carbon steel; Dry and hydraulic oil lubrication; AL: 17.6 N; SV: 0.024 m/s; SD: 6 mm; ST: 10 min for dry sliding, 20 min for lubricated condition | −91% (Dry) −59% (Oil) | −18% (Dry) −55% (Oil) | [115] |

| MoS2 D: 50 nm | −79% (Dry) −33% (Oil) | −62% (Dry) −49.44% (Oil) | |||

| PA−6 | Cu/Si | BOR; Steel ring AISI 1045; Dry; AL: 150 N; SV: 150 rpm; ST: 1 h | Wear scar width: −41% | −26% | [117] |

| Epoxy resin | Fc-BN | BOD (R); Si3N4 ball; Dry and seawater lubrication; AL: 5 N; SV: 5 Hz; SD: 5 mm; ST: 20 min | −75% (Dry) −70% (Seawater) | −10% (Dry) −30% (Seawater) | [118] |

| Fh-BN | −74% (Dry) −68% (Seawater) | −12% (Dry) −39% (Seawater) | |||

| PAEK | h-BN Thickness: 50 nm | POD; EN 31 steel; Dry; AL: 0.5–3.0 MPa; SV: 1 m/s; SD: 5000 m | −96% | +10% | [119] |

| Epoxy resin | Amine-capped aniline trimer-modified h-BN | POD; 316L steel ball; Dry and water lubrication; AL: 5 N; SV: 2 Hz; SD: 5 mm | −29% (Dry) −88% (Water) | −13% (Dry) −36% (Water) | [121] |

| PVA | IF-WS2 Particle size: 80–160 nm | Ball on 3 Plates; Steel; Dry; AL: 10 N; SV: 0 to 1 m/s | N/A | −70% | [124] |

| PI | g-C3N4 | BOD (R); stainless-steel ball (GCr15); Al: 2, 4, 50 N; SV: 0.42 m/s; ST: 10 min | −19% | −11% | [125] |

| PEEK | g-C3N4 | POR; Bearing steel ring (GCr15); PAO4 oil lubrication; AL: 400 N; SV: 0.03–0.8 m/s; ST: 3 h; Ra: 0.1–0.2 µm | −62% | −60% | [126] |

| Phenolic resin | g-C3N4 | BOR; Steel ring; Dry; AL: 320 N; SV: 2.5 m/s; ST: 1 h | −47% | −2% | [127] |

| PEEK | Si3N4 Particle size: 15–30 nm | BOD; Al2O3 ball; Dry; AL: 5 N; SV: 0.05 m/s; SD: 2000 m | −16% (Amorphous as basis, compared with coating consisting of a mixture of amorphous and crystalline structures) | −70% (Amorphous as basis, compared with coating consisting of a mixture of amorphous and crystalline structures) | [128] |

| UHMWPE | SiC | POD; Silver steel pin; Dry; AL: 64 N; SV: 0.5 m/s; SD: 500 m; Ra: 0.43 ± 0.04 µm | −22% (1 wt.% as basis, compared to 7 wt.%) | +6% (1 wt.% as basis, compared to 7 wt.%) | [129] |

| PA−6 | SiC Particle size: 40 nm | 304 stainless-steel; Dry; AL: 5 N; SV: 180 rpm | N/A | −61% | [130] |

| PMMA | CaTiZrO5 | POD; Dry; AL: 5N; ST: 5, 10, 15 min | −88% | N/A | [131] |

| PMMA | nHA | POD (R); Stainless-steel; Dry; AL: 3, 6, 9, 12 N; SV: 0.4 m/s; SD: 5 cm | −34% | −19% | [133] |

| POD (R); PMMA disk; Dry; AL: 3, 6, 9, 12 N; SV: 0.4 m/s; SD: 5 cm | −35% | −26% | |||

| PP | CaCO3 Particle size: 16nm | Steel; Dry; AL: 30 N | N/A | −30% | [134] |

| LLDPE | Al65Cu22Fe13 quasicrystals D: 0.01–3 µm | POD; Steel pin; Dry; AL: 47, 98, 147 N; SV: 25 rpm; SD: 2250 m | −57% | −58% | [135] |

