Effects of Lysine on the Interfacial Bonding of Epoxy Resin Cross-Linked Soy-Based Wood Adhesive

Abstract

:1. Introduction

2. Results and Discussion

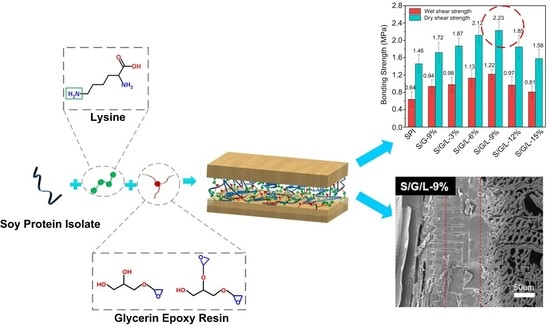

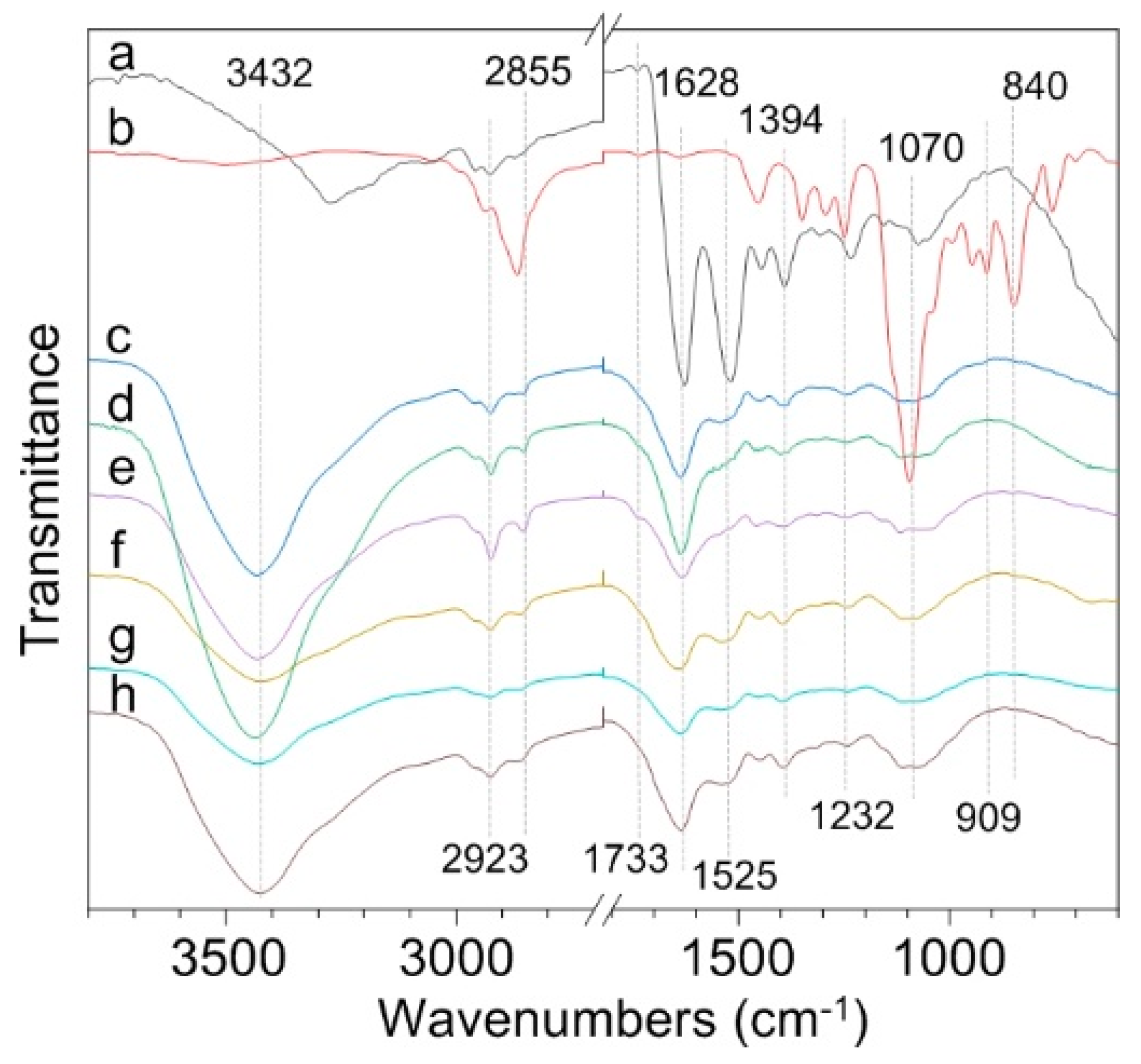

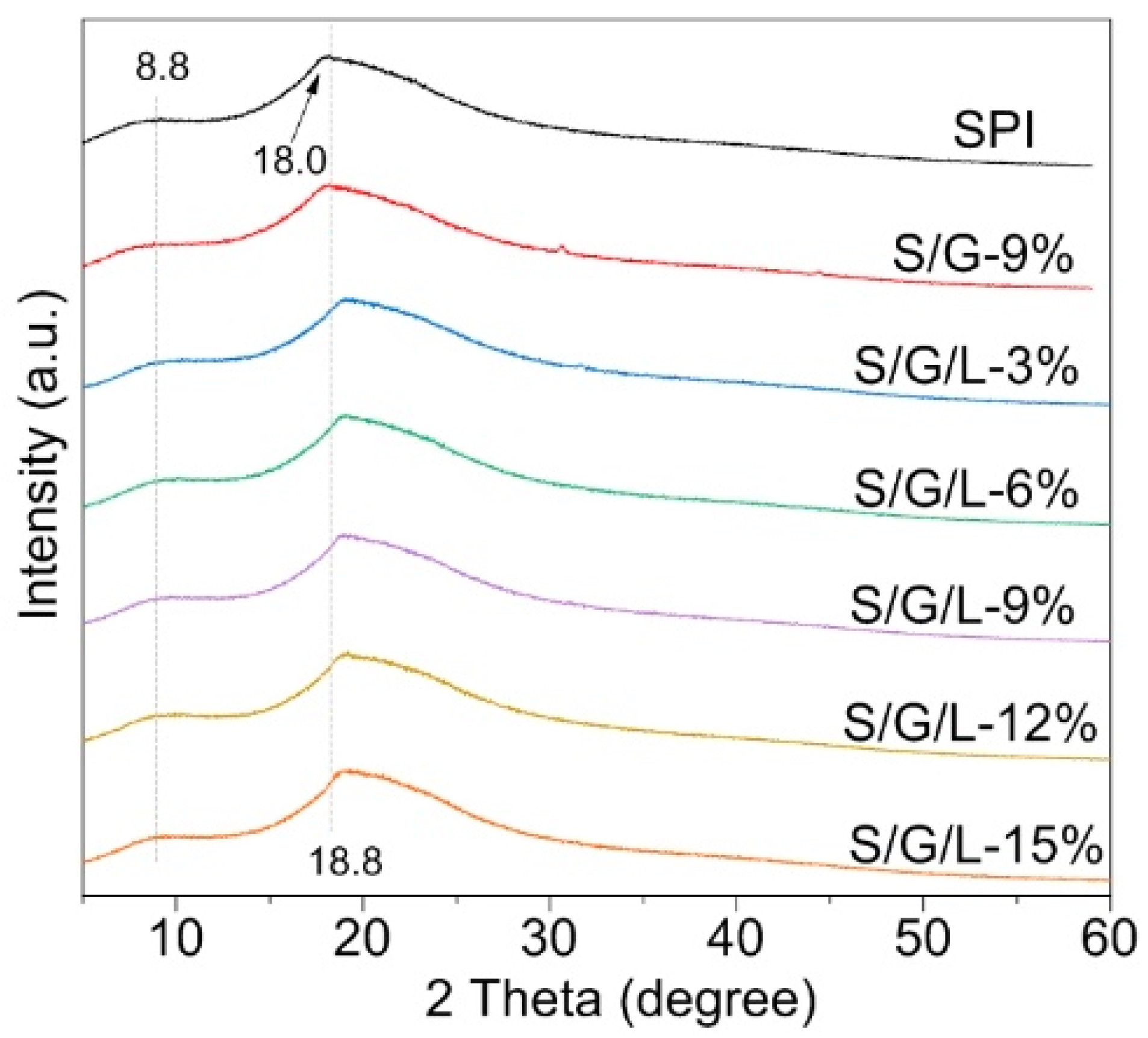

2.1. Fabrication and Structural Analysis of Modified Soy-Based Wood Adhesives

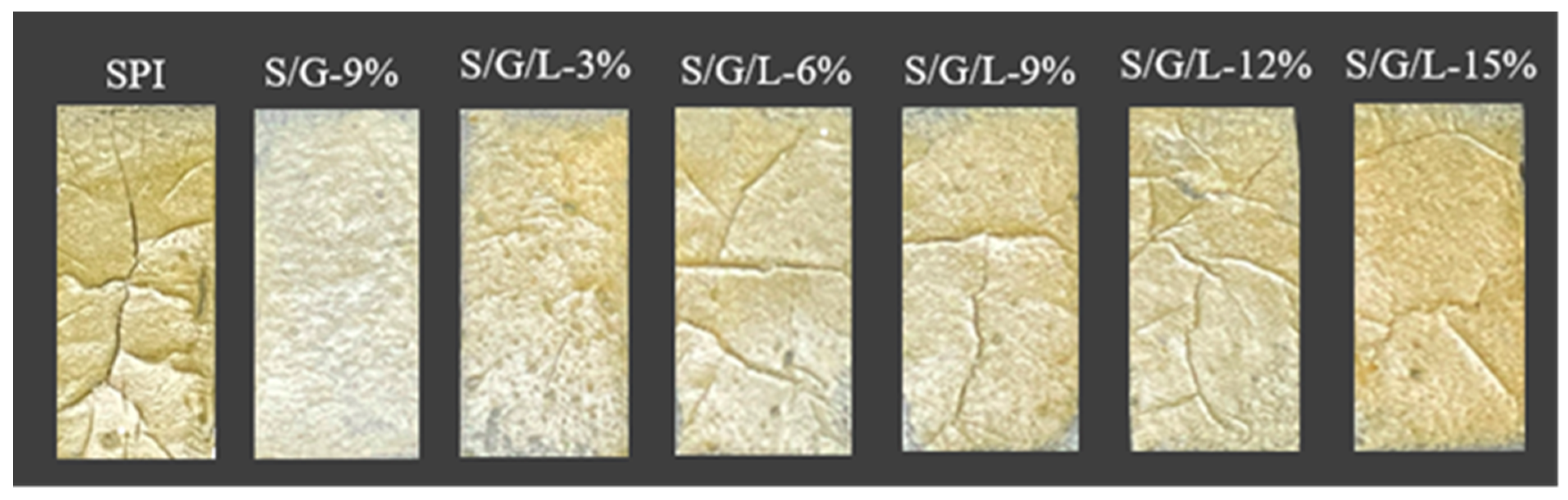

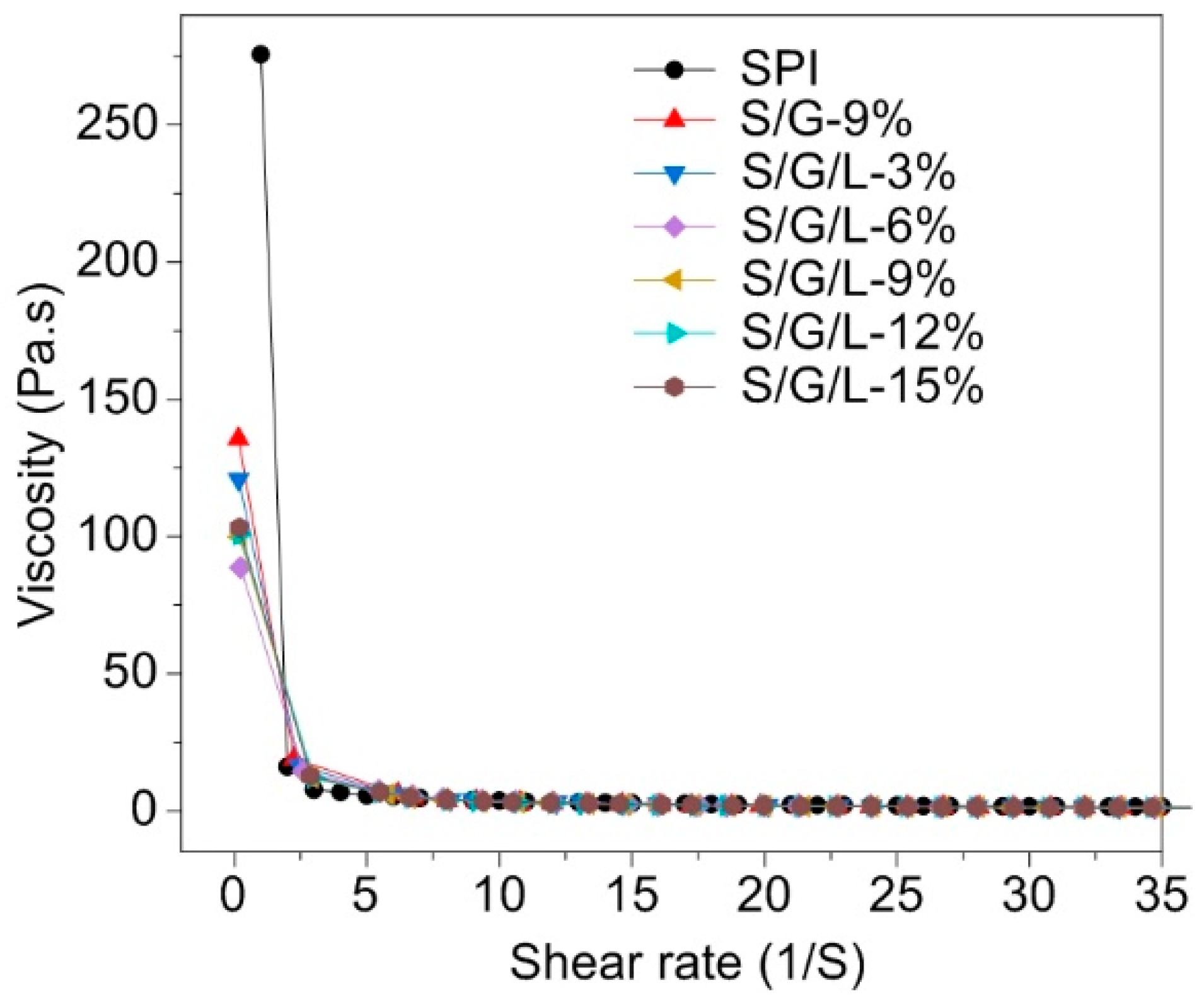

2.2. Apparent Toughness and Viscosity of SPI and Modified Soy-Based Wood Adhesives

