Optimization of Sensory Properties of Cold Brew Coffee Produced by Reduced Pressure Cycles and Its Physicochemical Characteristics

Abstract

:1. Introduction

2. Results and Discussion

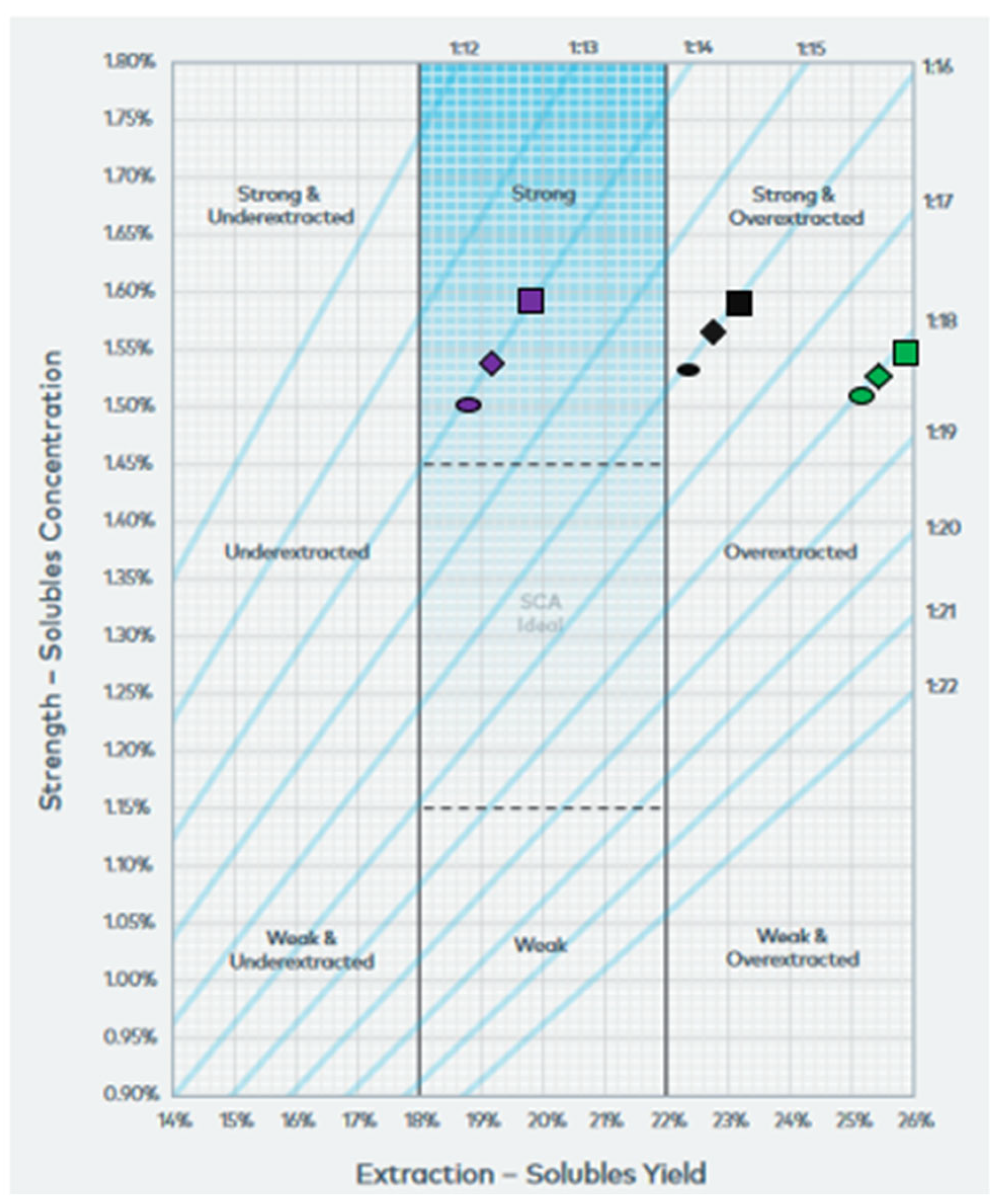

2.1. Specification of Extraction Parameters: Blend, Coffee/Water Ratio, Total Water Hardness and Grind Size

2.1.1. Coffee Blend

2.1.2. Number of Vacuum Cycles for Optimizing Extraction Parameters

2.1.3. Total Water Hardness and Coffee/Water Ratio

2.1.4. Selection of Coffee Grinding Degree

2.2. Optimization of Operating Parameters for the Vaccum Cycle Assisted Extraction

2.2.1. Effect of Vacuum Cycles on Physicochemical Properties

