Simultaneous Determination of 21 Sulfonamides in Poultry Eggs Using Ionic Liquid-Modified Molecularly Imprinted Polymer SPE and UPLC–MS/MS

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Method

2.2.1. Preparation of IL-MIP

2.2.2. Sample Preparation

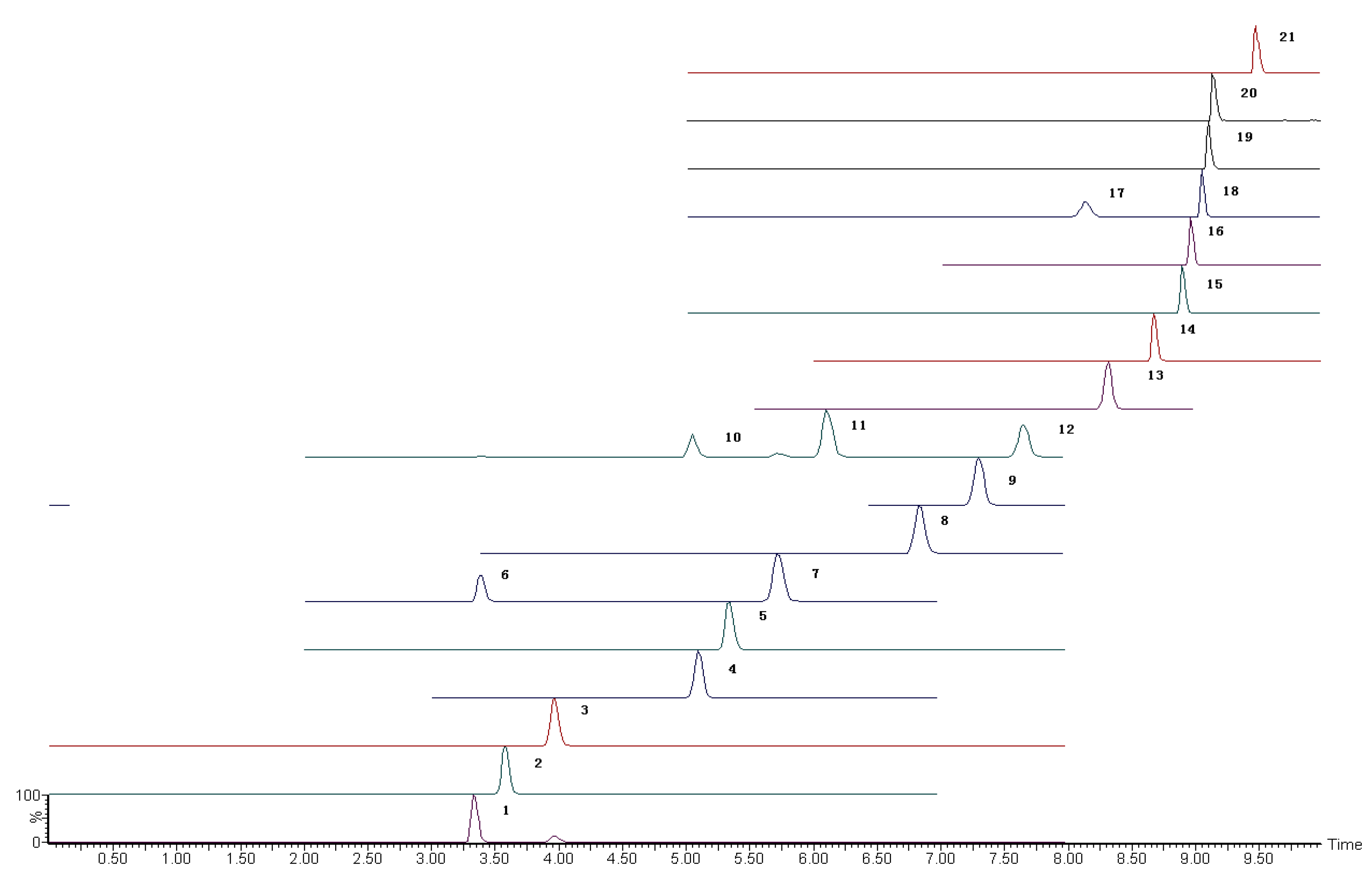

2.2.3. Instrumentation

3. Results and Discussion

3.1. Selection of IL

3.2. Evaluation of IL-MIPs

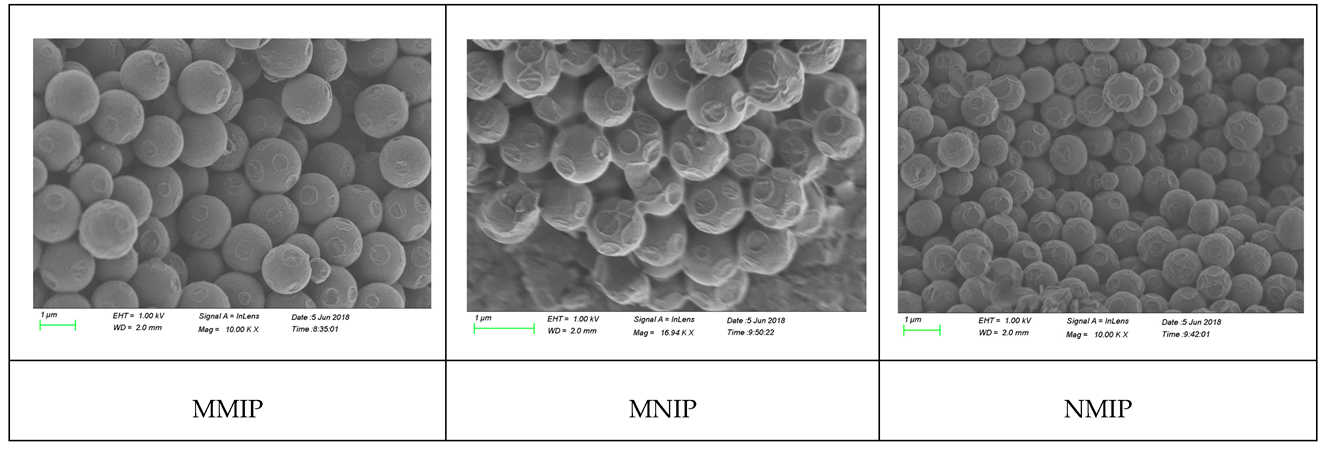

3.2.1. Characteristics of MIPs

3.2.2. Selectivity and Specificity of MMIP and Other MIPs

3.3. Optimization of SPE Purification Procedures

3.4. Validation of the Proposed Method

3.5. Evaluation of the SPE Reusability

3.6. Comparison with a Reported Method

3.7. Application and Confirmation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Henry, R.J. The Mode of Action of Sulfonamides. Acteriol. Rev. 1943, 7, 175–262. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.F.; Xie, S.G. Overview of sulfonamide biodegradation and the relevant pathways and microorganisms. Sci. Total Environ. 2018, 640–641, 1465–1477. [Google Scholar] [CrossRef] [PubMed]

