A Contemporary Review of Aluminium MMC Developed through Stir-Casting Route

Abstract

:1. Introduction

2. AMMCs with Various Reinforcing Materials

2.1. AMMCs Reinforced with SiC

2.2. AMMCs Reinforced with Aluminium Oxide (Al2O3)

2.3. AMMCs Reinforced with Boron Carbide (B4C)

2.4. AMMCs Reinforced with Fibers

2.5. AMMCs Reinforced with Zirconium

2.6. AMMCs Reinforced with Fly Ash (FA)

3. AMMCs Produced through Various Processing Techniques

3.1. Processing of AMMCs

3.2. AMMCs through Stir Casting Routes

4. Properties of AMMCs through Stir Casting Routes

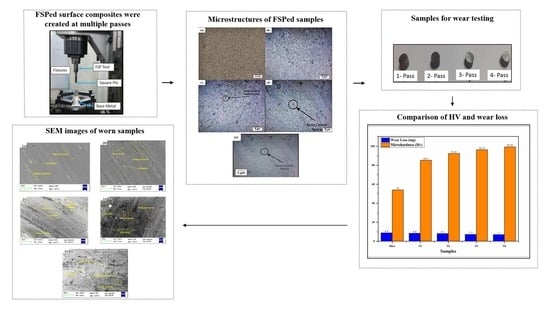

4.1. Microstructural Studiesof Reinforced AMMCs

4.2. Mechanical Studiesof Reinforced AMMCs

4.3. Tribological Studies of AMMCs

5. Conclusions and Future Work

- Dual- and hybrid-reinforcement metal matrices having superior properties as compared to single-reinforced aluminium matrix composites.

- Hybrid AMMCs with various reinforcement particles result in a more homogeneous microstructure into the matrix and can be fabricated through the stir casting technique.

- The processing parameters of stir casting, such as reinforcement size, stirrer speed, stirrer blade design, stirring time, and melt temperature, have significant impacts on the properties of AMMCs.

- The distribution of the reinforcement into the matrix brings an enhancement in mechanical properties such as microhardness, tensile, and ductility.

- The tensile strength and the ductility of composites increase integrally, as the grain refinement enhances the plastic deformation of the composites.

- The wear resistance of hybrid composites improves due to the strong bonding between the reinforcement and the base metal matrix.

- The low-cost leftovers of agricultural and industrial waste use in AMMCs as reinforcements improve the mechanical and tribological properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akinwamide, S.O.; Akinribide, O.J.; Olubambi, P.A. Microstructural evolution, mechanical and nanoindentation studies of stir cast binary and ternary aluminium based composites. J. Alloys Compd. 2021, 850, 156586. [Google Scholar] [CrossRef]

- Karthik, A.; Srinivasan, S.A.; Karunanithi, R.; Babu, S.K.; Jain, V.K.S. Influence of CeO2 reinforcement on microstructure, mechanical and wear behaviour of AA2219 squeeze cast composites. J. Mater. Res. Technol. 2021, 14, 797–807. [Google Scholar] [CrossRef]

- Arunachalam, R.; Krishnan, P.K. Compressive Response of Aluminum Metal Matrix Composites. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Rajak, D.K.; Menezes, P.L. Application of Metal Matrix Composites in Engineering Sectors. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Khan, A.; Reddy, M.M.; Reddy, M.P.; Shakoor, R.A.; Gupta, M. Development and Properties of Amorphous Particles Reinforced Al Matrix Nanocomposites. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Kar, C.; Surekha, B. Characterisation of aluminium metal matrix composites reinforced with titanium carbide and red mud. Mater. Res. Innov. 2021, 25, 67–75. [Google Scholar] [CrossRef]

- Choi, B.J.; Kim, I.Y.; Lee, Y.Z.; Kim, Y.J. Microstructure and friction/wear behavior of (TiB + TiC) particulate-reinforced titanium matrix composites. Wear 2014, 318, 68–77. [Google Scholar] [CrossRef]

- Kaczmar, J.W.; Pietrzak, K.; Włosiński, W. The production and application of metal matrix composite materials. J. Mater. Process. Technol. 2000, 106, 58–67. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Olubambi, P.A. Corrosion and wear behaviour of rice husk ash—Alumina reinforced Al–Mg–Si alloy matrix hybrid composites. J. Mater. Res. Technol. 2013, 2, 188–194. [Google Scholar] [CrossRef] [Green Version]

- Chelladurai, S.J.S.; Kumar, S.S.; Venugopal, N.; Ray, A.P.; Manjunath, T.C.; Gnanasekaran, S. A review on mechanical properties and wear behaviour of aluminium based metal matrix composites. Mater. Today Proc. 2021, 37, 908–916. [Google Scholar] [CrossRef]

- Kala, H.; Merb, K.K.S.; Kumar, S. A Review on Mechanical and Tribological Behaviors of Stir Cast Aluminum Matrix Composites. Procedia Mater. Sci. 2014, 6, 1951–1960. [Google Scholar] [CrossRef] [Green Version]

- Surappa, M.K. Aluminium matrix composites: Challenges and opportunities. Sadhana 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Rajmohan, K.; Vivekanandhan, M. A Review on Mechanical Properties and Tribological Characteristics of Stir Cast Aluminium Metal Matrix Composites. Int. J. Appl. Eng. Res. 2019, 14, 579–583. [Google Scholar]

- Ramnath, B.V.; Elanchezhian, C.; Annamalai, R.M.; Aravind, S.; Atreya, T.S.; Vignesh, V.; Subramanian, C. Aluminium metal matrix composites—A Review. Rev. Adv. Mater. Sci. 2014, 38, 55–60. [Google Scholar]