2.2.2. Effect of Pressure on Physicochemical Properties (2 and 7 Vacuum Cycles)

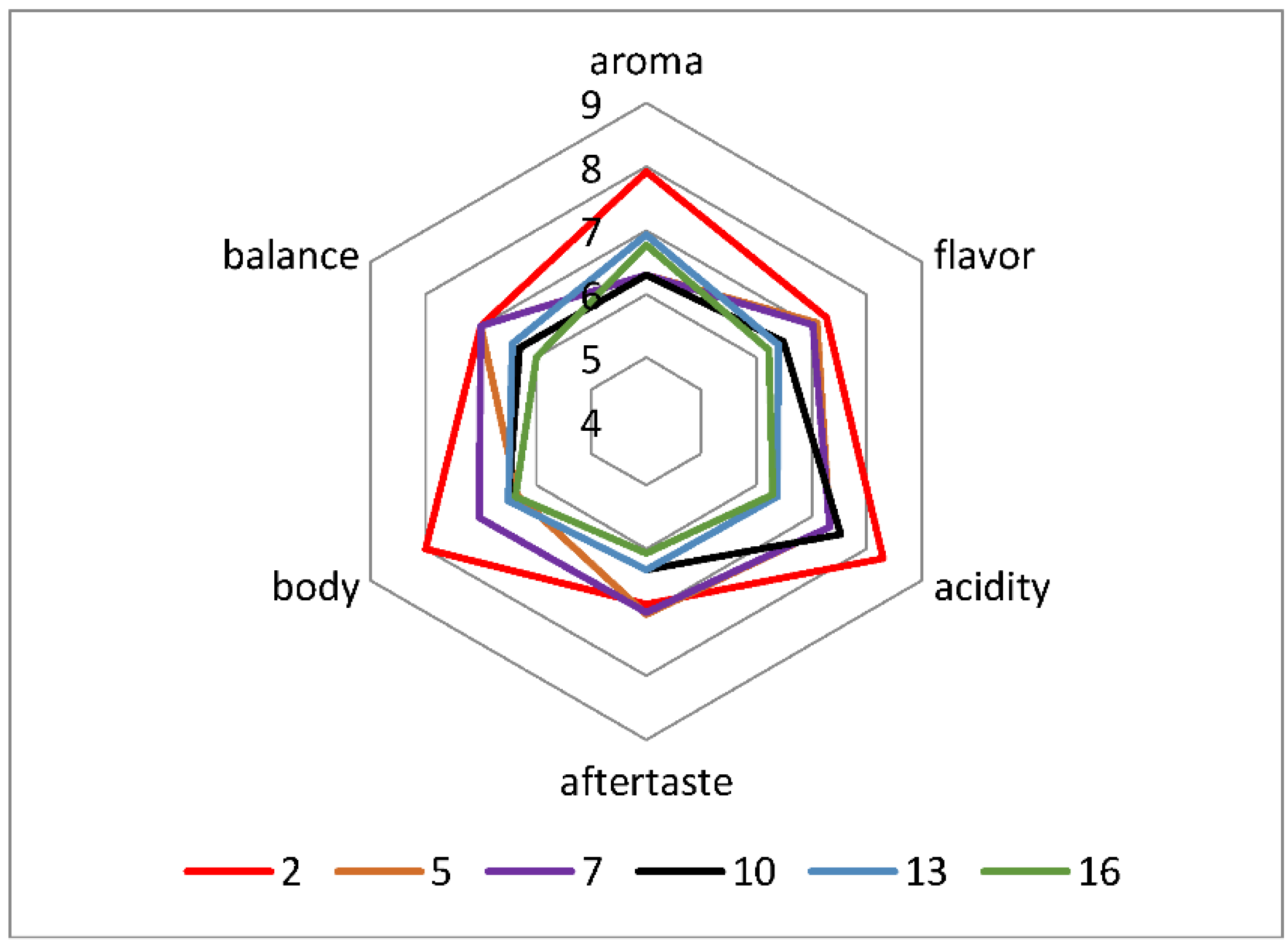

2.3. Descriptive Sensory Evaluation

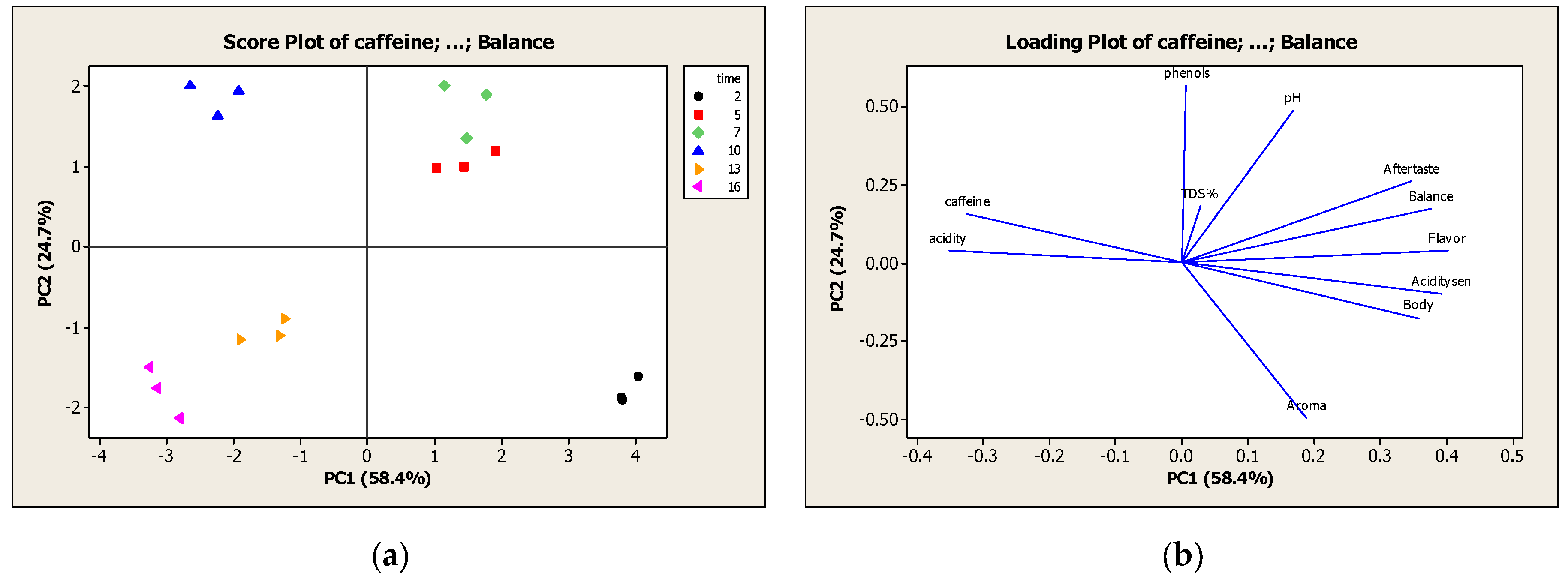

2.4. Principal Component Analysis (PCA)

2.4.1. Test of Vacuum Cycles at Constant Pressure

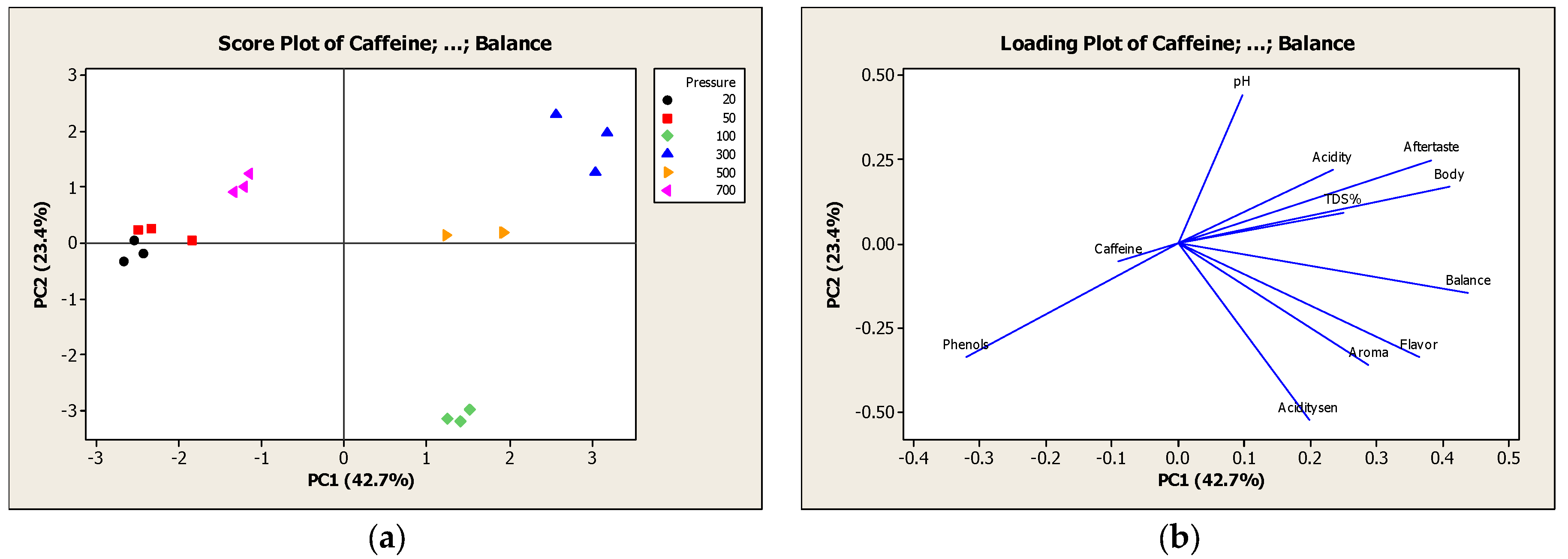

2.4.2. Test of Pressure

Two Vacuum Cycles

2.5. Comparison between Hot and Cold Coffee Extraction

3. Materials and Methods

3.1. Raw Materials and Reagents

Experimental Procedure

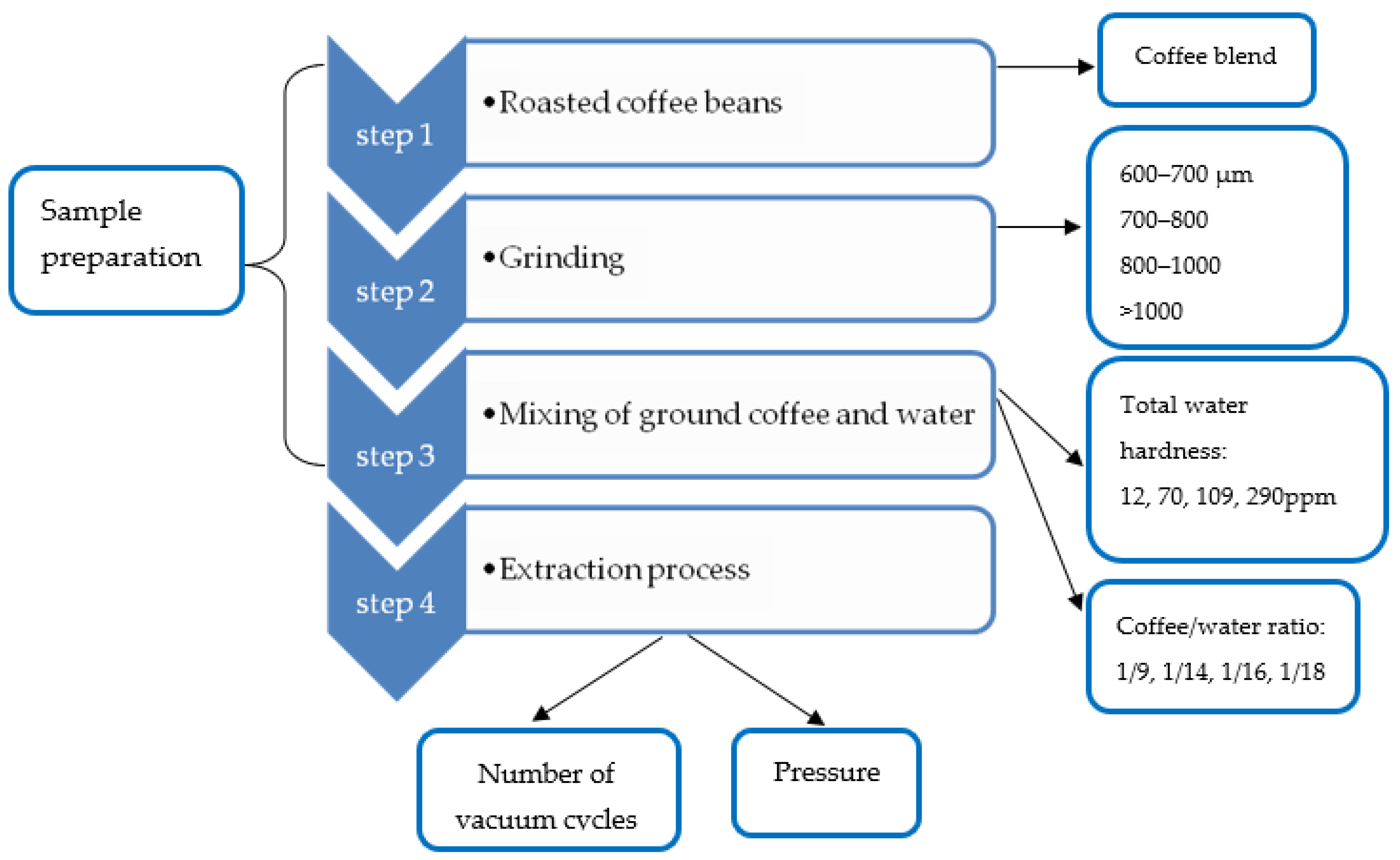

3.2. Sample Preparation

3.3. Extraction by Applying Vacuum Cycles

3.3.1. Specification of Extraction Parameters: Coffee/Water Ratio, Total Water Hardness and Grind Size