- Hoa, P.T.P.L.; Nonaka, V.P.H.; Suzuki, S. Detection of the sul1, sul2, and sul3 genes in sulfonamide-resistant bacteria from wastewater and shrimp ponds of north Vietnam. Sci. Total Environ. 2008, 405, 377–384. [Google Scholar]

- AnnaBiałk, B.M.; Aleksandra, C.; Piotr, P.S.; Stefan, S. Mixture toxicity of six sulfonamides and their two transformation products to green algae Scenedesmus vacuolatus and duckweed Lemna minor. Chemosphere 2017, 173, 542–550. [Google Scholar]

- Abdallah, H.; Arnaudguilhem, C.; Abdul, R.H.; Lobinski, R.; Jaber, F. Monitoring of twenty-two sulfonamides in edible tissues: Investigation of new metabolites and their potential toxicity. Food Chem. 2016, 192, 212–227. [Google Scholar]

- Hamscher, G.; Bachour, G. Veterinary Drugs in the Environment: Current Knowledge and Challenges for the Future. J. Agric. Food Chem. 2018, 66, 751–752. [Google Scholar] [CrossRef]

- Ying, C.W.; Chang, M.J.; Hu, C.H.; Chang, Y.T.; Chao, W.L.; Yeh, S.L.; Chang, S.J.; Hsu, J.T. The effects of marine farm-scale sequentially integrated multi-trophic aquaculture systems on microbial community composition, prevalence of sulfonamide-resistant bacteria and sulfonamide resistance gene sul1. Sci. Total Environ. 2018, 643, 681–691. [Google Scholar] [CrossRef]

