Compatibilization of Polylactide/Poly(ethylene 2,5-furanoate) (PLA/PEF) Blends for Sustainable and Bioderived Packaging

Abstract

:1. Introduction

2. Results and Discussion

2.1. Choice of the Compatibilizer

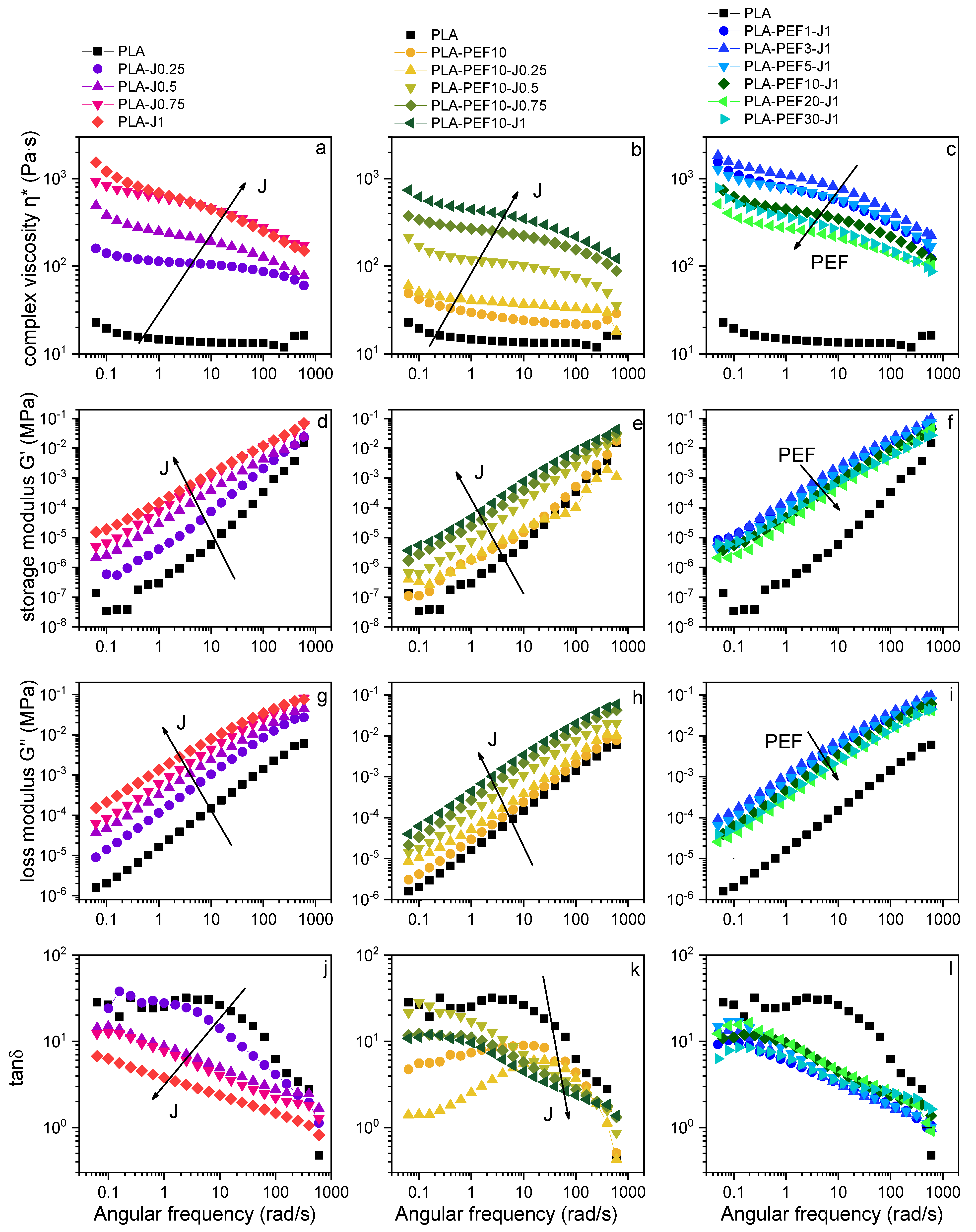

2.2. Dynamic Rheological Properties

2.3. Microstructural Properties

2.4. Thermal Properties

2.5. Mechanical Properties

2.6. Functional Properties

3. Materials and Methods

3.1. Materials

3.2. Sample Preparation

3.3. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Meraldo, A. 4—Introduction to Bio-Based Polymers. In Multilayer Flexible Packaging, 2nd ed.; Wagner, J.R., Ed.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 47–52. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, 1700782. [Google Scholar] [CrossRef]

