Valorisation of Broccoli By-Products: Technological, Sensory and Flavour Properties of Durum Pasta Fortified with Broccoli Leaf Powder

Abstract

:1. Introduction

2. Results and Discussion

2.1. Cooking Properties

2.2. Texture

2.3. Proximal Composition

2.4. Pasta Colour

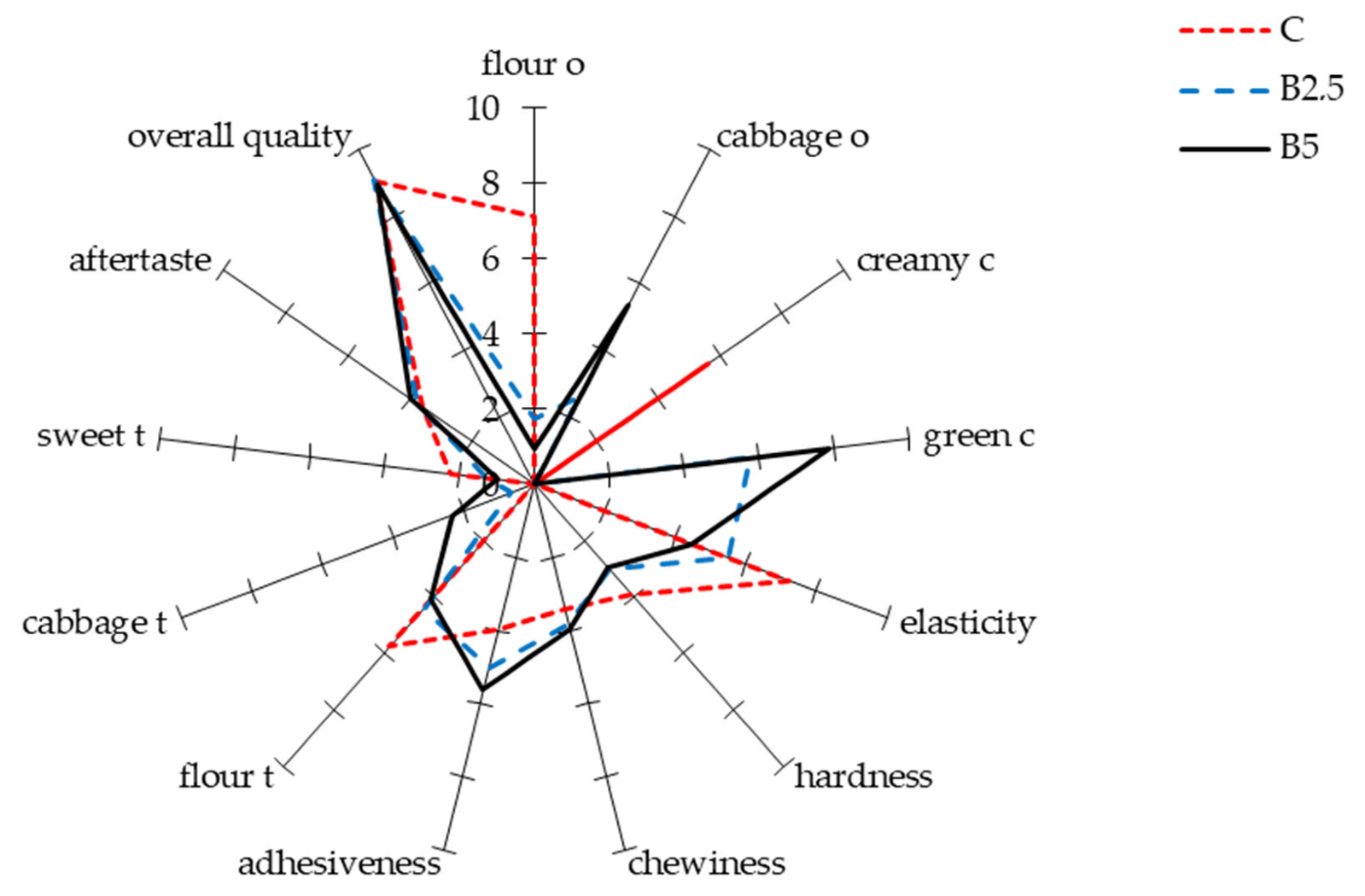

2.5. Sensory Analysis

2.6. Volatile Organic Compounds

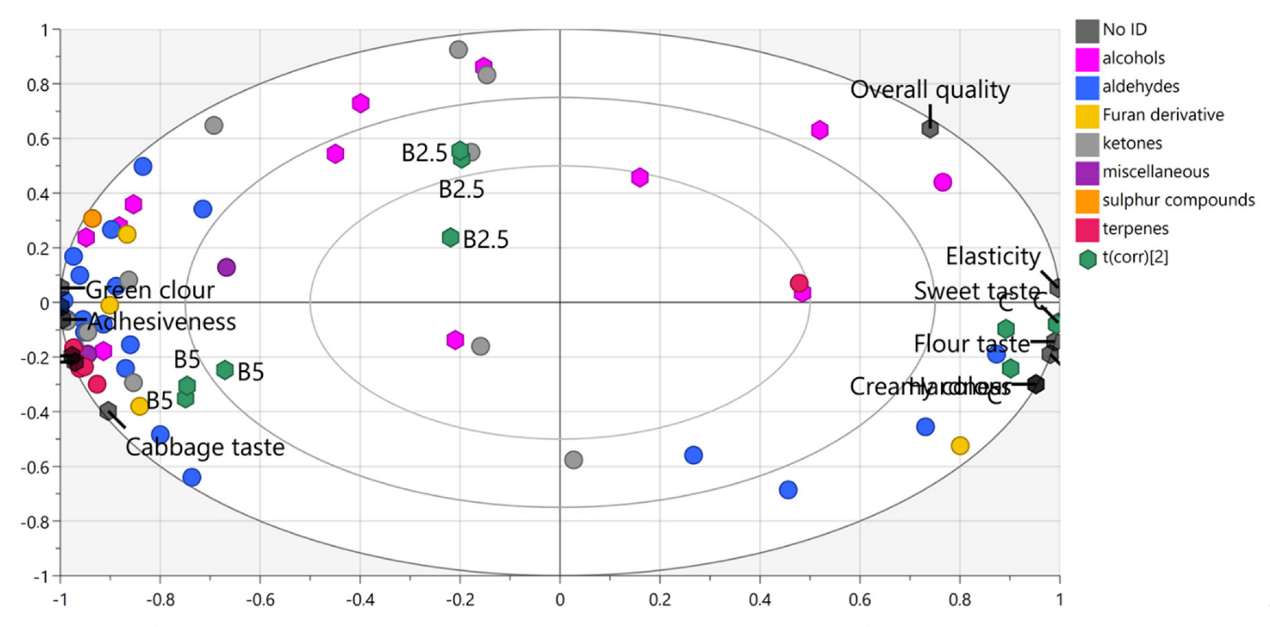

2.7. Association between Sensory Analysis and Volatile Organic Compounds

3. Materials and Methods

3.1. Broccoli Leaf Powder

3.2. Pasta Preparation

3.3. Cooking Properties

3.3.1. Optimal Cooking Time

3.3.2. Cooking Loss

3.3.3. Water Absorption

3.3.4. Swelling Index

3.4. Textural Properties

3.5. Colour Analysis

3.6. Proximate Composition

3.7. Sensory Analysis

3.8. Volatile Organic Compounds Analysis

3.9. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Oliviero, T.; Fogliano, V. Food Design Strategies to Increase Vegetable Intake: The Case of Vegetable Enriched Pasta. Trends Food Sci. Technol. 2016, 51, 58–64. [Google Scholar] [CrossRef]

- Folkvord, F.; Naderer, B.; Coates, A.; Boyland, E. Promoting Fruit and Vegetable Consumption for Childhood Obesity Prevention. Nutrients 2021, 14, 157. [Google Scholar] [CrossRef] [PubMed]

