Preharvest UVB Application Increases Glucosinolate Contents and Enhances Postharvest Quality of Broccoli Microgreens

Abstract

:1. Introduction

2. Materials and Methods

2.1. Seed Germination and Treatments

2.2. Extraction of Glucosinolates

2.3. UHPLC-ESI/ITMS

2.4. Qualitative and Quantitative Analysis of GLs

2.5. Postharvest Quality and Physiological Assessment

2.6. Quantitative RT-PCR (qRT-PCR) Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. Glucosinolate Levels of Microgreens during Cold Storage

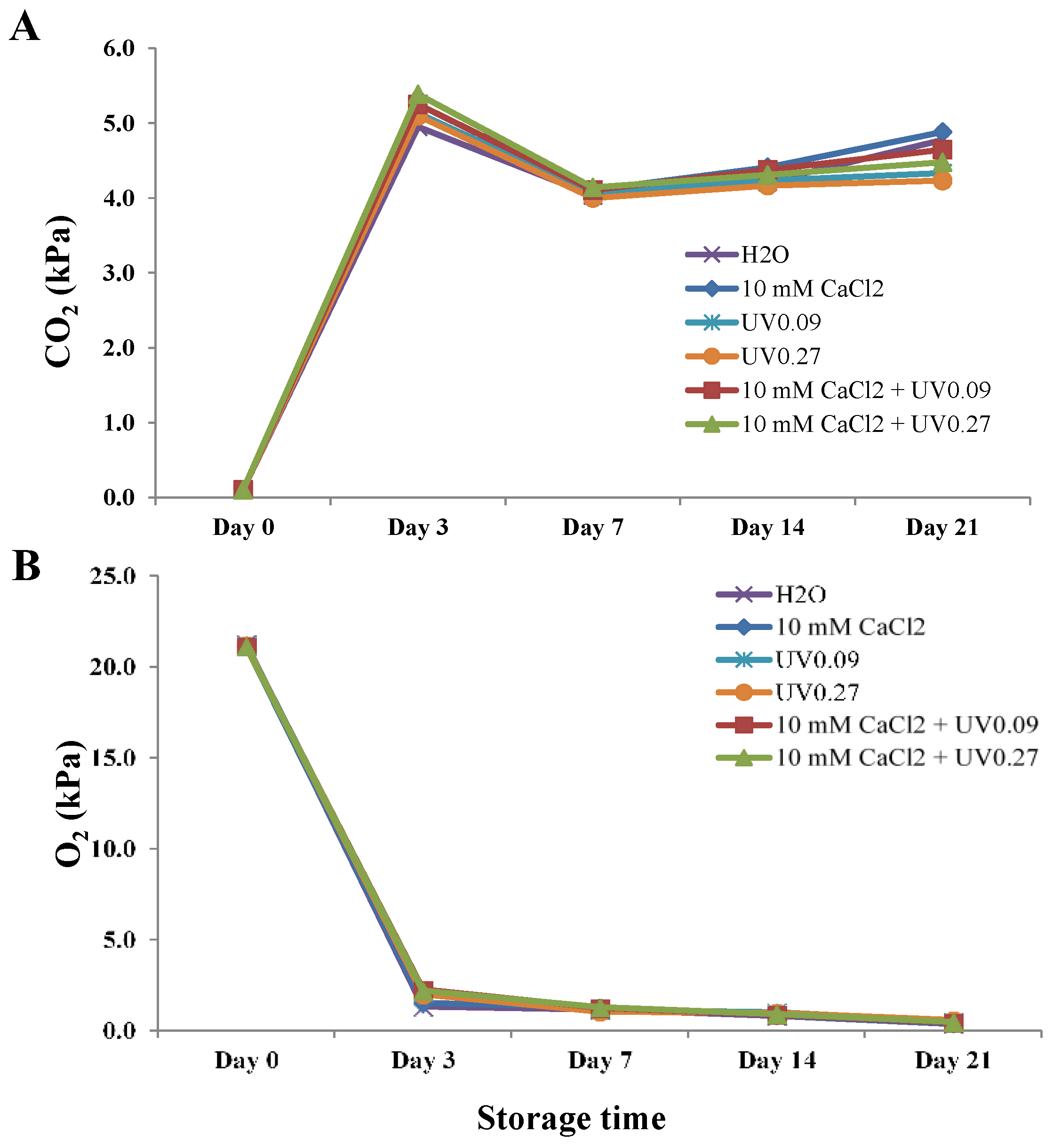

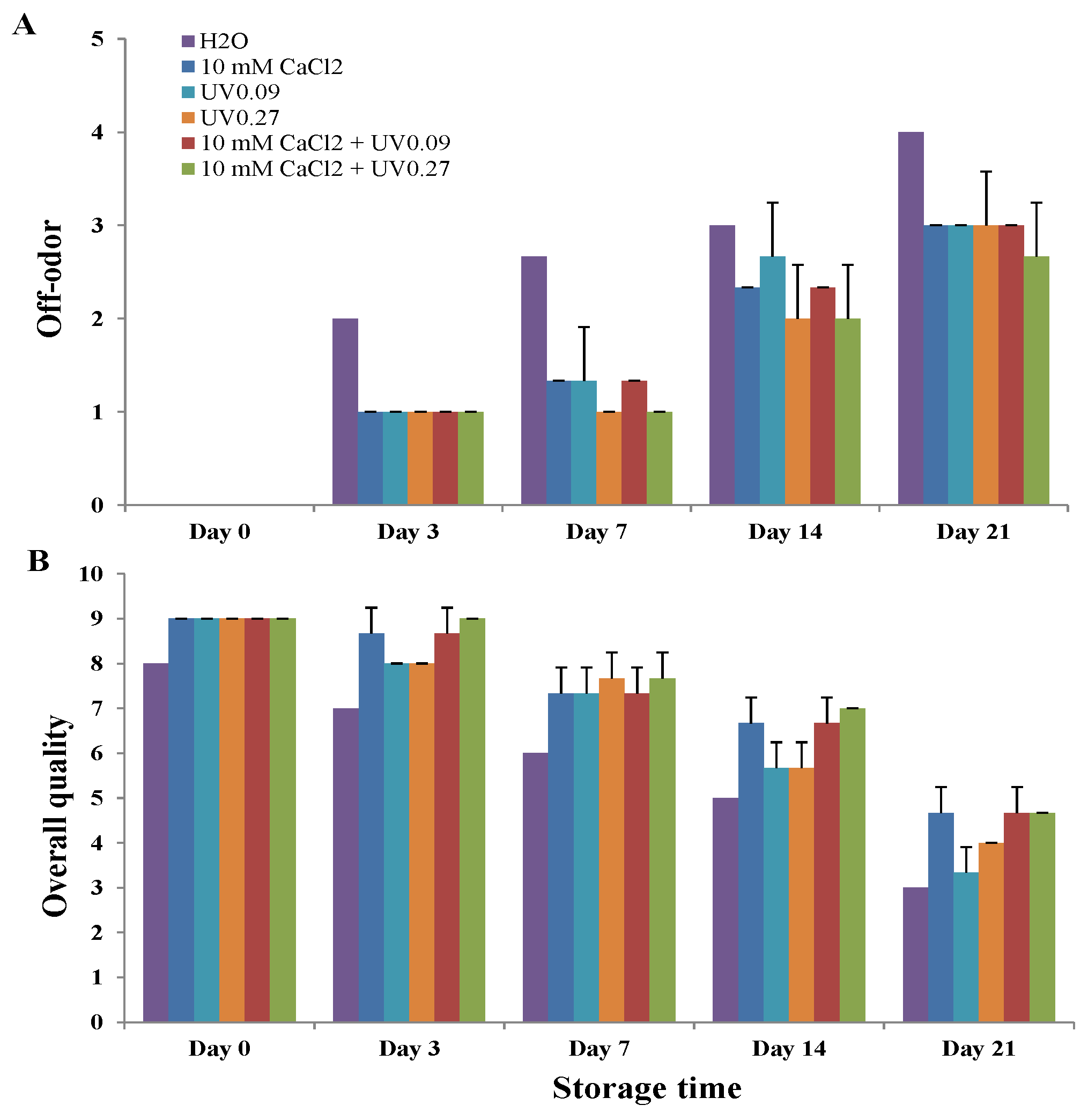

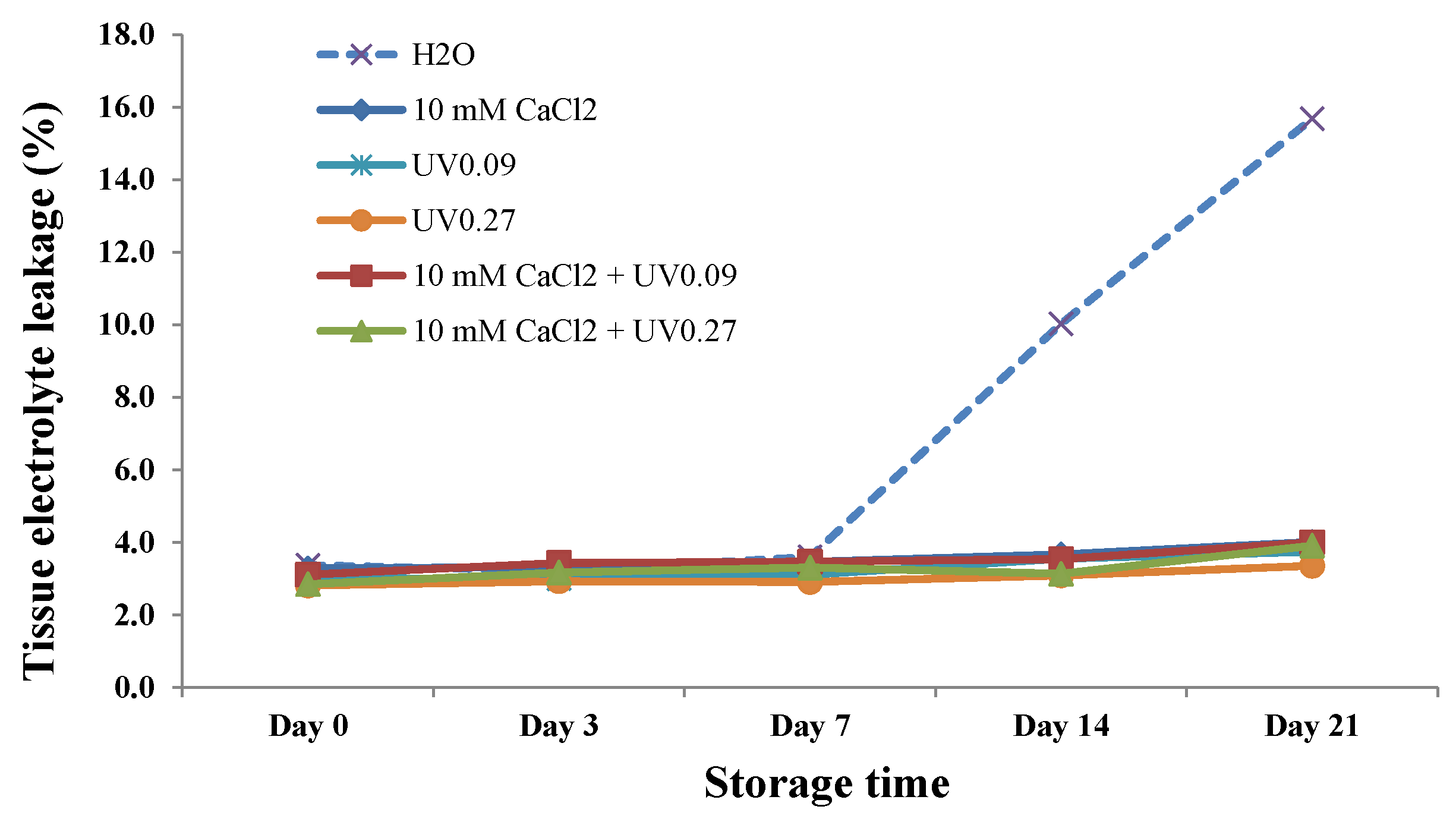

3.2. Effects of UVB Treatments on Microgreen Postharvest Quality Traits

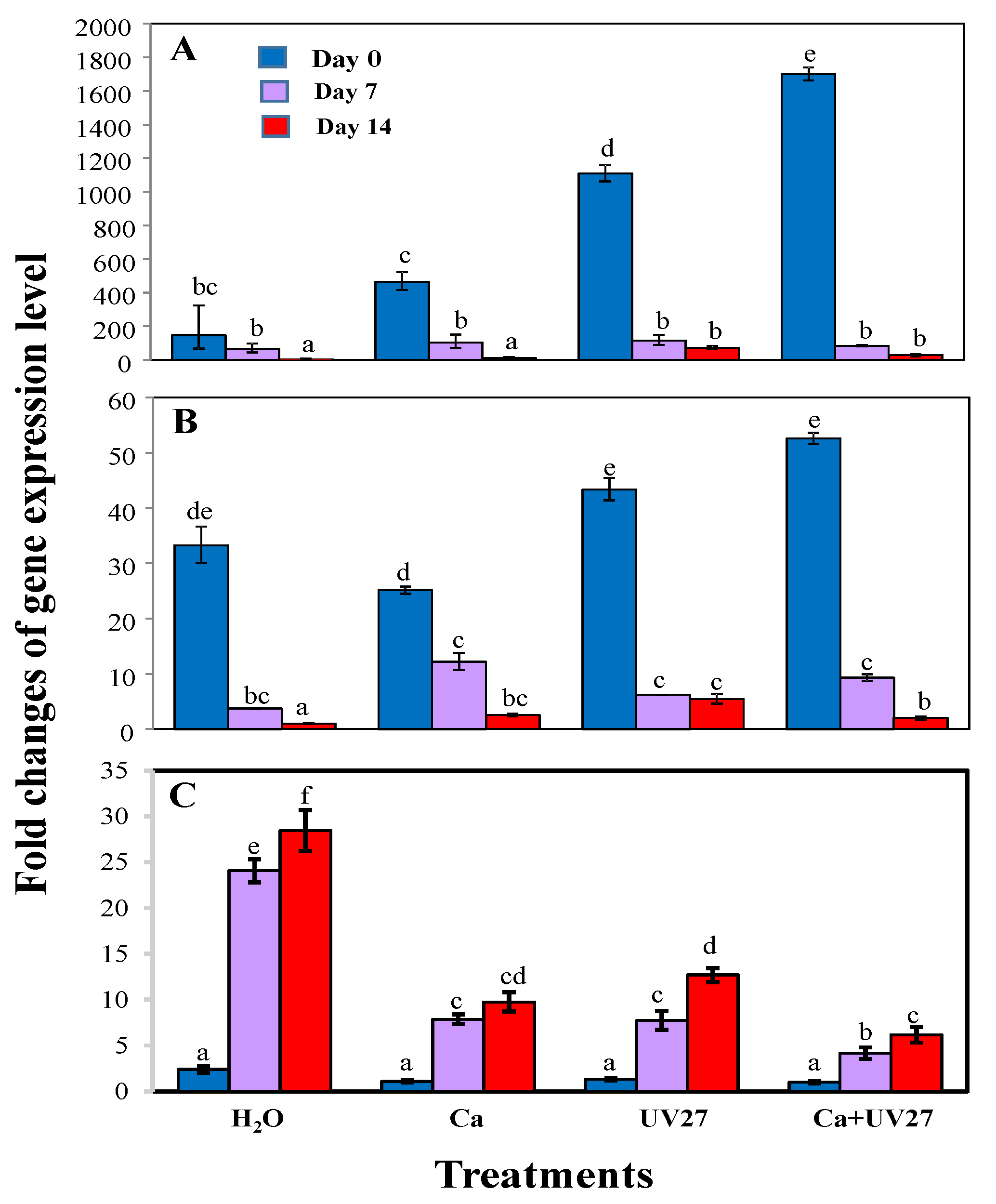

3.3. Expression Changes of Glucosinolate Biosynthetic and Breakdown Genes during Storage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Kou, L.; Yang, T.; Luo, Y.; Liu, X.; Huang, L.; Codling, E. Pre-harvest calcium application increases biomass and delays senescence of broccoli microgreens. Postharvest Biol. Technol. 2014, 87, 70–78. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, W.; Alcazar, J.; Yang, T.; Luo, Y.; Wang, Q.; Chen, P. Effect of preharvest CaCl2 spray and postharvest UV-B radiation on storage quality of broccoli microgreens, a richer source of glucosinolates. J. Food Compos. Anal. 2018, 67, 55–62. [Google Scholar] [CrossRef]

- Guo, R.F.; Yuan, G.F.; Wang, Q.M. Effect of sucrose and mannitol on the accumulation of health-promoting compounds and the activity of metabolic enzymes in broccoli sprouts. Sci. Hortic. 2011, 128, 159–165. [Google Scholar] [CrossRef]

