Interfacial Interaction of Clay and Saturates in Petroleum-Contaminated Soil: Effect of Clay Surface Heterogeneity

Abstract

:1. Introduction

2. Results and Discussions

2.1. Rheological Characterization of Saturates–Clay Suspensions

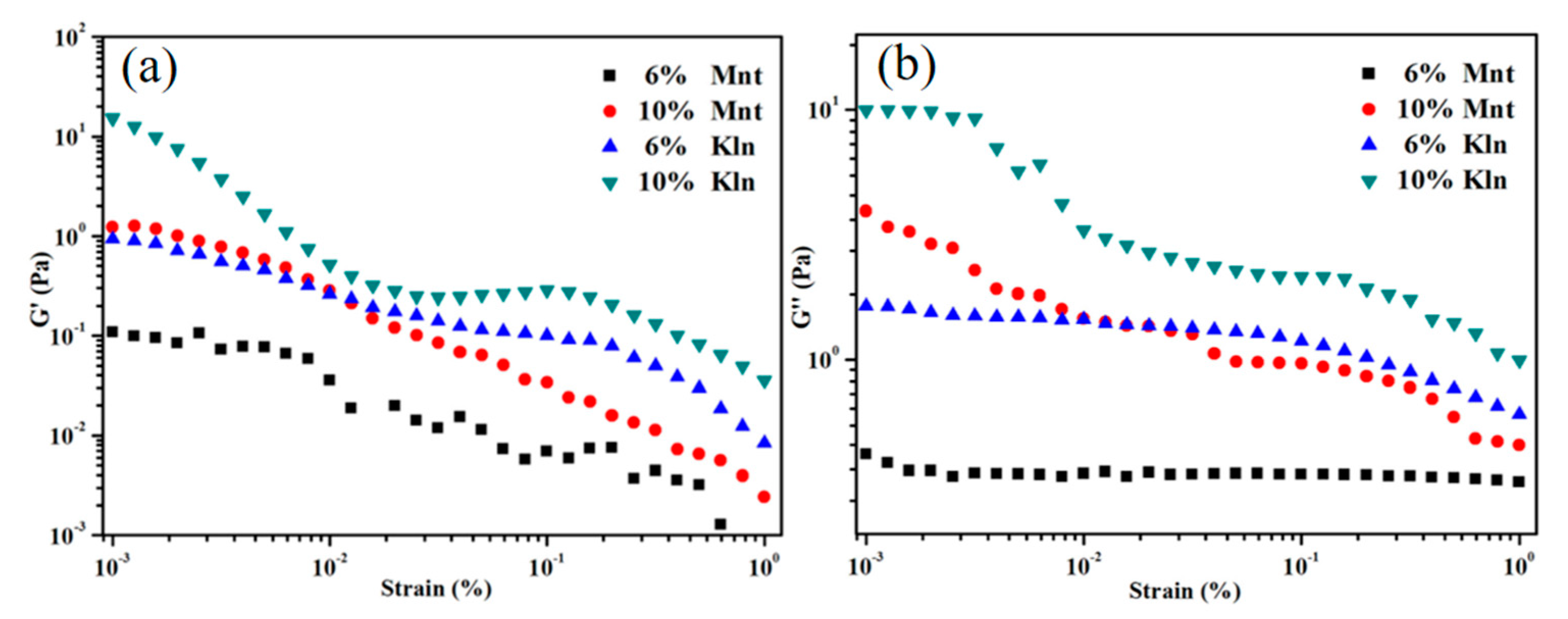

2.1.1. Dynamic Oscillations of Saturates with Clay

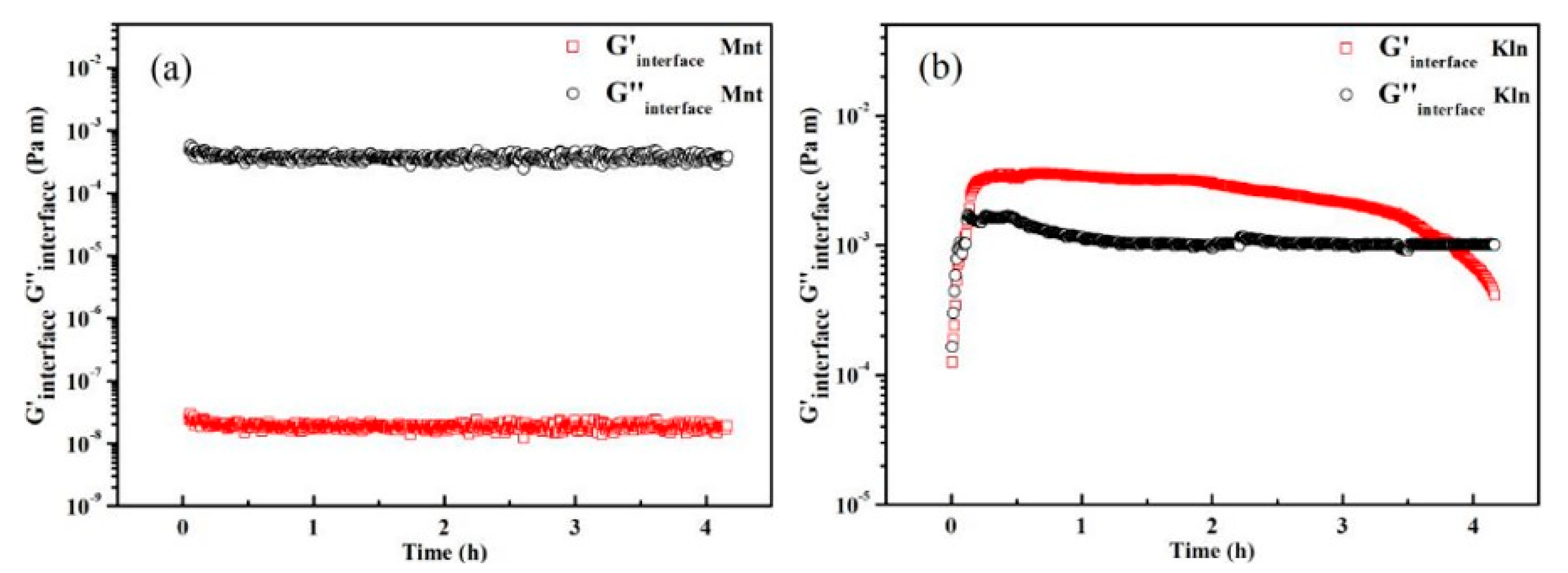

2.1.2. Interfacial Rheology of Saturates and Clay

2.2. Thermodynamics Adsorption Analysis of Saturates on Clay

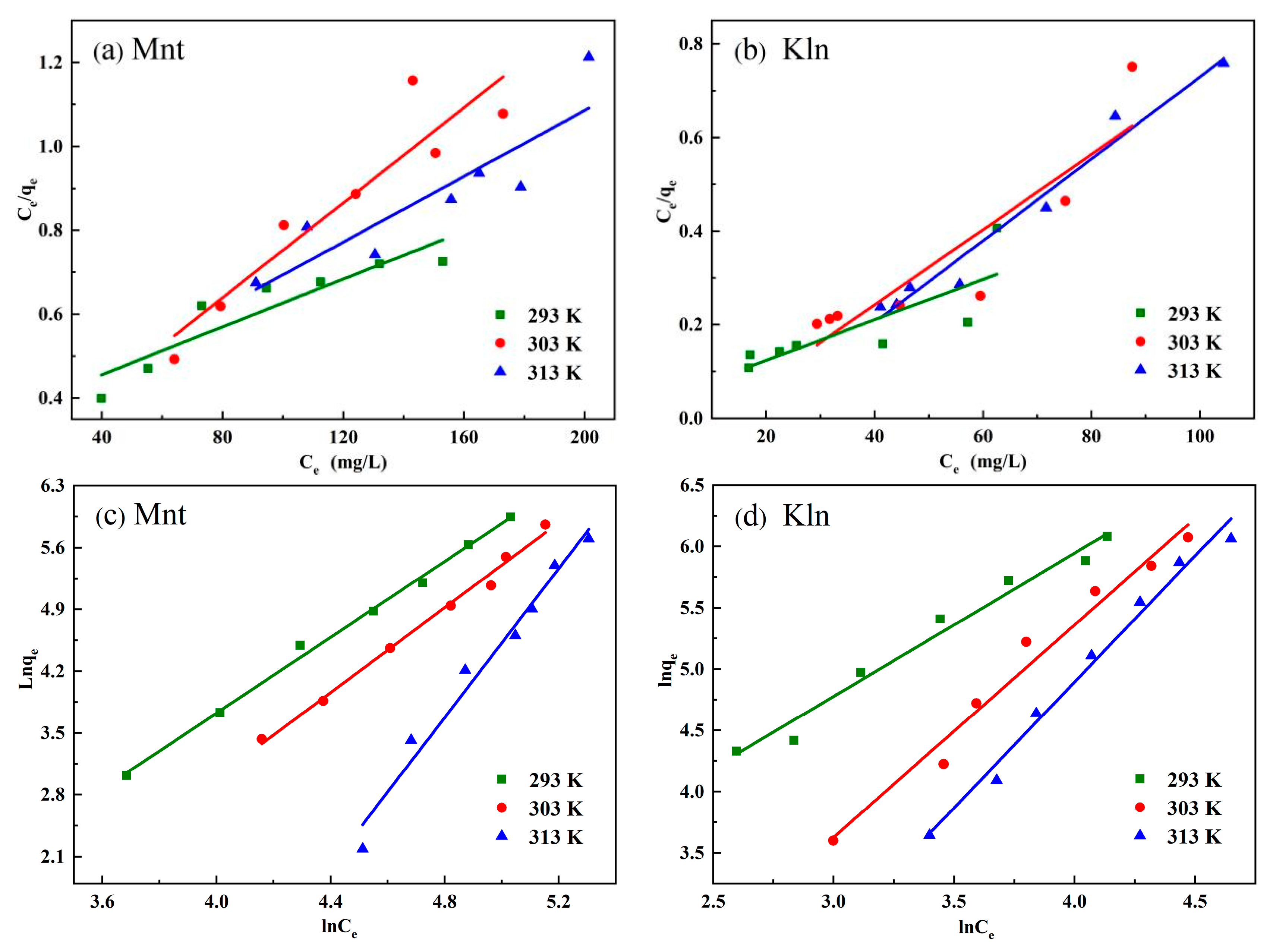

2.2.1. Adsorption Isotherms

2.2.2. Adsorption Heat Analysis

2.3. MD Simulation Analysis

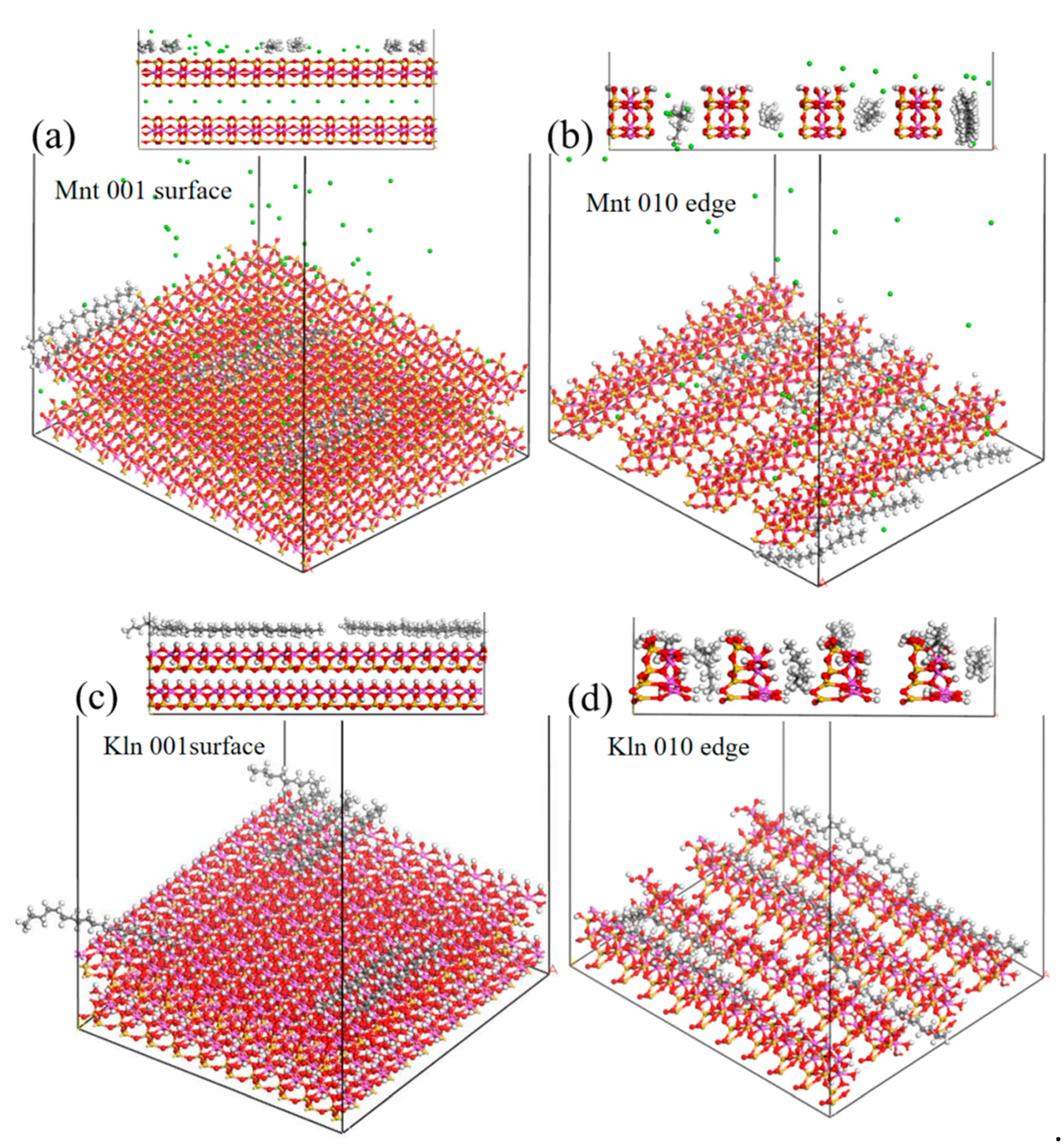

