Thermal Stability and Dynamic Mechanical Analysis of Benzoylation Treated Sugar Palm/Kenaf Fiber Reinforced Polypropylene Hybrid Composites

Abstract

:1. Introduction

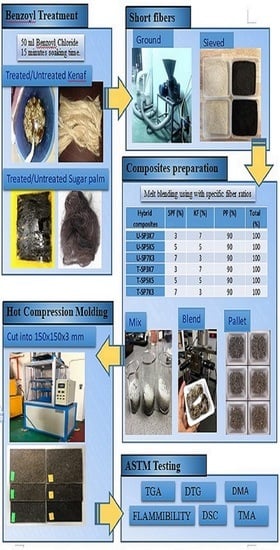

2. Material and Methods

2.1. Materials

2.2. Alkalization and Benzoylation of Kenaf and Sugar Palm Fiber (KF/SPF)

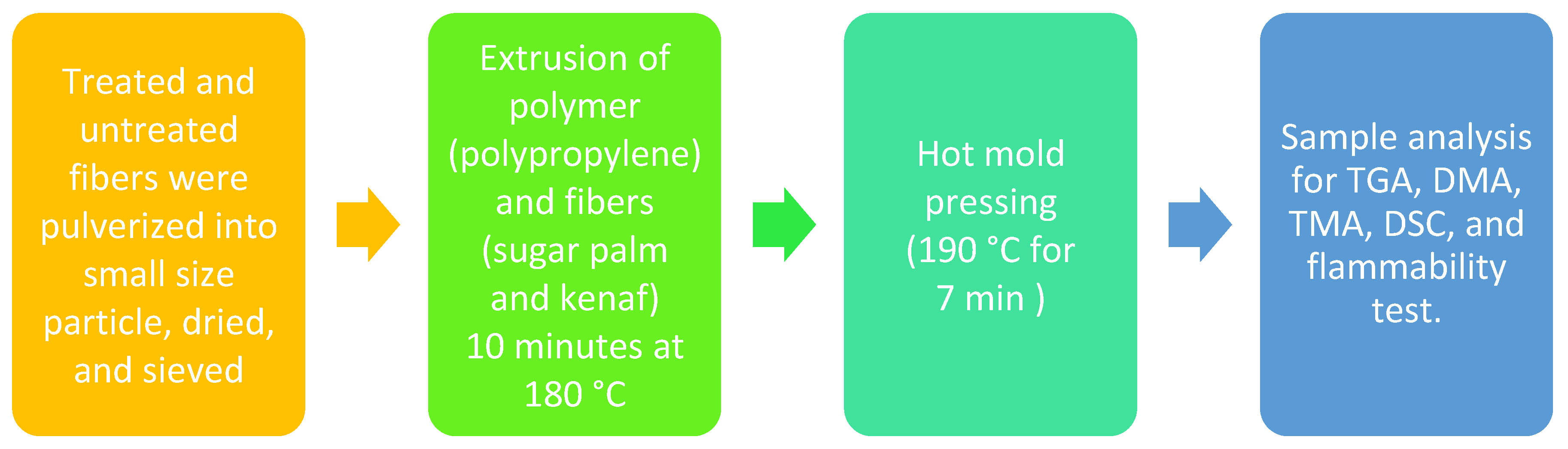

2.3. Compounding of Kenaf and Sugar Palm Fibers (KF/SPF) and Preparation of Particle Composite

2.4. Thermal Instrumentations

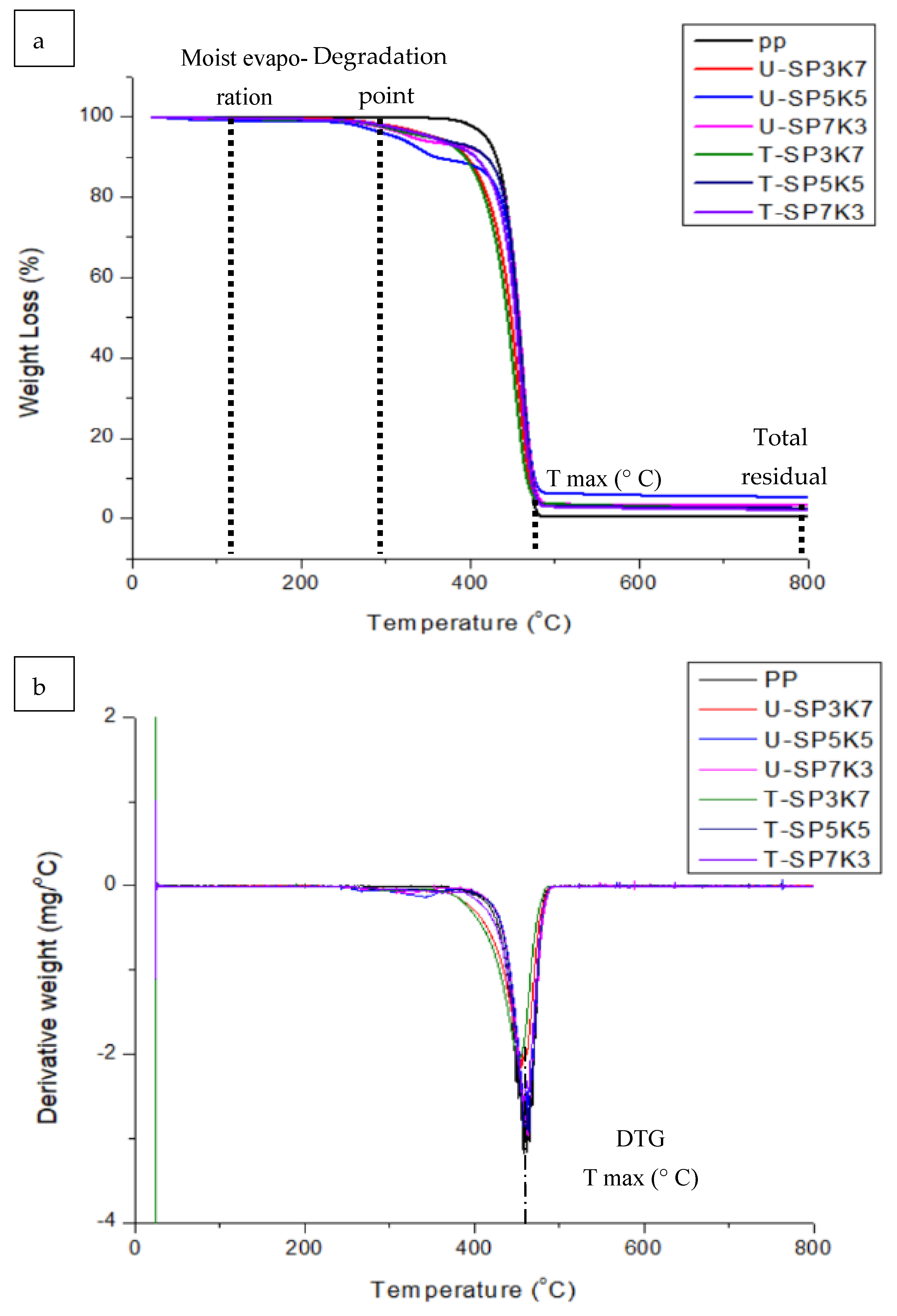

2.4.1. Thermogravimetric Analysis (TGA and DTG)

2.4.2. Differential Scanning Calorimetry Analysis (DSC)

2.4.3. Dynamic Mechanical Analysis (DMA)

2.4.4. Thermal Mechanical Analysis (TMA)

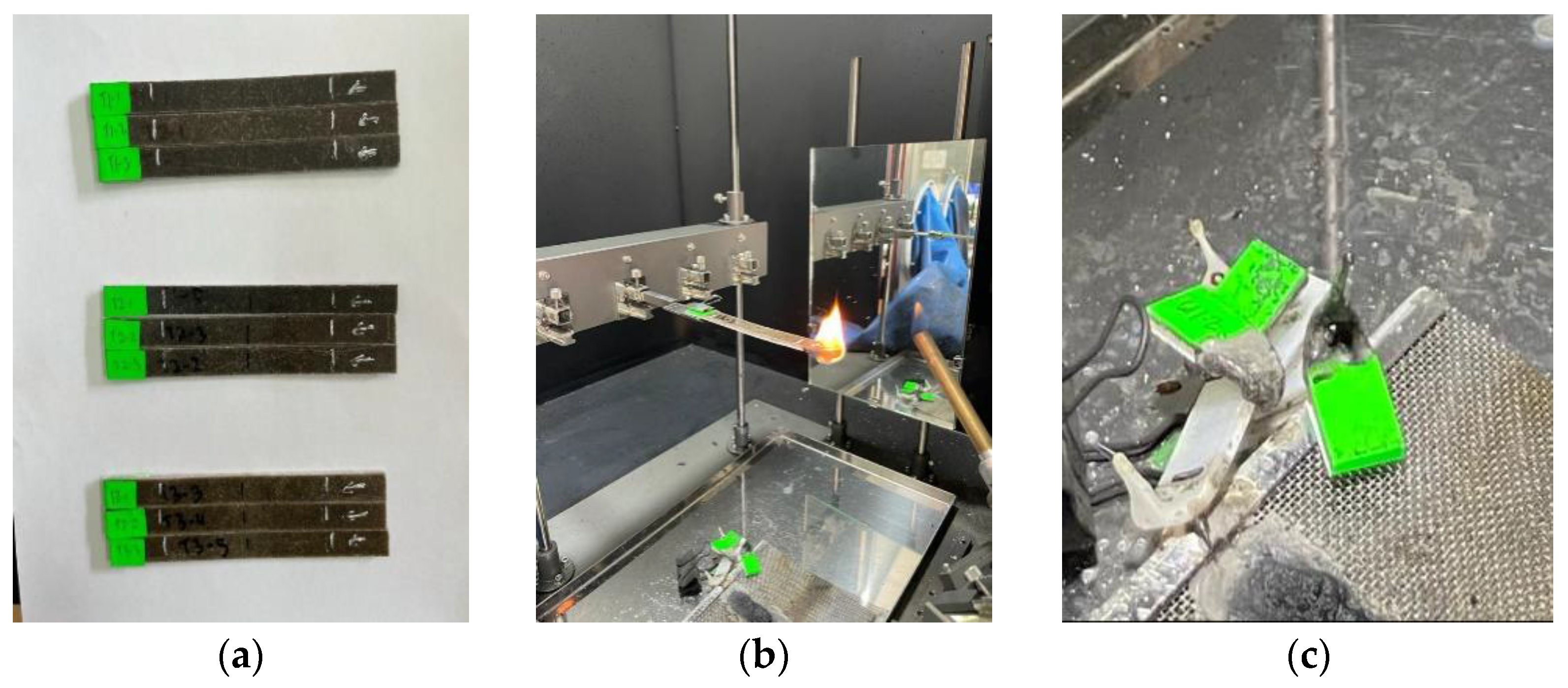

2.4.5. Flammability Analysis

3. Results and Discussions

3.1. Thermogravimetric Analysis (TGA and DTG)

