Effect of Molybdenum (Mo) Addition on Phase Composition, Microstructure, and Mechanical Properties of Pre-Alloyed Ti6Al4V Using Spark Plasma Sintering Technique

Abstract

1. Introduction

2. Results and Discussion

2.1. Densification

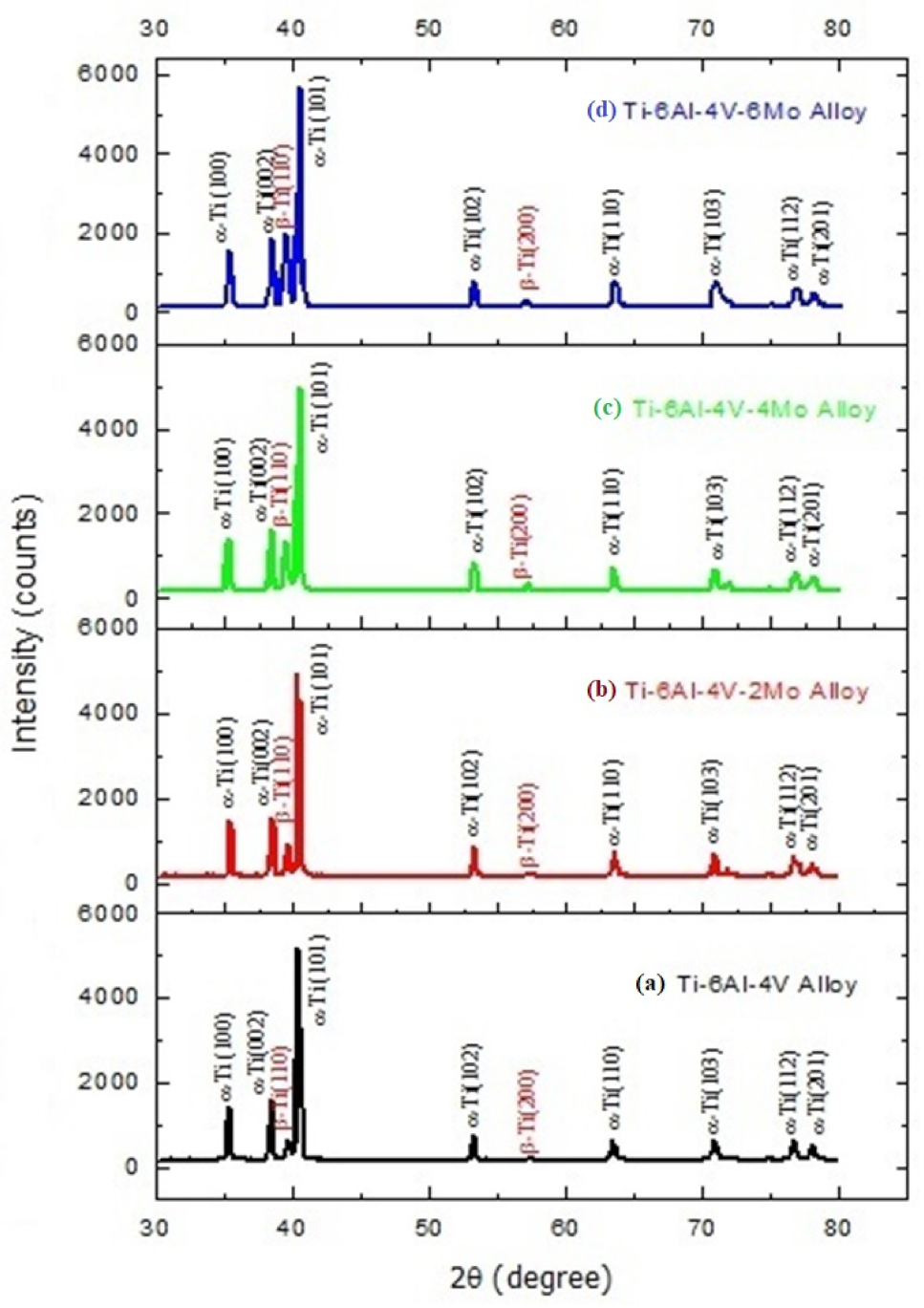

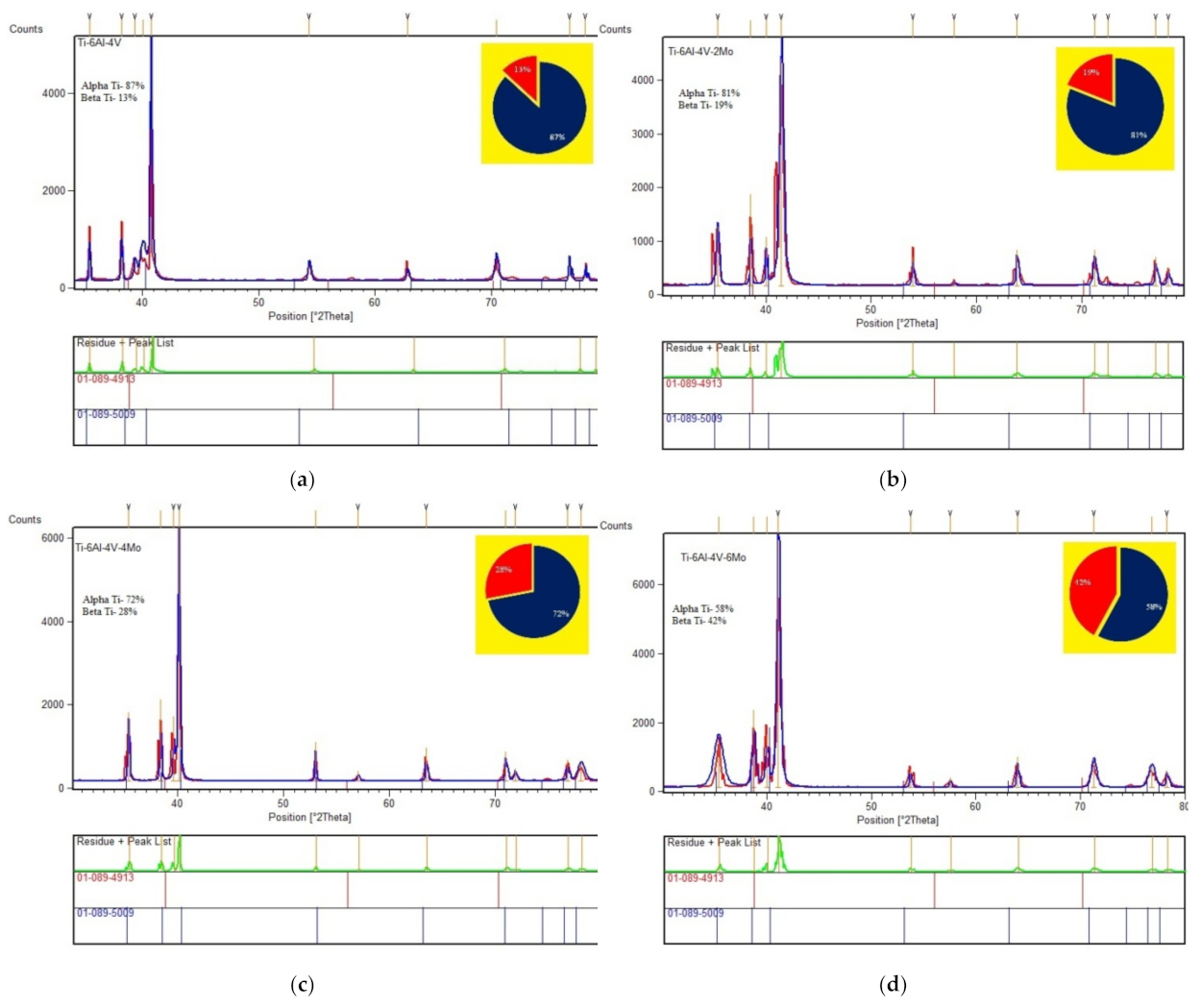

