1. Introduction

Theranostics is an emerging approach that combines therapeutic and diagnostic elements for effective cancer treatment [

1]. In this approach, radionuclides emitting low-energy gamma rays are used for diagnostic purposes, while those emitting charged particles such as beta rays and alpha particles are utilized for therapy. This fusion of diagnostics and therapy represents a significant advancement in personalized cancer treatment [

2,

3].

177Lu has garnered considerable interest as a theranostic radionuclide due to its emission of beta rays with an energy of 134 keV and low-energy gamma rays at 208 keV [

4,

5]. Combining

177Lu with other therapeutic radionuclides, such as

90Y/

177Lu and

67Cu/

177Lu, has shown great promise in cancer treatment [

6,

7]. The efficacy of

177Lu in neuroendocrine tumors has been acknowledged by the US Food and Drug Administration (approved in 2018) and the European Medicines Agency (approved in 2017) [

8].

The term “carrier-free” is used to describe radionuclides with the highest specific activity. This means that the final product has 100% isotopic abundance and is not contaminated with stable isotopes. 177Lu, which has a high specific activity, is particularly important in certain radiation therapies, although it may not be necessary for all types. For instance, in peptide receptor radionuclide therapy, the limited concentration of different cellular cognate receptors expressed on the tumor cell surface necessitates the use of 177Lu with high specific activity.

Currently, the production of

177Lu relies primarily on reactors using two production routes [

9,

10]: the “direct” route and the “indirect” route. In the direct route, the

176Lu target is subjected to neutron irradiation via

reactions. In comparison, the indirect route involves the use of a

176Yb target via

reactions. Each route has its advantages and disadvantages.

The direct route benefits from the high thermal neutron capture cross-sections of

176Lu, which is as high as 2090 barn [

11,

12]. However, a drawback of the direct route is the production of

177mLu as an impurity of concern.

177mLu has a relatively long half-life of 160.5 days, leading to an increasing ratio of

177mLu/

177Lu over time. This poses challenges in hospital preparations, as the presence of

177mLu triggers concerns regarding radioactive waste management. Currently, the average specific activity of the direct route is approximately 740 to 1100 GBq/mg, which needs further improvement.

The indirect production route is based on the

reactions. This route offers the advantage of producing high specific activity, approximately 2960 GBq/mg, as it does not generate

177mLu as an impurity. Furthermore, the product obtained via the indirect route can be carrier-free. However, there are some disadvantages associated with the indirect production route. It has low production yields due to the low cross-section of

176Yb, which is only 2.5 barns. Additionally, the chemical properties of Yb and Lu are very similar, posing challenges in the separation of Yb and Lu [

13]. For more information on the various methods under development for Yb/Lu separation, a comprehensive review can be found in reference [

13].

Considering the anticipated high market demand, alternative approaches utilizing accelerators have been investigated. These methods involve the use of protons [

14], deuterons [

15,

16,

17,

18], alpha particles [

19], and electron beams [

20]. Among various accelerator-based techniques, the most efficient method for producing

177Lu is via the irradiation of a pure Yb target with deuterium [

21]. This method has the highest yield in comparison with other possible choices, including

natYb(d,x)

177Lu,

natHf(p,x)

177Lu,

natHf(d,x)

177Lu,

natLu(p,x)

177Lu,

natLu(d,x)

177Lu, and

natYb(α,x)

177Lu.

Previous studies have modeled the utilization of deuteron irradiation on a Yb target for

177Lu production [

22,

23]. Kambali compared the production yields between (d,n) and (d,p) reactions [

22]. Nagai et al. systematically modeled the activities and specific activities of

177Lu using deuteron beams of different energies and Yb targets of varying purities [

23]. Both studies suggested the feasibility of the overall processes. The present study aims to accomplish two objectives: firstly, to assess the feasibility of producing

177Lu using a high-energy linear accelerator (LINAC); secondly, to optimize both the irradiation time and the post-irradiation processing time to attain the highest achievable specific activity.

