Evaluation of Mechanical and Tribological Properties of Corn Cob-Reinforced Epoxy-Based Composites—Theoretical and Experimental Study

Abstract

:1. Introduction

2. Materials and Methods

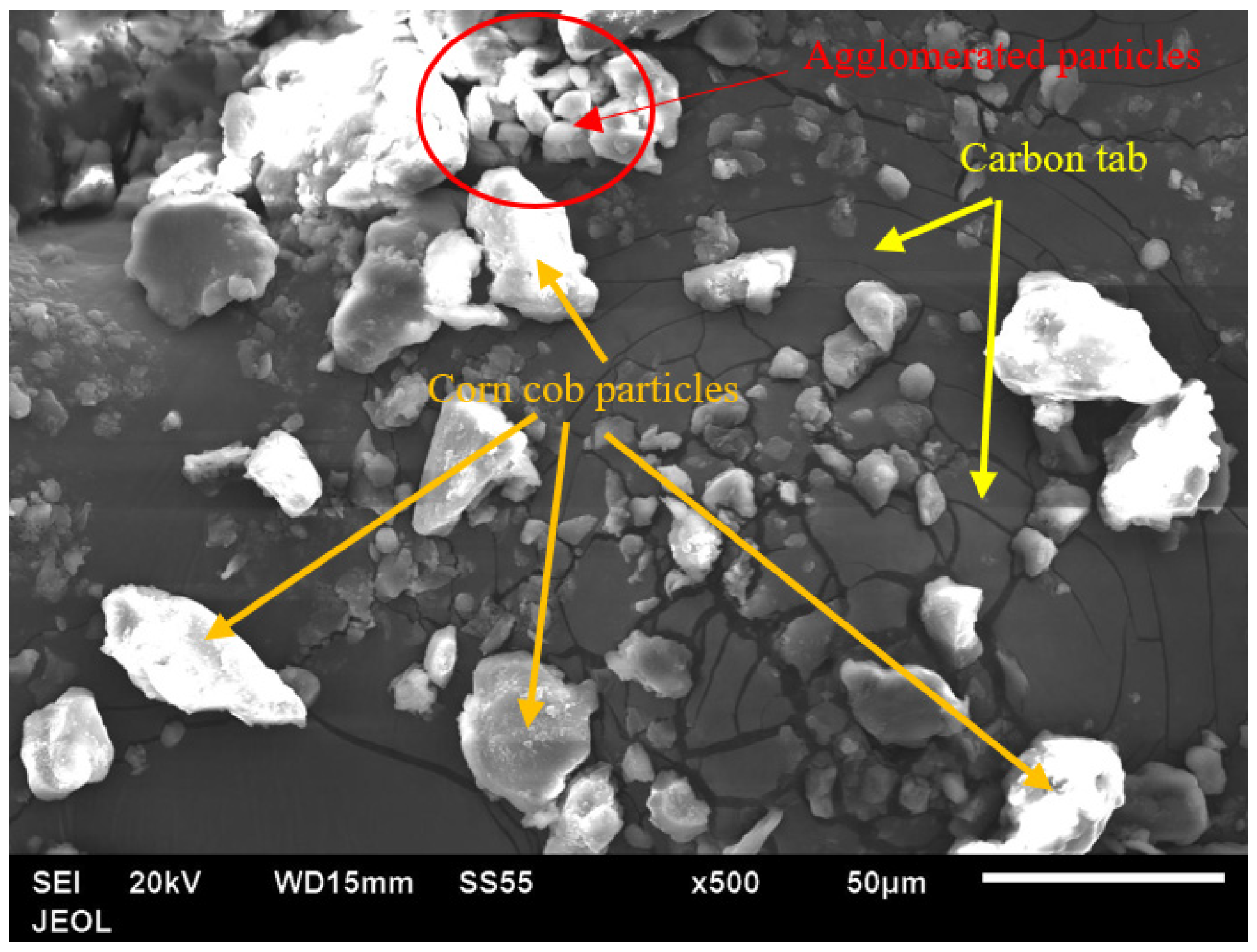

2.1. Preparation of Corn Cob Powder and Epoxy/Corn Cob Composite Samples

2.2. Mechanical Properties of Epoxy/Corn Cob Composites