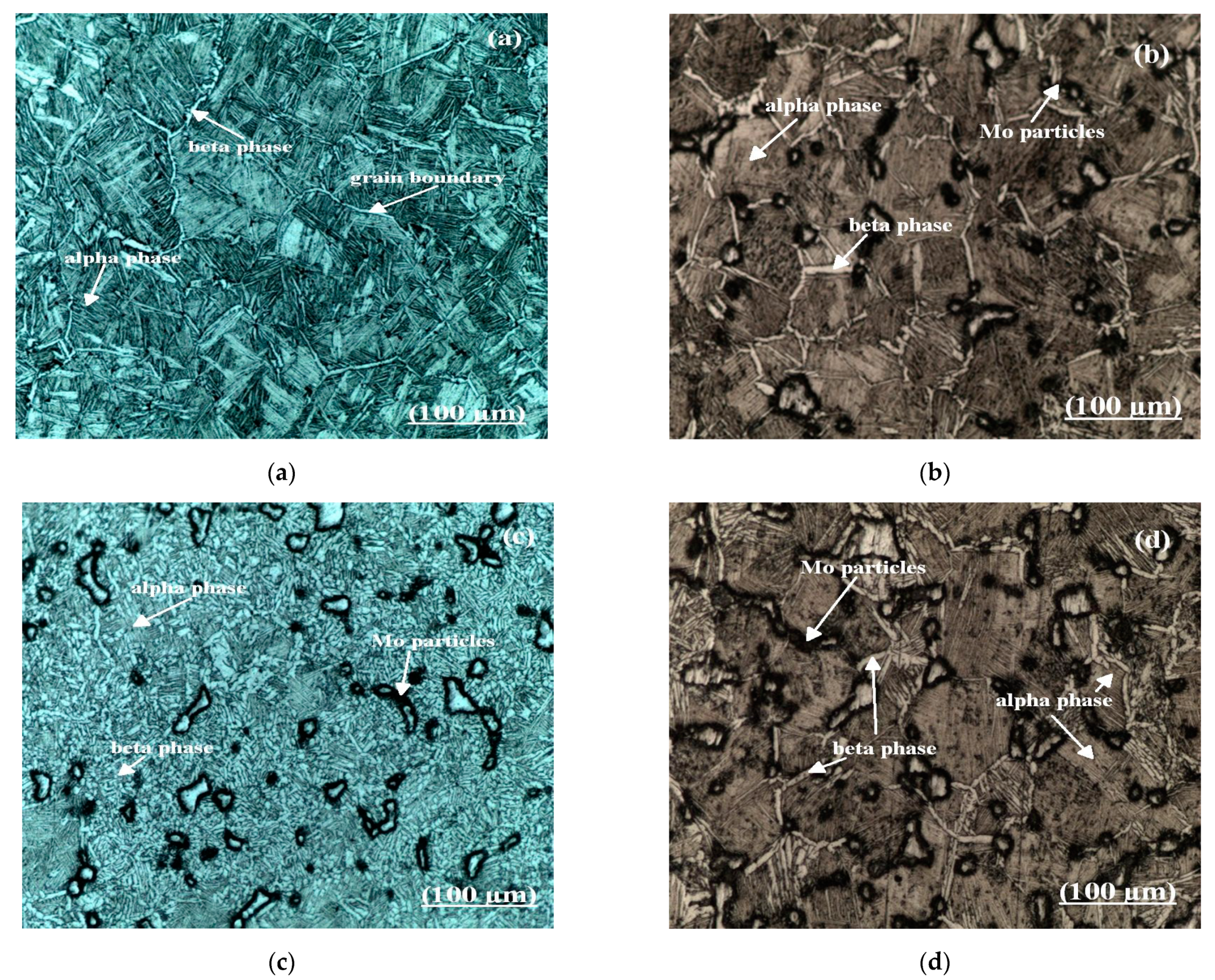

2.2. Phase Composition and Microstructural Development

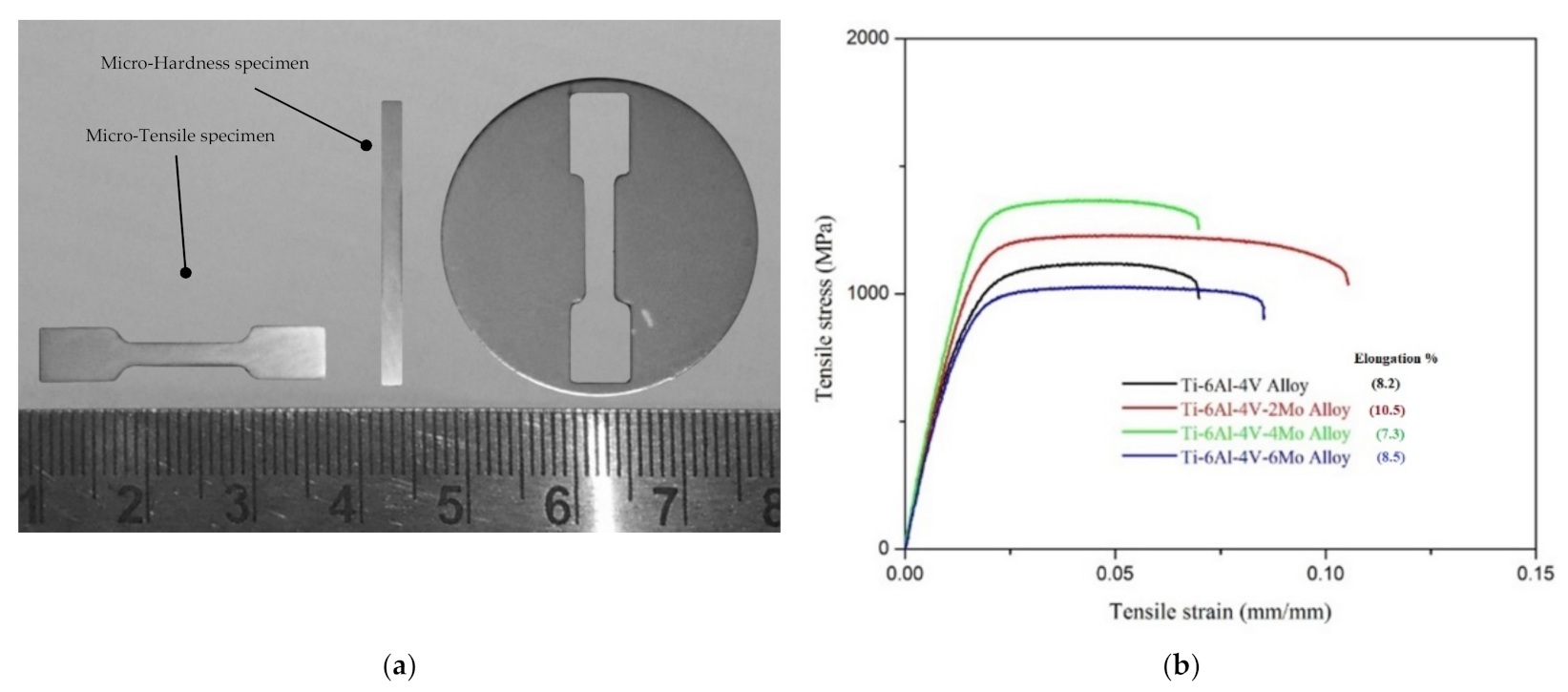

2.3. Mechanical Properties

3. Materials and Methods

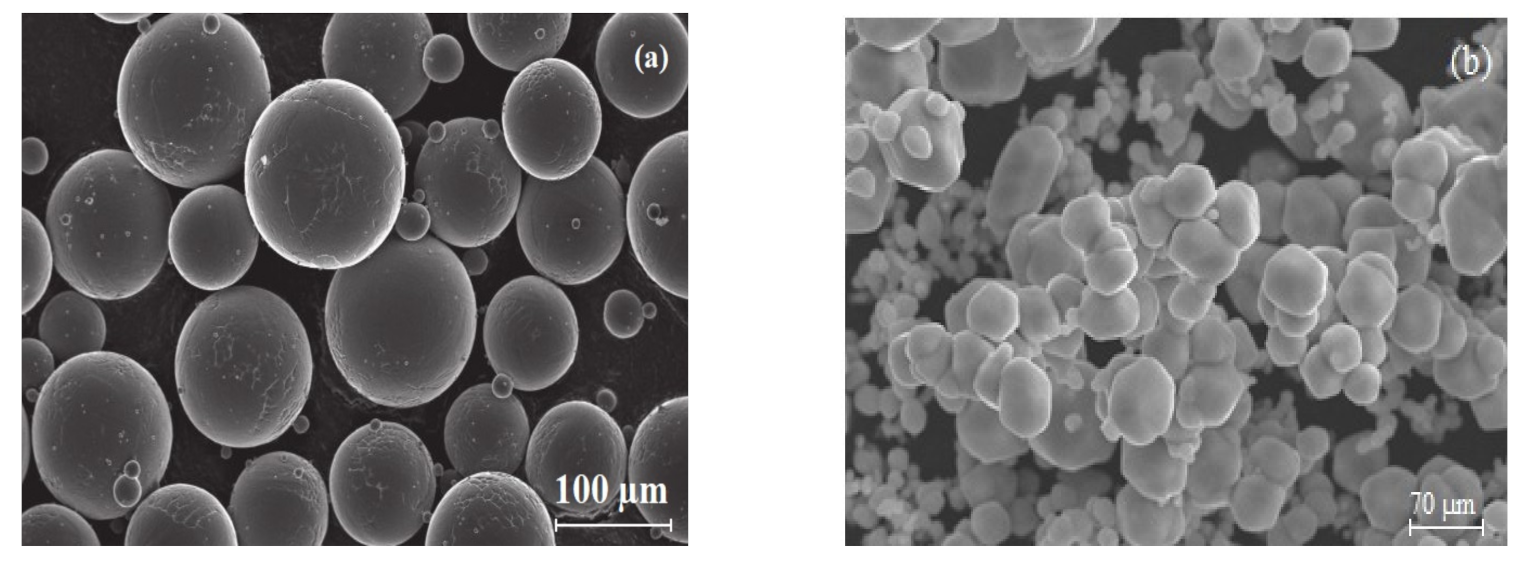

3.1. Powder Morphology

3.2. Alloy Preparations

3.3. Sintering

3.4. Characterization

3.5. Testing

4. Conclusions

- Molybdenum addition of 2 to 6 wt.% in pre-alloyed Ti6Al4V changes the microstructure from equiaxed primary alpha and Widmanstätten (alpha + beta) into a duplex and Globular model with a variation of pores.

- Mo acts as an effective solid solution strengthening agent, which is reflected in the improved mechanical properties of the alloys.

- Ti6Al4V-4Mo exhibits good mechanical values such as high yield stress (1174 MPa) and UTS (1368 MPa) with a lower percentage of elongation (7.3) than the remaining three alloys Ti6Al4V, Ti6Al4V-2Mo, Ti6Al4V-6Mo; the microhardness of Ti6Al4V-6Mo has the highest value (370 HV500) among all compositions.

