Antibacterial Cotton Fabric Functionalized with Copper Oxide Nanoparticles

Abstract

:1. Introduction

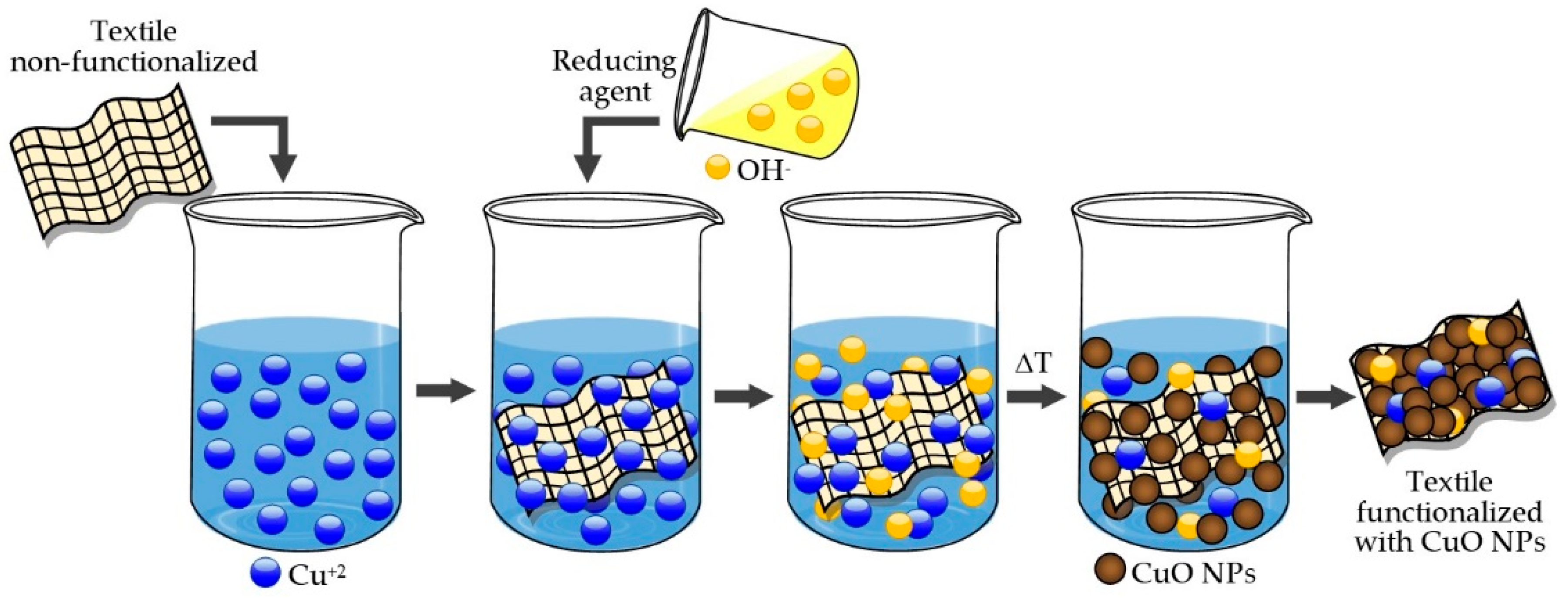

2. Textile Functionalization Methodologies

3. Antimicrobial Activity of Textiles Functionalized with CuO Nanoparticles

4. Wash Durability Test and Uses of Textiles Functionalized with CuO Nanoparticles

5. Cytotoxicity of Textiles Functionalized with CuO Nanoparticles

6. Conclusions and Future Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- World Health Organization. Available online: https://www.who.int/topics/infectious_diseases/en/ (accessed on 10 August 2020).

- Zorrilla-Vaca, A.; Escandón-Vargas, K. La importancia del control y prevención de enfermedades infecciosas en anestesiología. Rev. Colomb. Anestesiol. 2017, 45, 69–77. [Google Scholar] [CrossRef]

- Van Baarle, D.; Bollaerts, K.; Del Giudice, G.; Lockhart, S.; Luxemburger, C.; Postma, M.J.; Timen, A.; Standaert, B. Preventing infectious diseases for healthy ageing: The VITAL public-private partnership project. Vaccine 2020, 38, 5896–5904. [Google Scholar] [CrossRef]

- Scott, E.A.; Bruning, E.; Nims, R.W.; Rubino, J.R.; Ijaz, M.K. A 21st century view of infection control in everyday settings: Moving from the germ theory of disease to the microbial theory of health. Am. J. Infect. Control 2020, 44, 1387–1392. [Google Scholar] [CrossRef]

- Alshammari, T.M.; Altebainawi, A.F.; Alenzi, K.A. Importance of early precautionary actions in avoiding the spread of COVID-19: Saudi Arabia as an Example. Saudi Pharm. J. 2020, 28, 898–902. [Google Scholar] [CrossRef]

- Hossain, M.P.; Junus, A.; Zhu, X.; Jia, P.; Wen, T.H.; Pfeiffer, D.; Yuan, H.Y. The effects of border control and quarantine measures on the spread of COVID-19. Epidemics 2020, 32, 100397. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Li, H.; Hang, W.; Wang, D.W. Cardiac injuries in coronavirus disease 2019 (COVID-19). J. Mol. Cell. Cardiol. 2020, 145, 25–29. [Google Scholar] [CrossRef] [PubMed]

- Portincasa, P.; Krawczyk, M.; Machill, A.; Lammert, F.; Di Ciaula, A. Hepatic consequences of COVID-19 infection. Lapping or biting? Eur. J. Intern. Med. 2020, 77, 18–24. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. WHO Coronavirus Disease (COVID-19) Dashboard. Available online: https://covid19.who.int/ (accessed on 12 October 2020).

