3D-Printed Graphene-Based Bow-Tie Microstrip Antenna Design and Analysis for Ultra-Wideband Applications

Abstract

:1. Introduction

- : the angular frequency

- : the chemical potential

- : the scattering rate

- : the temperature

- : the relaxation time

- : the Boltzmann

- : the reduced Planck constant.

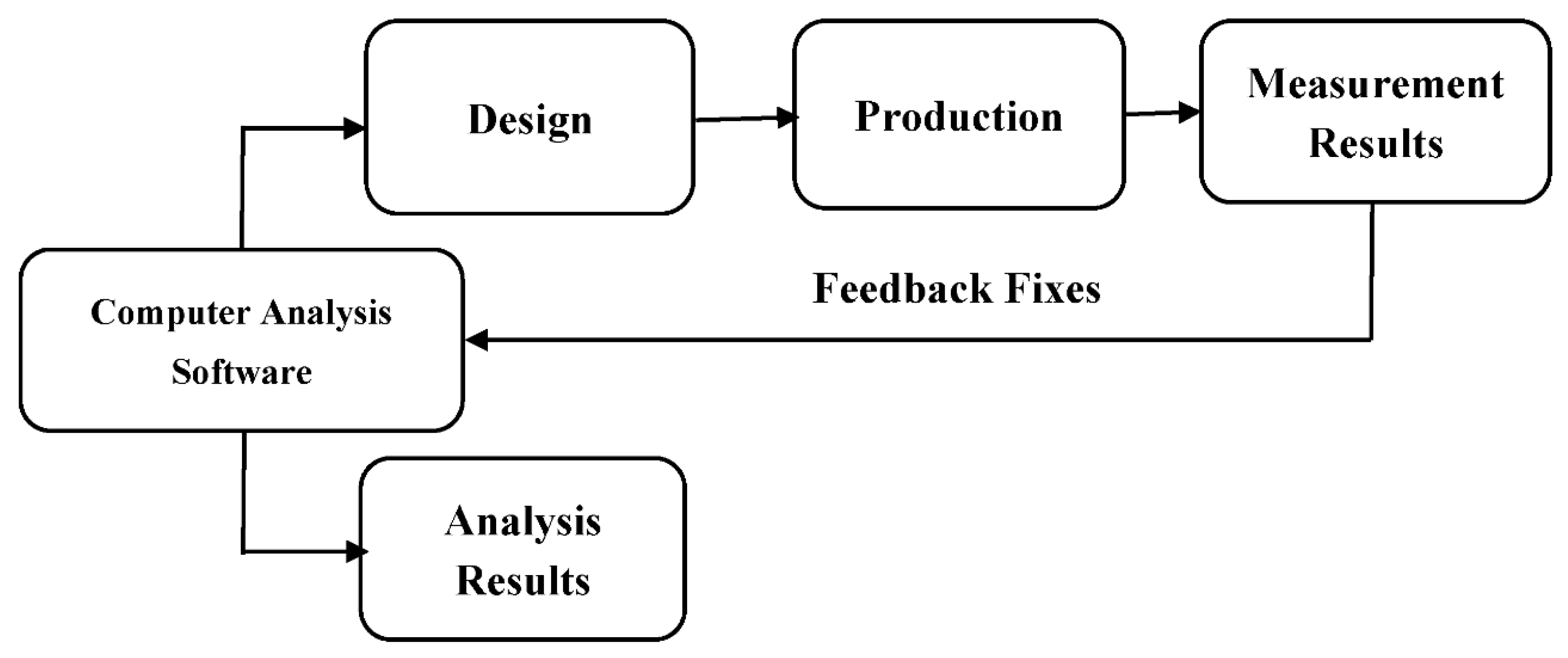

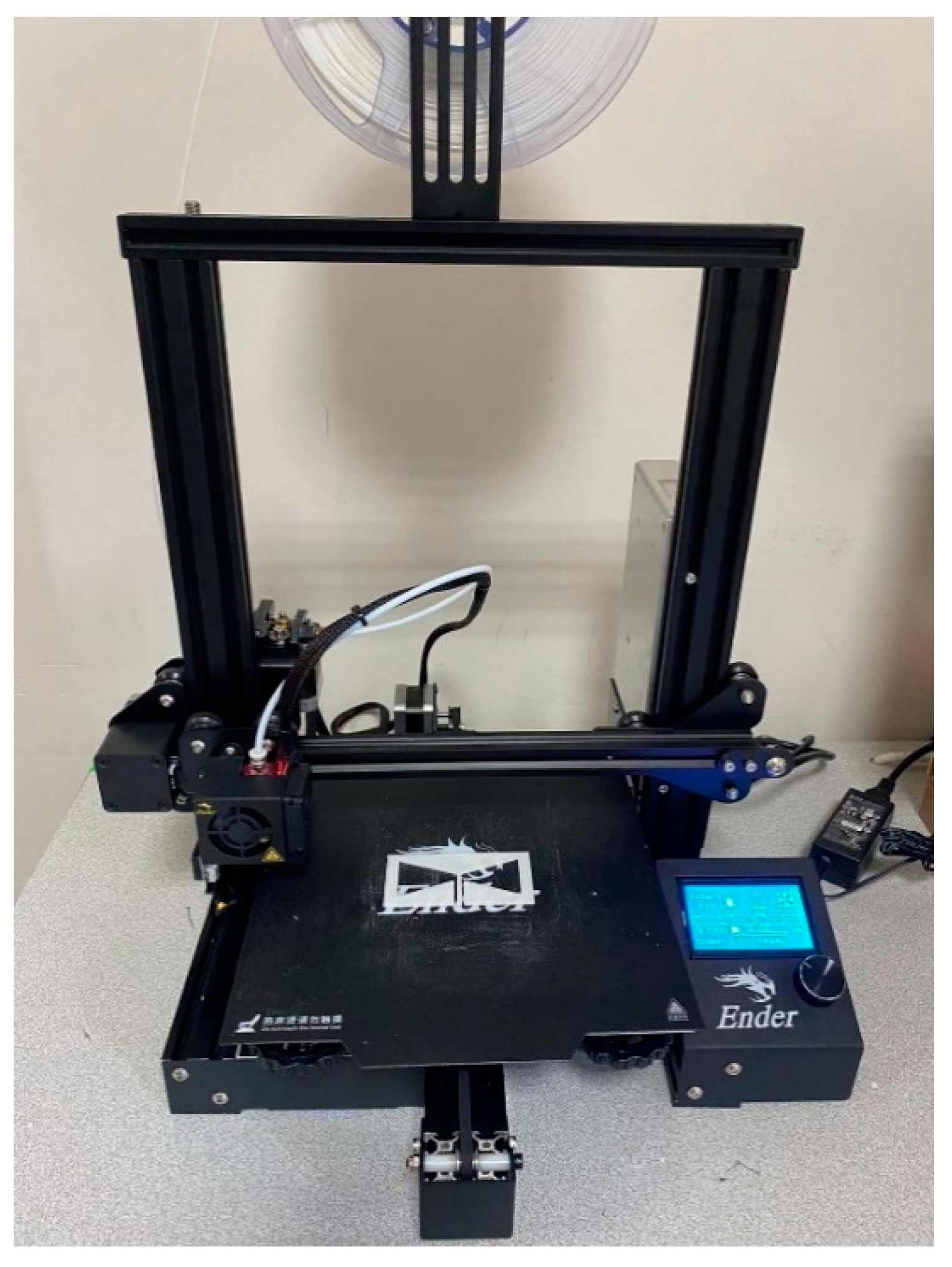

2. Material and Method

2.1. Materials

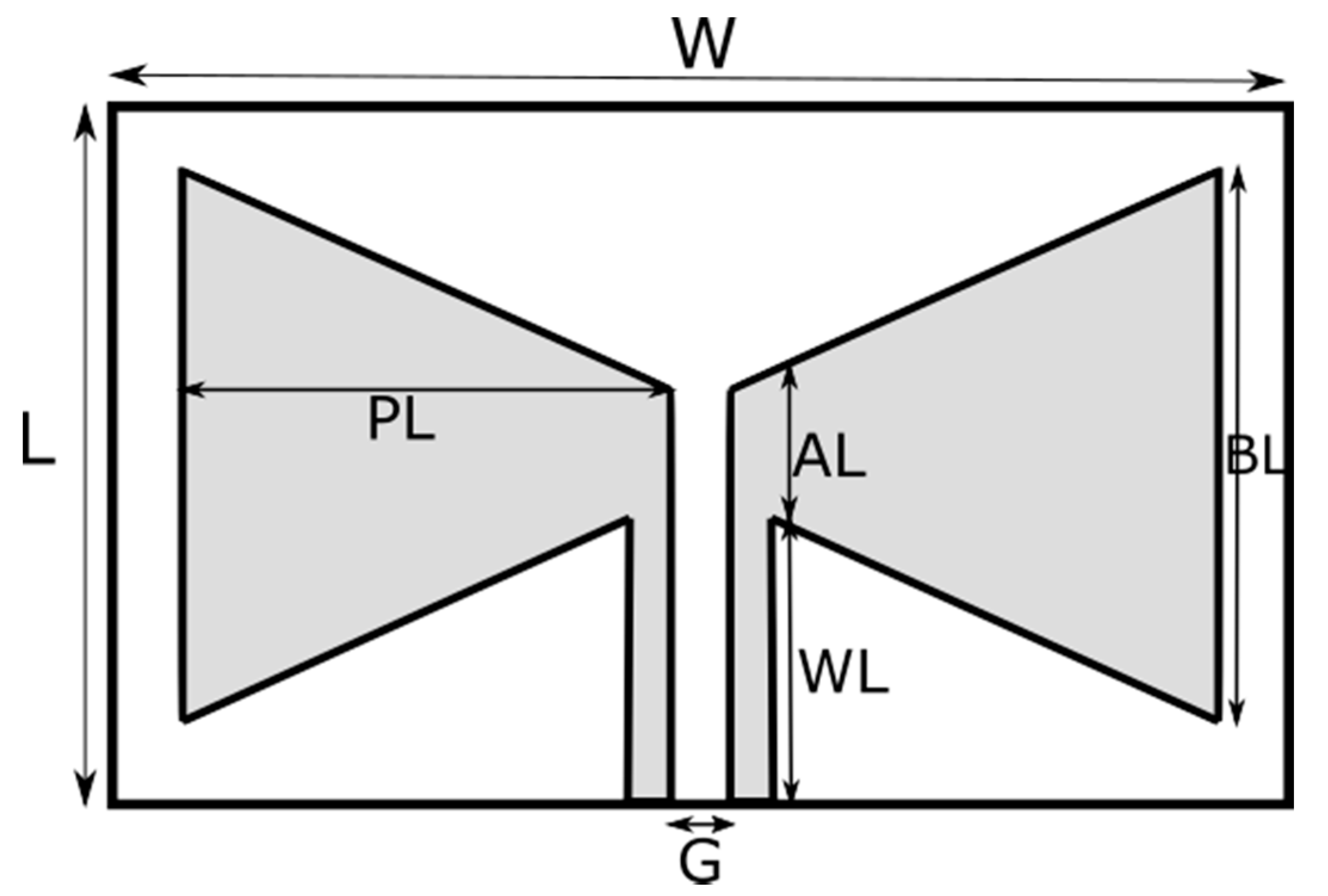

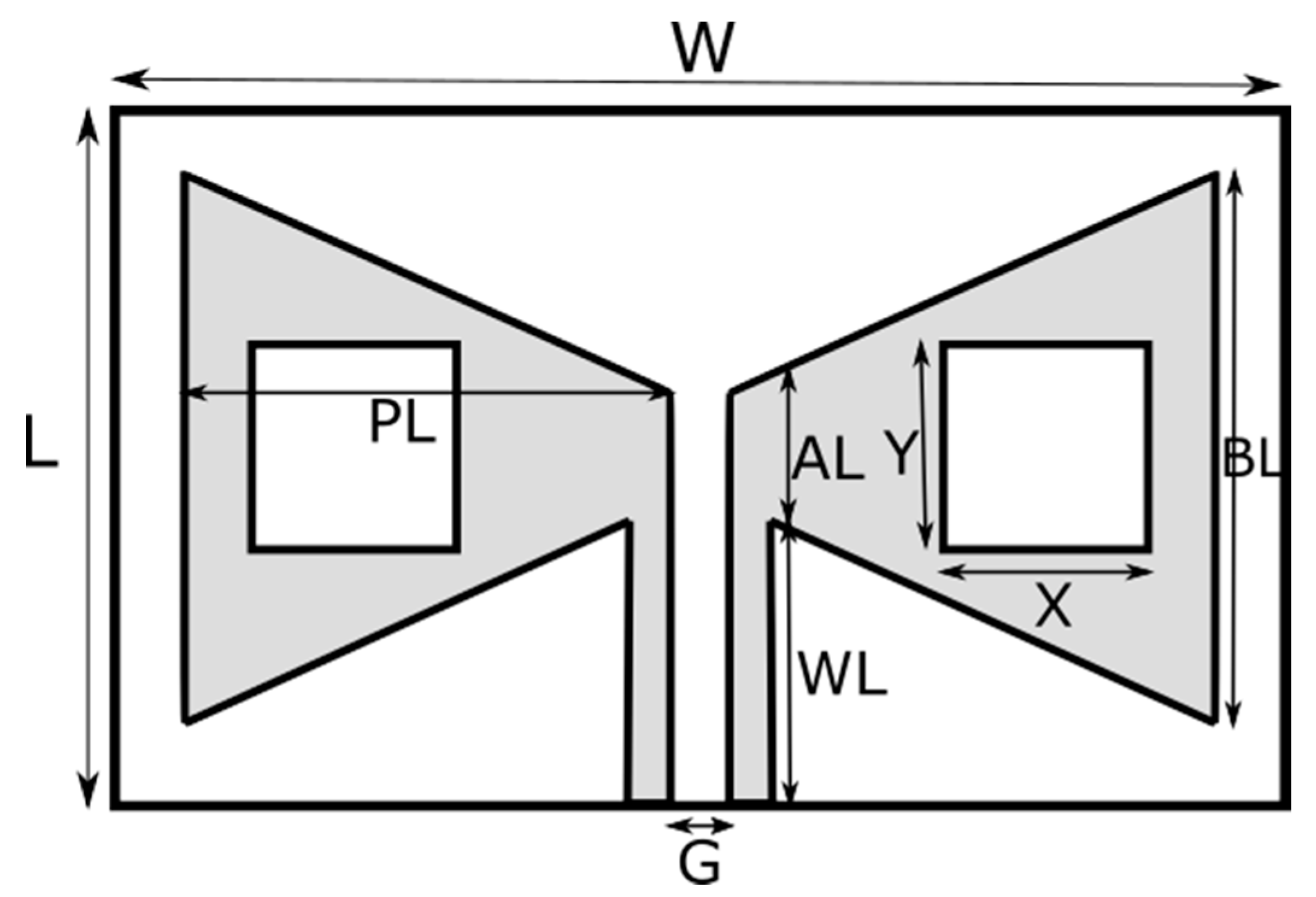

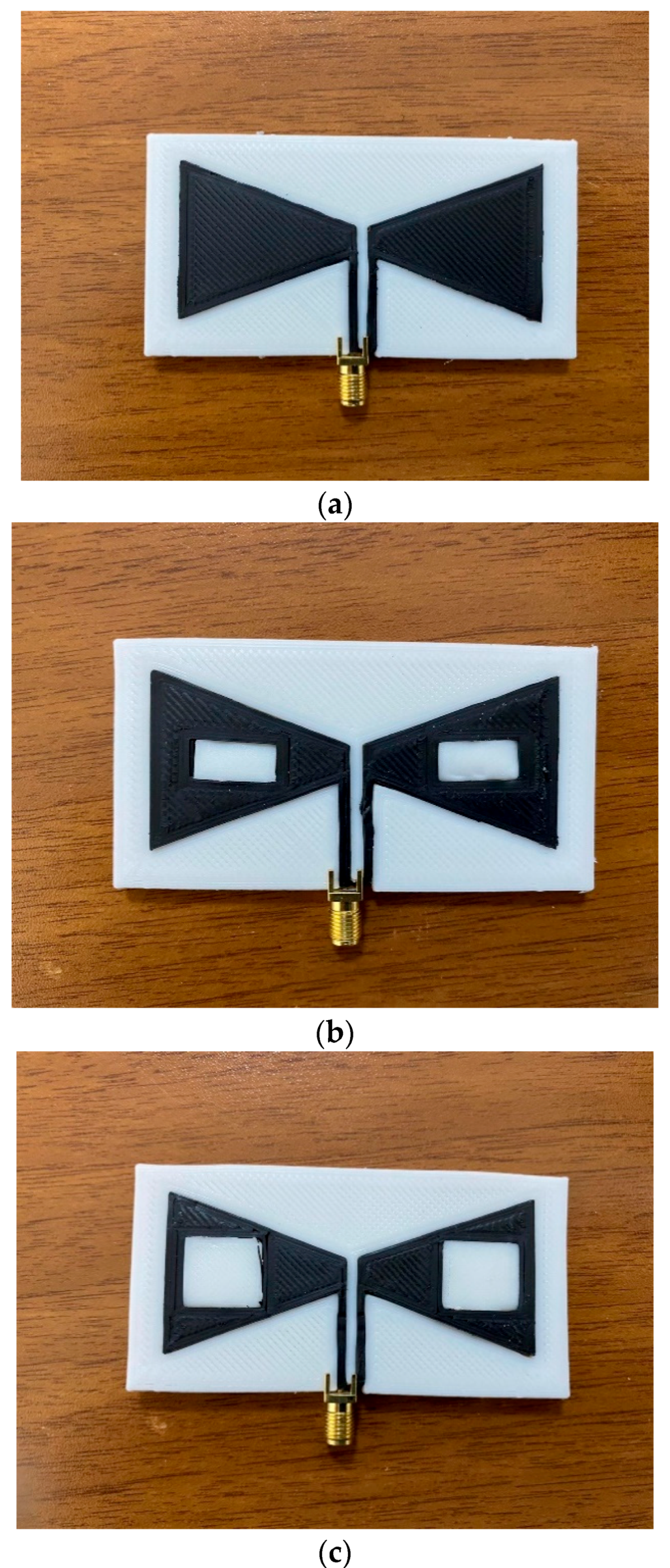

2.2. Design and Production of the Bow-Tie Microstrip Antenna