- Gao, P.; Mao, D.; Luo, Y.; Wang, L.; Xu, B.; Xu, L. Occurrence of sulfonamide and tetracycline-resistant bacteria and resistance genes in aquaculture environment. Water Res. 2012, 46, 2355–2364. [Google Scholar] [CrossRef]

- Zhou, Y.; Niu, L.; Zhu, S.; Lu, H.; Liu, L.W. Occurrence, abundance, and distribution of sulfonamide and tetracycline resistance genes in agricultural soils across china. Sci. Total Environ. 2017, 599–600, 1977–1983. [Google Scholar] [CrossRef] [PubMed]

- GB 31650-2019. National Food Safety Standard-Maximum Residue Limits for Veterinary Drugs in Foods. Available online: http://mall.foodmate.net/goods-93297.html (accessed on 1 April 2020).

- Announcement No.No.168 of the Ministry of Agriculture China, Specification for the Use of Feed Drug Additives. Available online: http://law.foodmate.net/show-207625.html (accessed on 3 July 2012).

- David, N.H.; Maureen, A.N.; Dan, D.H.; Lynda, P.; Herbert, R.; Michael, H.T. Identification of incurred sulfonamide residues in eggs: Methods for confirmation by liquid chromatography–tandem mass spectrometry and quantitation by liquid chromatography with ultraviolet detection. J. Chromatogr. B 2002, 774, 39–52. [Google Scholar]

- Xu, Y.; Ding, J.; Chen, H.Y.; Zhao, Q.; Hou, J.; Yan, J.; Wang, H.; Ding, L.; Ren, N.Q. Fast determination of sulfonamides from egg samples using magnetic multiwalled carbon nanotubes as adsorbents followed by liquid chromatography–tandem mass spectrometry. Food Chem. 2013, 140, 83–90. [Google Scholar] [CrossRef] [PubMed]

- David, N.H.; Nochetto, C.B.; Rummel, N.G.; Thomas, M.H. Development of multiclass methods for drug residues in eggs: Hydrophilic solid-phase extraction cleanup and liquid chromatography/tandem mass spectrometry analysis of tetracycline, fluoroquinolone, sulfonamide, and beta-lactam residues. J. Agric. Food Chem. 2006, 54, 5267–5278. [Google Scholar]

- SN/T 4057-2014. Determination of Sulfanilamide Residues in Food of Animal Origin for Export LC-MS/MS Method with Immunoaffinity Column Purification. Available online: http://down.foodmate.net/standard/sort/4/42519.html (accessed on 1 May 2015).

- Liu, H.B.; Yao, X.M.; Cai, Y.H.; Jiang, Y.B.; Yu, L. Simultaneous determination of sixteen sulfonamides residues in eggs using liquid chromatography coupled with electrospray ionization tandem mass spectrometry. Chin. J. Anal. Lab. 2015, 34, 1141–1144. [Google Scholar]

- Galarini, R.; Diana, F.; Moretti, S.; Puppini, B.; Saluti, G.; Persic, L. Development and validation of a new qualitative ELISA screening for multiresidue detection of sulfonamides in food and feed. Food Control 2014, 35, 300–310. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, S.; Yu, F.; Yan, N.; Qu, L.; Zhang, H. Hemiluminescence enzyme immunoassay for the determination of sulfamethoxydiazine. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2011, 81, 544–547. [Google Scholar] [CrossRef]

- Wang, X.L.; Li, K.; Shi, D.; Xiong, N.; Jin, X.; Yi, J.D.; Bi, D.R. Development of an immune chromatographic lateral-flow test strip for rapid detection of sulfonamides in eggs and chicken muscles. J. Agric. Food Chem. 2007, 55, 2072–2078. [Google Scholar] [CrossRef]

- Spinks, C.A.; Schut, C.G.; Wyatt, G.M.; Morgan, M.R.A. Development of an ELISA for sulfachlorpyridazine and investigation of matrixeffects from different sample extraction procedures. Food Addit. Contan. 2001, 18, 11–18. [Google Scholar] [CrossRef]