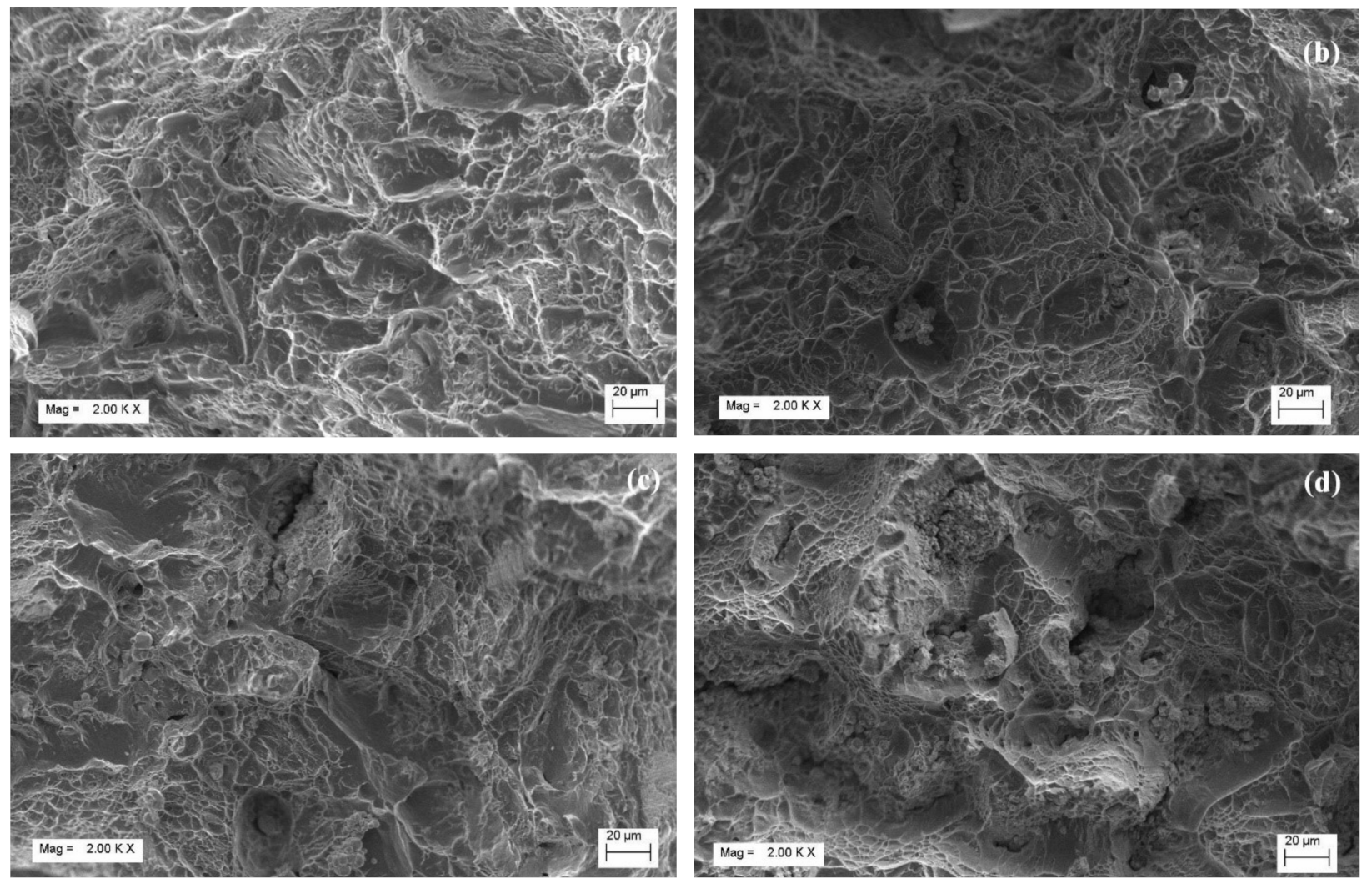

- From the fractography images, the high-density molybdenum (Mo) content forms the pore, modifies the shape and size of dimples, and indicates the brittle mode of fracture with a lower elongation %.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Boyer, R.R.; Briggs, R.D. The Use of β Titanium Alloys in the Aerospace Industry. J. Mater. Eng. Perform. 2005, 14, 681–685. [Google Scholar] [CrossRef]

- Yang, F.; Gabbitas, B. Feasibility of producing Ti-6Al-4V alloy for engineering application by powder compact extrusion of blended elemental powder mixtures. J. Alloys Compd. 2017, 695, 1455–1461. [Google Scholar] [CrossRef]

- Carman, A.; Zhang, L.C.; Ivasishin, O.M.; Savvakin, D.G.; Matviyc huk, M.V.; Pereloma, E.V. Role of alloying elements in microstructure evolution and alloying elements behaviour during sintering of a near-β titanium alloy. Mater. Sci. Eng. A 2011, 528, 1686–1693. [Google Scholar] [CrossRef]

- Esen, Z.; Bor, S. Characterization of Ti–6Al–4V alloy foams synthesized by space holder technique. Mater. Sci. Eng. A 2011, 528, 3200–3209. [Google Scholar] [CrossRef]

- Bao, J.; Yang, S.; Yang, T. Microstructural evolution, tensile property and dynamic compressive property of FSWed Ti–6Al–4V alloy. Rare Met. 2020, 39, 169–175. [Google Scholar] [CrossRef]

- Jabur, A.S.; Al-Haidary, J.T.; Al-Hasani, E.S. Characterization of Ni–Ti shape memory alloys prepared by powder metallurgy. J. Alloys Compd. 2013, 578, 136–142. [Google Scholar] [CrossRef]

- Chen, W.; Yamamoto, Y.; Peter, W.H.; Clark, M.B.; Nunn, S.D.; Kiggans, J.O.; Muth, T.R.; Blue, C.A.; Williams, J.C.; Akhtar, K. The investigation of die-pressing and sintering behavior of ITP CP-Ti and Ti-6Al-4V powders. J. Alloys Compd. 2012, 541, 440. [Google Scholar] [CrossRef]

- Brailovski, V.; Prokoshkin, S.; Gauthier, M.; Inaekyan, K.; Dubinskiy, S. Mechanical properties of porous metastable beta Ti–Nb–Zr alloys for biomedical applications. J. Alloys Compd. 2013, 577, S413–S417. [Google Scholar] [CrossRef]