- Silva, E.; Gerritsen, L.; Dekker, M.; van der Linden, E.; Scholten, E. High Amounts of Broccoli in Pasta-like Products: Nutritional Evaluation and Sensory Acceptability. Food Funct. 2013, 4, 1700–1708. [Google Scholar] [CrossRef]

- Petitot, M.; Boyer, L.; Minier, C.; Micard, V. Fortification of Pasta with Split Pea and Faba Bean Flours: Pasta Processing and Quality Evaluation. Food Res. Int. 2010, 43, 634–641. [Google Scholar] [CrossRef]

- Bustos, M.C.; Perez, G.T.; Leon, A.E. Structure and Quality of Pasta Enriched with Functional Ingredients. RSC Adv. 2015, 5, 30780–30792. [Google Scholar] [CrossRef]

- Nilusha, R.A.T.; Jayasinghe, J.M.J.K.; Perera, O.D.A.N.; Perera, P.I.P. Development of Pasta Products with Nonconventional Ingredients and Their Effect on Selected Quality Characteristics: A Brief Overview. Int. J. Food Sci. 2019, 2019, 6750726. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bruno, J.A.; Konas, D.W.; Matthews, E.L.; Feldman, C.H.; Pinsley, K.M.; Kerrihard, A.L. Sprouted and Non-Sprouted Chickpea Flours: Effects on Sensory Traits in Pasta and Antioxidant Capacity. Pol. J. Food Nutr. Sci. 2019, 69, 203–209. [Google Scholar] [CrossRef]

