Sustainable, Renewable and Environmental-Friendly Insulation Systems for High Voltages Applications

Abstract

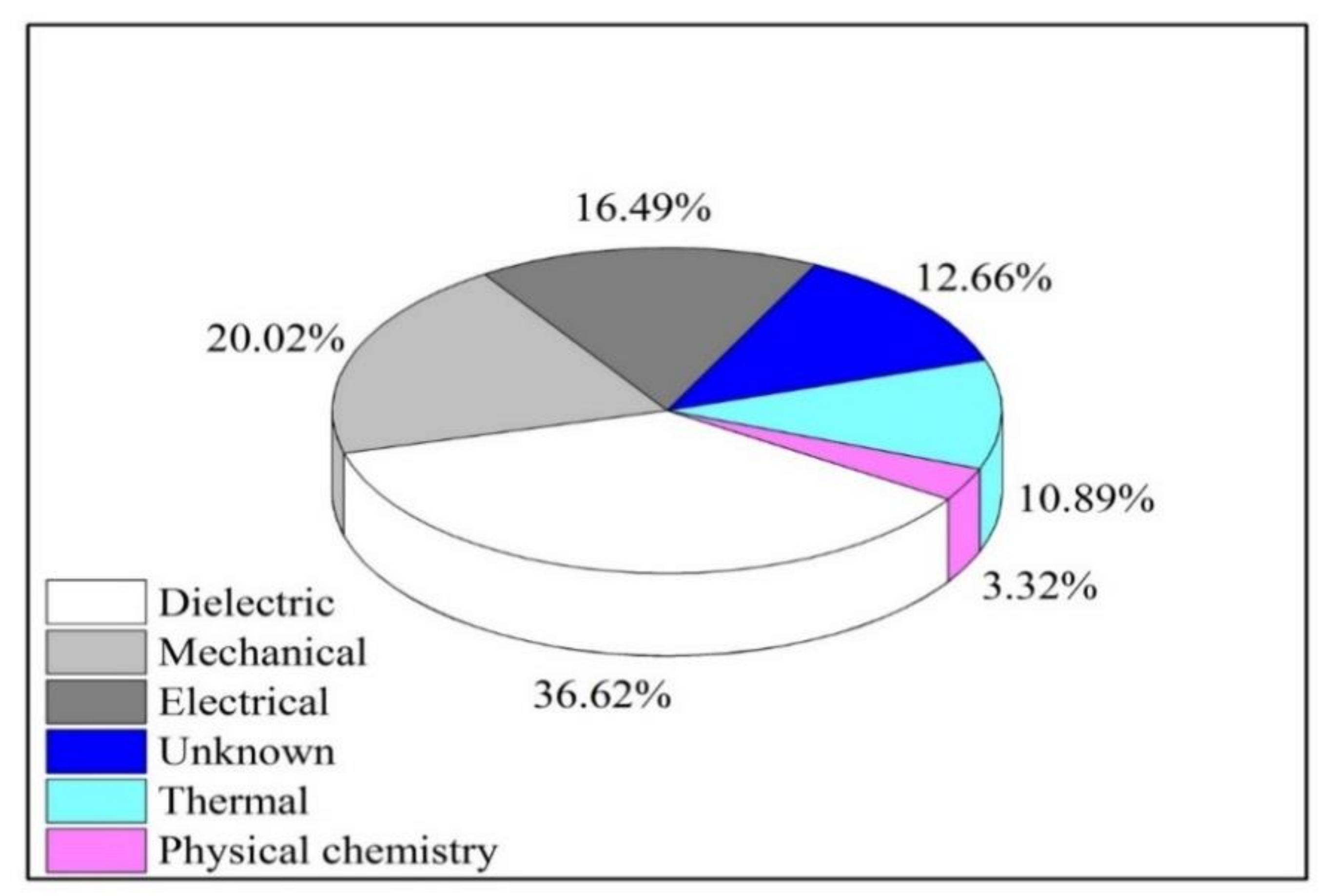

:1. Introduction

2. Dielectric Fluids HV Applications

3. Historical Journey Insulating Fluids

4. Major Features of Insulating Fluids

4.1. Electrical Properties

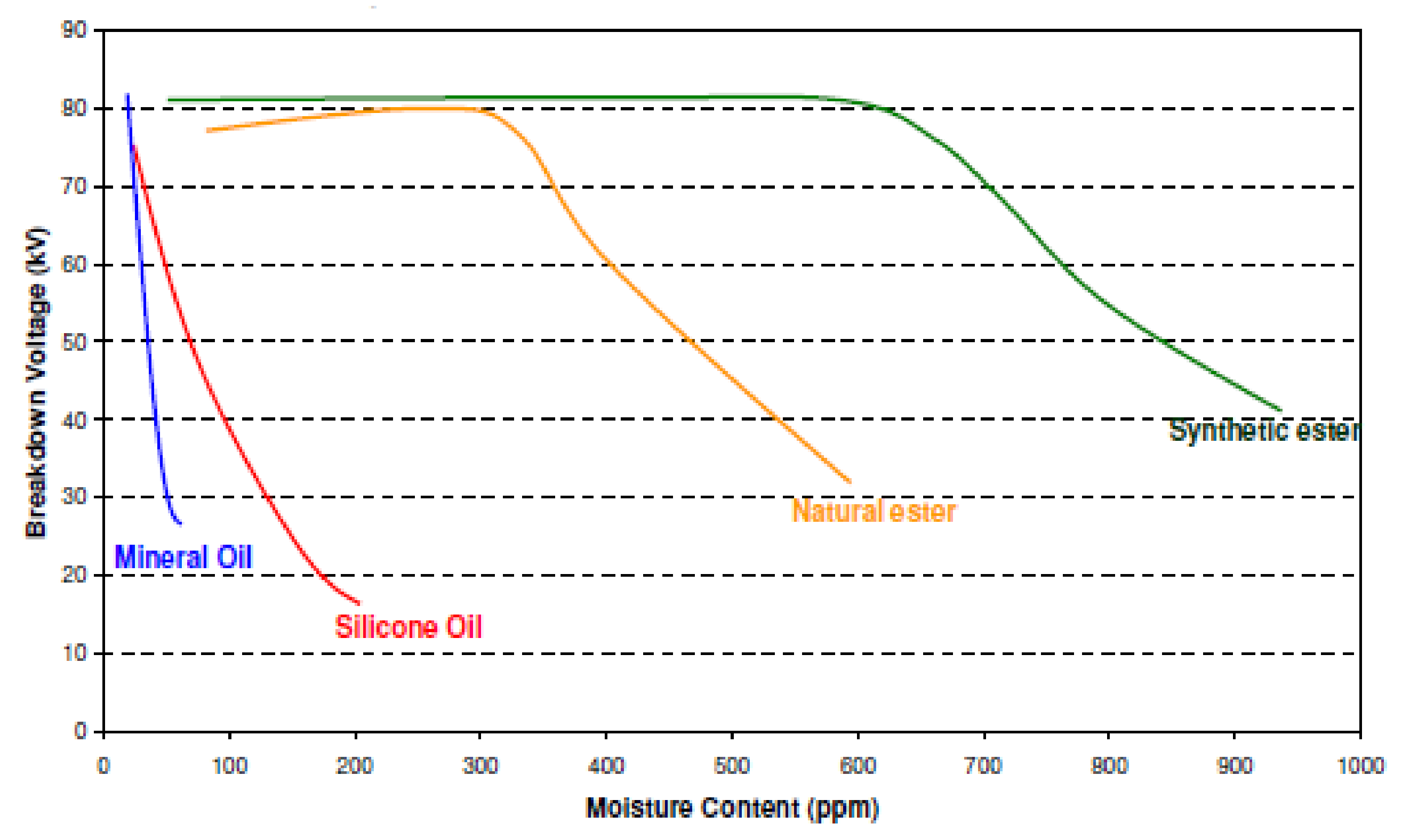

4.1.1. Dielectric Breakdown Voltages (BDVs)

AC-Breakdown Strength (AC BDS)

Impulse BDV Test

Impulse BDV of Alternative Liquid Insulation Impregnated Cellulose

4.1.2. Partial Discharge (PD) Tests

4.1.3. Dissipation Factor (DF)

4.1.4. Permittivity

4.2. Physical Properties

4.2.1. Color and Appearance

4.2.2. Relative Density (Specific Gravity)

4.2.3. Viscosity

4.2.4. Pour Point

4.2.5. Flash and Fire Point

4.2.6. Interfacial Tension (IFT)

4.2.7. Operating Temperature

4.2.8. Water Assimilation/Water Saturation

4.3. Chemical Features

4.3.1. Acidity (Neutralization Number)

4.3.2. Oxidation Stability

4.3.3. Aging Characteristics

4.3.4. Furans Content

4.3.5. Corrosive Sulfur Content

4.3.6. Total Gas Content/Dissolved Gas Analysis (DGA) and Stray Gassing

4.4. Environmental Properties

4.4.1. Biodegradability and Toxicity

4.4.2. Emission Profile

5. Performance, Evaluation and Analysis of Renewable Oils as Insulating Fluids

5.1. Electrical Properties

5.2. Physicochemical Properties

6. Technical Complications and Future Research Agenda

6.1. Technical Complications

- i.