- Sharma, R.; Jha, S.P.; Kakkar, K.; Kamboj, K.; Sharma, P. A Review of the Aluminium Metal Matrix Composite and its Properties. Int. Res. J. Eng. Technol. 2017, 4, 832–842. [Google Scholar]

- Ramanathan, A.; Krishnan, P.K.; Muraliraja, R. A review on the production of metal matrix composites through stir casting–Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 2019, 42, 213–245. [Google Scholar] [CrossRef]

- Sharma, A.K.; Bhandari, R.; Pinca-Bretotean, C. A systematic overview on fabrication aspects and methods of aluminum metal matrix composites. Mater. Today Proc. 2021, 45, 4133–4138. [Google Scholar] [CrossRef]

- Kareem, A.; Qudeiri, J.A.; Abdudeen, A.; Ahammed, T.; Ziout, A. A review on AA 6061 metal matrix composites produced by stir casting. Materials 2021, 14, 175. [Google Scholar] [CrossRef]

- Muley, A.V.; Aravindan, S.; Singh, I.P. Nano and hybrid aluminum based metal matrix composites: An overview. Manuf. Rev. 2015, 2, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Almadhoni, K.; Khan, S. Review of Effective Parameters of Stir Casting Process on Metallurgical Properties of Ceramics Particulate Al Composites. IOSR J. Mech. Civil. Eng. 2015, 12, 22–40. [Google Scholar]

- Ozben, T.; Kilickap, E.; Cakır, O. Investigation of mechanical and machinability properties of SiC particle reinforced Al-MMC. J. Mater. Process. Technol. 2008, 198, 220–225. [Google Scholar] [CrossRef]

- Ozden, S.; Ekici, R.; Nair, F. Investigation of impact behaviour of aluminium based SiC particle reinforced metal–matrix composites. Compos. Part. A Appl. Sci. Manuf. 2007, 38, 484–494. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Al-Hajri, M.; Vasudevan, V.K. Cyclic plastic strain response and fracture behavior of 2009 aluminum alloy metal-matrix composite. Int. J. Fatigue 2005, 27, 357–371. [Google Scholar] [CrossRef]

- Thünemann, M.; Beffort, O.; Kleiner, S.; Vogt, U. Aluminum matrix composites based on preceramic-polymer-bonded SiC preforms. Compos. Sci. Technol. 2007, 67, 2377–2383. [Google Scholar] [CrossRef]

- Sujan, D.; Oo, Z.; Rahman, M.E.; Maleque, M.A.; Tan, C.K. Physio-mechanical properties of Aluminium metal matrix composites reinforced with Al2O3 and SiC. Int. J. Mater. Metall. Eng. 2012, 6, 678–681. [Google Scholar]

- Zeng, Z.; Fuguo, L. Effects of particle clustering on the flow behavior of SiC particle reinforced Al metal matrix composites. Rare Metal. Mater. Eng. 2010, 39, 1525–1531. [Google Scholar]

- Prabu, S.B.; Karunamoorthy, L.; Kathiresan, S.; Mohan, B. Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite. J. Mater. Process. Technol. 2006, 171, 268–273. [Google Scholar] [CrossRef]

- Barekar, N.S.; Tzamtzis, S.; Babu, N.H.; Fan, Z.; Dhindaw, B.K. Processing of ultrafine-size particulate metal matrix composites by advanced shear technology. Metall. Mater. Trans. A 2009, 40, 691. [Google Scholar] [CrossRef] [Green Version]

- Palanikumar, K.; Karthikeyan, R. Assessment of factors influencing surface roughness on the machining of Al/SiC particulate composites. Mater. Des. 2007, 28, 1584–1591. [Google Scholar] [CrossRef]

- Kılıckap, E.; Cakır, O.; Aksoy, M.; Inan, A. Study of tool wear and surface roughness in machining of homogenized SiC-p reinforced aluminium metal matrix composite. J. Mater. Process. Technol. 2005, 164, 862–867. [Google Scholar] [CrossRef]

- Natarajan, N.; Vijayarangan, S.; Rajendran, I. Wear behaviour of A356/25SiCp aluminium matrix composites sliding against automobile friction material. Wear 2006, 261, 812–822. [Google Scholar] [CrossRef]

- Yanming, Q.; Zehua, Z. Tool wear and its mechanism for cutting SiC particle-reinforced aluminium matrix composites. J. Mater. Process. Technol. 2000, 100, 194–199. [Google Scholar] [CrossRef]

- Park, B.G.; Crosky, A.G.; Hellier, A.K. Fracture toughness of microsphere Al2O3–Al particulate metal matrix composites. Compos. Part B Eng. 2008, 39, 1270–1279. [Google Scholar] [CrossRef]

- Park, B.G.; Crosky, A.G.; Hellier, A.K. High cycle fatigue behaviour of microsphere Al2O3–Al particulate metal matrix composites. Compos. Part B Eng. 2008, 39, 1257–1269. [Google Scholar] [CrossRef]

- Tjong, S.C.; Wang, G.S.; Geng, L.; Mai, Y.W. Cyclic deformation behavior of in situ aluminum–matrix composites of the system Al–Al3Ti–TiB2–Al2O3. Compos. Sci. Technol. 2004, 64, 1971–1980. [Google Scholar] [CrossRef]

- Kok, M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J. Mater. Process. Technol. 2005, 161, 381–387. [Google Scholar] [CrossRef]

- Kumar, A.; Lal, S.; Kumar, S. Fabrication and characterization of A359/Al2O3 metal matrix composite using electromagnetic stir casting method. J. Mater. Res. Technol. 2013, 3, 250–254. [Google Scholar] [CrossRef] [Green Version]

- Abouelmagd, G. Hot deformation and wear resistance of P/M aluminium metal matrix composites. J. Mater. Process. Technol. 2004, 155, 1395–1401. [Google Scholar] [CrossRef]

