Thermoplastic Cellulose-Based Compound for Additive Manufacturing

Abstract

1. Introduction

2. Results and Discussion

2.1. Test Series

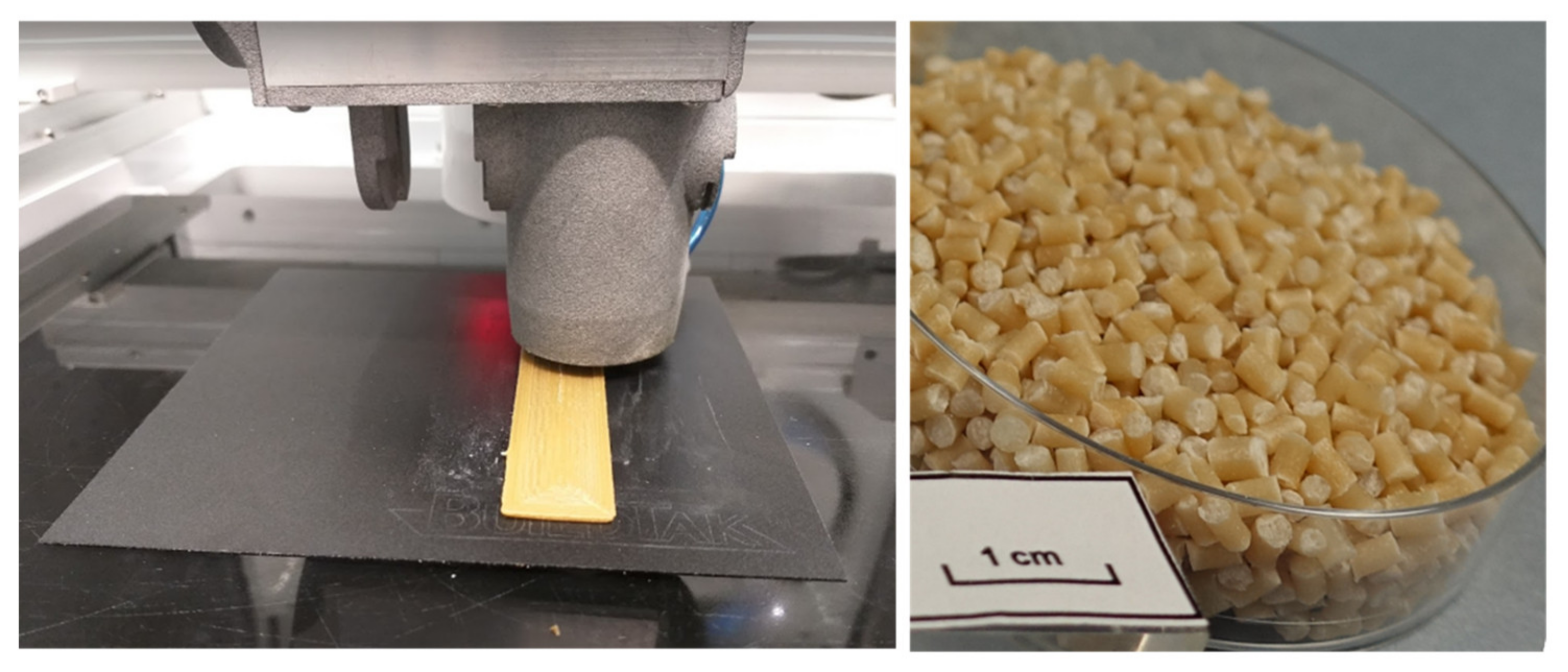

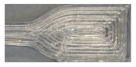

2.2. Results from the Printing Tests

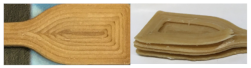

2.3. Visual Results for Injection Molded Samples

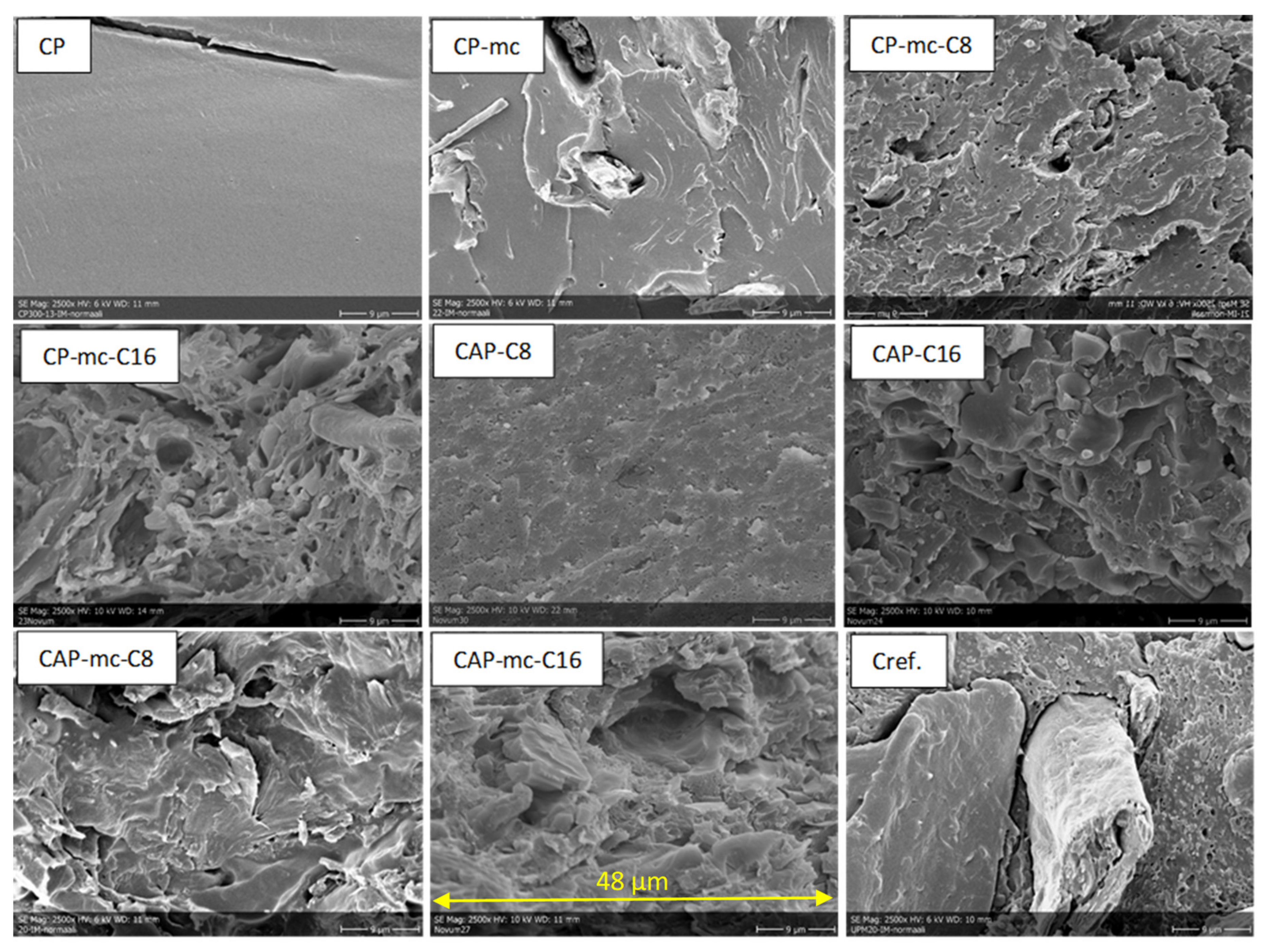

2.4. Scanning Electron Microscopy (SEM)