- The price of natural esters oil is generally dependent on the feedstock cost;

- ii.

- Storage and management of natural esters are problematic and very challenging;

- iii.

- Homogeneity of products is generally determined by the trader, starting material and fabrication procedures;

- iv.

- Approval by equipment industrialists is an additional problem;

- v.

- Uninterrupted accessibility of natural esters is required to be ensured launching on the main consumption of it in HV equipment;

- vi.

- Natural esters application in HV equipment subjected to freezing environments, has been a serious concern. The pour point of natural esters in no way proceeds beyond −30 °C even following the addition of depressants. Excluding additions, oil may frost at below zero temperatures;

- vii.

- HV equipment (especially transformers) filled with natural ester oil must be airtight to inhibit the entrance of humidity and air into the unit. Antioxidants must be present in the sealed unit due to the potential inclusion of the mentioned impurities throughout the lifespan of the unit.

6.2. Research gap and Future Research Agenda

6.2.1. Real-Time Condition Monitoring and Application in Existing Units

6.2.2. Application in On–Load Tap Changers (OLTCs)

6.2.3. Streamer Propagation Analysis

6.2.4. Comparison of Applicability Performance of Different Insulating Fluids

6.2.5. Additives and Chemical Scavengers

6.2.6. End-of-Life Criteria Studies

6.2.7. Nanotechnology and Insulating Fluids

6.2.8. Cost and Other Related Issues

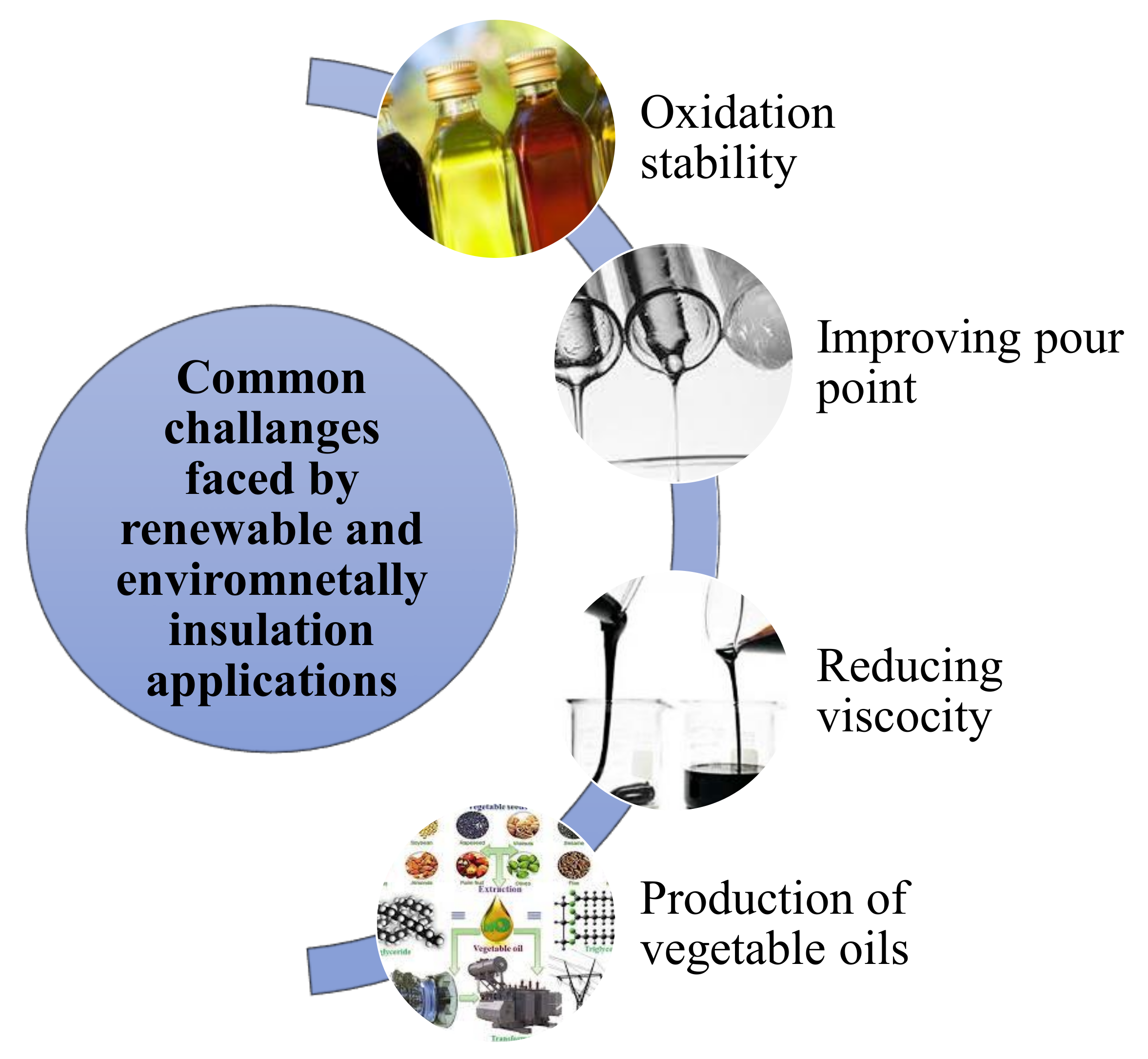

7. Challenges of Natural-Ester Insulating Fluids

7.1. Base Fluid Selection

7.2. Production and Usage of Vegetable Oil

7.3. Stabilization of the Oil

7.4. Improving Pour Point

7.5. Reducing the Viscosity

8. Potential Applications of Renewable and Eco-Friendly Insulating Fluids

9. New and Innovative Technologies for Environmentally Friendly Fluids

9.1. New Vegetable Oil Formulations

9.2. Nanofluids Based on Natural Esters

10. New Emerging and Changing Trends

11. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rosen, M.A. Teaching the Environmental Impact of Industrial Processes. Int. J. Mech. Eng. Educ. 2001, 29, 39–52. [Google Scholar] [CrossRef]

- Yahya, F.; Rafiq, M. Unraveling the contemporary drivers of renewable energy consumption: Evidence from regime types. Environ. Prog. Sustain. Energy 2019, 38, 13178. [Google Scholar] [CrossRef]

- Yahya, F.; Rafiq, M. Brownfield, greenfield, and renewable energy consumption: Moderating role of effective governance. Energy Environ. 2019, 31, 405–423. [Google Scholar] [CrossRef]

- Azam, A.; Rafiq, M.; Shafique, M.; Ateeq, M.; Yuan, J. Causality Relationship Between Electricity Supply and Economic Growth: Evidence from Pakistan. Energies 2020, 13, 837. [Google Scholar] [CrossRef] [Green Version]

- Rafiq, M.; Lv, Y.; Zhou, Y.; Ma, K.; Wang, W.; Li, C.; Wang, Q. Use of vegetable oils as transformer oils – a review. Renew. Sustain. Energy Rev. 2015, 52, 308–324. [Google Scholar] [CrossRef]

- Mazzanti, G.; Marzinotto, M. Extruded Cables for High-Voltage Direct-Current Transmission: Advances in Research and Development; John Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 9781118590423. [Google Scholar]

- Xu, Y.; Qian, S.; Liu, Q.; Wang, Z.D. Oxidation stability assessment of a vegetable transformer oil under thermal aging. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 683–692. [Google Scholar] [CrossRef]

- Oommen, T. Vegetable oils for liquid-filled transformers. IEEE Electr. Insul. Mag. 2002, 18, 6–11. [Google Scholar] [CrossRef]

- Rafiq, M.; Lv, Y.; Li, C. A Review on Properties, Opportunities, and Challenges of Transformer Oil-Based Nanofluids. J. Nanomater. 2016, 2016, 8371560. [Google Scholar] [CrossRef] [Green Version]

- Gonen, T. Electric Power Distribution Engineering; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Stockton, D.P.; Bland, J.R.; McClanahan, T.; Wilson, J.; Harris, D.L.; McShane, P. Natural Ester Transformer Fluids: Safety, Reliability & Environmental Performance. In Proceedings of the 2007 IEEE Petroleum and Chemical Industry Technical Conference, Calgary, AB, Canada, 17–19 September 2007; pp. 1–7. [Google Scholar]

- Fernández, I.; Ortiz, A.; Delgado, F.; Renedo, C.; Pérez, S. Comparative evaluation of alternative fluids for power transformers. Electr. Power Syst. Res. 2013, 98, 58–69. [Google Scholar] [CrossRef]

- Radhika, R.V.; Iruthayarajan, M.W.; Pakianathan, P.S. Investigation of critical parameters of mixed insulating fluids. In Proceedings of the 2014 International Conference on Circuits, Power and Computing Technologies [ICCPCT-2014], Nagercoil, India, 20–21 March 2014; pp. 357–362. [Google Scholar]