| Hydroxypropyl methylcellulose | Aluminum nanoparticles D: 110 nm | BOD: Chrome steel ball; Dry; AL: 2 N; SV: 3mm/s, SD: 30 m | −90% | −70% | [157] |

| Hybrid nanofillers | |||||

| PTFE | MWCNT D: 8–15 nm; L: 50 mm | POD; Dry; AL: 100 MPa; SV: 0.262 m/s | −33% | −3% | [39] |

| GO | −36% | −3% | |||

| Hybrid MWCNT/GO | −43% | −6% | |||

| PAEK | –COOH-functionalized MWCNT OD: 20 nm; ID: 16 nm; L: 20 µm | POD; EN31 alloy steel; Dry; AL: 20, 30 N; SV: 1, 2 m/s; SD: 600, 1200 m; ST: 10 min | −57% | N/A | [45] |

| B4C Particle size: 30–60 nm | −57% | N/A | |||

| Hybrid B4C/MWCNT–COOH | −71% | N/A | |||

| PI | CNTN OD: 8–15 nm; L: 50 µm | BOD (R); Stainless-steel ball; Dry; AL: 6 N; SV: 10 Hz; SD: 10 mm; ST: 10 min | −76% | −26% | [46] |

| MoS2-MA Particle size: 100 nm | −39% | −17% | |||

| Hybrid CNT-MoS2 | −61% | −22% | |||

| Hybrid CMS | −84% | −31% | |||

| UHMWPE | SWCNT D: 40–60 nm | BOD; Stainless-steel ball; Dry; AL: 7–15 N; SV: 0.1 m/s; SD: 3600–50,000 cycles | N/A | −54% (Compared to uncoated titanium) | [53] |

| Hybrid SWCNT/HA Thickness of HA: 0.3–0.5 µm | BOD; Stainless steel ball; Dry; AL: 12 N; SV: 0.1 m/s; SD: 34,000–250,000 cycles | −88% (Compared to uncoated titanium) | −57% (Compared to uncoated titanium) | ||

| UHMWPE | C15A modified with quaternary dimethyl dihydrogenated ammonium Platelet size: 8–15 µm | BOD; Stainless-steel ball; Dry; AL: 5–12 N; SV: 0.1–0.3 m/s; SD: 125 m | −48% | +6% | [54,55] |

| Hybrid C15A/MWCNT D: 23 nm | BOD; Stainless-steel ball; Dry; AL: 5–15 N; SV: 0.1–0.3 m/s; SD: 125–1300 m | −98% | N/A | ||

| PPESK | CNT OD: 50 nm; L: 15 µm | BOD; 440c stainless-steel ball; Dry; AL: 2, 5, 8 N; SV: 0.042, 0.083, 0.126 m/s; ST: 20 min | −76% | −38% | [58] |

| g-C3N4 | −47% | −42% | |||

| Hybrid g-C3N4/CNT | −84% | −65% | |||

| Epoxy resin | CNT OD: ≥50 nm; L: 10–20 µm | BOD; 440c stainless-steel ball; Dry; AL: 3–6 N; SV: 200–500 rpm; ST: 20 min | −91% | −16% | [59] |

| GO | −92% | −71% | |||

| MoS2 | −89% | −82% | |||

| Hybrid CNT/GO | −94% | −80% | |||

| Hybrid CNT/MoS2 | −92% | −81% | |||

| Hybrid CNT/GO/MoS2 | −96% | −91% | |||

| Epoxy resin | CNT OD: >50 nm; L: 10–20 µm | BOD; GCr15 steel ball; Dry; AL: 1.5 N; SV: 200 rpm; ST: 20 min | −86% | −10% | [60] |

| Acid-treated CNT | −90% | −11% | |||

| Hybrid acid treated CNT/ZnS | BOD; GCr15 steel ball; Dry; AL: 0.5–2 N; SV: 200–500 rpm; ST: 20 min | −95% | −45% | ||

| Epoxy resin | CNF | BOD; 440c ball; Dry; AL: 3–6 N; SV: 100–400 rpm; ST: 20 min | −80% | −19% | [62] |