- Bloomfield, S.F.; Rook, G.A.; Scott, E.A.; Shanahan, F.; Stanwell-Smith, R.; Turner, P. Time to abandon the hygiene hypothesis: New perspectives on allergic disease, the human microbiome, infectious disease prevention and the role of targeted hygiene. Perspect. Public Health 2016, 136, 213–224. [Google Scholar] [CrossRef] [PubMed]

- Flores Cabeza, E.; Sánchez Sánchez, M.; Añón Elizalde, J.M.; Gutiérrez Melón, C. Infecciones relacionadas con la asistencia sanitaria (nosocomiales). Medicine 2018, 12, 3076–3084. [Google Scholar] [CrossRef]

- Sturdy, A.; Basarab, M.; Cotter, M.; Hager, K.; Shakespeare, D.; Shah, N.; Randall, P.; Spray, D.; Arnold, A. Severe COVID-19 and healthcare-associated infections on the ICU: Time to remember the basics? J. Hosp. Infect. 2020, 105, 593–595. [Google Scholar] [CrossRef]

- Huerta-Gutierrez, R.; Braga, L.; Camacho-Ortiz, A.; Diaz-Ponce, H.; Garcia-Mollinedo, L.; Guzman-Blanco, M.; Valderrama-Beltran, S.; Landaeta-Nezer, E.; Moreno-Espinosa, S.; Morfin-Otero, R.; et al. One-day point prevalence of healthcare-associated infections and antimicrobial use in four countries in Latin America. Int. J. Infect. Dis. 2019, 86, 157–166. [Google Scholar] [CrossRef] [Green Version]

- Tchouaket Nguemeleu, E.; Beogo, I.; Sia, D.; Kilpatrick, K.; Seguin, C.; Baillot, A.; Jabbour, M.; Parisien, N.; Robins, S.; Boivin, S. Economic analysis of healthcare-associated infection prevention and control interventions in medical and surgical units: Systematic review using a discounting approach. J. Hosp. Infect. 2020, 106, 134–154. [Google Scholar] [CrossRef] [PubMed]

- Hanczvikkel, A.; Víg, A.; Tóth, Á. Survival capability of healthcare-associated, multidrug-resistant bacteria on untreated and on antimicrobial textiles. J. Ind. Text. 2018, 48, 1113–1135. [Google Scholar] [CrossRef]

- World Health Organization. The Burden of Health Care-Associated Infection Worldwide. Available online: https://www.who.int/gpsc/country_work/burden_hcai/en/ (accessed on 14 August 2020).

- European Centre for Disease Prevention and Control. Available online: https://www.ecdc.europa.eu/en/publications-data/antimicrobial-resistance-and-healthcare-associated-infections-annual#copy-to-clipboard (accessed on 12 August 2020).

- Xiao, J.; Fang, M.; Chen, Q.; He, B. SARS, MERS and COVID-19 among healthcare workers: A narrative review. J. Infect. Public Health 2020, 13, 843–848. [Google Scholar] [CrossRef] [PubMed]

- Muller, M.P.; MacDougall, C.; Lim, M. Antimicrobial surfaces to prevent healthcare-associated infections: A systematic review. J. Hosp. Infect. 2016, 92, 7–13. [Google Scholar] [CrossRef]

- Cohen, J. Why Flu Vaccines Don’t Protect People for Long. Available online: http://dx.doi.org/10.1126/science.abe3208 (accessed on 18 August 2020).

- Tiginyanu, I.M.; Lupan, O.; Ursaki, V.V.; Chow, L.; Enachi, M. Nanostructures of metal oxides. In Comprehensive Semiconductor Science and Technology, 1st ed.; Bhattacharya, P., Fornari, R., Kamimura, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 396–479. ISBN 978-0-444-53153-7. [Google Scholar]

- Vogel, A. Química Analítica Cualitativa; Kapelusz: Buenos Aires, Argentina, 1991; ISBN 978-9-5013-3550-7. [Google Scholar]

- Ghijsen, J.; Tjeng, L.H.; van Elp, J.; Eskes, H.; Westerink, J.; Sawatzky, G.A.; Czyzyk, M.T. Electronic structure of Cu2O and CuO. Phys. Rev. B Condens. Matter 1988, 38, 11322–11330. [Google Scholar] [CrossRef]

- Åsbrink, S.; Norrby, L.-J. A refinement of the crystal structure of copper (II) oxide with a discussion of some exceptional e.s.d.’s. Acta Crystallogr. Sect. B Struct. Sci. 1970, 26, 8–15. [Google Scholar] [CrossRef]

- Dharmadhikari, D.V.; Phirange, A.S.; Sabharwal, S.G.; Athawale, A.A. Precursor-dependent structural properties and antibacterial activity of copper oxide. Bull. Mater. Sci. 2018, 41, 98. [Google Scholar] [CrossRef] [Green Version]

- Weldegebrieal, G.K. Photocatalytic and antibacterial activity of CuO nanoparticles biosynthesized using Verbascum thapsus leaves extract. Optik 2020, 204, 164230. [Google Scholar] [CrossRef]

- Patel, R.H.; Kachhia, P.H.; Sharma, S. Studies on the high thermal conduction fluid by incorporating CuO nanoparticles in a liquid coolant. Mater. Today Proc. 2019, 18, 1291–1296. [Google Scholar] [CrossRef]

- Siddiqui, H.; Parra, M.R.; Pandey, P.; Qureshi, M.S.; Haque, F.Z. Utility of copper oxide nanoparticles (CuO-NPs) as efficient electron donor material in bulk-heterojunction solar cells with enhanced power conversion efficiency. J. Sci. Adv. Mater. Devices 2020, 5, 104–110. [Google Scholar] [CrossRef]

- Naveena, D.; Logu, T.; Sethuraman, K.; Bose, A.C. Significant enhancement of photo-physicochemical properties of Yb doped copper oxide thin films for efficient solid-state solar cell. J. Alloys Compd. 2019, 795, 187–196. [Google Scholar] [CrossRef]

- Li, D.; Tang, Y.; Ao, D.; Xiang, X.; Wang, S.; Zu, X. Ultra-highly sensitive and selective H2S gas sensor based on CuO with sub-ppb detection limit. Int. J. Hydrogen Energy 2019, 44, 3985–3992. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Li, L.; Wang, Y.; Zhang, L.; Zhang, B.; Wang, F. Formation of dumbbell and sphere-like CuO as high-performance anode materials for lithium ion batteries. Mater. Lett. 2020, 261, 127058. [Google Scholar] [CrossRef]

- Azam, A.; Ahmed, A.S.; Oves, M.; Khan, M.S.; Memic, A. Size-dependent antimicrobial properties of CuO nanoparticles against Gram-positive and -negative bacterial strains. Int. J. Nanomed. 2012, 7, 3527–3535. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Allaker, R.P. Nanoparticles and the control of oral biofilms. In Nanobiomaterials in Clinical Dentistry; Subramani, K., Ahmed, W., Hartsfield, J.K., Eds.; Elsevier: Cambridge, MA, USA, 2013; pp. 203–227. ISBN 978-1-4557-3127-5. [Google Scholar]