- Chandrasekar, S.; Montanari, G.C. Analysis of partial discharge characteristics of natural esters as dielectric fluid for electric power apparatus applications. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1251–1259. [Google Scholar] [CrossRef]

- Martins, M.A.G. Vegetable oils, an alternative to mineral oil for power transformers-experimental study of paper aging in vegetable oil versus mineral oil. IEEE Electr. Insul. Mag. 2010, 26, 7–13. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Z.; Grzybowski, S.; Liu, Y. Characteristics of moisture diffusion in vegetable oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1650–1656. [Google Scholar] [CrossRef]

- Abdelmalik, A.A.; Fothergill, J.; Dodd, S.J.; Abbott, A.P.; Harris, R. Effect of side chains on the dielectric properties of alkyl esters derived from palm kernel oil. In Proceedings of the 2011 IEEE International Conference on Dielectric Liquids, Trondheim, Norway, 26–30 June 2011; pp. 1–4. [Google Scholar]

- Liao, R.; Hao, J.; Chen, G.; Ma, Z.; Yang, L. A comparative study of physicochemical, dielectric and thermal properties of pressboard insulation impregnated with natural ester and mineral oil. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1626–1637. [Google Scholar] [CrossRef] [Green Version]

- Azis, N.; Wang, Z.D. Acid generation study of natural ester. In Proceedings of the XVII International Symposium on High Voltage Engineering, Hannover, Germany, 22–26 August 2011. [Google Scholar]

- Gomez, N.; Wilhelm, H.M.; Santos, C.C.; Stocco, G.B. Dissolved gas analysis (DGA) of natural ester insulating fluids with different chemical compositions. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1071–1078. [Google Scholar] [CrossRef]

- Oommen, T.V.; Claiborne, C.C.; Walsh, E.J.; Baker, J.P. Biodegradable transformer fluid from high oleic vegetable oils. In Proceedings of the International Conference of Doble Clients, Boston, MA, USA, 12–16 April 1999; ESCO Technologies Company: St. Louis, MO, USA, 1999. [Google Scholar]

- Oommen, T.V.; Claiborne, C.C. Electrical Transformers Containing Electrical Insulation Fluids Comprising High Oleic Acid Oil Compositions. U.S. Patent 5,949,017[P], 7 September 1999. [Google Scholar]

- Cannon, G.S.; Honary, L.A.T. Soybean Based Transformer Oil and Transmission Line Fluid. U.S. Patent 5,958,851[P], 28 September 1999. [Google Scholar]

- McShane, C.P.; Corkran, J.L.; Harthun, R.A.; Gauger, G.A.; Rapp, K.J.; Howells, E. Vegetable Oil Based Dielectric Coolant. U.S. Patent 6,037,537[P], 14 March 2000. [Google Scholar]

- Vishal, S.; Vikas, P. Transformer’s history and its insulating oil. In Proceedings of the 5th National Conference, INDIACom, Computing For Nation Development, New Delhi, India, 10–11 March 2011; 2011. [Google Scholar]

- Rafiq, M.; Khan, D.; Ali, M. “Dielectric Properties of Transformer oil based silica nanofluids,” (PGSRET). In Proceedings of the 5th National Conference IEEE conference of Power Generation System and Renewable Energy Technologies, Islamabad, Pakistan, 10–11 June 2015. [Google Scholar]

- Cherry, D. Insulating Fluids: An Overview of Dielectric Fluids Used in Transformers; ABB Ltd.: Zurich, Switzerland, 2009; pp. 1–3. [Google Scholar]

- EPRI Portfolio 2007—Transmission Reliability and Performance: 37.002, Transformer Life Extension. Available online: http://www.epri.com/portfolio/ (accessed on 17 May 2016).

- Rafiq, M.; Shafique, M.; Azam, A.; Ateeq, M. The impacts of nanotechnology on the improvement of liquid insulation of transformers: Emerging trends and challenges. J. Mol. Liq. 2020, 302, 112482. [Google Scholar] [CrossRef]

- Karthik, R.; Raja, T.S.R. Investigations of transformer oil characteristics. IEEJ Trans. Electr. Electron. Eng. 2012, 7, 369–374. [Google Scholar] [CrossRef]

- Swift, G.; Molinski, T.S.; Lehn, W. A fundamental approach to transformer thermal modeling. I. Theory and equivalent circuit. IEEE Trans. Power Deliv. 2001, 16, 171–175. [Google Scholar] [CrossRef]

- Kulkarni, S.V.; Khaparde, S.A. Transformer Engineering Design, Technology, and Diagnostics; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9788578110796. [Google Scholar]

- Li, J.; He, Z.; Grzybowski, S. Electrical aging lifetime model of oil-impregnated paper under pulsating DC voltage influenced by temperature. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1992–1997. [Google Scholar] [CrossRef]

- Wang, S.-Q.; Zhang, G.-J.; Wei, J.-L.; Yang, S.-S.; Dong, M.; Huang, X. Investigation on dielectric response characteristics of thermally aged insulating pressboard in vacuum and oil-impregnated ambient. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1853–1862. [Google Scholar] [CrossRef]

- Yun, F. Characteristics and Mechanisms of Aging of Oil-Paper Insulation in Power Transformers; Chongqing University: Chongqing, China, 2007. [Google Scholar]

- Harlow, J.H. Electric Power Transformer Engineering; CRC Press: Boca Raton, FL, USA, 2004; ISBN 9780203486481. [Google Scholar]

- Borsi, H. Dielectric behavior of silicone and ester fluids for use in distribution transformers. IEEE Trans. Electr. Insul. 1991, 26, 755–762. [Google Scholar] [CrossRef]

- Yamagishi, A.; Sampei, H.; Kojima, H.; Morooka, H. Prospect of environmentally friendly and less-flammable transformer with low viscosity silicone fluid. In Proceedings of the International Conference on Electrical Engineering, Sapporo, Japan, 4–8 July 2004; pp. 1–6. [Google Scholar]

- Borsi, H. Ester fluid Midel 7131 as PCB-substitute for distribution transformers. In Proceedings of the 10th International Conference on Conduction and Breakdown in Dielectric Liquids, Grenoble, France, 10–14 September 1990. [Google Scholar]

- Contreras, J.E.; Rodríguez-Díaz, J.; Rodriguez, E.A. Environmentally Friendly Fluids for High-Voltage Applications. In Handbook of Ecomaterials; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 9783319682556. [Google Scholar]

- Owuna, F.J.; Dabai, M.U.; Sokoto, M.A.; Dangoggo, S.M.; Bagudo, B.U.; Birnin-Yauri, U.A.; Hassan, L.G.; Sada, I.; Abubakar, A.L.; Jibrin, M.S. Chemical modification of vegetable oils for the production of biolubricants using trimethylolpropane: A review. Egypt. J. Pet. 2020, 29, 75–81. [Google Scholar] [CrossRef]

- McShane, C.P.; Luksich, J.; Martins, M.N. Field Experience with Natural Ester (Vegetable Oil) Dielectric Fluid—The First Decade. In Proceedings of the IV Workspot—CE A2 Transformador, Paris, France, 21–25 August 2006; CIGRE: Paris, France, 2006. [Google Scholar]

- Abeysundara, D.C.; Weerakoon, C.; Lucas, J.R.; Gunatunga, K.A.I.; Obadage, K.C. Coconut oil as an alternative to transformer oil. In Proceedings of the ERU Symposium, Sri Lanka, 1 November 2001; Volume 1, pp. 1–11. [Google Scholar]

- Fofana, I.; Wasserberg, V.; Borsi, H.; Gockenbach, E. Challenge of mixed insulating liquids for use in high-voltage transformers.1. Investigation of mixed liquids. IEEE Electr. Insul. Mag. 2002, 18, 18–31. [Google Scholar] [CrossRef]

- Prevost, T.A. Dielectric properties of natural esters and their influence on transformer insulation system design and performance—An update. In Proceedings of the 2009 IEEE Power and Energy Society General Meeting, Calgary, AB, Canada, 26–30 July 2009. [Google Scholar]

- Gnanasekaran, D.; Chavidi, V.P. Properties of Vegetable Fluids: A Green Insulator for Power Sector. In Vegetable Oil Based Bio-Lubricants and Transformer Fluids; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Beroual, A.; Khaled, U.; Noah, P.S.M.; Sitorus, H. Comparative Study of Breakdown Voltage of Mineral, Synthetic and Natural Oils and Based Mineral Oil Mixtures under AC and DC Voltages. Energies 2017, 10, 511. [Google Scholar] [CrossRef]

- Standard I.E.C. 60156: 1995 Insulating Liquids–Determination of the Breakdown Voltage at Power Frequency–Test Method; International Electrotechnology Commission: Geneva, Switzerland, 1995. [Google Scholar]

- ASTM International. Standard Test Method for Dielectric Breakdown Voltage of Insulating Liquids Using; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar] [CrossRef]