LINAC is a unique type of accelerator that can achieve very high beam energy at a relatively low cost. However, both the ion species and beam energies are fixed characteristics determined by the beam design. In other words, if it is designed at high energy, it cannot be operated at low energies. A high-energy LINAC provides opportunities for isotope production that requires high threshold beam energies. Conversely, a high-energy beam may be less suitable for isotope production that necessitates low threshold energies. An example of such a high-energy accelerator is the LINAC, located in Denton, Texas. Originally manufactured as part of the superconducting supercollider project, it was designed to operate at a beam energy close to 70 MeV for isotope production. This LINAC utilized a design that originated from Los Alamos National Laboratory in the 1980s, specifically tailored for an energy range of 70 to 90 MeV for the nuclear medicine program at that time [

24,

25]. Therefore, exploring the applications of high-energy LINACs for isotope production holds commercial value. It is worthwhile to investigate the feasibility of utilizing high-energy accelerators as versatile instruments capable of accommodating a wide range of isotopes requiring thermal energy at different energy levels, both low and high.

The current study utilized 80 MeV as an illustrative example of a high-energy LINAC. However, the proposed methodology is applicable to various high-energy LINACs, regardless of whether they operate at 80 MeV or not. The multiple foil target configurations, as proposed in the present study, can be adjusted based on the specific beam energy of any LINAC, making the approach versatile and not limited to Denton LINAC. For the same reason, the beam current was chosen to be typical of the Denton LINAC. Nevertheless, the obtained yields can be readily converted for other LINACs. Hence, the impact of this study extends to general high-energy LINACs and is not specific to the Denton LINAC.

2. Modeling Procedure

The modeling approach employed in this study consists of the following steps: (1) a Monte Carlo simulation code was utilized to determine the energy of deuterons at different penetration depths; (2) the localized energy is converted into localized isotope production using energy-dependent activation functions; (3) the effects of continuous ion bombardment (gain) and decay (loss) are calculated as functions of irradiation time and post-irradiation processing time; and (4) the amount of produced isotopes is integrated over the region of interest to calculate activity and specific activity.

The Stopping and Range of Ions in Matter (SRIM) code has been widely used in materials science for irradiation studies [

26]. However, SRIM does not directly provide detailed information about the local beam energy at different penetration depths as an output. Nevertheless, this information can be estimated reasonably well by analyzing the projected range of ions at various incident energies.

Figure 1 plots the projected ranges of deuterons as a function of incident energy. For instance, at an incident energy of 80 MeV, the projected range of deuterium in Yb is approximately 9.2 mm. Conversely, at a lower energy of 60 MeV, the projected range reduces to 8 mm. This difference of 1 mm in range suggests that, in order for an 80 MeV beam to stop at 9.2 mm, its energy at a depth of 1 mm must be around 60 MeV. In other words, if we denote the projected range curve as

R(E), where

E is the incident energy as a variable, then for a selected incident energy

, the energy at a depth of

from the surface is

.

Figure 2 plots the local energy as a function of depth for different incident energies, calculated using the procedure described.

The utilization of

Figure 2 to convert local beam energy into isotope production, based on energy-dependent cross-sections, assumes that straggling can be neglected. As a result, for a given incident energy, the energy values at each depth point are precise and have minimal uncertainty. This approximation holds true for protons and deuterons because their collisions with target atoms are primarily influenced by glancing angle collisions. Consequently, the ion trajectory remains a straight line for most of the penetration, except towards the very end, where low-energy collisions favor the creation of small damage cascades.

The available cross-section data for deuterium bombardment of

and other Yb isotopes are quite limited. Khandaker et al. conducted measurements on natural Yb and reported cross-section data for (d,x) reactions up to 24 MeV [

27]. Nagai et al. fitted these cross-section data and experimentally validated the integrated yields [

23].

Figure 3 plots the experimental activation functions for producing

in pure

[

27], along with the fitted functions [

23]. Two reactions result in the production of

177Lu. The first reaction is

, and the second reaction is

. The cross-section of the

reaction is higher than that of the

reaction.

undergoes β emission followed by gamma transitions in

, with a relatively short half-life of 1.88 h. Therefore,

can be approximated as the direct product of deuteron irradiation. It is important to note that the available experimental data is limited to energies up to 24 MeV. Further validation is required to assess the accuracy of the data at higher energies.