- White, E.; Bassilakis, R.; Nogués, S. From the Plastics Present to a Sustainable Future: The Bioplastics Innovation Landscape, Players and Market Opportunities; Clarivate: London, UK, 2020. [Google Scholar]

- Konstantopoulou, M.; Terzopoulou, Z.; Nerantzaki, M.; Tsagkalias, J.; Achilias, D.S.; Bikiaris, D.N.; Exarhopoulos, S.; Papageorgiou, D.G.; Papageorgiou, G.Z. Poly(ethylene furanoate-co-ethylene terephthalate) biobased copolymers: Synthesis, thermal properties and cocrystallization behavior. Eur. Polym. J. 2017, 89, 349–366. [Google Scholar] [CrossRef]

- Niaounakis, M. Biopolymers Reuse, Recycling, and Disposal, 1st ed.; PDL Handbook series; William Andrew (Elsevier): Oxford, UK, 2013. [Google Scholar]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Pegoretti, A.; Fambri, L.; Migliaresi, C. In vitro degradation of poly(L-lactic acid) fibers produced by melt spinning. J. Appl. Polym. Sci. 1997, 64, 213–223. [Google Scholar] [CrossRef]

- Tait, M.; Pegoretti, A.; Dorigato, A.; Kaladzidou, K. The effect of filler type and content and the manufacturing process on the performance of multifunctional carbon/poly-lactide composites. Carbon 2011, 49, 4280–4290. [Google Scholar] [CrossRef]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(lactic Acid): A Versatile Biobased Polymer for the Future with Multifunctional Properties-From Monomer Synthesis, Polymerization Techniques and Molecular Weight Increase to PLA Applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Sun, J.; Shen, J.; Chen, S.; Cooper, M.; Fu, H.; Wu, D.; Yang, Z. Nanofiller Reinforced Biodegradable PLA/PHA Composites: Current Status and Future Trends. Polymers 2018, 10, 505. [Google Scholar] [CrossRef]

- Swaroop, C.; Shukla, M. Nano-magnesium oxide reinforced polylactic acid biofilms for food packaging applications. Int. J. Biol. Macromol. 2018, 113, 729–736. [Google Scholar] [CrossRef]

- Dickmann, M.; Tarter, S.; Egger, W.; Pegoretti, A.; Rigotti, D.; Brusa, R.S.; Checchetto, R. Interface nanocavities in poly (lactic acid) membranes with dispersed cellulose nanofibrils: Their role in the gas barrier performances. Polymer 2020, 202, 122729. [Google Scholar] [CrossRef]

- Rigotti, D.; Checchetto, R.; Tarter, S.; Caretti, D.; Rizzuto, M.; Fambri, L.; Pegoretti, A. Polylactic acid-lauryl functionalized nanocellulose nanocomposites: Microstructural, thermo-mechanical and gas transport properties. Express Polym. Lett. 2019, 13, 858–876. [Google Scholar] [CrossRef]

- Perego, G.; Cella, G.D.; Bastioli, C. Effect of molecular weight and crystallinity on poly(lactic acid) mechanical properties. J. Appl. Polym. Sci. 1996, 59, 37–43. [Google Scholar] [CrossRef]

- Labrecque, L.V.; Kumar, R.A.; Dave, V.; Gross, R.A.; McCarthy, S.P. Citrate esters as plasticizers for poly(lactic acid). J. Appl. Polym. Sci. 1997, 66, 1507–1513. [Google Scholar] [CrossRef]

- Jacobsen, S.; Fritz, H.G. Plasticizing polylactide-the effect of different plasticizers on the mechanical properties. Polym. Eng. Ans Sci. 2004, 39, 1303–1310. [Google Scholar] [CrossRef]

- Kulinski, Z.; Piorkowska, E.; Galeski, A.; Masirek, R. Plasticization of semicrystalline poly(l-lactide) with poly(propylene glycol). Polymer 2006, 47, 7178–7188. [Google Scholar] [CrossRef]