- Padalino, L.; Mastromatteo, M.; Lecce, L.; Cozzolino, F.; del Nobile, M.A. Manufacture and Characterization of Gluten-Free Spaghetti Enriched with Vegetable Flour. J. Cereal Sci. 2013, 57, 333–342. [Google Scholar] [CrossRef] [Green Version]

- Lorusso, A.; Verni, M.; Montemurro, M.; Coda, R.; Gobbetti, M.; Rizzello, C.G. Use of Fermented Quinoa Flour for Pasta Making and Evaluation of the Technological and Nutritional Features. LWT 2017, 78, 215–221. [Google Scholar] [CrossRef] [Green Version]

- Desai, A.S.; Brennan, M.A.; Brennan, C.S. Effect of Fortification with Fish (Pseudophycis bachus) Powder on Nutritional Quality of Durum Wheat Pasta. Foods 2018, 7, 62. [Google Scholar] [CrossRef] [Green Version]

- Michalak-Majewska, M.; Teterycz, D.; Muszyński, S.; Radzki, W.; Sykut-Domańska, E. Influence of Onion Skin Powder on Nutritional and Quality Attributes of Wheat Pasta. PLoS ONE 2020, 15, e0227942. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gómez, M.; Martinez, M.M. Fruit and Vegetable By-Products as Novel Ingredients to Improve the Nutritional Quality of Baked Goods. Crit. Rev. Food Sci. Nutr. 2018, 58, 2119–2135. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Perles, R.; Martínez-Ballesta, M.C.; Carvajal, M.; García-Viguera, C.; Moreno, D.A. Broccoli-Derived by-Products—A Promising Source of Bioactive Ingredients. J. Food Sci. 2010, 75, C383–C392. [Google Scholar] [CrossRef] [PubMed]

- Reguengo, L.M.; Salgaço, M.K.; Sivieri, K.; Maróstica Júnior, M.R. Agro-Industrial by-Products: Valuable Sources of Bioactive Compounds. Food Res. Int. 2022, 152, 110871. [Google Scholar] [CrossRef]

- Orak, H.H.; Bahrisefit, I.S.; Sabudak, T. Antioxidant Activity of Extracts of Soursop (Annona muricata L.) Leaves, Fruit Pulps, Peels, and Seeds. Pol. J. Food Nutr. Sci. 2019, 69, 359–366. [Google Scholar] [CrossRef]

- Savić, A.; Alimpić Aradski, A.; Živković, J.; Šavikin, K.; Jarić, S.; Marin, P.D.; Duletić-Laušević, S. Phenolic Composition, and Antioxidant and Antineurodegenerative Potential of Methanolic Extracts of Fruit Peel and Flesh of Pear Varieties from Serbia. Pol. J. Food Nutr. Sci. 2021, 71, 225–236. [Google Scholar] [CrossRef]

- Guglielmetti, A.; Fernandez-Gomez, B.; Zeppa, G.; del Castillo, M.D. Nutritional Quality, Potential Health Promoting Properties and Sensory Perception of an Improved Gluten-Free Bread Formulation Containing Inulin, Rice Protein and Bioactive Compounds Extracted from Coffee Byproducts. Pol. J. Food Nutr. Sci. 2019, 69, 157–166. [Google Scholar] [CrossRef]

- Karwacka, M.; Gumkowska, M.; Rybak, K.; Ciurzyńska, A.; Janowicz, M. Impact of Sodium Alginate and Dried Apple Pomace Powder as a Carrier Agent on the Properties of Freeze-Dried Vegetable Snacks. Pol. J. Food Nutr. Sci. 2021, 71, 451–461. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, L.; Ser, S.L.; Cumming, J.R.; Ku, K.-M. Comparative Phytonutrient Analysis of Broccoli By-Products: The Potentials for Broccoli By-Product Utilization. Molecules 2018, 23, 900. [Google Scholar] [CrossRef] [Green Version]

- Drabińska, N.; Ciska, E.; Szmatowicz, B.; Krupa-Kozak, U. Broccoli By-Products Improve the Nutraceutical Potential of Gluten-Free Mini Sponge Cakes. Food Chem. 2018, 267, 170–177. [Google Scholar] [CrossRef]

- Drabińska, N. The Evaluation of Amino Acid Profiles in Gluten-Free Mini Sponge Cakes Fortified with Broccoli By-Product. Separations 2022, 9, 81. [Google Scholar] [CrossRef]

- Li, H.; Xia, Y.; Liu, H.-Y.; Guo, H.; He, X.-Q.; Liu, Y.; Wu, D.-T.; Mai, Y.-H.; Li, H.-B.; Zou, L.; et al. Nutritional Values, Beneficial Effects, and Food Applications of Broccoli (Brassica oleracea Var. Italica plenck). Trends Food Sci. Technol. 2022, 119, 288–308. [Google Scholar] [CrossRef]