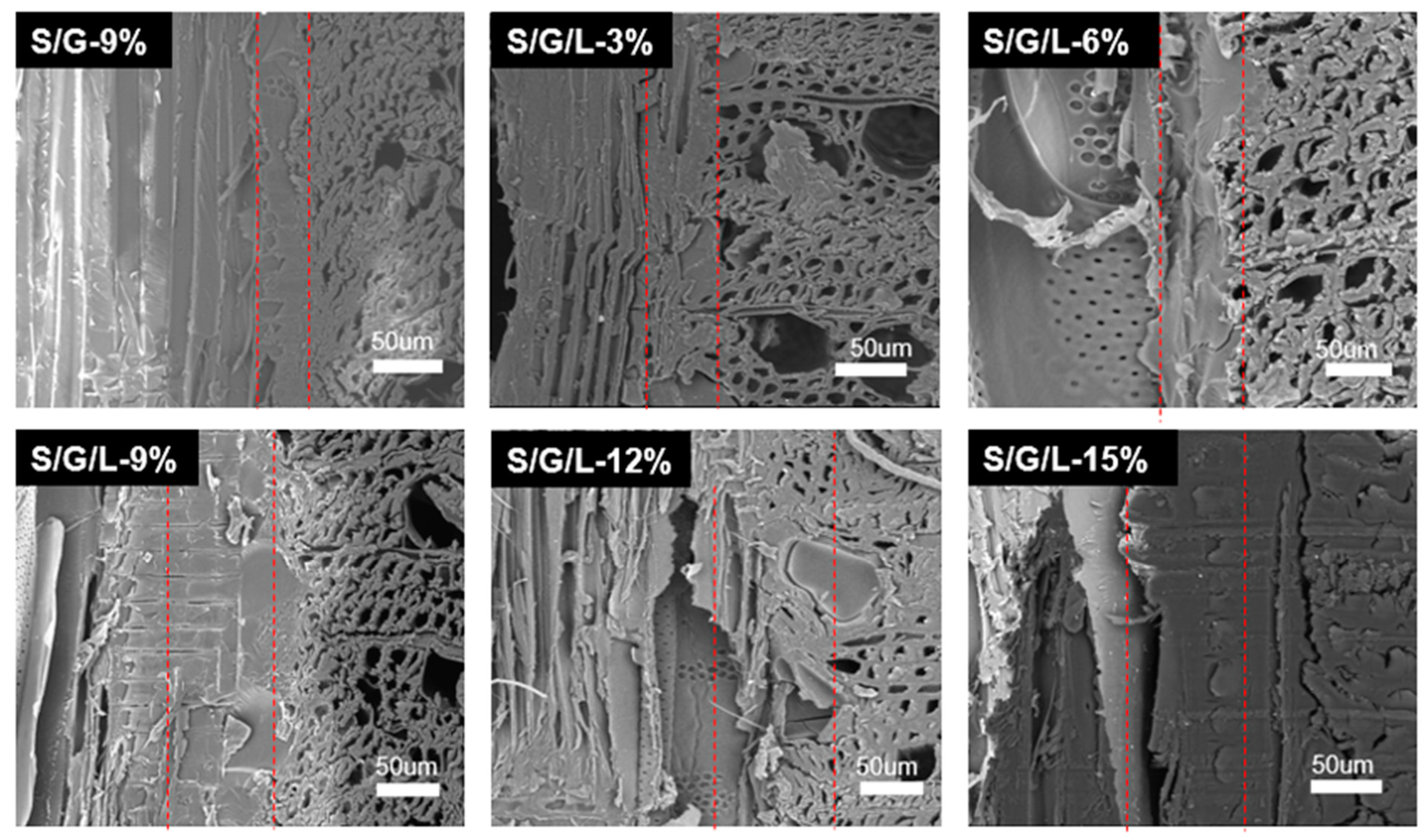

2.3. Micromorphology of the Modified Soy-Based Wood Adhesives

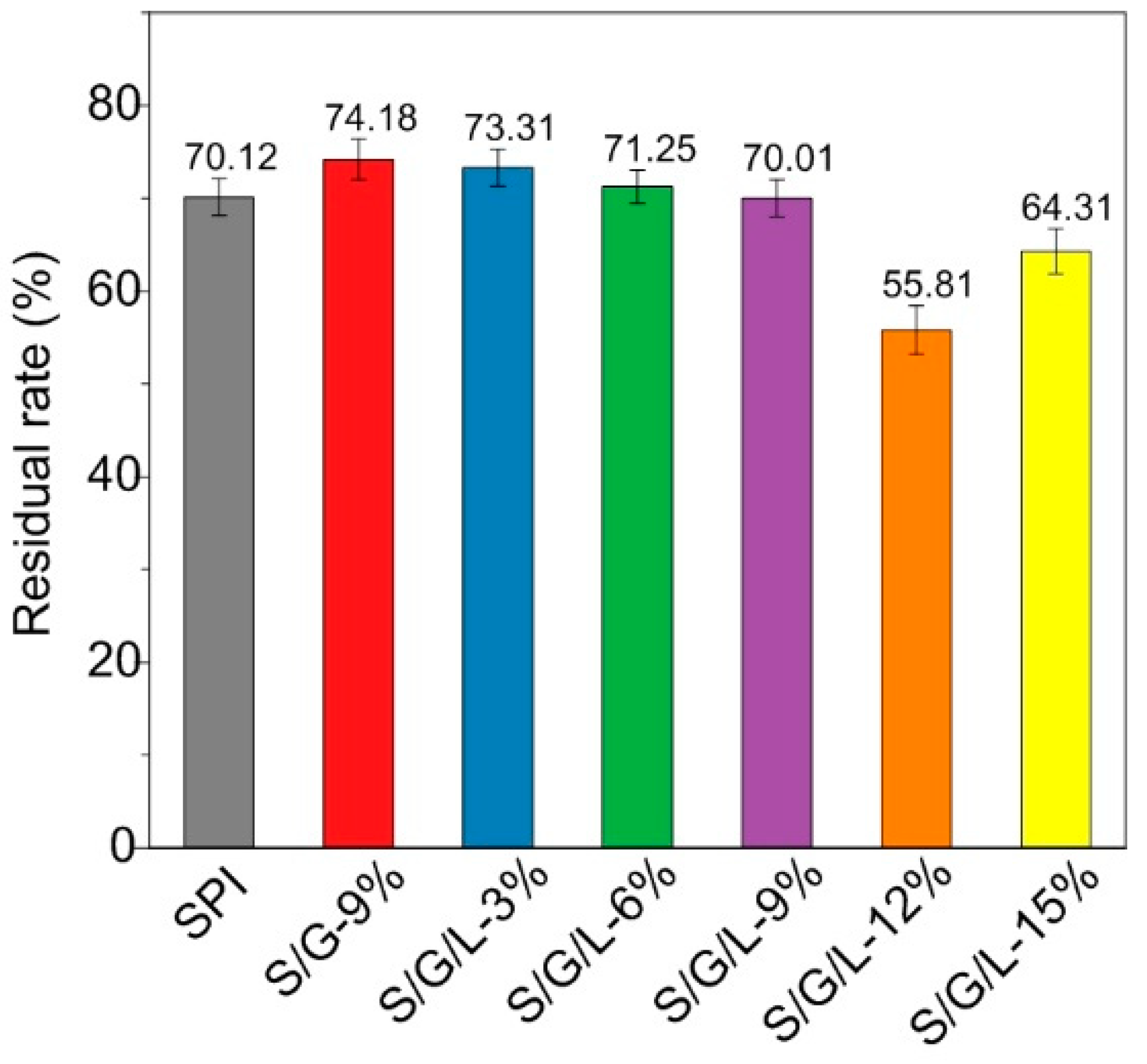

2.4. Performance of the SPI and Modified Soy-Based Wood Adhesives

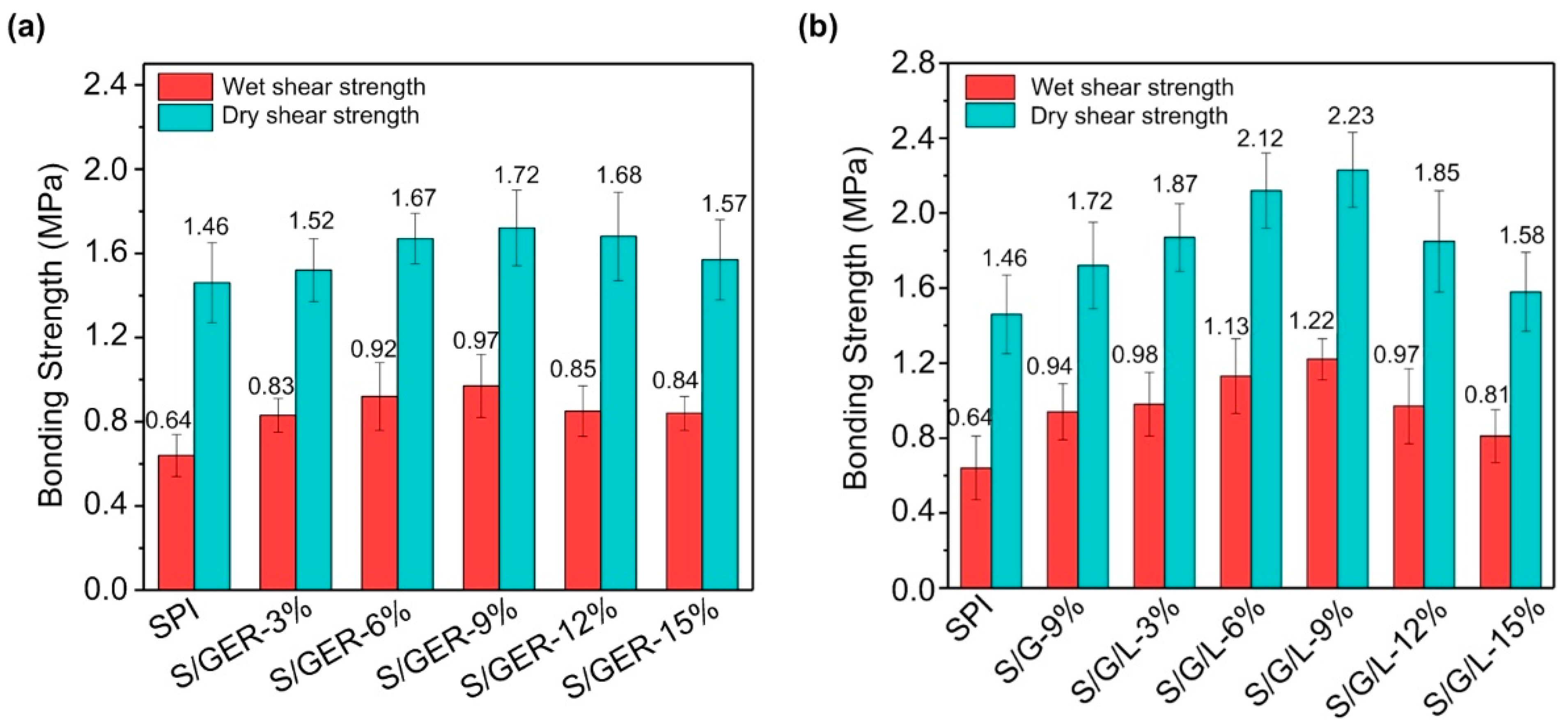

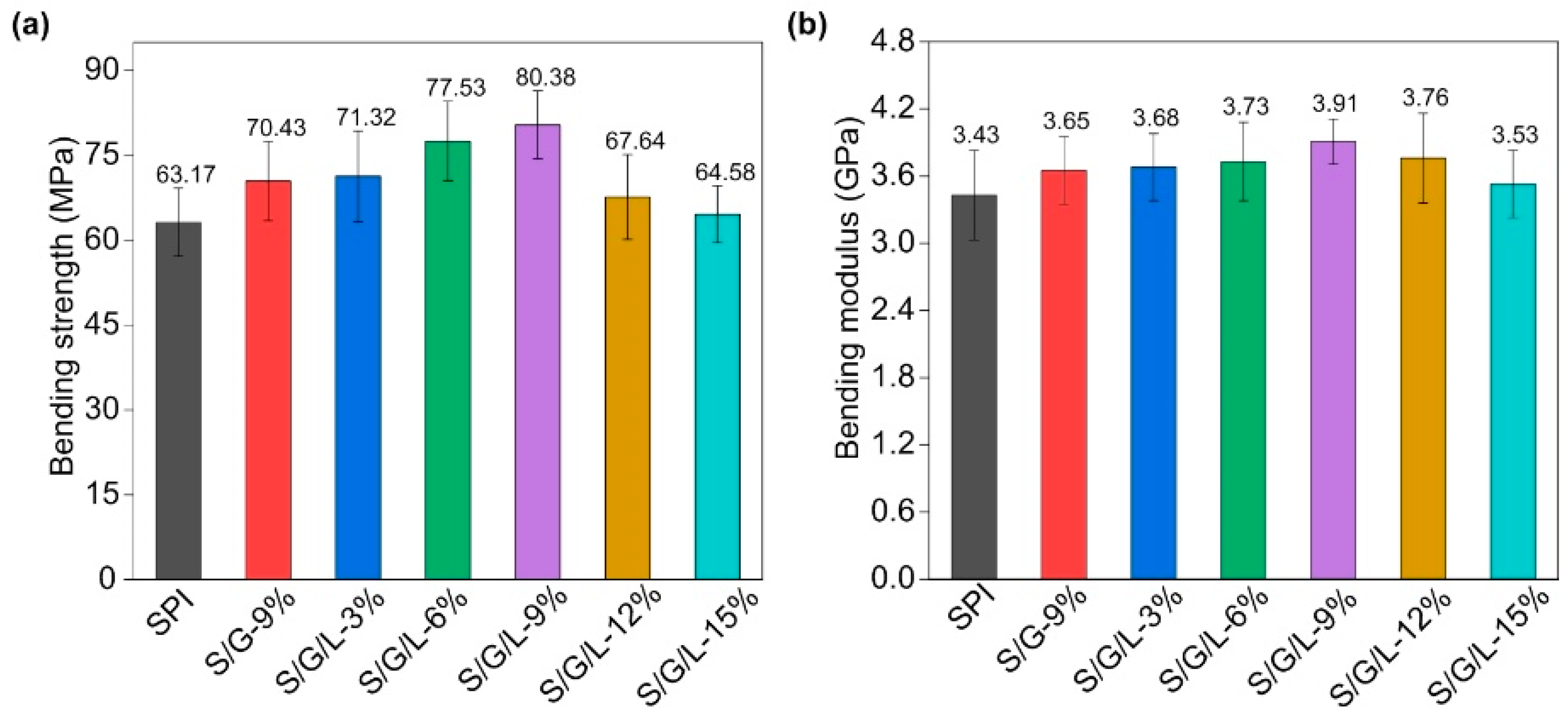

2.5. Mechanical Performance of the SPI and Modified Soy-Based Wood Adhesives

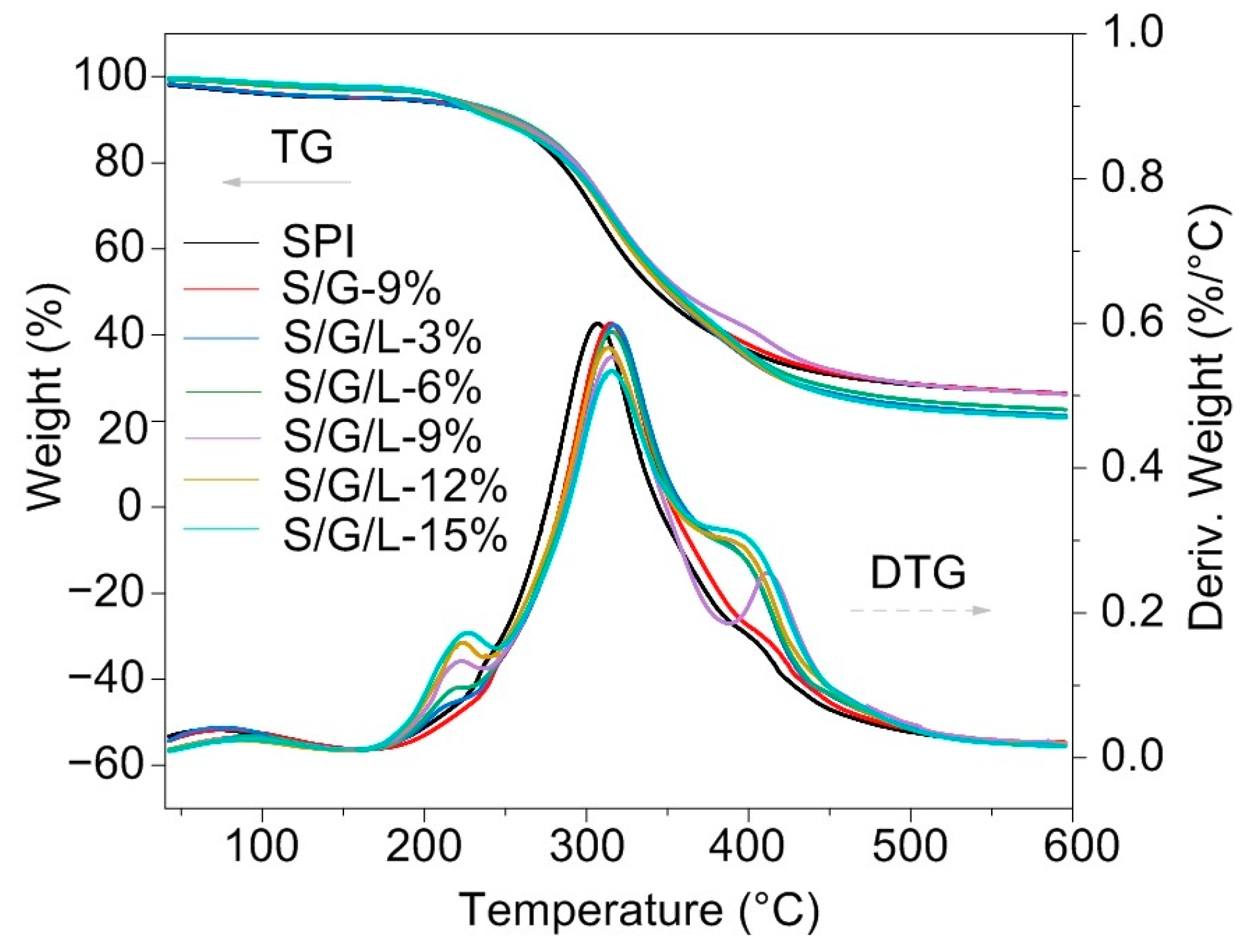

2.6. Thermal Stability of SPI and Modified Soy-Based Wood Adhesives

3. Materials and Methods

