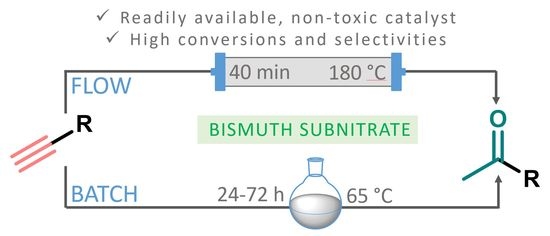

Bismuth Subnitrate-Catalyzed Markovnikov-Type Alkyne Hydrations under Batch and Continuous Flow Conditions

Abstract

Share and Cite

Szécsényi, Z.; Fülöp, F.; Ötvös, S.B. Bismuth Subnitrate-Catalyzed Markovnikov-Type Alkyne Hydrations under Batch and Continuous Flow Conditions. Molecules 2021, 26, 2864. https://doi.org/10.3390/molecules26102864

Szécsényi Z, Fülöp F, Ötvös SB. Bismuth Subnitrate-Catalyzed Markovnikov-Type Alkyne Hydrations under Batch and Continuous Flow Conditions. Molecules. 2021; 26(10):2864. https://doi.org/10.3390/molecules26102864

Chicago/Turabian StyleSzécsényi, Zsanett, Ferenc Fülöp, and Sándor B. Ötvös. 2021. "Bismuth Subnitrate-Catalyzed Markovnikov-Type Alkyne Hydrations under Batch and Continuous Flow Conditions" Molecules 26, no. 10: 2864. https://doi.org/10.3390/molecules26102864

APA StyleSzécsényi, Z., Fülöp, F., & Ötvös, S. B. (2021). Bismuth Subnitrate-Catalyzed Markovnikov-Type Alkyne Hydrations under Batch and Continuous Flow Conditions. Molecules, 26(10), 2864. https://doi.org/10.3390/molecules26102864