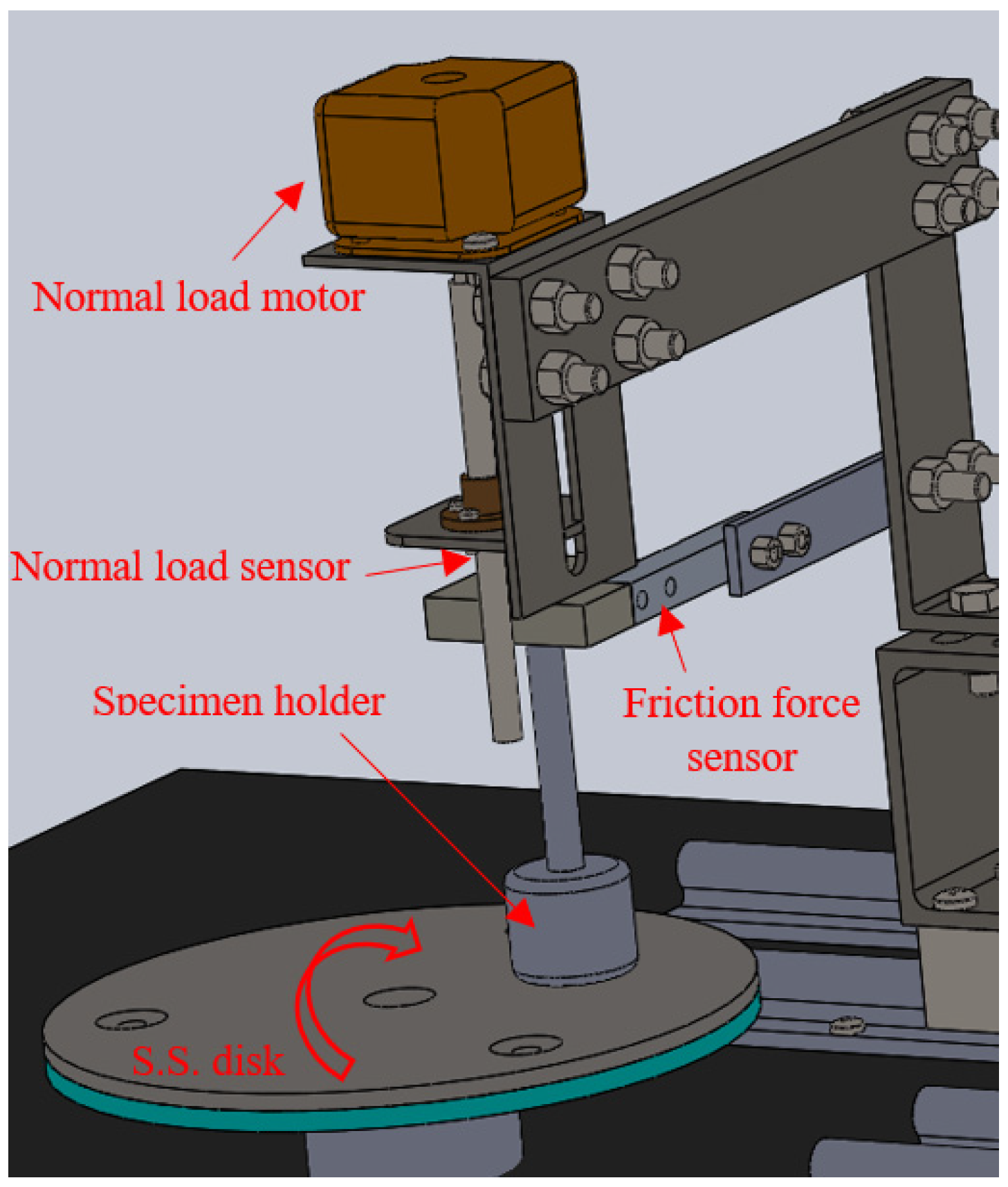

2.3. Tribological Properties of Epoxy/Corn Cob Composites

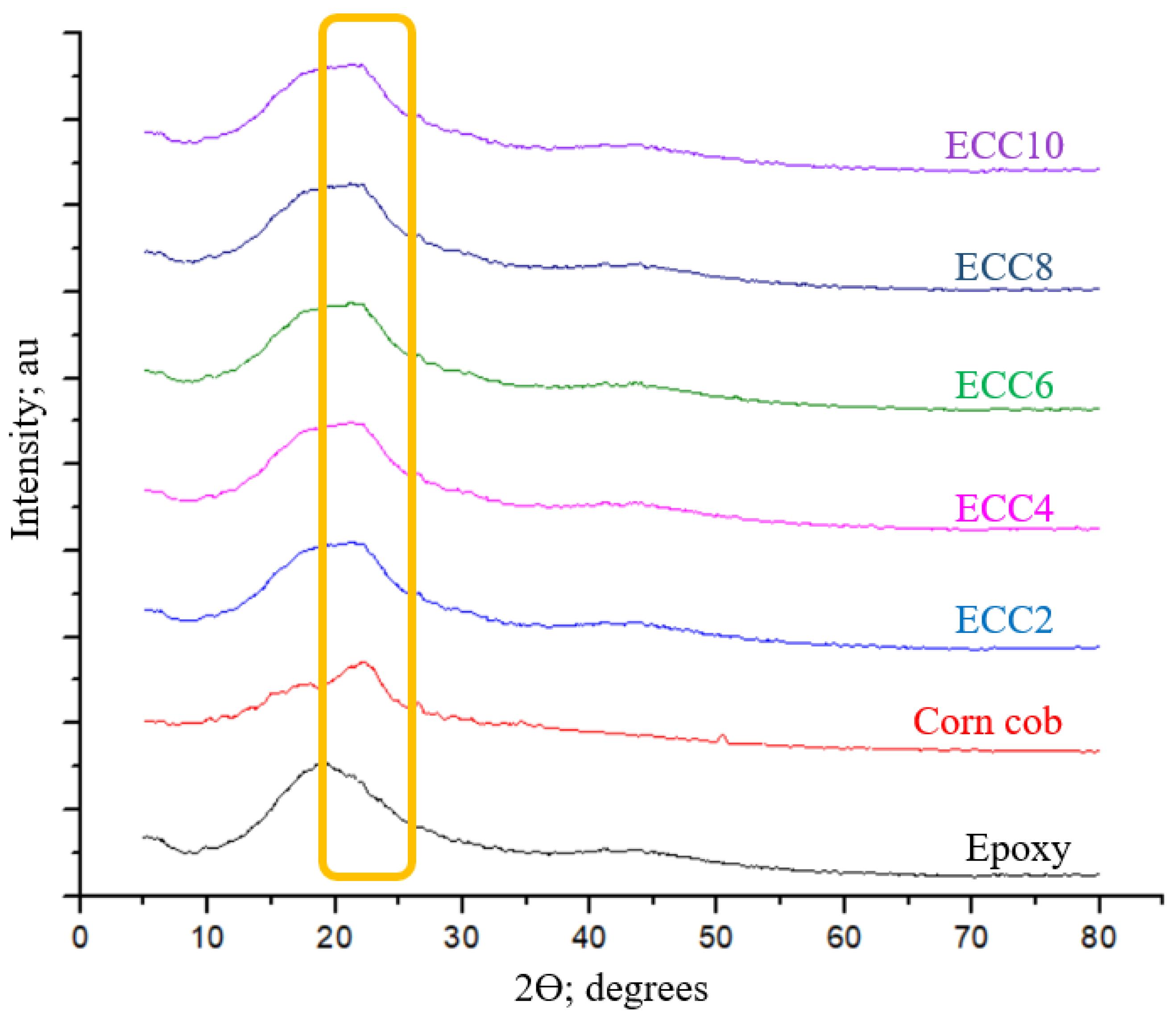

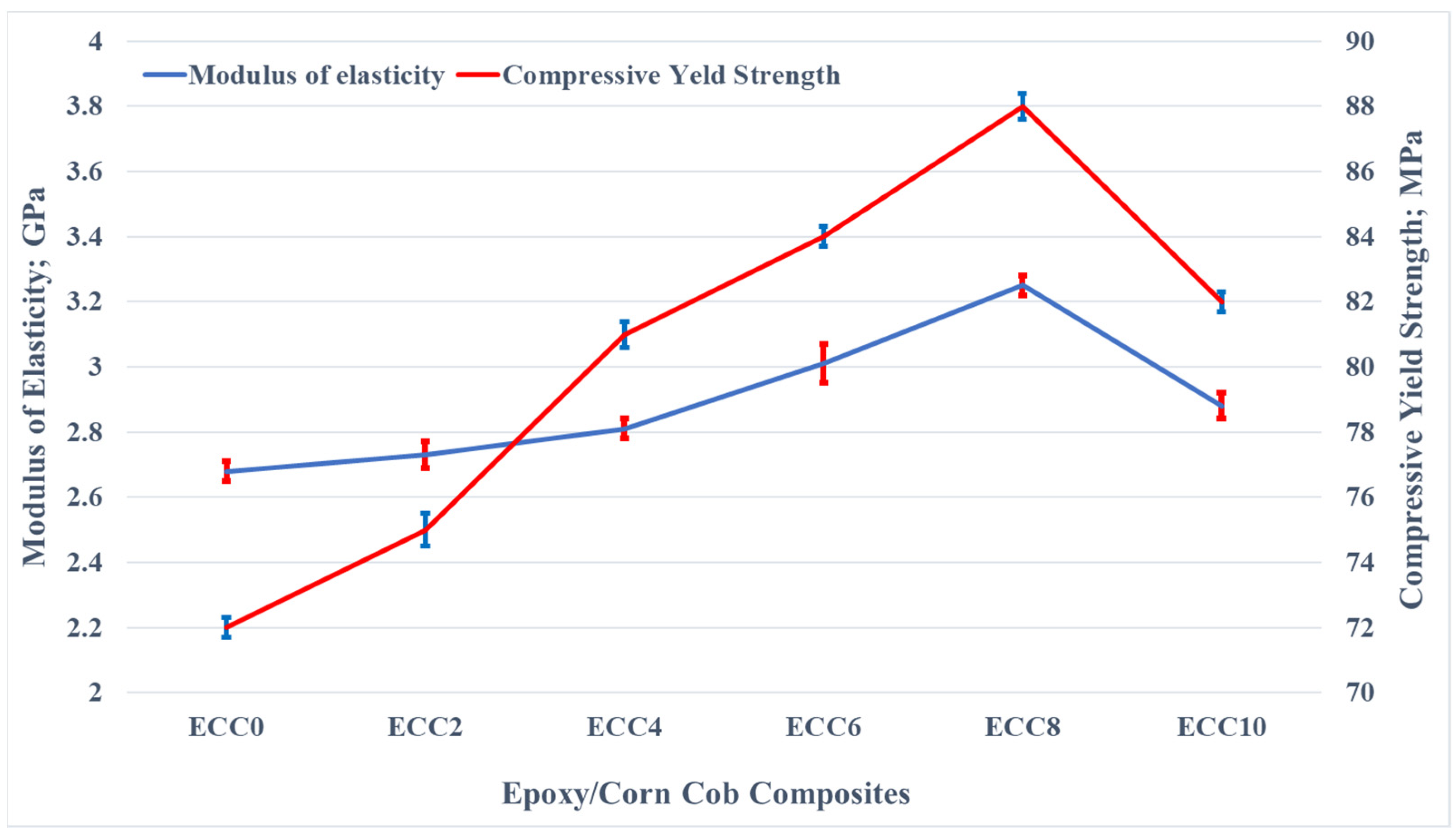

3. Results and Discussion

4. Conclusions

- The results revealed that corn cob could be used as a natural reinforcement for polymer-based composites.

- Without using an agent to enhance the bonding between the epoxy and the corn cob, the weight fraction of the corn cob is limited to 8 wt%.

- Increasing the corn cob weight fraction to 10 wt% decreased both density and hardness of the composite by 22.87% and 17.24%, respectively.

- For 8 wt% corn cob, Young’s modulus and compressive yield strength of the epoxy composite reached 21.26% and 22.22%, respectively.

