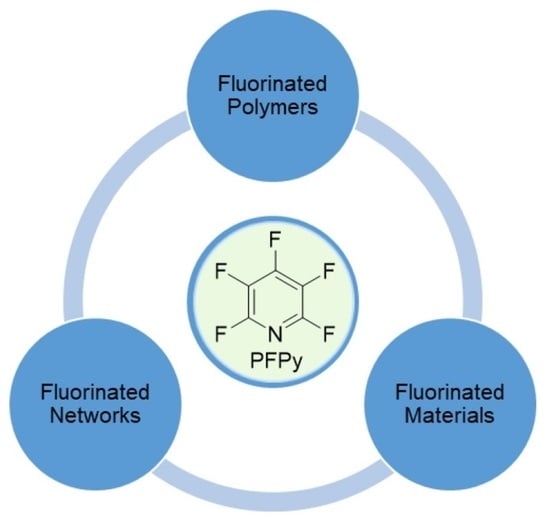

4. Perfluoropyridine Used in Polymers and Materials

Since Teflon’s serendipitous discovery in 1938 by Roy J. Plunkett [

50], the search for new fluorinated polymers and materials has continued. There are a considerable number of peer-reviewed reports highlighting this unique class of materials, their highly sought after properties, and advanced applications. In fact, just within the last five years alone, over 100 review articles and book chapters have been published on the topic of fluorinated materials and polymers [

35]. The driving force for this is the continued demand for new and improved materials for advanced applications. Adding to the properties observed with simple organofluorine compounds, fluoropolymers and materials are also endowed with having low dielectric constants, refractive indexes, surface energy, flammability, and water absorptivity [

51]. Furthermore, these materials are often more mechanically durable and morphologically diverse [

52]. With such robust attributes, this unique class of materials has found use in a variety of specialized areas including the aerospace and automotive industries, advanced surfaces and coatings, medical devices, structural components, and many more [

53,

54].

Synthetic methods to obtain fluoropolymers and networks vary widely. As with simple organofluorine molecules, a fluoropolymer or fluorinated material can be achieved by direct fluorination methods [

55] or by using a fluorinated monomer or building block [

11]. With PFPy’s unique and high reactivity, it has been utilized in both routes—to fluorinate an existing polymer or material and to prepare more diverse fluorinated building blocks. The use of PFPy in fluorinated networks and polymers will be discussed below.

One of the first known reports of using PFPy for the synthesis of polymeric materials was presented in the late 1970s by Johncock, Hewins, and Cunliffe [

56]. With the implementation of PFPy in the polymers, the authors’ objective was to obtain fluoropolymers that exhibited enhanced structural and oxidative stability, low glass transition temperatures (

Tgs), and elastomeric properties, making the fluoropolymers appropriate materials for applications in the aerospace industry. With the knowledge that PFPy is reactive towards nucleophilic substitution and that it exhibits bifunctionality, the authors employed the Williamson Ether synthetic method to prepare new PFPy-based fluoropolymers. In one example, the authors initially reacted PFPy with the sodium salt of 2,2,3,3,4,4,4-heptafluoro-1-butanol to obtain a polymeric precursor,

1. Precursor

1 was further reacted with the sodium salt of 2,2,3,3,4,4-hexafluoro-1-5-pentandiol to obtain a PFPy-based polymer (

2,

Scheme 8) [

56].

Upon purification of the sample by solvent fractionation and characterization by

19F NMR, the authors determined that the fluoropolymer obtained was a mixture of a homopolymer (

n = 0, m = 1), which was the result of the expected nucleophilic addition at 4-position, and copolymer (

n/m = 2), which was the result of the nucleophilic substitution reaction in the 4-position and the competing displacement reaction between the fluorinated butoxy group and the fluorine atoms in the 2- and 6-positions [

57].

In another example, the authors also prepared a different copolymer by reacting the sodium salt of 2,2,3,3,4,4-hexafluoro-1-5-pentandiol with PFPy (

Scheme 9) [

56]. Under these conditions, the authors were able to obtain about 70% soluble polymer and roughly 6% of an insoluble gel. The gel was believed to be a network which resulted from the tri-substitution of the PFPy ring. The polymer fraction was isolated by solvent displacement.

The copolymer structure of

3 was determined by

19F NMR. Since the nucleophilic substitution of PFPy is more favorable at the 4-position than the 2 or 6-position [

58,

59], the authors concluded, that intermediates

4 and

5 (

Figure 1) will likely form first. Intermediates

4 and

5 would then serve as the main building blocks of the fluoropolymer and support the structure of

3 [

56].