- Tavakoli, A.; Hashemzadeh, M.S. Inhibition of herpes simplex virus type 1 by copper oxide nanoparticles. J. Virol. Methods 2020, 275, 113688. [Google Scholar] [CrossRef] [PubMed]

- Minoshima, M.; Lu, Y.; Kimura, T.; Nakano, R.; Ishiguro, H.; Kubota, Y.; Hashimoto, K.; Sunada, K. Comparison of the antiviral effect of solid-state copper and silver compounds. J. Hazard. Mater. 2016, 312, 1–7. [Google Scholar] [CrossRef]

- Devipriya, D.; Roopan, S.M. Cissus quadrangularis mediated ecofriendly synthesis of copper oxide nanoparticles and its antifungal studies against Aspergillus niger, Aspergillus flavus. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 80, 38–44. [Google Scholar] [CrossRef]

- Amiri, M.; Etemadifar, Z.; Daneshkazemi, A.; Nateghi, M. Antimicrobial effect of copper oxide nanoparticles on some oral bacteria and candida species. J. Dent. Biomater. 2017, 4, 347–352. [Google Scholar]

- Mageshwari, K.; Sathyamoorthy, R. Flower-shaped CuO nanostructures: Synthesis, characterization and antimicrobial activity. J. Mater. Sci. Technol. 2013, 29, 909–914. [Google Scholar] [CrossRef]

- Montazer, M.; Maali Amiri, M. ZnO nano reactor on textiles and polymers: Ex situ and in situ synthesis, application, and characterization. J. Phys. Chem. B 2014, 118, 1453–1470. [Google Scholar] [CrossRef] [PubMed]

- Tamayo, L.; Azocar, M.; Kogan, M.; Riveros, A.; Paez, M. Copper-polymer nanocomposites: An excellent and cost-effective biocide for use on antibacterial surfaces. Mater. Sci. Eng. C 2016, 69, 1391–1409. [Google Scholar] [CrossRef] [PubMed]

- Emam, H.E. Generic strategies for functionalization of cellulosic textiles with metal salts. Cellulose 2019, 26, 1431–1447. [Google Scholar] [CrossRef]

- Perelshtein, I.; Applerot, G.; Perkas, N.; Wehrschuetz-Sigl, E.; Hasmann, A.; Guebitz, G.; Gedanken, A. CuO–cotton nanocomposite: Formation, morphology, and antibacterial activity. Surf. Coat. Technol. 2009, 204, 54–57. [Google Scholar] [CrossRef]

- Abramov, O.V.; Gedanken, A.; Koltypin, Y.; Perkas, N.; Perelshtein, I.; Joyce, E.; Mason, T.J. Pilot scale sonochemical coating of nanoparticles onto textiles to produce biocidal fabrics. Surf. Coat. Technol. 2009, 204, 718–722. [Google Scholar] [CrossRef]

- El-Nahhal, I.; Zourab, S.; Kodeh, F.; Selmane, M.; Genois, I.; Babonneau, F. Nanostructured copper oxide-cotton fibers: Synthesis, characterization, and applications. Int. Nano Lett. 2012, 2, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Mantecca, P.; Kasemets, K.; Deokar, A.; Perelshtein, I.; Gedanken, A.; Bahk, Y.K.; Kianfar, B.; Wang, J. Airborne nanoparticle release and toxicological risk from metal-oxide-coated textiles: Toward a multiscale safe-by-design approach. Environ. Sci. Technol. 2017, 51, 9305–9317. [Google Scholar] [CrossRef]

- Beddow, J.; Singh, G.; Blanes, M.a.; Molla, K.; Perelshtein, I.; Gedanken, A.; Joyce, E.; Mason, T. Sonochemical coating of textile fabrics with antibacterial nanoparticles. In AIP Conference Proceedings, Proceedings of the International Congress on Ultrasonics, Gdansk, Poland, 5–8 September 2009; American Institute of Physics: Melville, NY, USA, 2012; Volume 1433, pp. 400–403. [Google Scholar]

- Sharaf, S.; Farouk, A.; El-Hady, M.M. Novel conductive textile fabric based on polyaniline and CuO nanoparticles. Int. J. PharmTech Res. 2016, 9, 461–472. [Google Scholar]

- Marković, D.; Ašanin, J.; Nunney, T.; Radovanović, Z.; Radoičić, M.; Mitrić, M.; Mišić, D.; Radetić, M. Broad spectrum of antimicrobial activity of cotton fabric modified with oxalic acid and CuO/Cu2O nanoparticles. Fibers Polym. 2019, 20, 2317–2325. [Google Scholar] [CrossRef]

- Nabil, B.; Ahmida, E.A.; Christine, C.; Julien, V.; Abdelkrim, A. Polyfunctional cotton fabrics with catalytic activity and antibacterial capacity. Chem. Eng. J. 2018, 351, 328–339. [Google Scholar] [CrossRef]

- Rezaie, A.B.; Montazer, M.; Rad, M.M. A cleaner route for nanocolouration of wool fabric via green assembling of cupric oxide nanoparticles along with antibacterial and UV protection properties. J. Cleaner Prod. 2017, 166, 221–231. [Google Scholar] [CrossRef]

- Román, L.E.; Amézquita, M.J.; Uribe, C.L.; Maurtua, D.J.; Costa, S.A.; Costa, S.M.; Keiski, R.; Solís, J.L.; Gómez, M.M. In situ growth of CuO nanoparticles onto cotton textiles. Adv. Nat. Sci. Nanosci. Nanotechnol. 2020, 11, 025009. [Google Scholar] [CrossRef]

- Perelshtein, I.; Ruderman, Y.; Perkas, N.; Beddow, J.; Singh, G.; Vinatoru, M.; Joyce, E.; Mason, T.J.; Blanes, M.; Mollá, K.; et al. The sonochemical coating of cotton withstands 65 washing cycles at hospital washing standards and retains its antibacterial properties. Cellulose 2013, 20, 1215–1221. [Google Scholar] [CrossRef]