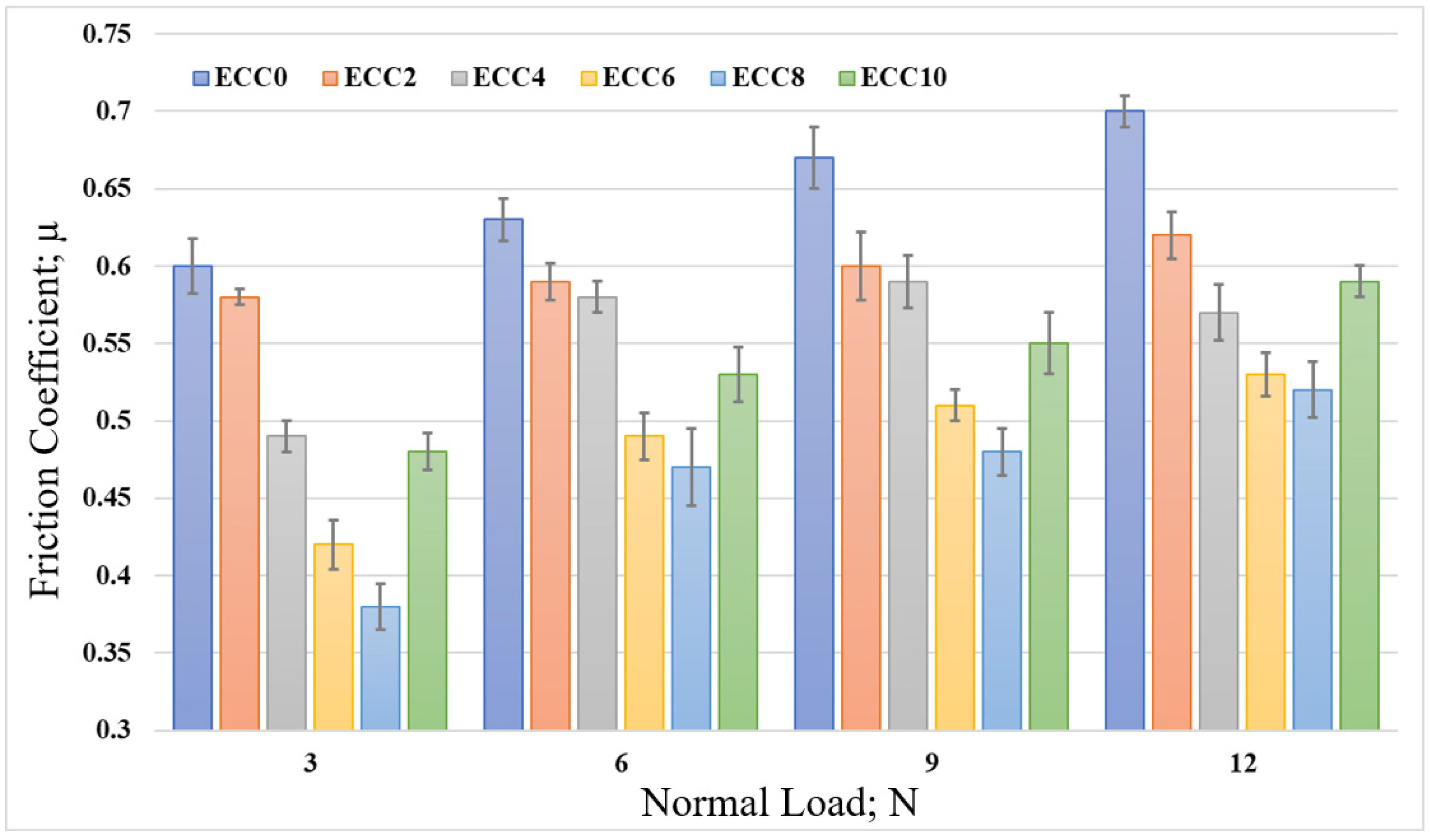

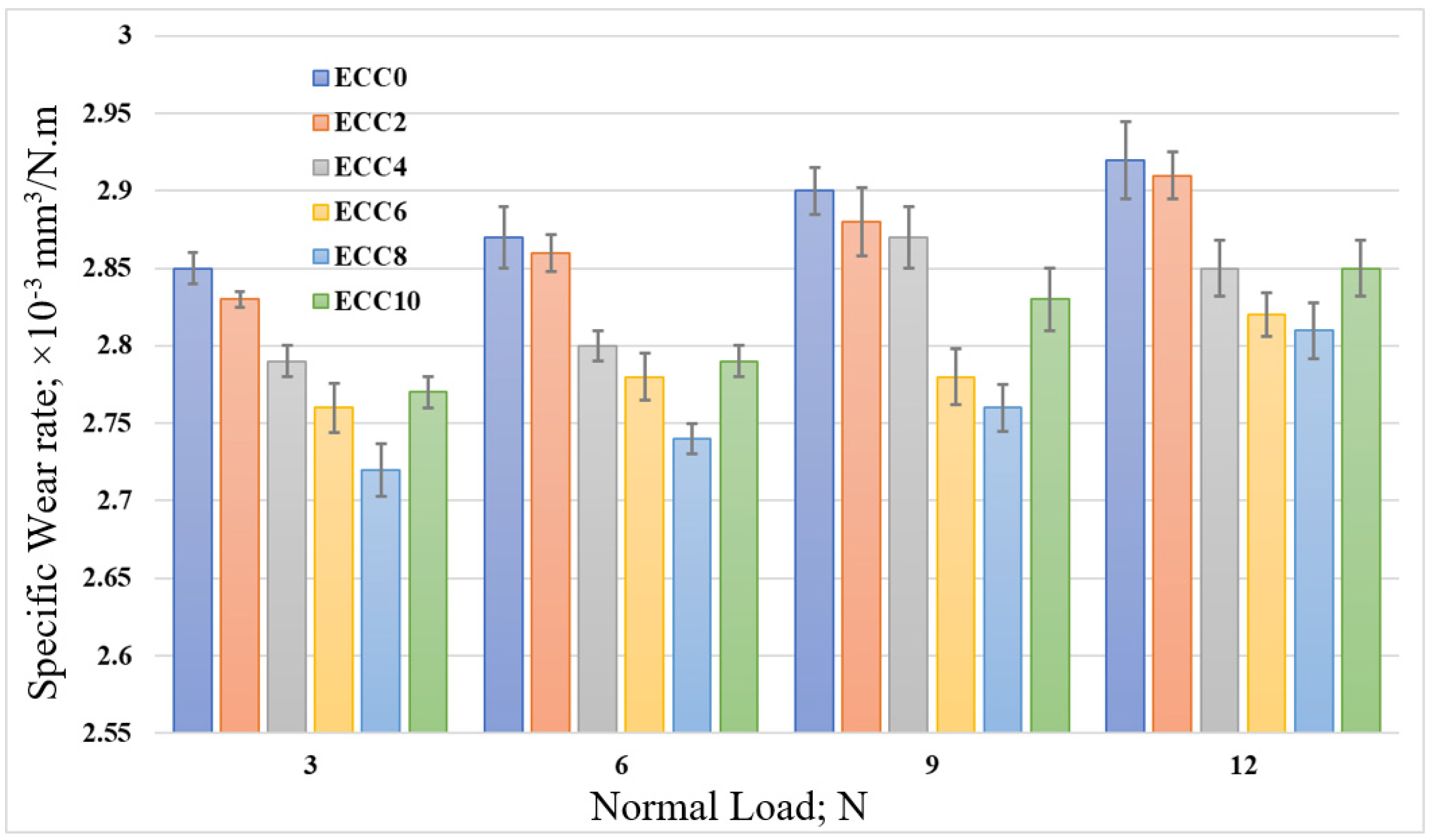

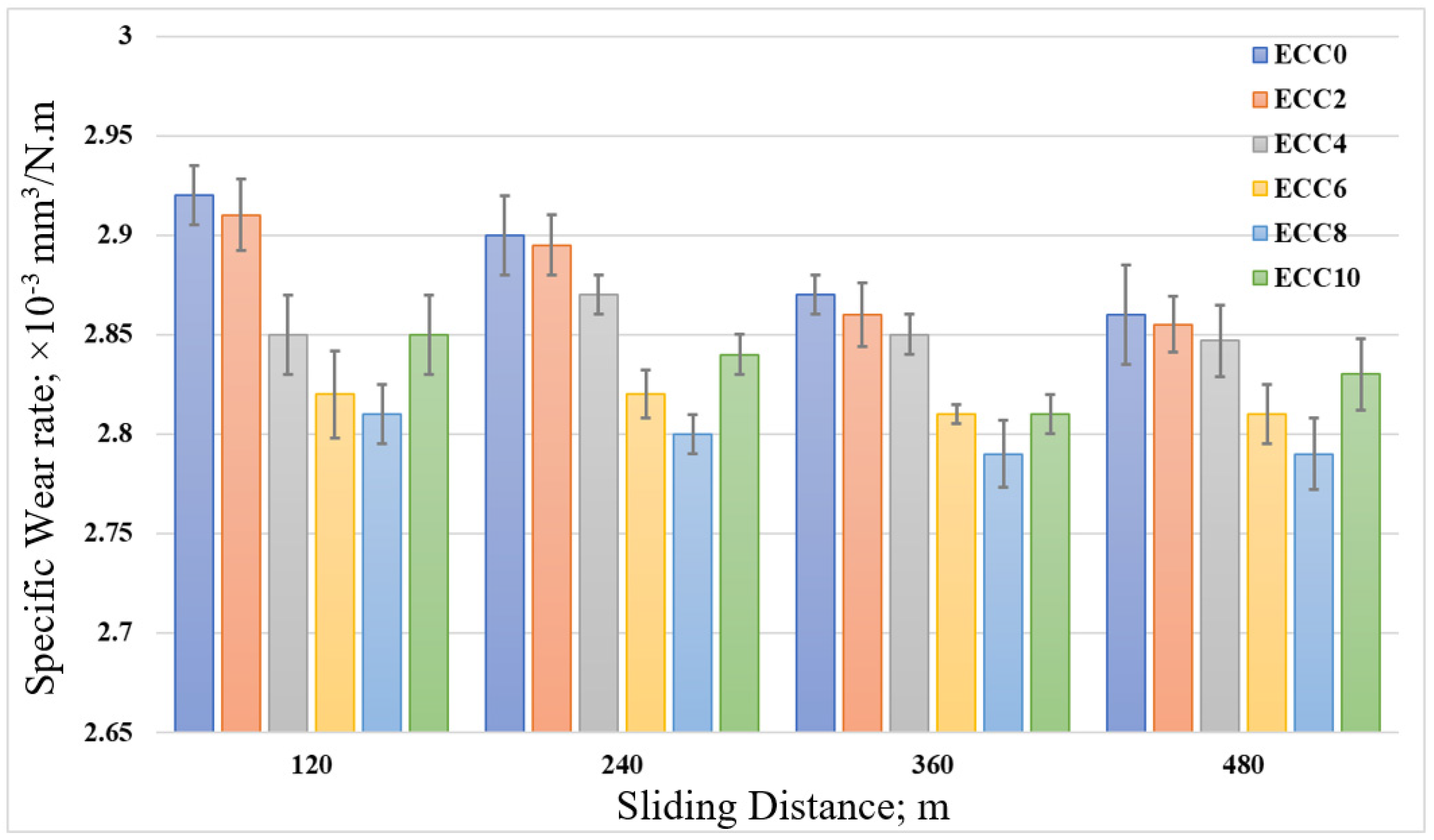

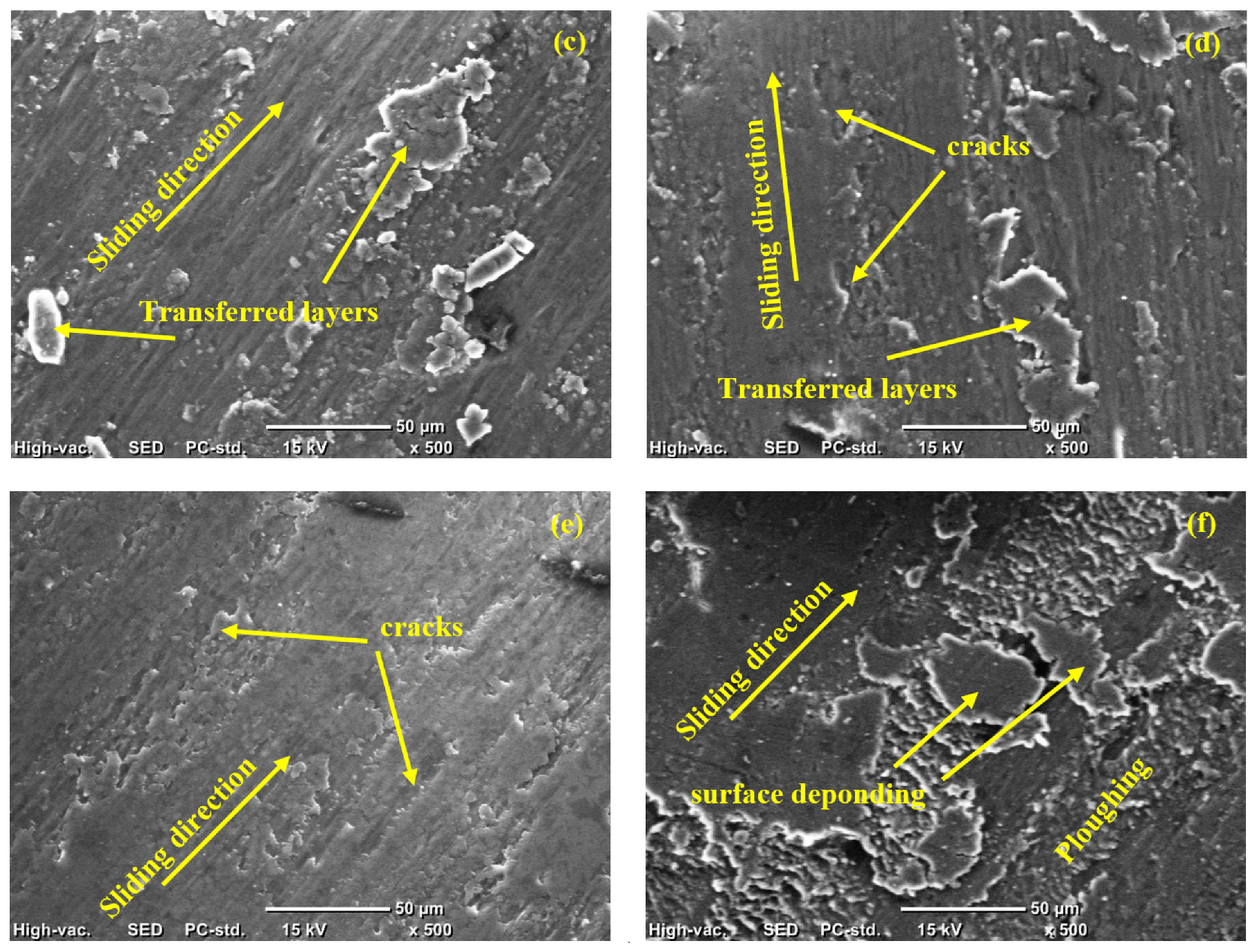

- For 8 wt% epoxy/corn cob, the composite recorded a frictional coefficient of 35% less than pure epoxy, as well as enhanced wear resistance.