- Cabedo, L.; Feijoo, J.L.; Villanueva, M.P.; Lagaron, J.M.; Gimenez, E. Optimization of Biodegradable Nanocomposites Based on aPLA/PCL Blends for Food Packaging Applications. Macromol. Symp. 2006, 233, 191–197. [Google Scholar] [CrossRef]

- Wang, L.; Ma, W.; Gross, R.A.; McCarthy, S.P. Reactive compatibilization of biodegradable blends of poly(lactic acid) and poly(ε-caprolactone). Polym. Degrad. Stab. 1998, 59, 161–168. [Google Scholar] [CrossRef]

- Barrows, T.H. Degradable implant materials: A review of synthetic absorbable polymers and their applications. Clin. Mater. 1986, 1, 233–257. [Google Scholar] [CrossRef]

- Bastioli, C. Handbook of Biodegradable Polymers; RapraTechnology Limited: Shawbury, UK, 2005. [Google Scholar]

- Engelberg, I.; Kohn, J. Physico-mechanical properties of degradable polymers used in medical applications: A comparative study. Biomaterials 1991, 12, 292–304. [Google Scholar] [CrossRef]

- Ljungberg, N.; Wesselen, B. The effects of plasticizers on the dynamic mechanical and thermal properties of poly(lactic acid). J. Appl. Polym. Sci. 2002, 86, 1227. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Plasticizers; ChemTec Publishing: Toronto, ON, Canada, 2004. [Google Scholar]

- Xu, H.; Zhou, J.; Odelius, K.; Guo, Z.; Guan, X.; Hakkarainen, M. Nanostructured Phase Morphology of a Biobased Copolymer for Tough and UV-Resistant Polylactide. ACS Appl. Polym. Mater. 2021, 3, 1973–1982. [Google Scholar] [CrossRef]

- Bozell, J.J.; Petersen, G.R. Technology development for the production of biobased products from biorefinery carbohydrates—The US Department of Energy’s “Top 10” revisited. Green Chem. 2010, 12, 539. [Google Scholar] [CrossRef]

- Poulopoulou, N.; Smyrnioti, D.; Nikolaidis, G.N.; Tsitsimaka, I.; Christodoulou, E.; Bikiaris, D.N.; Charitopoulou, M.A.; Achilias, D.S.; Kapnisti, M.; Papageorgiou, G.Z. Sustainable Plastics from Biomass: Blends of Polyesters Based on 2,5-Furandicarboxylic Acid. Polymers 2020, 12, 225. [Google Scholar] [CrossRef]

- Sousa, A.F.; Patrício, R.; Terzopoulou, Z.; Bikiaris, D.N.; Stern, T.; Wenger, J.; Loos, K.; Lotti, N.; Siracusa, V.; Szymczyk, A.; et al. Recommendations for replacing PET on packaging, fiber, and film materials with biobased counterparts. Green Chem. 2021, 23, 8795–8820. [Google Scholar] [CrossRef]

- Sousa, A.F.; Silvestre, A.J.D. Plastics from renewable sources as green and sustainable alternatives. Curr. Opin. Green Sustain. Chem. 2022, 33, 100557. [Google Scholar] [CrossRef]

- Eerhart, A.J.J.E.; Faaij, A.P.C.; Patel, M.K. Replacing fossil based PET with biobased PEF; process analysis, energy and GHG balance. Energy Environ. Sci. 2012, 5, 6407. [Google Scholar] [CrossRef]

- Poulopoulou, N.; Pipertzis, A.; Kasmi, N.; Bikiaris, D.N.; Papageorgiou, D.G.; Floudas, G.; Papageorgiou, G.Z. Green polymeric materials: On the dynamic homogeneity and miscibility of furan-based polyester blends. Polymer 2019, 174, 187–199. [Google Scholar] [CrossRef]

- Poulopoulou, N.; Kasmi, N.; Bikiaris, D.N.; Papageorgiou, D.G.; Floudas, G.; Papageorgiou, G.Z. Sustainable Polymers from Renewable Resources: Polymer Blends of Furan-Based Polyesters. Macromol. Mater. Eng. 2018, 303, 1800153. [Google Scholar] [CrossRef]