- Martin, R.; Athanassatou, H.; Duart, J.C.; Perrier, C.; Sitar, I.; Walker, J.; Claiborne, C.; Boche, T.; Cherry, D.; Darwin, A.; et al. Experiences in Service with New Insulating Liquids; Cigre Working Group A: Paris, France, 2010; pp. 2–35. [Google Scholar]

- Arakelian, V.G.; Fofana, I. Water in Oil-Filled High-Voltage Equipment Part I: States, Solubility, and Equilibrium in Insulating Materials. IEEE Electr. Insul. Mag. 2014, 23, 15–27. [Google Scholar] [CrossRef]

- Darwin, A.; Perrier, C.; Foliot, P. The use of natural ester fluids in transformers. In Proceedings of the MATPOST Conference, Lyon, France, 15–16 November 2007; Volume 36, pp. 15–16. [Google Scholar]

- Vukovic, D.; Tenbohlen, S. Comparative evaluation of breakdown strength of natural esters and mineral oil. In Proceedings of the 16th International Symposium on High Voltage Engineering, Cape Town, South Africa, 24–28 August 2009; Volume 100, pp. 1–6. [Google Scholar]

- Martin, D.; Wang, Z.D.; Darwin, A.W.; James, I. A Comparative Study of the Chemical Stability of Esters for Use in Large Power Transformers. In Proceedings of the 2006 IEEE Conference on Electrical Insulation and Dielectric Phenomena, Kansas City, MO, USA, 15–18 October 2006; pp. 493–496. [Google Scholar]

- Zabeschek, S. Design of Oil-Processing Units for Mineral Oils and Natural Ester Fluids (Fr3). In Proceedings of the HEDRICH Vacuum Systems, Weidmann Transformer and Technology Seminar, Päffikon, Switzerland, 25–29 August 2014. [Google Scholar]

- Binns, D.; Yoon, K. Breakdown phenomena in Midel 7131, silicone fluid 561 and transformer oil. J. Electrost. 1982, 12, 593–600. [Google Scholar] [CrossRef]

- Mohamed, M.; Bin Bakharazi, M.A.H.; Kitagawa, H.; Matsumoto, S.; Kato, M. Partial discharge inception voltage measurements of ester dielectric fluid for insulation diagnosis. In Proceedings of the 2017 6th International Youth Conference on Energy (IYCE), Budapest, Hungary, 21–24 June 2017. [Google Scholar]

- N’Cho, J.S.; Loiselle, L.; Fofana, I.; Beroual, A.; Aka-Ngnui, T. Parameters affecting the electrical and thermal properties of transformer oils. In Proceedings of the 2010 Annual Report Conference on Electrical Insulation and Dielectic Phenomena, West Lafayette, IN, USA, 17–20 October 2010. [Google Scholar]

- Tenbohlen, S.; Koch, M.; Vukovic, D.; Weinläder, A. Application of vegetable oil-based insulating fluids to hermetically sealed power transformers. In Proceedings of the CIGRE Paris Conference, Paris, France, 24–29 August 2008. [Google Scholar]

- Rafiq, M.; Chengrong, L.; Lv, Y. Effect of Al2O3 nanorods on dielectric strength of aged transformer oil/paper insulation system. J. Mol. Liq. 2019, 284, 700–708. [Google Scholar] [CrossRef]

- Ten, C.; Fernando, M.; Wang, Z. Dielectric properties measurements of transformer oil, paper and pressboard with the effect of moisture and ageing. In Proceedings of the 2007 Annual Report—Conference on Electrical Insulation and Dielectric Phenomena, Vancouver, BC, Canada, 14–17 October 2007. [Google Scholar]

- Saha, T.K.; Purkait, P. Understanding the impacts of moisture and thermal ageing on transformer’s insulation by dielectric response and molecular weight measurements. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 568–582. [Google Scholar] [CrossRef]

- Martin, D.; Wang, Z.D.; Dyer, P.; Darwin, A.W.; James, I.R. A Comparative Study of the Dielectric Strength of Ester Impregnated Cellulose for Use in Large Power Transformers. In Proceedings of the 2007 IEEE International Conference on Solid Dielectrics, Winchester, UK, 8–13 July 2007. [Google Scholar]

- IEEE Natural Ester Working Group. IEEE Guide for Acceptance and Maintenance of Natural Ester Fluids in Transformers; Std. C57 147; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar]

- IEC. 60296 Fluids for Electrotechnical Applications-Unused Mineral Insulating Oils for Transformers and Switchgear; International Electrotechnical Commission: Geneva, Switzerland, 2012. [Google Scholar]

- IEC. 62770 Fluids for Electrotechnical Applications-Unused Natural Esters for Transformers and Similar Electrical Equipment; International Electrotechnical Commission: Geneva, Switzerland, 2013. [Google Scholar]

- Forma, M.W.E.; Jungemann, F.A.; Norris, S.N. Base Oil Handbook, 4th ed.; Wiley: New York, NY, USA, 1979. [Google Scholar]

- Noureddini, H.; Teoh, B.C.; Clements, L.D. Densities of vegetable oils and fatty acids. J. Am. Oil Chem. Soc. 1992, 69, 1184–1188. [Google Scholar] [CrossRef]

- Yao, W.; Huang, Z.; Li, J.; Wu, L.; Xiang, C. Enhanced Electrical Insulation and Heat Transfer Performance of Vegetable Oil Based Nanofluids. J. Nanomater. 2018, 2018, 4504208. [Google Scholar] [CrossRef] [Green Version]

- Gockenbach, E.; Borsi, H. Natural and Synthetic Ester Liquids as alternative to mineral oil for power transformers. In Proceedings of the 2008 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008. [Google Scholar]

- Smith, S.D. Design and test experience with natural ester fluid for power transformers. In Proceedings of the IEEE Power Engineering Society Transmission and Distribution Conference, Dallas, TX, USA, 21–26 May 2006. [Google Scholar]

- Bertrand, Y.; Hoang, L. Vegetal oils as substitute for mineral oils. In Proceedings of the Proceedings of the 7th International Conference on Properties and Applications of Dielectric Materials, Nagoya, Japan, 1–5 June 2003. [Google Scholar]

- Rycroft, M. Vegetable oil as insulating fluid for transformers. Energize 2014, 4, 37–40. [Google Scholar]

- Bertrand, Y.; Lauzevis, P. Development of a low viscosity insulating liquid based on natural esters for distribution transformers. In Proceedings of the 2013 IEEE Electrical Insulation Conference (EIC), Ottawa, ON, Canada, 2–5 June 2013. [Google Scholar]

- Sindhuja, K.; Srinivasan, M.; Niveditha, N. Natural esters as an alternative to mineral oil in transformer applications. Int. J. Pure Appl. Math. 2018, 118, 723–731. [Google Scholar]

- Rapp, K.; Gauger, G.; Luksich, J. Behavior of ester dielectric fluids near the pour point. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Austin, TX, USA, 17–20 October 1999. [Google Scholar]

- Holser, R. Transesterification of epoxidized soybean oil to prepare epoxy methyl esters. Ind. Crops Prod. 2008, 27, 130–132. [Google Scholar] [CrossRef]

- Lawate, S.; Unger, R.; Huang, C. Commercial Additives for Vegetable Lubricants. Lubr. World 1999, 5, 43–45. [Google Scholar]

- Dunn, R.O.; Shockley, M.W.; Bagby, M.O. Improving the low-temperature properties of alternative diesel fuels: Vegetable oil-derived methyl esters. J. Am. Oil Chem. Soc. 1996, 73, 1719–1728. [Google Scholar] [CrossRef]

- Mehta, D.M.; Kundu, P.; Chowdhury, A.; Lakhiani, V.K.; Jhala, A.S. A review on critical evaluation of natural ester vis-a-vis mineral oil insulating liquid for use in transformers: Part 1. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 873–880. [Google Scholar] [CrossRef]

- Moore, S.P.; Wangard, W.; Rapp, K.J.; Woods, D.L.; Del Vecchio, R.M. Cold Start of a 240-MVA Generator Step-Up Transformer Filled With Natural Ester Fluid. IEEE Trans. Power Deliv. 2014, 30, 256–263. [Google Scholar] [CrossRef]

- Frotscher, R.; Vuković, D.; Jovalekic, M.; Tenbohlen, S.; Harthun, J.; Perrier, C.; Schäfer, M. Behaviour of ester liquids under dielectric and thermal stress—From laboratory testing to practical use. In Proceedings of the 44th International Conference on Large High Voltage Electric Systems, Paris, France, 27 August 2012. [Google Scholar]

- Gnanasekaran, D.; Chavidi, V.P. Vegetable Oil: An Eco-friendly Liquid Insulator. In Vegetable Oil Based Bio-Lubricants and Transformer Fluids; Springer: Berlin/Heidelberg, Germany, 2018; pp. 101–124. [Google Scholar]

- Level, I. Draft Standard for General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers; IEEE: Piscataway, NJ, USA, 2015. [Google Scholar]

- Gumilang, H. Unique relationship between interfacial tension test (IFT) and neutral number test (Acidity) of transformer insulation oil in PLN P3B JB—Jakarta and Banten Regional. In Proceedings of the 2009 IEEE 9th International Conference on the Properties and Applications of Dielectric Materials, Harbin, China, 19–23 July 2009. [Google Scholar]