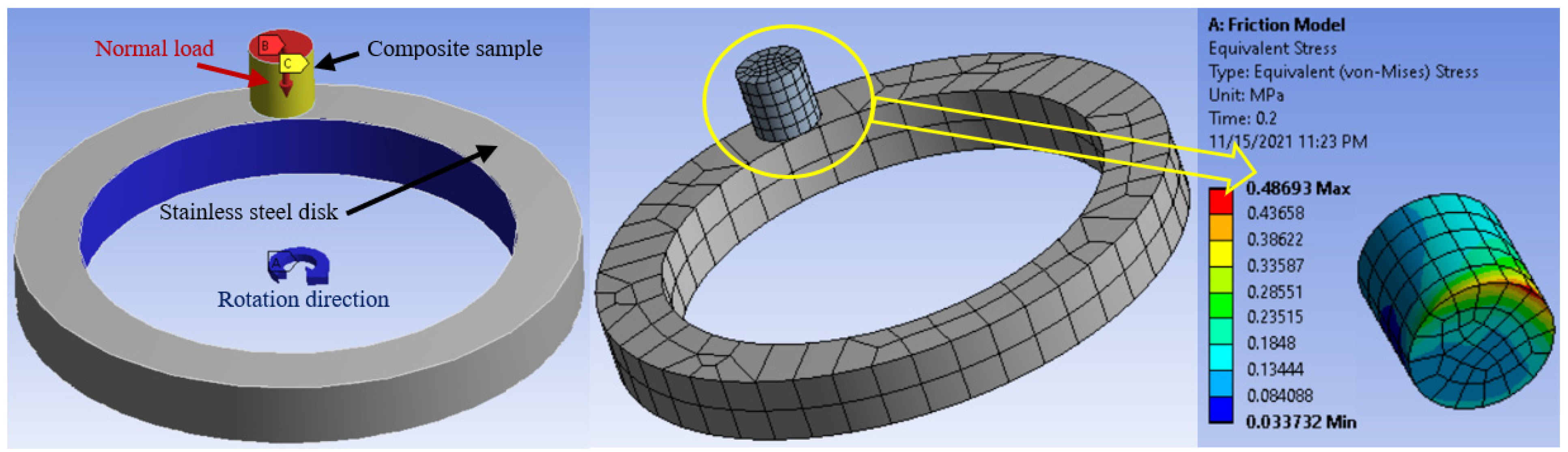

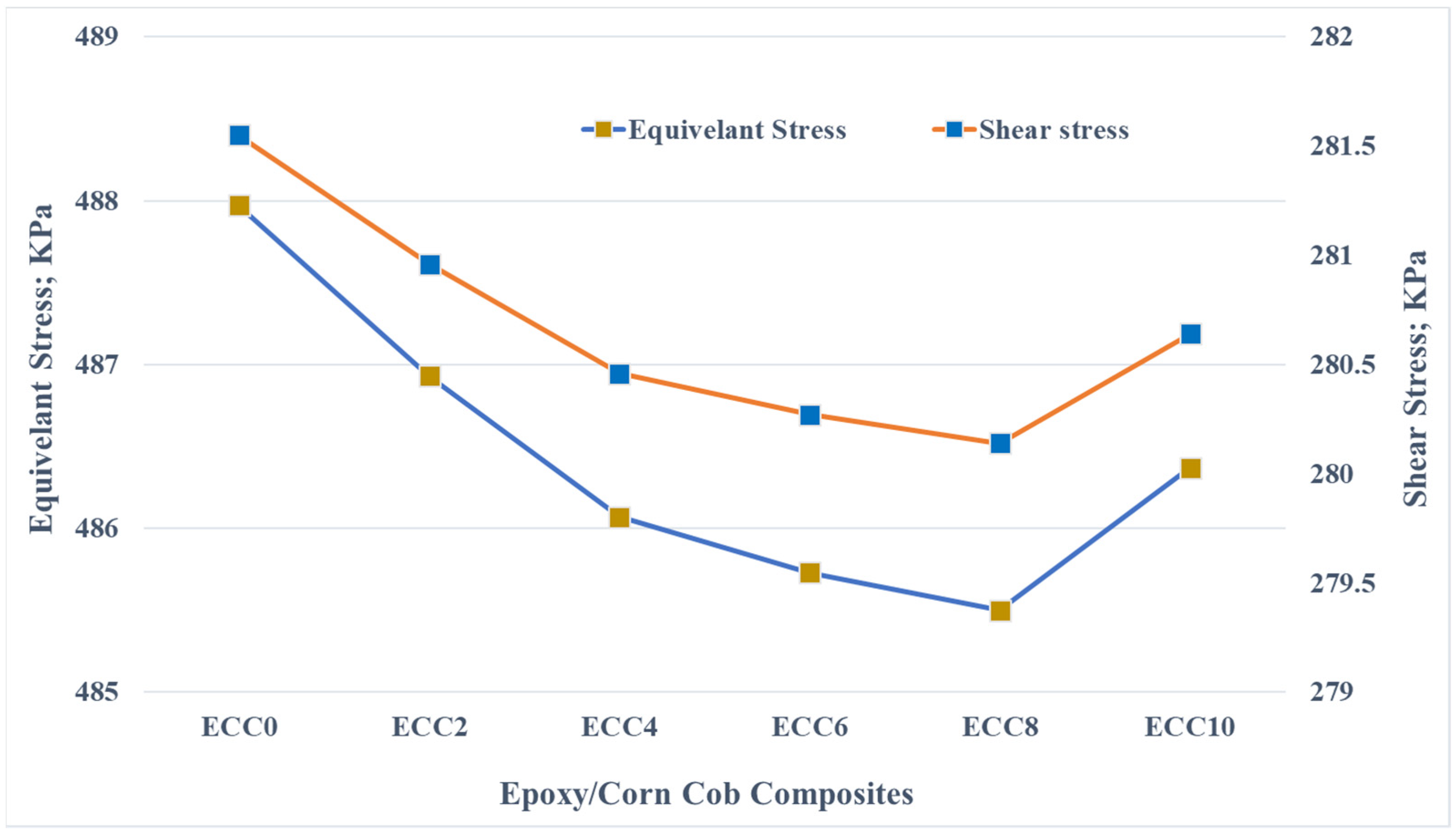

- The finite element results showed an enhanced load-carrying capacity due to corn cob incorporation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chavali, P.J.; Taru, G.B. Effect of Fiber Orientation on Mechanical and Tribological Properties of Banana-Reinforced Composites. J. Fail. Anal. Prev. 2021, 21, 1–8. [Google Scholar] [CrossRef]