- Hagiwara, M.; Emura, S. Blended elemental P/M synthesis and property evaluation of Ti-1100 alloy. Mater. Sci. Eng. A 2003, 352, 85–92. [Google Scholar] [CrossRef]

- Wang, M.; Li, H.Q.; Guo, H.; Feng, L.; Liu, S.Y.; Fang, X.Y. Evolution of microstructure and intervariant boundaries of α phase in electron beam melted and heat-treated Ti–6Al–4V alloy. Rare Met. 2020. [Google Scholar] [CrossRef]

- Henriques, V.A.R.; de Campos, P.P.; Cairo, C.A.A.; Bressiani, J.C. Production of titanium alloys for advanced aerospace systems by powder metallurgy. Mater. Res. 2005, 8. [Google Scholar] [CrossRef]

- Chen, B.-Y.; Hwang, K.-S.; Ng, K.-L. Effect of cooling process on the α phase formation and mechanical properties of sintered Ti–Fe alloys. Mater. Sci. Eng. A 2011, 528, 4556–4563. [Google Scholar] [CrossRef]

- Nouri, A.; Hodgson, P.D.; Wen, C.E. Effect of process control agent on the porous structure and mechanical properties of a biomedical Ti–Sn–Nb alloy produced by powder metallurgy. Acta Biomater. 2010, 6, 1630–1639. [Google Scholar] [CrossRef]

- Dewidar, M. Microstructure and mechanical properties of biocompatible high density Ti–6Al–4V/W produced by high frequency induction heating sintering. Mater. Des. 2010, 31, 3964–3970. [Google Scholar] [CrossRef]

- Tabrizi, S.G.; Sajjadi, S.A.; Babakhani, A.; Lu, W. Influence of spark plasma sintering and subsequent hot rolling on microstructure and flexural behavior of in-situ TiB and TiC reinforced Ti6Al4V composite. Mater. Sci. Eng. A 2015, 624, 271–278. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Q.; Zhao, S.; Chen, J. Effect of Pulse Current on Bending Behavior of Ti6Al4V Alloy. Procedia Eng. 2014, 81, 1799–1804. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Titanium alloys in total joint replacement—a materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Miura, K.; Yamada, N.; Hanada, S.; Jung, T.K.; Itoi, E. The bone tissue compatibility of a new Ti–Nb–Sn alloy with a low Young’s modulus. Acta Biomater. 2011, 7, 2320–2326. [Google Scholar] [CrossRef]

- Wang, J.L.; Liu, L.B.; Tuo, B.Y.; Bai, W.M.; Wang, X.; Li, X.; Hu, X.P. Computational Study of Mobilities and Diffusion in Ti-Sn Alloy. J. Phase Equilib. Diffus. 2015, 36, 248–253. [Google Scholar] [CrossRef]

- Hsu, H.C.; Wu, S.C.; Hong, Y.S.; Ho, W.F. Mechanical properties and deformation behavior of as-cast Ti–Sn alloys. J. Alloys Compd. 2009, 479, 390–394. [Google Scholar] [CrossRef]

- Huan, Z.Y.W.; Peng, G.; Wei, Z. Effect of β Stabilizing Elements on the Strengthening Behavior of Titanium α Phase. Rare Met. Mat. Eng. 2012, 41, 805–810. [Google Scholar]

- Zhao, Y.Q.; Peng, G.E. Current Situation and Development of New Titanium Alloys Invented in China. J. Aero. Mater. 2014, 34, 51–61. [Google Scholar]

- Cai, J.M.; Cao, C.X. Alloy Design and Application Expectation of A New Generation 600 High Temperature Titanium Alloy. J. Aero. Mater. 2014, 34, 27–36. [Google Scholar]

- Ho, W.F.; Ju, C.P.; Lin, J.H.C. Structure and properties of cast binary Ti–Mo alloys. Biomaterials 1999, 20, 2115–2122. [Google Scholar] [CrossRef]

- Sukedai, E.; Yoshimitsu, D.; Matsumoto, H.; Hashimoto, H.; Kiritani, M. β to ω phase transformation due to aging in a Ti–Mo alloy deformed in impact compression. Mater. Sci. Eng. A 2003, 350, 133–138. [Google Scholar] [CrossRef]

- Guo, H.; Enomoto, M. Surface reconstruction associated with α precipitation in a Ti–Mo alloy. Scr. Mater. 2006, 54, 1409–1413. [Google Scholar] [CrossRef]

- Sugano, M.; Tsuchida, Y.; Satake, T.; Ikeda, M. A microstructural study of fatigue fracture in titanium–molybdenum alloys. Mater. Sci. Eng. A 1998, 243, 163–168. [Google Scholar] [CrossRef]

- Zhang, L.C.; Zhou, T.; Alpay, S.P.; Aindow, M.; Wu, M.H. Origin of pseudoelastic behavior in Ti–Mo-based alloys. Appl. Phys. Lett. 2005, 87, 241909. [Google Scholar] [CrossRef]