- Perelshtein, I.; Lipovsky, A.; Perkas, N.; Tzanov, T.; Arguirova, M.; Leseva, M.; Gedanken, A. Making the hospital a safer place by sonochemical coating of all its textiles with antibacterial nanoparticles. Ultrason. Sonochem. 2015, 25, 82–88. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Nahhal, I.M.; Elmanama, A.A.; Amara, N.; Qodih, F.S.; Selmane, M.; Chehimi, M.M. The efficacy of surfactants in stabilizing coating of nano-structured CuO particles onto the surface of cotton fibers and their antimicrobial activity. Mater. Chem. Phys. 2018, 215, 221–228. [Google Scholar] [CrossRef]

- Perelshtein, I.; Perkas, N.; Gedanken, A. Ultrasonic coating of textiles by antibacterial and antibiofilm nanoparticles. In Handbook of Ultrasonics and Sonochemistry; Ashokkumar, M., Ed.; Springer: Singapore, 2015; pp. 967–993. ISBN 978-981-287-278-4. [Google Scholar]

- Zarbaf, D.; Montazer, M.; Sadeghian Maryan, A. In-situ synthesis of nano-copper on denim garment along with nano-clay for antibacterial and decoloration purposes. Cellulose 2017, 24, 4083–4095. [Google Scholar] [CrossRef]

- Rezaie, A.B.; Montazer, M.; Rad, M.M. Environmentally friendly low cost approach for nano copper oxide functionalization of cotton designed for antibacterial and photocatalytic applications. J. Clean. Prod. 2018, 204, 425–436. [Google Scholar] [CrossRef]

- Rezaie, A.B.; Montazer, M.; Rad, M.M. Photo and biocatalytic activities along with UV protection properties on polyester fabric through green in-situ synthesis of cauliflower-like CuO nanoparticles. J. Photochem. Photobiol. B 2017, 176, 100–111. [Google Scholar] [CrossRef] [PubMed]

- Paramasivan, S.; Nagarajan, E.R.; Nagarajan, R.; Anumakonda, V.R.; Hariram, N. Characterization of cotton fabric nanocomposites with in situ generated copper nanoparticles for antimicrobial applications. Prep. Biochem. Biotechnol. 2018, 48, 574–581. [Google Scholar] [CrossRef] [PubMed]

- Khani, A.; Talebian, N. In vitro bactericidal effect of ultrasonically sol–gel-coated novel CuO/TiO2/PEG/cotton nanocomposite for wound care. J. Coat. Technol. Res. 2017, 14, 651–663. [Google Scholar] [CrossRef]

- Markovic, D.; Deeks, C.; Nunney, T.; Radovanovic, Z.; Radoicic, M.; Saponjic, Z.; Radetic, M. Antibacterial activity of Cu-based nanoparticles synthesized on the cotton fabrics modified with polycarboxylic acids. Carbohydr. Polym. 2018, 200, 173–182. [Google Scholar] [CrossRef] [PubMed]

- Sedighi, A.; Montazer, M. Tunable shaped N-doped CuO nanoparticles on cotton fabric through processing conditions: Synthesis, antibacterial behavior and mechanical properties. Cellulose 2016, 23, 2229–2243. [Google Scholar] [CrossRef]

- Sedighi, A.; Montazer, M.; Hemmatinejad, N. Copper nanoparticles on bleached cotton fabric: In situ synthesis and characterization. Cellulose 2014, 21, 2119–2132. [Google Scholar] [CrossRef]

- Perelshtein, I.; Lipovsky, A.; Perkas, N.; Tzanov, T.; Gedanken, A. Sonochemical co-deposition of antibacterial nanoparticles and dyes on textiles. Beilstein J. Nanotechnol. 2016, 7, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Gouda, M.; Aljaafari, A.; Al-Fayz, Y.; Boraie, W.E. Preparation and characterization of some nanometal oxides using microwave technique and their application to cotton fabrics. J. Nanomater. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Yoosefi, A.; Wang, R.; Xu, R. Simple method of deposition of CuO nanoparticles on a cellulose paper and its antibacterial activity. Chem. Eng. J. 2015, 262, 999–1008. [Google Scholar] [CrossRef]

- Shahidi, S.; Jamali, A.; Dalal Sharifi, S.; Ghomi, H. In-situ synthesis of CuO nanoparticles on cotton fabrics using spark discharge method to fabricate antibacterial textile. J. Nat. Fibers 2017, 15, 870–881. [Google Scholar] [CrossRef]

- Fernades, F.; Filho, E.R.; Souza, I.; Nascimento, I.; Sousa, R.; Almeida, E.; Feitor, M.; Costa, T.; Naeem, M.; Iqbal, J. Novel synthesis of copper oxide on fabric samples by cathodic cage plasma deposition. Polym. Adv. Technol. 2020, 31, 520–526. [Google Scholar] [CrossRef]

- Thampi, V.V.A.; Thanka Rajan, S.; Anupriya, K.; Subramanian, B. Functionalization of fabrics with PANI/CuO nanoparticles by precipitation route for anti-bacterial applications. J. Nanopart. Res. 2015, 17, 57. [Google Scholar] [CrossRef]

- Vasantharaj, S.; Sathiyavimal, S.; Saravanan, M.; Senthilkumar, P.; Gnanasekaran, K.; Shanmugavel, M.; Manikandan, E.; Pugazhendhi, A. Synthesis of ecofriendly copper oxide nanoparticles for fabrication over textile fabrics: Characterization of antibacterial activity and dye degradation potential. J. Photochem. Photobiol. B 2019, 191, 143–149. [Google Scholar] [CrossRef]

- Cha, S.M.; Nagaraju, G.; Chandra Sekhar, S.; Yu, J.S. A facile drop-casting approach to nanostructured copper oxide-painted conductive woven textile as binder-free electrode for improved energy storage performance in redox-additive electrolyte. J. Mater. Chem. A 2017, 5, 2224–2234. [Google Scholar] [CrossRef] [Green Version]

- Abramova, A.; Gedankenb, A.; Popov, V.; Ooi, E.; Masond, T.J.; Joyce, E.M. Sonochemical technology for coating of textiles with antibacterial nanoparticles and equipment for its implementation. Mater. Lett. 2013, 96, 121–124. [Google Scholar] [CrossRef]

- Gedanken, A.; Perkas, N.; Perelshtein, I.; Applerot, G.; Lipovsky, A.; Nitzan, Y.; Lubart, R. Preparation of antimicrobial textiles using a sonochemical method. Recent Pat. Biomed. Eng. 2011, 4, 1–5. [Google Scholar] [CrossRef]

