Supercritical Fluid Microcellular Foaming of High-Hardness TPU via a Pressure-Quenching Process: Restricted Foam Expansion Controlled by Matrix Modulus and Thermal Degradation

Abstract

1. Introduction

2. Results and Discussion

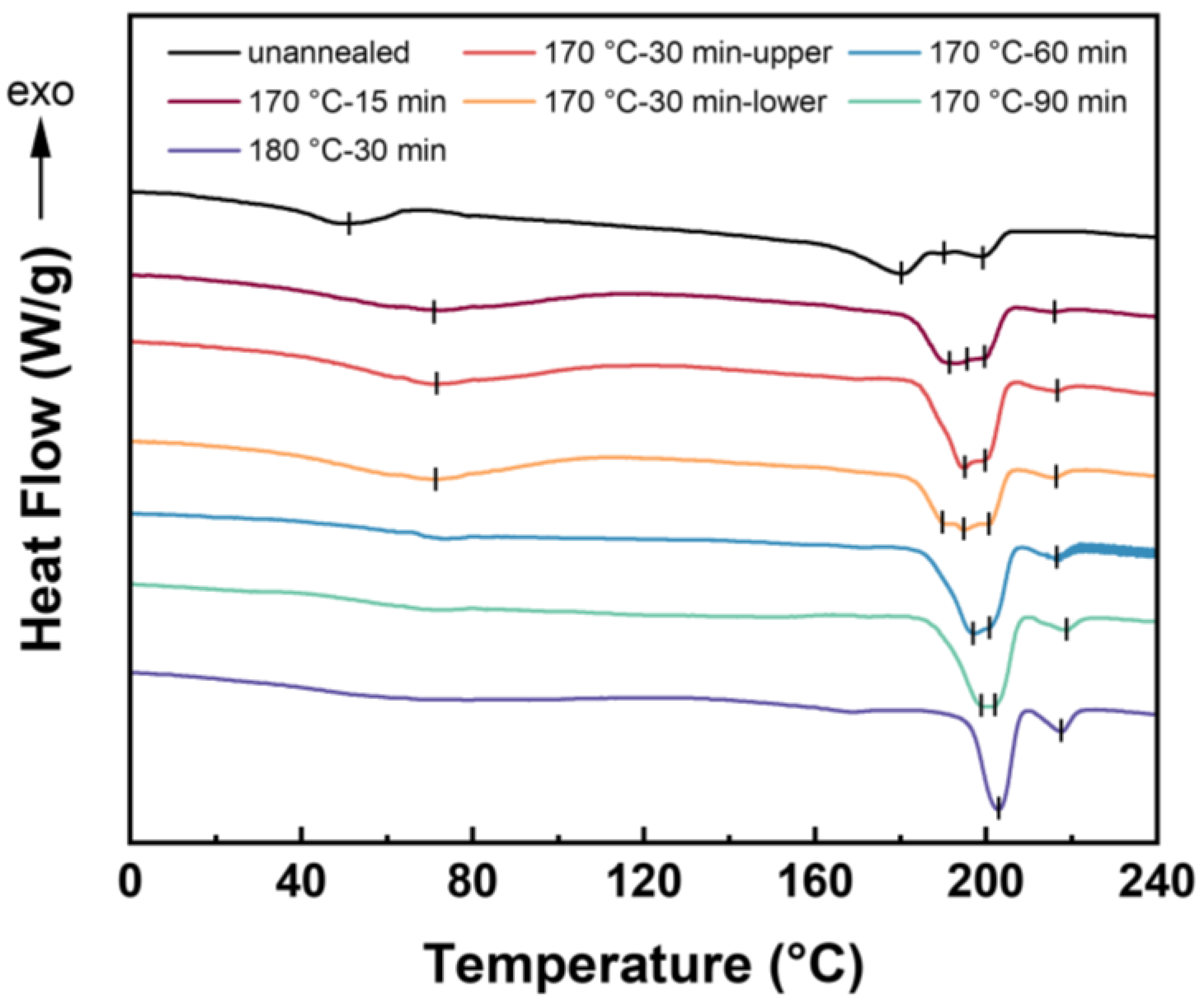

2.1. Ordered Microstructure Evolution of HD-TPU

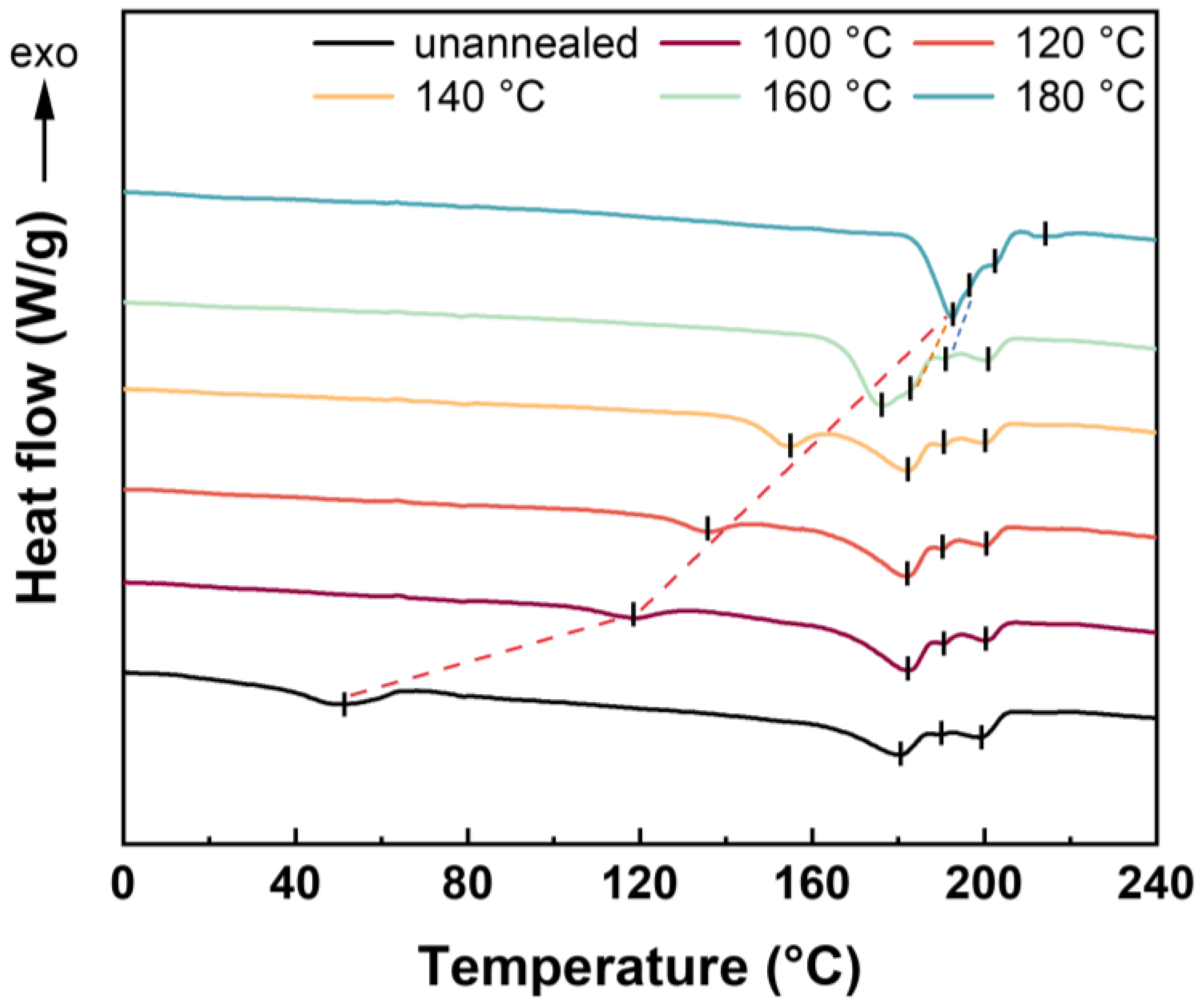

2.1.1. Isothermal Annealing Analysis

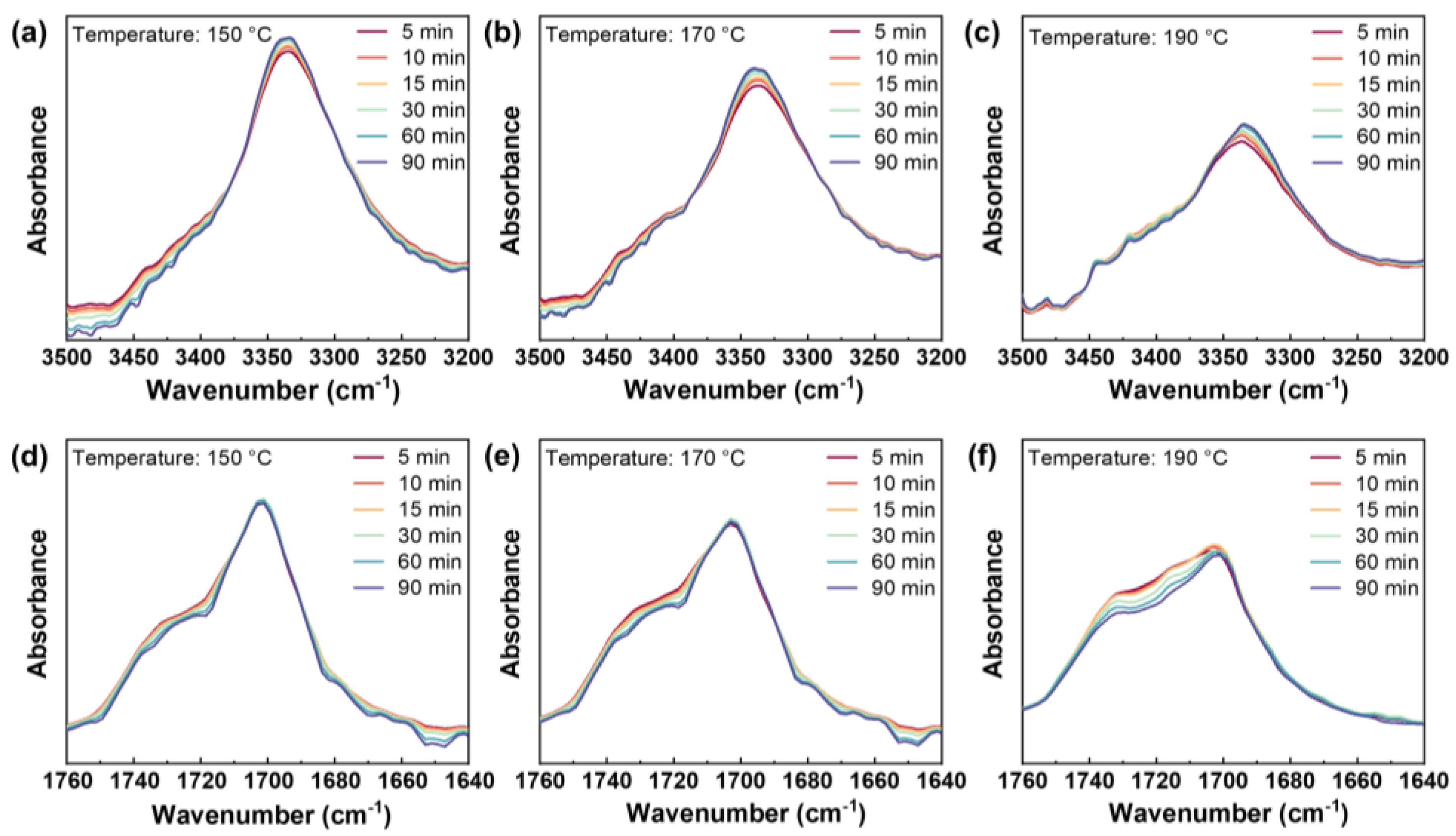

2.1.2. Microphase Separation Behavior

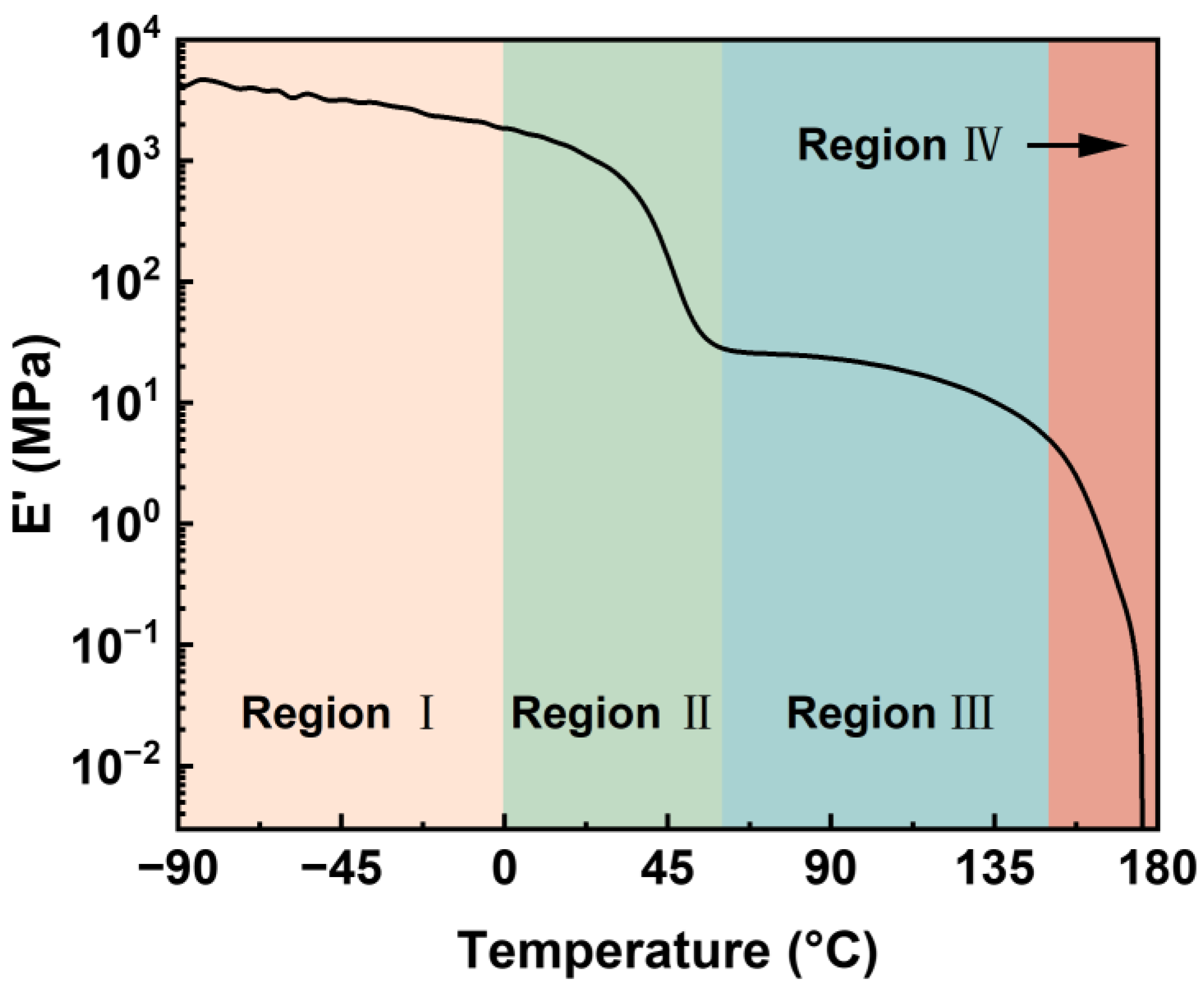

2.2. Dynamic Mechanical Analysis

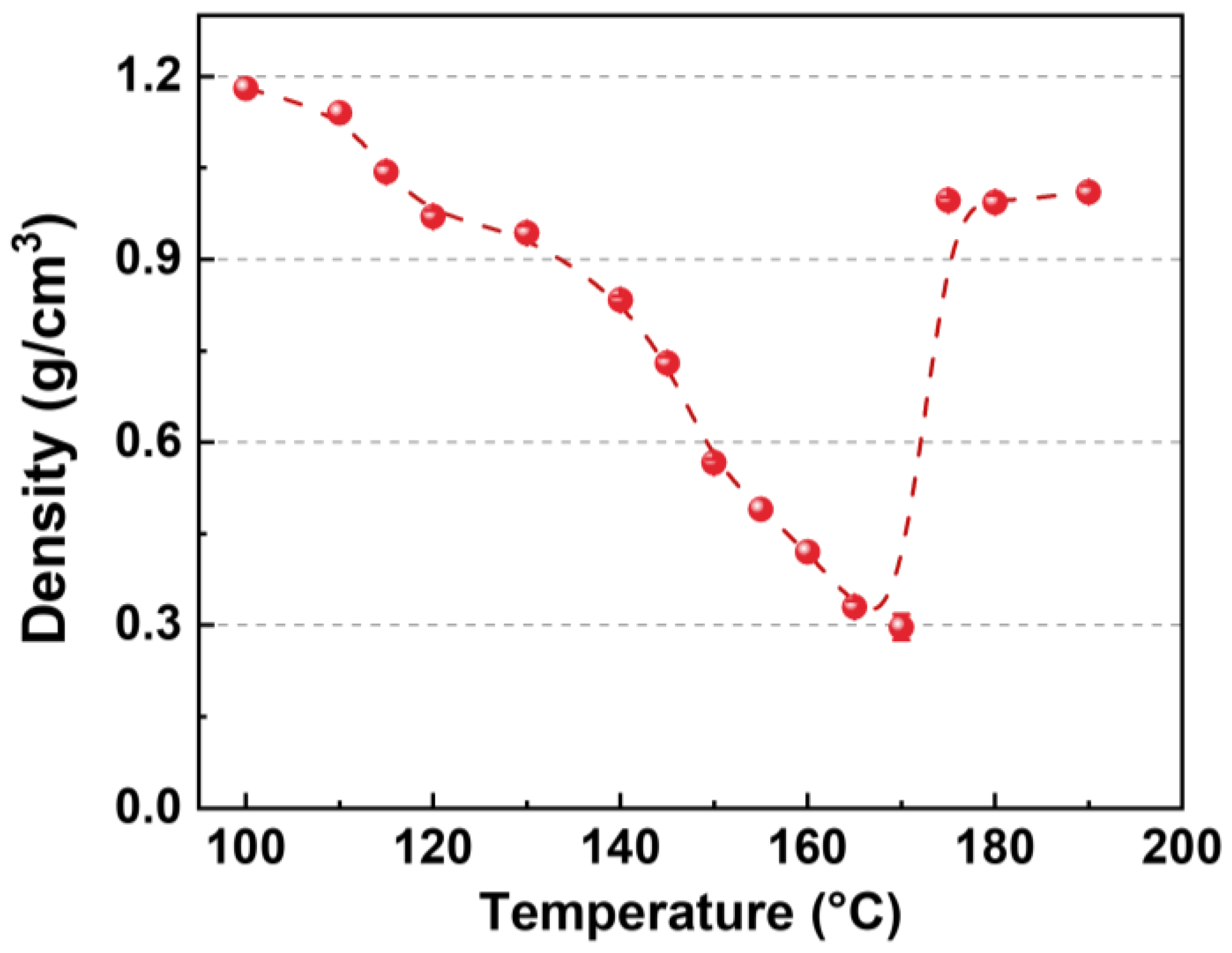

2.3. Foaming Behaviors of HD-TPU Sheets