3.1. Materials

3.2. Preparation of the Modified Soy-Based Wood Adhesives

3.3. Characterizations

3.4. Cracking Observation

3.5. Thermal Performance

3.6. Mechanical Performance

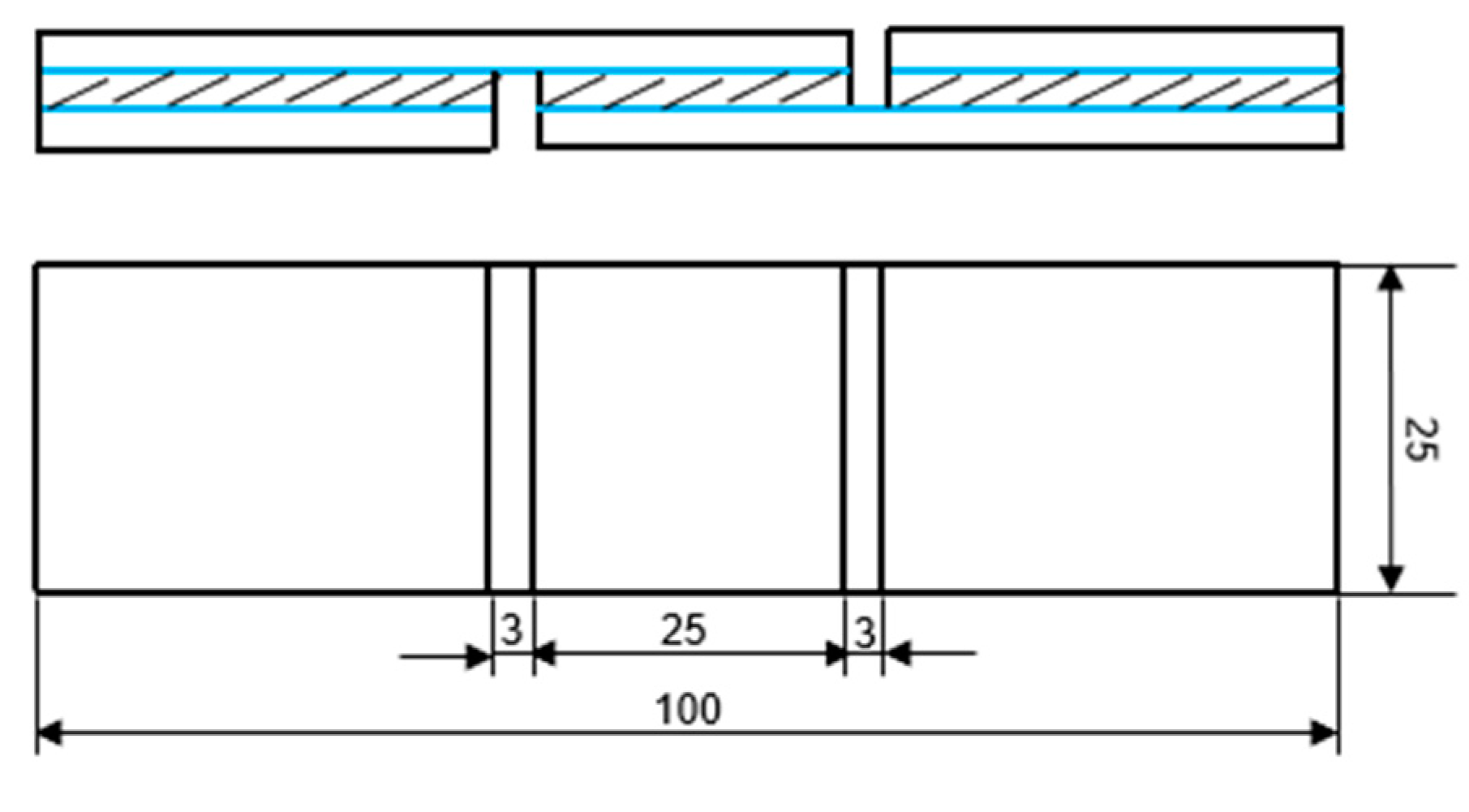

3.7. Plywood Preparation and Measurement

3.8. Apparent Viscosity Measurement

3.9. Residual Rate Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, W.; Li, F.; Liu, X.; Gao, Q.; Gong, S.; Li, J.; Shi, S.Q. Borate chemistry inspired by cell walls converts soy protein into