To maximize the specific activity of

177Lu, minimizing the production of other isotopes is crucial. This is why purified

176Yb is preferred over natural Yb. Natural Yb consists of seven stable isotopes:

176Yb,

174Yb,

173Yb,

172Yb,

171Yb,

170Yb, and

168Yb, with

174Yb being the most abundant at 31.8% of natural abundance.

Figure 4a–f presents the fitted cross-sections for producing isotopes other than

177Lu in

176Yb,

174Yb,

173Yb,

172Yb,

171Yb, and

170Yb, respectively.

168Yb is not included due to its very low abundance (0.126%). It is observed that almost all cross-sections of (d,x) reactions are higher than that for producing

177Lu in

176Yb (

Figure 3). Therefore, utilizing purified

176Yb instead of natural Yb is the most effective approach to avoid the generation of unwanted isotopes.

Table 1 summarizes Lu isotopes (only relevant ones are selected) and their half-lives and decay modes [

28,

29]. As for specific isotope products in

Figure 4,

173Lu produced from the bombardment of

174Yb or

173Yb decays into

173Yb via electron capture (EC) with a half-life of 1.37 years. For

172g+mLu produced from both

173Yb and

172Yb,

172Lu decays into

172Yb via β+ decay with a half-life of 6.7 days.

172mLu decays into

172Lu via isomeric transition (IT) with a half-life of 3.7 min. For

171g+mLu produced from

172Yb and

171Yb,

171Lu decays to

171Yb via b β

+ decay with a half-life of 8.24 days.

171mYb decays to

171Lu via IT decay with a half-life of 79 s. For

170g+mLu produced from

171Yb and

170Yb,

170Lu undergoes β+ decay into

170Yb with a half-life of 2 days.

170mLu decays rapidly into

170Lu via IT decay with a half-life of 670 milliseconds. For

169Lu produced from bombarding

170Yb, it decays into

169Yb with a half-life of 34 h.

Figure 4a is important in minimizing the presence of unwanted isotopes when using a purified

176Yb target.

176mLu, in particular, undergoes β

− decay into

176Hf (99.9%) and EC decay into

176Yb (0.095%). With a relatively short half-life of 3.664 h, it is feasible to wait for a sufficient time period for

176mLu to decay before initiating the chemical separation process. By optimizing the timing, the specific activity of

177Lu can be maximized while minimizing the presence of

176mLu and its decay products.

174gLu, with a half-life of 3.31 years, decays into 174Yb via β+ decay. The long half-life of 174gLu poses a challenge in achieving a high specific activity of 177Lu. However, the reactions leading to its production start above 15 MeV and become significant above 20 MeV. Therefore, the concentration of 174gLu can be minimized by optimizing the beam energy (E < 20 MeV). Regarding 174mLu, it undergoes IT decay into 174Lu (99.38%) and EC decay into 174Yb (0.62%). Its relatively long half-life of 142 days presents concerns about quality control. However, since 174mLu has a higher threshold energy at 20 MeV, its concentration can also be minimized via beam energy optimization (E < 20 MeV).

The distinctive energy dependence of the production of

177Lu and other isotopes in pure

176Yb leads to the difference in their isotope distribution profiles, as shown in

Figure 5 for the case of 80 MeV deuteron irradiation. The dashed line in

Figure 5 represents the local deuteron energy as a function of penetration depth. The symbols represent the cross-section of producing

177Lu,

176mLu,

174gLu, and

174mLu. At shallow depths, where the deuteron energy is high, the production of isotopes is relatively low. As the deuteron energy decreases to approximately 40 MeV, corresponding to a depth of around 6 mm, the cross-section for producing

174g+mLu increases (as shown in

Figure 4a). At an energy of approximately 30 MeV, corresponding to a depth of about 7.5 mm,

177Lu production starts to increase. At an energy of around 20 MeV and a corresponding depth of 8.3 mm, the cross-section for

176mLu production begins to rise. The

174mLu cross-section reaches its peak at a depth of approximately 7.7 mm and then decreases to almost zero at a depth of 8.3 mm. For

174gLu, its cross-section reaches its peak at a depth of around 7.9 mm and drops to almost zero at a depth of 8.5 mm. For both

177Lu and

176mLu, they exhibit increasing cross-sections and peak at a depth of approximately 8.8 mm. The corresponding deuteron energy at this depth is approximately 13 MeV. Both

177Lu and

176Lu cross-sections decrease and approach zero at a depth of approximately 9 mm. As to be discussed shortly, the differences in in-depth profiles of different isotopes are important in maximizing the specific activity of

177Lu.