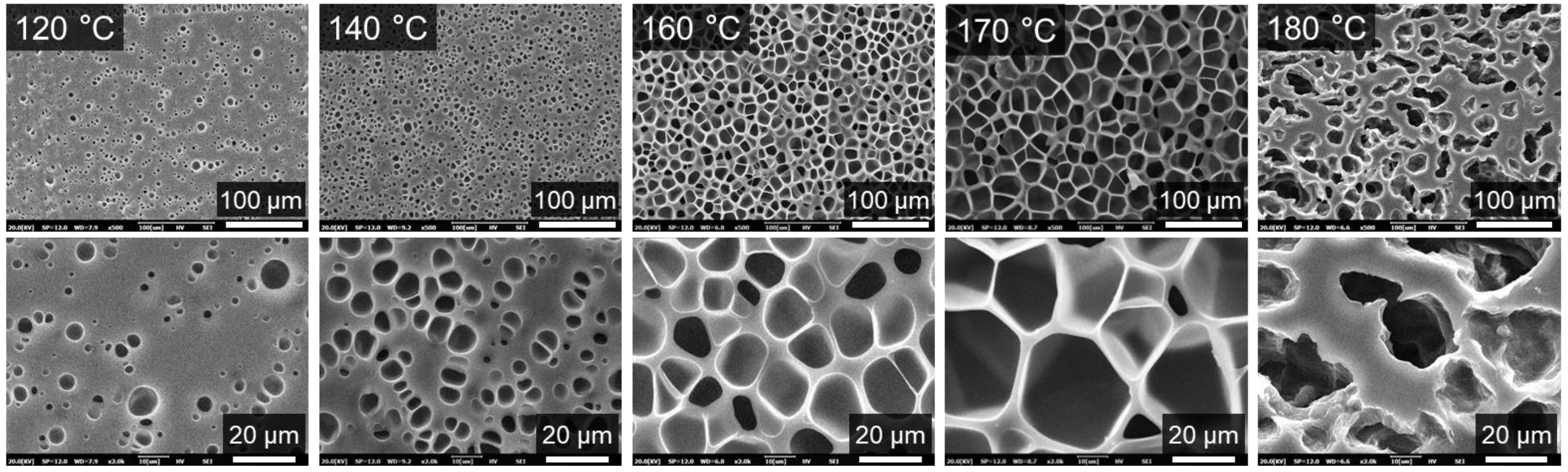

2.3.1. Effect of Saturation Temperature

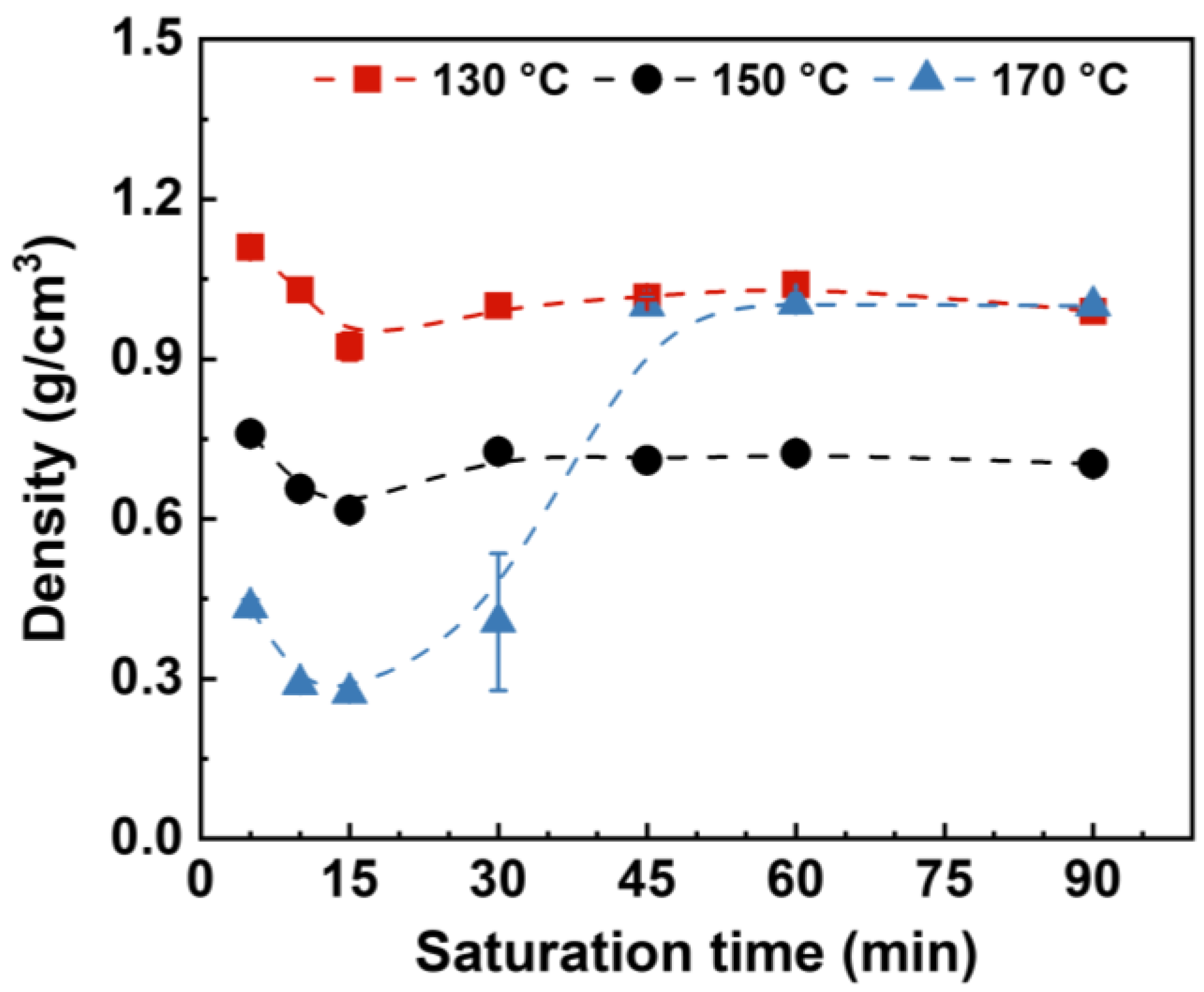

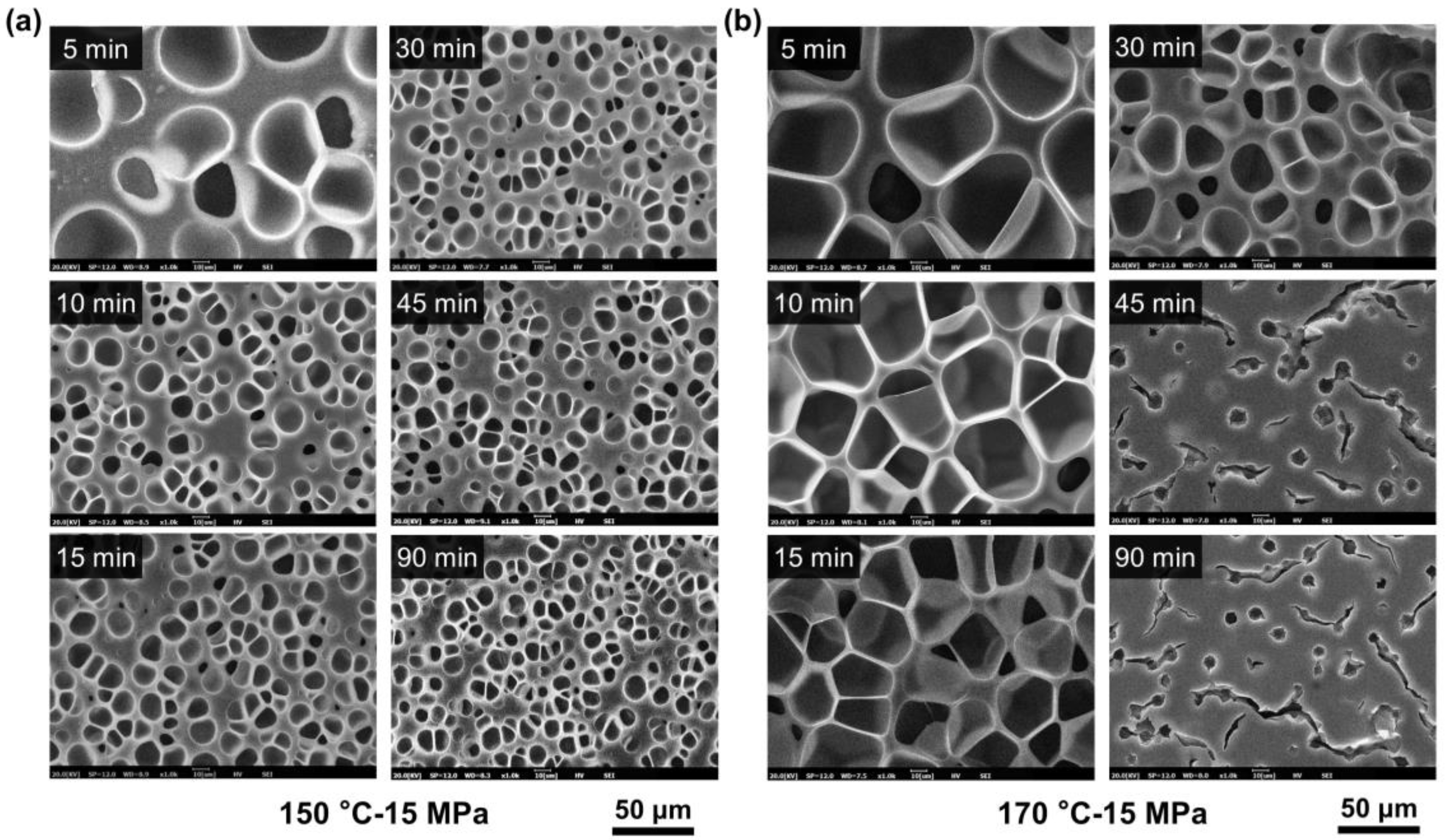

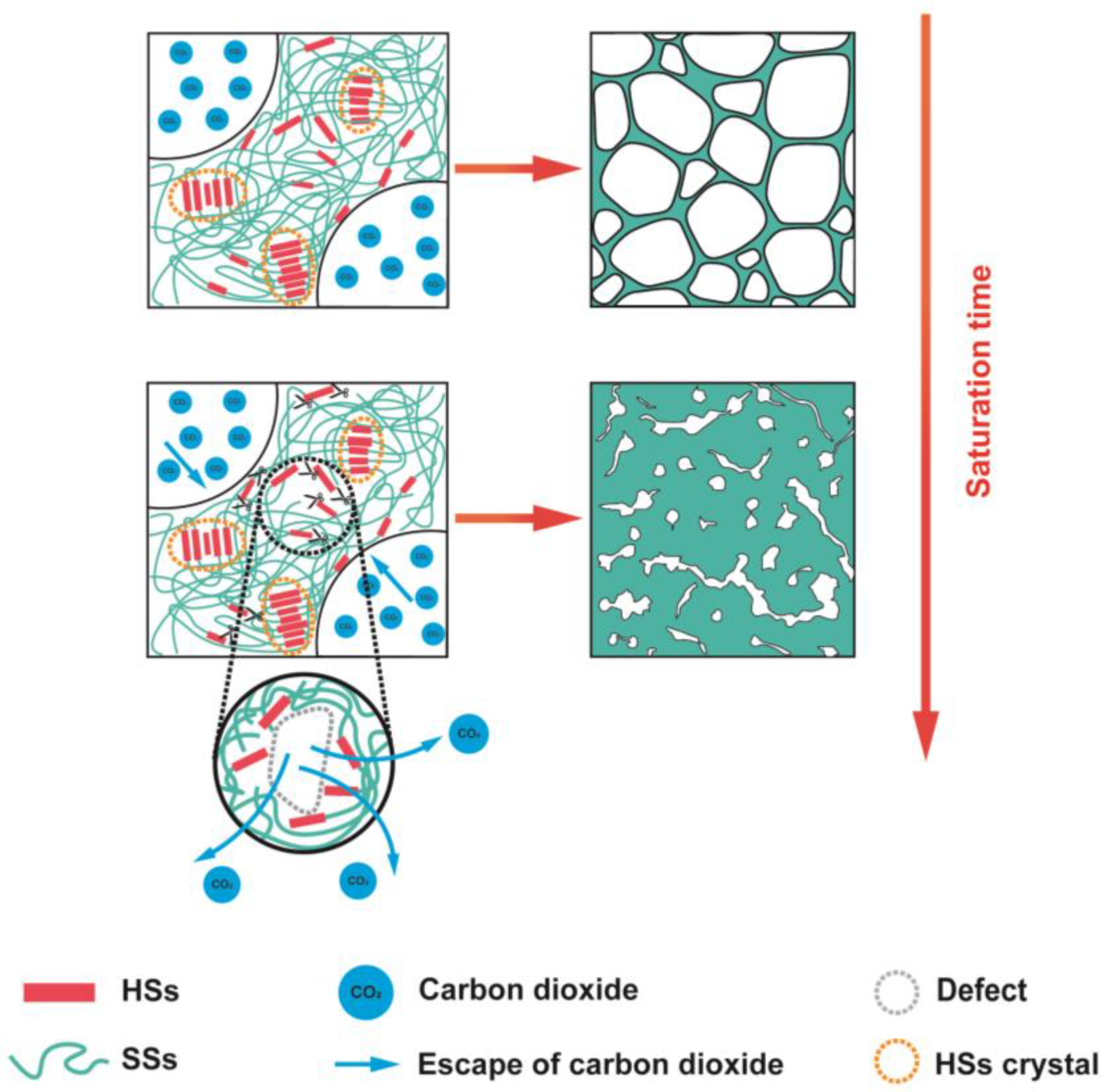

2.3.2. Effect of Saturation Time

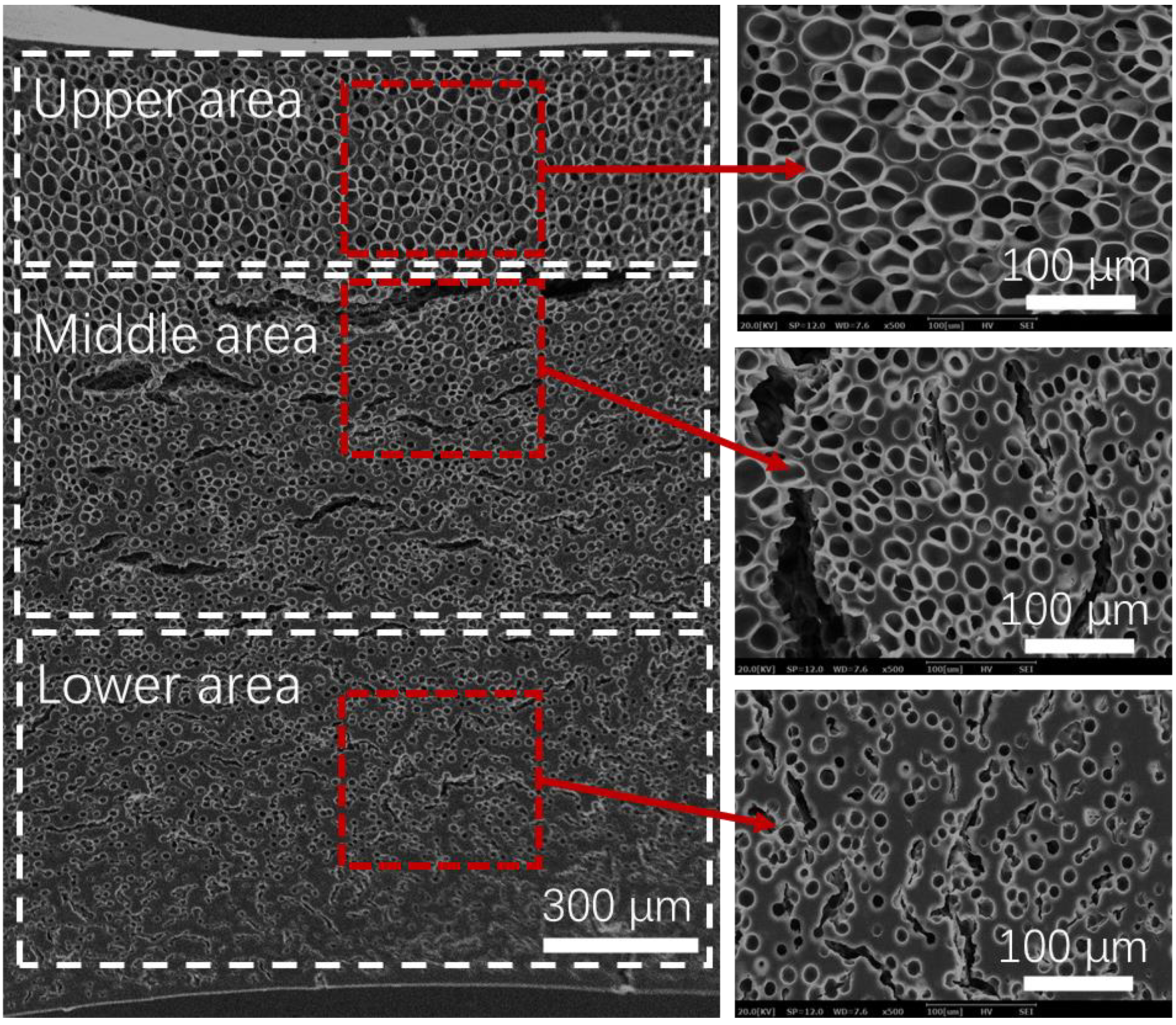

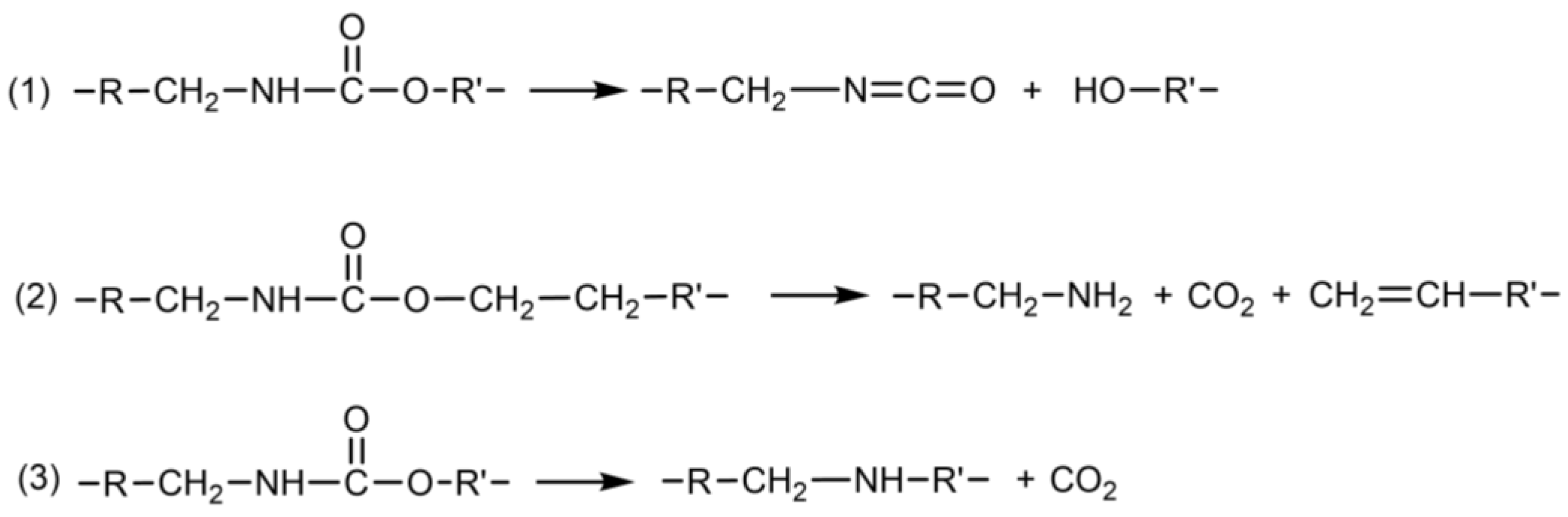

2.4. Molecular Weight Change of HD-TPU before and after Foaming

2.5. The Cell Growth Mechanism of HD-TPU Foams in Degradation Environment

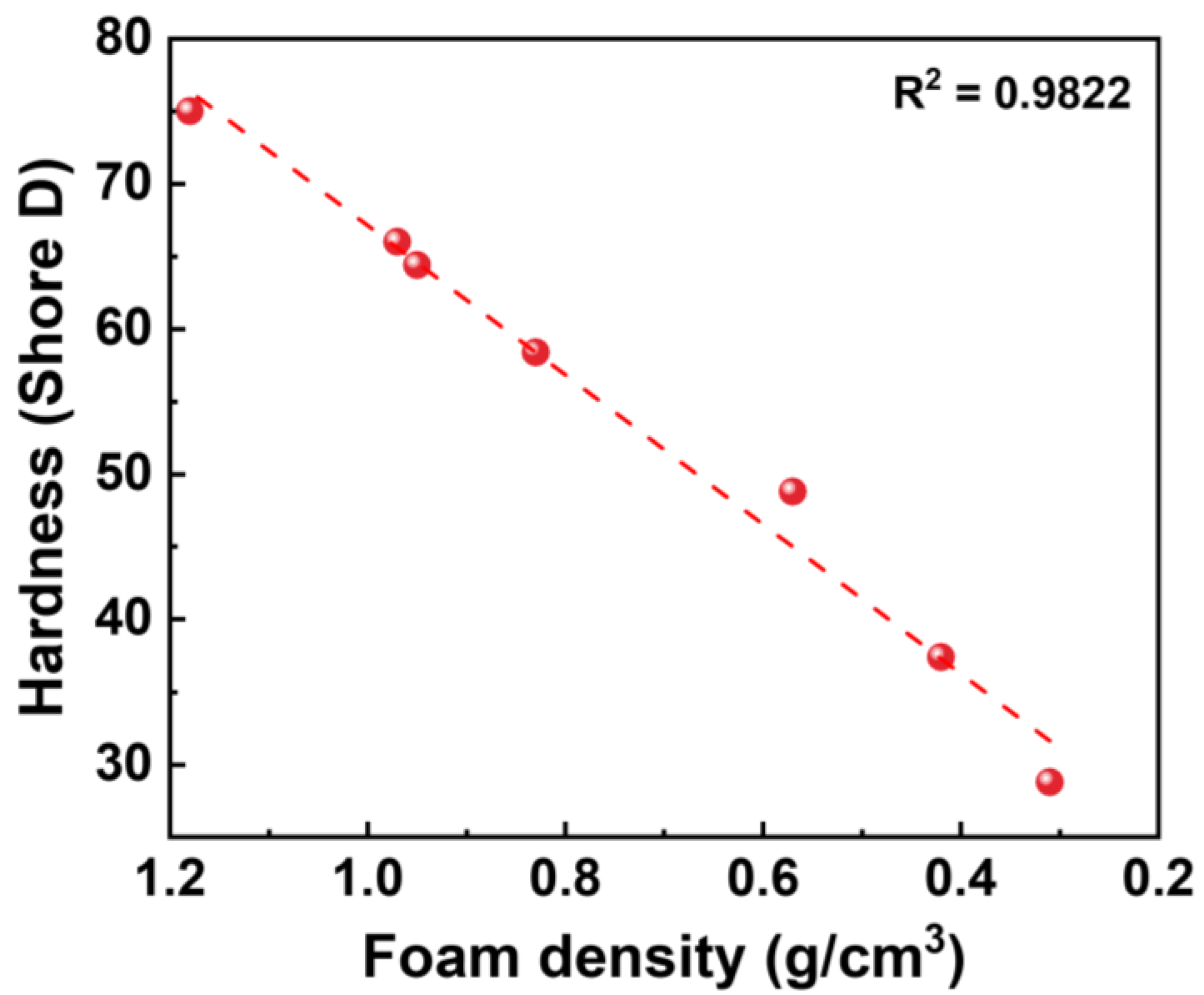

2.6. Hardness of HD-TPU Foams

3. Experimental Section

3.1. Materials

3.2. Sample Preparation

3.3. Characterization

3.3.1. Isothermal Annealing Analysis

3.3.2. FTIR Analysis