- Huertas-Pérez, J.F.; Arroyo-Manzanares, N.; Havlíková, L.; Gámiz-Gracia, L.; Solich, P.; García-Campa, A.M. Method optimization and validation for the determination of eight sulfonamides in chicken muscle and eggs by modified quechers and liquid chromatography with fluorescence detection. J. Pharm. Biomed. Anal. 2016, 124, 261–266. [Google Scholar] [CrossRef]

- Fang, G.Z.; He, J.X.; Wang, S. Multiwalled carbon nanotubes as sorbent for on-line coupling of solid-phase extraction to high-performance liquid chromatography for simultaneous determination of 10 sulfonamides in eggs and pork. J. Chromatogr. A 2006, 1127, 12–17. [Google Scholar] [CrossRef]

- Furusawa, N. Determination of Sulfonamide Residues in Eggs by Liquid Chromatography. J. AOAC Int. 2002, 85, 848–852. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deng, K.J.; Lan, X.H.; Sun, G. Determination of Sulfonamide Residues in Chicken Liver Using High-Performance Liquid Chromatography. Food Anal. Methods 2016, 9, 3337–3344. [Google Scholar] [CrossRef]

- Cheong, W.J.; Yang, S.H.; Ali, F. Molecular imprinted polymers for separation science: A review of reviews. J. Sep. Sci. 2013, 36, 609–628. [Google Scholar] [CrossRef]

- Zhao, X.L.; Wang, J.Y.; Wang, J.P.; Wang, S. Development of water-compatible molecularly imprinted solid-phaseextraction coupled with high performance liquidchromatography–tandem mass spectrometry for the detection of six sulfonamides in animal-derived foods. J. Chromatogr. A 2018, 1574, 9–17. [Google Scholar] [CrossRef] [PubMed]

- He, J.X.; Wang, S.; Fang, G.Z.; Zhu, H.P.; Zhang, Y. Molecularly Imprinted Polymer Online Solid-Phase Extraction Coupled with High-Performance Liquid Chromatography-UV for the Determination of Three Sulfonamides in Pork and Chicken. J. Agric. Food Chem. 2008, 56, 2919–2925. [Google Scholar] [CrossRef] [PubMed]

- Kliangsuwan, A.; Phonchai, A.; Bunkoed, O. A magnetic molecularly imprinted polymer hierarchical composite adsorbent embedded with a zinc oxide carbon foam anocomposite for the extraction of sulfonamides. Microchem. J. 2022, 179, 107443. [Google Scholar] [CrossRef]

- Fan, J.P.; Tian, Z.Y.; Tong, S.; Zhang, X.H.; Xie, Y.L.; Xu, R.; Qin, Y.; Li, L.; Zhu, J.H.; Ouyang, X.K. A novel molecularly imprinted polymer of the specific ionic liquid monomer for selective separation of synephrine from methanol-water media. Food Chem. 2013, 141, 3578–3585. [Google Scholar] [CrossRef]

- Zhu, X.D.; Zeng, Y.B.; Zhang, Z.L. A new composite of graphene and molecularly imprinted polymer based on ionic liquids as functional monomer and cross-linker for electrochemical sensing 6-benzylaminopurine. Biosens. Bioelectron. 2018, 108, 38–45. [Google Scholar] [CrossRef]

- Yan, H.Y.; Yang, C.; Sun, Y.Y.; Row, Y.H. Ionic liquid molecularly imprinted polymers for application in pipette-tip solid-phase extraction coupled with gas chromatography for rapid screening of dicofol in celery. J. Chromatogr. A 2014, 1361, 53–59. [Google Scholar] [CrossRef]

- Lu, X.; Yang, Y.; Zeng, Y.; Li, L.; Wu, X. Rapid and reliable determination of p-nitroaniline in wastewater by molecularly imprinted fluorescent polymeric ionic liquid microspheres. Biosens. Bioelectron. 2017, 99, 47–55. [Google Scholar] [CrossRef]

- Zhu, G.; Li, W.; Wang, L.; Wang, P.; Shi, D.; Wang, J.; Fan, J. sing ionic liquid monomer to improve the selective recognition performance of surface imprinted polymer for sulfamonomethoxine in strong polar medium. J. Chromatogr. A 2019, 1592, 38–46. [Google Scholar] [CrossRef]