- Sathiyavimal, S.; Vasantharaj, S.; Bharathi, D.; Saravanan, M.; Manikandan, E.; Kumar, S.S.; Pugazhendhi, A. Biogenesis of copper oxide nanoparticles (CuONPs) using Sida acuta and their incorporation over cotton fabrics to prevent the pathogenicity of Gram negative and Gram positive bacteria. J. Photochem. Photobiol. B 2018, 188, 126–134. [Google Scholar] [CrossRef] [PubMed]

- Teli, M.D.; Sheikh, J. Bamboo rayon–copper nanoparticle composites as durable antibacterial textile materials. Compos. Interfaces 2013, 21, 161–171. [Google Scholar] [CrossRef]

- Agrawal, N.; Low, P.S.; Tan, J.S.J.; Fong, E.W.M.; Lai, Y.; Chen, Z. Durable easy-cleaning and antibacterial cotton fabrics using fluorine-free silane coupling agents and CuO nanoparticles. Nano Mater. Sci. 2019, 2, 281–291. [Google Scholar] [CrossRef]

- Anita, S.; Ramachandran, T.; Rajendran, R.; Koushik, C.V.; Mahalakshmi, M. A study of the antimicrobial property of encapsulated copper oxide nanoparticles on cotton fabric. Text. Res. J. 2011, 81, 1081–1088. [Google Scholar] [CrossRef]

- Kara, S.; Ureyen, M.E.; Erdogan, U.H. Structural and antibacterial properties of PP/CuO composite filaments having different cross sectional shapes. Intern. Polym. Process. 2016, 31, 398–409. [Google Scholar] [CrossRef]

- Hobot, J.A. Bacterial ultrastructure. In Molecular Medical Microbiology, 2nd ed.; Tang, Y., Liu, D., Schwartzman, J., Sussman, M., Poxton, I., Eds.; Elsevier: London, UK, 2015; pp. 7–32. ISBN 978-0-12-397169-2. [Google Scholar]

- Nanninga, N. Cell Structure, organization, bacteria and archaea. In Encyclopedia of Microbiology, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 357–374. [Google Scholar] [CrossRef]

- Lovitt, R.W.; Wright, C.J. Bacteria: The bacterial cell. In Encyclopedia of Food Microbiology, 2nd ed.; Elsevier: Swansea, UK, 2014; pp. 151–159. [Google Scholar] [CrossRef]

- Murray, P.; Rosenthal, K.; Pfaller, M. Medical Microbiology, 8th ed.; Elsevier: Philadelphia, PA, USA, 2016; ISBN 978-0-323-29956-5. [Google Scholar]

- Pankratova, G.; Hederstedt, L.; Gorton, L. Extracellular electron transfer features of Gram-positive bacteria. Anal. Chim. Acta 2019, 1076, 32–47. [Google Scholar] [CrossRef]

- Beveridge, T.J. Ultrastructure, chemistry, and function of the bacterial wall. Int. Rev. Cytol. 1981, 72, 229–317. [Google Scholar] [CrossRef]

- Vollmer, W. Peptidoglycan. In Molecular Medical Microbiology, 2nd ed.; Tang, Y., Liu, D., Schwartzman, J., Sussman, M., Poxton, I., Eds.; Elsevier: London, UK, 2015; pp. 105–124. ISBN 978-0-12-397169-2. [Google Scholar]

- Palza, H. Antimicrobial polymers with metal nanoparticles. Int. J. Mol. Sci. 2015, 16, 2099–2116. [Google Scholar] [CrossRef] [Green Version]

- Stanić, V.; Tanasković, S.B. Antibacterial activity of metal oxide nanoparticles. In Nanotoxicity, 1st ed.; Rajendran, S., Mukherjee, A., Nguyen, T.A., Godugu, C., Shukla, R.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 241–274. ISBN 978-0-12-819943-5. [Google Scholar]

- Radetić, M.; Marković, D. Nano-finishing of cellulose textile materials with copper and copper oxide nanoparticles. Cellulose 2019, 26, 8971–8991. [Google Scholar] [CrossRef]

- Hasheminya, S.-M.; Rezaei Mokarram, R.; Ghanbarzadeh, B.; Hamishekar, H.; Kafil, H.S. Physicochemical, mechanical, optical, microstructural and antimicrobial properties of novel kefiran-carboxymethyl cellulose biocomposite films as influenced by copper oxide nanoparticles (CuONPs). Food Packag. Shelf Life 2018, 17, 196–204. [Google Scholar] [CrossRef]

- Shankar, S.; Wang, L.F.; Rhim, J.W. Preparation and properties of carbohydrate-based composite films incorporated with CuO nanoparticles. Carbohydr. Polym. 2017, 169, 264–271. [Google Scholar] [CrossRef] [PubMed]

- Thomas III, K.J.; Rice, C.V. Equilibrium binding behavior of magnesium to wall teichoic acid. Biochim. Biophys. Acta Biomembr. 2015, 1848, 1981–1987. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hou, J.; Wang, X.; Hayat, T.; Wang, X. Ecotoxicological effects and mechanism of CuO nanoparticles to individual organisms. Environ. Pollut. 2017, 221, 209–217. [Google Scholar] [CrossRef] [PubMed]

- Cossart, P.; Helenius, A. Endocytosis of viruses and bacteria. Cold Spring Harb Perspect. Biol. 2014, 6, a016972. [Google Scholar] [CrossRef] [Green Version]

- Giannousi, K.; Pantazaki, A.; Dendrinou-Samara, C. Copper-based nanoparticles as antimicrobials. In Nanostructures for Antimicrobial Therapy, 1st ed.; Ficai, A., Grumezescu, A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 515–529. ISBN 978-0-323-46152-8. [Google Scholar]

- Bedlovicova, Z.; Strapac, I.; Balaz, M.; Salayova, A. A brief overview on antioxidant activity determination of silver nanoparticles. Molecules 2020, 25, 3191. [Google Scholar] [CrossRef]

- Li, R.; Jia, Z.; Trush, M.A. Defining ROS in biology and medicine. React. Oxyg. Species 2016, 1, 9–21. [Google Scholar] [CrossRef] [Green Version]

- Applerot, G.; Lellouche, J.; Lipovsky, A.; Nitzan, Y.; Lubart, R.; Gedanken, A.; Banin, E. Understanding the antibacterial mechanism of CuO nanoparticles: Revealing the route of induced oxidative stress. Small 2012, 8, 3326–3337. [Google Scholar] [CrossRef]