- Berndtsson, E.; Andersson, R.; Johansson, E.; Olsson, M.E. Side Streams of Broccoli Leaves: A Climate Smart and Healthy Food Ingredient. Int. J. Environ. Res. Public Health 2020, 17, 2406. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lafarga, T.; Gallagher, E.; Bademunt, A.; Viñas, I.; Bobo, G.; Villaró, S.; Aguiló-Aguayo, I. Bioaccessibility, Physicochemical, Sensorial, and Nutritional Characteristics of Bread Containing Broccoli Co-Products. J. Food Processing Preserv. 2019, 43, e13861. [Google Scholar] [CrossRef]

- Krupa-Kozak, U.; Drabińska, N.; Bączek, N.; Šimková, K.; Starowicz, M.; Jeliński, T. Application of Broccoli Leaf Powder in Gluten-Free Bread: An Innovative Approach to Improve Its Bioactive Potential and Technological Quality. Foods 2021, 10, 819. [Google Scholar] [CrossRef] [PubMed]

- Dominguez-Perles, R.; Moreno, D.A.; Carvajal, M.; Garcia-Viguera, C. Composition and Antioxidant Capacity of a Novel Beverage Produced with Green Tea and Minimally-Processed Byproducts of Broccoli. Innov. Food Sci. Emerg. Technol. 2011, 12, 361–368. [Google Scholar] [CrossRef]

- Campas-Baypoli, O.N.; Snchez-Machado, D.I.; Bueno-Solano, C.; Núñez-Gastélum, J.A.; Reyes-Moreno, C.; López-Cervantes, J. Biochemical Composition and Physicochemical Properties of Broccoli Flours. Int. J. Food Sci. Nutr. 2009, 60, 163–173. [Google Scholar] [CrossRef]

- Ajila, C.M.; Aalami, M.; Leelavathi, K.; Rao, U.J.S.P. Mango Peel Powder: A Potential Source of Antioxidant and Dietary Fiber in Macaroni Preparations. Innov. Food Sci. Emerg. Technol. 2010, 11, 219–224. [Google Scholar] [CrossRef]

- Brennan, C.S.; Kuri, V.; Tudorica, C.M. Inulin-Enriched Pasta: Effects on Textural Properties and Starch Degradation. Food Chem. 2004, 86, 189–193. [Google Scholar] [CrossRef]

- Stable Micro Systems Cutting and Shearing Testing|Texture Analyser. Available online: https://www.stablemicrosystems.com/cutting-and-shearing-testing.html (accessed on 11 January 2022).

- Gull, A.; Prasad, K.; Kumar, P. Effect of Millet Flours and Carrot Pomace on Cooking Qualities, Color and Texture of Developed Pasta. LWT—Food Sci. Technol. 2015, 63, 470–474. [Google Scholar] [CrossRef]

- Ranawana, V.; Campbell, F.; Bestwick, C.; Nicol, P.; Milne, L.; Duthie, G.; Raikos, V. Breads Fortified with Freeze-Dried Vegetables: Quality and Nutritional Attributes. Part II: Breads Not Containing Oil as an Ingredient. Foods 2016, 5, 62. [Google Scholar] [CrossRef] [PubMed]

- Özyurt, G.; Uslu, L.; Yuvka, I.; Gökdoğan, S.; Atci, G.; Ak, B.; Işik, O. Evaluation of the Cooking Quality Characteristics of Pasta Enriched with Spirulina Platensis. J. Food Qual. 2015, 38, 268–272. [Google Scholar] [CrossRef]

- Cappa, C.; Alamprese, C. Brewer’s Spent Grain Valorization in Fiber-Enriched Fresh Egg Pasta Production: Modelling and Optimization Study. LWT—Food Sci. Technol. 2017, 82, 464–470. [Google Scholar] [CrossRef]

- Beleggia, R.; Platani, C.; Spano, G.; Monteleone, M.; Cattivelli, L. Metabolic Profiling and Analysis of Volatile Composition of Durum Wheat Semolina and Pasta. J. Cereal Sci. 2009, 49, 301–309. [Google Scholar] [CrossRef]

- de Flaviis, R.; Sacchetti, G.; Mastrocola, D. Wheat Classification According to Its Origin by an Implemented Volatile Organic Compounds Analysis. Food Chem. 2021, 341, 128217. [Google Scholar] [CrossRef]

- Kreissl, J.; Mall, V.; Steinhaus, P.; Steinhaus, M. Leibniz-LSB@TUM Odorant Database, Version 1.0. Available online: https://www.leibniz-lsb.de/en/databases/leibniz-lsbtum-odorant-database (accessed on 1 January 2022).