- Martinez-Villaluenga, C.; Peñas, E.; Ciska, E.; Piskula, M.K.; Kozlowska, H.; Vidal-Valverde, C.; Frias, J. Time dependence of bioactive compounds and antioxidant capacity during germination of different cultivars of broccoli and radish seeds. Food Chem. 2010, 120, 710–716. [Google Scholar] [CrossRef]

- Weng, R.; Tsai, C.H.; Kulp, S.K.; Chen, C.S. Indole-3-carbinol as a chemopreventive and anti-cancer agent. Cancer Lett. 2008, 262, 153–163. [Google Scholar] [CrossRef] [Green Version]

- Barillari, J.; Canistro, D.; Paolini, M.; Ferroni, F.; Pedulli, G.F.; Iori, R.; Valgimigli, L. Direct antioxidant activity of purified glucoerucin, the dietary secondary metabolite contained in rocket (Eruca sativa Mill.) seeds and sprouts. J. Agric. Food Chem. 2005, 53, 2475–2482. [Google Scholar] [CrossRef] [PubMed]

- Fahey, J.W.; Talalay, P. Antioxidant functions of sulforaphane: A potent inducer of Phase II detoxication enzymes. Food Chem. Toxicol. 1999, 37, 973–979. [Google Scholar] [CrossRef]

- Nestle, M. Broccoli sprouts as inducers of carcinogen-detoxifying enzyme systems: Clinical, dietary, and policy implications. Proc. Natl. Acad. Sci. USA 1997, 94, 11149–11151. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, N.; Rivero, R.M.; Shulaev, V.; Blumwald, E.; Mittler, R. Abiotic and biotic stress combinations. New Phytol. 2014, 203, 32–43. [Google Scholar] [CrossRef] [PubMed]

- Tohge, T.; Watanabe, M.; Hoefgen, R.; Fernie, A.R. The evolution of phenylpropanoid metabolism in the green lineage. Crit. Rev. Biochem. Mol. Biol. 2012, 48, 123–152. [Google Scholar] [CrossRef] [PubMed]

- Kuhlmann, F.; Muller, C. Independent responses to ultraviolet radiation and herbivore attack in broccoli. J. Exp. Bot. 2009, 60, 3467–3475. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jones, R.B.; Faragher, J.D.; Winkler, S. A review of the influence of postharvest treatments on quality and glucosinolate content in broccoli (Brassica oleracea var. Italica) heads. Postharvest Biol. Technol. 2006, 41, 1–8. [Google Scholar] [CrossRef]

- Verkerk, R.; Schreiner, M.; Krumbein, A.; Ciska, E.; Holst, B.; Rowland, I.; De Schrijver, R.; Hansen, M.; Gerhäuser, C.; Mithen, R.; et al. Glucosinolates in Brassica vegetables: The influence of the food supply chain on intake, bioavailability and human health. Mol. Nutr. Food Res. 2008, 53, S219–S265. [Google Scholar] [CrossRef] [PubMed]

- Mewis, I.; Schreiner, M.; Nguyen, C.N.; Krumbein, A.; Ulrichs, C.; Lohse, M.; Zrenner, R. UV-B irradiation changes specifically the secondary metabolite profile in broccoli sprouts: Induced signaling overlaps with defense response to biotic stressors. Plant Cell Physiol. 2012, 53, 1546–1560. [Google Scholar] [CrossRef] [Green Version]

- Heinze, M.; Hanschen, F.S.; Wiesner-Reinhold, M.W.; Baldermann, S.; Gräfe, J.; Schreiner, M.; Neuqart, S. Effects of developmental stages and reduced UVB and low UV conditions on plant secondary metabolite profiles in Pak Choi (Brassica rapa subsp. chinensis). J. Agric. Food Chem. 2018, 66, 1678–1692. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Yang, R.; Gu, Z. Cloning of genes related to aliphatic glucosinolate metabolism and the mechanism of sulforaphane accumulationin broccoli sprouts under jasmonic acid treatment. J. Sci. Food Agric. 2016, 96, 4329–4336. [Google Scholar] [CrossRef]

- Grubb, C.D.; Abel, S. Glucosinolate metabolism and its control. Trends Plant Sci. 2006, 11, 89–100. [Google Scholar] [CrossRef]