- Brynildsen, M.P.; Winkler, J.A.; Spina, C.S.; MacDonald, I.C.; Collins, J.J. Potentiating antibacterial activity by predictably enhancing endogenous microbial ROS production. Nat. Biotechnol. 2013, 31, 160–165. [Google Scholar] [CrossRef] [Green Version]

- American Association of Textile Chemists and Colorists. Test Method 61—Colorfastness to Laundering: Accelerated; American Association of Textile Chemists and Colorists (AATCC): Research Triangle Park, NC, USA, 2010; Volume 85. [Google Scholar]

- Singh, G.; Beddow, J.; Mee, C.; Maryniak, L.; Joyce, E.M.; Mason, T.J. Cytotoxicity study of textile fabrics impregnated with CuO nanoparticles in mammalian cells. Int. J. Toxicol. 2017, 36, 478–484. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.-N.; Zhang, M.; Xia, L.; Zhang, J.; Xing, G. The toxic effects and mechanisms of CuO and ZnO nanoparticles. Materials 2012, 5, 2850–2871. [Google Scholar] [CrossRef] [Green Version]

- Cohen, D.; Soroka, Y.; Ma’or, Z.; Oron, M.; Portugal-Cohen, M.; Bregegere, F.M.; Berhanu, D.; Valsami-Jones, E.; Hai, N.; Milner, Y. Evaluation of topically applied copper(II) oxide nanoparticle cytotoxicity in human skin organ culture. Toxicol. In Vitro 2013, 27, 292–298. [Google Scholar] [CrossRef] [PubMed]

- Borkow, G.; Zhou, S.S.; Page, T.; Gabbay, J. A novel anti-influenza copper oxide containing respiratory face mask. PLoS ONE 2010, 5, e11295. [Google Scholar] [CrossRef] [Green Version]

- Borkow, G.; Sidwell, R.W.; Smee, D.F.; Barnard, D.L.; Morrey, J.D.; Lara-Villegas, H.H.; Shemer-Avni, Y.; Gabbay, J. Neutralizing viruses in suspensions by copper oxide-based filters. Antimicrob. Agents Chemother. 2007, 51, 2605–2607. [Google Scholar] [CrossRef] [Green Version]

- Borkow, G.; Lara, H.H.; Covington, C.Y.; Nyamathi, A.; Gabbay, J. Deactivation of human immunodeficiency virus type 1 in medium by copper oxide-containing filters. Antimicrob. Agents Chemother. 2008, 52, 518–525. [Google Scholar] [CrossRef] [Green Version]

- Hang, X.; Peng, H.; Song, H.; Qi, Z.; Miao, X.; Xu, W. Antiviral activity of cuprous oxide nanoparticles against Hepatitis C Virus in vitro. J. Virol. Methods 2015, 222, 150–157. [Google Scholar] [CrossRef]

- van Doremalen, N.; Bushmaker, T.; Morris, D.H.; Holbrook, M.G.; Gamble, A.; Williamson, B.N.; Tamin, A.; Harcourt, J.L.; Thornburg, N.J.; Gerber, S.I.; et al. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N. Engl. J. Med. 2020, 382, 1564–1567. [Google Scholar] [CrossRef]

- Behzadinasab, S.; Chin, A.; Hosseini, M.; Poon, L.; Ducker, W.A. A surface coating that rapidly inactivates SARS-CoV-2. ACS Appl. Mater. Interfaces 2020, 12, 34723–34727. [Google Scholar] [CrossRef]

- Imoto, Y.; Seino, S.; Nakagawa, T.; Yamamoto, T.A. Quantitative methods for testing antiviral activities of textile fabrics. J. Antimicrob. Agents 2017, 03, 1000146. [Google Scholar] [CrossRef] [Green Version]

- International Organization for Standardization. ISO 18184 Textiles—Determination of Antiviral Activity of Textile Products; ISO: Geneva, Switzerland, 2014. [Google Scholar]

| Precursor | Textile Substrate | Shape of Particles/Structure | Crystal Structure/Size of Particles | Application Method | Additional Treatment/Others | Functionality | Washing Testing | Antimicrobial Activity | Antimicrobial Test | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.005 M Cu(Ac)2·XH2O | Cotton | NR | 15 nm | Sonochemical/ultrasonic irradiation (20 kHz) | No additional treatment | Antibacterial activity | NR | E. coli (ATCC 10407), S. aureus (ATCC 29067) | NR | [42] |

| 0.04 mol Cu(CH3COO)2·H2O | Cotton | NR | ~10–20 nm | Sonochemical/ultrasonic irradiation (20–27 kHz) | No additional treatment | Antibacterial activity | NR | E. coli (ATCC 10407) | USP 51 | [43] |

| 4.8 × 10−4 M CuSO4·5H2O | Cotton | NR | 10 nm | Ultrasonic irradiation (20 kHz) | Fabric was washed with 5% sodium dodecyl sulfate at 40 °C for 1 h. | Antibacterial activity | NR | S. aureus, E. coli | NR | [44] |

| 8 g Cu(CH3COO)2·H2O | Cotton | NR | 60–80 nm | Sonochemical | Roll to roll coating | Antibacterial activity | 65 cycles The hospital protocols of hygienic washing (75 °C) was used. EN ISO 6330 | S. aureus (ATCC 6538), E. coli (ATCC 8739) | BS EN ISO 20743:2007 | [52] |

| 0.01 M Cu(Ac)2 | Cotton | NR | Monoclinic Crystallite size: ~10 nm. Particle size on cotton: ~30 nm | Sonochemical (20 kHz) | Roll-to-roll coating | Antibacterial activity | NR | S. aureus, Acinetobacter baumannii (A. baumannii), E. coli | NR | [53] |

| 0.01 M Cu(Ac)2·XH2O | Cotton and hybrid fabric polyester: cotton (65:35) | NR | ~80 nm | Sonochemical installation | Roll to roll coating | Antibacterial activity | NR | S. aureus, E. coli | NR | [45] |

| 0.005 mol CuSO4·5H2O | Cotton | NR | NR | Ultrasound irradiation (20 kHz) | 0.001 M sodium dodecyl sulfate, cetyl tri-methyl ammonium bromide, triton X-100, and 0.001 M alkyl hydroxy-ethyl dimethyl ammonium chloride surfactants were used in the functionalization process. | Antibacterial activity | 5 and 10 cycles at room temperature | E. coli, S. aureus, Candida albicans (C. albicans), Microsporum canis (M. canis) | AATCC 100 (2004) | [54] |