2.5. Thermal Resistance Related Results

2.5.1. Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) Results

2.5.2. Heat Distortion Temperature (HDT) Analysis

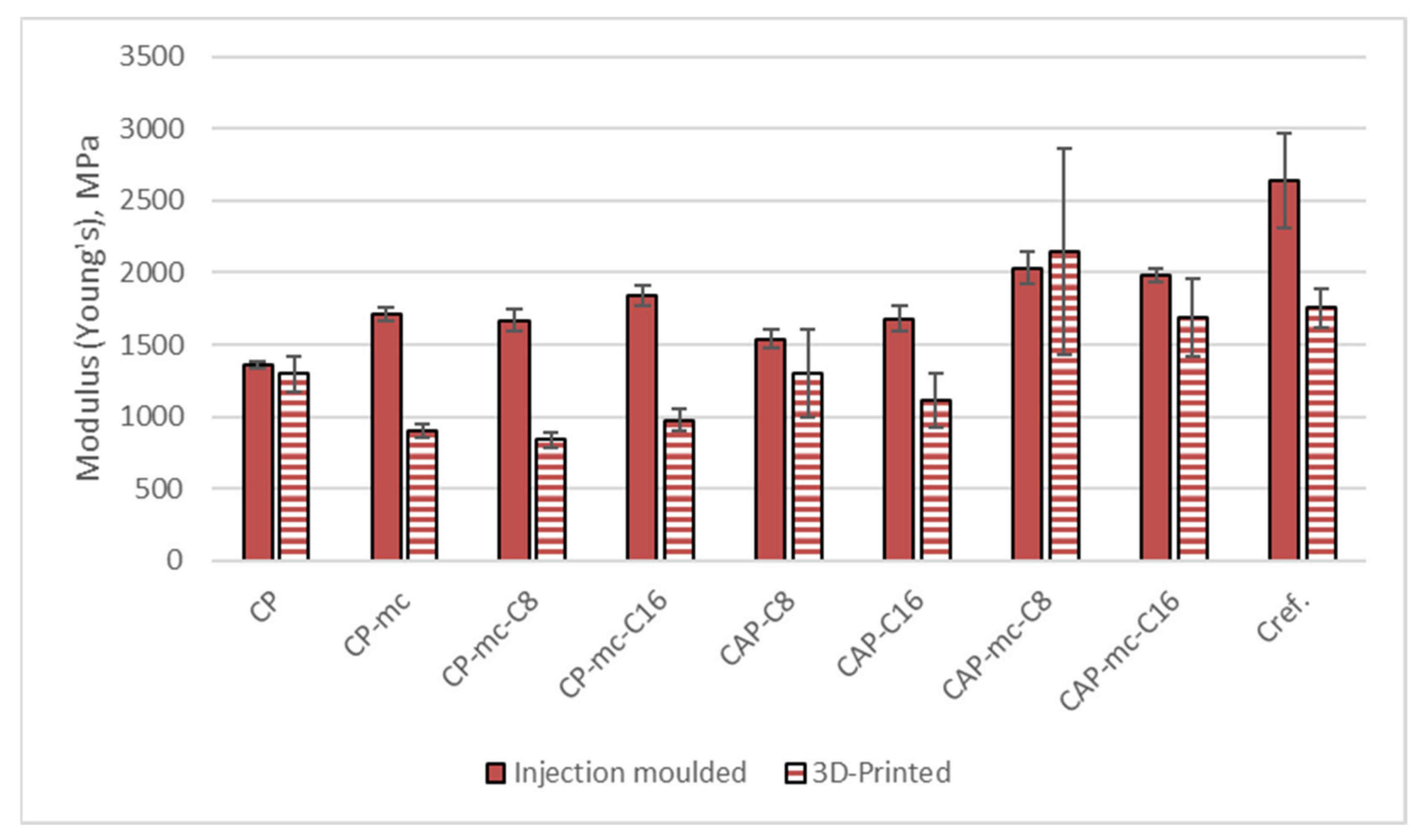

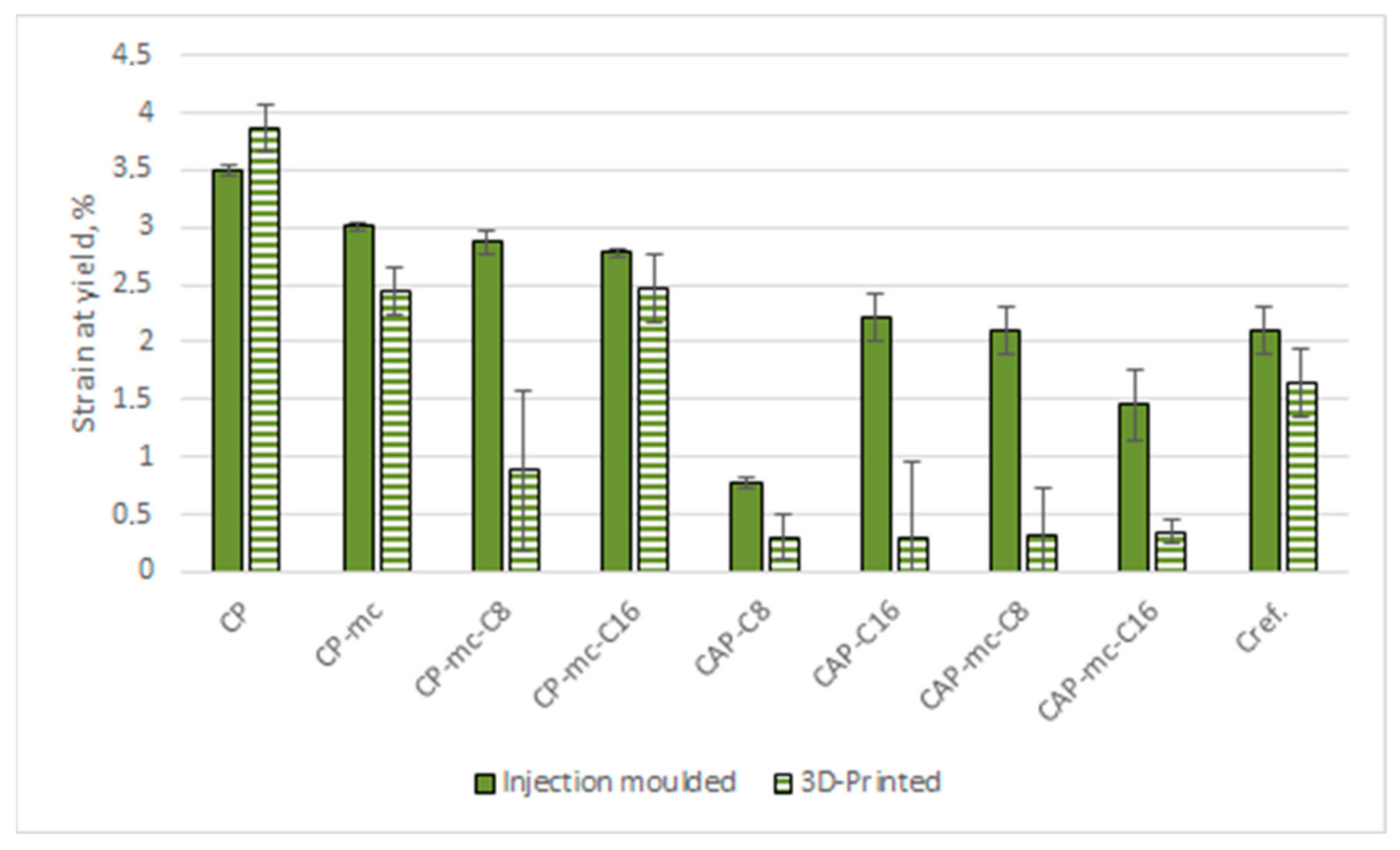

2.6. Results from the Mechanical Tests

2.6.1. Tensile Strength

2.6.2. Charpy Impact Strength

3. Materials and Methods

3.1. Materials

3.1.1. Materials in Production of Thermoplastic Cellulose Additive

3.1.2. Materials in Manufacturing of Cellulose-Based Compound

3.2. Methods

3.2.1. Preparation of Thermoplastic Cellulose Additive

3.2.2. Processing of Thermoplastic Materials

3.2.3. Additive Manufacturing

3.2.4. Thermal Analytics

3.2.5. Scanning Electron Microscopy (SEM)

3.2.6. Mechanical Tests

3.2.7. Heat Distortion Temperature (HDT)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample availability

References

- AMFG. Available online: https://amfg.ai/industrial-applications-of-3d-printing-the-ultimate-guide/ (accessed on 12 February 2021).

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J.R. Environmental Dimensions of Additive Manufacturing: Mapping Application Domains and Their Environmental Implications. J. Ind. Ecol. 2017, 21, S49–S68. [Google Scholar] [CrossRef]

- European Commission. Available online: https://ec.europa.eu/info/policies/climate-action_en (accessed on 12 February 2021).