3.3.3. DMA of HD-TPU

3.3.4. Thermal Properties of HD-TPU Foams

3.3.5. Cellular Morphology

3.3.6. Determination of Relative Molecular Weight and Dispersibility

3.3.7. Hardness Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- He, Y.; Xie, D.; Zhang, X. The structure, microphase-separated morphology, and property of polyurethanes and polyureas. J. Mater. Sci. 2014, 49, 7339–7352. [Google Scholar] [CrossRef]

- Li, Y.; Ren, Z.; Zhao, M.; Yang, H.; Chu, B. Multiphase structure of segmented polyurethanes: Effects of hard-segment flexibility. Macromolecules 1993, 26, 612–622. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, G.; Zhang, A.; Zhao, G.; Park, C.B. Nanocellular TPU composite foams achieved by stretch-assisted microcellular foaming with low-pressure gaseous CO2 as blowing agent. J. CO2 Util. 2021, 53, 101708. [Google Scholar] [CrossRef]

- Cheng, B.-X.; Gao, W.-C.; Ren, X.-M.; Ouyang, X.-Y.; Zhao, Y.; Zhao, H.; Wu, W.; Huang, C.-X.; Liu, Y.; Liu, X.-Y.; et al. A review of microphase separation of polyurethane: Characterization and applications. Polym. Test. 2022, 107, 107489. [Google Scholar] [CrossRef]

- Shabani, A.; Fathi, A.; Erlwein, S.; Altstädt, V. Thermoplastic polyurethane foams: From autoclave batch foaming to bead foam extrusion. J. Cell. Plast. 2021, 57, 391–411. [Google Scholar] [CrossRef]