| Cu(Ac)2·XH2O | Cotton | NR | NR | Sonochemical/ultrasonic irradiation (20 kHz) | Two pilot scale machines | Antibacterial activity | NR | S. aureus (ATCC 6538), Pseudomonas aeruginosa (P. aeruginosa) (ATCC 15442), A. baumannii (NCTC 10303), E. coli (ATCC 8739), methicillin-resistant Staphylococcus aureus (MRSA) (NCTC 10442) | BS EN ISO 20743:2007 | [46] |

| Copper ions | Cotton | NR | Monoclinic Various sizes | Ultrasonic irradiation (19 kHz) | No additional treatment | Antibacterial activity | 65 cycles Washed at 75 °C | S. aureus, MRSA, A. baumannii, E. coli, P. aeruginosa | NR | [55] |

| Cu(NO3)2·3H2O | Polyaniline/cotton | NR | Monoclinic | Ultrasonic treatment (40 kHz) | Aniline polymerization | Antibacterial activity, electrical conductivity | NR | S. aureus, E. coli, C. albicans | NR | [47] |

| 0.1–15% owf CuSO4·5H2O | Cotton | Rod and wheat-like | 40–70 nm | Dip coating | Anti-creasing agent in the functionalization process | Antibacterial activity | 10 and 30 cycles. 1 mL/L standard detergent at 60 °C-30 min was used. | S. aureus, E. coli | AATCC 100 (2004) | [56] |

| 0.2 M CuSO4 | Cotton | NR | NR | Dip coating | The fabric was cleaned with hydrogen peroxide, ammonium hydroxide. 3-chloropropyltriethoxisilane, diethanolamine in the functionalization process | Catalytic activity, antibacterial activity | NR | S. epidermidis, E. coli | Diffusivity zone inhibitory tests | [49] |

| 0.2 M Cu(CH3COO)2 | Cotton | NR | Crystallite size on cotton: 10.6 nm | Dip coating | The fabric was washed with a 1-g/L nonionic detergent solution as a pretreatment. | Photocatalytic activity, antibacterial activity | 5 cycles | S. epidermidis, E. coli | AATCC 100 | [57] |

| 10 mM CuSO4 | Cotton | NR | NR | Dip coating | The fabric was washed with nonionic agent Felosan RG-N and modified with 20 mL of the oxalic acid solutions of different concentrations (4, 6, and 10 w/v%). | Antibacterial activity | NR | E. coli (ATCC 25922, NCTC 13846, ATCC BAA-2469), S. aureus (ATCC 25,923 and 43,300), P. aeruginosa (ATCC 27853), C. albicans (ATCC 24433), K. pneumoniae (ATCC BAA-2146) | ASTM E 2149-01 | [48] |

| 0.2 M Cu(CH3COO)2 | Polyester | Cauliflower-like | Crystallite size on PES: ~27.5 nm. Particle size on PES: 222.5 nm | Dip coating | The fabric was washed with nonionic detergent as a pretreatment. The Seidlitzia Rosmarinus plant (Keliab) solution was used as reagent alkaline in the functionalization process. | Photocatalytic activity, self-cleaning properties, UV protection, antibacterial activity | NR | S. aureus, E. coli | AATCC 100 | [58] |

| Cu(CH3COO)2 | Wool | NR | Crystallite size on wool: ~8.5 nm. Particle size on wool: 36.5 nm | Dip coating | The fabric was washed with nonionic detergent as a pretreatment. The Seidlitzia Rosmarinus plant (Keliab) solution was used as reagent alkaline in the functionalization process. | Antibacterial activity, UV protection | 1 and 5 cycles | S. aureus, E. coli | AATCC 100 | [50] |

| 5, 25, 125, and 250 mM % CuSO4·5H2O | Cotton | Spherical | 40–100 nm | Dip coating + shaking | Cassia alata leaf extract as a pretreatment | Antibacterial activity | 5, 10, and 15 cycles | E. coli | Diffusion method | [59] |

| 2 mmol Cu(Ac)2·2H2O | Cotton | Round clusters | Monoclinic 40–94 nm | Ultrasonic-mediated dip coating | Two metal oxide sols were prepared: TiO2 and CuO sol syntheses. The modification of the cotton surface was achieved by the incorporation of citric acid (CA) and polyethylene glycol (PEG) to improve the attachment. The amount of TiO2 and CuO on cotton fibers was in the range of 10–12 wt%. | Antibacterial activity | 10 cycles The treated cotton was washed with 2 g/L nonionic detergent at 50 °C-15 min, rinsed with water, and dries at 100 °C-5 min. | S. aureus (ATCC 6538), E. coli (ATCC 25922) | Agar diffusion test Dynamic shake test. | [60] |

| 10 mM CuSO4·5H2O | Cotton | NR | NR | Dip coating + dry + cure | Fabric was washed with nonionic agent Felosan RG-N. Succinic, 1,2,3,4-butanetetracarboxylic and citric acids in the functionalization process. | Antibacterial activity | NR | S. aureus (ATCC 25923), E. coli (ATCC 25922) | ASTM E 2149-01 | [61] |

| 18 w/w% CuSO4·5H2O | Cotton | Various morphologies | Monoclinic Crystallite size on cotton: ~15.9 and 12.4 nm | Dip coating + shaking | The fabric was washed with 2 g/L nonionic detergent at 60 °C for 45 min as a pretreatment. | Antibacterial activity | 10, 20 and 30 cycles AATCC 61(2A)-1996 | E. coli, S. aureus | ISO 20645:2004 and AATCC 100:2004 | [62] |

| 4 wt% CuSO4 | Cotton | NR | Various sizes | Dip coating + shaking | The fabric was washed with 1 g/L nonionic detergent at 60 °C for 20 min. The citric acid and sodium hypophosphite were used as a stabilizing protective and reducing agent, respectively, in the functionalization process. | Antibacterial activity | 10, 20 and 30 cycles AATCC 61(2A)-1996 | E. coli, S. aureus | AATCC 147 and AATCC 100:2004 | [63] |

| 0.022 g MCu(CH3COO)2 | Cotton | Needles, prolate spheroidal | L: 80 nm, D: 10 nm | Coating/dyeing process + ultrasonic irradiation (20 kHz) | The 0.16 g reactive orange 16 (RO16) and 0.16 g reactive black 5 (RB5) dyes were used in the functionalization process | Antibacterial activity | Not specified | E. coli | NR | [64] |