- Poulopoulou, N.; Kasmi, N.; Siampani, M.; Terzopoulou, Z.N.; Bikiaris, D.N.; Achilias, D.S.; Papageorgiou, D.G.; Papageorgiou, G.Z. Exploring Next-Generation Engineering Bioplastics: Poly(alkylene furanoate)/Poly(alkylene terephthalate) (PAF/PAT) Blends. Polymers 2019, 11, 556. [Google Scholar] [CrossRef]

- Poulopoulou, N.; Kantoutsis, G.; Bikiaris, D.N.; Achilias, D.S.; Kapnisti, M.; Papageorgiou, G.Z. Biobased Engineering Thermoplastics: Poly(butylene 2,5-furandicarboxylate) Blends. Polymers 2019, 11, 937. [Google Scholar] [CrossRef] [Green Version]

- Long, Y.; Zhang, R.Y.; Huang, J.C.; Wang, J.G.; Jiang, Y.H.; Hu, G.H.; Yang, J.; Zhu, J. Tensile Property Balanced and Gas Barrier Improved Poly(lactic acid) by Blending with Biobased Poly(butylene 2,5-furan dicarboxylate). Acs Sustain. Chem. Eng. 2017, 5, 9244–9253. [Google Scholar] [CrossRef]

- Fredi, G.; Dorigato, A.; Bortolotti, M.; Pegoretti, A.; Bikiaris, D.N. Mechanical and Functional Properties of Novel Biobased Poly(decylene-2,5-furanoate)/Carbon Nanotubes Nanocomposite Films. Polymers 2020, 12, 2459. [Google Scholar] [CrossRef]

- Rigotti, D.; Soccio, M.; Dorigato, A.; Gazzano, M.; Siracusa, V.; Fredi, G.; Lotti, N. Novel biobased polylactic acid/poly(pentamethylene 2,5-furanoate) blends for sustainable food packaging. ACS Sustain. Chem. Eng. 2021, 9, 13742–13750. [Google Scholar] [CrossRef]

- Fredi, G.; Jafari, M.K.; Dorigato, A.; Bikiaris, D.N.; Pegoretti, A. Improving the Thermomechanical Properties of Poly(lactic acid) via Reduced Graphene Oxide and Bioderived Poly(decamethylene 2,5-furandicarboxylate). Materials 2022, 15, 1316. [Google Scholar] [CrossRef]

- Fredi, G.; Jafari, M.K.; Dorigato, A.; Bikiaris, D.N.; Checchetto, R.; Favaro, M.; Brusa, R.S.; Pegoretti, A. Multifunctionality of reduced graphene oxide in bioderived polylactide/poly(dodecylene furanoate) nanocomposite films. Molecules 2021, 26, 2398. [Google Scholar] [CrossRef]

- Fredi, G.; Rigotti, D.; Bikiaris, D.N.; Dorigato, A. Tuning thermo-mechanical properties of poly(lactic acid) films through blending with bioderived poly(alkylene furanoate)s with different alkyl chain length for sustainable packaging. Polymer 2021, 218, 123527. [Google Scholar] [CrossRef]

- Perin, D.; Rigotti, D.; Fredi, G.; Papageorgiou, G.Z.; Bikiaris, D.N.; Dorigato, A. Innovative bio-based poly(lactic acid)/poly(alkylene furanoate) fiber blends for sustainable textile applications. J. Polym. Environ. 2021, 29, 3948–3963. [Google Scholar] [CrossRef]

- Perin, D.; Fredi, G.; Rigotti, D.; Lotti, N.; Dorigato, A. Sustainable textile fibers made of bioderived polylactide/poly(pentamethylene 2,5-furanoate) blends. J. Appl. Polym. Sci. 2022, 139, 51740. [Google Scholar] [CrossRef]

- Rigotti, D.; Fredi, G.; Perin, D.; Bikiaris, D.N.; Pegoretti, A.; Dorigato, A. Statistical Modeling and Optimization of the Drawing Process of Bioderived Polylactide/Poly(Dodecylene Furanoate) Wet-Spun Fibers. Polymers 2022, 14, 396. [Google Scholar] [CrossRef]

- Grigora, M.E.; Terzopoulou, Z.; Tsongas, K.; Klonos, P.; Kalafatakis, N.; Bikiaris, D.N.; Kyritsis, A.; Tzetzis, D. Influence of Reactive Chain Extension on the Properties of 3D Printed Poly(Lactic Acid) Constructs. Polymers 2021, 13, 1381. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, H.; Wang, X.; Yu, X.; Zhou, W.; Peng, S. Super tough poly(lactic acid) blends: A comprehensive review. RSC Adv. 2020, 10, 13316–13368. [Google Scholar] [CrossRef]