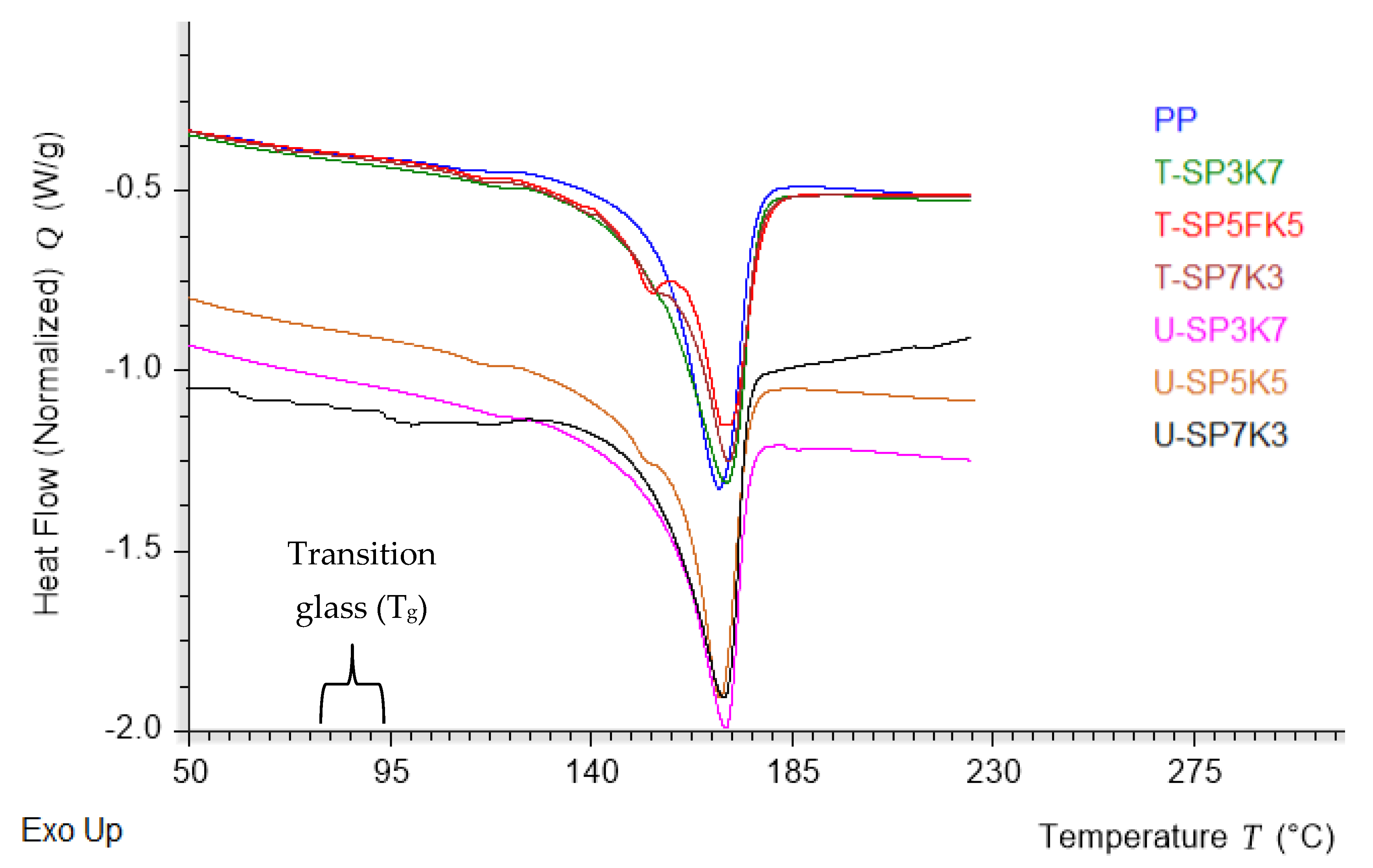

3.2. Differential Scanning Calorimetry Analysis

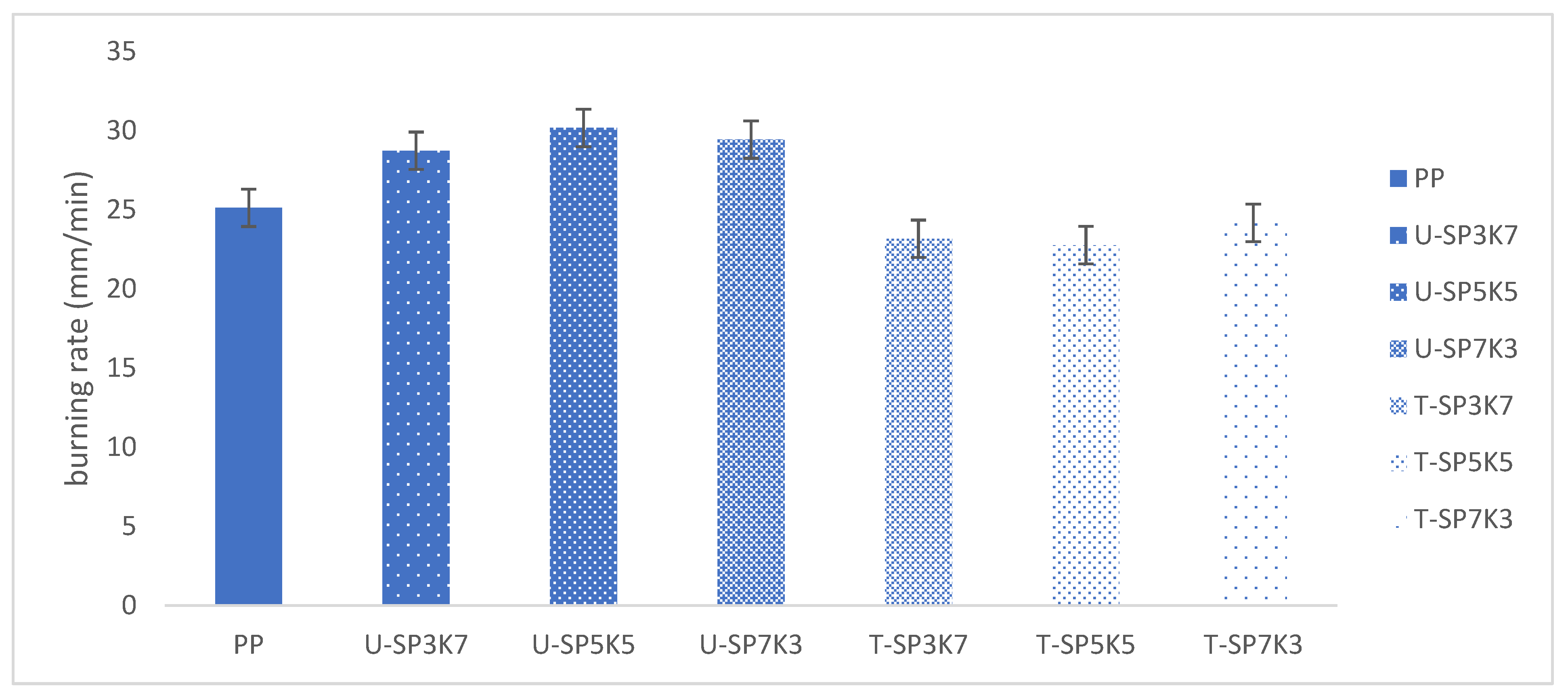

3.3. Flammability Analysis (FA)

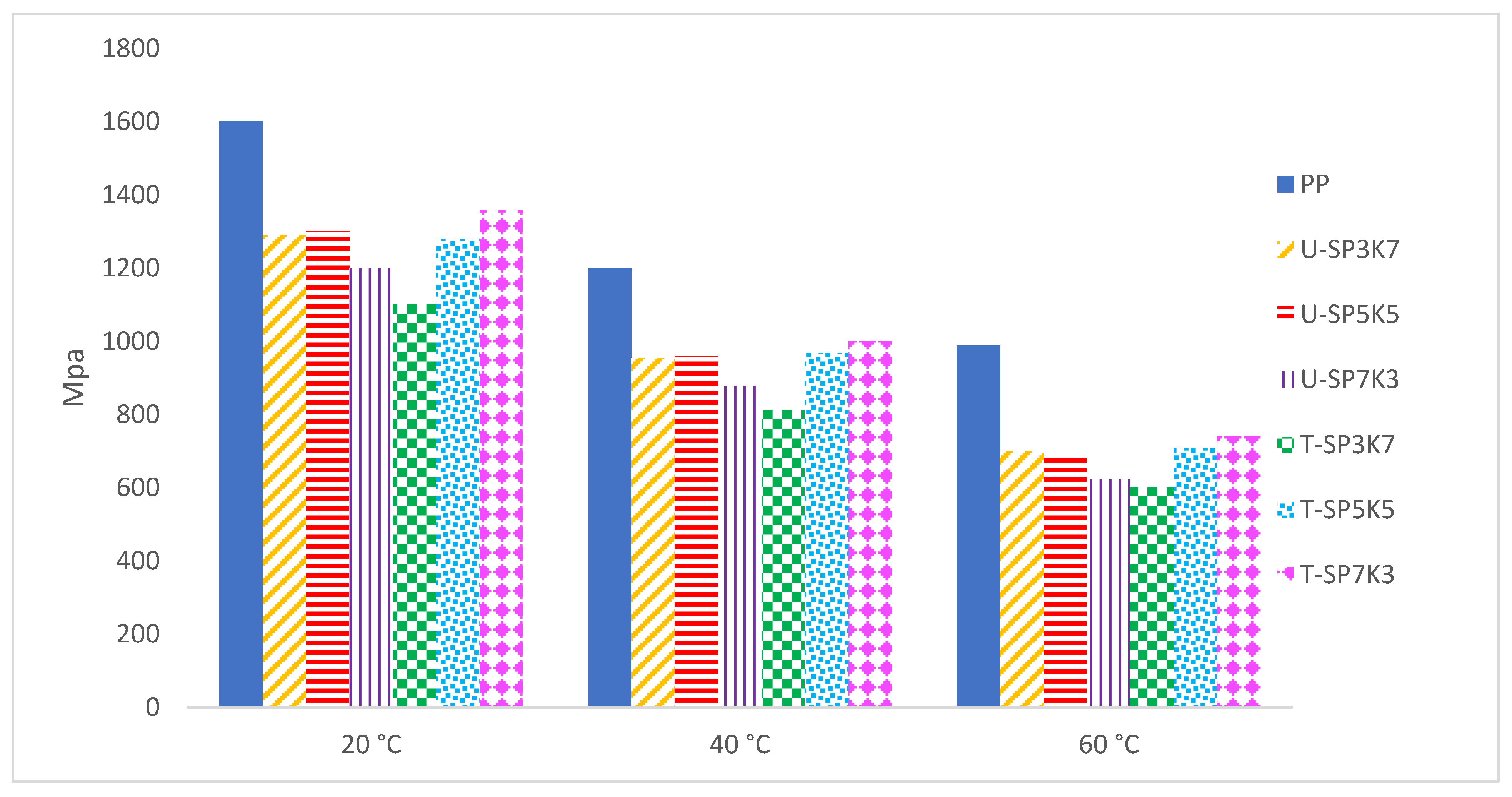

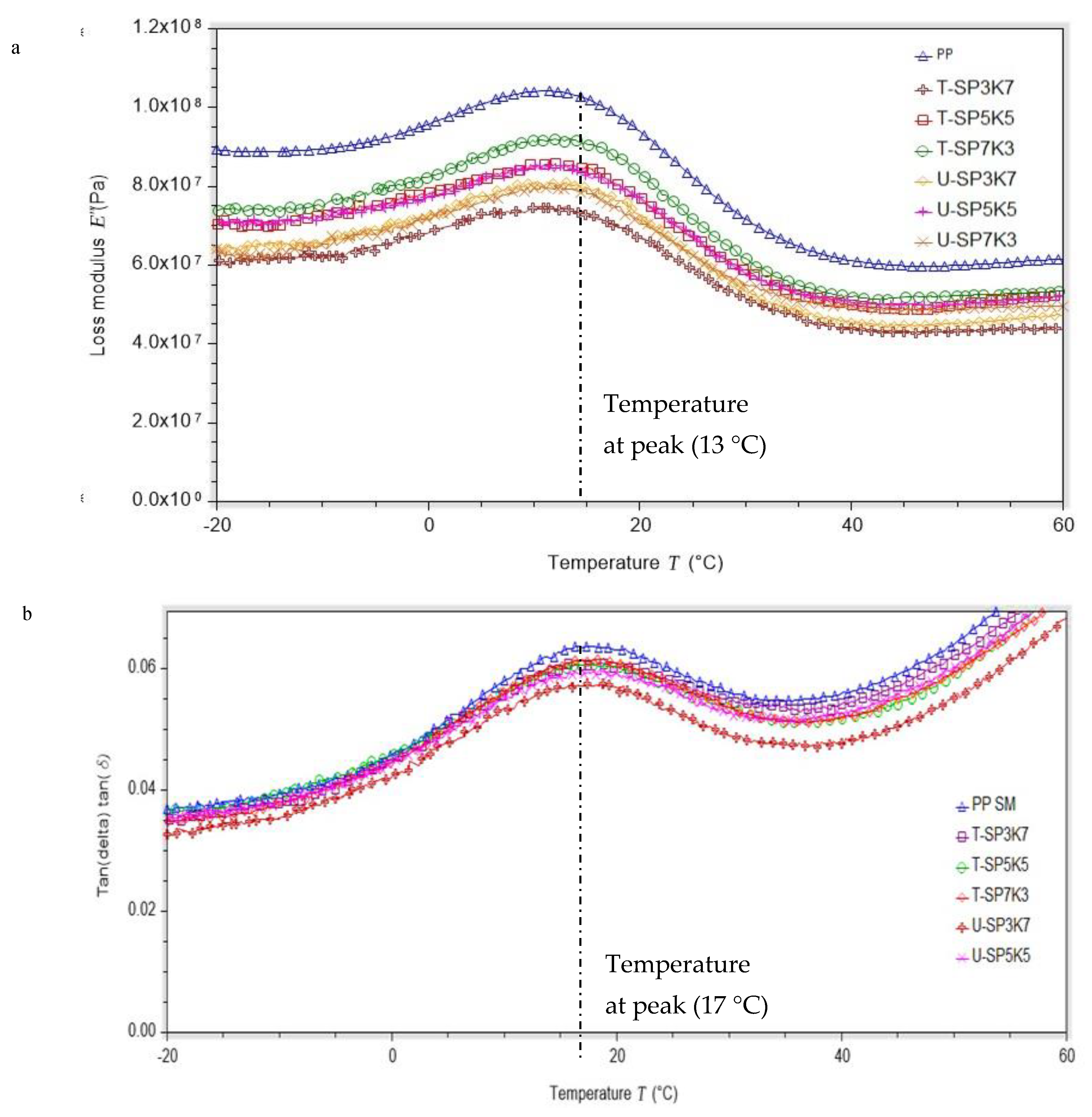

3.4. Dynamic Mechanical Analysis (DMA)

3.5. Thermomechanical Analysis (TMA)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sreenivas, H.T.; Krishnamurthy, N.; Murali, M.S.; Arpitha, G.R. Influence of stacking sequence and orientation of the fabric on mechanical properties of twill Kenaf/Kevlar reinforced unsaturated polyester hybrid composites. J. Ind. Text. 2021, 29, 179–189. [Google Scholar]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. A comprehensive review on advanced sustainable woven natural fibre polymer composites. Polymers 2021, 13, 471. [Google Scholar] [CrossRef] [PubMed]