- Kannan, S.; Kishawy, H.A. Surface characteristics of machined aluminium metal matrix composites. Int. J. Mach. Tools Manuf. 2006, 46, 2017–2025. [Google Scholar] [CrossRef]

- Yao, B.; Hofmeister, C.; Patterson, T.; Sohn, Y.H.; van den Bergh, M.; Delahanty, T.; Cho, K. Microstructural features influencing the strength of trimodal aluminum metal-matrix-composites. Compos. Part. A Appl. Sci. Manuf. 2010, 41, 933–941. [Google Scholar] [CrossRef]

- Vogt, R.G.; Zhang, Z.; Topping, T.D.; Lavernia, E.J.; Schoenung, J.M. Cryo milled aluminum alloy and boron carbide nano-composite plate. J. Mater. Process. Technol. 2009, 209, 5046–5053. [Google Scholar] [CrossRef]

- Babu, T.M.; Sugin, M.A.; Muthukrishnan, N. Investigation on the characteristics of surface quality on machining of hybrid metal matrix composite (Al-SiC-B4C). Procedia Eng. 2012, 38, 2617–2624. [Google Scholar] [CrossRef] [Green Version]

- Previtali, B.; Pocci, D.; Taccardo, C. Application of traditional investment casting process to aluminium matrix composites. Compos. Part. A Appl. Sci. Manuf. 2008, 39, 1606–1617. [Google Scholar] [CrossRef]

- Sayman, O.; Akbulut, H.; Meric, C. Elasto-plastic stress analysis of aluminum metal-matrix composite laminated plates under in-plane loading. Comput. Struct. 2000, 75, 55–63. [Google Scholar] [CrossRef]

- Sayman, O. An elastic–plastic thermal stress analysis of aluminum metal–matrix composite beams. Compos. Struct. 2001, 53, 419–425. [Google Scholar] [CrossRef]

- Atas, C.; Sayman, O. Elastic–plastic stress analysis and expansion of plastic zone in clamped and simply supported aluminum metal–matrix laminated plates. Compos. Struct. 2000, 49, 9–19. [Google Scholar] [CrossRef]

- Ding, H.Z.; Biermann, H.; Hartmann, O. Low cycle fatigue crack growth and life prediction of short-fibre reinforced aluminium matrix composites. Int. J. Fatigue 2003, 25, 209–220. [Google Scholar] [CrossRef]

- Ding, H.Z.; Biermann, H.; Hartmann, O. A low cycle fatigue model of a short-fibre reinforced 6061 aluminium alloy metal matrix composite. Compos. Sci. Technol. 2002, 62, 2189–2199. [Google Scholar] [CrossRef]

- Lee, W.S.; Sue, W.C.; Lin, C.F. The effects of temperature and strain rate on the properties of carbon-fiber-reinforced 7075 aluminum alloy metal-matrix composite. Compos. Sci. Technol. 2000, 60, 1975–1983. [Google Scholar] [CrossRef]

- Guden, M.; Hall, I.W. High strain rate deformation behavior of a continuous fiber reinforced aluminum metal matrix composite. Comput. Struct. 2000, 76, 139–144. [Google Scholar] [CrossRef] [Green Version]

- Rams, J.; Urena, A.; Escalera, M.D.; Sanchez, M. Electroless nickel coated short carbon fibres in aluminium matrix composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 566–575. [Google Scholar] [CrossRef]

- Fu, H.H.; Han, K.S.; Song, J.I. Wear properties of saffil/Al, saffil/Al2O3/Al and saffil/SiC/Al hybrid metal matrix composites. Wear 2004, 256, 705–713. [Google Scholar] [CrossRef]

- Dinesh, S.K.; Ravichandran, M.; Meignanamoorthy, M. Aluminium Metal Matrix Composite with Zirconium diboride Reinforcement: A Review. Mater. Today Process. 2018, 5, 19844–19847. [Google Scholar] [CrossRef]

- Jino, J.J.; Sivalingappa, D.; Koti, H.; Jebin, V.D. Properties of Al6063 MMC reinforced with zircon sand and alumina. IOSR J. Mech. Civil. Eng. 2013, 5, 72–77. [Google Scholar]

- Das, S.; Das, S.; Das, K. RETRACTED: Abrasive wear of zircon sand and alumina reinforced Al–4.5 wt% Cu alloy matrix composites—A comparative study. Compos. Sci. Technol. 2007, 67, 746–751. [Google Scholar] [CrossRef]

- Scudino, S.; Liu, G.; Prashanth, K.G.; Bartusch, B.; Surreddi, K.B.; Murty, B.S.; Eckert, J. Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Materialia 2009, 57, 2029–2039. [Google Scholar] [CrossRef]

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C.; Satyanarayana, K.G.; Rohatgi, P.K. Fabrication and characterisation of Al–7Si–0.35 Mg/fly ash metal matrix composites processed by different stir casting routes. Compos. Sci. Technol. 2007, 67, 3369–3377. [Google Scholar] [CrossRef]

- Dou, Z.; Wu, G.; Huang, X.; Sun, D.; Jiang, L. Electromagnetic shielding effectiveness of aluminum alloy–fly ash composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 186–191. [Google Scholar] [CrossRef]

- Ramachandra, M.; Radhakrishna, K. Effect of reinforcement of flyash on sliding wear, slurry erosive wear and corrosive behavior of aluminium matrix composite. Wear 2007, 262, 1450–1462. [Google Scholar] [CrossRef]

- Saravanan, C.; Subramanian, K.; Sivakumar, D.B.; Sathyanandhan, M.; Narayanan, R.S. Fabrication of aluminium metal matrix composite—A review. J. Chem. Pharm. Sci. 2015, 974, 82–87. [Google Scholar]