- Yahyaee, N.; Javadi, A.; Garmabi, H.; Khaki, A. Effect of Two-Step Chain Extension using Joncryl and PMDA on the Rheological Properties of Poly (lactic acid). Macromol. Mater. Eng. 2019, 305, 1900423. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skorczewska, K.; Matykiewicz, D. Correlation between Processing Parameters and Degradation of Different Polylactide Grades during Twin-Screw Extrusion. Polymers 2020, 12, 1333. [Google Scholar] [CrossRef] [PubMed]

- Peinado, V.; Castell, P.; Garcia, L.; Fernandez, A. Effect of Extrusion on the Mechanical and Rheological Properties of a Reinforced Poly(Lactic Acid): Reprocessing and Recycling of Biobased Materials. Materials 2015, 8, 7106–7117. [Google Scholar] [CrossRef]

- Kahraman, Y.; Alkan Goksu, Y.; Özdemir, B.; Eker Gümüş, B.; Nofar, M. Composition design of PLA/TPU emulsion blends compatibilized with multifunctional epoxy-based chain extender to tackle high impact resistant ductile structures. J. Appl. Polym. Sci. 2021, 139, 51833. [Google Scholar] [CrossRef]

- Gere, D.; Czigany, T. Future trends of plastic bottle recycling: Compatibilization of PET and PLA. Polym. Test. 2020, 81, 106160. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2011, 25, 927–948. [Google Scholar] [CrossRef]

- Xie, H.; Wu, L.; Li, B.-G.; Dubois, P. Poly(ethylene 2,5-furandicarboxylate-mb-poly(tetramethylene glycol)) multiblock copolymers: From high tough thermoplastics to elastomers. Polymer 2018, 155, 89–98. [Google Scholar] [CrossRef]

- Sanusi, O.M.; Papadopoulos, L.; Klonos, P.A.; Terzopoulou, Z.; Hocine, N.A.; Benelfellah, A.; Papageorgiou, G.Z.; Kyritsis, A.; Bikiaris, D.N. Calorimetric and Dielectric Study of Renewable Poly(hexylene 2,5-furan-dicarboxylate)-Based Nanocomposites In Situ Filled with Small Amounts of Graphene Platelets and Silica Nanoparticles. Polymers 2020, 12, 1239. [Google Scholar] [CrossRef]

- Matos, M.; Sousa, A.F.; Silva, N.H.C.S.; Freire, C.S.R.; Andrade, M.; Mendes, A.; Silvestre, A.J.D. Furanoate-Based Nanocomposites: A Case Study Using Poly(Butylene 2,5-Furanoate) and Poly(Butylene 2,5-Furanoate)-co-(Butylene Diglycolate) and Bacterial Cellulose. Polymers 2018, 10, 810. [Google Scholar] [CrossRef] [Green Version]

- Gomes, M.; Gandini, A.; Silvestre, A.J.D.; Reis, B. Synthesis and characterization of poly(2,5-furan dicarboxylate)s based on a variety of diols. J. Polym. Sci. Part A Polym. Chem. 2011, 49, 3759–3768. [Google Scholar] [CrossRef]

- Meng, Q.; Heuzey, M.-C.; Carreau, P.J. Control of thermal degradation of polylactide/clay nanocomposites during melt processing by chain extension reaction. Polym. Degrad. Stab. 2012, 97, 2010–2020. [Google Scholar] [CrossRef]

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.C. Poly (lactic acid) blends: Processing, properties and applications. Int. J. Biol. Macromol. 2019, 125, 307–360. [Google Scholar] [CrossRef] [PubMed]

- Papageorgiou, G.Z.; Papageorgiou, D.G.; Terzopoulou, Z.; Bikiaris, D.N. Production of bio-based 2,5-furan dicarboxylate polyesters: Recent progress and critical aspects in their synthesis and thermal properties. Eur. Polym. J. 2016, 83, 202–229. [Google Scholar] [CrossRef]