- Wieczorek, M.N.; Jeleń, H.H. Volatile Compounds of Selected Raw and Cooked Brassica Vegetables. Molecules 2019, 24, 391. [Google Scholar] [CrossRef] [Green Version]

- Marcinkowska, M.; Frank, S.; Steinhaus, M.; Jeleń, H.H. Key Odorants of Raw and Cooked Green Kohlrabi (Brassica oleracea Var. Gongylodes L.). J. Agric. Food Chem. 2021, 69, 12270–12277. [Google Scholar] [CrossRef]

- Wieczorek, M.N.; Majcher, M.; Jeleń, H. Comparison of Three Extraction Techniques for the Determination of Volatile Flavor Components in Broccoli. Foods 2020, 9, 398. [Google Scholar] [CrossRef] [Green Version]

- Wieczorek, M.N.; Majcher, M.A.; Jeleń, H.H. Identification of Aroma Compounds in Raw and Cooked Broccoli. Flavour Fragr. J. 2021, 36, 576–583. [Google Scholar] [CrossRef]

- Van Gemert, L.J. Compilations of Odour Threshold Values in Air, Water and Other Media; Second Enlarged and Revised Edition; Oliemans, Punter & Partners BV: Utrecht, The Netherlands, 2011; ISBN 9789081089401. [Google Scholar]

- Giannetti, V.; Boccacci Mariani, M.; Mannino, P.; Testani, E. Furosine and Flavour Compounds in Durum Wheat Pasta Produced under Different Manufacturing Conditions: Multivariate Chemometric Characterization. LWT—Food Sci. Technol. 2014, 56, 15–20. [Google Scholar] [CrossRef]

- Wieczorek, M.N.; Zhou, W.; Pawliszyn, J. Sequential Thin Film-Solid Phase Microextraction as a New Strategy for Addressing Displacement and Saturation Effects in Food Analysis. Food Chem. 2022, 389, 133038. [Google Scholar] [CrossRef] [PubMed]

- Gaggiotti, S.; Shkembi, B.; Sacchetti, G.; Compagnone, D. Study on Volatile Markers of Pasta Quality Using GC-MS and a Peptide Based Gas Sensor Array. LWT 2019, 114, 108364. [Google Scholar] [CrossRef]

- AACC Approved Methods of Analysis, 11th ed.; American Association of Cereal Chemists: Northwood Circle, MN, USA, 2000.

- Association of Official Analytical Chemists. AOAC Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2005. [Google Scholar]

| C | B2.5 | B5 | |

|---|---|---|---|

| Semolina [g] | 400.0 | 400.0 | 400.0 |

| Water [g] | 140.0 | 140.0 | 140.0 |

| Olive oil [g] | 15.0 | 15.0 | 15.0 |

| Salt [g] | 2.0 | 2.0 | 2.0 |

| BLP [g] | 0.0 | 10.0 | 20.0 |

| BLP | C | B2.5 | B5 | |

|---|---|---|---|---|

| Moisture (%) | - | 61.04 ± 0.26 a* | 63.64 ± 0.01 b | 60.75 ± 0.15 a |

| Ash (%) | 10.94 ± 0.04 | 0.88 ± 0.01 a | 1.00 ± 0.03 b | 1.19 ± 0.01 c |

| Protein (%) | 25.66 ± 0.27 | 13.06 ± 0.21 a | 13.17 ± 0.21 a | 13.26 ± 0.07 a |

| Fat (%) | 3.94 ± 0.21 | 3.94 ± 0.15 a | 4.79 ± 0.04 c | 4.45 ± 0.10 b |

| Carbohydrate (%) | 59.46 ± 0.07 | 21.08 ± 0.5 a | 17.41 ± 0.18 b | 20.23 ± 0,16 a |

| L* | 46.18 ± 0.03 | 87.51 ± 0.01 a | 76.05 ± 0.03 b | 67.61 ± 0.02 c |

| A* | −9.33 ± 0.03 | −0.12 ± 0.01 a | −6.25 ± 0.02 b | −6.26 ± 0.02 b |

| B* | 27.39 ± 0.06 | 14.05 ± 0.02 a | 28.14 ± 0.03 b | 31.48 ± 0.02 c |

| WI | 38.89 ± 0.05 | 81.20 ± 0.02 a | 62.52 ± 0.03 b | 54.41 ± 0.02 c |

| BI | 66.67 ± 0.29 | 16.99 ± 0.02 a | 38.20 ± 0.07 b | 52.57 ± 0.06 c |

| OCT (min) | - | 3.56 ± 0.08 a | 3.03 ± 0.04 b | 3.44 ± 0.10 a |

| Cooking loss (%) | - | 5.96 ± 0.38 b | 7.47 ± 0.19 a | 5.95 ± 0.05 b |

| Water absorption (%) | - | 62.26 ± 1.36 a | 55.55 ± 5.65 a | 60.45 ± 3.88 a |

| Swelling index (%) | - | 0.82 ± 0.04 b | 1.08 ± 0.05 a | 1.07 ± 0.04 a |

| Firmness (kg) | - | 13.37 ± 0.17 a | 12.09 ± 0.10 b | 11.96 ± 0.24 b |

| TSF (kg s−1) | - | 87.30 ± 4.11 a | 76.09 ± 1.52 b | 73.90 ± 5.53 b |

| Volatile Compound | RIExp * | RILit ** | BLP | C | B2.5 | B5 | Odour Description *** |