- Prevost, T.A. Dielectric properties of natural esters and their influence on transformer insulation system design and performance. In Proceedings of the IEEE Power Engineering Society Transmission and Distribution Conference, Montreal, QC, Canada, 18–22 June 2006. [Google Scholar]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A.; Rahman, S.A.; Habibullah, M.; Syazwan, M. Study of the Effect of Storage Time on the Oxidation and Thermal Stability of Various Biodiesels and Their Blends. Energy Fuels 2014, 28, 1081–1089. [Google Scholar] [CrossRef]

- Obadiah, A.; Kannan, R.; Ramasubbu, A.; Vasanthkumar, S. Studies on the effect of antioxidants on the long-term storage and oxidation stability of Pongamia pinnata (L.) Pierre biodiesel. Fuel Process. Technol. 2012, 99, 56–63. [Google Scholar] [CrossRef]

- Saha, T.K.; Purkait, P. Transformer Insulation Materials and Ageing; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Raymon, A.; Pakianathan, P.S.; Rajamani, M.P.E.; Karthik, R. Enhancing the critical characteristics of natural esters with antioxidants for power transformer applications. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 899–912. [Google Scholar] [CrossRef]

- McShane, C.; Gauger, G.; Luksich, J. Fire resistant natural ester dielectric fluid and novel insulation system for its use. In Proceedings of the 1999 IEEE Transmission and Distribution Conference, New Orleans, LA, USA, 11–16 April 1999. [Google Scholar] [CrossRef]

- Choi, S.-H.; Huh, C.-S. Analysis of the chemical and electrical characteristic of vegetable insulating oils exposed to accelerated aging. In Proceedings of the 2nd International Conference on Innovations in Electrical and Civil Engineering (ICIECE’2013), Pattaya, Thailand, 17–18 December 2013; pp. 17–18. [Google Scholar]

- N’Cho, J.S.; Fofana, I.; Hadjadj, Y.; Beroual, A. Review of Physicochemical-Based Diagnostic Techniques for Assessing Insulation Condition in Aged Transformers. Energies 2016, 9, 367. [Google Scholar] [CrossRef]

- Khan, I.U.; Wang, Z.; Cotton, I.; Northcote, S. Dissolved gas analysis of alternative fluids for power transformers. IEEE Electr. Insul. Mag. 2007, 23, 5–14. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Yi, X.; Li, S.; Hinshaw, J. Gas generation in natural ester and mineral oil under partial discharge and sparking faults. IEEE Electr. Insul. Mag. 2013, 29, 62–70. [Google Scholar] [CrossRef]

- Martin, D.; Lelekakis, N.; Davydov, V.; Odarenko, Y. Preliminary results for dissolved gas levels in a vegetable oil-filled power transformer. IEEE Electr. Insul. Mag. 2010, 26, 41–48. [Google Scholar] [CrossRef]

- Aluyor, E.O.; Obahiagbon, K.O.; Ori-Jesu, M. Biodegradation of vegetable oils: A review. Sci. Res. Essays 2009, 4, 543–548. [Google Scholar]

- Chemicals, D. OECD Guideline for Testing of Chemicals Proposal for Revised Introduction to the OECD Guidelines for Testing of Chemicals, Section 3 Part. Strategies; Organisation for Economic Co-Operation and Development: Paris, France, 2005. [Google Scholar]

- Díaz, E. Microbial Biodegradation: Genomics and Molecular Biology; Horizon Scientific Press: Madrid, Spain, 2008; ISBN 1904455174. [Google Scholar]

- Ndubuisi, E.V.; Ugbeh, J.I.; Iwuorah, C.C.; Abayeh, O.M.; Abayeh, O.J. Synthesis of a green detergent from castor seed [Ricinnus Comminus] oil. J. Chem. Soc. Niger. 2015, 40, 76–82. [Google Scholar]

- Aluyor, E.O.; Ori-Jesu, M. The use of antioxidants in vegetable oils—A review. Afr. J. Biotechnol. 2008, 7, 4836–4842. [Google Scholar]

- Fofana, I. 50 years in the development of insulating liquids. IEEE Electr. Insul. Mag. 2013, 29, 13–25. [Google Scholar] [CrossRef]

- Rao, U.M.; Sood, Y.R.; Jarial, R.K. Ester Dielectrics: Current Perspectives and Future Challenges. IETE Tech. Rev. 2016, 34, 448–459. [Google Scholar] [CrossRef]

- McShane, C. Vegetable-oil-based dielectric coolants. IEEE Ind. Appl. Mag. 2002, 8, 34–41. [Google Scholar] [CrossRef]

- Tenbohlen, S.; Koch, M. Aging Performance and Moisture Solubility of Vegetable Oils for Power Transformers. IEEE Trans. Power Deliv. 2010, 25, 825–830. [Google Scholar] [CrossRef]

- Vihacencu, M.S.; Ciuriuc, A.; Marius, L. Experimental study of electrical properties of mineral and vegetable transformer oils. UPB Sci. Bull. Ser. C Electr. Eng. 2013, 75, 171–182. [Google Scholar]

- Rapp, K.J.; Luksich, J. Review of Kraft paper/natural ester fluid insulation system aging. In Proceedings of the 2011 IEEE International Conference on Dielectric Liquids, Trondheim, Norway, 26–30 June 2011; pp. 1–4. [Google Scholar]

- Ab Ghani, S.; Muhamad, N.A.; Chairul, I.S.; Jamri, N. A study of moisture effects on the breakdown voltage and spectral characteristics of mineral and palm oil-based insulation oils. ARPN J. Eng. Appl. Sci. 2016, 11, 5012–5020. [Google Scholar]

- Martin, D.; Wang, Z.D. A Comparative Study of the Impact of Moisture on the Dielectric Capability of Esters for Large Power Transformers. In Proceedings of the 2006 IEEE Conference on Electrical Insulation and Dielectric Phenomena, Kansas City, MO, USA, 15–18 October 2006. [Google Scholar]

- Divakaran, D.; Kalaivanan, C. Investigation of lightning impulse voltage characteristics and other thermo-physical characteristics of vegetable oils for power apparatus applications. In Proceedings of the 2012 IEEE 10th International Conference on the Properties and Applications of Dielectric Materials, Bangalore, India, 24–28 July 2012. [Google Scholar]

- Guo, P.; Liao, R.; Hao, J.; Ma, Z.; Yang, L. Research on the temperature dielectric spectrum of vegetable oil, mineral oil and their relevant oil-impregnated papers. In Proceedings of the 2012 International Conference on High Voltage Engineering and Application, Shanghai, China, 17–20 September 2012. [Google Scholar]

- Hemmer, M.; Badent, R.; Leibfried, T. Electrical properties of vegetable oil-impregnated paper insulation. In Proceedings of the 2003 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Albuquerque, NM, USA, 19–22 October 2003. [Google Scholar]

- Sitorus, H.B.; Beroual, A.; Setiabudy, R.; Bismo, S. Comparison of streamers characteristics in jatropha curcas methyl ester oil and mineral oil under lightning impulse voltage. In Proceedings of the 2014 IEEE 18th International Conference on Dielectric Liquids (ICDL), Bled, Slovenia, 29 June–3 July 2014. [Google Scholar]

- Ramos, C.G.A.; Cavallini, A.; Piovan, U. A comparison of the PDIV characteristics of ester and mineral oils. Bol. IIE, September–October 2014; 123–132. [Google Scholar]

- Kanoh, T.; Iwabuchi, H.; Hoshida, Y.; Yamada, J.; Hikosaka, T.; Yamazaki, A.; Hatta, Y.; Koide, H. Analyses of electro-chemical characteristics of Palm Fatty Acid Esters as insulating oil. In Proceedings of the 2008 IEEE International Conference on Dielectric Liquids, Futuroscope-Chasseneuil, Grenoble, France, 30 June–3 July 2008; pp. 1–4. [Google Scholar]

- Al-Ammar, E.A.; Qureshi, M.I. Probing the Use of Green Insulating Oils in transformers based on their statistical breakdown data. In Proceedings of the 2009 International Conference on Electric Power and Energy Conversion Systems (EPECS), Sharjah, United Arab Emirates, 10–12 November 2009; pp. 1–6. [Google Scholar]

- Dang, V.-H.; Beroual, A.; Al-Ammar, E.; Qureshi, M. Streamer propagation in seed based insulating oils under lightning impulse voltages. In Proceedings of the 2012 International Conference on High Voltage Engineering and Application, Shanghai, China, 17–20 September 2012. [Google Scholar]

- Li, Y.; Zhu, M.-X.; Mu, H.-B.; Deng, J.; Zhang, G.-J.; Jadidian, J.; Zahn, M.; Zhang, W.Z.; Li, Z.M. Transformer Oil Breakdown Dynamics Stressed by Fast Impulse Voltages: Experimental and Modeling Investigation. IEEE Trans. Plasma Sci. 2014, 42, 3004–3013. [Google Scholar] [CrossRef]