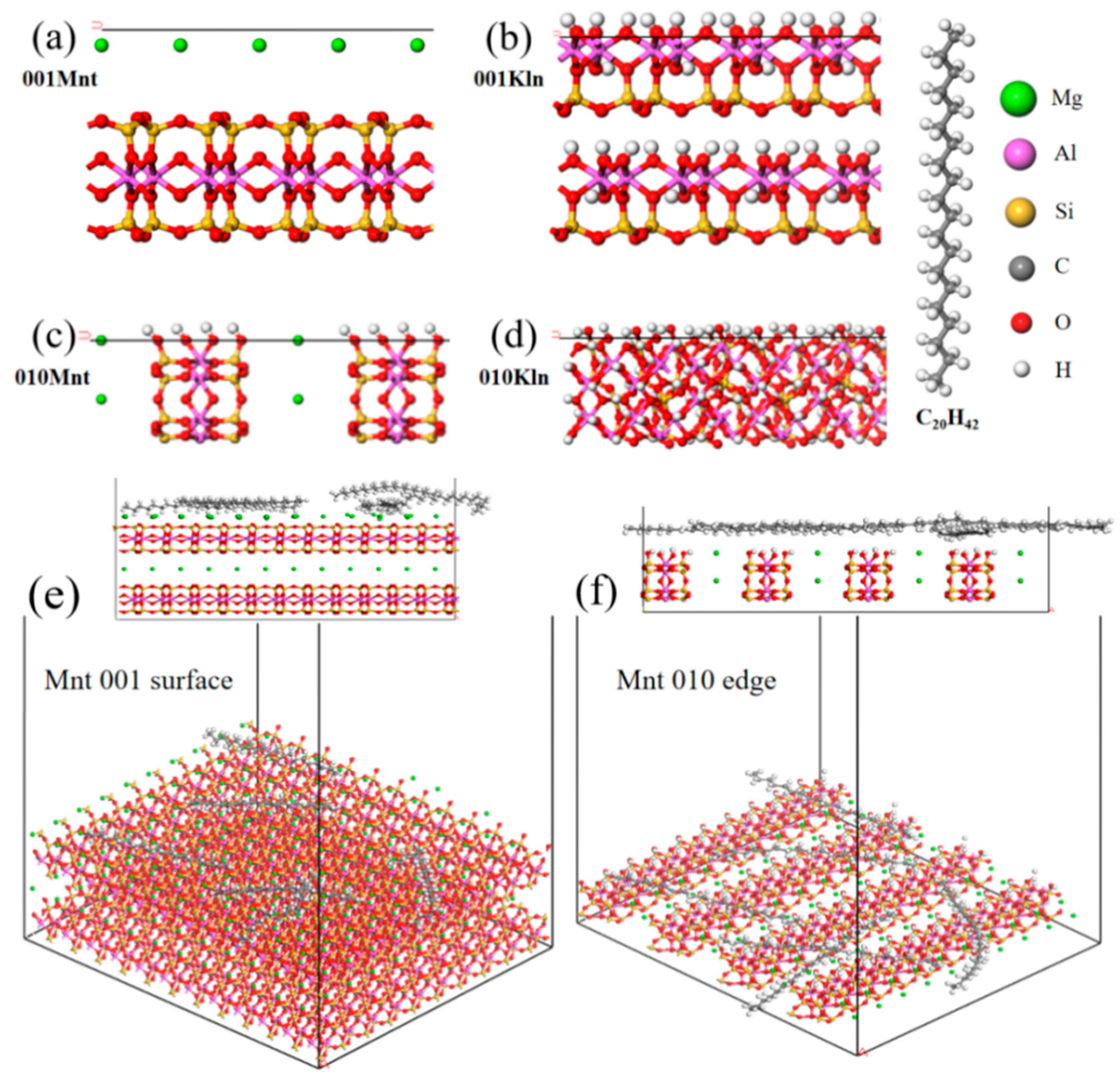

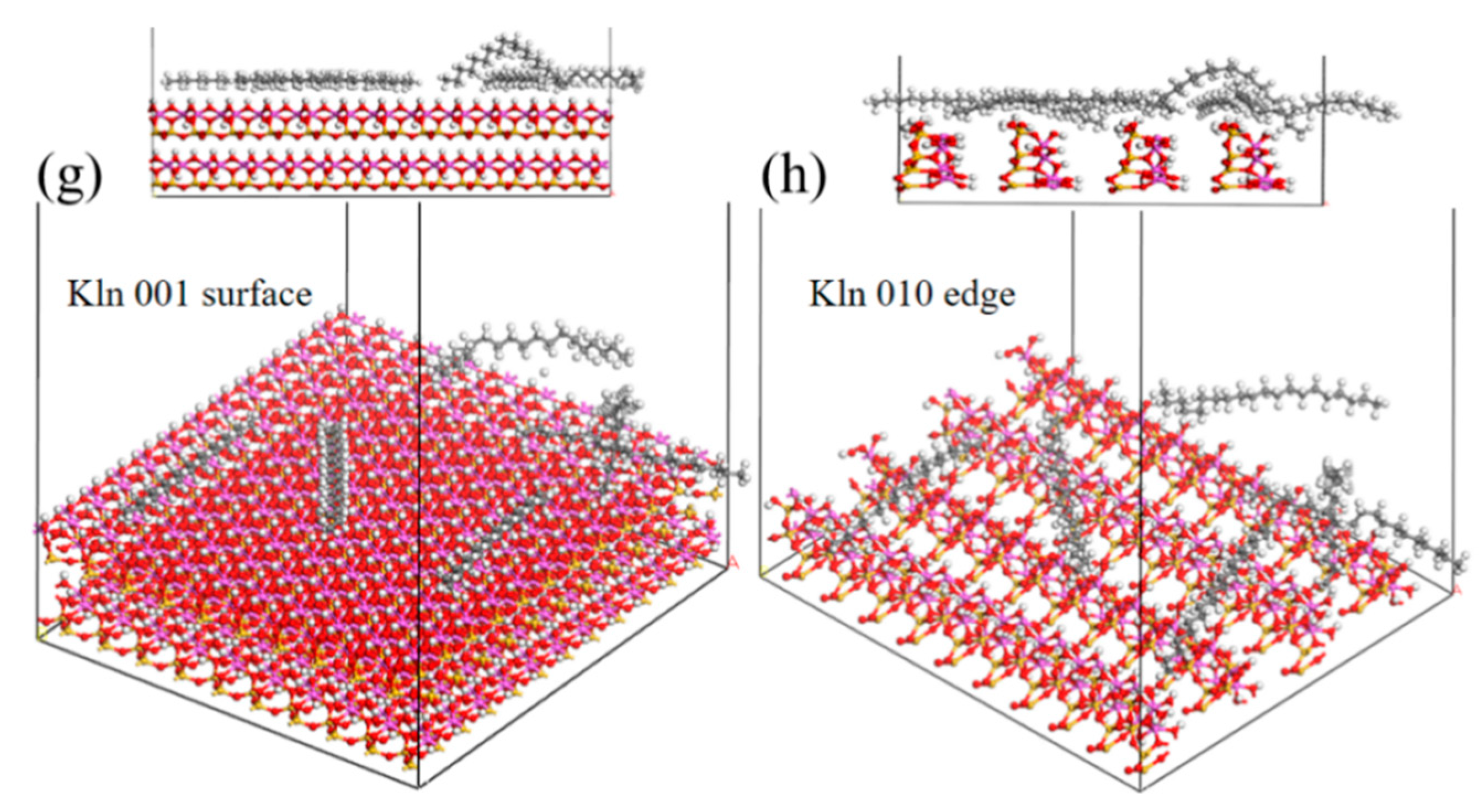

2.3.1. Conformational Analysis of Clay Adsorption Saturates Process

2.3.2. Analysis of Saturates Distributions on Surfaces and Edges of Clay

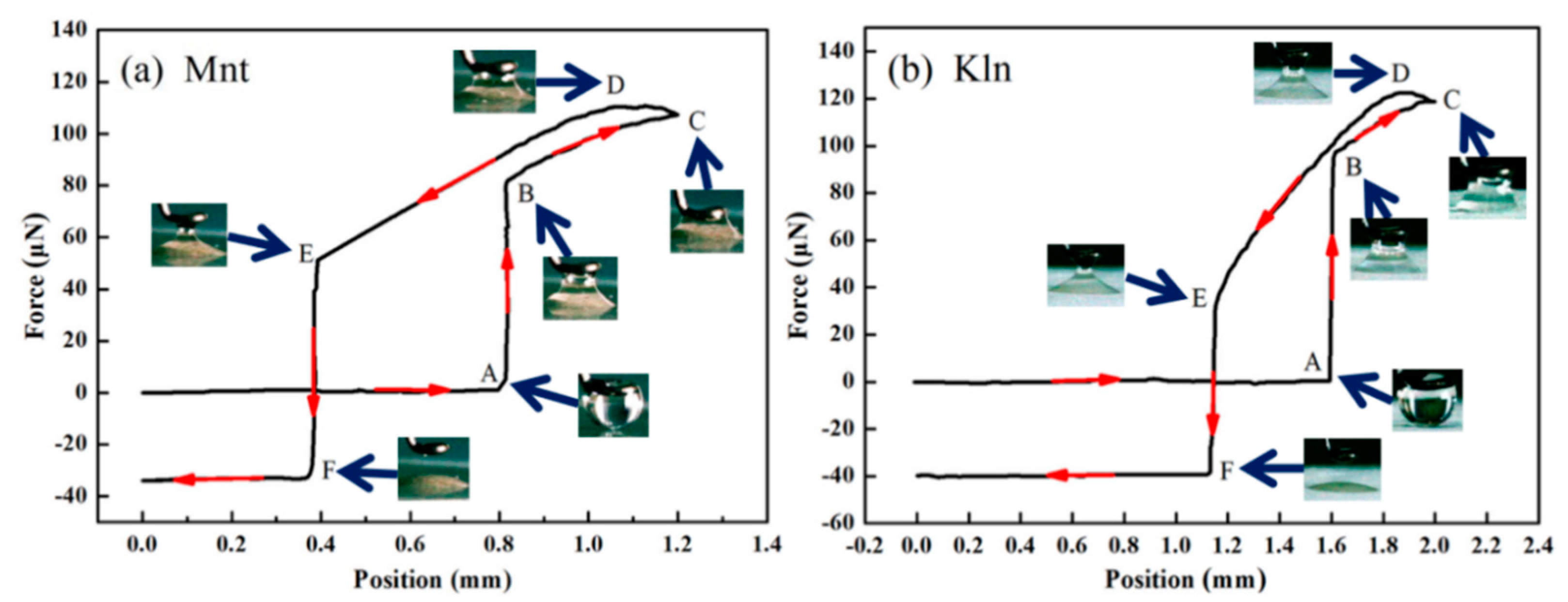

2.4. Interaction Forces between Clay and Saturates

3. Materials and Methods

3.1. Materials and Preparation of Clay Dispersions

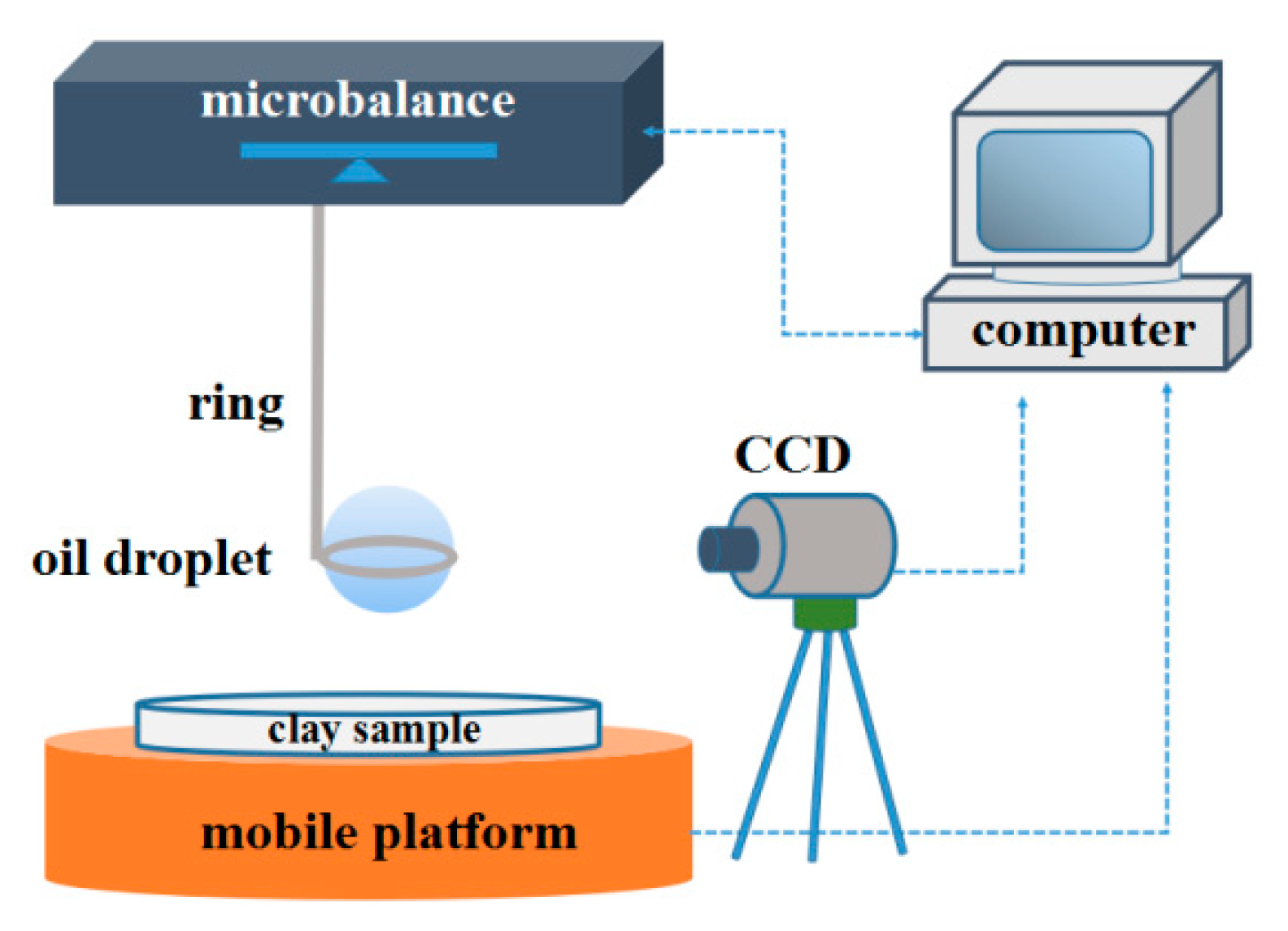

3.2. Adhesive Force Measurements

3.3. Rheological Measurements

3.4. Adsorption Heat Measurements

3.5. Thermodynamic Adsorption Measurements

3.6. MD Simulation Details