- Suo, D.C.; Wang, P.C.; Xiao, Z.M.; Zhang, S.; Zhuang, H.T.; Li, Y.; Su, X.O. Multiresidue Determination of 27 Sulfonamides in Poultry Feathers and Its Application to a Sulfamethazine Pharmacokinetics Study on Laying Hen Feathers and Sulfonamide Residue Monitoring on Poultry Feathers. J. Agric. Food Chem. 2019, 67, 11236–11243. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.M.; Zhang, M.Y.; Peng, G.Y.; Feng, Y.Q. Monitoring of sulfonamide antibacterial residues in milk and egg by polymer monolith microextraction coupled to hydrophilic interaction chromatography/mass spectrometry. Anal. Chim. Acta 2008, 625, 160–172. [Google Scholar] [CrossRef]

- Commission of Chinese Veterinary Pharmacopoeia. Chinese Veterinary Pharmacopoeia; China Agriculture Press: Beijing, China, 2020. [Google Scholar]

- Baran, W.; Sochacka, J.; Wardas, W. Toxicity and biodegradability of sulfonamides and products of their photocatalytic degradation in aqueous solutions. Chemosphere 2006, 65, 1295–1299. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; He, X.; Lin, G.; Suo, H.; Zhao, C. On-line analysis of sulfonamides in pharmaceutical wastewater based on magnetic molecularly imprinted polymer extraction and near infrared spectroscopy. Anal. Methods 2012, 4, 1813–1816. [Google Scholar] [CrossRef]

- Chen, L.G.; Zhang, X.P.; Yang, L.S. Fast and Selective Extraction of Sulfonamides from Honey Based on Magnetic Molecularly Imprinted Polymer. J. Agric. Food Chem. 2009, 57, 10073–10080. [Google Scholar] [CrossRef]

- Xiang, H.Y.; Peng, M.J.; Li, H.; Peng, S.; Shi, S.Y. High-capacity hollow porous dummy molecular imprinted polymers using ionic liquid as functional monomer for selective recognition of salicylic acid. J. Pharm. Biomed. Anal. 2017, 133, 75–81. [Google Scholar] [CrossRef]

- Bogialli, S.; Curini, R.; Di Corcia, A. Rapid Confirmatory Assay for Determining 12 Sulfonamide Antimicrobials in Milk and Eggs by Matrix Solid-Phase Dispersion and Liquid Chromatography Mass Spectrometry. J. Agric. Food Chem. 2003, 51, 4225–4232. [Google Scholar] [CrossRef]

| Drug | Adsorption Rate (%) | |||||

|---|---|---|---|---|---|---|

| MMIP | MNIP | NMIP | VMIP | BMIP | EMIP | |

| Sulfadiazine | 80 ± 0.9 | 21 ± 71.5 | 74.4 ± 2.8 | 83.6 ± 2.3 | 72.5 ± 2.8 | 74.1 ± 16.2 |

| Sulfamethoxazole | 60.7 ± 10.5 | 41.2 ± 8.3 | 26.3 ± 11.1 | 58.4 ± 9.6 | 42.3 ± 8.7 | 63.5 ± 11.6 |

| Sulfathiazole | 78.6 ± 3 | 17.3 ± 7.3 | 41.6 ± 1.4 | 40.2 ± 2.5 | 46.4 ± 3.3 | 35.6 ± 5.5 |

| Sulfamerazine | 94.3 ± 5.6 | 89.2 ± 13.1 | 67.5 ± 10 | 82.3 ± 13.2 | 86.2 ± 25.1 | 57.4 ± 16 |

| Sulfafurazole | 75.4 ± 64 | 18.5 ± 30.9 | 39.8 ± 3.9 | 47.9 ± 0.9 | 37.9 ± 0.9 | 23.3 ± 3.6 |

| Sulfadimethoxine | 92.3 ± 10 | 84 ± 55.4 | 84.1 ± 10.4 | 91.2 ± 16.3 | 90.3 ± 12.1 | 87.6 ± 18.3 |

| Sulfadimoxine | 93.6 ± 2.9 | 81.3 ± 35.7 | 76.8 ± 4.8 | 72.4 ± 3.8 | 62.4 ± 4.1 | 43.1 ± 8.1 |

| Sulfamethizole | 62.7 ± 8.6 | 35 ± 22.9 | 36.2 ± 8.8 | 79.9 ± 8.2 | 46.2 ± 3.9 | 71.6 ± 14 |