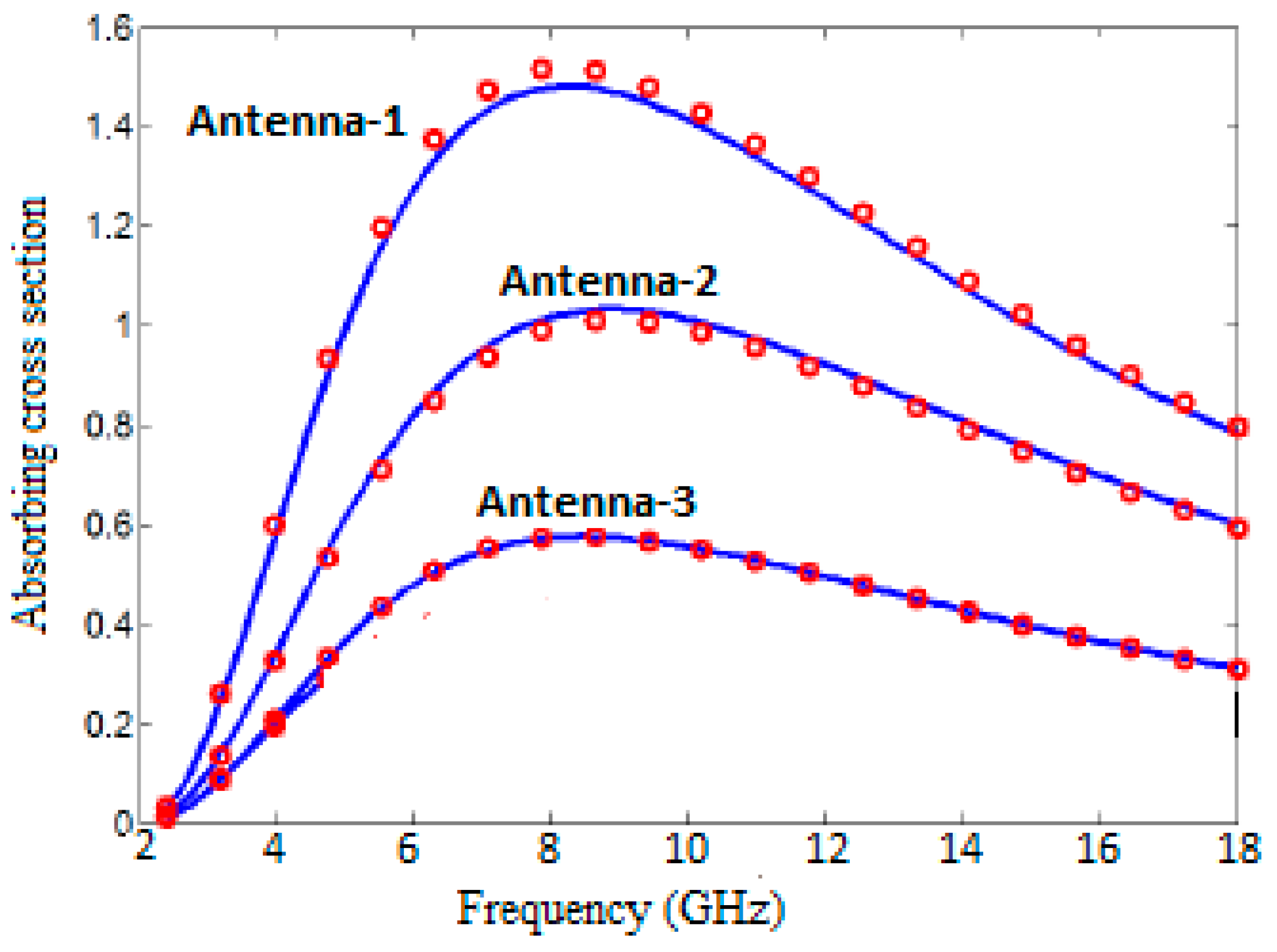

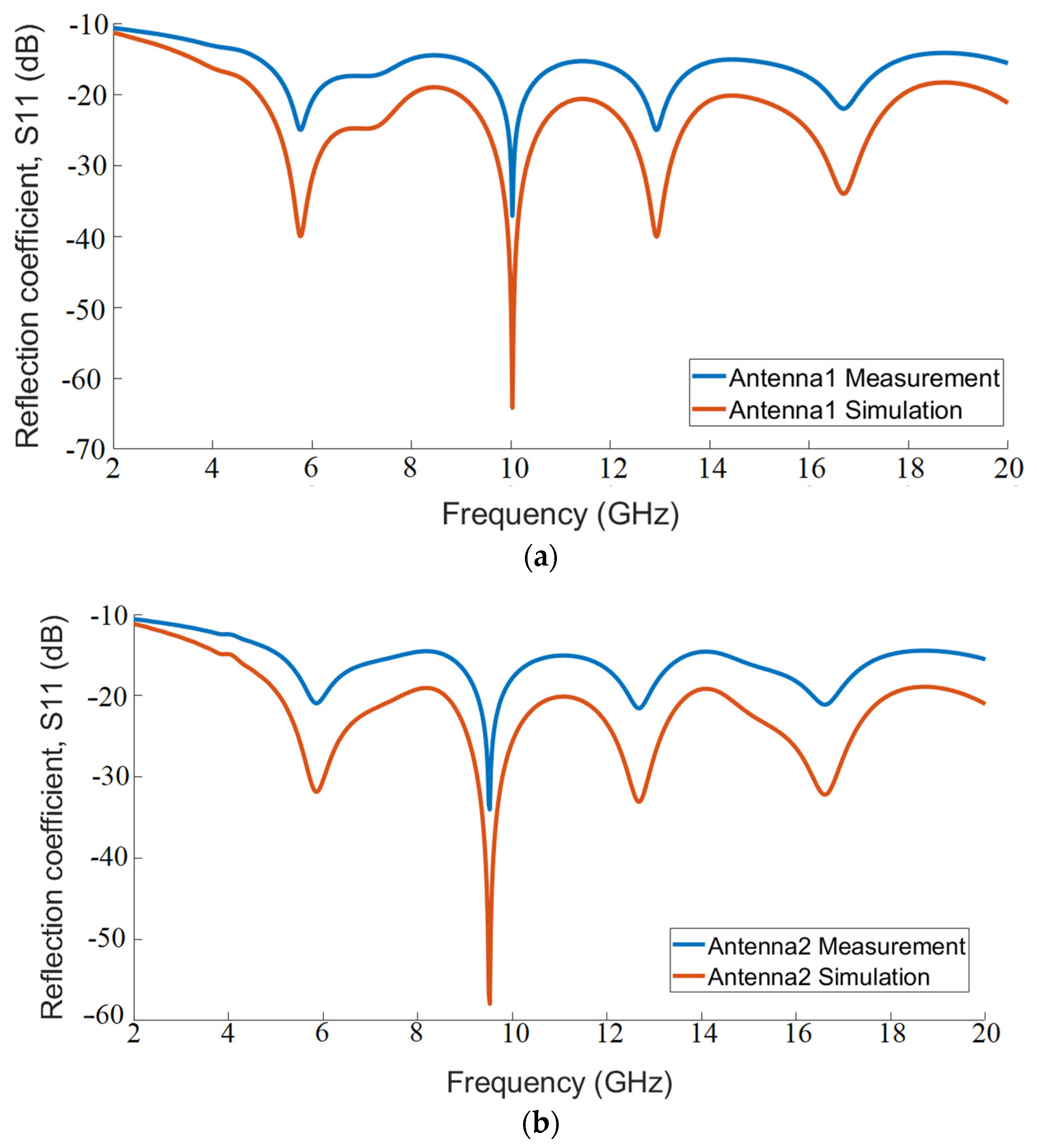

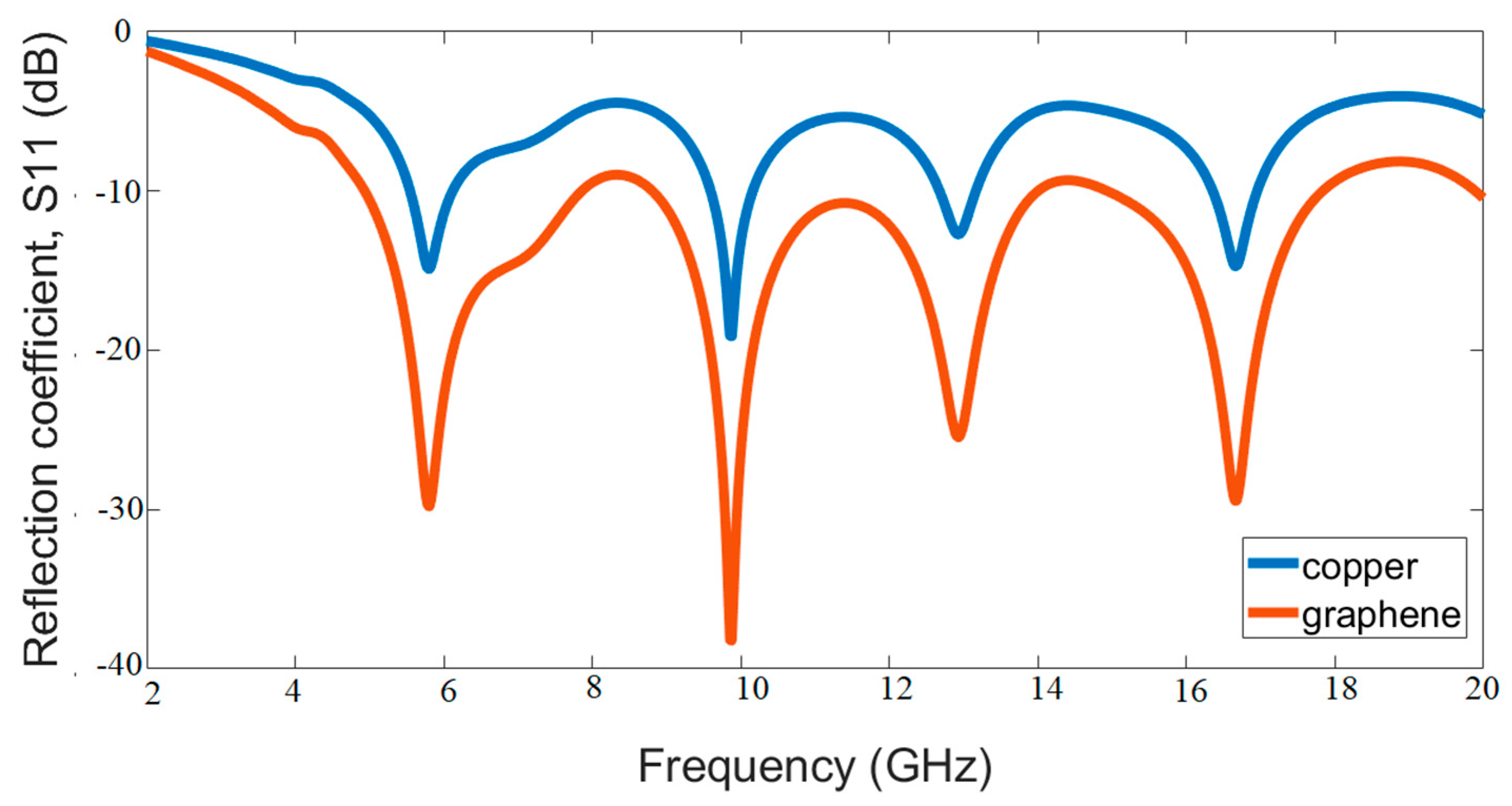

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Pozar, D.M. Microstrip antennas. Proc. IEEE 2017, 80, 79–91. [Google Scholar] [CrossRef]

- Balanis, C.A. Antenna Theory: Analysis and Design, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Yang, Z.; Browning, K.C.; Warnick, K.F. High-Efficiency Stacked Shorted Annular Patch Antenna Feed for Ku-Band Satellite Communications. IEEE Trans. Antennas Propag. 2016, 64, 2568–2572. [Google Scholar] [CrossRef]