- Ellen Macarthur Foundation. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/NPEC-Hybrid_English_22-11-17_Digital.pdf (accessed on 12 February 2021).

- Campbell, I.; Bourell, D.; Gibson, I. Additive manufacturing: Rapid prototyping comes of age. Rapid Prototyp. J. 2012, 18, 255–258. [Google Scholar] [CrossRef]

- SFS-EN ISO/ASTM 52900:2017. Additive manufacturing-General principles-Terminology; Suomen Standardisoimisliitto: Helsinki, Finland, 2017. [Google Scholar]

- Woern, A.; Byard, D.; Oakley, R.; Fiedler, M.; Snabes, S.; Pearce, J. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [PubMed]

- Cincinnati. Available online: https://www.e-ci.com/3d-scoop/2020/9/17/pellet-vs-filament-3d-printing (accessed on 12 February 2021).

- Fabbaloo. Available online: https://www.fabbaloo.com/blog/2018/5/10/the-other-reason-for-3d-printing-pellets (accessed on 12 February 2021).

- Klemm, D.; Philipp, B.; Heinze, T.; Heinze, U.; Wagenknecht, W. Comprehensive Cellulose Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 1998; Volume 1, ISBN 3527294139. [Google Scholar]

- Edgar, K.J.; Buchanan, C.; Debenham, J.; Rundquist, P.; Seiler, B.; Shelton, M.; Tindall, D. Advances in cellulose ester performance and application. Prog. Polym. Sci. 2001, 26, 1605–1688. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.-P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chemie Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Luan, Y.; Wu, J.; Zhan, M.; Zhang, J.; Zhang, J.; He, J. “One pot” homogeneous synthesis of thermoplastic cellulose acetate-graft-poly(l-lactide) copolymers from unmodified cellulose. Cellul. 2013, 20, 327–337. [Google Scholar] [CrossRef]

- Havimo, M.; Jalomäki, J.; Granström, M.; Rissanen, A.; Iivanainen, T.; Kemell, M.; Heikkilä, M.; Sipi, M.; Kilpeläinen, I. Mechanical strength and water resistance of paperboard coated with long chain cellulose esters. Packag. Technol. Sci. 2011, 24, 249–258. [Google Scholar] [CrossRef]

- Crépy, L.; Chaveriat, L.; Banoub, J.; Martin, P.; Joly, N. Synthesis of cellulose fatty esters as plastics-influence of the degree of substitution and the fatty chain length on mechanical properties. ChemSusChem 2009, 2, 165–170. [Google Scholar] [CrossRef]

- Willberg-Keyriläinen, P.; Orelma, H.; Ropponen, J. Injection Molding of Thermoplastic Cellulose Esters and Their Compatibility with Poly(Lactic Acid) and Polyethylene. Materials 2018, 11, 2358. [Google Scholar] [CrossRef] [PubMed]

- Willberg-Keyriläinen, P.; Rokkonen, T.; Malm, T.; Harlin, A.; Ropponen, J. Melt spinnability of long chain cellulose esters. J. Appl. Polym. Sci. 2020, 49588. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part.Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Nath, S.D.; Nilufar, S. An Overview of Additive Manufacturing of Polymers and Associated Composites. Polym. 2020, 12, 2719. [Google Scholar] [CrossRef]

- Calì, M.; Pascoletti, G.; Gaeta, M.; Milazzo, G.; Ambu, R. A New Generation of Bio-Composite Thermoplastic Filaments for a More Sustainable Design of Parts Manufactured by FDM. Appl. Sci. 2020, 10, 5852. [Google Scholar] [CrossRef]

- UPM Formi 3D-Printing Products. Available online: https://www.upmformi.com/biocomposite-products/3d-printing/ (accessed on 16 February 2021).

- ColorFabb Filled Filaments. Available online: https://colorfabb.com/filaments/special-filaments (accessed on 16 February 2021).