- Baihaqi, N.N.; Khalina, A.; Nurazzi, N.M.; Aisyah, H.A.; Sapuan, S.M.; Ilyas, R.A. Effect of fiber content and their hybridization on bending and torsional strength of hybrid epoxy composites reinforced with carbon and sugar palm fibers. Polimery 2021, 66, 36–43. [Google Scholar] [CrossRef]

- Singh, K.; Das, D.; Nayak, R.K.; Khandai, S.; Kumar, R.; Routara, B.C. Effect of silanizion on mechanical and tribological properties of kenaf-carbon and kenaf-glass hybrid polymer composites. Mater. Today Proc. 2020, 26, 2094–2098. [Google Scholar] [CrossRef]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R.; Ilyas, R.A.; Asyraf, M.R.M. Potential of natural fiber reinforced polymer composites in sandwich structures: A review on its mechanical properties. Polymers 2021, 13, 423. [Google Scholar] [CrossRef] [PubMed]

- Sabaruddin, F.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.M.; Abdul Khalil, H.P.S. The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites. Polymers 2021, 13, 116. [Google Scholar] [CrossRef] [PubMed]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syafiq, R.; Sherwani, S.F.K. Nanocellulose reinforced thermoplastic starch (TPS), polylactic acid (PLA), and polybutylene succinate (PBS) for food packaging applications. Front. Chem. 2020, 8, 213. [Google Scholar] [CrossRef]

- Rashid, M.; Chetehouna, K.; Cablé, A.; Gascoin, N. Analysing Flammability Characteristics of Green Biocomposites: An Overview. Fire Technol. 2021, 57, 31–67. [Google Scholar] [CrossRef]

- Sukumaran, N.P.; Gopi, S. Overview of biopolymers: Resources, demands, sustainability, and life cycle assessment modeling and simulation. In Biopolymers and Their Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–19. [Google Scholar]

- Edhirej, R.A.; Aisyah, H.A.; Ibrahim, R.; Atikah, M.S.N.; Salwa, H.N.; Aung, M.M.; SaifulAzry, S.O.A.; Megashah, L.N.; Ainun, Z.M.A. Renewable Sources for Packaging Materials. In Bio-Based Packaging: Material, Environmental and Economic Aspects; John Wiley & Sons: Hoboken, NJ, USA, 2021; pp. 353–370. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Preparation and characterization of cassava bagasse reinforced thermoplastic cassava starch. Fibers Polym. 2017, 18, 162–171. [Google Scholar] [CrossRef]

- Thomas, S.K.; Parameswaranpillai, J.; Krishnasamy, S.; Begam, P.M.S.; Nandi, D.; Siengchin, S.; George, J.J.; Hameed, N.; Salim, N.V.; Sienkiewicz, N. A comprehensive review on cellulose, chitin, and starch as fillers in natural rubber biocomposites. Carbohydr. Polym. Technol. Appl. 2021, 2, 100095. [Google Scholar]