| Sulfabenzamide | 88.1 ± 3.4 | 42.1 ± 6.2 | 22.6 ± 10.1 | 23.1 ± 0.1 | 78.1 ± 3.4 | 93.1 ± 4.5 |

| Sulfisomidine | 65.3 ± 4.2 | 65 ± 16.2 | 0.3 ± 0.3 | 72.1 ± 6.9 | 52.1 ± 6.9 | 75.2 ± 15.3 |

| Sulfamethazine | 98.1 ± 14.8 | 44.9 ± 16.4 | 78.1 ± 17.3 | 70.5 ± 1.6 | 86.2 ± 25.1 | 70.5 ± 9 |

| Sulfametoxydiazine | 67.2 ± 12.4 | 55.1 ± 29.7 | 5.1 ± 1.1 | 44.2 ± 6.9 | 66.7 ± 9.9 | 55.3 ± 3.8 |

| Sulfamethoxypyridazine | 92.1 ± 9.2 | 77.2 ± 18.5 | 32.6 ± 21 | 44.8 ± 13.2 | 82.1 ± 9 | 25.2 ± 14.9 |

| Sulfamonomethoxine | 87.2 ± 10.4 | 82.5 ± 21.2 | 57 ± 15.2 | 57.5 ± 36.3 | 88.3 ± 15.2 | 62.8 ± 8.8 |

| Sulfachloropyridazine | 78 ± 8.1 | 23.2 ± 21.4 | 65.1 ± 24.9 | 74 ± 27.5 | 55.1 ± 4.4 | 40.3 ± 20.3 |

| Sulfachloropyrazine | 75.5 ± 9.8 | 32.3 ± 23.2 | 56.9 ± 16.2 | 64.2 ± 1.7 | 67.3 ± 5.7 | 77.9 ± 35.7 |

| Sulfaquinoxaline | 85.6 ± 15.8 | 88.5 ± 25.3 | 29.4 ± 11.8 | 81.7 ± 24.2 | 90.7 ± 13.5 | 74.7 ± 21.3 |

| Sulfanitran | 95.2 ± 41 | 96.1 ± 1.9 | 93.7 ± 4.0 | 93.4 ± 21.6 | 93.4 ± 2.6 | 99.8 ± 3.2 |

| Sulfisoxazole | 75.1 ± 8.6 | 45.1 ± 27.6 | 32.2 ± 13.2 | 52.6 ± 8.5 | 36.6 ± 1.5 | 44.4 ± 13.6 |

| Sulfaphenazole | 68.3 ± 12.9 | 27.6 ± 39.8 | 18.4 ± 1.3 | 22.7 ± 0.5 | 25.4 ± 3.5 | 11.8 ± 8.7 |

| Sulfapyrazole | 67.5 ± 11.2 | 9.7 ± 2.4 | 31 ± 0.4 | 34.4 ± 11.3 | 19.7 ± 3.4 | 35.8 ± 4.8 |

| Drugs | Linear Equations | Concentration Range (ng/mL) | R | LOD (μg/g) | LOQ (μg/g) |