- Huda, D.; El Baradie, M.A.; Hashmi, M.S.J. Metal-matrix composites: Manufacturing aspects. Part, I. J. Mater. Process. Technol. 1993, 37, 513–528. [Google Scholar] [CrossRef]

- Dao, V.; Zhao, S.; Lin, W.; Zhang, C. Effect of process parameters on microstructure and mechanical properties in AlSi9Mg connecting-rod fabricated by semi-solid squeeze casting. Mater. Sci. Eng. A 2012, 558, 95–102. [Google Scholar] [CrossRef]

- Senthil, P.; Amirthagadeswaran, K.S. Optimization of squeeze casting parameters for non symmetrical AC2A aluminium alloy castings through Taguchi method. J. Mech. Sci. Technol. 2012, 26, 1141–1147. [Google Scholar] [CrossRef]

- Sukumaran, K.; Ravikumar, K.K.; Pillai, S.G.K.; Rajan, T.P.D.; Ravi, M.; Pillai, R.M.; Pai, B.C. Studies on squeeze casting of Al 2124 alloy and 2124-10% SiCp metal matrix composite. Mater. Sci. Eng. A 2008, 490, 235–241. [Google Scholar] [CrossRef]

- Maleki, A.; Niroumand, B.; Shafyei, A. Effects of squeeze casting parameters on density, macrostructure and hardness of LM13 alloy. Mater. Sci. Eng. A 2006, 428, 135–140. [Google Scholar] [CrossRef]

- Yong, M.S.; Clegg, A.J. Process optimisation for a squeeze cast magnesium alloy metal matrix composite. J. Mater. Process. Technol. 2005, 168, 262–269. [Google Scholar] [CrossRef]

- Umunakwe, R.; Okoye, O.C.; Nwigwe, U.S.; Oyetunji, A.; Umunakwe, I.J. Effects of stirring time and particles preheating on porosity, mechanical properties and microstructure of periwinkle shell-aluminium metal matrix composite (PPS-ALMMC). Ann. Fac. Eng. Hunedoara 2017, 15, 133. [Google Scholar]

- Hashim, J. The Production of Metal Matrix Composites Using the Stir Casting Technique. Ph.D. Thesis, Dublin City University, Dublin, Ireland, 1999. [Google Scholar]

- Cao, A.G.; Kobliska, J.; Konishi, H.; Li, X. Tensile properties and microstructure of SiC nanoparticle reinforced Mg-4Zn Alloyfabricated by ultrasonic cavitations based solidification processing. Metall. Mater. Trans. A 2008, 39, 880–886. [Google Scholar] [CrossRef]

- Cao, G.; Konishi, H.; Li, X. Recent developments on ultrasonic cavitation based solidification processing of bulk magnesiumnanocomposites. Int. J. Met. 2008, 2, 57–68. [Google Scholar]

- Yang, Y.; Lan, J.; Li, X. Study on bulk aluminium matrix nanocomposite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminium alloy. Mater. Sci. Eng. A 2004, 380, 378–383. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X. Ultrasonic cavitations based nano-manufacturing of bulk aluminium matrix nanocomposites. Trans. ASME 2007, 129, 252–255. [Google Scholar]

- Li, X.; Yang, Y.; Cheng, X. Ultrasonic assisted fabrication of metal matrix composites. J. Mater. Sci. 2004, 39, 3211–3212. [Google Scholar] [CrossRef]

- Sunnel, D.; Rao, D.N.; Satyanarayana, C.; Jain, P.K. Estimation of cavitations pressure to disperse carbon nanotube in aluminium matrix composites. AIJSPTME 2009, 2, 53–60. [Google Scholar]

- Donthamsetty, S.; Damera, N.R.; Jain, P.K. Ultrasonic cavitations assisted fabrication and characterisation of A356 metal matrix nanocomposite reinforced with SiC, B4C, CNTs. AIJTPME 2009, 2, 27–34. [Google Scholar]

- Murthy, I.N.; Venkarao, D.; Rao, J.R. Microstructure and mechanical properties of aluminium-fly ash nano composite made by ultrasonic method. Mater. Des. 2012, 35, 55–65. [Google Scholar] [CrossRef]

- Miranda, A.; Alba-Baena, N.; McKay, B.J.; Eskin, D.G.; Ko, S.H.; Shin, J.S. Study of mechanical properties of an LM24composites alloy reinforced with Cu-CNT nanofillers, processed using ultrasonic cavitations. Mater. Sci. Forum 2013, 765, 245–249. [Google Scholar] [CrossRef]

- Zok, F.; Jansson, S.; Evans, A.G.; Nardone, V. Thermo-mechanical behaviour of a hybrid metal matrix composite. Metall. Trans. A 1991, 25, 2107–2117. [Google Scholar] [CrossRef]

- Jang, J.H.; Han, K.S. Fabrication of graphite nanofibers reinforced metal matrix composites by powder metallurgy and their mechanical and physical characteristics. J. Compos. Mater. 2007, 41, 1431–1443. [Google Scholar] [CrossRef]

- Mula, S.; Padhi, P.; Panigrahi, S.C.; Pabi, S.K.; Ghosh, S. On structure and mechanical properties of ultrasonically cast Al–2% Al2O3 nanocomposite. Mater. Res. Bull. 2009, 44, 1154–1160. [Google Scholar] [CrossRef]

- Lin, T.Z.; Tan, C.; Liu, B.; McDonald, A. Microstructure of AA2024-SiC nanostructured metal matrix composites. J. Mater. Sci. 2008, 43, 7507–7512. [Google Scholar] [CrossRef]

- Liu, H.; Wang, L.; Wang, A.; Lou, T.; Ding, B.; Hu, Z. Study of SiC/Al nanocomposites under high pressure. Nanostructured Mater. 1997, 9, 225–228. [Google Scholar] [CrossRef]