| MoS2 | −75% | −80% | |||

| Hybrid CNF/MoS2 | −92% | −90% | |||

| PI | HCNF D: 100 nm; L: 2–20 µm | BOD; GCr15 steel (AISI 52100) ball; Dry, water and paraffin oil-lubrication; AL: 20 N; SV: 20 Hz; ST: 30 min | −30% (Dry) −56% (Water) −67% (Oil) | −10% (Dry) −27% (Water) −50% (Oil) | [64] |

| MoS2 | −69% (Dry) −61% (Water) −62% (Oil) | −11% (Dry) −24% (Water) −23% (Oil) | |||

| Hybrid MoS2/HCNF | −55% (Dry) −79% (Water) −66% (Oil) | −18% (Dry) −22% (Water) −51% (Oil) | |||

| Epoxy | Graphene | POD; Steel; Dry; T: 25, 60, 95 °C; AL: 10 N; SV: 0.5 m/s; SD: 1000 m | −29% | −34% | [72] |

| MMT | −14% | −14% | |||

| Hybrid graphene/MMT | −29% | −33% | |||

| PI | GO | BOD (R); Steel ball; Dry; AL: 10 N; SV: 10 cm/s; SD: 500 m | −38% | −7% | [79] |

| POSS-GO | −90% | −18% | |||

| Epoxy | GO | BOD (R); GCr15 steel ball; Dry; AL:2, 5, 10N; SV: 0.04, 0.1, 0.4 m/s; SD: 5 mm; ST: 1 h | −47% | −11% | [86] |

| Polyetheramine-functionalized GO | −94% | −54% | |||

| Epoxy resin | RGO | BOD; GCr15 steel ball; Dry; AL: 10 N; SV: 0.033 m/s; ST: 30 min; Ra: 0.301 µm | −60% | −60% | [87] |

| ZnS | −30% | −60% | |||

| Hybrid RGO/ZnS | BOD; GCr15 steel ball; Dry; AL: 5–25 N; SV: 0.033 m/s; ST: 30 min; Ra: 0.301 µm | −81% | −84% | ||

| BMI resin | ZrO2 | POR; Steel ring; Dry; AL: 196 N; SV: 200 rpm; ST: 120 min | −96% | −5% | [88] |

| RGO | −80% | −17% | |||

| MoS2 | −82% | −27% | |||

| Hybrid RGO/MoS2 | −82% | −46% | |||

| Hybrid NH2-RGO/MoS2/ZrO2 | −91% | −68% | |||

| Epoxy | Al2O3 D: 30 nm | POR; GCr15 steel; Ultra-low-sulfur diesel lubrication; AL: 100 N; SV: 0.4 m/s; ST: 1 h | −95% | −65% | [109] |

| Ti3C2Tx | −46% | −35% | |||

| Hybrid Al2O3/Ti3C2Tx | −97% | −95% | |||

| PTFE | Hybrid CuO nanogranules/CF Particle size of CuO: 40 nm; D of CF: 20 µm; L of CF: 150 µm | ROR; AISI 1045 steel ring; Dry; AL: 250 N; SV: 1.4 m/s; ST: 2 h | −11% | +13% | [116] |

| Hybrid CuO nanorods/CF D of CuO: 50 nm; L of CuO: 1.5 µm | −15% | +9% | |||

| Hybrid CuO nanosheets/CF Thickness of CuO: 13 nm | −51% | −6% | |||

| POM | h-BN D: 100 nm | BOR; Austenitic stainless-steel; Water lubrication; AL: 50–300 N; SV: 0.445 m/s; ST: 150 min | −85% | −29% | [120] |

| Hybrid h-BN/SCF D of SCF: 7 μm; L of SCF: 20 to 50 μm | −52% (Compared to SCF/POM) | −13% (Compared to SCF/POM) | |||

| PI | MoS2 | BOD (R); GCr15 alloy steel ball; Dry; AL: 3 N; SV: 0.083 m/s; ST: 30 min | −47% | −11% | [123] |

| Hybrid MoS2/polyacrylonitrile-based CF | BOD (R); GCr15 alloy steel ball; Dry; AL: 3, 4.5 N; SV: 0.083,0.116 m/s; ST: 30 min | −63% | −10% | ||

| PAEK/PDMS blend | nHA | POD; EN31 alloy steel; Dry; AL: 5, 30, 60 N; SV: 1.7 m/s; SD: 6000 m | −61% | +56% | [132] |