- Chang, E.; Long, S.; Richards, W. An experimental investigation of electrically thick rectangular microstrip antennas. IRE Trans. Antennas Propag. 1986, 34, 767–772. [Google Scholar] [CrossRef]

- Hall, P. Probe compensation in thick microstrip patches. Electron. Lett. 1987, 23, 606–607. [Google Scholar] [CrossRef]

- Kovitz, J.M.; Rahmat-Samii, Y. Using Thick Substrates and Capacitive Probe Compensation to Enhance the Bandwidth of Traditional CP Patch Antennas. IEEE Trans. Antennas Propag. 2014, 62, 4970–4979. [Google Scholar] [CrossRef]

- Nasimuddin, K.P.E.; Verma, A.K. Wideband circularly polarized stacked microstrip antennas. IEEE Antennas Wirel. Propag Lett. 2007, 6, 21–24. [Google Scholar] [CrossRef]

- Liu, N.-W.; Zhu, L.; Choi, W.-W.; Zhang, X. A Low-Profile Aperture-Coupled Microstrip Antenna with Enhanced Bandwidth under Dual Resonance. IEEE Trans. Antennas Propag. 2017, 65, 1055–1062. [Google Scholar] [CrossRef]

- Pues, H.F.; de Capelle, A.R. Van An impedance-matching technique for increasing the bandwidth of microstrip antennas. IEEE Trans. Antennas Propag. 1989, 37, 1345–1354. [Google Scholar] [CrossRef]

- Motevasselian, A.; Whittow, W.G. Miniaturization of a circular patch microstrip antenna using an arc projection. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 517–520. [Google Scholar] [CrossRef]