- Mohan, D.; Teong, Z.K.; Bakir, A.N.; Sajab, M.S.; Kaco, H. Extending cellulose-based polymers application in additive manufacturing technology: A review of recent approaches. Polym. 2020, 12, 1876. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Sun, J.; Yao, Q.; Ji, C.; Liu, J.; Zhu, Q. 3D printing with cellulose materials. Cellulose 2018, 25, 4275–4301. [Google Scholar] [CrossRef]

- Martikka, O.; Kärki, T.; Wu, Q. Mechanical properties of 3D-printed wood-plastic composites. Key Eng. Mater. 2018, 777, 499–507. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polym. 2019, 11, 1094. [Google Scholar] [CrossRef]

- Khan, M.Z.R.; Srivastava, S.K.; Gupta, M.K. A state-of-the-art review on particulate wood polymer composites: Processing, properties and applications. Polym. Test. 2020, 89, 106721. [Google Scholar] [CrossRef]

- Karakoç, A.; Rastogi, V.K.; Isoaho, T.; Tardy, B.; Paltakari, J.; Rojas, O.J. Comparative screening of the structural and thermomechanical properties of FDM filaments comprising thermoplastics loaded with cellulose, carbon and glass fibers. Materials 2020, 13. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Teramoto, Y. Functional Thermoplastic Materials from Derivatives of Cellulose and Related Structural Polysaccharides. Molecules 2015, 20, 5487–5527. [Google Scholar] [CrossRef]

- Böhler, S.; Bartel, M.; Bohn, A.; Jacob, R.; Ganster, J.; Büsse, T.; Balko, J. Highly dense cellulose acetate specimens with superior mechanical properties produced by fused filament fabrication. Polym. 2020, 194, 122388. [Google Scholar] [CrossRef]

- Azad, M.A.; Olawuni, D.; Kimbell, G.; Badruddoza, A.Z.M.; Hossain, M.S.; Sultana, T. Polymers for Extrusion-Based 3D Printing of Pharmaceuticals: A Holistic Materials–Process Perspective. Pharm. 2020, 12, 124. [Google Scholar] [CrossRef] [PubMed]

- Mervine, N.; Brätt, K.; Saloni, D. A Review of Sustainable Materials Used in Thermoplastic Extrusion and Powder Bed Melting Additive Manufacturing. In Proceedings of the Advances in Intelligent Systems and Computing; Volume 1216 AISC; Springer International Publishing: Cham, Switzerland, 2020; pp. 95–102. [Google Scholar]

- Lamm, M.E.; Wang, L.; Kishore, V.; Tekinalp, H.; Kunc, V.; Wang, J.; Gardner, D.J.; Ozcan, S. Material extrusion additive manufacturing of wood and lignocellulosic filled composites. Polymers 2020, 12, 2115. [Google Scholar] [CrossRef] [PubMed]

- Willberg-Keyriläinen, P.; Asikainen, S.; Harlin, A.; Talja, R.; Ropponen, J. The effect of cellulose molar mass on the properties of palmitate esters. Carbohydr. Polym. 2016, 151, 988–995. [Google Scholar] [CrossRef]

- Duchatel-Crépy, L.; Joly, N.; Martin, P.; Marin, A.; Tahon, J.-F.; Lefebvre, J.-M.; Gaucher, V. Substitution degree and fatty chain length influence on structure and properties of fatty acid cellulose esters. Carbohydr. Polym. 2020, 234, 115912. [Google Scholar] [CrossRef]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Rynkowska, E.; Fatyeyeva, K.; Kujawa, J.; Dzieszkowski, K.; Wolan, A.; Kujawski, W. The effect of reactive ionic liquid or plasticizer incorporation on the physicochemical and transport properties of cellulose acetate propionate-based membranes. Polym. 2018, 10, 86. [Google Scholar] [CrossRef] [PubMed]

- Merck. Cellulose Acetate Propionate Product Information. Available online: https://www.sigmaaldrich.com/catalog/product/aldrich/330183?lang=fi®ion=FI (accessed on 16 February 2021).

- Albis Plastics GmbH Material Data Center Datasheet for Cellidor CP300-13. Available online: https://www.materialdatacenter.com/ms/en/Cellidor/ALBIS+PLASTIC+GmbH/10 (accessed on 16 February 2021).