|---|---|---|---|---|---|---|---|

| Aldehydes | |||||||

| Propanal | 817 | 801 | 4.85 ± 0.45 | ND **** | 5.17 ± 0.55 a***** | 5.89 ± 0.25 a | fresh, fruity, malty |

| Butanal | 891 | 883 | 2.01 ± 0.13 | ND | ND | 0.40 ± 0.04 | malty, sweaty |

| 2-Methylbutanal | 922 | 915 | 5.48 ± 0.42 | ND | 0.19 ± 0.02 b | 0.30 ± 0.03 a | malty |

| 3-Methylbutanal | 927 | 920 | 7.87 ± 0.49 | ND | 0.41 ± 0.05 a | 0.54 ± 0.09 a | malty |

| Pentanal | 987 | 983 | ND | 2.22 ± 0.19 b | 2.74 ± 0.15 a | 2.98 ± 0.08 a | green, fatty, mouldy |

| Hexanal | 1087 | 1093 | 50.83 ± 0.98 | 53.66 ± 4.91 a | 31.91 ± 1.53 b | 28.05 ± 1.98 b | green grass, fatty |

| (E)-2-Methyl-2-butenal | 1097 | 1098 | 12.81 ± 1.15 | ND | 0.53 ± 0.28 b | 2.14 ± 0.31 a | green, fruity, aromatic |

| (E)-2-Pentenal | 1139 | 1140 | 20.12 ± 0.2 | 0.13 ± 0.00 c | 1.49 ± 0.11 b | 2.24 ± 0.07 a | oily, fatty, fruity |

| Heptanal | 1189 | 1188 | ND | 5.29 ± 0.39 a | 3.97 ± 0.61 b | 4.78 ± 0.15 a, b | fatty, citrus-like |

| (E)-2-Hexenal | 1227 | 1220 | 30.85 ± 0.53 | 1.38 ± 0.11 c | 4.01 ± 0.22 b | 5.28 ± 0.21 a | green apple-like, bitter almond-like |

| (Z)-4-Heptenal | 1251 | 1235 | 13.92 ± 0.07 | ND | 0.87 ± 0.24 b | 1.45 ± 0.16 a | fish-like, train oil-like |

| Octanal | 1293 | 1291 | 3.38 ± 0.11 | 1.73 ± 0.29 b | 5.48 ± 0.62 a | 4.63 ± 0.40 a | citrus-like, green |

| Nonanal | 1398 | 1390 | 7.47 ± 0.13 | 2.39 ± 0.33 b | 4.01 ± 0.29 a | 4.88 ± 0.65 a | citrus-like, soapy |

| (E)-2-Octenal | 1440 | 1437 | 2.76 ± 0.1 | 3.01 ± 0.18 b | 6.59 ± 0.66 a | 6.52 ± 0.77 a | fatty, nutty |

| (E,E)-2,4-Heptadienal | 1477 | 1497 | 26.15 ± 0.47 | ND | 1.04 ± 0.11 b | 1.65 ± 0.18 a | green, fatty, flowery |

| Benzaldehyde | 1538 | 1530 | 37.59 ± 0.92 | 2.26 ± 0.94 a | 1.32 ± 0.10 a | 1.95 ± 0.34 a | bitter almond-like, marzipan-like |

| (E)-2-Nonenal | 1547 | 1543 | ND | 1.96 ± 0.15 c | 3.78 ± 0.45 b | 5.10 ± 0.48 a | fatty |

| (E,Z)-2,6-Nonadienal | 1598 | 1596 | 2.05 ± 0.71 | ND | 0.26 ± 0.04 b | 0.55 ± 0.06 a | green, cucumber-like |

| Safranal | 1661 | 1648 | 4.71 ± 0.78 | ND | 0.36 ± 0.06 b | 0.53 ± 0.04 a | herbal |

| (E,E)-2,4-Nonadienal | 1716 | 1691 | ND | 0.29 ± 0.03 a | 0.11 ± 0.04 b | 0.10 ± 0.04 b | fatty, green |

| (E,E)-2,4-Decadienal | 1779 | 1786 | ND | 0.64 ± 0.07 a | 0.88 ± 0.07 a | 0.84 ± 0.09 a | fatty, deep-fried |

| Ketones | |||||||

| Acetone | 838 | 813 | 8.08 ± 0.32 | ND | 0.30 ± 0.09 | ND | pungent, sweet |

| 2-Butanone | 909 | 905 | 1.31 ± 0.3 | ND | 0.49 ± 0.05 a | 0.26 ± 0.04 b | ethereal, fruity |