- Torralba, J.D.; Da Costa, C.E.; Velasco, F. P/M aluminum matrix composites: An overview. J. Mater. Process. Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Woo, K.D.; Zhang, D.L. Fabrication of Al–7 wt% Si–0.4 wt% Mg/SiC nanocomposite powders and bulk nanocomposites by high energy ball milling and powder metallurgy. Curr. Appl. Phys. 2004, 4, 175–178. [Google Scholar] [CrossRef]

- Zhang, X.N.; Geng, L.; Wang, G.S. Fabrication of Al-based hybrid composites reinforced with SiC whiskers and SiC nanoparticles by squeeze casting. J. Mater. Process. Technol. 2006, 176, 146–151. [Google Scholar] [CrossRef]

- Babu, J.S.; Nair, K.P.; Kang, C.G. Fabrication and characterization of aluminum based nano-micro hybrid metal matrix composites. In Proceedings of the 16th International Conference on Composite Materials, Kyoto, Japan, 8–13 July 2007. [Google Scholar]

- Feng, Y.C.; Geng, L.; Zheng, P.Q.; Zheng, Z.Z.; Wang, G.S. Fabrication and characteristic of Al-based hybrid composite reinforced with tungsten oxide particle and aluminum borate whisker by squeeze casting. Mater. Des. 2008, 29, 2023–2026. [Google Scholar] [CrossRef]

- Lin, G.E.N.G.; Zhnag, X.N.; Wang, G.S.; Zheng, Z.Z.; Bin, X.U. Effect of aging treatment on mechanical properties of (SiCw+ SiCp)/2024Al hybrid nanocomposites. Trans. Nonferrous Met. Soc. China 2006, 16, 387–391. [Google Scholar]

- Reddy, B.S.B.; Rajasekhar, K.; Venu, M.; Dilip, J.J.S.; Das, S.; Das, K. Mechanical activation-assisted solid-state combustion synthesis of in situ aluminum matrix hybrid (Al3Ni/Al2O3) nanocomposites. J. Alloys Compd. 2008, 465, 97–105. [Google Scholar] [CrossRef]

- Wang, H.; Li, G.; Zhao, Y.; Chen, G. In situ fabrication and microstructure of Al2O3 particles reinforced aluminum matrix composites. Mater. Sci. Eng. A 2010, 527, 2881–2885. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Keshavamurthy, R.; Channabasappa, B.H.; Ahmed, A. Microstructure and mechanical properties of Ni–P coated Si3N4 reinforced Al6061 composites. Mater. Sci. Eng. A 2009, 502, 99–106. [Google Scholar] [CrossRef]

- Schultz, B.F.; Ferguson, J.B.; Rohatgi, P.K. Microstructure and hardness of Al2O3 nanoparticle reinforced Al–Mg composites fabricated by reactive wetting and stir mixing. Mater. Sci. Eng. A 2011, 530, 87–97. [Google Scholar] [CrossRef]

- Hashmi, J.; Looney, L.; Hashmi, M.S.J. Metal matrix composites: Production by the stir casting method. J. Mater. Process. Technol. 1999, 92, 1–7. [Google Scholar] [CrossRef]

- Sharifian, K.; Emamy, M.; Tavighi, K.; Yeganeh, S.V. Microstructures and Tensile Properties of Hot-Extruded Al Matrix Composites Containing Different Amounts of Al 4 Sr. Metall. Mater. Trans. A 2014, 45, 5344–5350. [Google Scholar] [CrossRef]

- Alizadeh, A.; Taheri-Nassaj, E.; Hajizamani, M. Hot extrusion process effect on mechanical behavior of stir cast Al based composites reinforced with mechanically milled B4C nanoparticles. J. Mater. Sci. Technol. 2011, 27, 1113–1119. [Google Scholar] [CrossRef]

- The Aluminum Association. Selection and Applications n.d. Available online: https://www.aluminum.org/ (accessed on 1 September 2021).

- Pitchayyapillai, G.; Seenikannan, P.; Balasundar, P.; Narayanasamy, P. Effect of nano-silver on microstructure, mechanical and tribological properties of cast 6061 aluminum alloy. Trans. Nonferrous Met. Soc. China 2017, 27, 2137–2145. [Google Scholar] [CrossRef]

- Deshpande, M.; Gondil, R.; Murty, S.N.; Kalal, R.K. Studies on 7075 aluminium alloy MMCs with milled carbon fibers as reinforcements. Trans. Indian Inst. Met. 2018, 71, 993–1002. [Google Scholar] [CrossRef]

- Rahimi, B.; Khosravi, H.; Haddad-Sabzevar, M. Microstructural characteristics and mechanical properties of Al-2024 alloy processed via a rheocasting route. Int. J. Miner. Metall. Mater. 2015, 22, 59–67. [Google Scholar] [CrossRef]

- Nissar, A.; Kazi, Z.; Safiulla, A.M.; Faisal, M. A thorough study: In-situ aluminium LM6 metal matrix composites reinforced with iron oxide and MWCNTs. Mater. Today Proc. 2017, 4, 11999–12006. [Google Scholar] [CrossRef]

- Radhika, N. Fabrication of LM25/SiO2 Metal Matrix Composite and Optimization of Wear Process Parameters Using Design of Experiment. Tribol. Ind. 2017, 39, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Khanna, V.; Kumar, V.; Bansal, S.A. Mechanical properties of aluminium-graphene/carbon nanotubes (CNTs) metal matrix composites: Advancement, opportunities and perspective. Mater. Res. Bull. 2021, 138, 111224. [Google Scholar] [CrossRef]

