Femtosecond Laser Drilling of Cylindrical Holes for Carbon Fiber-Reinforced Polymer (CFRP) Composites

Abstract

1. Introduction

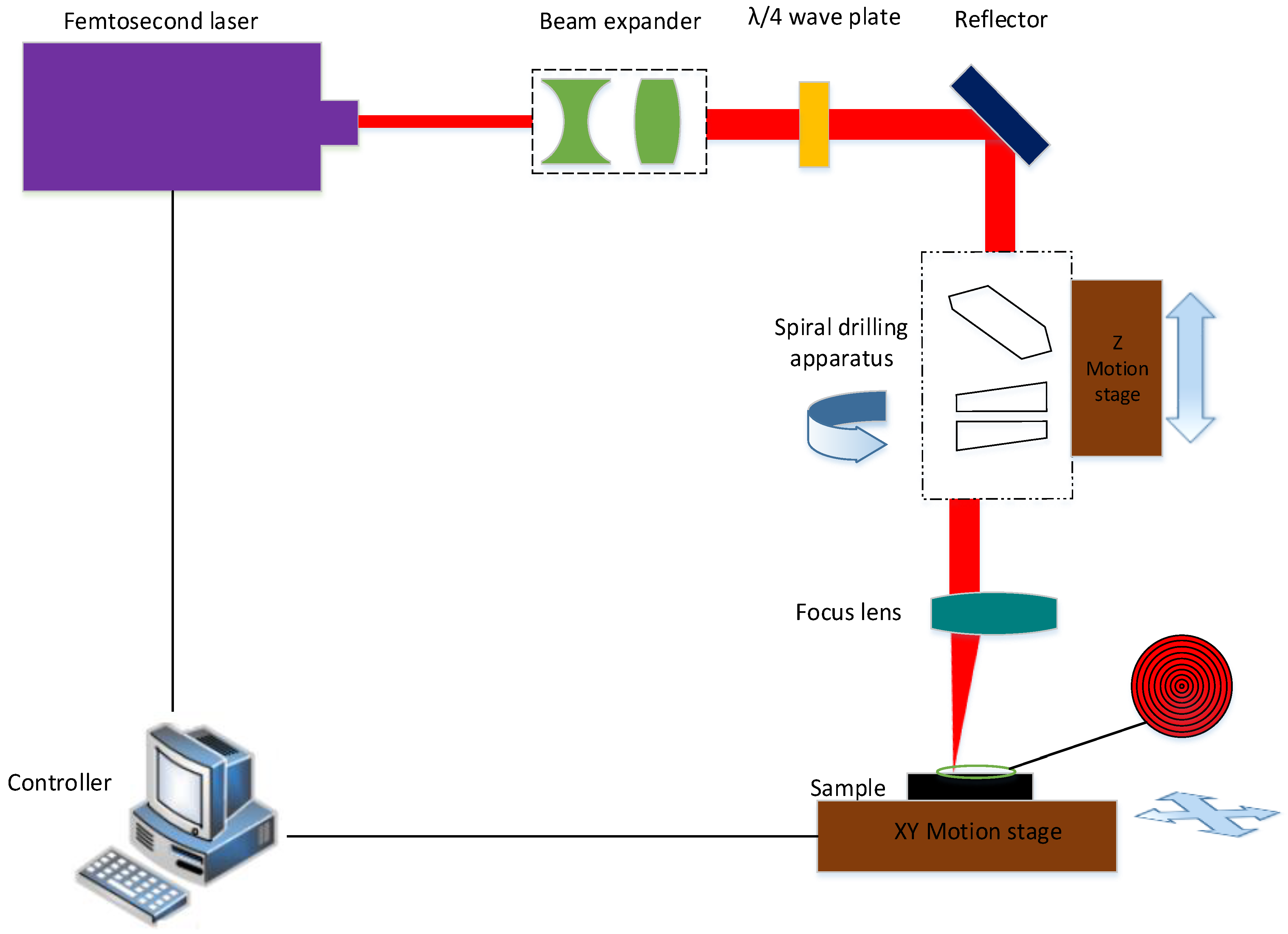

2. Materials and Experimental Setup

3. Results and Discussion

3.1. Effect of Laser Power and Rotational Speed of Laser on HAZ and Ablation Depth

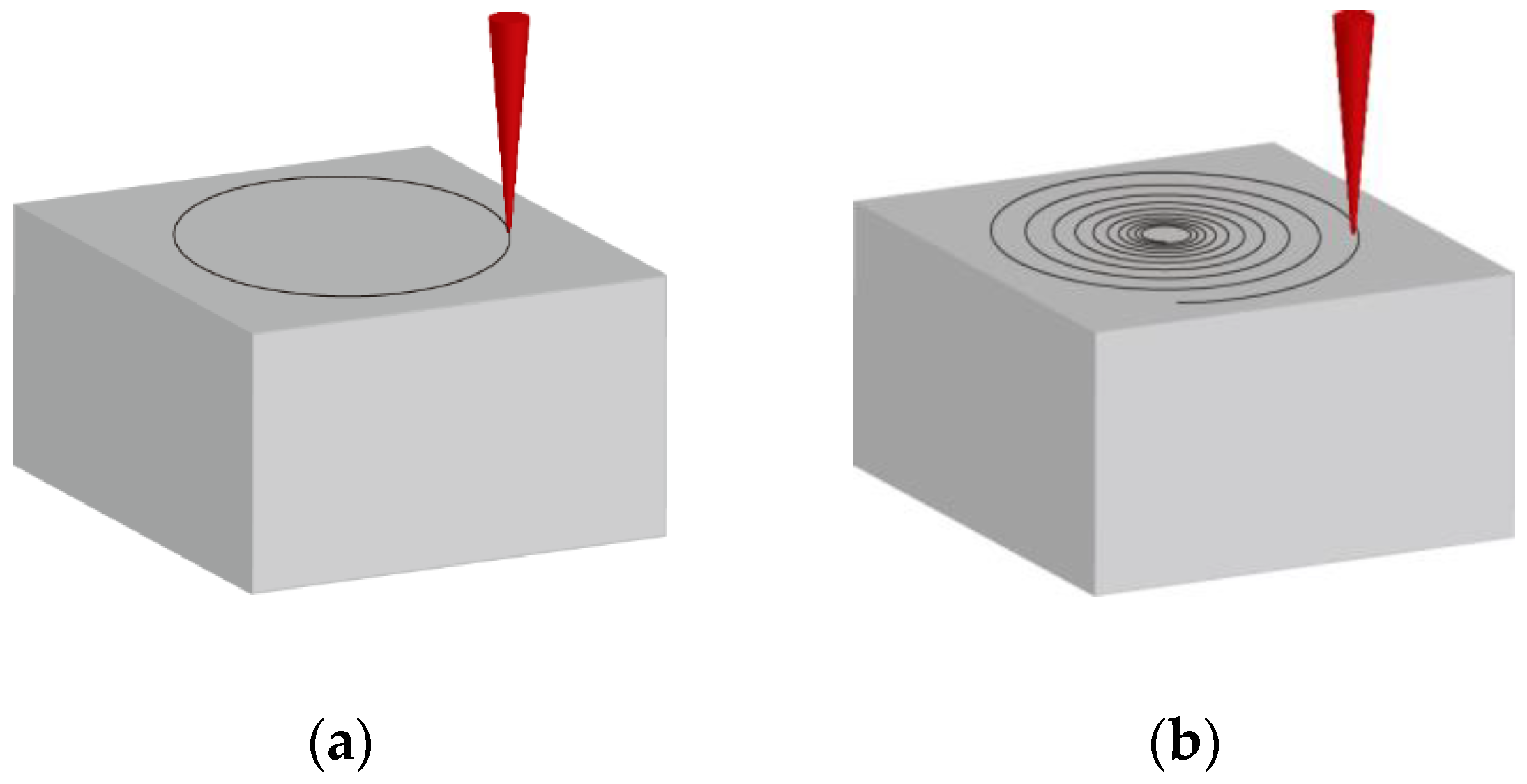

3.1.1. Circular Laser Drilling Trajectories

3.1.2. Spiral Laser Drilling Trajectories

3.2. Effect of Number of Passes on HAZ and Ablation Depth Using Spiral Drilling

3.3. Effect of Laser Power and Drilling Feed Depth on Hole Diameter and Hole Taper

3.4. Cylindrical Holes Drilling Realized by Spiral Drilling

4. Conclusions

- (1)

- Spiral drilling can greatly reduce the HAZ sizes and increase the drilling depth compared with drilling with circular laser drilling trajectories under the same processing parameters.

- (2)

- When using a spiral drilling apparatus, the distribution of the spiral pitch is sparse at first and then dense due to the double optical wedges rotating at a fixed angular velocity. This change causes the hole to penetrate quickly and provides an escape channel for the residue and plasma generated by the drilling.

- (3)

- The diameters at the entrance and exit increase with the increase of laser power and drilling feed depth, especially for the diameters at the exit, while the taper of the cross section of the hole changes in an opposite trend.