- Jaramillo, A.; Medina, C.; Flores, P.; Canales, C.; Maldonado, C.; Rivera, P.C.; Rojas, D.; Meléndrez, M.; Castaño, P. Improvement of thermomechanical properties of composite based on hydroxyapatite functionalized with alkylsilanes in epoxy matrix. Ceram. Int. 2020, 46, 8368–8378. [Google Scholar] [CrossRef]

- Fouly, A.; Ibrahim, A.M.M.; Sherif, E.-S.M.; FathEl-Bab, A.M.R.; Badran, A.H. Effect of Low Hydroxyapatite Loading Fraction on the Mechanical and Tribological Characteristics of Poly (Methyl Methacrylate) Nanocomposites for Dentures. Polymers 2021, 13, 857. [Google Scholar] [CrossRef]

- Yousif, B.F. Design of newly fabricated tribological machine for wear and frictional experiments under dry/wet condition. Mater. Des. 2013, 48, 2–13. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Tribological behavior of natural fiber reinforced PLA composites. Wear 2013, 297, 829–840. [Google Scholar] [CrossRef]

- Ibrahim, A.M.M.; Mohamed, A.F.A.; Fathelbab, A.M.; Essa, F.A. Enhancing the tribological performance of epoxy composites utilizing carbon nano fibers additives for journal bearings. Mater. Res. Express 2018, 6, 035307. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Tapia-Gaspar, M.; Pérez-González, J. Tribology of Polymer Matrix Composites within the Automotive Industry; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Kim, K.; Kim, M.; Hwang, Y.; Kim, J. Chemically modified boron nitride-epoxy terminated dimethylsiloxane composite for improving the thermal conductivity. Ceram. Int. 2014, 40, 2047–2056. [Google Scholar] [CrossRef]

- Rusly SN, A.; Ismail, I.; Matori, K.A.; Abbas, Z.; Shaari, A.H.; Awang, Z.; Ibrahim, I.R.; Idris, F.M.; Zaid, M.H.M.; Mahmood, M.K.A.; et al. Influence of different BFO filler content on microwave absorption performances in BiFeO3/epoxy resin composites. Ceram. Int. 2020, 46, 737–746. [Google Scholar] [CrossRef]

- Dass, K.; Chauhan, S.R.; Gaur, B.V. Study on the effects of nano-aluminum-oxide particulates on mechanical and tribological characteristics of chopped carbon fiber reinforced epoxy composites. Proc. Inst. Mech. Eng. Part J. Mater. Des. Appl. 2017, 231, 403–422. [Google Scholar] [CrossRef]

- Che, Y.; Sun, Z.; Zhan, R.; Wang, S.; Zhou, S.; Huang, J. Effects of graphene oxide sheets-zirconia spheres nanohybrids on mechanical, thermal and tribological performances of epoxy composites. Ceram. Int. 2018, 44, 18067–18077. [Google Scholar] [CrossRef]

- Fouly, A.; Ibrahim, A.M.M.; El-Bab, A.M. Promoting the tribological Properties of epoxy Composites via using Graphene Nanoplatelets as a functional Additive. KGK-Kautsch Gummi Kunstst. 2020, 73, 25–32. [Google Scholar]

- Mostovoy, A.; Yakovlev, A.; Tseluikin, V.; Lopukhova, M. Epoxy nanocomposites reinforced with functionalized carbon nanotubes. Polymers 2020, 12, 1816. [Google Scholar] [CrossRef]

- Bajpai, A.; Wetzel, B.; Klingler, A.; Friedrich, K. Mechanical properties and fracture behavior of high-performance epoxy nanocomposites modified with block polymer and core–shell rubber particles. J. Appl. Polym. Sci. 2020, 137, 48471. [Google Scholar] [CrossRef]

- Kim, J.; Cha, J.; Chung, B.; Ryu, S.; Hong, S.H. Fabrication and mechanical properties of carbon fiber/epoxy nanocomposites containing high loadings of noncovalently functionalized graphene nanoplatelets. Compos. Sci. Technol. 2020, 192, 108101. [Google Scholar] [CrossRef]

- Upadhyay, R.K.; Kumar, A. Effect of particle weight concentration on the lubrication properties of graphene based epoxy composites. Colloid Interface Sci. Commun. 2019, 33, 100206. [Google Scholar] [CrossRef]

- Xian, G.; Walter, R.; Haupert, F. Friction and wear of epoxy/TiO2 nanocomposites: Influence of additional short carbon fibers, Aramid and PTFE particles. Compos. Sci. Technol. 2006, 66, 3199–3209. [Google Scholar] [CrossRef]

- Srivastava, S.; Tiwari, R.K. Synthesis of epoxy-TiO2 nanocomposites: A study on sliding wear behavior, thermal and mechanical properties. Int. J. Polym. Mater. 2012, 61, 999–1010. [Google Scholar] [CrossRef]

- Bazrgari, D.; Moztarzadeh, F.; Sabbagh-Alvani, A.A.; Rasoulianboroujeni, M.; Tahriri, M.; Tayebi, L. Mechanical properties and tribological performance of epoxy/Al2O3 nanocomposite. Ceram. Int. 2018, 44, 1220–1224. [Google Scholar] [CrossRef]

- Fouly, A.; Alkalla, M.G. Effect of low nanosized alumina loading fraction on the physicomechanical and tribological behavior of epoxy. Tribol. Int. 2020, 152, 106550. [Google Scholar] [CrossRef]

- Daramola, O.O.; Akinwekomi, A.D.; Adediran, A.A.; Akindote-White, O.; Sadiku, E.R. Mechanical performance and water uptake behaviour of treated bamboo fibre-reinforced high-density polyethylene composites. Heliyon 2019, 5, e02028. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A.; Alavudeen, A.; Thiruchitrambalam, M. Mechanical and water absorption behaviour of banana/sisal reinforced hybrid composites. Mater. Des. 2011, 32, 4017–4021. [Google Scholar] [CrossRef]

- Oladele, I.O.; Makinde-Isola, B.A.; Adediran, A.A.; Oladejo, M.O.; Owa, A.F.; Olayanju, T.M.A. Mechanical and wear behaviour of pulverised poultry eggshell/sisal fiber hybrid reinforced epoxy composites. Mater. Res. Express 2020, 7, 045304. [Google Scholar] [CrossRef]