The depth-dependent cross-sections are used to calculate the quantity of isotope products at different depths for specific bombardment time and processing time. The change of isotopes per unit volume (

) is determined by the following equation [

30],

with the solution

where

is time,

is the end of irradiation time,

R is the reaction rate per unit volume,

is the decay constant,

denotes the atomic density (which is 2.422 × 10

22 atoms/cm³ for Yb), and

the number of deuterons arriving on the surface per unit area per unit of time. For

, a value of 1 × 10

16 deuterons/cm

2/s is used, which is typical for a high-performance plasma source. Note that 1 × 10

16 deuterons/cm²/s corresponds to 1.6 mA/cm

2. The decay constants λ used in the calculations are based on the half-life times

: 6.65d for

, 3.66h for

, 3.31y for

, and 142d for

.

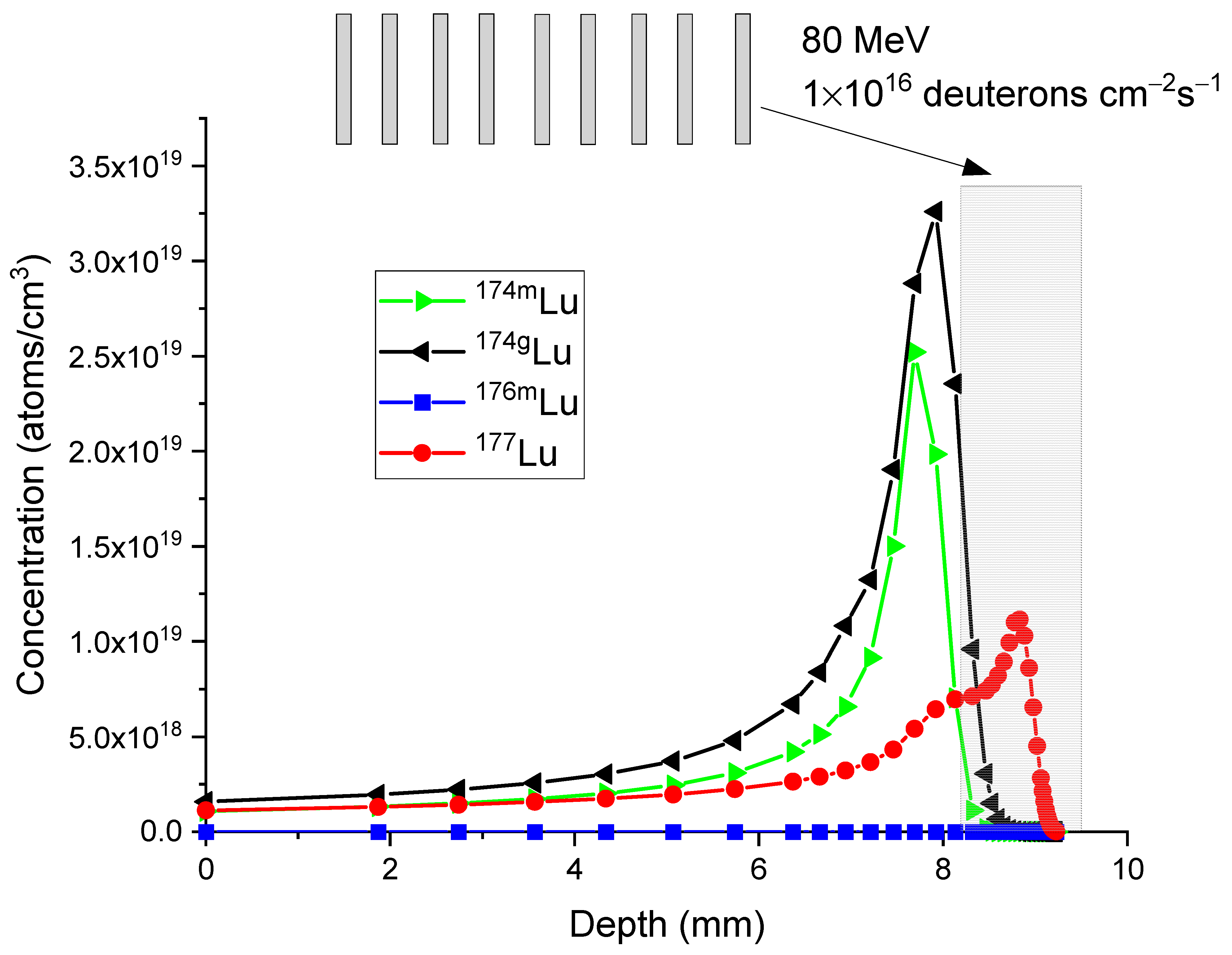

Figure 6 plots the calculated depth profiles of

in 80 MeV deuteron-irradiated

176Yb at three different time points: 0 h, 3 h, and 24 h after the completion of irradiation. The irradiation time is set to 3 days. Three hours after the irradiation, the concentration changes of

due to its decay are minimal. In 24 h after the irradiation, concentration decreases become apparent. However, the overall concentration changes are not significant. At the depth of peak concentration, 8.8 mm, the concentration of

decreases from 1.24 × 10

19 atoms/cm

3 to 1.21 × 10

19 atoms/cm

3 after three hours and further decreases to 1.12 × 10

19 atoms/cm

3 after 24 h.

As a result of its much faster decay, the concentration change of

176mLu differs significantly from that of

177Lu.

Figure 7 plots the

176mLu concentration profiles at the same time points as shown in

Figure 6. At the end of irradiation, the peak concentration of

176mLu is 1.09 × 10

18 atoms/cm

3. After 3 h, the concentration decreases to 4.22 × 10

17 atoms/cm

3 and further decreases to 1.16 × 10

16 atoms/cm

3 after 24 h. In contrast, both

174gLu and

174mLu exhibit negligible concentration changes, as shown in

Figure 8 and