The polymers shown in

Scheme 8 and

Scheme 9 were also characterized by differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and their viscosities were determined.

Table 2 summarizes the data collected for

2 and

3 [

56].

About 10 years later, the next known study of using PFPy in a polymer was reported by Banks and Tsilliopoulos [

60]. In their example, the authors initially brominated and then lithiated linear polystyrene. The lithiated polystyrene was then reacted with PFPy to yield

6 (

Scheme 10) [

60]. Polymer

6 was fully fluorinated by treatment with F

2/N

2. No experimental or characterization data were provided for

6, or the final, fully fluorinated material. This is the first study where PFPy is employed as a pendant group on the polymer vs. the backbone of the polymer/network. The PFPy was also not included in the original monomer but incorporated as the pendant group, post-polymerization.

In a later study by Seyb and Kerres, the authors used PFPy to prepare sulfonated poly(arylene ethers) for potential applications in proton exchange membranes (PEMs) [

61]. Initially, compound

7 was prepared by the nucleophilic thiolation of PFPy, followed by oxidation of the thiol to sulfonic acid. Next,

7 was reacted with 4.4′-thiobisbenzenethiol or 4,4′-dihydroxybiphenol to obtain a new poly(arylene thioether) or poly(arylene ether), respectively (

8 or

9,

Scheme 11) [

61]. Characterization of polymer

8 and

9 by

19F NMR analysis indicated the structures shown.

GPC analysis was used to determine the number average molecular weight (

Mn), weighted average molecular weight (

Mw), and dispersity (

Ɖ) of

8 and

9. Once characterized, the authors blended the polymers shown with polybenzimidazole (PBI)-Celazol

® in order to obtain PEMs that could be utilized in polymer electrolyte fuel cells. By incorporating

8 or

9 into the blend, the authors hoped to enhance the thermal stability and chemical resistance of the membrane towards H

3PO

4. Characterization of the polymers and blends by TGA-FTIR demonstrated that the onset of degradation for the sulfonic acid groups (T

SO3H) ranged between 328 and 419 °C, whereas the degradation of the polymer backbone (T

backbone) ranged between 332 and 461 °C. Additionally,

9 and its corresponding blend were more thermally stable than the

8 and its blend. Overall, the blends were more thermally stable than the polymers alone. In terms of oxidative stability, as determined by Fenton’s test, the authors concluded that future work to obtain higher molecular weight polymers was needed to fully optimize this parameter. The conductivity of the blends was also tested and compared to Nafion

®. The films were stable up to 180 °C and also outperformed Nafion

®. The results from the analyses performed by Seyb and Kerres are summarized in

Table 3 [

61].

Between 2007 and 2013, Vaganova et al. utilized PFPy to make a number of fluorinated pryidylenediamine monomers (

10–

14,

Scheme 12) [

62,

63,

64].

These monomers were then used in a later study to prepare fluorinated polyimides (PIs) and co-polyimides (co-PIs), using one-step polycondensation reactions. The polymers were prepared for potential applications as materials for carbonized membranes [

64]. For the PIs, a stepped heating was used and all polymerizations were carried out in benzoic acid (BA) melts (

Scheme 13) [

64]. The number average molecular weights of the PIs were determined by

19F NMR.

Similarly, the co-PIs were prepared from monomers

11–

14 and 4,4′-oxydianiline in order to obtain higher molecular weight polymers that exhibit enhanced mechanical properties (

Scheme 14) [

63]. The molecular weights were not determined for the co-PIs, but the authors concluded that they had higher molecular weights than the PIs because these materials had increased viscosities.

The PIs and co-PIs were thermally and thermo-oxidatively characterized using DSC and TGA analysis. The

Tgs of the PIs were found to be higher than the co-PIs. The lower

Tgs obtained for the co-PIs were attributed to the increased flexibility of the polymers as a result of the incorporation of 4,4′-oxydianiline. The polymeric materials demonstrated good thermal and oxidative stabilities, with most having T

5% ≥ 500 °C.

Table 4 summarizes some of the characterization data obtained by Vaganova et al. [

64]. Mechanical testing was performed using dynamic mechanical analysis (DMA) on films prepared from the co-PIs. These materials retained their storage modulus up to their

Tgs. The authors concluded that the co-PI films had good thermomechanical properties as a result of the 4,4′-oxydianiline; however, the PIs were not analyzed by DMA.