- Adeyeye, O.A.; Sadiku, E.R.; Reddy, A.B.; Ndamase, A.S.; Makgatho, G.; Sellamuthu, P.S.; Perumal, A.B. The use of biopolymers in food packaging. In Green Biopolymers and Their Nanocomposites; Springer: Singapore, 2019; pp. 137–158. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N. Effect of sugar palm nanofibrillated cellulose concentrations on morphological, mechanical and physical properties of biodegradable films based on agro-waste sugar palm (Arenga pinnata (Wurmb.) Merr) starch. J. Mater. Res. Technol. 2019, 8, 4819–4830. [Google Scholar] [CrossRef]

- Verma, A.; Gaur, A.; Singh, V.K. Mechanical properties and microstructure of starch and sisal fiber biocomposite modified with epoxy resin. Mater. Perform. Charact. 2017, 6, 500–520. [Google Scholar] [CrossRef]

- Amin, U.; Khan, M.U.; Majeed, Y.; Rebezov, M.; Khayrullin, M.; Bobkova, E.; Shariati, M.A.; Chung, I.M.; Thiruvengadam, M. Potentials of polysaccharides, lipids and proteins in biodegradable food packaging applications. Int. J. Biol. Macromol. 2021, 183, 2148–2198. [Google Scholar] [CrossRef]

- Villadiego, K.M.; Tapia, M.J.A.; Useche, J.; Macías, D.E. Thermoplastic Starch (TPS)/Polylactic Acid (PLA) Blending Methodologies: A Review. J. Polym. Environ. 2021, 323, 1–17. [Google Scholar]

- Akil, H.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.Z.A.M.; Ishak, Z.A.M.; Bakar, A.A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Saad, M.J.; Kamal, I. Kenaf core particleboard and its sound absorbing properties. J. Sci. Technol. 2012, 4, 23–34. [Google Scholar]

- Asdrubali, F. Survey on the acoustical properties of new sustainable materials for noise control. In Proceedings of the Euronoise, Tampere, Finland, 30 May–1 June 2006; Volume 30, pp. 1–10. [Google Scholar]

- Fu, S.-Y.; Xu, G.; Mai, Y. On the elastic modulus of hybrid particle/short-fiber/polymer composites. Compos. Part. B Eng. 2002, 33, 291–299. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.M.; Zainudin, E.S.; Maleque, M.A. Thermo-mechanical behaviors of thermoplastic starch derived from sugar palm tree (Arenga pinnata). Carbohydr. Polym. 2013, 92, 1711–1716. [Google Scholar] [CrossRef]

- Lumingkewas, R.H.; Setyadi, R.; Yanita, R.; Akbar, S.; Yuwono, A.H. Tensile behavior of composite concrete reinforced sugar palm fiber. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2018; Volume 777, pp. 471–475. [Google Scholar]

- Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Rahman, M.Z.A.; Anwar, U.M.K.; Siregar, J.P. Sugar palm (Arenga pinnata): Its fibres, polymers and composites. Carbohydr. Polym. 2013, 91, 699–710. [Google Scholar] [CrossRef]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.R.M. Antimicrobial activity, physical, mechanical and barrier properties of sugar palm based nanocellulose/starch biocomposite films incorporated with cinnamon essential oil. J. Mater. Res. Technol. 2021, 11, 144–157. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Naveen, J.; Satheeshkumar, S. Hybrid fiber reinforced polymer composites–a review. J. Reinf. Plast. Compos. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Devi, L.U.; Bhagawan, S.S.; Thomas, S. Dynamic mechanical analysis of pineapple leaf/glass hybrid fiber reinforced polyester composites. Polym. Compos. 2010, 31, 956–965. [Google Scholar] [CrossRef]

- Nikmatin, S.; Syafiuddin, A.; Hong Kueh, A.B.; Maddu, A. Physical, thermal, and mechanical properties of polypropylene composites filled with rattan nanoparticles. J. Appl. Res. Technol. 2017, 15, 386–395. [Google Scholar] [CrossRef]

- Bachtiar, D.; Siregar, J.P.; bin Sulaiman, A.S.; bin Mat Rejab, M.R. Tensile Properties of Hybrid Sugar Palm/Kenaf Fibre Reinforced Polypropylene Composites. Appl. Mech. Mater. 2015, 695, 155–158. [Google Scholar] [CrossRef]

- Izwan, S.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Mohamed, A.R. Effects of benzoyl treatment on NaOH treated sugar palm fiber: Tensile, thermal, and morphological properties. J. Mater. Res. Technol. 2020, 9, 5805–5814. [Google Scholar] [CrossRef]

- Clyne, T.W.; Hull, D. An Introduction to Composite Materials; University of Cambridge UK: Cambridge, UK, 2019. [Google Scholar]

- Safri, S.N.A.; Sultan, M.T.H.; Saba, N.; Jawaid, M. Effect of benzoyl treatment on flexural and compressive properties of sugar palm/glass fibres/epoxy hybrid composites. Polym. Test. 2018, 71, 362–369. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Influence of chemical treatments on the mechanical and water absorption properties of bamboo fiber composites. J. Reinf. Plast. Compos. 2011, 30, 73–85. [Google Scholar] [CrossRef]

- Mittal, V.; Saini, R.; Sinha, S. Natural fiber-mediated epoxy composites–A review. Compos. Part. B Eng. 2016, 99, 425–435. [Google Scholar] [CrossRef]