Figure 9. This lack of changes is due to their relatively long half-lives, which are 3.31 years for

174gLu and 142 days for

174mLu. It is worth noting that the peak concentrations of both isotopes, at 2.5–3.5 × 10

19/cm³, are higher than the peak concentration of

177Lu (about 1 × 10

19/cm³).

Considering the differences in concentration distributions and decay rates, we propose two methods to increase the specific activity of

177Lu. The first method involves reducing the deuteron beam energy to a value close to 21 MeV. This energy is high enough to activate the production of

177Lu but not high enough to produce significant amounts of

174gLu and

174mLu.

Figure 10 compares the isotope profiles for an incident energy of 80 MeV and an incident energy of 21 MeV. The calculations correspond to a post-irradiation processing time of 24 h, with the irradiation time set to 3 days. In the case of 21 MeV,

177Lu reaches its peak concentration at a depth of 0.6 mm and drops to zero at approximately 1 mm depth. The unwanted isotope

174gLu is present in small quantities near the surface and rapidly decreases to nearly zero at a depth of around 0.4 mm. The concentration of

174mLu is located at even shallower depths and is negligible. Due to its rapid decay, the concentration of

176mLu is reduced to a negligible level as well.

The second method involves the use of a stacked foil target. The stacked-foil technique is commonly employed to measure excitation functions of nuclear reactions involving light ions as projectiles [

31,

32,

33]. In this technique, a target composed of multiple foils is used. In the present study, stacked foils are proposed to harvest isotopes at specific beam energies.

Figure 11 illustrates the arrangement where

176Yb targets with approximately 1 mm thickness are stacked and exposed to deuteron beams. The thickness of the target foils is slightly adjusted to ensure that the last foil corresponds to a depth ranging from 8.22 mm to 9.22 mm. The gray colored box indicates the last foil, where the specific activity of

177Lu is maximized, and the unwanted isotopes are minimized.