The PIs were pyrolyzed under inert conditions and the chemical composition was analyzed at various temperatures in order to evaluate the polymers’ potential for use in carbonized materials. It was determined that the PIs underwent a selective and consecutive elimination of the different heteroatoms contained within and this could be utilized to tailor the properties of the nanostructured carbonized membranes formed from PIs

10–

14 [

64].

In 2018, Nedel’ko et al. synthesized 3,5-difluoro-2-4-6-triazidopyridine using a previously published method, which involved the SNAr of PFPy with sodium azide [

65]. The authors then studied the thermal decomposition of

15 using DSC. The degradation products were also characterized using IR spectroscopy [

66]. Comparing the IR spectra of the degradation products of

15 with previously studied compounds (2,4,6-triazidopyridne, 2,4,6-triazidopyrimidine, and cyanuric triazide), the authors determined that because

15 lacks hydrogen atoms, its degradation mechanism favors the formation of a network of planar polyconjugated carbon–nitrogen porphyrin-like structures as a result of a complex chain polymerization (

Scheme 15) [

66].

Additionally, in 2018, Yu and co-workers utilized PFPy to prepare porous β-cyclodextrin (β-CD) polymers for use in the removal of heavy metals and organic pollutants from water [

67]. In their study, the authors utilized PFPy to join EDTA-modified chitosan with β-CD (or cellulose, sodium alginate, and alkali lignin) through the SNAr reaction of the hydroxyl groups of the biomolecules (

Scheme 16) [

67].

The resulting polymer,

16, was characterized by FT-IR and solid state

13C NMR spectroscopy, which confirmed the incorporation of PFPy with the EDTA-modified chitosan and β-CD polymers. Further characterization by Brunauer–Emmett–Teller (BET) surface area analysis and scanning electron microscopy (SEM) indicated that

16 was porous and had a specific surface area of 47.8 m

2/g, making it a promising material for an adsorbent. Energy dispersive X-ray analysis showed that

16 contained both nitrogen and fluorine, supporting the results observed by FT-IR and solid state

13C NMR spectroscopy. Adsorption studies were conducted with

16 and Pb (II), Ni (II), Cu (II), bisphenol A, trichlorophenol, and 6-bromo-2-napthol. The polymer was found to remove the contaminants with over 91% efficiency, whereas a sample consisting of cross-linked β-CD polymer only had a 40% efficiency under comparable conditions. Furthermore,

16 was found to be recyclable and, after five cycles, still maintained over 91% adsorption capacity [

67].

In 2019, Corley et al. demonstrated [2 + 2 + 2] cyclopolymerizations of 2,6-bis(4-ethynylphenoxy)-3,5-difluoro-4-aryloxypyridine (

17) for thermoset resins having intractable polyarylene networks [

68]. All the polymeric products communicated in their work were derived from commercially sourced feed stocks of PFPy and functionalized phenols. To synthesize

17, oxygen-based nucleophiles go through a selective SNAr reaction with PFPy specifically at the 4-postion using potassium carbonate. The additions at the 2 and 6-positions onto PFPy are then favorable with 4-iodo-phenol when using cesium carbonate in DMF. To complete the monomer (

17), palladium and copper iodide are used to couple an ethyne onto the aromatic ring, by way of interacting TMS-ethyne with the iodo-bond on the aromatic ring. Thermal analysis indicated crosslinking of the monomer to form Network

17 (

Scheme 17) [

68].

Further cycloadditions were also considered and demonstrated. For example, 1,3-dipolar alkyne-azide “click” cycloaddition reactions were accomplished with the reaction of

17 with mono- or bis-(azidomethyl) benzene, generating a variety of polytriazole polymers (

Figure 2) [

68].

In all cases, these network materials showed excellent temperature resistance. The 2 + 2 + 2 cycloaddition networks exhibited thermal decomposition onset at 450 °C. The slow, near-linear weight loss of 45 wt% from 500 °C to 1000 °C (0.9 wt% °C − 1) under nitrogen is indicative of a highly dense network of carbonaceous material. A 20 wt% glassy carbon char was evident at 1000 °C. For the “click” cycloaddition polymer, the onset of degradation at 300 °C with linear decomposition to a glassy carbon char yield of 10 wt% is typical for polytriazoles with molecular weights between 2000 and 8000 g/mol. The authors also suggested that the high thermal stability indicated that the cycloadditions did not compromise the fluorinate pyridine core repeat unit [

68].