- Zhang, L.C.; Zhou, T.; Aindow, M.; Alpay, S.P.; Blackbur, M.J.; Wu, M.H. Nucleation of stress-induced martensites in a Ti/Mo-based alloy. J. Mater. Sci. 2005, 40, 2833–2836. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, W.F.; Zhou, K.C.; Chenl, F.; Tang, H.P. Microstructures and mechanical behavior of PM Ti-Mo alloy. J. Cent. South Univ. Technol. 2003, 2, 81–86. [Google Scholar] [CrossRef]

- Oliveira, N.T.C.; Biaggio, S.R.; Piazza, S.; Sunseri, C.; Di Quarto, F. Photo-electrochemical and impedance investigation of passive layers grown anodically on titanium alloys. Electrochim. Acta 2004, 49, 4563–4576. [Google Scholar] [CrossRef]

- Zhou, Y.; Wen, S.F.; Song, B.; Zhou, X.; Teng, Q.; Wei, Q.S.; Shi, Y.S. A novel titanium alloy manufactured by selective laser melting: Microstructure, high temperature oxidation resistance. Mater. Des. 2016, 89, 1199–1204. [Google Scholar] [CrossRef]

- Zhang, W.F.; Huang, X.; Li, X.W.; Ma, J.M.; Cao, C.X. Design Method and Current Research Development of Titanium Alloys. Mater. Rev. 2005, 3, 1. [Google Scholar]

- Sun, F.; Zhang, J.Y.; Marteleur, M.; Brozek, C.; Rauch, E.F.; Veron, M.; Vermaut, P.; Jacques, P.J.; Prima, F. A new titanium alloy with a combination of high strength, high strain hardening and improved ductility. Scr. Mater. 2015, 94, 17–20. [Google Scholar] [CrossRef]

- Abkowitz, S.; Rowell, D. Superior Fatigue Properties for Blended Elemental P/M Ti-6Al-4V. JOM 1986, 38, 36–39. [Google Scholar] [CrossRef]

- Zhang, C.L.; Attar, H. Selective Laser Melting of Titanium Alloys and Titanium Matrix Composites for Biomedical Applications: A Review. Adv. Eng. Mater. 2015, 18, 463–475. [Google Scholar] [CrossRef]

- Henriques, V.A.R.; Galvani, E.T.; Petroni, S.L.G.; Paula, M.S.M.; Lemos, T.G. Production of Ti–13Nb–13Zr alloy for surgical implants by powder metallurgy. J. Mater. Sci. 2010, 45, 5844–5850. [Google Scholar] [CrossRef]

- Zheng, D.; Li, X.; Li, Y.; Qu, S.; Yang, C. ZrO2 (3Y) toughened WC composites prepared by spark plasma sintering. J. Alloys Compd. 2013, 572, 62–67. [Google Scholar] [CrossRef]

- Borkar, T.; Nag, S.; Ren, Y.; Tiley, J.; Banerje, R. Reactive spark plasma sintering (SPS) of nitride reinforced titanium alloy composites. J. Alloys Compd. 2014, 617, 933–945. [Google Scholar] [CrossRef]

- Yamanoglu, R.; Gulsoy, N.; Olevsky, E.A.; Gulsoy, H.O. Production of porous Ti5Al2.5Fe alloy via pressureless spark plasma sintering. J. Alloys Compd. 2016, 680, 654–658. [Google Scholar] [CrossRef]

- Guan, A.; Sun, N. Synthesis and tribological properties of high purity Ti2SC nanolamellas by microwave hybrid heating. J. Alloys Compd. 2017, 699, 25–30. [Google Scholar] [CrossRef]

- Tan, A.; Wang, G.; Ji, L.; Tong, Y.; Duan, X.M. Investigation on 316L/W functionally graded materials fabricated by mechanical alloying and spark plasma sintering. J. Nucl. Mater. 2016, 469, 32–38. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, E.-P.; Song, Y.-B.; Lee, S.H.; Kwon, Y.S. Microstructure and mechanical properties of hot isostatically pressed Ti–6Al–4V alloy. J. Alloys Compd. 2014, 603, 207–212. [Google Scholar] [CrossRef]

- Zhang, F.; Reich, M.; Kessler, O.; Burkel, E. The potential of rapid cooling spark plasma sintering for metallic materials. Mater. Today 2013, 16, 192–197. [Google Scholar] [CrossRef]

- Abe, J.O.; Popoola, A.P.I.; Popoola, O.M. Consolidation of Ti6Al4V alloy and refractory nitride nanoparticles by spark plasma sintering method: Microstructure, mechanical, corrosion and oxidation characteristics. Mater. Sci. Eng. A 2020, 774, 138920. [Google Scholar] [CrossRef]

- Abe, J.O.; Popoola, O.M.; Popoola, A.P.I.; Ajenifuja, E.; Adebiyi, D.I. Application of Taguchi design method for optimization of spark plasma sintering process parameters for Ti-6Al-4V/h-BN binary composite. Eng. Res. Express 2019, 1, 025043. [Google Scholar] [CrossRef]

- Okoroa, A.M.; Machakab, R.; Lephuthinga, S.S.; Okea, S.R.; Awotundea, M.A.; Olubambia, P.A. Evaluation of the sinterability, densification behaviour and microhardness of spark plasma sintered multiwall carbon nanotubes reinforced Ti6Al4V nanocomposites. Ceram. Int. 2019, 45, 19864–19878. [Google Scholar] [CrossRef]