3.3.2. Optimization of Operating Parameters for the Vacuum-Cycle Assisted Extraction

Effect of Vacuum Cycles on Physicochemical Properties

Effect of Pressure on Physicochemical Properties at Constant Number of Cycles

3.4. Physicochemical Characterization of Samples

3.4.1. Percentage of Total Dissolved Solids TDS%

3.4.2. pH

3.4.3. Acidity

3.4.4. Phenolic Content

3.4.5. Caffeine Concentration

3.4.6. Color Measurement

3.5. Sensory Test

3.6. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- International Coffee Organization. Coffee Market Report; ICO: London, UK, 2022; Available online: https://www.ico.org/documents/cy2021-22/cmr-0222-e.pdf (accessed on 1 March 2022).

- Cordoba, N.; Pataquiva, L.; Osorio, C.; Moreno, F.L.M.; Ruiz, R.Y. Effect of Grinding, Extraction Time and Type of Coffee on the Physicochemical and Flavour Characteristics of Cold Brew Coffee. Sci. Rep. 2019, 9, 8440. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yashin, A.; Yashin, Y.; Wang, J.Y.; Nemzer, B. Antioxidant and Antiradical Activity of Coffee. Antioxidants 2013, 2, 230. [Google Scholar] [CrossRef] [PubMed]

- Farah, A. Coffee Constituents. In Coffee: Emerging Health Effects and Disease Prevention; Chu, Y.-F., Ed.; John Wiley & Sons: Oxford, UK, 2012; pp. 21–58. [Google Scholar] [CrossRef]