- Ab Ghani, S.; Muhamad, N.A.; Noorden, Z.A.; Zainuddin, H.; Abu Bakar, N.; Talib, M.A. Methods for improving the workability of natural ester insulating oils in power transformer applications: A review. Electr. Power Syst. Res. 2018, 163, 655–667. [Google Scholar] [CrossRef]

- Unge, M.; Singha, S.; Van Dung, N.; Linhjell, D.; Ingebrigtsen, S.; Lundgaard, L.E. Enhancements in the lightning impulse breakdown characteristics of natural ester dielectric liquids. Appl. Phys. Lett. 2013, 102, 172905. [Google Scholar] [CrossRef]

- Rao, U.M.; Fofana, I.; Loiselle, L. Preliminary Studies On Soluble and Colloidal Decomposition Products In Ester Filled Transformers. In Proceedings of the 2019 IEEE 20th International Conference on Dielectric Liquids (ICDL), Roma, Italy, 23–27 June 2019. [Google Scholar]

- Lau, K.Y.; Vaughan, A.S.; Chen, G. Nanodielectrics: Opportunities and challenges. IEEE Electr. Insul. Mag. 2015, 31, 45–54. [Google Scholar] [CrossRef]

- Lv, Y.; Rafiq, M.; Li, C.; Shan, B. Study of Dielectric Breakdown Performance of Transformer Oil Based Magnetic Nanofluids. Energies 2017, 10, 1025. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Rafiq, M.; Lv, Y.; Li, C.; Yi, K. Preparation of Three Types of Transformer Oil-Based Nanofluids and Comparative Study on the Effect of Nanoparticle Concentrations on Insulating Property of Transformer Oil. J. Nanotechnol. 2016, 2016, 5802753. [Google Scholar] [CrossRef] [Green Version]

- Rafiq, M.; Lv, Y.; Li, C. Effect of Shape, Surface Modification and Concentration of Al2O3 Nanoparticles on Breakdown Performance of Transformer Oil. J. Electr. Eng. Technol. 2019, 15, 457–468. [Google Scholar] [CrossRef]

- Lv, Y.; Yi, K.; Li, C.; Sun, Q.; Rafiq, M.; Li, C.; Qi, B. Fabrication, characterization, and insulating property of Fe3O4 nanofluids. Integr. Ferroelectr. 2017, 180, 37–43. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, F.; Wang, Q.; Yao, W.; Sun, K.; Zhang, R.; Zhao, J.; Lou, Z.; Li, J. Significantly Enhanced Electrical Performances of Eco-Friendly Dielectric Liquids for Harsh Conditions with Fullerene. Nanomaterials 2019, 9, 989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khaled, U.; Beroual, A.; Beroua, A. Statistical Investigation of AC Dielectric Strength of Natural Ester Oil-Based Fe3O4, Al2O3, and SiO2 Nano-Fluids. IEEE Access 2019, 7, 60594–60601. [Google Scholar] [CrossRef]

- Rafiq, M.; Cheng-Rong, L.; Yu-Zhen, L. The Effect of Alumina Nanorods on Breakdown Performance of Transformer oil. In Proceedings of the 2018 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Athens, Greece, 10–13 September 2018. [Google Scholar]

- Jain, S.; Sharma, M. Prospects of biodiesel from Jatropha in India: A review. Renew. Sustain. Energy Rev. 2010, 14, 763–771. [Google Scholar] [CrossRef]

- Kumar, G.; Kumar, D.; Singh, S.; Kothari, S.K.; Bhatt, S.; Singh, C.P. Continuous Low Cost Transesterification Process for the Production of Coconut Biodiesel. Energies 2010, 3, 43–56. [Google Scholar] [CrossRef] [Green Version]

- Rapp, K.J.; Luksich, J.; Sbravati, A. Application of Natural Ester Insulating Liquids in Power Transformers. In Proceedings of the My Transfo, Turin, Italy, 18–19 November 2014. [Google Scholar]

- Moore, S.P. Some considerations for new and retrofill applications of natural ester dielectric fluids in medium and large power transformers revisited. In Proceedings of the 2009 IEEE Power & Energy Society General Meeting, Calgary, AB, Canada, 26–30 July 2009; pp. 1–7. [Google Scholar]

- Lashbrook, M. Ester Fluids for Power Transformers at> 100kV. Transform. Mag. 2014, 1, 14–19. [Google Scholar]

- Liu, Q.; Wang, Z. Streamer characteristic and breakdown in synthetic and natural ester transformer liquids under standard lightning impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 285–294. [Google Scholar] [CrossRef]

- Moore, H.R. Requirements and expectations of natural ester fluids for application in power transformers. In Proceedings of the IEEE Transmission and Distribution Conference and Exhibition, Dallas, TX, USA, 21–24 May 2006; Volume 1, pp. 23–24. [Google Scholar]

- Dai, J.; Wang, Z. A Comparison of the Impregnation of Cellulose Insulation by Ester and Mineral oil. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 374–381. [Google Scholar] [CrossRef]

- Oommen, T.V.; Le, H.D.; Claiborne, C.C.; Walsh, E.J.; Baker, J.P. Enhanced cellulosic insulation life in a high oleic vegetable oil dielectric fluid. In Proceedings of the 69th International Conference Doble Clients, Boston, MA, USA, 7–12 April 2002. [Google Scholar]

- Martin, D.; Khan, I.; Dai, J.; Wang, Z.D. An overview of the suitability of vegetable oil dielectrics for use in large power transformers. In Proceedings of the 5th Annual Euro TechCon Chester, Chester, UK, 28–30 November 2006; pp. 28–30. [Google Scholar]

- Liland, K.B.; Linhjell, D.; Lesaint, C.; Ese, M.-H.G.; Lundgaard, L.E.; Mavrommatis, P.; Stjepanovic, N. Comparison between synthetic ester and mineral oil impregnated transformer paper aging markers. In Proceedings of the 2017 IEEE 19th International Conference on Dielectric Liquids (ICDL), Manchester, UK, 25–29 June 2017; pp. 1–6. [Google Scholar]

- Lazari, A. ERNCIP Training for Professionals in Critical Infrastructure Protection: From Risk Management to Resilience; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Rapp, K.J.; McShane, C.P.; Gauger, G.A.; Lemm, A.W. Vegetable Oil Dielectric Fluid Composition. U.S. Patent 8,801,975[P], 12 August 2014. [Google Scholar]

- Kumar, S.S.; Iruthayarajan, M.W.; Bakrutheen, M. Investigations on the suitability of rice bran oil and corn oil as alternative insulating liquids for transformers. IEEJ Trans. Electr. Electron. Eng. 2015, 11, 10–14. [Google Scholar] [CrossRef]

- Abdelmalik, A.A. Chemically modified palm kernel oil ester: A possible sustainable alternative insulating fluid. Sustain. Mater. Technol. 2014, 1, 42–51. [Google Scholar] [CrossRef] [Green Version]

- Azis, N.; Jasni, J.; Ab Kadir, M.Z.A.; Mohtar, M.N. Suitability of Palm Based Oil as Dielectric Insulating Fluid in Transformers. J. Electr. Eng. Technol. 2014, 9, 662–669. [Google Scholar] [CrossRef] [Green Version]

- Obande, J.O.; Agber, J.U. Palm Oil As An Alternative Dielectric Transformer Coolant. Int. J. Res. Eng. Sci. 2014, 2, 8–13. [Google Scholar]

- Masarakall, V.H.; Sikdar, D.C.; Madalageri, S.B.; Nitture, M.R.; Naidu, J.C. Development of new dielectric liquid from Pongamia oil as alternative for transformer oil. Int. J. Tech. Res. Appl. 2015, 3, 304–309. [Google Scholar]

- Mariprasath, T.; Kirubakaran, V. Pongamia pinnata as alternate liquid dielectrics in distribution transformer: A critical study on the property of viscosity. Adv. Energy Power 2015, 3, 1–7. [Google Scholar]

- Sato, M.; de Carvalho Bueno, O.; Esperancini, M.S.T.; Frigo, E.P. A cultura do pinhão-manso (Jatropha curcas L.): Uso para fins combustíveis e descrição agronômica. Varia Sci. 2009, 7, 47–62. [Google Scholar]

- Sitorus, H.B.H.; Setiabudy, R.; Bismo, S.; Beroual, A. Physicochemical and electrical properties of jatropha curcas methyl ester oil as a substitute for mineral oil. In Proceedings of the 2014 IEEE 18th International Conference on Dielectric Liquids (ICDL), Bled, Slovenia, 29 June–3 July 2014; pp. 1–4. [Google Scholar]

- Evangelista, J.M.G., Jr.; Coelho, F.E.B.; Carvalho, J.A.O.; Araújo, E.M.R.; Miranda, T.L.S.; Salum, A. Development of a new bio-based insulating fluid from Jatropha curcas oil for power transformers. Adv. Chem. Eng. Sci. 2017, 7, 235. [Google Scholar] [CrossRef] [Green Version]