Table 2 and

Table 3 compare the daily isotope production from different depth regions: 8.22 mm to 9.22 mm (the last foil) and the entire depth range of 0 to 9.22 mm (all foils). The daily production is based on two rounds of irradiation, with each round lasting 12 h. For each round, the post-irradiation chemical separation time is 28 h. This condition arises after optimization to maximize specific activities. It does not represent the conditions to maximize radionuclidic purity nor the conditions optimized to balance both specific activity and radionuclidic purity. The conditions for different optimization needs will be discussed shortly.

Table 2 presents the first optimization condition, prioritizing specific activity. The tables provide information on the activity, mass, specific activity, and radionuclidic purity of

174mLu,

174gLu,

176mLu, and

177Lu.

In

Table 2, which pertains to the last foil only, the activity of daily produced

177Lu is 304 GBq, and its specific activity is 3084 GBq/mg. Although the activity is relatively low, the specific activity is remarkably high. Note that the majority of reactor-based neutron irradiation produces

177Lu with a specific activity ranging from 740 to 1100 GBq/mg. In

Table 3, which covers the entire depth region from 0 to 9.22 mm, the activity of

177Lu is 1119 GBq, with an average specific activity of 1022 GBq/mg. Even though the specific activity is lower compared to the previous cases, it is still comparable to the quality of reactor-produced isotopes.

To maximize

177Lu production, both in terms of total activity and specific activity, calculations were performed to determine the optimized conditions. The calculations changed both the irradiation time and the post-irradiation processing time incrementally.

Figure 12 and

Figure 13 compare the isotope quality of the last foil and all foils. These plots emphasize the significance of selecting the appropriate processing time window. In the calculations, irradiation time changes using a step of 12 h, while post-irradiation processing time changes using a step of 4 h. All plots are normalized to one day of operation. If each batch requires a 12 h irradiation period, then one day of operation combines the yields from two batches. The post-irradiation processing start time is not limited to a duration shorter than one day. The calculation takes into account continuous operations, allowing the post-irradiation processing time to extend beyond one day if necessary.

Figure 12 provides a summary of the product quality of the last foil. All figures correspond to one day of operation (two batches per day). In

Figure 12a, the total activity of

177Lu reaches the maximum of approximately 337 GBq/day for an irradiation time of 12 h and a post-irradiation processing time of 4 h. Increasing either the irradiation time or the post-irradiation processing time leads to a decrease in activity.

Figure 12b plots the specific activity and exhibits the existence of a peak region. At a given irradiation time, the specific activity initially increases and then decreases with increasing post-irradiation processing time. The peak value is approximately 3071 GBq/mg. For maximizing specific activity, the optimal post-irradiation processing time is around 20 h for short irradiation. The optimal post-irradiation processing time slightly reduces to about 12 h for long irradiation. Prolonged irradiation and post-irradiation processing times result in a drop in specific activity, with the lowest value reaching approximately 2590 GBq/mg, representing the worst scenario in the mapping. However, an overall high specific activity can still be ensured.

In

Figure 12c, the radionuclidic purity of the last foil is plotted. Unlike activity and specific activity, the radionuclidic purity approaches a saturated maximum of 99.6%. To achieve a high radionuclidic purity, an extended post-irradiation processing time is needed. By combining

Figure 12a–c, an optimized time window can be identified. In summary, maximizing activity requires a short irradiation time and a short post-irradiation processing time, maximizing specific activity necessitates a post-irradiation processing time window of approximately 20 h, and maximizing radionuclidic purity calls for a prolonged post-irradiation processing time. A balanced condition can be achieved, such as selecting a 12 h irradiation time and a 28 h post-irradiation processing time, resulting in an activity of 304 GBq/day, a specific activity of 3084 GBq/mg, and a radionuclidic purity of 95.4%. As mentioned earlier, this is not the condition to maximize radionuclidic purity. The condition for maximizing radionuclidic purity will be discussed shortly.