high-strength, antibacterial, flame-retardant adhesive. Green Chem. 2020, 22, 1319–1328. [Google Scholar] [CrossRef]

- Cong, Y.; Chen, Y.; Xi, X.; Du, G.; Xu, G.; Lei, H. Polyamine-based polymer modified room temperature curing MUF adhesive. J. For. Eng. 2022, 7, 100–106. [Google Scholar] [CrossRef]

- Hussin, M.H.; Abd Latif, N.H.; Hamidon, T.S.; Idris, N.N.; Hashim, R.; Appaturi, J.N.; Brosse, N.; Ziegler-Devin, I.; Chrusiel, L.; Fatriasari, W.; et al. Latest advancements in high-performance bio-based wood adhesives: A critical review. J. Mater. Res. Technol. 2022, 21, 3909–3946. [Google Scholar] [CrossRef]

- Antov, P.; Lee, S.H.; Lubis, M.A.R.; Yadav, S.M. Potential of Nanomaterials in Bio-Based Wood Adhesives: An Overview. Emerg. Nanomater. Oppor. Chall. For. Sect. 2022, 25–63. [Google Scholar] [CrossRef]

- Tian, F.; Xu, X. Dynamical mechanical behaviors of rubber-filled wood fiber composites with urea formaldehyde resin. J. Bioresour. Bioprod. 2022, 7, 320–327. [Google Scholar] [CrossRef]