- Kreicbergs, V.; Dimins, F.; Mikelsone, V.; Cinkmanis, I. Biologically Active Compounds in Roasted Coffee. In Proceedings of the 6th Baltic Conference on Food Science and Technology: Innovations for Food Science and Production, Foodbalt, Jelgava, Latvia, 5–6 May 2011; pp. 110–115. [Google Scholar]

- Caporaso, N.; Genovese, A.; Canela, M.D.; Civitella, A.; Sacchi, R. Neapolitan Coffee Brew Chemical Analysis in Comparison to Espresso, Moka and American Brews. Food Res. Int. 2014, 61, 152–160. [Google Scholar] [CrossRef]

- Gloess, A.N.; Schönbächler, B.; Klopprogge, B.; D’Ambrosio, L.; Chatelain, K.; Bongartz, A.; Strittmatter, A.; Rast, M.; Yeretzian, C. Comparison of Nine Common Coffee Extraction Methods: Instrumental and Sensory Analysis. Eur. Food Res. Technol. 2013, 236, 607–627. [Google Scholar] [CrossRef] [Green Version]

- Fuller, M.; Rao, N.Z. The Effect of Time, Roasting Temperature, and Grind Size on Caffeine and Chlorogenic Acid Concentrations in Cold Brew Coffee. Sci. Rep. 2017, 7, 17979. [Google Scholar] [CrossRef] [Green Version]

- Kyroglou, S.; Thanasouli, K.; Vareltzis, P. Process Characterization and Optimization of Cold Brew Coffee: Effect of Pressure, Temperature, Time and Solvent Volume on Yield, Caffeine and Phenol Content. J. Sci. Food Agric. 2021, 101, 4789–4798. [Google Scholar] [CrossRef]

- Ahmed, M.; Jiang, G.; Park, J.; Ki-Chang, L.; Yoon, Y.; Eun, J.-B. Effects of Ultrasonication, Agitation and Stirring Extraction Techniques on the Physicochemical Properties, Health-promoting Phytochemicals, and Structure of Cold Brewed Coffee. J. Sci. Food Agric. 2018, 99, 290–301. [Google Scholar] [CrossRef] [Green Version]

- Zhai, X.; Yang, M.; Zhang, J.; Zhang, L.; Tian, Y.; Li, C.; Bao, L.; Ma, C.; Abd El-Aty, A.M. Feasibility of Ultrasound-Assisted Extraction for Accelerated Cold Brew Coffee Processing: Characterization and Comparison With Conventional Brewing Methods. Front. Nutr. 2022, 9, 849811. [Google Scholar] [CrossRef]

- Caudill, M.; Caudill, M.; Osborne, J.; Sandeep, K.P.; Simunovic, J.; Harris, G.K. Viability of Microwave Technology for Accelerated Cold Brew Coffee Processing vs Conventional Brewing Methods. J. Food Eng. 2022, 317, 110866. [Google Scholar] [CrossRef]

- Rao, N.Z.; Fuller, M. Acidity and Antioxidant Activity of Cold Brew Coffee. Sci. Rep. 2018, 8, 16030. [Google Scholar] [CrossRef] [Green Version]

- McCain-Keefer, H.R.; Meals, S.; Drake, M.A. The Sensory Properties and Consumer Acceptance of Cold Brew Coffee. J. Sens. Stud. 2020, 35, e12604. [Google Scholar] [CrossRef]

- Hendon, C.H.; Colonna-Dashwood, L.; Colonna-Dashwood, M. The Role of Dissolved Cations in Coffee Extraction. J. Agric. Food Chem. 2014, 62, 4947–4950. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Specialty Coffee Association of America. SCAA Standard | Water for Brewing Specialty Coffee. Available online: www.scaa.org/PDF/resources/water-standards.pdf (accessed on 20 February 2022).

- Specialty Coffee Association. Coffee Brewing Control Chart. Available online: https://static1.squarespace.com/static/587af1d4db29d69a1a226b95/t/60aece65e4f2134d99f6e646/1622068839009/SCA+Brewing+Chart+-+Revised+March+2019-US-Letter.pdf (accessed on 11 January 2022).

- Toddy Cafe. Recommended Protocols: Cold Brew Cupping. Available online: https://wholesale.toddycafe.com/downloads/Toddy_cold_brew_cupping_protocol.pdf (accessed on 2 March 2022).