- Fredi, G.; Rigotti, D.; Bikiaris, D.N.; Dorigato, A. Tuning thermo-mechanical properties of poly(lactic acid) films through blending with bioderived poly(alkylene furanoate)s with different alkyl chain length for sustainable packaging. In Proceedings of the 16th AIMAT Congress—Associazione Italiana di Ingegneria dei Materiali, Cagliari, Italy, 15 September 2021. [Google Scholar]

- Roy, S.; Rhim, J.W. Preparation of bioactive functional poly(lactic acid)/curcumin composite film for food packaging application. Int. J. Biol. Macromol. 2020, 162, 1780–1789. [Google Scholar] [CrossRef]

- Borisova, N.N.; Kul’nevich, V.G. UV spectra of carbonyl-contaiming furan compounds. Chem. Heterocycl. Compd. 1973, 9, 546–549. [Google Scholar] [CrossRef]

- Csapó, J.; Prokisch, J.; Albert, C.; Sipos, P. Effect of UV light on food quality and safety. Acta Univ. Sapientiae Aliment. 2019, 12, 21–41. [Google Scholar] [CrossRef]

- Burgess, S.K.; Karvan, O.; Johnson, J.R.; Kriegel, R.M.; Koros, W.J. Oxygen sorption and transport in amorphous poly(ethylene furanoate). Polymer 2014, 55, 4748–4756. [Google Scholar] [CrossRef]

- Kasmi, N.; Majdoub, M.; Papageorgiou, G.Z.; Achilias, D.S.; Bikiaris, D.N. Solid-State Polymerization of Poly(ethylene furanoate) Biobased Polyester, I: Effect of Catalyst Type on Molecular Weight Increase. Polymers 2017, 9, 607. [Google Scholar] [CrossRef]

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

| Sample | Domain Size (Experimental) (µm) | Domain Size (Log-Normal Distribution) (µm) | R2 |