|---|---|---|---|---|---|

| Sulfadiazine | Y = 0.0066 + 8.086X | 1–100 | 0.9961 | 0.6 | 2 |

| Sulfamethoxazole | Y = −0.0077 + 6.813X | 1–100 | 0.9972 | 0.6 | 2 |

| Sulfathiazole | Y = 0.0068 + 6.82X | 1–100 | 0.9956 | 0.7 | 2 |

| Sulfamerazine | Y = −0.0001 + 12.39X | 0.5–200 | 0.9973 | 0.3 | 1 |

| Sulfafurazole | Y = −0.0023 + 13.38X | 1–100 | 0.9985 | 0.3 | 1 |

| Sulfadimethoxine | Y = 0.0083 + 1.883X | 1–100 | 0.9977 | 0.3 | 1 |

| Sulfadimoxine | Y = 0.0066 + 16.923X | 1–100 | 0.9981 | 0.3 | 1 |

| Sulfamethizole | Y = 0.0006 + 10.667X | 1–100 | 0.9964 | 0.2 | 0.6 |

| Sulfabenzamide | Y = −0.0096 + 1.762X | 1–100 | 0.9976 | 0.3 | 1 |

| Sulfisomidine | Y = −0.0027 + 6.626X | 0.5–50 | 0.9974 | 0.1 | 0.3 |

| Sulfamethazine | Y = 0.0082 + 7.666X | 0.5–50 | 0.9973 | 0.1 | 0.3 |

| Sulfametoxydiazine | Y = −0.0081 + 6.697X | 1–100 | 0.9967 | 0.3 | 1 |

| Sulfamethoxypyridazine | Y = −0.0019 + 9.768X | 0.5–50 | 0.9968 | 0.3 | 1 |

| Sulfamonomethoxine | Y = 0.0021 + 2.81X | 0.5–50 | 0.9991 | 0.2 | 0.6 |

| Sulfachloropyridazine | Y = −0.0006 + 3.976X | 1–100 | 0.9991 | 0.3 | 1 |

| Sulfachloropyrazine | Y = −0.0013 + 7.713X | 1–100 | 0.9979 | 0.3 | 1 |

| Sulfaquinoxaline | Y = −0.0063 + 6.301X | 1–100 | 0.9974 | 1.5 | 5 |

| Sulfanitran | Y = 0.0076 + 13.006X | 2–200 | 1.000 | 1.5 | 5 |

| Sulfisoxazole | Y = 0.0003 + 12.186X | 1–100 | 0.9986 | 0.7 | 2 |

| Sulfaphenazole | Y = −0.0068 + 11.336X | 1–100 | 0.9956 | 0.2 | 0.6 |

| Sulfapyrazole | Y = 0.0003 + 6.61X | 1–100 | 0.9992 | 0.2 | 0.6 |

| Drugs | Within-Day (Recovery ± RSD%) | Between-Day (Recovery ± RSD%) | ||||

|---|---|---|---|---|---|---|

| 5 (μg/kg) | 10 (μg/kg) | 100 (μg/kg) | 5 (μg/kg) | 10(μg/kg) | 100 (μg/kg) | |

| Sulfadiazine | 89 ± 11.7 | 91.5 ± 14.4 | 84.9 ± 17.9 | 86.3 ± 5.5 | 92.4 ± 7.4 | 91 ± 11.7 |

| Sulfamethoxazole | 89 ± 4.3 | 86 ± 5.1 | 86.6 ± 14.8 | 97.6 ± 7.2 | 91.5 ± 10.9 | 86.9 ± 8.1 |

| Sulfathiazole | 88.9 ± 12.5 | 94.5 ± 8.2 | 95.7 ± 13.6 | 90.3 ± 3.2 | 98.3 ± 9 | 103.4 ± 8.4 |

| Sulfamerazine | 93.6 ± 1.9 | 97.6 ± 1.7 | 93 ± 8.7 | 93.2 ± 7.6 | 103.6 ± 12.4 | 96.9 ± 2.0 |

| Sulfafurazole | 93.6 ± 9.7 | 92.6 ± 11.5 | 94.5 ± 11.6 | 92 ± 11.2 | 92.6 ± 12 | 99 ± 13.4 |

| Sulfadimethoxine | 86.9 ± 7.2 | 89.6 ± 7.5 | 86.2 ± 9.3 | 99.5 ± 12.1 | 89 ± 0.6 | 92.8 ± 4.7 |

| Sulfadimoxine | 90.8 ± 13.5 | 102 ± 1.2 | 88.9 ± 13.6 | 86.2 ± 14.6 | 95.9 ± 0.4 | 85.9 ± 4.6 |

| Sulfamethizole | 100.1 ± 3.6 | 87.4 ± 4.8 | 93.7 ± 9.6 | 105.8 ± 4.8 | 90.3 ± 10.1 | 102.9 ± 9.5 |

| Sulfabenzamide | 102.3 ± 13.1 | 89.4 ± 12.6 | 99.3 ± 7 | 93.1 ± 6.2 | 95 ± 12.4 | 103.7 ± 10.1 |

| Sulfisomidine | 93.3 ± 6.9 | 104.5 ± 1.2 | 102.8 ± 10.1 | 101 ± 9.2 | 100.4 ± 3.1 | 94.1 ± 4.7 |

| Sulfamethazine | 97.2 ± 1.4 | 99.7 ± 2.7 | 103.7 ± 9.6 | 90 ± 4.6 | 104.9 ± 10.8 | 93.1 ± 10.5 |