- Singha, A.S.; Rana, A.K. A study on benzoylation and graft copolymerization of lignocellulosic cannabis indica fiber. J. Polym. Environ. 2012, 20, 361–371. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal stability of natural fibers and their polymer composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Pilarska, A.; Bula, K.; Myszka, K.; Rozmanowski, T.; Szwarc-Rzepka, K.; Pilarski, K.; Chrzanowski, Ł.; Czaczyk, K.; Jesionowski, T. Functional polypropylene composites filled with ultra-fine magnesium hydroxide. Open Chem. 2015, 13, 161. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S. The effect of process and structural parameters on the stability, thermo-mechanical and thermal degradation of polymers with hydrocarbon skeleton containing PE, PP, PS, PVC, NR, PBR and SBR. J. Therm. Anal. Calorim. 2021, 143, 2867–2882. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M. Mechanical, Physical and Thermal Properties of Sugar Palm Nanocellulose Reinforced Thermoplastic Starch (TPS)/Poly (Lactic Acid) (PLA) Blend Bionanocomposites. Polymers 2020, 12, 2216. [Google Scholar] [CrossRef]

- Saba, N.; Safwan, A.; Sanyang, M.L.; Mohammad, F.; Pervaiz, M.; Jawaid, M.; Alothman, O.Y.; Sain, M. Thermal and dynamic mechanical properties of cellulose nanofibers reinforced epoxy composites. Int. J. Biol. Macromol. 2017, 102, 822–828. [Google Scholar] [CrossRef] [PubMed]

- Khan, T.; Sultan, M.T.H.; Jawaid, M.; Safri, S.N.A.; Shah, A.U.M.; Majid, M.S.A.; Zulkepli, N.N.; Jaya, H. The Effects of Stacking Sequence on Dynamic Mechanical Properties and Thermal Degradation of Kenaf/Jute Hybrid Composites. J. Renew. Mater. 2021, 9, 73–84. [Google Scholar] [CrossRef]

- Veerasimman, A.; Shanmugam, V.; Rajendran, S.; Johnson, D.J.; Subbiah, A.; Koilpichai, J.; Marimuthu, U. Thermal Properties of Natural Fiber Sisal Based Hybrid Composites–A Brief Review. J. Nat. Fibers 2021, 1–11. [Google Scholar] [CrossRef]

- Phiri, G.; Khoathane, M.C.; Sadiku, E.R. Effect of fibre loading on mechanical and thermal properties of sisal and kenaf fibre-reinforced injection moulded composites. J. Reinf. Plast. Compos. 2014, 33, 283–293. [Google Scholar] [CrossRef]

- Gargol, M.; Klepka, T.; Klapiszewski, Ł.; Podkościelna, B. Synthesis and Thermo-Mechanical Study of Epoxy Resin-Based Composites with Waste Fibers of Hemp as an Eco-Friendly Filler. Polymers 2021, 13, 503. [Google Scholar] [CrossRef] [PubMed]

- Ghori, S.W.; Rao, G.S. Mechanical and thermal properties of date palm/kenaf fiber-reinforced epoxy hybrid composites. Polym. Compos. 2021, 42, 2217–2224. [Google Scholar] [CrossRef]

- Ismail, N.F.; Mohd Radzuan, N.A.; Sulong, A.B.; Muhamad, N.; Che Haron, C.H. The Effect of Alkali Treatment on Physical, Mechanical and Thermal Properties of Kenaf Fiber and Polymer Epoxy Composites. Polymers 2021, 13, 2005. [Google Scholar] [CrossRef]

- Kathirselvam, M.; Kumaravel, A.; Arthanarieswaran, V.P.; Saravanakumar, S.S. Characterization of Cellulose Fibers in Thespesia Populnea Barks: Influence of Alkali Treatment. Carbohydr. Polym. 2019, 217, 178–189. [Google Scholar] [CrossRef]

- AlMaadeed, M.A.; Kahraman, R.; Khanam, P.N.; Madi, N. Date Palm Wood Flour/Glass Fibre Reinforced Hybrid Composites of Recycled Polypropylene: Mechanical and Thermal Properties. Mater. Des. 2012, 42, 289–294. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Zhang, J.; Lu, B.-X.; Xin, Z.X.; Kang, C.K.; Kim, J.K. Effect of flame retardants on mechanical properties, flammability and foamability of PP/wood-fiber composites. Compos. Part. B Eng. 2012, 43, 150–158. [Google Scholar] [CrossRef]

- Nishimura, N.; Izumi, A.; Kuroda, K. Structural characterization of kenaf lignin: Differences among kenaf varieties. Ind. Crop. Prod. 2002, 15, 115–122. [Google Scholar] [CrossRef]

- Li, B.; He, J. Investigation of mechanical property, flame retardancy and thermal degradation of LLDPE-wood-fibre composites. Polym. Degrad. Stab. 2004, 83, 241–246. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre Hybridisation in Polymer Composites: A Review Part A Applied Science and Manufacturing. Composites 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Suriani, M.J.; Sapuan, S.M.; Ruzaidi, C.M.; Nair, D.S.; Ilyas, R.A. Flammability, morphological and mechanical properties of sugar palm fiber/polyester yarn-reinforced epoxy hybrid biocomposites with magnesium hydroxide flame retardant filler. Text. Res. J. 2021. [Google Scholar] [CrossRef]

- Anuar, H.; Zuraida, A. Thermal properties of injection moulded polylactic acid–kenaf fibre biocomposite. Malays. Polym. J. 2011, 6, 51–57. [Google Scholar]

- Majhi, S.K.; Sanjay, N.K.; Mohanty, S.; Unnikrishnan, L. Mechanical and fracture behavior of banana fiber reinforced Polylactic acid biocomposites. Int. J. Plast. Technol. 2010, 14, 57–75. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.A.; Hassan, A.; Dungani, R.; Hadiyane, A. Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos. Part. B Eng. 2013, 45, 619–624. [Google Scholar] [CrossRef]

- Behazin, E.; Misra, M.; Mohanty, A.K. Sustainable biocomposites from pyrolyzed grass and toughened polypropylene: Structure-property relationships. ACS Omega 2017, 2, 2191–2199. [Google Scholar] [CrossRef] [Green Version]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 28, 2675–2695. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Park, S.Y.; Song, H.S. Lamellar crystalline structure of hard elastic HDPE films and its influence on microporous membrane formation. Polymer 2006, 47, 3540–3547. [Google Scholar] [CrossRef]