- Pinhas, S.; Shtrikman, S. Comparison between computed and measured bandwidth of quarter-wave microstrip radiators. IEEE Trans. Antennas Propag. 1988, 36, 1615–1616. [Google Scholar] [CrossRef]

- Waterhouse, R. Small microstrip patch antenna. Electron. Lett. 1995, 31, 604–605. [Google Scholar] [CrossRef]

- Wong, H.; Lau, P.-Y.; Mak, K.-M.; Luk, K.-M. Small circularly polarised folded patch antenna. Electron. Lett. 2005, 41, 1363–1365. [Google Scholar] [CrossRef]

- Lee, B.; Harackiewicz, F. Miniature microstrip antenna with a partially filled high-permittivity substrate. IEEE Trans. Antennas Propag. 2002, 50, 1160–1162. [Google Scholar] [CrossRef]

- Lee, K.; Guo, Y.; Hawkins, J.; Chair, R.; Luk, K. Theory and experiment on microstrip patch antennas with shorting walls. IEE Proc.-Microw. Antennas Propag. 2000, 147, 521–525. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Mishra, A.K.; Khanra, P.; Kim, N.H.; Lee, J.H. Chemical functionalization of graphene and its applications. Prog. Mater. Sci. 2012, 57, 1061–1105. [Google Scholar] [CrossRef]

- Avouris, P.; Dimitrakopoulos, C. Graphene: Synthesis and applications. Mater. Today 2012, 15, 86–97. [Google Scholar] [CrossRef]

- Hussain, A.; Mehdi, S.M.; Abbas, N.; Hussain, M.; Naqvi, R.A. Synthesis of graphene from solid carbon sources: A focused review. Mater. Chem. Phys. 2020, 248, 122924. [Google Scholar] [CrossRef]

- Jang, S.; Hwang, E.; Lee, J.H.; Park, H.S.; Cho, J.H. Graphene-Graphene Oxide Floating Gate Transistor Memory. Small 2015, 11, 311–318. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Liu, P.; Yu, D.; Li, G.; Tao, F. Dual-Band Reconfigurable Terahertz Patch Antenna with Graphene-Stack-Based Backing Cavity. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1541–1544. [Google Scholar] [CrossRef]

- Cai, Y.; Guo, Y.J.; Qin, P.; Weily, A.R. Frequency reconfigurable quasi-Yagi dipole antenna. IEEE Antennas Wirel. Propag. Lett. 2010, 9, 883–886. [Google Scholar] [CrossRef]

- Piazza, D.; Mookiah, P.; Michele, D.; Dandekar, K.R. Pattern and polarization reconfigurable circular patch for MIMO systems. In Proceedings of the 2009 3rd European Conference on Antennas and Propagation, Berlin, Germany, 23–27 March 2009; pp. 1047–1051. [Google Scholar]

- Li, F.; Chen, H.; Zhou, Y.; You, J.; Panoiu, N.C.; Zhou, P.; Deng, L. Generation and Focusing of Orbital Angular Momentum Based on Polarized Reflectarray at Microwave Frequency. IEEE Trans. Microw. Theory Tech. 2021, 69, 1829–1837. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, L.-S.; Tang, M.; Mao, J. Design of a Beam Reconfigurable THz Antenna with Graphene-Based Switchable High-Impedance Surface. IEEE Trans. Nanotechnol. 2012, 11, 836–842. [Google Scholar] [CrossRef]

- Falkovsky, L.A. Optical properties of graphene. J. Phys. Conf. Ser. 2008, 129, 012004. [Google Scholar] [CrossRef]

- Loh, K.; Bao, Q.; Eda, G.; Chhowalla, M. Graphene oxide as a chemically tunable platform for optical applications. Nat. Chem. 2010, 2, 1015–1024. [Google Scholar] [CrossRef] [PubMed]

- Castro Neto, A.H.; Guinea, F.; Peres, N.M.R.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109–162. [Google Scholar] [CrossRef]

- Ajlani, H.; Azizi, M.K.; Gharsallah, A.; Oueslati, M. Graphene-GaAs-graphene stacked layers for the improvement of the transmission at the wavelength of 1.55 μm. Opt. Mater. 2016, 57, 120–124. [Google Scholar] [CrossRef]

- Ajlani, H.; Azizi, M.K.; Gharsallah, A.; Meftah, A.; Oueslati, M. Graphene-based reconfigurable transmission filter near the wavelength of 1.55 μm. Opt. Mater. 2017, 66, 201–206. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, G.; Zhang, B.; He, T.; He, Y.; Shen, J. Photo-excited broadband tunable terahertz metamaterial absorber. Opt. Mater. 2016, 54, 32–36. [Google Scholar] [CrossRef]

- Seyedsharbaty, M.M.; Sadeghzadeh, R.A. Antenna gain enhancement by using metamaterial radome at THz band with reconfigurable characteristics based on graphene load. Opt. Quantum Electron. 2017, 49, 221. [Google Scholar] [CrossRef]

- Zarrabi, F.B.; Seyedsharbaty, M.M.; Ahmed, Z.; Arezoomand, A.S.; Heydari, S. Wide band yagi antenna for terahertz application with graphene control. Optik 2017, 140, 866–872. [Google Scholar] [CrossRef]

- Inum, R.; Rana, M.; Shushama, K.N. Development of Graphene Based Tapered Slot Antennas for Ultra-Wıdeband Applıcatıons. Prog. Electromagn. Res. C 2017, 79, 241–255. [Google Scholar] [CrossRef]

- Gatte, M.T.; Soh, P.J.; Rahim, H.A.; Ahmad, R.; Malek, F. The Performance Improvement of Thz Antenna Vıa Modelıng and Characterızatıon of Doped Graphene. Prog. Electromagn. Res. M 2016, 49, 21–31. [Google Scholar] [CrossRef]

- Ben Krid, H.; Houaneb, Z.; Zairi, H. Reconfıgurable Graphene Annular Rıng Antenna for Medıcal and Imagıng Applıcatıons. Prog. Electromagn. Res. M 2020, 89, 53–62. [Google Scholar] [CrossRef]

- Prasanna, R.; Banu, N.M. Effect of Copper and Graphene Material on Bow-tie Structured Antenna for 1.2 GHz Application. Radioelectron. Commun. Syst. 2019, 62, 189–194. [Google Scholar] [CrossRef]

- Hu, J.; Hao, Z.-C.; Hong, W. Design of a Wideband Quad-Polarization Reconfigurable Patch Antenna Array Using a Stacked Structure. IEEE Trans. Antennas Propag. 2017, 65, 3014–3023. [Google Scholar] [CrossRef]

- Wi, S.-H.; Lee, Y.-S.; Yook, J.-G. Wideband Microstrip Patch Antenna with U-Shaped Parasitic Elements. IEEE Trans. Antennas Propag. 2007, 55, 1196–1199. [Google Scholar] [CrossRef]

- Yoshida, S.; Gupta, K.C.; Benalla, A.; House, A.; Talty, T.; Lee, K.F.; Aikawa, M.; Egashira, S.; Nishiyama, E.; Sipus, Z.; et al. A Wideband L-Probes Fed Circularly-Polarized Reconfigurable Microstrip Patch Antenna. IEEE Trans. Antennas Propag. 2008, 56, 581–584. [Google Scholar]

- Antenna, P.M. A Broadband Impedance Matching Method for proximity-coupled microstrip antenna. IEEE Trans. Antennas Propag. 2010, 58, 1392–1397. [Google Scholar]

- Bilal, R.M.H.; Rahim, A.A.; Maab, H.; Ali, M.M. Modified Wang Shaped Ultra-Wideband (UWB) Fractal Patch Antenna for Millimetre-Wave Applications. In Proceedings of the 2018 Progress in Electromagnetics Research Symposium (PIERS-Toyama), Toyama, Japan, 1–4 August 2018. [Google Scholar] [CrossRef]

- Bilal, R.M.H.; Saeed, M.A.; Choudhury, P.K.; Baqir, M.A.; Kamal, W.; Ali, M.M.; Rahim, A.A. Elliptical metallic rings-shaped fractal metamaterial absorber in the visible regime. Sci. Rep. 2020, 10, 14035. [Google Scholar] [CrossRef]