| 1-Penten-3-one | 1030 | 1024 | 2.23 ± 0.12 | ND | 0.17 ± 0.09 a | 0.25 ± 0.06 a | green, pungent, mustard |

| 3-Penten-2-one | 1136 | 1123 | 5.75 ± 0.08 | ND | ND | ND | fruity, pungent |

| 4-Methyl-2-hexanone | 1188 | NA | 3.41 ± 0.33 | 0.28 ± 0.06 b | 0.75 ± 0.15 a | 0.35 ± 0.06 b | ethereal, bitter almond-like |

| 6-Methyl-2-heptanone | 1246 | 1228 | 6.19 ± 0.23 | ND | 0.61 ± 0.11 b | 1.16 ± 0.06 a | fruity, sour |

| 2-Octanone | 1291 | 1287 | 0.87 ± 0.04 | ND | 0.33 ± 0.08 | ND | soapy, fruity |

| 6-Methyl-5-hepten-2-one | 1348 | 1341 | 88.61 ± 0.55 | 0.85 ± 0.11 c | 6.31 ± 0.83 b | 9.63 ± 0.46 a | citrus |

| 3,5,5-Trimethyl-2-cyclohexen-1-one | 1413 | 1544 | 10.77 ± 0.16 | ND | 1.39 ± 0.35 b | 1.96 ± 0.28 a | woody |

| 3-Octen-2-one | 1416 | 1408 | ND | 1.06 ± 0.12 a | 1.73 ± 0.05 a | 1.26 ± 0.26 a | flowery, spicy |

| (E,E)-3,5-octadien-2-one | 1531 | 1569 | 188.13 ± 4.64 | ND | 2.22 ± 0.3 b | 4.42 ± 0.32 a | fruity, musty, fatty |

| 4-Acetyl-1-methylcyclohexene | 1568 | 1570 | 3.26 ± 0.39 | ND | ND | ND | seasoning |

| (E)-6-Methyl-3,5-heptadien-2-one | 1606 | 1582 | 11.24 ± 0.86 | ND | 0.43 ± 0.07 a | 0.73 ± 0.17 a | spicy |

| Acetophenone | 1668 | 1660 | 2.76 ± 0.69 | 0.29 ± 0.05 a | 0.22 ± 0.01 a | 0.30 ± 0.09 a | fruity, foxy, bitter almond-like, rubber-like |

| 6,10-Dimethyl-5,9-undecadien-2-one | 1865 | 1867 | 10.57 ± 0.51 | ND | 0.67 ± 0.07 b | 1.23 ± 0.16 a | floral |

| Alcohols | |||||||

| Ethanol | 944 | 934 | 2.26 ± 0.12 | ND | ND | ND | alcoholic |

| 1-Butanol | 1152 | 1125 | 19.18 ± 0.38 | ND | 0.24 ± 0.12 b | 0.42 ± 0.04 a | malty |

| 1-Penten-3-ol | 1167 | 1175 | 105.58 ± 2.07 | ND | 3.00 ± 0.18 a | 0.77 ± 0.11 b | pungent, milk-like |

| 1-Pentanol | 1256 | 1252 | 10.77 ± 0.24 | 3.38 ± 0.46 a | 3.01 ± 0.3 a,b | 2.24 ± 0.21 b | fruity, ethereal |

| (E)-2-Penten-1-ol | 1317 | 1313 | 3.88 ± 0.25 | ND | ND | ND | green |

| (Z)-2-Penten-1-ol | 1326 | 1323 | 69.57 ± 0.76 | ND | 1.16 ± 0.17 | ND | musty, compost-like |

| 1-Hexanol | 1358 | 1360 | ND | 14.63 ± 2.09 a,b | 15.00 ± 1.47 a | 11.38 ± 0.05 b | herbal, grassy, marzipan-like |

| (Z)-3-Hexen-1-ol | 1369 | 1386 | ND | 0.38 ± 0.03 b | 0.96 ± 0.09 a | 1.01 ± 0.04 a | green |

| 1-Octen-3-ol | 1455 | 1446 | 15.77 ± 0.17 | 3.74 ± 0.48 b | 14.45 ± 2.81 a | 13.16 ± 1.52 a | earthy, mushroom-like |

| Heptanol | 1459 | 1456 | ND | 1.12 ± 0.09 a | 1.05 ± 0.11 a | 1.02 ± 0.02 a | fruity, soapy |

| 3-Octanol | 1472 | 1423 | ND | 0.17 ± 0.02 a | 0.18 ± 0.02 a | 0.16 ± 0.02 a | citrus-like, soapy |

| 2-Ethyl-1-Hexanol | 1492 | 1490 | 2.66 ± 0.06 | 1.57 ± 0.17 a | 1.58 ± 0.18 a | 1.67 ± 0.06 a | ethereal, fruity |