Figure 13a–c plots the activity, specific activity, and radionuclidic purity for all foils (corresponding to a depth region of 0 to 9.22 mm). As mentioned earlier, including these foils containing a high concentration of

174gLu and

174mLu degrade the overall isotope quality. However, these foils can still be used in certain medical applications where low specific activity is acceptable. In

Figure 13a, it is evident that including all foils significantly increases the total activity. The highest activity of ~1260 GBq/day can be achieved by minimizing both the irradiation time (12 h) and the post-irradiation processing time (4 h). Regarding specific activity, as shown in

Figure 13b, the highest value of about 1100 GBq/mg can be obtained by minimizing the irradiation and post-irradiation processing time. Even in the worst-case scenario with a prolonged post-irradiation processing time exceeding 60 h, the specific activity remains at approximately 740 GBq/mg or above, which is comparable to typical products obtained via reactor irradiation. For radionuclidic purity, a prolonged post-irradiation processing time is favored, and the maximum value saturates at around 93%.

Different from

Figure 12b, which shows a post-irradiation processing time window for achieving maximum specific activity, there is no such window observed from

Figure 13b. This discrepancy arises from the high sensitivity of specific activity to the changes of

176mLu quantity in the last foil, given that

176mLu and

177Lu are the predominant isotopes present, with

176mLu having a rapid decay. In contrast, when all foils are considered, the mass changes contributed by

176mLu are relatively insignificant due to the substantial contributions from

174gLu and

174mLu, which have almost negligible changes due to their relatively long half-lives. Consequently, the specific activity becomes less sensitive to changes in

176mLu and more responsive to the activity changes of

177Lu itself.

Back to the approach of harvesting

177Lu from the last foil only, the obtained

177Lu under optimized conditions, as shown in

Figure 12b, exhibits a remarkably high specific activity of about 3084 GBq/mg. This makes the process very attractive for hospital applications. This specific activity clearly surpasses the current achieved results using reactors.

Table 4 provides a summary of the typical specific activities of

177Lu from different sources [

13]. It is worth noting that 3084 GBq/mg is about 75% of the highest specific activity achievable in carrier-free

177Lu. The theoretically predicted maximum is 4104 GBq/mg [

13].

Having all foils made of 176Yb is not a requirement in the stacked foil approach. Sacrificial materials of less expensive materials can be used in the other foils while reserving the last foil specifically for 176Yb. Alternatively, for isotope production other than 177Lu, different target materials can be used to replace the other foils. This flexibility is particularly valuable for isotopes that require a higher threshold energy for production.

The discussion above has assumed a

176Yb target with a purity level of 100%, which represents an ideal scenario. In reality, targets of a purity level of >99.6% are commercially available (i.e., from ISOFLEX USA, San Francisco, CA, USA). In commercially enriched

176Yb targets, impurity levels of other Yb isotopes decrease significantly as the mass numbers of Yb decrease [

23]. Consequently,

174Yb is more abundant than other isotope impurities in

176Yb-enriched targets. The three unwanted products originating from

174Yb are

174g+mLu and

173Lu. These isotopes have relatively long lifetimes compared to others, resulting in their minimal contribution to the radionuclide impurities of

177Lu.

To model the effect of purity, calculations were performed for the production and decay of

177Lu,

174mLu,

174gLu,

176mLu, and

173Lu. The production calculations utilized cross-section data from

Figure 4 and

Figure 5, while the decay calculations were based on the half-life times provided in

Table 1.

Table 5 compares the activity, specific activity, and radionuclidic purity of

177Lu in

176Yb targets at purity levels of 100%, 99.6%, 99%, and 98%, respectively. All values correspond to daily production, assuming two rounds of irradiation per day with a 12 h irradiation time for each batch and a 28 h post-irradiation processing time for each batch. The conditions include an 80 MeV beam energy, 1.6 mA beam current, and a 1cm

2 beam spot size. The comparison is made for collecting Lu from all foils (0 to 9.22 mm) and from the last foil (8.22 mm to 9.22 mm).