- Auyeung, R.C.Y.; Nurnberger, M.W.; Wendland, D.J.; Pique, A.; Arnold, C.; Abbott, A.R.; Schuette, L.C. Laser fabrication of GPS conformal antennas. Lasers Appl. Sci. Eng. 2004, 5339, 292–297. [Google Scholar] [CrossRef]

- Conneely, A.J.; O’Connor, G.M.; John, M.; Ammann, M.J.; Molloy, D.; Lotya, M.; Finn, D. Laser micromachining of contactless RF antenna modules for payment cards and wearable objects. Int. Congr. Appl. Lasers Electro-Opt. 2016, 2016, M501. [Google Scholar] [CrossRef]

- Kumar, A. Challenges and Issues in the Design of Micro-machined Antennas—A Review. Recent Adv. Electr. Electron. Eng. Formerly Recent Patents Electr. Electron. Eng. 2021, 14, 75–89. [Google Scholar] [CrossRef]

- Bhattacharyya, B.; Doloi, B. Modern Machining Technology: Advanced, Hybrid, Micro Machining and Super Finishing Technology, 1st ed.; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Nayeri, P.; Liang, M.; Austreberto Sabory-Garcı´a, R.; Tuo, M.; Yang, F.; Gehm, M.; Xin, H.; Elsherbeni, A.Z. 3D printed dielectric reflectarrays: Low-cost high-gain antennas at sub-millimeterwaves. IEEE Trans. Antennas Propag. 2014, 62, 2000–2008. [Google Scholar] [CrossRef]

- Wu, Z.; Liang, M.; Ng, W.R.; Gehm, M.; Xin, H. Terahertz horn antenna based on hollow-core electromagnetic crystal (EMXT) structure. IEEE Trans. Antennas Propag. 2012, 60, 5557–5563. [Google Scholar] [CrossRef]

- Yi, H.; Qu, S.W.; Ng, K.B.; Chan, C.H.; Bai, X. 3-D printed millimeterwave and terahertz lenses with fixed and frequency scanned beam. IEEE Trans. Antennas Propag. 2016, 64, 442–449. [Google Scholar] [CrossRef]

- Zhang, B.; Zhan, Z.; Cao, Y.; Gulan, H.; Linner, P.; Sun, J.; Zwick, T.; Zirath, H. Metallic 3-D printed antennas for millimeter- and submillimeter wave applications. IEEE Trans. Terahertz Sci. Technol. 2016, 6, 592–600. [Google Scholar] [CrossRef]

- Huang, G.-L.; Zhou, S.-G.; Chio, T.-H.; Yeo, T.S. Fabrication of a High-Efficiency Waveguide Antenna Array via Direct Metal Laser Sintering. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 622–625. [Google Scholar] [CrossRef]

- Huang, G.-L.; Zhou, S.-G.; Chio, T.-H. Highly-Efficient Self-Compact Monopulse Antenna System with Integrated Comparator Network for RF Industrial Applications. IEEE Trans. Ind. Electron. 2016, 64, 674–681. [Google Scholar] [CrossRef]

- Zhu, Y.-J.; Li, J.; Zhang, X.; Yuan, T.; Zhong, Z.-P.; Tan, T.-Y.; Bi, X.-K. A 3-D Printed Spherical Antenna with Bandwidth Enhancement under Operation of Dual Resonance. IEEE Access 2020, 8, 19345–19352. [Google Scholar] [CrossRef]

- Wahyudi, A.H.; Sumantyo, J.T.S.; Wijaya, S.; Munir, A. PLA-based 3D printed circularly polarized X-band horn array antenna for CP-SAR sensor. In Proceedings of the 2018 International Workshop on Antenna Technology (iWAT), Nanjing, China, 5–7 March 2018; pp. 1–4. [Google Scholar]

- Muntoni, G.; Montisci, G.; Casula, G.A.; Chietera, F.P.; Michel, A.; Colella, R.; Catarinucci, L.; Mazzarella, G. A Curved 3-D Printed Microstrip Patch Antenna Layout for Bandwidth Enhancement and Size Reduction. IEEE Antennas Wirel. Propag. Lett. 2020, 19, 1118–1122. [Google Scholar] [CrossRef]

- Lomakin, K.; Sippel, M.; Ullmann, I.; Helmreich, K.; Gold, G. 3D Printed Helix Antenna for 77 GHz. In Proceedings of the 2020 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020. [Google Scholar]

- Sarjoghian, S.; Alfadhl, Y.; Chen, X.; Parini, C.G. A 3-D-Printed High-Dielectric Materials-Filled Pyramidal Double-Ridged Horn Antenna for Abdominal Fat Measurement System. IEEE Trans. Antennas Propag. 2021, 69, 64–73. [Google Scholar] [CrossRef]

- Raniszewski, A.; Slojewska, B.; Piasecki, P.; Strycharz, J. Miniaturized 3D-printed Antenna Realizations for Cylindrical Surface Mounting. In Proceedings of the 2020 23rd International Microwave and Radar Conference (MIKON), Warsaw, Poland, 5–7 October 2020. [Google Scholar]

- Njogu, P.; Sanz-Izquierdo, B.; Elibiary, A.; Jun, S.Y.; Chen, Z.; Bird, D. 3D Printed Fingernail Antennas for 5G Applications. IEEE Access 2020, 8, 228711–228719. [Google Scholar] [CrossRef]

- Mitra, D.; Striker, R.; Cleveland, J.; Braaten, B.D.; Kabir, K.S.; Aqueeb, A.; Burczek, E.; Roy, S.; Ye, S. A 3D Printed Microstrip Patch Antenna using Electrifi Filament for In-Space Manufacturing. In Proceedings of the 2021 United States National Committee of URSI National Radio Science Meeting (USNC-URSI NRSM), Boulder, CO, USA, 4–9 January 2021. [Google Scholar]

- Belen, A.; Güneş, F.; Mahouti, P.; Palandöken, M. A novel design of high performance multilayered cylindrical dielectric lens antenna using 3D printing technology. Int. J. RF Microw. Comput.-Aided Eng. 2020, 30, e21988. [Google Scholar] [CrossRef]

- Chen, W.L.; Wang, G.M.; Zhang, C.X. Bandwidth enhancement of a microstrip-line-fed printed wide-slot antenna with a fractal-shaped slot. IEEE Trans. Antennas Propag. 2009, 57, 2176–2179. [Google Scholar] [CrossRef]

- See, C.H.; Abd-Alhameed, R.A.; Zhou, D.; Lee, T.H.; Excell, P.S.A. Crescent-Shaped Multiband Planar Monopole Antenna for MobileWireless Applications. IEEE Antennas Wirel. Propag. Lett. 2010, 9, 152–155. [Google Scholar] [CrossRef]

- Eskandari, H.; Booket, M.R.; Kamyab, M.; Veysi, M. Investigations on a Class of Wideband Printed Slot Antenna. IEEE Antennas Wirel. Propag. Lett. 2010, 9, 1221–1224. [Google Scholar] [CrossRef]

- Gosalvitr, J.; Mahatthanajatuphat, C.; Akkaraekthalin, P.; Chaimool, S. CPW-fed slot antenna with fractal tuning stub for wideband circular polarization. In Proceedings of the 8th Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI) Association of Thailand—Conference 2011, Khon Kaen, Thailand, 17–19 May 2011; pp. 212–215. [Google Scholar]

- Song, K.; Yin, Y.-Z.; Chen, B.; Fan, S.-T.; Gao, F. Bandwıdth Enhancement Desıgn of Compact Uwb Step-Slot Antenna Wıth Rotated Patch. Prog. Electromagn. Res. Lett. 2011, 22, 39–45. [Google Scholar] [CrossRef]

- Tze-Hsuan, C.; Jean-Fu, K. Compact Multi-Band H-Shaped Slot Antenna. IEEE Trans. Antennas Propag. 2013, 61, 4345–4349. [Google Scholar]