- Yeh, S.-K.; Chen, Y.-R.; Kang, T.-W.; Tseng, T.-J.; Peng, S.-P.; Chu, C.-C.; Rwei, S.-P.; Guo, W.-J. Different approaches for creating nanocellular TPU foams by supercritical CO2 foaming. J. Polym. Res. 2017, 25, 30. [Google Scholar] [CrossRef]

- Nozaki, S.; Masuda, S.; Kamitani, K.; Kojio, K.; Takahara, A.; Kuwamura, G.; Hasegawa, D.; Moorthi, K.; Mita, K.; Yamasaki, S. Superior Properties of Polyurethane Elastomers Synthesized with Aliphatic Diisocyanate Bearing a Symmetric Structure. Macromolecules 2017, 50, 1008–1015. [Google Scholar] [CrossRef]

- Solouki Bonab, V.; Manas-Zloczower, I. Revisiting thermoplastic polyurethane, from composition to morphology and properties. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1553–1564. [Google Scholar] [CrossRef]

- Wu, G.; Xie, P.; Yang, H.; Dang, K.; Xu, Y.; Sain, M.; Turng, L.-S.; Yang, W. A review of thermoplastic polymer foams for functional applications. J. Mater. Sci. 2021, 56, 11579–11604. [Google Scholar] [CrossRef]

- Zhao, D.; Lu, X. Chemical mechanical polishing: Theory and experiment. Friction 2013, 1, 306–326. [Google Scholar] [CrossRef]

- Zhai, W.; Jiang, J.; Park, C.B. A review on physical foaming of thermoplastic and vulcanized elastomers. Polym. Rev. 2022, 62, 95–141. [Google Scholar] [CrossRef]