Table 5 shows that there is no significant difference when the purity is reduced from 100% to 99.6%. In the case of the last foil, the activity changes from 304 to 302 GBq and the specific activity changes from 3084 to 3052 GBq/mg. Even in the worst-case scenario of 98% purity, the activity is 335 GBq, and the specific activity is 2912 GBq/mg. These results suggest that a purity level of around 98% and above does not significantly degrade the quality of the final product.

Using 99.6% purity as the example,

Table 6 lists the activity, mass, and specific activity of each Lu isotope, giving further details about the impurity effect. Judged by the radionuclidic purity, the largest impurity effect comes from

176mLu, at a value of 4.3%.

176mLu has a specific activity of 137 GBq/mg. Although its mass is not the largest, its short half-life of 3.66 h makes its contribution large. On the other hand,

173Lu, as a unique product from

174Yb, has the smallest contribution in influencing

177Lu radionuclidic purity.

As one highlight of the present study, irradiation, and processing conditions are identified to provide the quality range that is of particular interest to the isotope production community. The most demanded quality is specific activity > 2960 GBq/mg and radionuclidic purity > 99.5%.

Figure 14a–d are for

176Yb of 100% purity and for the last foil only (depth from 8.22 mm to 9.22 mm).

Figure 14a maps the region where the activity exceeds 185 GBq/day, a condition that can be easily achieved based on the modeled conditions. The majority of regions surpass 259 GBq/day, except for a specific corner associated with significantly longer irradiation time and post-irradiation processing times. In

Figure 14b, the plot showcases the region that surpasses 99.5% radionuclidic purity, which can be attained with post-irradiation processing times longer than 40 h. This region appears to be less sensitive to variations in irradiation times.

Figure 14c presents the region of the specific activity exceeding 2960 GBq/mg. It shows a trade-off between irradiation time and post-irradiation processing times, whereby a longer irradiation time necessitates a shorter post-irradiation processing time.

Figure 14d provides a summary of the region that satisfies the combined criteria of activity > 259 GBq/day, specific activity > 2960 GBq/mg, and radionuclidic purity > 99.5%. It represents the optimized conditions obtained by considering all restrictions. This region corresponds to irradiation times shorter than 60 h and post-irradiation processing times between 44 and 64 h.

For a purity of 99.6%,

Figure 15a–d plots the corresponding activity, specific activity, radionuclidic purity, and the optimized conditions for achieving activity > 259 GBq/day, specific activity > 2960 GBq/mg, and radionuclidic purity > 99.5%. These maps exhibit similarities to the case of 100% purity, with the expected difference that the regions are slightly smaller. The shrinking specific activity region and specific activity region impose further constraints on the conditions. As shown in

Figure 15d, although conditions are narrowed down, a region still exists for attaining the required quality. The necessary irradiation time ranges from 12 to 24 h, while the post-irradiation processing time is around 48 h.

As pointed out in the introduction, the present study used 80 MeV as one example of high-energy LINAC facilities. However, the proposed multiple foil targets can be easily adjusted for other energies. The deuteron ions enter into the last foil at an energy of about 21 MeV. For other beam energies, as long as the foils prior to the last one can reduce beam energies down to 21 MeV, the product of the same quality can be obtained.

As shown in

Figure 2, for deuterons reaching 21 MeV, deuterons penetrate about 4.7 mm for an initial beam energy of 60 MeV and about 1.9 mm for an initial beam energy of 40 MeV. As long as the foils ahead of the last one have a combined thickness matching these numbers, the same optimized conditions can be reached for the last foil.

Currently, isotope production is primarily dominated by reactor irradiation and cyclotrons. Most cyclotrons operate at relatively lower beam energies, typically around 40 MeV or lower. In contrast, LINACs are capable of delivering beam energies exceeding 40 MeV. LINACs can serve as versatile devices for isotope production, even for isotopes that favor lower beam energies, utilizing techniques like the one proposed in this study. It is important to note that typical beam currents for cyclotrons are around 100s μA, whereas LINACs can achieve beam currents of a few mA. For a high-energy LINAC, it is not ideal for Lu isotope production since much power is wasted if only the last foil is used. However, the design allows replacing these wasted foils with targets for producing other isotopes that require higher threshold (or optimized) energy.