| (E)-2-Octen-1-ol | 1621 | 1618 | ND | 0.41 ± 0.08 b | 4.30 ± 1.01 a | 4.17 ± 0.74 b | soapy |

| 1-Nonanol | 1664 | 1665 | ND | 0.48 ± 0.03 a | 0.66 ± 0.13 a | 0.57 ± 0.02 a | soapy, fruity |

| Sulphur compounds | |||||||

| Dimethyl sulphide | 715 | 720 | 4.62 ± 0.36 | ND | 0.42 ± 0.03 a | 0.41 ± 0.03 a | cabbage-like, sulphur |

| Dimethyl sulphoxide | 1587 | 1584 | 5.2 ± 1.03 | ND | ND | ND | alliaceous |

| Terpenes | |||||||

| Limonene | 1198 | 1190 | 24.94 ± 1.12 | 13.04 ± 0.72 a | 10.35 ± 1.24 b | 12.69 ± 0.42 a,b | citrus-like |

| Linalool | 1553 | 1545 | ND | 0.28 ± 0.05 c | 1.26 ± 0.13 b | 2.17 ± 0.06 a | citrus-like, flowery |

| Beta-cyclocitral | 1637 | 1617 | 51.08 ± 2.21 | ND | 1.63 ± 0.22 b | 3.45 ± 0.14 a | tropical, fruity |

| β-ionone | 1955 | 1898 | 34.98 ± 0.64 | ND | 0.99 ± 0.08 b | 2.16 ± 0.17 a | floral |

| β-ionone-5,6-epoxide | 2011 | 2008 | 27.37 ± 0.33 | ND | 0.74 ± 0.10 b | 1.61 ± 0.21 a | fruity |

| Dihydroactinidiolide | 2385 | 2332 | 35.45 ± 1.65 | ND | 0.55 ± 0.06 b | 1.35 ± 0.23 a | fruity |

| Alkanes | |||||||

| Dodecane | 1194 | 1227 | 6.51 ± 0.13 | ND | ND | ND | alkane |

| Tetradecane | 1396 | 1400 | 11.93 ± 1.25 | ND | ND | ND | waxy |

| Furan derivatives | |||||||

| 2-ethylfuran | 962 | 955 | 2.41 ± 0.37 | ND | 0.43 ± 0.06 b | 0.69 ± 0.21 a | sweet, burnt, earthy, malty |

| 2-pentylfuran | 1234 | 1249 | 1.96 ± 0.33 | 5.52 ± 0.84 a | 1.02 ± 0.31 b | 2.23 ± 0.32 b | fruity |

| cis-Linalool oxide | 1451 | 1513 | 7.48 ± 0.25 | ND | 0.08 ± 0.04 b | 0.20 ± 0.02 a | earthy |

| 5-Ethyl-2(5H)-furanone | 1781 | 1757 | 4.04 ± 0.38 | ND | 0.16 ± 0.04 a | 0.15 ± 0.03 a | sweet, spicy |

| Miscellaneous | |||||||

| Styrene | 1264 | 1273 | ND | 0.38 ± 0.03 a | 0.63 ± 0.16 a | 0.62 ± 0.12 a | balsamic |

| 4-(2-Propenyl)-phenol | 1748 | 2342 | 3.47 ± 0.3 | ND | 0.19 ± 0.05 a | 0.34 ± 0.06 a | sweet, burned |

| Total peak area | 1038.02 ± 6.67 | 122.51 ± 9.33 c | 140.97 ± 9.85 b | 162.4.16 ± 4.16 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drabińska, N.; Nogueira, M.; Szmatowicz, B. Valorisation of Broccoli By-Products: Technological, Sensory and Flavour Properties of Durum Pasta Fortified with Broccoli Leaf Powder. Molecules 2022, 27, 4672. https://doi.org/10.3390/molecules27154672

Drabińska N, Nogueira M, Szmatowicz B. Valorisation of Broccoli By-Products: Technological, Sensory and Flavour Properties of Durum Pasta Fortified with Broccoli Leaf Powder. Molecules. 2022; 27(15):4672. https://doi.org/10.3390/molecules27154672

Chicago/Turabian StyleDrabińska, Natalia, Mariana Nogueira, and Beata Szmatowicz. 2022. "Valorisation of Broccoli By-Products: Technological, Sensory and Flavour Properties of Durum Pasta Fortified with Broccoli Leaf Powder" Molecules 27, no. 15: 4672. https://doi.org/10.3390/molecules27154672

APA StyleDrabińska, N., Nogueira, M., & Szmatowicz, B. (2022). Valorisation of Broccoli By-Products: Technological, Sensory and Flavour Properties of Durum Pasta Fortified with Broccoli Leaf Powder. Molecules, 27(15), 4672. https://doi.org/10.3390/molecules27154672