- Dayo, Z.A.; Cao, Q.; Soothar, P.; Lodro, M.M.; Li, Y. A compact coplanar waveguide feed bow-tie slot antenna for WIMAX, C and X band applications. In Proceedings of the 2019 IEEE International Conference on Computational Electromagnetics (ICCEM), Shanghai, China, 20–22 March 2019; pp. 1–3. [Google Scholar]

- Awl, H.N.; Abdulkarim, Y.I.; Deng, L.; Bakır, M. Bandwidth improvement in bow-tie microstrip antennas: The effect of substrate type and design dimensions. Appl. Sci. 2020, 10, 504. [Google Scholar] [CrossRef]

- Nguyen, C.; Technologies, A.; Schneider, M.V.; Chew, W.C.; Liu, Q.H.; Richards, W.F.; Lo, Y.T.; Harrison, D.D.; Ray, S.; Kumar, G.; et al. A Compact Dual-Polarızed Cavıty-Backed Annular Slot. Wiley Microw. Opt. Technol. Lett. 2015, 57, 384–388. [Google Scholar] [CrossRef]

- Dastranj, A. Very small planar broadband monopole antenna with hybrid trapezoidal–elliptical radiator. IET Microw. Antennas Propag. 2017, 11, 542–547. [Google Scholar] [CrossRef]

- Ju, J.; Jin, L.; Jin, W.; Wang, S.J.; Jia, P.G.; Huang, J.; Lan, X.W.; Wang, H.Z.; Jiang, L.; Xiao, H.; et al. A Novel Compact Uwb Monopole Antenna Wıth Enhanced Bandwıdth Usıng Trıangular Defected Mıcrostrıp Structure and Stepped Cut Technıque. Wiley Microw. Opt. Technol. Lett. 2016, 58, 1561–1563. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, Y.; Zhang, W.; Wang, G. A Broadband Crossed-Slot Cırcularly Polarızed Antenna Wıth Stable Phase Center for Gnss Applıcatıons. Prog. Electromagn. Res. C 2018, 86, 55–67. [Google Scholar] [CrossRef]

- Hu, H.-T.; Chen, F.-C.; Chu, Q.-X. A Wideband U-Shaped Slot Antenna and Its Application in MIMO Terminals. IEEE Antennas Wirel. Propag. Lett. 2015, 15, 508–511. [Google Scholar] [CrossRef]

- Jan, J.; Su, J. Bandwidth Enhancement of a Printed Wide-Slot Antenna with a Rotated Slot. IEEE Trans. Antennas Propag. 2005, 53, 2111–2114. [Google Scholar] [CrossRef]

- Kumar, B.; Shukla, B.K.; Somkuwar, A.; Raghuvanshi, D.K. A Study of Hybrıd Wıde Slot Antenna Wıth Hybrıd Parasıtıc Element for Wıdeband Applıcatıons. Prog. Electromagn. Res. C 2019, 89, 27–38. [Google Scholar] [CrossRef]

- Yilmaz, T.; Foster, R.; Hao, Y. Broadband Tissue Mimicking Phantoms and a Patch Resonator for Evaluating Noninvasive Monitoring of Blood Glucose Levels. IEEE Trans. Antennas Propag. 2014, 62, 3064–3075. [Google Scholar] [CrossRef]

- Asif, S.M.; Iftikhar, A.; Braaten, B.D.; Khan, M.S. Design of an ultra-wideband antenna using flexible graphene-based conductor sheets. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, PR, USA, June 2016–July 2016; pp. 1863–1864. [Google Scholar]

- Aziz, A.A.A.; Abdel-Motagaly, A.T.; Ibrahim, A.A.; El Rouby, W.M.; Abdalla, M. A printed expanded graphite paper based dual band antenna for conformal wireless applications. AEU-Int. J. Electron. Commun. 2019, 110, 152869. [Google Scholar] [CrossRef]

- Sa’Don, S.; Jamaluddin, M.; Kamarudin, M.; Ahmad, F.; Yamada, Y.; Kamardin, K.; Idris, I.; Seman, N. Characterisation of tunable graphene antenna. AEU-Int. J. Electron. Commun. 2020, 118, 153170. [Google Scholar] [CrossRef]

- Singh, N.; Kumar, S.; Kanaujia, B.K.; Beg, M.T.; Kumar, S. A compact and efficient graphene FET based RF energy harvester for green communication. AEU-Int. J. Electron. Commun. 2020, 115, 153059. [Google Scholar] [CrossRef]

- Dash, S.K.K.; Cheng, Q.S.; Barik, R.K.; Khan, T.; Subramanian, K.S. A compact dual-fed highly isolated SIW based self-diplexing antenna. AEU-Int. J. Electron. Commun. 2021, 132, 153613. [Google Scholar] [CrossRef]

- Satitchantrakul, T.; Silapunt, R.; Sirivisoot, S. Meander implantable antenna for biomedical wireless communication. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, PR, USA, 26 June–1 July 2016; pp. 1173–1174. [Google Scholar]

- Yasir, M.; Savi, P.; Bistarelli, S.; Cataldo, A.; Bozzi, M.; Perregrini, L.; Bellucci, S. A Planar Antenna with Voltage-Controlled Frequency Tuning Based on Few-Layer Graphene. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 2380–2383. [Google Scholar] [CrossRef]

- Kirtania, S.G.; Elger, A.W.; Hasan, R.; Wisniewska, A.; Sekhar, K.; Karacolak, T.; Sekhar, P.K. Flexible Antennas: A Review. Micromachines 2020, 11, 847. [Google Scholar] [CrossRef]

- Fang, R.; Song, R.; Zhao, X.; Wang, Z.; Qian, W.; He, D. Compact and Low-Profile UWB Antenna Based on Graphene-Assembled Films for Wearable Applications. Sensors 2020, 20, 2552. [Google Scholar] [CrossRef]

- Products & Services|eSUN 3D Printing Materials. Available online: https://www.esun3d.net/products/ (accessed on 20 October 2021).

- Black Magic 3D Conductive Graphene Composite 1.75 mm—3D Compare Materials. Available online: https://3dcompare.com/materials/product/black-magic-3d-conductive-graphene-composite-1-75-mm/ (accessed on 20 October 2021).

- Supermarket, G. Conductive, Graphene, PLA, Flament. Available online: https://graphene-supermarket.com/Conductive-Graphene-PLA-Filament.html (accessed on 2 March 2021).

- Sheet Resistance and the Calculation of Resistivity or Thickness Relative to Semiconductor Applications. Available online: http://four-point-probes.com/sheet-resistance-and-the-calculation-of-resistivity-or-thickness-relative-to-semiconductor-applications/ (accessed on 20 July 2021).

- Understanding Volume Resistivity Measurements. Available online: http://four-point-probes.com/understanding-volume-resistivity-measurements/ (accessed on 20 July 2021).

- Volume Resistivity, vs. Volume Conductivity vs. Surface Resistivity|CAPLINQ BLOG. Available online: https://www.caplinq.com/blog/linqstat-volume-resistivity-vs-volume-conductivity-vs-surface-resistivity_267/ (accessed on 20 July 2021).