- Wang, Y.-Q.; Wu, Z.-F.; Ke, G.; Yang, M. An Effective Vacuum Assisted Extraction Method for the Optimization of Labdane Diterpenoids from Andrographis Paniculata by Response Surface Methodology. Molecules 2014, 20, 430. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Piskov, S.; Timchenko, L.; Grimm, W.-D.; Rzhepakovsky, I.; Avanesyan, S.; Sizonenko, M.; Kurchenko, V. Effects of Various Drying Methods on Some Physico-Chemical Properties and the Antioxidant Profile and ACE Inhibition Activity of Oyster Mushrooms (Pleurotus Ostreatus). Foods 2020, 9, 160. [Google Scholar] [CrossRef] [Green Version]

- Toor, R.K.; Savage, G.P. Effect of Semi-Drying on the Antioxidant Components of Tomatoes. Food Chem. 2006, 94, 90–97. [Google Scholar] [CrossRef]

- Ranjbar, N.; Eikani, M.H.; Javanmard, M.; Golmohammad, F. Impact of Instant Controlled Pressure Drop on Phenolic Compounds Extraction from Pomegranate Peel. Innov. Food Sci. Emerg. Technol. 2016, 37, 177–183. [Google Scholar] [CrossRef]

- Xie, P.J.; Huang, L.X.; Zhang, C.H.; You, F.; Zhang, Y.L. Reduced Pressure Extraction of Oleuropein from Olive Leaves (Olea Europaea L.) with Ultrasound Assistance. Food Bioprod. Processing 2015, 93, 29–38. [Google Scholar] [CrossRef]

- Wu, Z.; Xie, L.; Li, Y.; Wang, Y.; Wang, X.; Wan, N.; Huang, X.; Zhang, X.; Yang, M. A Novel Application of the Vacuum Distillation Technology in Extracting Origanum Vulgare, L. Essential Oils. Ind. Crops Prod. 2019, 139, 111516. [Google Scholar] [CrossRef]

- Andueza, S.; Vila, M.A.; de Peña, M.; Cid, C. Influence of Coffee/Water Ratio on the Final Quality of Espresso Coffee. J. Sci. Food Agric. 2007, 87, 586–592. [Google Scholar] [CrossRef]

- Cordoba, N.; Fernandez-Alduenda, M.; Moreno, F.L.; Ruiz, Y. Coffee Extraction: A Review of Parameters and Their Influence on the Physicochemical Characteristics and Flavour of Coffee Brews. Trends Food Sci. Technol. 2020, 96, 45–60. [Google Scholar] [CrossRef]

- Farah, A.; Monteiro, M.C.; Calado, V.; Franca, A.S.; Trugo, L.C. Correlation between Cup Quality and Chemical Attributes of Brazilian Coffee. Food Chem. 2006, 98, 373–380. [Google Scholar] [CrossRef]

- Clifford, M.N. Chlorogenic Acids and Other Cinnamates—Nature, Occurrence, Dietary Burden, Absorption and Metabolism. J. Sci. Food Agric. 2000, 80, 1033–1043. [Google Scholar] [CrossRef]

- Angeloni, G.; Guerrini, L.; Masella, P.; Innocenti, M.; Bellumori, M.; Parenti, A. Characterization and Comparison of Cold Brew and Cold Drip Coffee Extraction Methods. J. Sci. Food Agric. 2019, 99, 391–399. [Google Scholar] [CrossRef] [PubMed]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices, 2nd ed.; Springer-Verlag: New York, NY, USA, 2010. [Google Scholar] [CrossRef]

- Espresso & Coffee Guide. What Is Coffee “Body”? Available online: https://espressocoffeeguide.com/all-about-coffee-2/coffee-flavor/body/ (accessed on 7 March 2022).

- Toci, A.T.; Neto, V.J.M.F.; Torres, A.G.; Farah, A. Changes in Triacylglycerols and Free Fatty Acids Composition during Storage of Roasted Coffee. LWT-Food Sci. Technol. 2013, 50, 581–590. [Google Scholar] [CrossRef] [Green Version]

- Çengel, Y.A. Thermodynamics: An Engineering Approach, 7th ed.; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Muzykiewicz-Szymá Nska, A.; Nowak, A.; Wira, D.; Klimowicz, A.; Oszmianski, J.; Lachowicz, S.; Cacciola, F. Molecules The Effect of Brewing Process Parameters on Antioxidant Activity and Caffeine Content in Infusions of Roasted and Unroasted Arabica Coffee Beans Originated from Different Countries. Molecules 2021, 26, 3681. [Google Scholar] [CrossRef]

- Lane, S.; Palmer, J.; Christie, B.; Ehlting, J.; Le, C. Can Cold Brew Coffee Be Convenient? A Pilot Study For Caffeine Content in Cold Brew Coffee Concentrate Using High Performance Liquid Chromatography. Arbutus Rev. 2017, 8, 15–23. [Google Scholar] [CrossRef]

- Fibrianto, K.; Wulandari, E.S. Effect of Roasting Profiles and Brewing Methods on the Characteristics of Bali Kintamani Coffee. In Proceedings of the International Conference on Food, Agriculture and Natural Resources (FANRes 2018), Bantul, Indonesia, 12–14 September 2018; Series: Advances in Engineering Research; Atlantis Press: Dordrecht, The Netherlands, 2018; Volume 172, pp. 193–196. Available online: https://www.atlantis-press.com/proceedings/fanres-18/25907137 (accessed on 17 December 2021).