- Premnath, A.A.; Alwarsamy, T.; Rajmohan, T.; Prabhu, R. The influence of alumina on mechanical and tribological characteristics of graphite particle reinforced hybrid Al-MMC. J. Mech. Sci. Technol. 2014, 28, 4737–4744. [Google Scholar] [CrossRef]

- Abd El-Azim, A.N.; Kassem, M.A.; El-Baradie, Z.M.; Waly, M. Structure and properties of short alumina fibre reinforced AlSi18CuNi produced by stir casting. Mater. Lett. 2002, 56, 963–969. [Google Scholar] [CrossRef]

- Vasamsetti, S.; Dumpala, L.; Subbarao, V.V. Synthesis, characterization and hardness studies of nano rice husk ash reinforced Al6061 nanocomposites. J. Eng. Sci. Technol. 2018, 13, 2916–2929. [Google Scholar]

- Auradi, V.; Rajesh, G.L.; Kori, S.A. Preparation and evaluation of mechanical properties of 6061Al–B4Cp composites produced via two-stage melt stirring. Mater. Manuf. Process. 2014, 29, 194–200. [Google Scholar] [CrossRef]

- Basavarajappa, S. Tool wear in turning of graphitic hybrid metal matrix composites. Mater. Manuf. Process. 2009, 24, 484–487. [Google Scholar] [CrossRef]

- Zhang, J.; Guan, R.G.; Tie, D.; Wang, X.; Guan, X.H.; Chen, B.C.; Chen, Y. Effects of technical parameters of semi-solid stirring and rheo-rolling on microstructure of A356–5wt.% B4C composite strip. Mater. Manuf. Process. 2015, 30, 340–345. [Google Scholar] [CrossRef]

- Ghandvar, H.; Farahany, S.; Idris, J. Effect of SiC Particles Treatment and Mg Addition on Improvement of Micro-structural and Mechanical Properties of Al356/SiCp Composite Using Semisolid Process. Mater. Manuf. Process. 2015, 30, 1442–1449. [Google Scholar] [CrossRef]

- Huang, S.J.; Lin, P.C.; Aoh, J.N. Mechanical behavior enhancement of AM60/Al2O3p magnesium metal–matrix nanocomposites by ECAE. Mater. Manuf. Process. 2015, 30, 1272–1277. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Muthuramalingam, T.; Anbuchezhiyan, G. Effect of B4C and MOS2 reinforcement on micro structure and wear properties of aluminum hybrid composite for automotive applications. Compos. Part B Eng. 2019, 176, 107329. [Google Scholar] [CrossRef]

- Akbar, H.I.; Surojo, E.; Ariawan, D.; Putra, G.A.; Wibowo, R.T. Effect of Reinforcement Material on Properties of Manufactured Aluminum Matrix Composite Using Stir Casting Route. Procedia Struct. Integr. 2020, 27, 62–68. [Google Scholar] [CrossRef]

- Bauri, R.; Surappa, M.K. Processing and compressive strength of Al-Li-SiCp composite fabricated by a compound billettechnique. J. Mater. Process. Technol. 2009, 209, 2077–2084. [Google Scholar] [CrossRef]

- Banerji, A.; Surappa, M.K.; Rohatgi, P.K. Cast aluminum alloys containing dispersions of zircon particles. Metall. Trans. B 1983, 14, 273–283. [Google Scholar] [CrossRef]

- Panwar, R.S.; Pandey, O.P. Analysis of wear track and debris of stir cast LM13/Zr composite at elevated temperatures. Mater. Charact. 2013, 75, 200–213. [Google Scholar] [CrossRef]

- Das, S.; Udhayabanu, V.; Das, S.; Das, K. Synthesis and characterization of zircon sand/Al-4.5 wt% Cu composite produced by stir casting route. J. Mater. Sci. 2006, 41, 4668–4677. [Google Scholar] [CrossRef]

- Sharma, A.; Das, S. Study of age hardening behavior of Al–4.5 wt% Cu/zircon sand composite in different quenching media—A comparative study. Mater. Des. 2009, 30, 3900–3903. [Google Scholar] [CrossRef]

- Gopi, K.R.; Mohandas, K.N.; Reddappa, H.N.; Ramesh, M.R. Characterization of as cast and heat treated aluminium 6061/Zircon sand/graphite particulate hybrid composites. Int. J. Eng. Adv. Technol. 2013, 2, 340–344. [Google Scholar]

- Li, B.J.; Chao, C.G. Mechanical properties and 95 aging characteristics of zircon-reinforced Zn-4AI-3Cu alloy. Metall. Mater. Trans. A 1996, 27, 809–818. [Google Scholar] [CrossRef]

- Kumar, S.; Panwar, R.S.; Pandey, O.P. Effect of dual reinforced ceramic particles on high temperature tribological properties of aluminum composites. Ceram. Int. 2013, 39, 6333–6342. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, S.; Panwar, R.S.; Pandey, O.P. Microstructural and wear behavior of dual reinforced particle (DRP) aluminum alloy composite. J. Mater. Sci. 2012, 47, 6633–6646. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, V.; Panwar, R.S.; Pandey, O.P. Wear behavior of dual particle size (DPS) zircon sand reinforced aluminum alloy. Tribol. Lett. 2012, 47, 231–251. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Ashuri, M.; Moghadam, P.T.; Nouribahadory, A.; Baharvandi, H.R. Improvement in physical and mechanical properties of aluminum/zircon composites fabricated by powder metallurgy method. Mater. Des. 1997, 32, 4417–4423. [Google Scholar] [CrossRef]

- Kalaiselvan, K.; Murugan, N.; Parameswaran, S. Production and characterization of AA6061–B4C stir cast composite. Mater. Des. 2011, 32, 4004–4009. [Google Scholar] [CrossRef]