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Liu, J.; Wei, K.; Xu, S.; Cui, J.; Ma, J.; Xiao, X.; Xi, B.; He, X. Surfactant-enhanced remediation of oil-contaminated soil and groundwater: A review. Sci. Total Environ. 2021, 756, 144142. [Google Scholar] [CrossRef]

- Lim, M.W.; Lau, E.V.; Poh, P.E. A comprehensive guide of remediation technologies for oil contaminated soil—Present works and future directions. Mar. Pollut. Bull. 2016, 109, 14–45. [Google Scholar] [CrossRef]

- Khan, M.A.I.; Biswas, B.; Smith, E.; Naidu, R.; Megharaj, M. Toxicity assessment of fresh and weathered petroleum hydrocarbons in contaminated soil- a review. Chemosphere 2018, 212, 755–767. [Google Scholar] [CrossRef] [PubMed]

- Quintella, C.M.; Mata, A.M.T.; Lima, L.C.P. Overview of bioremediation with technology assessment and emphasis on fungal bioremediation of oil contaminated soils. J. Environ. Manage. 2019, 241, 156–166. [Google Scholar] [CrossRef] [PubMed]

- Asghar, H.N.; Rafique, H.M.; Zahir, Z.A.; Khan, M.Y.; Akhtar, M.J.; Naveed, M.; Saleem, M. Petroleum Hydrocarbons-Contaminated Soils: Remediation Approaches; Springer International Publishing: Cham, Switzerland, 2016; pp. 105–129. [Google Scholar]

- Dadrasnia, A.; Salmah, I.; Emenike, C.U.; Shahsavari, N. Remediation of oil contaminated media using organic material supplementation. Pet. Sci. Technol. 2014, 33, 1030–1037. [Google Scholar] [CrossRef]