- Sønderby, I.E.; Hansen, B.G.; Bjarnholt, N.; Ticconi, C.; Halkier, B.A.; Kliebenstein, D.J. A systems biology approach identifies a R2R3 MYB gene subfamily with distinct and overlapping functions in regulation of aliphatic glucosinolates. PLoS ONE 2007, 2, 1322. [Google Scholar] [CrossRef]

- Levy, M.; Wang, Q.; Kaspi, R.; Parrella, M.; Abel, S. Arabidopsis IQD1, a novel calmodulin-binding nuclear protein, stimulates glucosinolate accumulation and plant defense. Plant J. 2005, 43, 79–96. [Google Scholar] [CrossRef] [PubMed]

- Zang, Y.X.; Kim, H.U.; Kim, J.A.; Lim, M.H.; Jin, M.; Lee, S.C.; Kwon, S.-J.; Lee, S.-I.; Hong, J.K.; Park, T.-H.; et al. Genome-wide identification of glucosinolate synthesis genes in Brassica rapa. FEBS J. 2009, 276, 3559–3574. [Google Scholar] [CrossRef]

- Hansen, C.H.; Wittstock, U.; Olsen, C.E. Cytochrome P450 CYP79F1 from Arabidopsis catalyzes the conversion of dihomomethionine and trihomomethionine to the corresponding aldoximes in the biosynthesis of aliphatic glucosinolates. J. Biol. Chem. 2001, 276, 11078–11085. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, J.; Kou, L.; Geng, P.; Huang, H.; Yang, T.; Luo, Y.; Chen, P. Metabolomic assessment reveals an elevated level of glucosinolate content in CaCl2 treated broccoli microgreens. J. Agric. Food Chem. 2015, 63, 1863–1868. [Google Scholar] [CrossRef]

- Singh, D.P.; Beloy, J.; McInerney, J.K.; Day, L. Impact of boron, calcium and genetic factors on vitamin C, carotenoids, phenolic acids, anthocyanins and antioxidant capacity of carrots (Daucus carota). Food Chem. 2012, 132, 1161–1170. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; McEvoy, J.; Wachtel, M. Package atmosphere affects postharvest biology and quality of fresh-cut cilantro leaves. HortScience 2004, 39, 567–570. [Google Scholar] [CrossRef]

- Meilgaard, M.C. Individual differences in sensory threshold for aroma chemicals added to beer. Food Qual. Prefer. 1993, 4, 153–167. [Google Scholar] [CrossRef]

- Schmittgen, T.D.; Livak, K.J. Analyzing real-time PCR data by the comparative C(T) method. Nat. Protoc. 2008, 3, 1101–1108. [Google Scholar] [CrossRef] [PubMed]