- Willberg-Keyriläinen, P.; Vartiainen, J.; Harlin, A.; Ropponen, J. The effect of side-chain length of cellulose fatty acid esters on their thermal, barrier and mechanical properties. Cellulose 2017, 24, 505–517. [Google Scholar] [CrossRef]

| Code | Thermoplastic Cellulose Ester (C) Type | Thermoplastic Cellulose Ester (C) Content, (%) | Cellulose Fibre Content, (%) | Description |

|---|---|---|---|---|

| CP | 0 | 0 | Commercial thermoplastic cellulose polymer | |

| CP-mc | 0 | 20 | ||

| CP-mc-C8 | C8 | 4 | 20 | |

| CP-mc-C16 | C16 | 4 | 20 | |

| CAP-C8 | C8 | 17 | 0 | CAP without commercial plasticizer |

| CAP-C16 | C16 | 17 | 0 | CAP without commercial plastizicer |

| CAP-mc-C8 | C8 | 17 | 20 | CAP without commercial plastizicer |

| CAP-mc-C16 | C16 | 17 | 20 | CAP without commercial plastizicer |

| Cref | 0 | 20 | Commercial cellulose fibre containing reference material |

| Code | 3D printability | Image |

|---|---|---|

| CP | Good |  |

| CP-mc | Good |  |

| CP-mc-C8 | Good |  |

| CP-mc-C16 | Good |  |

| CAP-C8 | Good, however poor layer adhesion, oily material, fragile |  |

| CAP-C16 | Limited, however poor layer adhesion, oily material, fragile |  |

| CAP-mc-C8 | Limited, and poor layer adhesion, oily material |  |

| CAP-mc-C16 | Good, however poor layer adhesion, oily material, fragile |  |

| Cref | Good |  |

| Code | First Heating | Cooling | Second Heating | TGA, 5% Degraded | ||

|---|---|---|---|---|---|---|

| Tsoft, °C | Tm, °C | Tc, °C | Tg, °C | Tm, °C | Tdeg, °C | |

| CP | 42 | 158 | 122 | 95 | 159 | 267 |

| CP-mc | 47 | 157 | 124 | 97 | 160 | 273 |

| CP-mc-C8 | 40 | 161 | 123 | 103 | 160 | 264 |

| CP-mc-C16 | 34 | 114/161 | n.d. | 103 | 163 | 277 |

| CAP-C8 | 54 | 173/191 | n.d. | 55 | 154/181 | 267 |

| CAP-C16 | 36 | 173/206 | n.d. | 32 | 146/172 | 298 |

| CAP-mc-C8 | 72 | 161/182 | 145 | 78 | 142/194 | 309 |

| CAP-mc-C16 | 34 | 98/168 | n.d. | 84 | 175/194 | 305 |

| Cref | 61 | 149 | 125 | 60 | 165 | 304 |

| Code | HDT, °C |

|---|---|

| CP | 58 ± 0.8 |

| CP-mc | 58.6 ± 0.3 |

| CP-mc-C8 | 59.6 ± 0.3 |

| CP-mc-C16 | 62.1 ± 0.9 |

| CAP-C8 | 68.6 ± 5.6 |

| CAP-C16 | 82.1 ± 0.7 |

| CAP-mc-C8 | 74.8 ± 2.3 |

| CAP-mc-C16 | 72.9 ± 2.4 |

| Cref | 55.4 ± 0.8 |

| Injection Moulded | Granule Printed | |||||

|---|---|---|---|---|---|---|

| Strength at Yield, MPa | Young’s Modulus, MPa | Strain at Yield, % | Strength at Yield, MPa | Young’s Modulus, MPa | Strain at Yield, % | |

| CP | 26.0 ± 0.3 | 1360 ± 25 | 3.5 ± 0.04 | 23.6 ± 2.5 | 1297 ± 121 | 3.9 ± 0.2 |

| CP-mc | 28.9 ± 0.1 | 1710 ± 45 | 3.0 ± 0.04 | 11.6 ± 0.7 | 902 ± 42 | 2.5 ± 0.2 |

| CP-mc-C8 | 26.0 ± 0.1 | 1670 ± 74 | 2.9 ± 0.1 | 8.8 ± 1.3 | 837 ± 54 | 0.9 ± 0.7 |