- Kang, C.; Kim, D.; Khan, M.A.; Kumar, R.; Ji, S.; Choi, K.; Paeng, K.; Park, S.; Jeon, B. Pyrolytic remediation of crude oil-contaminated soil. Sci. Total Environ. 2020, 713, 136498. [Google Scholar] [CrossRef]

- Azubuike, C.C.; Chikere, C.B.; Okpokwasili, G.C. Bioremediation techniques–classification based on site of application: Principles, advantages, limitations and prospects. World J. Microb. Biot. 2016, 32, 180. [Google Scholar] [CrossRef] [Green Version]

- Liang, J.; Zhao, L.; Du, N.; Li, H.; Hou, W. Solid effect in solvent extraction treatment of pre-treated oily sludge. Sep. Purif. Technol. 2014, 130, 28–33. [Google Scholar] [CrossRef]

- Chen, H.; Li, X.; Zhang, Q.; Liu, Y. Effects of hot water-based extraction process on the removal of petroleum hydrocarbons from the oil-contaminated soil. Energy Fuel 2020, 34, 3621–3627. [Google Scholar] [CrossRef]

- Jacob Masliyah, Z.J.Z.; Zhenghe, X.; Jan, C.A.; Hamza, H. Understanding water-based bitumen extraction from athabasca oil sands. Can. J. Chem. Eng. 2004, 82, 628–654. [Google Scholar] [CrossRef]

- Abiram Karanam Rathankumar, A.K.S.A.; Ponnusamy Senthil Kumar, B.S.V.C.; Nikhil Bharadwaj, A.J.G.A. Surfactant-aided mycoremediation of soil contaminated with polycyclic aromatic hydrocarbon (PAHs): Progress, limitation, and countermeasures. J. Chem. Technol. Biot. 2022, 97, 391–408. [Google Scholar] [CrossRef]