| Glucoerucin (µmol/g) | Glucoraphanin (µmol/g) | Total (µmol/g) | |

|---|---|---|---|

| Day 0 Control | 28.89 ± 0.57 d | 1.51 ± 0.03 cd | 30.10 ± 0.58 d |

| Day 0 10 mM CaCl2 | 39.07 ± 0.53 f | 1.68 ± 0.02 d | 40.75 ± 0.54 f |

| Day 0 UV0.09 | 32.76 ± 0.59 e | 1.89 ± 0.03 e | 34.65 ± 0.58 e |

| Day 0 UV0.27 | 33.76 ± 0.37 e | 1.93 ± 0.06 e | 35.69 ± 0.32 e |

| Day 0 10 mM CaCl2 + UV0.09 | 46.60 ± 0.29 g | 2.00 ± 0.04 e | 48.59 ± 0.31 g |

| Day 0 10 mM CaCl2 + UV0.27 | 48.86 ± 2.24 g | 2.01 ± 0.11 e | 50.87 ± 2.34 g |

| Day 3 Control | 23.21 ± 0.51 c | 1.32 ± 0.03 c | 24.53 ± 0.53 c |

| Day 3 10 mM CaCl2 | 36.08 ± 1.34 ef | 1.64 ± 0.02 d | 37.72 ± 1.36 ef |

| Day 3 UV0.09 | 31.79 ± 0.17 e | 1.87 ± 0.02 e | 33.67 ± 0.16 e |

| Day 3 UV0.27 | 32.80 ± 0.98 e | 1.92 ± 0.02 e | 34.72 ± 1.00 e |

| Day 3 10 mM CaCl2 + UV0.09 | 45.64 ± 0.59 g | 1.97 ± 0.05 e | 47.60 ± 0.56 g |

| Day 3 10 mM CaCl2 + UV0.27 | 47.15 ± 1.88 g | 1.99 ± 0.05 e | 49.14 ± 1.84 g |

| Day 7 Control | 18.71 ± 0.33 b | 1.01 ± 0.02 b | 19.72 ± 0.34 b |

| Day 7 10 mM CaCl2 | 34.06 ± 0.64 e | 1.54 ± 0.01 cd | 35.61 ± 0.66 e |

| Day 7 UV0.09 | 29.42 ± 1.82 d | 1.78 ± 0.06 de | 31.20 ± 1.77 d |

| Day 7 UV0.27 | 30.17 ± 0.18 d | 1.85 ± 0.07 e | 32.02 ± 0.25 d |

| Day 7 10 mM CaCl2 + UV0.09 | 45.01 ± 0.83 g | 1.83 ± 0.07 de | 46.84 ± 0.77 g |

| Day 7 10 mM CaCl2 + UV0.27 | 45.46 ± 1.58 g | 1.86 ± 0.03 e | 47.32 ± 1.56 g |

| Day 14 Control | 13.98 ± 0.22 a | 0.85 ± 0.09 a | 14.83 ± 0.30 a |

| Day 14 10 mM CaCl2 | 27.52 ± 0.59 d | 1.37 ± 0.07 c | 28.90 ± 0.52 d |

| Day 14 UV0.09 | 28.41 ± 1.75 d | 1.59 ± 0.08 cd | 30.00 ± 1.77 d |

| Day 14 UV0.27 | 28.38 ± 0.33 d | 1.64 ± 0.05 d | 30.11 ± 0.38 d |

| Day 14 10 mM CaCl2 + UV0.09 | 38.72 ± 0.81 f | 1.83 ± 0.07 de | 40.55 ± 0.79 f |

| Day 14 10 mM CaCl2 + UV0.27 | 39.17 ± 0.47 f | 1.86 ± 0.03 e | 41.03 ± 0.45 f |

| Day 21 Control | 12.85 ± 0.41 a | 0.71 ± 0.05 a | 13.56 ± 0.45 a |

| Day 21 10 mM CaCl2 | 23.25 ± 0.70 c | 1.14 ± 0.07 b | 24.39 ± 0.76 c |

| Day 21 UV0.09 | 21.62 ± 0.38 c | 1.32 ± 0.07 c | 22.94 ± 0.44 c |

| Day 21 UV0.27 | 22.62 ± 1.22 c | 1.43 ± 0.05 c | 24.05 ± 1.24 c |

| Day 21 10 mM CaCl2 + UV0.09 | 34.44 ± 0.47 e | 1.41 ± 0.06 c | 35.85 ± 0.53 e |

| Day 21 10 mM CaCl2 + UV0.27 | 36.15 ± 0.47 ef | 1.44 ± 0.03 c | 37.59 ± 0.43 ef |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Dong, W.; Yang, T.; Luo, Y.; Chen, P. Preharvest UVB Application Increases Glucosinolate Contents and Enhances Postharvest Quality of Broccoli Microgreens. Molecules 2021, 26, 3247. https://doi.org/10.3390/molecules26113247

Lu Y, Dong W, Yang T, Luo Y, Chen P. Preharvest UVB Application Increases Glucosinolate Contents and Enhances Postharvest Quality of Broccoli Microgreens. Molecules. 2021; 26(11):3247. https://doi.org/10.3390/molecules26113247

Chicago/Turabian StyleLu, Yingjian, Wen Dong, Tianbao Yang, Yaguang Luo, and Pei Chen. 2021. "Preharvest UVB Application Increases Glucosinolate Contents and Enhances Postharvest Quality of Broccoli Microgreens" Molecules 26, no. 11: 3247. https://doi.org/10.3390/molecules26113247

APA StyleLu, Y., Dong, W., Yang, T., Luo, Y., & Chen, P. (2021). Preharvest UVB Application Increases Glucosinolate Contents and Enhances Postharvest Quality of Broccoli Microgreens. Molecules, 26(11), 3247. https://doi.org/10.3390/molecules26113247