- Karthick, R.; Sirisha, P.; Sankar, M.R. Mechanical and tribological properties of PMMA-sea shell based biocomposite for dental application. Procedia Mater. Sci. 2014, 6, 1989–2000. [Google Scholar] [CrossRef]

- Sim, J.; Kang, Y.; Kim, B.J.; Park, Y.H.; Lee, Y.C. Preparation of fly ash/epoxy composites and its effects on mechanical properties. Polymers 2020, 12, 79. [Google Scholar] [CrossRef]

- Atmakuri, A.; Palevicius, A.; Siddabathula, M.; Vilkauskas, A.; Janusas, G. Analysis of mechanical and wettability properties of natural fiber-reinforced epoxy hybrid composites. Polymers 2020, 12, 2827. [Google Scholar] [CrossRef]

- Chen, B.; Cai, D.; Luo, Z.; Chen, C.; Zhang, C.; Qin, P.; Cao, H.; Tan, T. Corncob residual reinforced polyethylene composites considering the biorefinery process and the enhancement of performance. J. Clean. Prod. 2018, 198, 452–462. [Google Scholar] [CrossRef]

- Zhu, S.; Guo, Y.; Tu, D.; Chen, Y.; Liu, S.; Li, W.; Wang, L. Water absorption, mechanical, and crystallization properties of high-density polyethylene filled with corncob powder. BioResources 2018, 13, 3778–3792. [Google Scholar] [CrossRef]

- Zhao, H.; Allanson, D.; Ren, X.J. Use of shore hardness tests for in-process properties estimation/monitoring of silicone rubbers. J. Mater. Sci. Chem. Eng. 2015, 3, 142–147. [Google Scholar] [CrossRef]

- BS EN ISO. 14126: 1999-Fibre-Reinforced Plastic Composites. Determination of Compressive Properties in the In-Plane Direction; International Organization for Standardization: Geneva, Switzerland, 1999. [Google Scholar]

- ASTM. G99, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Sharmila, T.B.; Antony, J.V.; Jayakrishnan, M.P.; Beegum, P.S.; Thachil, E.T. Mechanical, thermal and dielectric properties of hybrid composites of epoxy and reduced graphene oxide/iron oxide. Mater. Des. 2016, 90, 66–75. [Google Scholar] [CrossRef]

- Yu, J.; Qian, Q.; Zhao, X. Research progress on effects of structural planes of rock mass on stress wave propagation law. Acta Armamentarii 2009, 30, 308–316. [Google Scholar]

- Guo, R.Q.; Rohatgi, P.K.; Nath, D. Preparation of aluminium-fly ash particulate composite by powder metallurgy technique. J. Mater. Sci. 1997, 32, 3971–3974. [Google Scholar] [CrossRef]

- Khun, N.W.; Zhang, H.; Lim, L.H.; Yue, C.Y.; Hu, X.; Yang, J. Tribological properties of short carbon fibers reinforced epoxy composites. Friction 2014, 2, 226–239. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Zhang, H.; Friedrich, K. Effect of nanoparticles on the tribological behaviour of short carbon fibre reinforced poly (etherimide) composites. Tribol. Int. 2005, 38, 966–973. [Google Scholar] [CrossRef]

- Kuminek, T.; Aniołek, K.; Młyńczak, J. A numerical analysis of the contact stress distribution and physical modelling of abrasive wear in the tram wheel-frog system. Wear 2015, 328, 177–185. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, Y.; Zhu, H.; Yang, H. The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Marra, K.G.; Szem, J.W.; Kumta, P.N.; DiMilla, P.A.; Weiss, L.E. In vitro analysis of biodegradable polymer blend/hydroxyapatite composites for bone tissue engineering. J. Biomed. Mater. Res. Off. J. Soc. Biomater. Jpn. Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater. 1999, 47, 324–335. [Google Scholar] [CrossRef]

- Fouly, A.; Almotairy, S.M.; Aijaz, M.O.; Alharbi, H.F.; Abdo, H.S. Balanced Mechanical and Tribological Performance of High-Frequency-Sintered Al-SiC Achieved via Innovative Milling Route—Experimental and Theoretical Study. Crystals 2021, 11, 700. [Google Scholar] [CrossRef]

- Ibrahim, A.M.M.; Shi, X.; Radwan, A.R.; Mohamed, A.F.A.; Ezzat, M.F. Enhancing the tribological properties of NiAl based nano-composites for aerospace bearing applications. Mater. Res. Express 2019, 6, 085067. [Google Scholar] [CrossRef]

| Code | Corn Cob wt% | Epoxy wt% | Hardener wt% |

|---|---|---|---|

| ECC0 | 0 | 66.67 | 33.33 |

| ECC2 | 2 | 65.33 | 32.67 |

| ECC4 | 4 | 64 | 32 |

| ECC6 | 6 | 62.67 | 31.33 |

| ECC8 | 8 | 61.33 | 30.67 |

| ECC10 | 10 | 60 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fouly, A.; Abdo, H.S.; Seikh, A.H.; Alluhydan, K.; Alkhammash, H.I.; Alnaser, I.A.; Abdo, M.S. Evaluation of Mechanical and Tribological Properties of Corn Cob-Reinforced Epoxy-Based Composites—Theoretical and Experimental Study. Polymers 2021, 13, 4407. https://doi.org/10.3390/polym13244407

Fouly A, Abdo HS, Seikh AH, Alluhydan K, Alkhammash HI, Alnaser IA, Abdo MS. Evaluation of Mechanical and Tribological Properties of Corn Cob-Reinforced Epoxy-Based Composites—Theoretical and Experimental Study. Polymers. 2021; 13(24):4407. https://doi.org/10.3390/polym13244407

Chicago/Turabian StyleFouly, Ahmed, Hany S. Abdo, Asiful H. Seikh, Khalid Alluhydan, Hend I. Alkhammash, Ibrahim A. Alnaser, and Mohamed S. Abdo. 2021. "Evaluation of Mechanical and Tribological Properties of Corn Cob-Reinforced Epoxy-Based Composites—Theoretical and Experimental Study" Polymers 13, no. 24: 4407. https://doi.org/10.3390/polym13244407

APA StyleFouly, A., Abdo, H. S., Seikh, A. H., Alluhydan, K., Alkhammash, H. I., Alnaser, I. A., & Abdo, M. S. (2021). Evaluation of Mechanical and Tribological Properties of Corn Cob-Reinforced Epoxy-Based Composites—Theoretical and Experimental Study. Polymers, 13(24), 4407. https://doi.org/10.3390/polym13244407