- Fei, Y.; Chen, F.; Fang, W.; Xu, L.; Ruan, S.; Liu, X.; Zhong, M.; Kuang, T. High-strength, flexible and cycling-stable piezo-resistive polymeric foams derived from thermoplastic polyurethane and multi-wall carbon nanotubes. Compos. Part B Eng. 2020, 199, 108279. [Google Scholar] [CrossRef]

- Raps, D.; Hossieny, N.; Park, C.B.; Altstädt, V. Past and present developments in polymer bead foams and bead foaming technology. Polymer 2015, 56, 5–19. [Google Scholar] [CrossRef]

- Ge, C.; Ren, Q.; Wang, S.; Zheng, W.; Zhai, W.; Park, C.B. Steam-chest molding of expanded thermoplastic polyurethane bead foams and their mechanical properties. Chem. Eng. Sci. 2017, 174, 337–346. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, K.; Hu, S.; Liu, Q.; Zhao, X.; Liu, Y. Improved cell morphology and reduced shrinkage ratio of ETPU beads by reactive blending. Polym. Test. 2017, 63, 38–46. [Google Scholar] [CrossRef]

- Jiang, X.; Zhao, L.; Feng, L.; Chen, C. Microcellular thermoplastic polyurethanes and their flexible properties prepared by mold foaming process with supercritical CO2. J. Cell. Plast. 2019, 55, 615–631. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Dong, G.; Mu, Y.; Park, C.B.; Wang, G. Lightweight, super-elastic, and thermal-sound insulation bio-based PEBA foams fabricated by high-pressure foam injection molding with mold-opening. Eur. Polym. J. 2018, 103, 68–79. [Google Scholar] [CrossRef]

- Jiang, J.; Zheng, H.; Liu, H.; Zhai, W. Tunable cell structure and mechanism in porous thermoplastic polyurethane micro-film fabricated by a diffusion-restricted physical foaming process. J. Supercrit. Fluids 2021, 171, 105205. [Google Scholar] [CrossRef]

- Ito, S.; Matsunaga, K.; Tajima, M.; Yoshida, Y. Generation of microcellular polyurethane with supercritical carbon dioxide. J. Appl. Polym. Sci. 2007, 106, 3581–3586. [Google Scholar] [CrossRef]

- Fei, Y.; Jiang, R.; Fang, W.; Liu, T.; Saeb, M.R.; Hejna, A.; Ehsani, M.; Barczewski, M.; Sajadi, S.M.; Chen, F.; et al. Highly sensitive large strain cellulose/multiwalled carbon nanotubes (MWCNTs)/thermoplastic polyurethane (TPU) nanocomposite foams: From design to performance evaluation. J. Supercrit. Fluids 2022, 188, 105653. [Google Scholar] [CrossRef]

- Jiang, J.; Zhou, M.; Li, Y.; Chen, B.; Tian, F.; Zhai, W. Cell structure and hardness evolutions of TPU foamed sheets with high hardness via a temperature rising foaming process. J. Supercrit. Fluids 2022, 188, 105654. [Google Scholar] [CrossRef]

- Sarver, J.A.; Kiran, E. Foaming of polymers with carbon dioxide–The year-in-review—2019. J. Supercrit. Fluids 2021, 173, 105166. [Google Scholar] [CrossRef]

- Leung, L.M.; Koberstein, J.T. DSC annealing study of microphase separation and multiple endothermic behavior in polyether-based polyurethane block copolymers. Macromolecules 1986, 19, 706–713. [Google Scholar] [CrossRef]

- Frick, A.; Rochman, A. Characterization of TPU-elastomers by thermal analysis (DSC). Polym. Test. 2004, 23, 413–417. [Google Scholar] [CrossRef]

- Saiani, A.; Novak, A.; Rodier, L.; Eeckhaut, G.; Leenslag, J.W.; Higgins, J.S. Origin of Multiple Melting Endotherms in a High Hard Block Content Polyurethane: Effect of Annealing Temperature. Macromolecules 2007, 40, 7252–7262. [Google Scholar] [CrossRef]

- Zhai, W.; Ko, Y.; Zhu, W.; Wong, A.; Park, C.B. A Study of the Crystallization, Melting, and Foaming Behaviors of Polylactic Acid in Compressed CO2. Int. J. Mol. Sci. 2009, 10, 5381–5397. [Google Scholar] [CrossRef]

- Koberstein, J.T.; Galambos, A.F. Multiple melting in segmented polyurethane block copolymers. Macromolecules 1992, 25, 5618–5624. [Google Scholar] [CrossRef]

- Li, Y.; Liu, J.; Yang, H.; Ma, D.; Chu, B. Multiphase structure of segmented polyurethanes: Its relation with spherulite structure. J. Polym. Sci. Part B Polym. Phys. 1993, 31, 853–867. [Google Scholar] [CrossRef]

- Saiani, A.; Daunch, W.A.; Verbeke, H.; Leenslag, J.W.; Higgins, J.S. Origin of Multiple Melting Endotherms in a High Hard Block Content Polyurethane. 1. Thermodynamic Investigation. Macromolecules 2001, 34, 9059–9068. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, F.; Yang, X.; Xiong, Z.; Liu, H.; Xu, D.; Zhai, W. Evolution of ordered structure of TPU in high-elastic state and their influences on the autoclave foaming of TPU and inter-bead bonding of expanded TPU beads. Polymer 2021, 228, 123872. [Google Scholar] [CrossRef]

- Balko, J.; Fernández-d’Arlas, B.; Pöselt, E.; Dabbous, R.; Müller, A.J.; Thurn-Albrecht, T. Clarifying the Origin of Multiple Melting of Segmented Thermoplastic Polyurethanes by Fast Scanning Calorimetry. Macromolecules 2017, 50, 7672–7680. [Google Scholar] [CrossRef]

- Kong, Z.; Ying, W.B.; Hu, H.; Wang, K.; Chen, C.; Tian, Y.; Li, F.; Zhang, R. Formation of crystal-like structure and effective hard domain in a thermoplastic polyurethane. Polymer 2020, 210, 123012. [Google Scholar] [CrossRef]

- Pongkitwitoon, S.; Hernández, R.; Weksler, J.; Padsalgikar, A.; Choi, T.; Runt, J. Temperature dependent microphase mixing of model polyurethanes with different intersegment compatibilities. Polymer 2009, 50, 6305–6311. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhou, T.; Li, L.; Zhang, J.; Liu, X.; Ke, X.; Zhang, A. Hydrogen bond breaking of TPU upon heating: Understanding from the viewpoints of molecular movements and enthalpy. RSC Adv. 2015, 5, 31153–31165. [Google Scholar] [CrossRef]

- Bonart, R. Thermoplastic elastomers. Polymer 1979, 20, 1389–1403. [Google Scholar] [CrossRef]

- Gallu, R.; Méchin, F.; Dalmas, F.; Gérard, J.-F.; Perrin, R.; Loup, F. On the use of solubility parameters to investigate phase separation-morphology-mechanical behavior relationships of TPU. Polymer 2020, 207, 122882. [Google Scholar] [CrossRef]

- Wu, C.-H.; Huang, Y.-C.; Chen, W.-L.; Lin, Y.-Y.; Dai, S.A.; Tung, S.-H.; Jeng, R.-J. Size-dependent phase separation and thermomechanical properties of thermoplastic polyurethanes. Polymer 2020, 210, 123075. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, F.; Chen, B.; Li, Y.; Yang, X.; Tian, F.; Xu, D.; Zhai, W. Microstructure development of PEBA and its impact on autoclave foaming behavior and inter-bead bonding of EPEBA beads. Polymer 2022, 256, 125244. [Google Scholar] [CrossRef]

- Ren, Q.; Wang, J.; Zhai, W.; Su, S. Solid State Foaming of Poly(lactic acid) Blown with Compressed CO2: Influences of Long Chain Branching and Induced Crystallization on Foam Expansion and Cell Morphology. Ind. Eng. Chem. Res. 2013, 52, 13411–13421. [Google Scholar] [CrossRef]