- Ju, J.W.; Lee, H.-K. A micromechanical damage model for effective elastoplastic behavior of partially debonded ductile matrix composites. Int. J. Solids Struct. 2001, 38, 6307–6332. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. A review on thermomechanical properties of polymers and fibers reinforced polymer composites. J. Ind. Eng. Chem. 2018, 67, 1–11. [Google Scholar] [CrossRef]

| Hybrid Composites | SPF (g) | KF (g) | PP (g) | Total Weight (g) |

|---|---|---|---|---|

| U-SP3K7 | 0.6 | 1.4 | 18 | 20 |

| U-SP5K5 | 1 | 1 | 18 | 20 |

| U-SP7K3 | 1.4 | 0.6 | 18 | 20 |

| T-SP3K7 | 0.6 | 1.4 | 18 | 20 |

| T-SP5K5 | 1 | 1 | 18 | 20 |

| T-SP7K3 | 1.4 | 0.6 | 18 | 20 |

| Samples | Ton (°C) | Tmax (°C) | Weight Loss at Tmax (wt%) | Char at 800 °C (wt%) |

|---|---|---|---|---|

| PP | - | 439 | 99.46 | 0.53 |

| U-SP3K7 | 274 | 421.8 | 93.37 | 2.02 |

| U-SP5K5 | 276.1 | 442.9 | 91.22 | 2.357 |

| U-SP7K3 | 298.6 | 437.3 | 90.84 | 1.86 |

| T-SP3K7 | 294.2 | 425.8 | 92.65 | 2.1 |

| T-SP5K5 | 285.8 | 443.13 | 85.02 | 5.22 |

| T-SP7K3 | 279.4 | 442.7 | 83.05 | 3.196 |

| Sample | Transition Glass Temperature (Tg) | Melting Point Temperature (Tm) | Enthalpy ΔH (J/g) | Degree Crystallinity (%) |

|---|---|---|---|---|

| PP | - | 146.43 | 126.11 | 60.00 |

| U-SP7K3 | 115.23 | 149.43 | 97.460 | 46.63 |

| U-SP5K5 | 118.23 | 155.63 | 120.95 | 57.87 |

| U-SP3K7 | 119.13 | 148.33 | 99.160 | 47.44 |

| T-SP7K3 | 122.53 | 160.53 | 111.23 | 53.22 |

| T-SP5K5 | 127.63 | 165.63 | 116.78 | 55.88 |

| T-SP3K7 | 125.43 | 161.43 | 105.89 | 50.66 |

| Sample with Storage Modulus (MPa) | |||||||

|---|---|---|---|---|---|---|---|

| Temperature | PP | U-SP3K7 | U-SP5K5 | U-SP7K3 | T-SP3K7 | T-SP5K5 | T-SP7K3 |

| 20 °C | 1600 | 1290 | 1300 | 1200 | 1100 | 1360 | 1312 |

| 40 °C | 1200 | 954 | 958 | 879 | 813 | 991 | 968 |

| 60 °C | 989 | 701 | 695 | 622 | 601 | 711 | 709 |

| Sample | Loss Modulus at Peak (E″) (MPa) | Damping at Peak (Tan δ) (Pa) |

|---|---|---|

| PP | 105.3 ± 2.16 | 0.0617 ± 0.012 |

| U-SP7K3 | 81.5 ± 1.34 | 0.0564 ± 0.034 |

| U-SP5K5 | 80.7 ± 1.14 | 0.0585 ± 0.041 |

| U-SP3K7 | 79.8 ± 1.27 | 0.0572 ± 0.032 |

| T-SP7K3 | 71.3 ± 1.62 | 0.0513 ± 0.023 |

| T-SP5K5 | 86.2 ± 1.06 | 0.0531 ± 0.041 |

| T-SP3K7 | 85.2 ± 1.11 | 0.0529 ± 0.022 |

| Samples | Thermal Expansion (CTE) after 45 °C | Thermal Expansion (CTE) after 105 °C |

|---|---|---|

| PP | 10.21 ± 0.12 | 31.23 ± 1.82 |

| U-SP7K3 | 1.13 ± 0.12 | 11.31 ± 0.49 |

| U-SP5K5 | 3.21 ± 0.14 | 24.93 ± 0.74 |

| U-SP3K7 | 2.14 ± 0.41 | 24.74 ± 0.45 |

| T-SP7K3 | 1.23 ± 0.53 | 12.74 ± 0.61 |

| T-SP5K5 | 7.32± 0.81 | 30.11 ± 0.43 |

| T-SP3K7 | 6.14 ± 0.73 | 18.23 ± 0.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Izwan, S.; Sapuan, S.M.; Zuhri, M.Y.M.; Mohamed, A.R. Thermal Stability and Dynamic Mechanical Analysis of Benzoylation Treated Sugar Palm/Kenaf Fiber Reinforced Polypropylene Hybrid Composites. Polymers 2021, 13, 2961. https://doi.org/10.3390/polym13172961

Mohd Izwan S, Sapuan SM, Zuhri MYM, Mohamed AR. Thermal Stability and Dynamic Mechanical Analysis of Benzoylation Treated Sugar Palm/Kenaf Fiber Reinforced Polypropylene Hybrid Composites. Polymers. 2021; 13(17):2961. https://doi.org/10.3390/polym13172961

Chicago/Turabian StyleMohd Izwan, S., S.M. Sapuan, M.Y.M. Zuhri, and A.R. Mohamed. 2021. "Thermal Stability and Dynamic Mechanical Analysis of Benzoylation Treated Sugar Palm/Kenaf Fiber Reinforced Polypropylene Hybrid Composites" Polymers 13, no. 17: 2961. https://doi.org/10.3390/polym13172961

APA StyleMohd Izwan, S., Sapuan, S. M., Zuhri, M. Y. M., & Mohamed, A. R. (2021). Thermal Stability and Dynamic Mechanical Analysis of Benzoylation Treated Sugar Palm/Kenaf Fiber Reinforced Polypropylene Hybrid Composites. Polymers, 13(17), 2961. https://doi.org/10.3390/polym13172961