- Beltrán, N.; Palacios, E.; Blass, G. Potential of Jatropha curcas oil as a dielectric fluid for power transformers. IEEE Electr. Insul. Mag. 2017, 33, 8–15. [Google Scholar] [CrossRef]

- Adeolu, O.; Adejumobi, I.A. Breakdown voltage characteristics of castor oil as alternative to transformer insulation oil. Int. J. Sci. Eng. Res. 2014, 2, 31–37. [Google Scholar]

- Naranpanawe, W.M.L.B.; Fernando, M.A.R.M.; Kumara, J.R.S.S.; Naramapanawa, E.M.S.N.; Kalpage, C.S. Performance analysis of natural esters as transformer liquid insulation—Coconut, castor and sesame oils. In Proceedings of the 2013 IEEE 8th International Conference on Industrial and Information Systems, Peradeniya, Sri Lanka, 17–20 December 2013; pp. 105–109. [Google Scholar]

- Shriram, R.K.A.; Chandrasekar, S.; Karthik, B. PD Signal Time-Frequency Map and PRPD Pattern Analysis of Nano SiO₂ Modified Palm Oil for Transformer Insulation Applications. J. Electr. Eng. Technol. 2018, 13, 902–910. [Google Scholar]

- Shafique, M.; Luo, X. Nanotechnology in transportation vehicles: An overview of its applications, environmental, health and safety concerns. Materials 2019, 12, 2493. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; Argonne National Laboratory: Lemont, IL, USA, 1995. [Google Scholar]

- Taha-Tijerina, J.; Narayanan, T.N.; Gao, G.; Rohde, M.; Tsentalovich, D.A.; Pasquali, M.; Ajayan, P.M. Electrically Insulating Thermal Nano-Oils Using 2D Fillers. ACS Nano 2012, 6, 1214–1220. [Google Scholar] [CrossRef] [PubMed]

- Contreras, J.; Rodriguez, E.; Taha-Tijerina, J. Nanotechnology applications for electrical transformers—A review. Electr. Power Syst. Res. 2017, 143, 573–584. [Google Scholar] [CrossRef]

- Li, J.; Liao, R.; Yang, L. Investigation of natural ester based liquid dielectrics and nanofluids. In Proceedings of the 2012 International Conference on High Voltage Engineering and Application, Shanghai, China, 17–20 September 2012; pp. 16–21. [Google Scholar]

- Karthik, R.; Raymon, A. Effect of silicone oxide nano particles on dielectric characteristics of natural ester. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; pp. 1–3. [Google Scholar]

- Du, B.X.; Li, X.L.; Li, J.; Tao, X.Y. Effects of BN nanoparticles on thermal conductivity and breakdown strength of vegetable oil. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 476–479. [Google Scholar]

- Saenkhumwong, W.; Suksri, A. Investigation on Voltage Breakdown of Natural Ester Oils Based-On Zno Nanofluids. Adv. Mater. Res. 2015, 1119, 175–178. [Google Scholar] [CrossRef]

- Srinivasan, M.; Ragupathy, U.S.; Sindhuja, K.; Raymon, A. Investigation and performance analysis of nanoparticles and antioxidants based natural ester. Int. J. Adv. Eng. Technol. 2016, 1000, 1007. [Google Scholar]

- Peppas, G.D.; Bakandritsos, A.; Charalampakos, V.P.; Pyrgioti, E.C.; Tucek, J.; Zbořil, R.; Gonos, I. Ultrastable Natural Ester-Based Nanofluids for High Voltage Insulation Applications. ACS Appl. Mater. Interfaces 2016, 8, 25202–25209. [Google Scholar] [CrossRef] [PubMed]

| Electrical Properties | Chemical Properties | Physical Properties |

|---|---|---|

| Alternating current (AC) Breakdown strength (BDS) | Oxidation stability | Thermal conductivity |

| Lightning impulse (LI) BDS | Gassing features under electric stress | Specific heat |

| Partial discharge inception voltage (PDIV) | Ionization situations (silent discharge) | Coefficient of volume expansion |

| Dielectric dissipation factor | Gassing features under high-temperature pyrolysis conditions (thermal and disruptive discharge) | Viscosity |

| Volume resistivity | Neutralization value | density |

| Permittivity | Saponification value | Pour point |

| Contaminants | Sulfur staining and corrosion | Refractive index |

| Nitrogen content | Molecular weight | |

| Ionic contamination | Solvent power | |

| Moisture content | Vapor pressure | |

| Flammability | ||

| Interfacial tension |

| Features | MO | Silicone Fluid | Synthetic Ester | NE |

|---|---|---|---|---|

| Category | Filtered from crude petroleum | Synthetic | Synthetic | Refined vegetable oil |

| Major component | Composite combination of hydrocarbons | di-alkyl silicone polymer | Pentaerythritol tetra ester | Plant-based natural ester |

| Origin | Refined from oil | Prepared from chemicals | Developed from chemicals | Derived from crops |

| Biodegradability | Slowly biodegradation | Really slow to biodegradation | Readily biodegradable | Readily biodegradable |

| Oxidation stability | Good stability | Outstanding stability | Outstanding stability | Normally oxidation vulnerable |

| Moisture saturation at ambient (ppm) | 55 | 220 | 2600 | 1100 |

| Flash point, °C | 160–170 | ˃300 | ˃250 | ˃300 |

| Fire point, °C | 170–180 | ˃350 | ˃300 | ˃350 |

| Fire categorization | O | K | K | K |

| Electric Features | MO | NE Fluid | References |

|---|---|---|---|

| Dielectric strength (BDV), kV | 54.9 | 56.7 | [46] |

| Dielectric dissipation factor | 0.081 | 0.45 | |

| Specific resistance, 1012 ohm cm─1@80 °C | 220 | 3 | |

| Gassing tendency, μL/min | −5 | −79 |

| Experiment | MO | Synthetic Ester | NE | Silicone Oil | Low Viscosity Silicone Oil | References |

|---|---|---|---|---|---|---|

| IEC 60,156 2.5 mm | 70 kV | ˃75 kV | ˃75 kV | 50 kV | 70 kV | [50,51] |

| ASTM 1816 1 mm | – | – | 37 kV | – | – | |

| ASTM 1816 2 mm | 60 kV | – | 76 kV | – | – | |

| ASTM D877 | 55 kV | 43 kV | 46 kV | 43 kV | – |

| Gap Distance (mm) | Mean Stress (kV/mm) | Ref. | ||

|---|---|---|---|---|

| MO | Silicone Oil | VO (MIDEL 7131) | ||

| 1.0 | 40.6 | 42.0 | 33.4 | [50,51] |

| 2.5 | 38.3 | 47.7 | 33.0 | |

| 2.0 | 45.8 | 42.3 | 44.6 | |

| 2.5 | 39.0 | 34.0 | 36.5 | |

| Physical Characteristics | MO | NE liquid | Ref. | |

|---|---|---|---|---|

| Viscosity, cSt | @40 °C | 7.800 | 35.12 | [46] |

| @100 °C | 2.240 | 8.010 | ||

| Density, @ 25 °C/Cg/cc | 0.855 | 0.924 | ||

| Pour point, °C | −40 | −21 | ||

| Flash point, °C | 145 | 275 | ||

| Interfacial tension, mN/M | 40 | 30 | ||

| Feature | Standard | MO | NE Fluid | Reference |

|---|---|---|---|---|

| Relative density (g/mL) (15 °C/15 °C) | ASTM | ≤ 0.91 | ≤ 0.92 | [64] |

| IEEE | ≤ 0.91 at 15 °C/15 °C | ≤ 0.96 at 25 °C | ||

| Density at 20 °C (g/mL) | IEC | Max. 0.895 | Max. 1.1 | [65,66] |

| Temperature °C | Density, g/cc | Reference | |||

|---|---|---|---|---|---|

| Soybean Oil | Coconut Oil | Corn Oil | Rapeseed Oil | ||

| 23.9 | 0.9193 | – | 0.9188 | 0.9078 | [67,68] |

| 37.8 | 0.9082 | 0.9107 | 0.9082 | 0.8977 | |

| 48.9 | 0.9023 | 0.9033 | 0.9028 | 0.8829 | |

| 60.0 | 0.8939 | 0.8949 | 0.8939 | 0.8829 | |

| 82.2 | 0.8795 | 0.8795 | 0.8800 | 0.8681 | |

| 100.0 | 0.8674 | 0.8669 | 0.8679 | 0.8564 | |

| 110.0 | 0.8615 | 0.8695 | 0.8610 | 0.8501 | |

| 25.0 | 0.915–0.918 | 0.916–0.918 | 0.915–0.917 | – | |

| Features | Standard | MO | NE Fluid | Reference |

|---|---|---|---|---|

| Pour point (°C) | ASTM | ≤ −40 °C | ≤ −10 °C | [80] |

| IEEE | − | ≤ −10 °C | ||

| Tendency to develop voids | Natural esters presented a reduction in trend to form cavities after cooled further than its pour point temperature | [80,81] | ||