- Satheesh, M.; Pugazhvadivu, M. Investigation on physical and mechanical properties of Al6061-Silicon Carbide (SiC)/Coconut shell ash (CSA) hybrid composites. Phys. B: Condens. Matter 2019, 572, 70–75. [Google Scholar] [CrossRef]

- Gudipudi, S.; Nagamuthu, S.; Subbian, K.S.; Chilakalapalli, S.P.R. Enhanced mechanical properties of AA6061-B4C composites developed by a novel ultra-sonic assisted stir casting. Eng. Sci. Technol. Int. J. 2020, 23, 1233–1243. [Google Scholar] [CrossRef]

- Sam, M.; Radhika, N. Influence of carbide ceramic reinforcements in improving tribological properties of A333 graded hybrid composites. Def. Technol. 2021, 1–31. [Google Scholar]

- Lakshmikanthan, P.; Prabu, B. Mechanical and tribologicalbeheaviour of aluminium Al6061-coconut shell ash composite using stir casting pellet method. J. Balk. Tribol. Assoc. 2016, 22, 4008–4018. [Google Scholar]

- Kumar, G.V.; Swamy, A.R.K.; Ramesha, A. Studies on properties of as-cast Al6061-WC-Gr hybrid MMCs. J. Compos. Mater. 2012, 46, 2111–2122. [Google Scholar] [CrossRef]

- Gopalakrishnan, S.; Murugan, N. Production and wear characterisation of AA 6061 matrix titanium carbide particulate reinforced composite by enhanced stir casting method. Compos. Part. B Eng. 2012, 43, 302–308. [Google Scholar] [CrossRef]

- Santosh, R.V.N.; Sarojini, J.; Shabana; Lakshmi, V.V.K. Enhancing the mechanical properties of metal matrix composites by reinforcing aluminium 6063 with SiC& graphite. Int. J. Eng. Res. Technol. 2018, 6, 1–5. [Google Scholar]

- Guan, L.N.; Lin, G.E.N.G.; Zhang, H.W.; Huang, L.J. Effects of stirring parameters on microstructure and tensile properties of (ABOw+ SiCp)/6061Al composites fabricated by semi-solid stirring technique. Trans. Nonferrous Met. Soc. China 2011, 21, s274–s279. [Google Scholar] [CrossRef]

- Girisha, L.; Raji, G. Study on Properties of Multi Walled Carbon Nanotube Reinforced Aluminum Matrix Composite through Casting Technique. Int. J. Eng. Res. Technol. 2014, 3, 1372–1375. [Google Scholar]

- Logesh, K.; Hariharasakthisudhan, P.; Moshi, A.A.M.; Rajan, B.S.; Sathickbasha, K. Mechanical Properties and Microstructure of A356 Alloy Reinforced AlN/MWCNT/Graphite/Al Composites Fabricated by Stir Casting. Mater. Res. Express 2019, 7, 015004. [Google Scholar] [CrossRef] [Green Version]

- Mondal, D.P.; Das, S.; Jha, A.K.; Yegneswaran, A.H. Abrasive wear of Al alloy–Al2O3 particle composite: A study on the combined effect of load and size of abrasive. Wear 1998, 223, 131–138. [Google Scholar] [CrossRef]

- Kumar, G.V.; Rao, C.S.P.; Selvaraj, N. Studies on mechanical and dry sliding wear of Al6061–SiC composites. Compos. Part. B Eng. 2012, 43, 1185–1191. [Google Scholar] [CrossRef]

- Tyagi, R. Synthesis and tribological characterization of in situ cast Al–TiC composites. Wear 2005, 259, 569–576. [Google Scholar] [CrossRef]

- Alpas, A.T.; Zhang, J. Effect of microstructure (particulate size and volume fraction) and counterface material on the sliding wear resistance of particulate-reinforced aluminum matrix composites. Metall. Mater. Trans. A 1994, 25, 969–983. [Google Scholar] [CrossRef]

- Ceschini, L.; Daehn, G.S.; Garagnani, G.L.; Martini, C. Friction and wear behavior of C4Al2O3Al composites under dry sliding conditions. Wear 1998, 216, 229–238. [Google Scholar] [CrossRef]

- Uyyuru, R.K.; Surappa, M.K.; Brusethaug, S. Effect of reinforcement volume fraction and size distribution on the tribological behavior of Al-composite/brake pad tribo-couple. Wear 2006, 260, 1248–1255. [Google Scholar] [CrossRef]

- Radhika, N.; Subramanian, R.; Prasat, S.V. Tribological behaviour of aluminium/alumina/graphite hybrid metal matrix composite using Taguchi’s techniques. J. Miner. Mater. Charact. Eng. 2011, 10, 427. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Olubambi, P.A.; Afolabi, A.S.; Bodurin, M.O. Corrosion and tribological studies of bamboo leaf ash and alumina reinforced Al-Mg-Si alloy matrix hybrid composites in chloride medium. Int. J. Electrochem. Sci. 2014, 9, 5663–5674. [Google Scholar]

- Raju, R.S.S.; Panigrahi, M.K.; Ganguly, R.I.; Rao, G.S. Tribological behaviour of al-1100-coconut shell ash (CSA) composite at elevated temperature. Tribol. Int. 2019, 129, 55–66. [Google Scholar] [CrossRef]

- Coyal, A.; Yuvaraj, N.; Butola, R.; Tyagi, L. An experimental analysis of tensile, hardness and wear properties of aluminium metal matrix composite through stir casting process. SN Appl. Sci. 2020, 2, 892. [Google Scholar] [CrossRef] [Green Version]

- Mahesh, V.; Joladarashi, S.; Kulkarni, M.S. Experimental study on abrasive wear behaviour of flexible green composite intended to be used as protective cladding for structures. Int. J. Mod. Manuf. Technol. 2019, 11, 69–76. [Google Scholar]