In early 2020, Moore and co-workers prepared a new class of semifluorinated thiol-ene thermoset materials that were explored as aerospace sealants and coatings [

69]. In this study, the authors developed two new trisubstituted alkene monomers,

18 and

19, by reacting 4-penten-1-ol and eugenol with PFPy (

Scheme 18) [

69].

Thiol-ene thermoset materials were synthesized using 3,6-dioxa-1,8-octan-edithiol (ODT) and trimethylolpropane tris(mercaptopropionate) (TMPMP) and the newly targeted alkene monomers. Formulations were mixed at a 1:1 thiol:ene ratio, with 1 wt% of 2,2-dimethoxy-2-phenylacetophe-none (DMPA) as the UV photo-initiator (

Figure 3) [

69].

The resulting polymeric systems based on these novel monomers demonstrated

Tgs ranging from −42 to 21 °C. The use of the trifunctional thiol results in a higher

Tg (i.e., TMPMP). Thermal degradation temperatures at 5% mass loss (

Td,5%) spanned from 274 to 348 °C in nitrogen and char yields varied from 13.2 to 28.7% (see

Table 5) [

69].

This new class of semifluorinated thermoset materials with their measured properties have several potential applications within the aerospace industry, such as sealants and coatings, where stability and survivability at high temperatures in harsh environmental conditions are imperative [

69].

At around the same time, Houck et al. reported the synthesis of two highly soluble high aromatic content (HAC) perflfluoropyridine-based thermosetting precursors [

70]. Previously, to obtain polymers or materials that contain HAC, transition-metal-catalyzed coupling or harsh fluorination methods were required. However, utilizing the reactivity of PFPy towards SNAr, Houck et al. readily obtain monomers

22 and

23 in moderate yields. Initially, regioselective nucleophilic addition takes place with PFPy by first reacting it with lithiated 1,2-diphenylethyne or anthracene at the 4-position, to generate compounds

20 and

21, respectively. To complete the monomers, further reactions are accomplished at both the 2 and 6-position by lithiated 1,2-diphenylethyne to generate monomers

22 and

23, respectively (

Scheme 19) [

70].

Upon curing

22 and

23 at 341 and 372 °C (

Tmax), respectively, both systems yielded insoluble cross-linked networks. The cured network of

22 displayed an onset of decomposition (

Td) of 470 °C and a char yield of 51% at 900 °C, while the cured network of

23 displayed a

Td of 456 °C and a char yield of 81% at 900 °C (

Table 6) [

70].

The ease of thermal setting, combined with the formation of rigid cross-linked networks of highly densified polyarylenes exhibiting high decomposition temperatures and high char yields indicate these thermoset polymers are promising templates for nanomaterials in microelectronics and for use in high-temperature applications in the aerospace industry [

70].

In mid-2020, Eismeier and co-workers employed PFPy to prepare step-growth polymers and networks [

71]. To prepare the step-growth polymers, compound

24 was prepared by SNAr reaction of PFPy with phenylmagnesium bromide [

72]. This was then reacted with bisphenol A (BPA) to obtain the step-growth polymer,

24 (

Scheme 20) [

71].

19F NMR indicated successful nucleophilic addition and formation of the desired polymer. End group analysis of

25 by

1H NMR indicated a molecular weight of 4000 g/mol.

Additionally, PFPy was reacted using similar conditions with 1,3,5-benzenetrimethanol or phloroglucinol to prepare fluorinated network materials,

26 and

27, respectively (

Scheme 21) [

71].

Networks

26 and

27 were thermally characterized by DSC and TGA. The results from these studies are summarized in

Table 7. The TGA analysis was performed under argon. Given the char yield of the networks and chemical composition of the materials,

25–

27 could find potential applications for resins in the aerospace industry, low surface energy materials, and low dielectric constant materials [

71].

In June of 2020, Gomri et al. prepared new poly(ether pyridine) polymers for the capture of aromatic pollutants such as p-hydroxybenzoic acid, toluic acid, deisopropylatrazine, and 2,4,6-trichlorophenol, along with their halogenated derivatives, in contaminated water sources [

73]. To synthesize the beginning monomers, SNAr was again utilized by adding nitrogen- and oxygen-based nucleophiles to PFPy (

Scheme 22) [

73]. In all cases, the nucleophile was added in the 4-position of PFPy, due to the stabilizing effect of the nitrogen carrying the extra but momentary negative charge, and resulted in the formation of pyridinium-based monomers.