| Cold launch/start | No specific care is necessary while cold launch of NE filled transformer | [81] | ||

| Ambient falls below 0 °C | Endorsed to operate transformer under without load circumstance | [82] | ||

| Characteristics | Standard | MO | NE | References |

|---|---|---|---|---|

| Fire protection category | IEC | O1 | K2 | [65,66,80] |

| Flash point (°C) | ASTM | Limit 145 | Limit 275 | |

| IEEE | − | Min. 275 | ||

| IEC | ≥135 | Min. 250 | ||

| Fire point (°C) | ASTM | Limit 170 | Limit 3000 | |

| IEEE | − | Min. 300 | ||

| IEC | − | Min. 300 | ||

| Calorific value MJ/kg | − | 46 | 37.5 | |

| Transformer parting space obligation from other transformer or structure or another substation apparatus | FM Universal Standard3990 | 1/10th clearance essential for MO filled transformers | ||

| Condition of the fire extinguishing system | required | Not essential even for indoor applications | ||

| Fluid | Flash Point (°C) | Fire Point (°C) | Category | References |

|---|---|---|---|---|

| MO | 160−170 | 170–180 | O | [5] |

| Silicone fluid | ˃300 | ˃350 | K3 | |

| Low viscosity silicon fluid | 268 | 312 | K3 | |

| Synthetic ester | ˃250 | ˃300 | K3 | |

| NE | ˃300 | ˃350 | K2 |

| Traits | MO | Hydrocarbon Oil | Silicone Oil | NE | References |

|---|---|---|---|---|---|

| Fire opposition | Poor | Outstanding | Outstanding | Outstanding | [50,51] |

| Environmental impression | Moderate | Reasonable | Reasonable | Outstanding | |

| Life probability at max. temperature rating | Good | Good | Good | High | |

| Efficiency | High | High | High | High | |

| Sound level | Low | Low | Low | Low | |

| Functioning temperature | Low | Low | Low | Low | |

| Impurity resistance | Outstanding | Outstanding | Outstanding | Outstanding | |

| Overload capability | Good | Outstanding | − | Outstanding | |

| Initial cost | Low | Low/reasonable | High | Reasonable | |

| Energy costs | Low | Low | Low | Low | |

| Recycle/discarding costs | Low | Low | High | Low |

| Fluid | Ester Associations | Approx. Moisture Saturation at 23 °C (ppm) | Reference |

|---|---|---|---|

| MO | 0 | 55 | [50,51] |

| Silicone oil | 0 | 220 | |

| NE | 3 | 1100 | |

| Synthetic ester | 4 | 2600 |

| Experiment Factor | Parameters | MO | NE | References |

|---|---|---|---|---|

| Moisture level, mg/kg | ˂200 | 15.0 | 20.7 | [46] |

| Neutralization value, mg of KOH/g of oil | ˂0.06 | 0.01 | 0.08 | |

| Erosive sulfur | Non-erosive | Non-erosive | Non-erosive |

| Oxidization Stability Limits | Mineral Oil | Natural Ester | Reference |

|---|---|---|---|

| According to IEC, experiment procedure is similar for both fluids, except a period of expedited aging | 164 h at 120 °C | 48 h at 120 °C | [74] |

| Oxidation stability | MO ˃˃˃ NE | [80] | |

| Oxidation stability values attained by Rotating Bomb Oxidation test (RBOT) | 300 min | ˂40 min | |

| Method of Measurement | MO | NE Fluid | Reference |

|---|---|---|---|

| DGA method | Identical analysis techniques are appropriate for NEs; though amidst all Duval triangle is the utmost trustworthy procedure to be used for NEs | [82,95,96] | |

| Duval triangle for electrical fault | Electric defects in NEs fluid (electric discharges, breakdown and PDs) may be discovered by the present MO dual triangle without any change. | [82,95] | |

| Duval triangle for thermal fault | Thermal faults may be discovered for NEs by changing zone limitations for thermal defects T1, T2 and T3 of present MO Duval triangle. | ||

| Relevant Duval triangle for small thermal issues and stray gassing | Duval Triangle 4 | Duval Triangle 6 | [29,82] |

| Characteristics | MO | Synthetic Ester (SE) | NE | References |

|---|---|---|---|---|

| Biochemical oxygen demand 5-day SM5210B (ppm) | 6 | 24 | 250 | [12,102,103] |

| Biodegradability | ||||

| ˂30% | 80% | 97% to 99% | |

| Not biodegradable | Readily biodegradable | Readily biodegradable | |

| Not biodegradable | Fully biodegradable | Fully biodegradable | |

| Toxicity | Yes | Low | No | |

| Sustainability | No | Yes | Yes | |

| Fire threat evaluation category (IEC 61039) | O (fire point 110–185 °C) | K (fire point ˃ 300 °C) | K (fire point ˃ 300 °C) | |

| Emission profile | Unacceptable | Questionable | Acceptable |

| Properties | Vegetable Oil | High temperature MO | Silicone Fluid |

|---|---|---|---|

| Appearance | Light yellow a | Light yellow | Colorless |

| Specific gravity (25 °C) | 0.91–0.92 | 0.89 | 0.96 |

| Kinematic viscosity (cSt) 0 °C 25 °C 40 °C 100 °C | 170–250 55–75 33–45 8–10 | 2200 300 125 13 | 95 50 38 16 |

| Pour point, °C | −15 to −25 | −20 max. | −50 max. |

| Interfacial tension (IFT), dynes/cm | 25 | 40–45 | 25 |

| Flash point, °C | 310–325 | 275 min. | 300 min. |

| Fire point, °C | 354–360 | 160–180 | 340 |

| Moisture content, ppm dry oil | 50–100 | 10–25 b | 50 |

| (water solubility at 25 °C) | 1200 | 60 | 200 |

| Thermal constants Heat capacity, cal/g °C | 0.50–0.57 | 0.488 | 0.363 |

| Thermal conductivity, W/mK | 0.17 a | 0.13 | 0.15 |

| Coefficient of expansion/°C | 0.0007 | 0.00073 | 0.00104 |

| Chemical Chemical type | Ester 0.06 a Pass | Hydrocarbon 0.01 Pass | Organo-silicon 0.01 Pass |

| Electrical Dielectric constant at 20 °C Volume resistivity at 25 °C, Ohm cm | 3.1 1014 | 2.2 1014–1015 | 2.71 1014 |

| Breakdown voltage, kV ASTM D 1816, 2-mm gap electrodes | 74 a | 60 | – |

| Impulse breakdown voltage, kV (needle negative) | 116 a | 145 | 136 |

| Dissipation factor (%) 25 °C 100 °C | 0.25 a 1.00 a | 0.05 max. 0.3 max. | −0.01 – |

| Grassing tendency-ASTM D2300 | −50 a | −19 to 20 | N/A |

| Biodegradability CEC-L-33 (21 days) | 97–99 | 30 | Very low |

| Characteristics | MO | Synthetic Ester | NE | References |

|---|---|---|---|---|

| Mixability | – | Miscible in all percentages | Miscible in all percentages | [12,102,103] |

| Appropriateness for cold environments | Acceptable | Acceptable | Questionable | |

| Soluble particles with aging | Yes | Yes (with bigger aging) | Yes (with bigger aging) | |

| Colloidal particles with aging | Yes | No (with lower/moderate aging) | No (with lower/moderate aging) | |

| Major gases created post aging | H2 and C2H2 | CO and CO2 | CO and CO2 | |

| Oxidation stability | Acceptable | Acceptable | Questionable | |

| Absorption capacity | Rises briskly with aging | Rises moderately | Initially high | |

| Antioxidants | required | Required | Strongly required | |

| Gelling | No | No | Partially yes (for breathing units) | |

| Gelling | faster | slower | slower |

| Apparatus | MO | Silicone Fluid | Synthetic Ester | Vegetable Oil (Natural Ester) | References |

|---|---|---|---|---|---|

| Power transformers | A | X | B | B | [50,51] |

| Traction transformer | A | A | A | X | |

| Distribution transformer | A | A | A | A | |

| Instrument transformer | A | X | X | X |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rafiq, M.; Shafique, M.; Azam, A.; Ateeq, M.; Khan, I.A.; Hussain, A. Sustainable, Renewable and Environmental-Friendly Insulation Systems for High Voltages Applications. Molecules 2020, 25, 3901. https://doi.org/10.3390/molecules25173901

Rafiq M, Shafique M, Azam A, Ateeq M, Khan IA, Hussain A. Sustainable, Renewable and Environmental-Friendly Insulation Systems for High Voltages Applications. Molecules. 2020; 25(17):3901. https://doi.org/10.3390/molecules25173901

Chicago/Turabian StyleRafiq, Muhammad, Muhammad Shafique, Anam Azam, Muhammad Ateeq, Israr Ahmad Khan, and Abid Hussain. 2020. "Sustainable, Renewable and Environmental-Friendly Insulation Systems for High Voltages Applications" Molecules 25, no. 17: 3901. https://doi.org/10.3390/molecules25173901