- He, L.; Lin, F.; Li, X.; Sui, H.; Xu, Z. Interfacial sciences in unconventional petroleum production: From fundamentals to applications. Chem. Soc. Rev. 2015, 44, 5446–5494. [Google Scholar] [CrossRef] [PubMed]

- Masliyah, J.H.; Czarnecki, J.; Xu, Z. Handbook on Theory and Practice of Bitumen Recovery from Athabasca Oil Sands; Kingsley Knowledge Publishing: Alberta, Canada, 2011. [Google Scholar]

- Castellini, E.; Andreoli, R.; Malavasi, G.; Pedone, A. Deflocculant effects on the surface properties of kaolinite investigated through malachite green adsorption. Colloids Surf. A 2008, 329, 31–37. [Google Scholar] [CrossRef]

- Papirer, A.S.B.S. Comparison of the hydrophilicity/hydrophobicity of illites and kaolinites. J. Colloid Interface Sci. 1995, 174, 185–190. [Google Scholar]

- Guo, Z.; Hakkou, R.; Yang, J.; Wang, Y. Effects of surface heterogeneities on wetting and contact line dynamics as observed with the captive bubble technique. Colloids Surf. A 2021, 615, 126041. [Google Scholar] [CrossRef]

- Tombácz, E.; Szekeres, M. Surface charge heterogeneity of kaolinite in aqueous suspension in comparison with montmorillonite. Appl. Clay Sci. 2006, 34, 105–124. [Google Scholar] [CrossRef]

- Alagha, L.; Wang, S.; Yan, L.; Xu, Z.; Masliyah, J. Probing adsorption of polyacrylamide-based polymers on anisotropic basal planes of kaolinite using quartz crystal microbalance. Langmuir 2013, 29, 3989–3998. [Google Scholar] [CrossRef]

- Tenney, C.M.; Cygan, R.T. Molecular simulation of carbon dioxide, brine, and clay mineral interactions and determination of contact angles. Environ. Sci. Technol. 2014, 48, 2035–2042. [Google Scholar] [CrossRef]

- Wu, G.; He, L.; Chen, D. Sorption and distribution of asphaltene, resin, aromatic and saturate fractions of heavy crude oil on quartz surface: Molecular dynamic simulation. Chemosphere 2013, 92, 1465–1471. [Google Scholar] [CrossRef]

- Logeshwaran, P.; Megharaj, M.; Chadalavada, S.; Bowman, M.; Naidu, R. Petroleum hydrocarbons (PH) in groundwater aquifers: An overview of environmental fate, toxicity, microbial degradation and risk-based remediation approaches. Environ. Technol. Innov. 2018, 10, 175–193. [Google Scholar] [CrossRef]

- Balestrin, L.B.D.S.; Cardoso, M.B.; Loh, W. Using atomic force microscopy to detect asphaltene colloidal particles in crude oils. Energy Fuel 2017, 31, 3738–3746. [Google Scholar] [CrossRef]

- Chen, H. Environmental Soil Science; Science Press: Beijing, China, 2010; pp. 1–50. [Google Scholar]

- Yan, F.; Xie, Y. Investigation on separation of four fractions and interfacial properties of daqing crude oil. Chem. Anal. Meterage 2009, 18, 20–24. [Google Scholar]

- Lei, Z.; Bin, G.; Yue, M.; Bo, Z.; Li-Hong, L. Study on the differentiation law of migration process of petroleum pollutants in homogeneous soil column. Contemp. Chem. Ind. 2021, 50, 14–18. [Google Scholar]

- Cruz, N.; Peng, Y. Rheology measurements for flotation slurries with high clay contents—A critical review. Miner. Eng. 2016, 98, 137–150. [Google Scholar] [CrossRef]

- Hong, J.S.; Kong, H.J.; Hyun, K.; Bergfreund, J.; Fischer, P.; Ahn, K.H. Rheological analysis of oil–water emulsions stabilized with clay particles by laos and interfacial shear moduli measurements. Rheol. Acta 2019, 58, 453–466. [Google Scholar] [CrossRef]

- Mironova, M.V.; Ilyin, S.O. Effect of silica and clay minerals on rheology of heavy crude oil emulsions. Fuel 2018, 232, 290–298. [Google Scholar] [CrossRef]

- Bergfreund, J.; Bertsch, P.; Kuster, S.; Fischer, P. Effect of oil hydrophobicity on the adsorption and rheology of β-lactoglobulin at oil–water interfaces. Langmuir 2018, 34, 4929–4936. [Google Scholar] [CrossRef]

- Silva, R.D.; Kuczera, T.; Picheth, G.; Menezes, L.; Wypych, F.; de Freitas, R.A. Pickering emulsions formation using kaolinite and brazil nut oil: Particle hydrophobicity and oil self emulsion effect. J. Dispersion Sci. Technol. 2018, 39, 901–910. [Google Scholar] [CrossRef]

- Tan, I.A.W.; Ahmad, A.L.; Hameed, B.H. Adsorption isotherms, kinetics, thermodynamics and desorption studies of 2,4,6-trichlorophenol on oil palm empty fruit bunch-based activated carbon. J. Hazard. Mater. 2009, 164, 473–482. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, R.; Xing, Y.; Gui, X. Improving the adsorption of oily collector on the surface of low-rank coal during flotation using a cationic surfactant: An experimental and molecular dynamics simulation study. Fuel 2019, 235, 687–695. [Google Scholar] [CrossRef]