- Córdoba, N.; Moreno, F.L.; Osorio, C.; Velásquez, S.; Fernandez-Alduenda, M.; Ruiz-Pardo, Y. Specialty and Regular Coffee Bean Quality for Cold and Hot Brewing: Evaluation of Sensory Profile and Physicochemical Characteristics. LWT 2021, 145, 111363. [Google Scholar] [CrossRef]

- Córdoba, N.; Moreno, F.L.; Osorio, C.; Velásquez, S.; Ruiz, Y. Chemical and Sensory Evaluation of Cold Brew Coffees Using Different Roasting Profiles and Brewing Methods. Food Res. Int. 2021, 141, 110141. [Google Scholar] [CrossRef]

- Rao, N.Z.; Fuller, M.; Grim, M.D. Physiochemical Characteristics of Hot and Cold Brew Coffee Chemistry: The Effects of Roast Level and Brewing Temperature on Compound Extraction. Foods 2020, 9, 902. [Google Scholar] [CrossRef]

- Batali, M.E.; Ristenpart, W.D.; Guinard, J.-X. Brew Temperature, at Fixed Brew Strength and Extraction, Has Little Impact on the Sensory Profile of Drip Brew Coffee. Sci. Rep. 2020, 10, 16450. [Google Scholar] [CrossRef]

- Klotz, J.A.; Winkler, G.; Lachenmeier, D.W. Influence of the Brewing Temperature on the Taste of Espresso. Foods 2020, 9, 36. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gómez, O.S. Converting Brix to TDS—An Independent Study. 2019. Available online: https://www.researchgate.net/publication/335608684_Converting_Brix_to_TDS_-_An_Independent_Study?channel=doilinkId=5d6fca204585151ee49dfa3fshowFulltext=true (accessed on 3 January 2022).

- Rostagno, M.A.; Celeghini, R.M.; Debien, I.C.; Nogueira, G.C.; Meireles, M.A.A. Phenolic Compounds in Coffee Compared to Other Beverages. In Coffee in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: London, UK, 2015; pp. 137–142. [Google Scholar] [CrossRef]

- Yao, L.; Liu, X.; Jiang, Y.; Caffin, N.; D’Arcy, B.; Singanusong, R.; Datta, N.; Xu, Y. Compositional Analysis of Teas from Australian Supermarkets. Food Chem. 2006, 94, 115–122. [Google Scholar] [CrossRef]

- Koturevic, B.; Adnadjevic, B.; Jovanovic, J. Isothermal Green Microwave-Assisted Extraction of Caffeine from Guarana: A Kinetic Study. Green Processing Synth. 2017, 6, 555–563. [Google Scholar] [CrossRef]

- Specialty Coffee Association of America. SCAA Protocols | Cupping Specialty Coffee. 2015. Available online: http://www.scaa.org/PDF/resources/cupping-protocols.pdf (accessed on 2 March 2022).

| First Test: Vacuum cycles selection for initial experiments (300 s each cycle, p = 205 mbar) |

|

| Second Test: Coffee-water ratio and total water hardness, with 7 cycles (300 s each), p = 205 mbar | |

| Blank |

|

| Water hardness: 70 ppm |

|

| Water hardness: 109 ppm |

|

| Water hardness: 290 ppm |

|

| Third Test: Selection of grind size, with coffee-water ratio: 1/14, 7 cycles (300 s each), p = 205 mbar | |

| Water hardness: 109 ppm |

|

| Coffee Blend | Coffee/Water Ratio | Total Water Hardness (ppm) | Coffee Grinding (μm) |

|---|---|---|---|

| Columbia-Tres Lomas Estate SHG | 1/14 | 109 | >1000 |

| Vacuum Cycles | Caffeine (mg/g Coffee) | Phenols (mg Gallic Acid/g Coffee) | Acidity (mL NaOH) | pH | TDS% | ΔΕ |

|---|---|---|---|---|---|---|

| 2 | 26.7 ± 1.3 C | 23.4 ± 0.7 C | 2.31 ± 0.06 E | 5.02 ± 0.01 B | 1.32 ± 0.04 B | 21.8 ± 0.6 AΒ |

| 5 | 29.7 ± 1.1 BC | 27.9 ± 0.7 AB | 2.52 ± 0.05 D | 5.02 ± 0.01 B | 1.40 ± 0.08 B | 21.5 ± 0.6 Β |

| 7 | 28.1 ± 1.8 C | 30.7 ± 1.8 A | 2.89 ± 0.08 BC | 5.04 ± 0.01 B | 1.51 ± 0.04 B | 21.8 ± 1.8 AΒ |

| 10 | 33.6 ± 0.8 A | 31.5 ± 1.7 A | 3.03 ± 0.05 B | 5.04 ± 0.00 A | 1.90 ± 0.21 A | 13.9 ± 0.3 C |

| 13 | 32.0 ± 1.0 AB | 24.0 ± 0.8 BC | 2.80 ± 0.05 C | 5.00 ± 0.01 B | 1.49 ± 0.04 B | 24.6 ± 0.8 A |

| 16 | 30.1 ± 0.7 AB | 23.0 ± 2.1 C | 3.38 ± 0.05 A | 4.99 ± 0.01 AB | 1.60 ± 0.08 AB | 14.4 ± 0.7 C |

| 2 Cycles | ||||||

|---|---|---|---|---|---|---|

| Pressure (mbar) | Caffeine (mg/g Coffee) | Phenols (mg Gallic Acid/g Coffee) | Acidity (mL NaOH) | pH | TDS% | ΔΕ |