Once the monomers were obtained, polycondensation reactions with bisphenol A (BPA) and isosorbide (IS) were performed to obtain the poly(ether pyridine) polymers. In order to perform the polycondensation, more forcing conditions were necessary. Both diols, BPA and IS, were heated to 140 °C and 160 °C, respectively (

Scheme 23) [

73].

The resulting polymers were thermally characterized by DSC and TGA. The polymers had a

Tg range of 102 to 206 °C and the 5% decomposition temperature ranged from 346 to 419 °C. The molecular weights determined by GPC did vary depending upon the monomers that were used. The largest molecular weight obtained with IS was evident with monomer

28, resulting in a number average molecular weight (

Mn) of 21,330 g/mol. Were as for BPA, there were two monomers which performed decently in the polymerization,

28 and

30 having

Mn of 105,700 g/mol and 25,170 g/mola, respectively. The dispersity for all the polymers ranged from 1.3 to 4.5 (see

Table 8) [

73].

The adsorption characteristics of the polymers were evaluated towards a variety of aromatic pollutants and their halogenated derivatives. Polymers based on IS showed improved adsorption capacity towards all the pollutants tested. Furthermore, polymers containing the morpholine-based monomer,

28, demonstrated enhanced absorption efficiencies greater than 90%. Thus, of all the polymers tested,

28/IS had the highest efficiency towards the pollutants and their derivatives. The adsorption kinetics were found to fit well to a pseudo-second order mechanism, obeying a Freundlich isotherm model [

73].

In mid-2021, Stewart and co-workers were able to demonstrate that PFPy could be deployed in high-temperature silicon-based linear and network elastomers and oils [

74]. As seen in the other examples above, the authors utilized the regioselective SNAr reaction to prepare a number of new PFPy-based monomers (

Scheme 24) [

74].

By reacting the terminal alkenes of these monomers with hydride-terminated polydimethylsiloxanes (H-PDMSs), linear silicon-based elastomers and oils were obtained. Interestingly, the polymer made from monomer

32 was found to be post-modifiable with 4-bromophenol to obtain a polymer with similar properties to that of one made from monomer

33 (

Scheme 25) [

74].

Additionally, compounds

18 and

19 that were previously reported, along with octadimethylhydrosilyl cubic siloxane (OctaSilane POSS), were utilized to form silicon-based networks (

Figure 4) [

69,

74].

The potential application of this work focused on heat-shielding materials (HSMs) in rocket motor casings. These protective coatings not only have to withstand high heat upon re-entry but also extreme cold when deep in space. Thermal characterization showed that the linear polymers made with H-PDMs (

poly32–

35) had

Tgs ranging from −28 to −12 °C and

Tds ranging from 382 to 404 °C. Network polymers made from H-PDMS (

net18a–

e and

net19a–

e) were thermally stable with no onset of degradation up to 431 and 430 °C, and char yields as high as 43 and 62%, under inert pyrolysis conditions, respectively. In addition, aliphatic or aromatic content are programmable in order to control glass transition temperatures of the networks, allowing for

Tgs ranging from −49 to 83 °C (

Table 9) [

74].

Later, in 2021, Houck et al. demonstrated the ability to prepare a variety of aryl ether-functionalized polymers using both pre- and post-functionalized approaches [

75]. In order to accomplish this, the authors initially prepared three monomers capable of undergoing ring-opening metathesis polymerization (ROMP) (

Scheme 26) [

75]. Compounds

37 and

38 had been previously reported [

76].

Monomer

36 was then either functionalized with ROH via SNAr or polymerized, to give

poly36.

Poly36 could then post-functionalized with the ROH nucleophiles (

Scheme 27) [

75].

Similar methods were applied to monomer

37, but only ROH =

a–

f were utilized. Interestingly, this is the first known report of chain growth polymers containing PFPy as a pendant group. Polymers prepared from

36 and

37 were characterized by GPC, TGA, and DSC (

Table 10) [

75].

Attempts to react monomer

38 with ROH resulted in a mixture of products and was attributed to the reversibility sometimes observed in the SNAr reaction at the 4-postion [

45,

68]. The reversibility was also seen when attempts to post-functionalize

poly38 with the various ROH nucleophiles resulted in densely cross-linked polymer. DFT calculations, along with the experimental observations on the monomers utilized in this study, support that the reversibility of

38 could be attributed to having a small dihedral angle [

75].