| Hybrid nHA/CNF | +500% | +11% | |||

| PA6 | Hybrid GO/GF Thickness: 0.8 to 2 mm | Gear to gear; Dry; AL: 150 N; SV: 1200 rpm; ST: 8 h | −74% | N/A | [136] |

| Epoxy resin | Hybrid SWCNT/banana fiber | Dry; AL: 10–30 N; SV: 1–1.5 m/s; SD: 500 m | Wear loss: −63% (Compared to banana fiber/epoxy) | N/A | [137] |

| PA | Hybrid fullerene soot/SCF Particle size of SCF: 40–50 μm | POR (for WR); Stainless-steel; Dry; AL: 80 N; SV: 1.9 m/s 3 Ball on Plate (for COF); Stainless-steel; Dry; AL: 10–50 N; SV: 0.015–0.75 m/s; SD: 2000 mm | WR: −55.88% (Compared SCF/PA) | +14% (Compared SCF/PA) | [138] |

| PEEK/PTFE blend | Hybrid graphene/SCF | POD; AISI 304 stainless-steel; Dry; T: 25, 100, 150 °C; AL: 1–4 MPa; SV: 1, 1.5, 2 m/s; ST: 3 h; Ra: 0.15–0.30 µm | −39% (Compared to SCF/blend) | −54% (Compared to SCF/blend) | [139] |

| Hybrid graphite/SCF | −24% (Compared to SCF/blend) | −20% (Compared to SCF/blend) | |||

| Epoxy | Hybrid MWCNT/graphite nanopowder/SCF L of SCF: 5–10 mm | A dynamometer coupled to the Aisin Toyota 5k engine; Dry; SV: 15.5–27.8 m/s | −100% | −2% | [140] |

| UHMWPE | Hybrid C15A/CNT D of CNT: 25 to 26 nm | BOD; 440C stainless-steel; Dry and water lubrication; AL: 30 N (Dry), 50 N (Wet); SV: 0.06 m/s; SD: 68.2 m (Dry), 6 km (Wet); ST: 5000 cycles (Dry), 150,000 cycles (Wet) | −64% (Dry) −47% (Water) | +35% (Dry) +30% (Water) | [141] |

| PEEK | Hybrid CuO/SiO2/SCF Particle size of CuO: 30 nm; Particle size of SiO2: 20 nm; D of SCF: 7 μm; L/D ratio of SCF: 1:5–1:10 | POR; Steel; Dry; AL: 300 N; SV: 1 m/s; ST: 5 h | −28% (Compared to PEEK/SCF) | −53% (Compared to PEEK/SCF) | [142] |

| Hybrid Bi2O3/SiO2/SCF Particle size of Bi2O3: 80- 200 nm | −29% (Compared to PEEK/SCF) | −53% (Compared to PEEK/SCF) | |||

| Hybrid WS2/SiC/SCF Particle size of WS2: 20–50 nm; Particle size of SiC: 20 to 100 nm | −38% (Compared to PEEK/SCF) | −81% (Compared to PEEK/SCF) | |||

| PEEK | Hybrid SCF-SiO2 D of SCF: 7 μm; L of SCF: 50 μm; Particle size of SiO2: 20 nm | BOR; steel ring; Dry; AL: 200, 400 N; SV: 200 rpm; ST: 2 h | −55% | −42% | [144] |

| Hybrid Cenosphere/SCF-SiO2 Particle size of cenosphere: 2.6 μm | −87% | −56% | |||

| PEEK | Hybrid β-SiC/SCF D of β-SiC: 35.3 ± 12.1 nm; L of SCF: 35 to 70 μm; D of SCF: 7 μm | POR; 316L stainless-steel; SBF lubrication; T: 37 °C; AL:100 N; SV: 0.1 m/s; ST: 2 h | −57% | −80% | [145] |

| PVDF | 3-hydroxytyramine hydrobromide-functionalized graphene D: 2–3 µm; Thickness: 6–8 nm | POD; steel ball; Dry; AL: 10 N; SV: 200 rpm: SD: 12 km; ST: 1 h | −61% | −14% | [146] |