- (4)

- The femtosecond laser and spiral drilling apparatus were successfully used to realize the drilling of a cylindrical hole with a taper < 0.32° under about 3:1 depth-to-diameter ratio. The HAZ size at the entrance hole was <10 μm, and no obvious HAZ was found in the cross section. Therefore, the femtosecond laser spiral drilling method can achieve high-precision drilling, thereby ensuring high joint strength and avoiding any weakening of the CFRP structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Dandekar, C.R.; Shin, Y.C. Modeling of machining of composite materials: A review. Int. J. Mach. Tools Manuf. 2012, 57, 102–121. [Google Scholar] [CrossRef]

- Khoathane, M.C.; Vorster, O.C.; Sadiku, E.R. Hemp Fiber-Reinforced 1-Pentene/Polypropylene Copolymer: The Effect of Fiber Loading on the Mechanical and Thermal Characteristics of the Composites. J. Reinf. Plast. Compos. 2008, 27, 1533–1544. [Google Scholar] [CrossRef]

- Herzog, D.; Jaeschke, P.; Meier, O.; Haferkamp, H. Investigations on the thermal effect caused by laser cutting with respect to static strength of CFRP. Int. J. Mach. Tools Manuf. 2008, 48, 1464–1473. [Google Scholar] [CrossRef]

- König, W.; Wulf, C.; Graß, P.; Willerscheid, H. Machining of Fibre Reinforced Plastics. CIRP Ann. 1985, 34, 537–548. [Google Scholar] [CrossRef]

- Kim, J.-D.; Lee, E.-S. A study of the ultrasonic-vibration cutting of carbon-fiber reinforced plastics. J. Mater. Process. Technol. 1994, 43, 259–277. [Google Scholar] [CrossRef]

- Johannes, W.S.; Michael, F.Z.; Justinian, P.S. Remote laser cutting of CFRP: Influence of the edge quality on fatigue strength. Proc. SPIE 2014, 8963, 89630T. [Google Scholar]

- Negarestani, R.; Li, L.; Sezer, H.K.; Whitehead, D.; Methven, J. Nano-second pulsed DPSS Nd:YAG laser cutting of CFRP composites with mixed reactive and inert gases. Int. J. Adv. Manuf. Technol. 2010, 49, 553–566. [Google Scholar] [CrossRef]

- Cenna, A.A.; Mathew, P. Evaluation of cut quality of fibre-reinforced plastics—A review. Int. J. Mach. Tools Manuf. 1997, 37, 723–736. [Google Scholar] [CrossRef]

- Riveiro, A.; Quintero, F.; Lusquiños, F.; del Val, J.; Comesaña, R.; Boutinguiza, M.; Pou, J. Experimental study on the CO2 laser cutting of carbon fiber reinforced plastic composite. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1400–1409. [Google Scholar] [CrossRef]

- Klotzbach, A.; Hauser, M.; Beyer, E. Laser Cutting of Carbon Fiber Reinforced Polymers using Highly Brilliant Laser Beam Sources. Phys. Procedia 2011, 12, 572–577. [Google Scholar] [CrossRef]

- Yung, W.; Mei, S.; Yue, T. A study of the heat-affected zone in the UV YAG laser drilling of GFRP materials. J. Mater. Process. Technol. 2002, 122, 278–285. [Google Scholar] [CrossRef]

- Freitag, C.; Wiedenmann, M.; Negel, J.P.; Loescher, A.; Onuseit, V.; Weber, R.; Ahmed, M.A.; Graf, T. High-quality processing of CFRP with a 1.1-kW picosecond laser. Appl. Phys. A 2015, 119, 1237–1243. [Google Scholar] [CrossRef]

- Salama, A.; Li, L.; Mativenga, P.; Sabli, A. High-power picosecond laser drilling/machining of carbon fibre-reinforced polymer (CFRP) composites. Appl. Phys. A 2016, 122, 73. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, D. Experimental study on the picosecond pulsed laser cutting of carbon fiber-reinforced plastics. J. Reinf. Plast. Compos. 2018, 37, 993–1003. [Google Scholar] [CrossRef]

- Fujita, M.; Ohkawa, H.; Somekawa, T.; Otsuka, M.; Maeda, Y.; Matsutani, T.; Miyanaga, N. Wavelength and Pulsewidth Dependences of Laser Processing of CFRP. Phys. Procedia 2016, 83, 1031–1036. [Google Scholar] [CrossRef]

- Sonoya, K.; Reza, I.; Ishida, K. Precision Cutting Fabrication of Carbon Composite Materials using Femtosecond Laser. J. Surface Finish. Soc. Jpn. 2013, 64, 127–132. [Google Scholar] [CrossRef][Green Version]

- Li, Y.; Shen, Y.; Huang, Y.; Zhao, Q.; Lu, C. Research on UV Femtosecond Pulsed Laser Cutting Carbon Fiber Composite Materials. In Proceedings of the 24th National Laser Conference & Fifteenth National Conference on Laser Technology and Optoelectronics, Shanghai, China, 17–20 October 2020. [Google Scholar]