| 20 | 29.0 ± 1.4 A | 26.1 ± 0.4 A | 2.30 ± 0.08 B | 5.09 ± 0.01 B | 1.20 ± 0.04 A | 19.3 ± 0.6 C |

| 50 | 24.7 ± 2.2 A | 25.9 ± 0.5 A | 2.21 ± 0.09 B | 5.12 ± 0.01 AB | 1.32 ± 0.04 A | 16.5 ± 1.1 D |

| 100 | 25.7 ± 2.8 A | 25.0 ± 1.0 A | 2.22 ± 0.05 B | 5.09 ± 0.01 B | 1.31 ± 0.04 A | 24.5 ± 0.03 A |

| 300 | 26.2 ± 2.0 A | 20.6 ± 0.8 B | 2.59 ± 0.05 A | 5.14 ± 0.01 A | 1.40 ± 0.04 A | 22.1 ± 0.4 AB |

| 500 | 23.2 ± 2.9 A | 20.5 ± 0.4 B | 2.20 ± 0.05 B | 5.13 ± 0.02 A | 1.51 ± 0.22 A | 23.7 ± 1.4 A |

| 700 | 24.7 ± 1.5 A | 21.8 ± 0.2 B | 2.10 ± 0.05 B | 5.15 ± 0.01 A | 1.39 ± 0.04 A | 20.7 ± 0.7 BC |

| 7 Cycles | ||||||

|---|---|---|---|---|---|---|

| Pressure (mbar) | Caffeine (mg/g Coffee) | Phenols (mg Gallic Acid/g Coffee) | Acidity (mL NaOH) | pH | TDS% | ΔΕ |

| 20 | 27.7 ± 1.0 A | 28.0 ± 0.6 C | 2.30 ± 0.02 C | 5.02 ± 0.01 B | 1.51 ± 0.08 AB | 16.1 ± 0.5 A |

| 50 | 29.1 ± 0.9 A | 31.2 ± 0.4 AB | 2.49 ± 0.05 BC | 5.06 ± 0.01 A | 1.51 ± 0.00 AB | 14.9 ± 0.1 A |

| 100 | 28.8 ± 1.2 A | 31.4 ± 0.8 A | 2.50 ± 0.05 BC | 5.06 ± 0.01 A | 1.60 ± 0.07 A | 17.4 ± 1.3 A |

| 300 | 28.6 ± 1.2 A | 29.1 ± 0.8 C | 3.02 ± 0.22 A | 5.07 ± 0.01 A | 1.32 ± 0.11 B | 15.8 ± 1.2 A |

| 500 | 28.7 ± 1.9 A | 29.3 ± 0.6 BC | 2.89 ± 0.05 AB | 5.06 ± 0.01 A | 1.59 ± 0.04 A | 16.9 ± 1.0 A |

| 700 | 25.6 ± 0.4 A | 28.1 ± 0.2 C | 2.60 ± 0.14 BC | 5.07 ± 0.01 A | 1.61 ± 0.07 A | 16.8 ± 0.4 A |

| Extraction Method | Phenols (mg Gallic Acid/g Coffee) | Caffeine (mg Caffeine/g Coffee) | Acidity (mL NaOH) | pH | TDS% |

|---|---|---|---|---|---|

| Hot brewing | 27.5 ± 1.1 A | 20.5 ± 2.9 B | 2.5 ± 0.4 A | 4.97 ± 0.08 B | 1.3 ± 0.3 A |

| Cold brewing | 23.4 ± 0.7 B | 26.7 ± 1.3 A | 2.3 ± 0.06 A | 5.02 ± 0.01 B | 1.3 ± 0.04 A |

| Commercial cold brewing | 24.6 ± 0.2 B | 28.9 ± 1.6 A | 2.5 ± 0.05 A | 5.35 ± 0.01 A | 1.7 ± 0.0 A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kyroglou, S.; Laskari, R.; Vareltzis, P. Optimization of Sensory Properties of Cold Brew Coffee Produced by Reduced Pressure Cycles and Its Physicochemical Characteristics. Molecules 2022, 27, 2971. https://doi.org/10.3390/molecules27092971

Kyroglou S, Laskari R, Vareltzis P. Optimization of Sensory Properties of Cold Brew Coffee Produced by Reduced Pressure Cycles and Its Physicochemical Characteristics. Molecules. 2022; 27(9):2971. https://doi.org/10.3390/molecules27092971

Chicago/Turabian StyleKyroglou, Smaro, Rafailia Laskari, and Patroklos Vareltzis. 2022. "Optimization of Sensory Properties of Cold Brew Coffee Produced by Reduced Pressure Cycles and Its Physicochemical Characteristics" Molecules 27, no. 9: 2971. https://doi.org/10.3390/molecules27092971

APA StyleKyroglou, S., Laskari, R., & Vareltzis, P. (2022). Optimization of Sensory Properties of Cold Brew Coffee Produced by Reduced Pressure Cycles and Its Physicochemical Characteristics. Molecules, 27(9), 2971. https://doi.org/10.3390/molecules27092971