|---|---|---|---|

| PLA-PEF10 | 0.67 ± 0.46 | 0.57 ± 0.48 | 0.83 |

| PLA-PEF10-J0.25 | 0.40 ± 0.29 | 0.41 ± 0.29 | 0.94 |

| PLA-PEF10-J0.5 | 0.28 ± 0.12 | 0.30 ± 0.14 | 0.95 |

| PLA-PEF10-J0.75 | 0.32 ± 0.14 | 0.37 ± 0.21 | 0.92 |

| PLA-PEF10-J1 | 0.26 ± 0.14 | 0.28 ± 0.17 | 0.91 |

| PLA-PEF1-J1 | 0.21 ± 0.09 | 0.23 ± 0.13 | 0.96 |

| PLA-PEF3-J1 | 0.25 ± 0.12 | 0.25 ± 0.09 | 0.94 |

| PLA-PEF5-J1 | 0.28 ± 0.14 | 0.28 ± 0.14 | 0.96 |

| PLA-PEF20-J1 | 0.53 ± 0.32 | 0.65 ± 0.55 | 0.86 |

| PLA-PEF30-J1 | 0.62 ± 0.40 | 0.63 ± 0.56 | 0.79 |

| Assignment | PLA | PEF | PLA-PEF30-J1 |

|---|---|---|---|

| νo.p. CH - Fu | - | 3163 | 3163 |

| νi.p. CH - Fu | - | 3128 | 3128 |

| νo.p. CH3 | 2997 | - | 2996 |

| νi.p. CH3 | 2948 | - | 2948 |

| νo.p. CH | 2963 | 2963 | 2963 |

| ν C = O | 1754 | 1714 | 1748; 1720 |

| ν C = C - Fu | - | 1580 | 1583 |

| ν C - O | 1179 | 1217 | 1179; 1217 |

| Fu ring breathing | - | 1016 | 1021 |

| Fu ring bending | - | 969; 827; 751 | 969; 823; 762 |

| Sample | (°C) | (°C) | (°C) | (°C) | (°C) | (%) |

|---|---|---|---|---|---|---|

| PLA | 305.1 | 330.6 | 339.1 | 355.5 | 380.3 | 0.0 |

| PEF-as received | 324.7 | 375.6 | 387.0 | 402.4 | 424.5 | 10.7 |

| PLA-J0.25 | 310.9 | 331.0 | 338.4 | 352.8 | 379.2 | 0.0 |

| PLA-J0.5 | 289.1 | 325.1 | 334.3 | 349.9 | 375.0 | 0.0 |

| PLA-J0.75 | 319.7 | 336.5 | 343.0 | 355.0 | 379.5 | 0.0 |

| PLA-J1 | 296.9 | 318.3 | 325.9 | 336.3 | 360.8 | 0.5 |

| PLA-PEF10 | 272.4 | 306.7 | 315.6 | 328.6 | 374.2 | 1.6 |

| PLA-PEF10-J0.25 | 255.9 | 320.8 | 331.2 | 348.4 | 376.0 | 0.5 |

| PLA-PEF10-J0.5 | 300.8 | 326.3 | 334.6 | 354.8 | 380.2 | 1.0 |

| PLA-PEF10-J0.75 | 290.1 | 326.4 | 335.3 | 354.1 | 380.9 | 0.9 |

| PLA-PEF10-J1 | 285.2 | 321.9 | 332.6 | 357.3 | 382.0 | 0.8 |

| PLA-PEF1-J1 | 297.1 | 329.7 | 338.3 | 354.5 | 379.3 | 0.0 |

| PLA-PEF3-J1 | 313.2 | 334.7 | 342.1 | 356.4 | 380.2 | 0.3 |

| PLA-PEF5-J1 | 313.3 | 333.1 | 340.8 | 356.9 | 380.5 | 0.4 |

| PLA-PEF20-J1 | 322.0 | 339.1 | 347.1 | 360.5 | 387.7 | 2.7 |

| PLA-PEF30-J1 | 309.9 | 335.1 | 344.7 | 363.1 | 386.3 | 4.1 |

| Scan | First Heating Scan | Cooling Scan | Second Heating Scan | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Property/ Sample | (°C) | (°C) | (J/g) | (°C) | (J/g) | (%) | (°C) | (J/g) | (°C) | (°C) | (J/g) | (°C) | (J/g) | (%) |

| PLA | 58.1 | 97.7 | 40.4 | 178.6 | 55.9 | 16.5 | 104.0 | 42.2 | 56.8 | 96 | 3.1 | 175.4 | 55.7 | 56.1 |

| PEF-as synthesized | 83.6 * | - | - | 218.4 * | 49.9 * | 35.6 * | - | - | 84.3 * | - | - | - | - | 0.0 * |

| PEF-film | 82.3 * | - | - | - | - | 0.0 * | - | - | 84.8 * | - | - | - | - | 0.0 * |