| Hybrid hydroxylated TiO2/functionalized graphene Particle size of TiO2: 25 nm | −76% | −16% | |||

| Epoxy | Hybrid MoO3/GO/GF | BOD; Steel; Dry; AL: 2, 4, 6, 8 N; SV: 20–120 mm/s; ST: 8 h | −59% (Compared to GF/epoxy) | −13% (Compared to GF/epoxy) | [148] |

| Hybrid f-MoO3/GO/GF | −81%% (Compared to GF/epoxy) | −42% (Compared to GF/epoxy) | |||

| PEEK | Hybrid h-BN/polyacrylonitrile-based SCF D of h-BN: 20 nm; L of SCF: 100 µm; D of SCF: 7 µm | POD (R); SUS 316 stainless-steel disc; Artificial seawater and deionized water lubrication; AL: 100 N; SV: 2 Hz; SD: 5 mm; ST: 120 min; Ra: 0.15 µm | −98% (Seawater) −98% (Deionized water) | −46% (Seawater) −51% (Deionized water) | [149] |

| PI | Hybrid SiO2/polyacrylonitrile-based SCF/graphite flake D of SiO2: 20 nm; L of SCF: 100 μm; D of SCF: 7 μm | POD; MCS35 or Alloy NiCrBSi coating; Dry; AL: 1, 4, 10 MPa; SV: 1, 3 m/s; ST: 5 h | −48% (MCS35) −18% (NiCrBSi) | −74% (MCS35) −27% (NiCrBSi) | [150] |

| Hybrid h-BN/polyacrylonitrile-based SCF/graphite flake D of h-BN: 120 nm | −62% (MCS35) −6% (NiCrBSi) | −54% (MCS35) −9% (NiCrBSi) | |||

| Epoxy | Hybrid graphene/basalt fiber | POD; Steel 52,100 Pin; Dry; AL: 20, 40N; SV: 0.5 m/s; SD: 1000 m | −38% | −58% | [151] |

| HDPE | Hybrid MMT/SF | POD; Dry; AL: 10, 20, 30N; SV: 200 rpm; SD: 3000 m; ST: 10–40 min | −23% | −33% | [152] |

| Epoxy | Hybrid organo-modified MMT/silane-treated E-type of plain-weave glass-woven roving fabric | POD; Alloy steel; Dry; AL: 75, 150, 300 N; SV: 1, 2, 3 m/s; SD: 2000, 6000, 10,000 m | −55% (Compared to glass/epoxy) | −45% (Compared to glass/epoxy) | [153] |

| Epoxy resin | Hybrid HTPB/QAS/MMT | BOR (R); AISI-C−52100 steel ring; Dry; AL: 300 N; SV: 200 Hz; ST: 20 min | −96% (2E4MI-cured) +150% (DDM-cured) | −57% (2E4MI-cured) +23% (DDM-cured) | [154] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, J.X.; Wong, J.F.; Petrů, M.; Hassan, A.; Nirmal, U.; Othman, N.; Ilyas, R.A. Effect of Nanofillers on Tribological Properties of Polymer Nanocomposites: A Review on Recent Development. Polymers 2021, 13, 2867. https://doi.org/10.3390/polym13172867

Chan JX, Wong JF, Petrů M, Hassan A, Nirmal U, Othman N, Ilyas RA. Effect of Nanofillers on Tribological Properties of Polymer Nanocomposites: A Review on Recent Development. Polymers. 2021; 13(17):2867. https://doi.org/10.3390/polym13172867

Chicago/Turabian StyleChan, Jia Xin, Joon Fatt Wong, Michal Petrů, Azman Hassan, Umar Nirmal, Norhayani Othman, and Rushdan Ahmad Ilyas. 2021. "Effect of Nanofillers on Tribological Properties of Polymer Nanocomposites: A Review on Recent Development" Polymers 13, no. 17: 2867. https://doi.org/10.3390/polym13172867

APA StyleChan, J. X., Wong, J. F., Petrů, M., Hassan, A., Nirmal, U., Othman, N., & Ilyas, R. A. (2021). Effect of Nanofillers on Tribological Properties of Polymer Nanocomposites: A Review on Recent Development. Polymers, 13(17), 2867. https://doi.org/10.3390/polym13172867