- Balanis, C.A. Antenna Theory: Analysis and Design, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Zarei, M.; Nazari, F.; Moravvej-Farshi, M.K. Tunable optical isolator using Graphene-photonic crystal-based hybrid system. Phys. Scr. 2021, 96, 095502. [Google Scholar] [CrossRef]

- Bagheri, A.; Nazari, F.; Moravvej-Farshi, M.K. Tunable Optical Demultiplexer for Dense Wavelength Division Multiplexing Systems Using Graphene–Silicon Microring Resonators. J. Electron. Mater. 2020, 49, 7410–7419. [Google Scholar] [CrossRef]

- Nazari, F.; Izadi, M. Tunable Autler–Townes splitting using graphene-based electro-optic effect. Phys. Lett. A 2018, 382, 1829–1834. [Google Scholar] [CrossRef]

- Nazari, F.; Izadi, M. Control of slow/fast light frequency via tunable EIT window. J. Opt. 2019, 21, 115801. [Google Scholar] [CrossRef]

- Azim, R.; Islam, M.T.; Misran, N. Compact Tapered-Shape Slot Antenna forUWBApplications. IEEE Antennas Wirel Propag. Lett. 2011, 10, 1190–1193. [Google Scholar] [CrossRef]

- Kim, S.-W.; Choi, D.-Y. Implementation of rectangular slit-inserted ultra-wideband tapered slot antenna. SpringerPlus 2016, 5, 1387. [Google Scholar] [CrossRef]

- Jiang, Y.; Yuan, R.; Gao, X.; Wang, J.; Li, S.; Lin, Y.-Y. An ultra-wideband pattern reconfigurable antenna based on graphene coating. Chin. Phys. B 2016, 25, 118402. [Google Scholar] [CrossRef]

- Azizi, M.K.; Ksiksi, M.A.; Ajlani, H.; Gharsallah, A.A. Terahertz Graphene-Based Reconfıgurable Patch Antenna. Prog. Electromagn. Res. Lett. 2017, 71, 69–76. [Google Scholar] [CrossRef]

- Scidà, A.; Haque, S.; Treossi, E.; Robinson, A.; Smerzi, S.; Ravesi, S.; Borini, S.; Palermo, V. Application of graphene-based flexible antennas in consumer electronic devices. Mater. Today 2018, 21, 223–230. [Google Scholar] [CrossRef]

- Dwivedi, R.P.; Kommuri, U.K. Compact high gain UWB antenna using fractal geometry and UWB-AMC. Microw. Opt. Technol. Lett. 2019, 61, 787–793. [Google Scholar] [CrossRef]

- Jilani, S.F.; Greinke, B.; Hao, Y.; Alomainy, A. Flexible millimetre-wave frequency reconfigurable antenna for wearable applications in 5G networks. In Proceedings of the 2016 URSI International Symposium on Electromagnetic Theory (EMTS), Espoo, Finland, 14–18 August 2016; pp. 846–848. [Google Scholar] [CrossRef]

- Liu, H.; Sun, S.; Wu, L.; Bai, P. Optical Near-Field Enhancement with Graphene Bowtie Antennas. Plasmonics 2014, 9, 845–850. [Google Scholar] [CrossRef]

- Lin, Y.-M.; Jenkins, K.A.; Valdes-Garcia, A.; Small, J.P.; Farmer, D.B.; Avouris, P. Operation of Graphene Transistors at Gigahertz Frequencies. Nano Lett. 2009, 9, 422–426. [Google Scholar] [CrossRef]

- Gusynin, V.P.; Sharapov, S.; Carbotte, J.P. Magneto-optical conductivity in graphene. J. Physics Condens. Matter 2006, 19. [Google Scholar] [CrossRef]

- Hanson, G.W. Dyadic Green’s Functions for an Anisotropic, Non-Local Model of Biased Graphene. IEEE Trans. Antennas Propag. 2008, 56, 747–757. [Google Scholar] [CrossRef]

- Gόmez-Dίaz, J.S.; Perruisseau-Carrier, J.; Sharma, P.; Ionescu, A. Non-contact characterization of graphene surface impedance at micro and millimeter waves. J. Appl. Phys. 2012, 111, 114908. [Google Scholar] [CrossRef]

- Perruisseau-Carrier, J.; Tamagnone, M.; Gomez-Diaz, J.S.; Carrasco, E. Graphene antennas: Can integration and reconfigurability compensate for the loss? In Proceedings of the 2013 European Microwave Conference, Nuremberg, Germany, 6–10 October 2013; pp. 369–372. [Google Scholar]

| Physical Performance Properties | Print Performance Properties | ||

|---|---|---|---|

| Parameters | PLA+ | Parameters | PLA+ |

| Appearance | white | Surface finish | No obvious layering |

| Tensile strength | 63 Mpa | Hole column fitting model | 0.3 mm |

| Elongation at break | 20% | Hanging model | <60° |

| Bending strength | 74 Mpa | Suspension bridge | 50 mm |

| Flexural modulus | 1934 Mpa | - | - |

| Notch impact | 9 | - | - |

| Properties | |

|---|---|

| Brand | Black Magic 3D |

| Weight | 0.1 |

| Volume resistivity | 0.6 ohm-cm |

| Color | Black |

| Diameter | 1.75 mm |

| Size | 100 g |

| Min/max printing temperature | 220 °C |

| Country | United States |

| Parameters | Dimensions Antenna-2 | Dimensions Antenna-3 |

|---|---|---|

| Patch length PL | 36 mm | 36 mm |

| Base length BL | 32 mm | 32 mm |

| Gap | 4 mm | 4 mm |

| Feedline width | 0.6 mm | 0.6 mm |

| Apex length AL | 5.4 mm | 5.4 mm |

| Substrate length L | 44 mm | 44 mm |

| Substrate width W | 88 mm | 88 mm |

| Aperture length for patch X | 8 mm | 14 mm |

| Aperture width for patch Y | 16 mm | 16 mm |

| Performance Parameters | Designed Bow-Tie Antennas | Conventional Antennas | Graphene-Based Antennas | ||||

|---|---|---|---|---|---|---|---|

| Ant.1 | Ant.2 | Ant.3 | [98] | [99] | [78] | [100] | |

| Return Loss (dB) | −38.85 | −34.28 | −29.95 | −32.50 | −64.00 | −25.23 | −39.92 |

| VSWR | 1.06 | 1.13 | 1.00 | 1.06 | 1.04 | NR | NR |

| Peak Gain (dBi) | 9.10 | 8.70 | 8.90 | 5.4 | 7.55 | 4.83 | NR |

| BandWidth (GHz) | 18 | 18 | 18 | 8.2 | 8.45 | 7.35 | 4.0 |

| Reference No. | Antenna Type | Dimensions mm3 and Applications | Substrate, Conductive Element | Bandwidth (FBW%) | Resonant Frequency | Antenna Gain and Efficiency |

|---|---|---|---|---|---|---|

| [102] | Elliptical quasi-dipole antenna | 46 × 45 mm2, 2 up to 5 GHz for low-cost wireless communications applications. | Kapton Polyimide, graphene flakes | 1–5 GHz | 2 GHz | 2.3 dBi at 4.8 GHz, 56 ± 5% |

| [103] | CPW-fed H-shaped slot antenna | 32 × 52 × 0.28, UWB antenna for wearable applications | Flexible ceramic substrate, graphene assembled film (GAF) | 4.1–8.0 GHz | 4.45, 5.6, and 7.1 GHz | 3.9 dBi at 7.45 GHz |

| [104] | CPW-fed rectangular slot with chamfer | 11.8 × 12.2 × 0.1, Mobile terminal for fifth generation (5G) | Kapton polyimide, Graphene ink | 14.30–15.71 GHz | 13.8 GHz | 9.28 dBi, 67.44% |

| [105] | Bow-tie antenna | Optical near-field enhancement | Glass graphene | 14.3–35.3 THz | - | - |

| This study | Bow-tie antenna | 44 × 88 (outer size), ultra-wideband applications for especially medical applications | PLA, graphene filament | 2–20 GHz | Antenna-1 10.01 GHz, Antenna-2 9.6 GHz, Antenna-3 9.8 GHz | Antenna-1 9.10 dBi, Antenna-2 8.70 dBi, Antenna-3 8.90 dBi |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avşar Aydın, E. 3D-Printed Graphene-Based Bow-Tie Microstrip Antenna Design and Analysis for Ultra-Wideband Applications. Polymers 2021, 13, 3724. https://doi.org/10.3390/polym13213724

Avşar Aydın E. 3D-Printed Graphene-Based Bow-Tie Microstrip Antenna Design and Analysis for Ultra-Wideband Applications. Polymers. 2021; 13(21):3724. https://doi.org/10.3390/polym13213724

Chicago/Turabian StyleAvşar Aydın, Emine. 2021. "3D-Printed Graphene-Based Bow-Tie Microstrip Antenna Design and Analysis for Ultra-Wideband Applications" Polymers 13, no. 21: 3724. https://doi.org/10.3390/polym13213724

APA StyleAvşar Aydın, E. (2021). 3D-Printed Graphene-Based Bow-Tie Microstrip Antenna Design and Analysis for Ultra-Wideband Applications. Polymers, 13(21), 3724. https://doi.org/10.3390/polym13213724