| Sulfametoxydiazine | 84.3 ± 6.9 | 94.7 ± 8 | 93.6 ± 10.6 | 88 ± 11.8 | 85.9 ± 6.8 | 89.4 ± 12 |

| Sulfamethoxypyridazine | 87.5 ± 9.8 | 89.7 ± 12.5 | 90.9 ± 12.9 | 89.1 ± 4.2 | 89.3 ± 2.9 | 88.2 ± 8.8 |

| Sulfamonomethoxine | 86.1 ± 1.7 | 103.5 ± 9.9 | 95.9 ± 10.8 | 98.2 ± 0.2 | 100.1 ± 9.4 | 98.3 ± 10.6 |

| Sulfachloropyridazine | 94.8 ± 8.5 | 87.8 ± 7.7 | 96.9 ± 12.3 | 87.7 ± 10.2 | 87.5 ± 13.4 | 94.2 ± 7.9 |

| Sulfachloropyrazine | 103.2 ± 6.5 | 96.6 ± 11.8 | 93 ± 15.3 | 88 ± 11.6 | 93.5 ± 8.6 | 86.9 ± 13.4 |

| Sulfaquinoxaline | 101.1 ± 2.5 | 103.7 ± 8.7 | 90.4 ± 10.5 | 103.8 ± 8.5 | 100.2 ± 12.2 | 96.6 ± 14.9 |

| Sulfanitran | 101.4 ± 10.1 | 102.2 ± 12.8 | 96.9 ± 1.8 | 92.5 ± 7.6 | 102.7 ± 13.7 | 94.1 ± 11.7 |

| Sulfisoxazole | 99.5 ± 3.3 | 90.7 ± 14 | 103.5 ± 11.3 | 93.3 ± 7.9 | 85.6 ± 10.6 | 104 ± 1.6 |

| Sulfaphenazole | 104.2 ± 12.5 | 90.1 ± 9.3 | 87.7 ± 12.9 | 103.1 ± 6.6 | 89.7 ± 4.9 | 95.7 ± 14.7 |

| Sulfapyrazole | 103.1 ± 9 | 101.3 ± 2.8 | 88.7 ± 9.9 | 99.7 ± 7.8 | 96.5 ± 3.4 | 88.2 ± 13.6 |

| Kind of Drugs | Extraction Solvent | Purification | LOD (μg/kg) | Reference |

|---|---|---|---|---|

| 14 | 20 mM phosphate solution | Polymer monolith microextraction | 0.9–9.8 | [35] Zheng, 2008 |

| 9 | Sodium succinate buffer | SPE (HLB) | 10–50 | [14] |

| 12 | Hot water | Matrix solid-phase dispersion | 2–6 | [41] |

| 7 | ACN | Magnetic-multiwall carbon nanotubes as adsorbents | 1.4–2.8 | [13] |

| 16 | Ethanol | Immunoaffinity column | 3.0 | [15] |

| 16 | Phosphate solution | SPE (MCX) | 0.5~1 | [16] |

| 21 | Phosphate solution | SPE (MIP) | 0.1~1.5 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suo, D.; Zhang, S.; Song, Z.; Wang, S.; Li, Y.; Fan, X. Simultaneous Determination of 21 Sulfonamides in Poultry Eggs Using Ionic Liquid-Modified Molecularly Imprinted Polymer SPE and UPLC–MS/MS. Molecules 2022, 27, 4953. https://doi.org/10.3390/molecules27154953

Suo D, Zhang S, Song Z, Wang S, Li Y, Fan X. Simultaneous Determination of 21 Sulfonamides in Poultry Eggs Using Ionic Liquid-Modified Molecularly Imprinted Polymer SPE and UPLC–MS/MS. Molecules. 2022; 27(15):4953. https://doi.org/10.3390/molecules27154953

Chicago/Turabian StyleSuo, Decheng, Su Zhang, Zhanteng Song, Shi Wang, Yang Li, and Xia Fan. 2022. "Simultaneous Determination of 21 Sulfonamides in Poultry Eggs Using Ionic Liquid-Modified Molecularly Imprinted Polymer SPE and UPLC–MS/MS" Molecules 27, no. 15: 4953. https://doi.org/10.3390/molecules27154953