- Bolzoni, L.; Ruiz-Navas, E.M.; Gordo, E. Influence of sintering parameters on the properties of powder metallurgy Ti–3Al–2.5V alloy. Mater. Charact. 2013, 84, 48–57. [Google Scholar] [CrossRef]

- Lu, X.; Sun, B.; Zhao, T.F.; Wang, L.N.; Liu, C.C.; Qu, X.H. Microstructure and mechanical properties of spark plasma sintered Ti-Mo alloys for dental applications. Int. J. Miner. Met. Mater. 2014, 21, 479–486. [Google Scholar] [CrossRef]

- Lu, J.W.; Zhao, Y.Q.; Ge, P.; Niu, H.Z. Microstructure and beta grain growth behavior of Ti–Mo alloys solution treated. Mater. Charact. 2013, 84, 105–111. [Google Scholar] [CrossRef]

| S. No. | Alloy | Theoretical Density (g/cm3) | Sintered Density (g/cm3) | Relative Density (%) |

|---|---|---|---|---|

| 1 | Ti6Al4V | 4.51 | 4.41 | 97.9 |

| 2 | Ti6Al4V-2Mo | 4.56 | 4.41 | 96.8 |

| 3 | Ti6Al4V-4Mo | 4.62 | 4.45 | 96.3 |

| 4 | Ti6Al4V-6Mo | 4.67 | 4.45 | 95.3 |

| S. No. | Alloy | % of α Phase | % of β Phase | Yield Stress (MPa) | UTS(MPa) | Elongation % | Avg. Hardness Value (HV500) |

|---|---|---|---|---|---|---|---|

| 1 | Ti6Al4V | 87 | 13 | 993 | 1120 | 8.2 | 330 |

| 2 | Ti6Al4V-2Mo | 81 | 19 | 1073 | 1230 | 10.5 | 340 |

| 3 | Ti6Al4V-4Mo | 72 | 28 | 1174 | 1368 | 7.3 | 345 |

| 4 | Ti6Al4V-6Mo | 58 | 42 | 885 | 1028 | 8.5 | 370 |

| S. No. | Powder Material | Supplier | Purity and Chemical Composition | Powder Particle Size |

|---|---|---|---|---|

| 1 | Pre-alloyed Ti6Al4V | AP&C, Canada | Purity > 99.6%; ~88.649% Ti, Al (6.40%), V (4.20%), C (0.01%), O (0.13%), N (0.01%), H (0.001%), Fe (0.21%), and Others (0.39%). | >106 μm (3.8%) ≤ 106 μm > 45 μm (94.6%) ≤45 (1.6%) |

| 2 | Molybdenum (Mo) | Sigma-Aldrich, Bangalore, India | Purity 99.95%; ~99.84% Mo, O (0.1%), N (0.01%), C (0.005%), W (0.025%), Fe (0.005%), Ni (0.005%), Cr (0.005%), and Si (0.005%) | ≤ 149 μm > 74 μm (5%) ≤74 μm (95%) |

| Sr. | Specimen | Nominal Composition | |

|---|---|---|---|

| No. | Ti6Al4V (wt.%) | Mo (wt.%) | |

| 1 | Ti6Al4V-0Mo | 100 | 0 |

| 2 | Ti6Al4V-2Mo | 98 | 2 |

| 3 | Ti6Al4V-4Mo | 96 | 4 |

| 4 | Ti6Al4V-6Mo | 94 | 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajadurai, M.; Muthuchamy, A.; Annamalai, A.R.; Agrawal, D.K.; Jen, C.-P. Effect of Molybdenum (Mo) Addition on Phase Composition, Microstructure, and Mechanical Properties of Pre-Alloyed Ti6Al4V Using Spark Plasma Sintering Technique. Molecules 2021, 26, 2894. https://doi.org/10.3390/molecules26102894

Rajadurai M, Muthuchamy A, Annamalai AR, Agrawal DK, Jen C-P. Effect of Molybdenum (Mo) Addition on Phase Composition, Microstructure, and Mechanical Properties of Pre-Alloyed Ti6Al4V Using Spark Plasma Sintering Technique. Molecules. 2021; 26(10):2894. https://doi.org/10.3390/molecules26102894

Chicago/Turabian StyleRajadurai, Murugesan, Ayyapparaj Muthuchamy, A. Raja Annamalai, Dinesh K. Agrawal, and Chun-Ping Jen. 2021. "Effect of Molybdenum (Mo) Addition on Phase Composition, Microstructure, and Mechanical Properties of Pre-Alloyed Ti6Al4V Using Spark Plasma Sintering Technique" Molecules 26, no. 10: 2894. https://doi.org/10.3390/molecules26102894

APA StyleRajadurai, M., Muthuchamy, A., Annamalai, A. R., Agrawal, D. K., & Jen, C.-P. (2021). Effect of Molybdenum (Mo) Addition on Phase Composition, Microstructure, and Mechanical Properties of Pre-Alloyed Ti6Al4V Using Spark Plasma Sintering Technique. Molecules, 26(10), 2894. https://doi.org/10.3390/molecules26102894