| PLA-J0.25 | 59.8 | 96.9 | 35.9 | 179.1 | 57.7 | 23.3 | 101.2 | 32.5 | 59.0 | 95.9 | 9.3 | 176.1 | 55.7 | 49.6 |

| PLA-J0.5 | 59.6 | 97.5 | 31.3 | 177.7 | 47.9 | 17.8 | 101.9 | 28.2 | 58.0 | 96.7 | 8.32 | 174.6 | 48.6 | 43.2 |

| PLA-J0.75 | 59.5 | 99.6 | 36.4 | 178.3 | 49.5 | 14.1 | 98.7 | 9.0 | 60.2 | 99.6 | 26.1 | 175.4 | 50 | 25.7 |

| PLA-J1 | 59.7 | 100.7 | 31.5 | 176.3 | 38.9 | 8.0 | 98.9 | 10.1 | 58.9 | 99.1 | 24.1 | 174.2 | 43.2 | 20.6 |

| PLA-PEF10 | 59.2 | 96.0 | 31.7 | 178.6 | 55.6 | 28.3 | 103.6 | 36.2 | 58.0 | 95.5 | 5.1 | 176.5 | 52.4 | 56.1 |

| PLA-PEF10-J0.25 | 55.3 | 96.3 | 37.7 | 178.8 | 49.7 | 14.3 | 100.8 | 19.2 | 57.5 | 96.4 | 17.7 | 174.8 | 50.6 | 39.1 |

| PLA-PEF10-J0.5 | 58.7 | 96.3 | 27.1 | 176.8 | 43.2 | 19.2 | 100.7 | 27.1 | 58.3 | 95.5 | 7.2 | 176.7 | 44.1 | 44.0 |

| PLA-PEF10-J0.75 | 59.5 | 98.3 | 35.1 | 177.2 | 39.8 | 5.6 | 99.3 | 8.4 | 58.6 | 98.5 | 24.8 | 173.9 | 45.9 | 25.2 |

| PLA-PEF10-J1 | 56.8 | 97.1 | 33.1 | 176.6 | 42.1 | 10.8 | 99.8 | 7.21 | 57.7 | 97.1 | 23.9 | 173.7 | 46.1 | 26.6 |

| PLA-PEF1-J1 | 60.8 | 99.6 | 28.5 | 176.9 | 45.0 | 18.0 | - | - | 56.0 | 100.5 | 28.8 | 175.1 | 44.5 | 17.1 |

| PLA-PEF3-J1 | 64.4 | 98.6 | 24.9 | 175.7 | 44.2 | 21.4 | 97.8 | 4.4 | 59.1 | 100.3 | 26.5 | 174.0 | 44.1 | 19.6 |

| PLA-PEF5-J1 | 61.6 | 98.7 | 30.3 | 176.5 | 43.7 | 15.2 | 98.4 | 5.6 | 59.8 | 100.1 | 27.1 | 174.4 | 43.7 | 18.8 |

| PLA-PEF20-J1 | 59.6 | 98.7 | 24.1 | 177.1 | 41.6 | 23.6 | 96.9 | 3.7 | 59.4 | 99.3 | 24.1 | 174.7 | 40.6 | 22.2 |

| PLA-PEF30-J1 | 59.3 | 98.3 | 19.3 | 176.5 | 35.2 | 24.5 | 99.4 | 4.9 | 60.0 | 98.1 | 13.8 | 174.6 | 33.8 | 30.8 |

| Label | PLA (wt %) | PEF (wt %) | J (phr) |

|---|---|---|---|

| PLA | 100 | 0 | 0 |

| PLA-J0.25 | 100 | 0 | 0.25 |

| PLA-J0.5 | 100 | 0 | 0.5 |

| PLA-J0.75 | 100 | 0 | 0.75 |

| PLA-J1 | 100 | 0 | 1 |

| PLA-PEF10 | 90 | 10 | 0 |

| PLA-PEF10-J0.25 | 90 | 10 | 0.25 |

| PLA-PEF10-J0.5 | 90 | 10 | 0.5 |

| PLA-PEF10-J0.75 | 90 | 10 | 0.75 |

| PLA-PEF10-J1 | 90 | 10 | 1 |

| PLA-PEF1-J1 | 99 | 1 | 1 |

| PLA-PEF3-J1 | 97 | 3 | 1 |

| PLA-PEF5-J1 | 95 | 5 | 1 |

| PLA-PEF20-J1 | 80 | 20 | 1 |

| PLA-PEF30-J1 | 70 | 30 | 1 |

| PEF | 0 | 100 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fredi, G.; Dorigato, A.; Dussin, A.; Xanthopoulou, E.; Bikiaris, D.N.; Botta, L.; Fiore, V.; Pegoretti, A. Compatibilization of Polylactide/Poly(ethylene 2,5-furanoate) (PLA/PEF) Blends for Sustainable and Bioderived Packaging. Molecules 2022, 27, 6371. https://doi.org/10.3390/molecules27196371

Fredi G, Dorigato A, Dussin A, Xanthopoulou E, Bikiaris DN, Botta L, Fiore V, Pegoretti A. Compatibilization of Polylactide/Poly(ethylene 2,5-furanoate) (PLA/PEF) Blends for Sustainable and Bioderived Packaging. Molecules. 2022; 27(19):6371. https://doi.org/10.3390/molecules27196371

Chicago/Turabian StyleFredi, Giulia, Andrea Dorigato, Alessandro Dussin, Eleftheria Xanthopoulou, Dimitrios N. Bikiaris, Luigi Botta, Vincenzo Fiore, and Alessandro Pegoretti. 2022. "Compatibilization of Polylactide/Poly(ethylene 2,5-furanoate) (PLA/PEF) Blends for Sustainable and Bioderived Packaging" Molecules 27, no. 19: 6371. https://doi.org/10.3390/molecules27196371

APA StyleFredi, G., Dorigato, A., Dussin, A., Xanthopoulou, E., Bikiaris, D. N., Botta, L., Fiore, V., & Pegoretti, A. (2022). Compatibilization of Polylactide/Poly(ethylene 2,5-furanoate) (PLA/PEF) Blends for Sustainable and Bioderived Packaging. Molecules, 27(19), 6371. https://doi.org/10.3390/molecules27196371