- Ahmad Sobri, S.; Heinemann, R.; Whitehead, D. Development of Laser Drilling Strategy for Thick Carbon Fibre Reinforced Polymer Composites (CFRP). Polymers 2020, 12, 2674. [Google Scholar] [CrossRef]

- Tao, N.; Chen, G.; Yu, T.; Li, W.; Fan, L. Dual-beam laser drilling process for thick carbon fiber reinforced plastic composites plates. J. Mater. Process. Technol. 2020, 281, 116590. [Google Scholar] [CrossRef]

- Jahns, D.; Kaszemeikat, T.; Mueller, N.; Ashkenasi, D.; Dietrich, R.; Eichler, H.J. Laser Trepanning of Stainless Steel. Phys. Procedia 2013, 41, 6307–6635. [Google Scholar] [CrossRef]

- Fornaroli, C.; Holtkamp, J.; Gillner, A. Laser-Beam Helical Drilling of High Quality Micro Holes. Phys. Procedia 2013, 41, 661–669. [Google Scholar] [CrossRef]

- Dou, J.; Sun, Y.; Xu, M.; Cui, J.; Mei, X.; Wang, W.; Wang, X. Process research on micro-machining diamond microgroove by femtosecond laser. Integr. Ferroelectr. 2019, 198, 9–19. [Google Scholar] [CrossRef]

- Weber, R.; Freitag, C.; Kononenko, T.V.; Hafner, M.; Onuseit, V.; Berger, P.; Graf, T. Short-pulse Laser Processing of CFRP. Phys. Procedia 2012, 39, 137–146. [Google Scholar] [CrossRef][Green Version]

- Li, Z.; Zheng, H.; Lim, G.; Chu, P.L.; Li, L. Study on UV laser machining quality of carbon fibre reinforced composites. Compos. Part. A Appl. Sci. Manuf. 2010, 41, 1403–1408. [Google Scholar] [CrossRef]

- Anisimov, S.I.; Kapeliovich, B.L.; Perelman, T.L. Electron emission from metal surfaces exposed to ultrashort laser pulses. Zhurnal Eksperimentalnoi Teor. Fiz. 1974, 66, 776. [Google Scholar]

- Ghoreishi, M.; Low, D.K.Y.; Li, L. Comparative statistical analysis of hole taper and circularity in laser percussion drilling. Int. J. Mach. Tools Manuf. 2002, 42, 985–995. [Google Scholar] [CrossRef]

| Laser Parameters | PHAROS-10 W |

|---|---|

| Max average power | 10 W |

| Pulse duration | <290 fs |

| Pulse energy | >0.2 mJ |

| Beam quality | M2 < 1.2 |

| Center wavelength | 1028 nm ± 5 nm |

| Beam diameter | 1.8 mm |

| Parameters | Parameter Value |

|---|---|

| Rotational speed of laser | Up to 3000 rpm |

| Drilling diameter | 0.08 mm to 1.2 mm |

| Inclination angle | −0.7° to +0.7° |

| HAZ | Femtosecond Lasers | Picosecond Lasers | Nanosecond Lasers | Millisecond Laser |

|---|---|---|---|---|

| <10 μm | <20 μm | <50 μm | Several Millimeters | |

| Taper of hole cross section of CFRP | Drilling with spiral drilling apparatus | Scanning with galvanometer scanner | Several steps scanning with galvanometer scanner | Dual-beam laser drilling with galvanometer scanner |

| Cylindrical, positive taper and inverted cones holes | Positive taper hole and cross-section taper > 1.25° | The bottom end of the hole is right angle, and the upper part of the hole still has a taper | The two ends of the hole are at right angles, and there is still a taper in the middle of the hole |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Ma, C.; Li, M.; Cao, Z. Femtosecond Laser Drilling of Cylindrical Holes for Carbon Fiber-Reinforced Polymer (CFRP) Composites. Molecules 2021, 26, 2953. https://doi.org/10.3390/molecules26102953

Jiang H, Ma C, Li M, Cao Z. Femtosecond Laser Drilling of Cylindrical Holes for Carbon Fiber-Reinforced Polymer (CFRP) Composites. Molecules. 2021; 26(10):2953. https://doi.org/10.3390/molecules26102953

Chicago/Turabian StyleJiang, Hao, Caiwen Ma, Ming Li, and Zhiliang Cao. 2021. "Femtosecond Laser Drilling of Cylindrical Holes for Carbon Fiber-Reinforced Polymer (CFRP) Composites" Molecules 26, no. 10: 2953. https://doi.org/10.3390/molecules26102953

APA StyleJiang, H., Ma, C., Li, M., & Cao, Z. (2021). Femtosecond Laser Drilling of Cylindrical Holes for Carbon Fiber-Reinforced Polymer (CFRP) Composites. Molecules, 26(10), 2953. https://doi.org/10.3390/molecules26102953