- Taki, K.; Tabata, K.; Kihara, S.-i.; Ohshima, M. Bubble coalescence in foaming process of polymers. Polym. Eng. Sci. 2006, 46, 680–690. [Google Scholar] [CrossRef]

- Zhai, W.; Kuboki, T.; Wang, L.C.; Park, C.B.; Lee, E.K.; Naguib, H.E. Cell Structure Evolution and the Crystallization Behavior of Polypropylene/Clay Nanocomposites Foams Blown in Continuous Extrusion. Ind. Eng. Chem. Res. 2010, 49, 9834–9845. [Google Scholar] [CrossRef]

- Nofar, M.; Büşra Küçük, E.; Batı, B. Effect of hard segment content on the microcellular foaming behavior of TPU using supercritical CO2. J. Supercrit. Fluids 2019, 153, 104590. [Google Scholar] [CrossRef]

- Ghariniyat, P.; Leung, S.N. Development of thermally conductive thermoplastic polyurethane composite foams via CO2 foaming-assisted filler networking. Compos. Part B Eng. 2018, 143, 9–18. [Google Scholar] [CrossRef]

- Wang, G.; Wan, G.; Chai, J.; Li, B.; Zhao, G.; Mu, Y.; Park, C.B. Structure-tunable thermoplastic polyurethane foams fabricated by supercritical carbon dioxide foaming and their compressive mechanical properties. J. Supercrit. Fluids 2019, 149, 127–137. [Google Scholar] [CrossRef]

- Lan, B.; Li, P.; Luo, X.; Luo, H.; Yang, Q.; Gong, P. Hydrogen bonding and topological network effects on optimizing thermoplastic polyurethane/organic montmorillonite nanocomposite foam. Polymer 2021, 212, 123159. [Google Scholar] [CrossRef]

- Zhuang, H.-T.; Zhang, L.; Bao, J.-B. Enhanced foaming behaviors and compression properties of thermoplastic polyurethane via constructing micro-crosslinking structure assisted by chain extender. Colloid Polym. Sci. 2022, 300, 851–859. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, G.; Wang, M. Investigation of the effect of foaming process parameters on expanded thermoplastic polyurethane bead foams properties using response surface methodology. J. Appl. Polym. Sci. 2018, 135, 46327. [Google Scholar] [CrossRef]

- Zhang, T.; Lee, S.-J.; Yoo, Y.H.; Park, K.-H.; Kang, H.-J. Compression Molding of Thermoplastic Polyurethane Foam Sheets with Beads Expanded by Supercritical CO2 Foaming. Polymers 2021, 13, 656. [Google Scholar] [CrossRef]

- Lan, B.; Li, P.; Yang, Q.; Gong, P. Dynamic self generation of hydrogen bonding and relaxation of polymer chain segment in stabilizing thermoplastic polyurethane microcellular foams. Mater. Today Commun. 2020, 24, 101056. [Google Scholar] [CrossRef]

- Wang, G.; Liu, J.; Zhao, J.; Li, S.; Zhao, G.; Park, C.B. Structure-gradient thermoplastic polyurethane foams with enhanced resilience derived by microcellular foaming. J. Supercrit. Fluids 2022, 188, 105667. [Google Scholar] [CrossRef]

- Xie, F.; Zhang, T.; Bryant, P.; Kurusingal, V.; Colwell, J.M.; Laycock, B. Degradation and stabilization of polyurethane elastomers. Prog. Polym. Sci. 2019, 90, 211–268. [Google Scholar] [CrossRef]

- Dyer, E.; Read, R.E. Thermal Degradation of O-1-Hexadecyl N-1-Naphthylcarbamates and Related Compounds. J. Org. Chem. 1961, 26, 4388–4394. [Google Scholar] [CrossRef]

- Ingham, J.D.; Rapp, N.S. Polymer degradation. II. Mechanism of thermal degradation of polyoxypropylene glycol-toluene 2,4-diisocyanate polymer (POPG-TDI) and a block polyether glycol-TDI polymer. J. Polym. Sci. A 1964, 2, 4941–4964. [Google Scholar] [CrossRef]

- Woolley, W.D. Nitrogen-containing products from the thermal decomposition of flexible polyurethane foams. Br. Polym. J. 1972, 4, 27–43. [Google Scholar] [CrossRef]

- Yang, W.P.; Macosko, C.W.; Wellinghoff, S.T. Thermal degradation of urethanes based on 4,4′-diphenylmethane diisocyanate and 1,4-butanediol (MDI/BDO). Polymer 1986, 27, 1235–1240. [Google Scholar] [CrossRef]

- Pang, Y.; Cao, Y.; Zheng, W.; Park, C.B. A comprehensive review of cell structure variation and general rules for polymer microcellular foams. Chem. Eng. J. 2022, 430, 132662. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, G.; Zhao, J.; Zhang, A.; Zhao, G. Super-elastic and structure-tunable poly(ether-block-amide) foams achieved by microcellular foaming. J. CO2 Util. 2022, 55, 101807. [Google Scholar] [CrossRef]

| Tm/°C | Tm1 | Tm2 | Tm3 | Tm4 | Tm5 | |

|---|---|---|---|---|---|---|

| Ta/°C | ||||||

| Unannealed | 51.2 | 180.4 | 190.0 | 199.3 | / | |

| 100 | 118.4 | 182.3 | 190.8 | 200.5 | / | |

| 120 | 135.7 | 182.3 | 190.4 | 200.6 | / | |

| 140 | 154.8 | 182.3 | 190.0 | 200.5 | / | |

| 160 | 176.5 | 183.2 | 190.8 | 200.8 | / | |

| 180 | / | 192.5 | 194.4 | 201.8 | 212.6 | |

| Sampels | Saturation Temperature (°C) | Saturation Time (min) | Mn (kg/mol) | Mw (kg/mol) | PDI |

|---|---|---|---|---|---|

| Unfoamed | / | / | 101.2 | 181.5 | 1.8 |

| Foam | 170 | 5 | 102.2 | 178.0 | 1.7 |

| Foam | 170 | 15 | 93.5 | 158.6 | 1.7 |

| Foam (upper) | 170 | 30 | 85.4 | 144.7 | 1.7 |

| Foam (lower) | 170 | 30 | 79.8 | 133.5 | 1.7 |

| Foam | 170 | 60 | 72.9 | 121.2 | 1.7 |

| Foam | 170 | 90 | 72.1 | 120.7 | 1.7 |

| Foam | 180 | 30 | 74.8 | 125.2 | 1.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Jiang, J.; Li, Y.; Zhou, M.; Wang, Z.; Wang, L.; Zhai, W. Supercritical Fluid Microcellular Foaming of High-Hardness TPU via a Pressure-Quenching Process: Restricted Foam Expansion Controlled by Matrix Modulus and Thermal Degradation. Molecules 2022, 27, 8911. https://doi.org/10.3390/molecules27248911

Chen B, Jiang J, Li Y, Zhou M, Wang Z, Wang L, Zhai W. Supercritical Fluid Microcellular Foaming of High-Hardness TPU via a Pressure-Quenching Process: Restricted Foam Expansion Controlled by Matrix Modulus and Thermal Degradation. Molecules. 2022; 27(24):8911. https://doi.org/10.3390/molecules27248911

Chicago/Turabian StyleChen, Bichi, Junjie Jiang, Yaozong Li, Mengnan Zhou, Zelin Wang, Liang Wang, and Wentao Zhai. 2022. "Supercritical Fluid Microcellular Foaming of High-Hardness TPU via a Pressure-Quenching Process: Restricted Foam Expansion Controlled by Matrix Modulus and Thermal Degradation" Molecules 27, no. 24: 8911. https://doi.org/10.3390/molecules27248911

APA StyleChen, B., Jiang, J., Li, Y., Zhou, M., Wang, Z., Wang, L., & Zhai, W. (2022). Supercritical Fluid Microcellular Foaming of High-Hardness TPU via a Pressure-Quenching Process: Restricted Foam Expansion Controlled by Matrix Modulus and Thermal Degradation. Molecules, 27(24), 8911. https://doi.org/10.3390/molecules27248911