- Bergaya, F.; Lagaly, G. General introduction: Clays, clay minerals, and clay science. Dev. Clay Sci. 2013, 5, 1–19. [Google Scholar]

- Sun, Y.; Jiang, Y.; Choi, C.; Xie, G.; Liu, Q.; Drelich, J.W. Direct measurements of adhesion forces for water droplets in contact with smooth and patterned polymers. Surf. Innov. 2017, 6, 93–105. [Google Scholar] [CrossRef]

- Jin, M.; Feng, X.; Feng, L.; Sun, T.; Zhai, J.; Li, T.; Jiang, L. Superhydrophobic aligned polystyrene nanotube films with high adhesive force. Adv. Mater. 2005, 17, 1977–1981. [Google Scholar] [CrossRef]

- Erni, P.; Fischer, P.; Windhab, E.J.; Kusnezov, V.; Stettin, H.; Läuger, J. Stress- and strain-controlled measurements of interfacial shear viscosity and viscoelasticity at liquid/liquid and gas/liquid interfaces. Rev. Sci. Instrum. 2003, 74, 4916–4924. [Google Scholar] [CrossRef]

- Zeitler, T.R.; Greathouse, J.A.; Cygan, R.T.; Fredrich, J.T.; Jerauld, G.R. Molecular dynamics simulation of resin adsorption at kaolinite edge sites: Effect of surface deprotonation on interfacial structure. J. Phys. Chem. C 2017, 121, 22787–22796. [Google Scholar] [CrossRef]

- Liu, X.; Lu, X.; Sprik, M.; Cheng, J.; Meijer, E.J.; Wang, R. Acidity of edge surface sites of montmorillonite and kaolinite. Geochim. Cosmochim. Acta 2013, 117, 180–190. [Google Scholar] [CrossRef] [Green Version]

- Tournassat, C.; Davis, J.A.; Chiaberge, C.; Grangeon, S.; Bourg, I.C. Modeling the acid–base properties of montmorillonite edge surfaces. Environ. Sci. Technol. 2016, 50, 13436–13445. [Google Scholar] [CrossRef] [Green Version]

- Underwood, T.; Erastova, V.; Greenwell, H.C. Wetting effects and molecular adsorption at hydrated kaolinite clay mineral surfaces. J. Phys. Chem. C 2016, 120, 11433–11449. [Google Scholar] [CrossRef] [Green Version]

- Luo, M.; Zhao, Z.; Zhang, Y.; Sun, Y.; Xing, Y.; Lv, F.; Yang, Y.; Zhang, X.; Hwang, S.; Qin, Y.; et al. Pdmo bimetallene for oxygen reduction catalysis. Nature 2019, 574, 81–85. [Google Scholar] [CrossRef]

- Cygan, R.T.; Liang, J.; Kalinichev, A.G. Molecular models of hydroxide, oxyhydroxide, and clay phases and the development of a general force field. J. Phys. Chem. B 2004, 108, 1255–1266. [Google Scholar] [CrossRef]

- Yang, Y.; Ma, Z.; Xia, F.; Li, X. Adsorption behavior of oil-displacing surfactant at oil/water interface: Molecular simulation and experimental. J. Water Process. Eng. 2020, 36, 101292. [Google Scholar] [CrossRef]

- Seniya, C.; Khan, G.J.; Uchadia, K. Identification of potential herbal inhibitor of acetylcholinesterase associated alzheimer’s disorders using molecular docking and molecular dynamics simulation. Biochem. Res. Int. 2014, 2014, 1–7. [Google Scholar] [CrossRef] [PubMed]

| Type | T (K) | Langmuir | Freundlich | ||||

|---|---|---|---|---|---|---|---|

| qm (mg/g) | Kl (L/mg) | Rl2 | Kf | 1/n | Rf2 | ||

| Mnt | 293 | 230.95 | 0.116 | 0.6037 | 35.52 | 0.615 | 0.9921 |

| 303 | 124.22 | −0.101 | 0.7874 | 31.48 | 0.407 | 0.9710 | |

| 313 | 114.29 | −0.060 | 0.9551 | 22.04 | 0.251 | 0.9828 | |

| Kln | 293 | 350.88 | 0.008 | 0.8273 | 50.34 | 0.721 | 0.9948 |

| 303 | 255.10 | 0.030 | 0.8494 | 42.17 | 0.559 | 0.9905 | |

| 313 | 176.68 | 0.013 | 0.7459 | 36.11 | 0.381 | 0.9895 | |

| Clay (w/w) | Adsorption Time (min) | Adsorption Heat (J/g) | |

|---|---|---|---|

| Mnt | 0.6% | 112 | −11.957 |

| 1.0% | 145 | −14.029 | |

| Kln | 0.6% | 73 | −15.333 |

| 1.0% | 90 | −24.985 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Liang, X.; Li, X. Interfacial Interaction of Clay and Saturates in Petroleum-Contaminated Soil: Effect of Clay Surface Heterogeneity. Molecules 2022, 27, 7950. https://doi.org/10.3390/molecules27227950

Yang Y, Liang X, Li X. Interfacial Interaction of Clay and Saturates in Petroleum-Contaminated Soil: Effect of Clay Surface Heterogeneity. Molecules. 2022; 27(22):7950. https://doi.org/10.3390/molecules27227950

Chicago/Turabian StyleYang, Yang, Xing Liang, and Xiaobing Li. 2022. "Interfacial Interaction of Clay and Saturates in Petroleum-Contaminated Soil: Effect of Clay Surface Heterogeneity" Molecules 27, no. 22: 7950. https://doi.org/10.3390/molecules27227950