| 1 mm CuCl2 | Cotton | Nanosphere | 25–30 nm | Dip padding + microwave irradiation (2455 MHz) | The fabrics were treated with 10% (v/v) mercaptoacetic acid in the presence of para-toluene sulphonic acid. | Antibacterial activity, UV protection, flame retardation | 10, 20, and 30 cycles AATCC 61(2A)-1996 | S. aureus, E. coli | NR | [65] |

| 0.5 M Cu(NO3)2·3H2O | Paper (cellulose) | Nano-leaves | W: 300 nm, L: 700 nm, T: 30 nm | Soak + drying | NR | Antibacterial activity | NR | E. coli (ATCC 8739), S. aureus (ATCC 6538) | NR | [66] |

| 0.2–30.0% owf Cu(CH3COO)2·H2O | Cotton | NR | NR | Exhaust dyeing | NR | Antibacterial activity, UV protection | 20 cycles ISO 105-C06:1994 | E. coli (ATCC 25922) | ASTM E 2149-01 | [51] |

| Copper wires—1 mm diameter | Cotton | NR | <100 nm | Spark discharge (1 kHz) | Ultrasonic pulse generator to avoid NP agglomeration in the functionalization process | Antibacterial activity | 15 cycles | S. aureus, E. coli | AATCC 100 | [67] |

| Copper cathodic | Polyester, polyamide | NR | NR | Cathodic cage plasma deposition | The argon atmosphere was used in the process. | Antibacterial activity | NR | NR | NR | [68] |

| Precursor | Textile Substrate | Shape of Particles/Structure | Crystal Structure/Size of Particles | Application Method | Additional Treatment/Others | Functionality | Washing Testing | Antimicrobial Activity | Antimicrobial Test | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| 10 mM Cu(CH3COO)2·H2O | Woven | Caterpillar-like Ellipsoidal body shaped architectures: | Monoclinic W: ~80–100 nm, L: 140–160 nm | Drop casting | CuO nanostructures were synthesized by green wet-chemical method | Energy storage | NR | – | – | [71] |

| CuO NPs, throwing stones mode | Cotton | Ellipsoidal | 200–400 nm | Sonochemical/Ultrasonic irradiation (19 kHz) | No additional treatment | Antibacterial activity | NR | E. coli, Klebsiella pneumoniae (K. pneumoniae), S. aureus, MRSA | BS EN ISO 20743:2007 | [72] |

| 0.75–1.4 wt% CuO NPs | Cotton | NR | NR | Sonochemical | No additional treatment | Antibacterial activity | 65 cycles Washed at 75 °C | S. aureus, E. coli | NR | [73] |

| 1 M CuSO4 | Cotton | NR | NR | Simple dipping technique | The CuO NPs were synthesized with a copper sulphate solution and Sida acuta extract. | Antibacterial activity | NR | S. aureus, E. coli, Proteus vulgaris (P. vulgaris) | Agar plates | [74] |

| CuSO4·7H2O:H2O (1:30) | Bamboo rayon | NR | NR | Dip coating | Bamboo rayon fabric grafted with acrylic acid | Antibacterial activity | 50 cycles | S. aureus, E. coli | AATCC 100 (2004) | [75] |

| CuSO4 | Cotton | NR | NR | Dip coating | The CuO NPs were synthesized with a copper sulphate solution and 50 mL of Ruellia tuberosa aqueous extract. | Antibacterial activity | NR | E. coli, K. pneumoniace, S. aureus | Agar plates | [70] |

| 3.2; 8.0; 16 g/m2 CuO NPs | Cotton | NR | <50 nm | Dip coating + shaking | Tetrahydrofuran, polydimethylsiloxane, and silanes were used in the process. | Superhydrophobicity, antibacterial activity | Triton-X, non-ionic detergent (1 g/L) was used to wash. | E. coli (ATCC 25922), S. aureus (ATCC 25923) | AATCC 100 (2004) | [76] |

| 1 mg CuO NPs–woven fabric 14 mg CuO NPs–non-woven fabric | Cotton | NR | Monoclinic 50 nm | Immersion | The fabric was washed with hydrochloric acid. The chemical precipitation method to synthesize CuO NPs from 0.2 M Cu(NO3)2·2H2O was used. | Antibacterial activity | NR | S. aureus, Bacilos subtilis (B. subtilis), E. coli, P. aeruginosa | Agar diffusion | [69] |

| 0.1 M CuSO4 | Cotton | NR | 50 nm | Exhaustion + pad–dry–cure | The CuO NPs were synthesized by a wet-type chemical method. Microencapsulation was conducted by the ionic gelation method using 3% sodium alginate and 2% CuO NPs. | Antibacterial activity | 5 and 10 cycles AATCC61 (1A)-2001 | S. aureus (ATCC 6538), E. coli (ATCC 11,230 and 8739) | AATCC 147 and AATCC 100 | [77] |

| 0.3 and 1.0%(w/w) CuO | Polypropile-ne | Round clusters | <0.5 µm | Spinning process | The fibers were produced with polypropylene chips and CuO microparticles. Melt was performed using a twin screw extruder. | Antibacterial activity | NR | E. coli (ATCC 25922) | JIS L 1902:2002 | [78] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Román, L.E.; Gomez, E.D.; Solís, J.L.; Gómez, M.M. Antibacterial Cotton Fabric Functionalized with Copper Oxide Nanoparticles. Molecules 2020, 25, 5802. https://doi.org/10.3390/molecules25245802

Román LE, Gomez ED, Solís JL, Gómez MM. Antibacterial Cotton Fabric Functionalized with Copper Oxide Nanoparticles. Molecules. 2020; 25(24):5802. https://doi.org/10.3390/molecules25245802

Chicago/Turabian StyleRomán, Luz E., Enrique D. Gomez, José L. Solís, and Mónica M. Gómez. 2020. "Antibacterial Cotton Fabric Functionalized with Copper Oxide Nanoparticles" Molecules 25, no. 24: 5802. https://doi.org/10.3390/molecules25245802

APA StyleRomán, L. E., Gomez, E. D., Solís, J. L., & Gómez, M. M. (2020). Antibacterial Cotton Fabric Functionalized with Copper Oxide Nanoparticles. Molecules, 25(24), 5802. https://doi.org/10.3390/molecules25245802