- Kumar, B.; Birru, A. Microstructure and mechanical properties of aluminium metal matrix composites with addition of bamboo leaf ash by stir casting method. Trans. Nonferrous Met. Soc. China 2017, 27, 2555–2572. [Google Scholar] [CrossRef]

| Method | Cost | Application | Remarks |

|---|---|---|---|

| Stir casting | Least cost | Applicable for mass production | Appropriate for particulate reinforcement in aluminium metal matrix composites (AMMCs), depending on matrix metals, reinforcement properties, and casting speed and duration |

| Powder metallurgy | Medium cost | Used in the production of parts that are heat-resistant (e.g., piston and valves) | Matrix metal and reinforcements are required in powder form. Due to the absence of a reactive zone, the manufactured metal matrix composite (MMC) has a high strength. |

| Diffusion bonding | High cost | For sheets, vane shafts, and blades, this process is used. | Suitable for Matrix Metal in the form of sheets; Reinforcements in the form filaments. |

| Liquid infiltration | Low cost | Structural component manufacturing such as rods, beam, and tubes | A reinforcement in form of filament is used. |

| Squeeze casting | Medium cost | Engine parts production, e.g., piston, connecting rods, and cylinder head | Generally preferred for the type of reinforcement. Used for mass-scale production. |

| Compocasting | Low cost | Applicable to the automobile industry | Conducive for discontinuous fibre in particle form |

| Insitu | Medium cost | Applicable to the automobile sector | It results in a homogeneousdistribution of reinforcing particles. |

| Ultrasonic-assisted casting | High cost | Suitable for mesh-shaped components. Preferred for large-scale manufacturing. | Almost a uniform dispersion of particulate reinforcements. |

| Types of Composites | Method | Outcomes | References |

|---|---|---|---|

| Al6061/Al2O3 (45 µm)/Gr (60 µm)/Gr (60 µm) | Stir casting | Increased hardness increases/increased density/good wear behavior | [103] |

| AlSi18CuNi/Al2O3p | Stir casting | Two wt% of Al2O3 increases the tensile strength (505 MPa) and hardness (123 Hv) as compared to the unreinforced matrix. | [104] |

| Al6061/nano-RHA | Ultrasonic and stirring | Increased microhardness | [105] |

| Al6061/B4C (10 µm) | Stir casting-modified method | Enhanced macro- and microhardness values and enhanced tensile strength | [106] |

| Al6061/B4Cp (88 µm) (5 and 7 wt% of B4C) | Two-Stage Melt Stirring |

| [106] |

| A2219/15 vol% silicon carbide particle (SiCp)/3 vol% Gr (25 µm) | Liquid stir casting technique |

| [107] |

| A356/5 wt% B4C (20–50 mm)/20 wt% A356 (32–80 µm) | Semi-solid material (SSM) stirring technique |

| [108,109] |

| AM60/Al2O3p (25 nm) and Al2024/Al2O3 (16, 32, and 66 µm) | Stircasting method |

| [36,110] |

| Al7075/B4C/MoS2 | Stir casting |

| [111] |

| Al6061/seasand/SiC/Al2O3 | Stir casting | The Al6061/sea sand composite showsa higher density a and lower porosity as compared to the Al6061/Al2O3 and Al6061/SiC composites. | [112] |

| Al2124/Al5083 and Al6063 reinforced by SiC (157–511 µm) | Stir-casting method | The impact strength increases with particle aggregation, while it isreduced with an increased extrusion ratio and an increased particle size. In addition, the matrix-reinforcement bonding and particle cracking have effects on the impact characteristics of the composites. | [22] |

| Al/Al2O3/SiC | Stir casting |

| [25] |

| Al384/SiC (60 µm) and A356/SiCp (4 µm) | Stir casting |

| [27,28] |

| Al/SiC | Stir casting |

| [29] |

| Al356/SiCp/B4Cp | Stir casting |

| [42] |

| Al6063/ZrSiO4 and Al2O3 | Stir casting |

| [54] |

| Al–7Si–0.35Mg/fly ash | Liquid-metal stir casting, compocasting and modified compocasting | In liquid-metal stir-cast composites, interfacial interactions at the fly ash particle–matrix intefacelead to the synthesis of MgAl2O4. Well-dispersed, reasonable agglomeration and porous-free composites areformed. | [57] |

| Al/15 wt% flyash | Stir casting | The wear resistance of the flyash-reinforced material improves as the flyash content increases, but decreased when the load and the track speed increase. The base alloy wears predominates as a result of microcutting, according to the microscopic analysis of worn surfaces, wear debris, and the subsurface. However, delamination, microcutting, oxidation, and thermal softening cause the MMCs to wear out. Corrosion increases as the amount of flyash has increases. | [59] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yadav, P.; Ranjan, A.; Kumar, H.; Mishra, A.; Yoon, J. A Contemporary Review of Aluminium MMC Developed through Stir-Casting Route. Materials 2021, 14, 6386. https://doi.org/10.3390/ma14216386

Yadav P, Ranjan A, Kumar H, Mishra A, Yoon J. A Contemporary Review of Aluminium MMC Developed through Stir-Casting Route. Materials. 2021; 14(21):6386. https://doi.org/10.3390/ma14216386

Chicago/Turabian StyleYadav, Poonam, Alok Ranjan, Harish Kumar, Abhishek Mishra, and Jonghun Yoon. 2021. "A Contemporary Review of Aluminium MMC Developed through Stir-Casting Route" Materials 14, no. 21: 6386. https://doi.org/10.3390/ma14216386

APA StyleYadav, P., Ranjan, A., Kumar, H., Mishra, A., & Yoon, J. (2021). A Contemporary Review of Aluminium MMC Developed through Stir-Casting Route. Materials, 14(21), 6386. https://doi.org/10.3390/ma14216386