| CP-mc-C16 | 25.5 ± 0.1 | 1840 ± 69 | 2.8 ± 0.04 | 12.9 ± 1.3 | 977 ± 81 | 2.5 ± 0.3 |

| CAP-C8 | 10.9 ± 0.4 | 1539 ± 65 | 0.8 ± 0.04 | 6.7 ± 1.0 | 1297 ± 307 | 0.3 ± 0.2 |

| CAP-C16 | 29.0 ± 2.2 | 1680 ± 87 | 2.2 ± 0.2 | 10.0 ± 1.9 | 1115 ± 185 | 0.3 ± 0.7 |

| CAP-mc-C8 | 31.8 ± 1.0 | 2034 ± 116 | 2.1 ± 0.2 | 11.0 ± 2.1 | 2147 ± 717 | 0.3 ± 0.4 |

| CAP-mc-C16 | 24.0 ± 2.8 | 1981 ± 51 | 1.5 ± 0.3 | 5.4 ± 1.1 | 1690 ± 274 | 0.4 ± 0.1 |

| Cref | 26.6 ± 0.2 | 2642 ± 329 | 2.1 ± 0.2 | 11.6 ± 0.3 | 1754 ± 133 | 1.6 ± 0.3 |

| Code | Injection Moulded | 3D Printed |

|---|---|---|

| kJ/m2 | kJ/m2 | |

| CP | no break unnotched 20.1 ± 0.7 notched | no break unnotched 26.0 ± 19.0 notched |

| CP-mc | 21.9 ± 1.1 | 5.1 ± 0.8 |

| CP-mc-C8 | 22.5 ± 1.6 | 6.0 ± 0.7 |

| CP-mc-C16 | 20.9 ± 2.7 | 5.1 ± 0.3 |

| CAP-C8 | 4.5 ± 0.7 | 8.4 ± 2.5 |

| CAP-C16 | 15.2 ± 5.0 | 16 ± 3.0 |

| CAP-mc-C8 | 6.8 ± 0.6 | 8.3 ± 4.3 |

| CAP-mc-C16 | 7.8 ± 2.0 | 7.2 ± 0.9 |

| Cref | 18.8 ± 2.0 | 7.7 ± 1.2 |

| Code | Temperature Nozzle/Bed (°C) | Layer Height (mm) |

|---|---|---|

| CP | 200/60 | 0.5 |

| CP-mc | 215/60 | 0.5 |

| CP-mc-C8 | 210/60 | 0.5 |

| CP-mc-C16 | 219/60 | 0.5 |

| CAP-C8 | 185/60 | 0.5 |

| CAP-C16 | 220/60 | 0.5 |

| CAP-mc-C8 | 220/60 | 0.25 |

| CAP-mc-C16 | 224/60 | 0.5 |

| Cref | 215/60 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Immonen, K.; Willberg-Keyriläinen, P.; Ropponen, J.; Nurmela, A.; Metsä-Kortelainen, S.; Kaukoniemi, O.-V.; Kangas, H. Thermoplastic Cellulose-Based Compound for Additive Manufacturing. Molecules 2021, 26, 1701. https://doi.org/10.3390/molecules26061701

Immonen K, Willberg-Keyriläinen P, Ropponen J, Nurmela A, Metsä-Kortelainen S, Kaukoniemi O-V, Kangas H. Thermoplastic Cellulose-Based Compound for Additive Manufacturing. Molecules. 2021; 26(6):1701. https://doi.org/10.3390/molecules26061701

Chicago/Turabian StyleImmonen, Kirsi, Pia Willberg-Keyriläinen, Jarmo Ropponen, Asta Nurmela, Sini Metsä-Kortelainen, Otto-Ville Kaukoniemi, and Heli Kangas. 2021. "Thermoplastic Cellulose-Based Compound for Additive Manufacturing" Molecules 26, no. 6: 1701. https://doi.org/10.3390/molecules26061701

APA StyleImmonen, K., Willberg-Keyriläinen, P., Ropponen, J., Nurmela, A., Metsä-Kortelainen, S., Kaukoniemi, O.-V., & Kangas, H. (2021). Thermoplastic Cellulose-Based Compound for Additive Manufacturing. Molecules, 26(6), 1701. https://doi.org/10.3390/molecules26061701