- Pang, B.; Zhou, T.; Cao, X.-F.; Zhao, B.-C.; Sun, Z.; Liu, X.; Chen, Y.-Y.; Yuan, T.-Q. Performance and environmental implication assessments of green bio-composite from rice straw and bamboo. J. Clean. Prod. 2022, 375, 134037. [Google Scholar] [CrossRef]

- Lam, S.S.; Xia, C.; Sonne, C. Plastic crisis underscores need for alternative sustainable-renewable materials. J. Bioresour. Bioprod. 2022, 7, 145–147. [Google Scholar] [CrossRef]

- Ye, Q.; Han, Y.; Zhang, J.; Zhang, W.; Xia, C.; Li, J. Bio-based films with improved water resistance derived from soy protein isolate and stearic acid via bioconjugation. J. Clean. Prod. 2019, 214, 125–131. [Google Scholar] [CrossRef]

- Zeng, Y.; Yang, W.; Xu, P.; Cai, X.; Dong, W.; Chen, M.; Du, M.; Liu, T.; Lemstra, P.J.; Ma, P.J. The bonding strength, water resistance and flame retardancy of soy protein-based adhesive by incorporating tailor-made core–shell nanohybrid compounds. Chem. Eng. J. 2022, 428, 132390. [Google Scholar] [CrossRef]

- Li, Y.; Cai, L.; Chen, H.; Liu, Z.; Zhang, X.; Li, J.; Shi, S.Q.; Li, J.; Gao, Q.J. Preparation of a high bonding performance soybean protein-based adhesive with low crosslinker addition via microwave chemistry. Int. J. Biol. Macromol. 2022, 208, 45–55. [Google Scholar] [CrossRef]

- Xu, C.; Xu, Y.; Chen, M.; Zhang, Y.; Li, J.; Gao, Q.; Shi, S.Q.J. Soy protein adhesive with bio-based epoxidized daidzein for high strength and mildew resistance. Chem. Eng. J. 2020, 390, 124622. [Google Scholar] [CrossRef]

- Gu, W.; Liu, X.; Ye, Q.; Gao, Q.; Gong, S.; Li, J.; Shi, S.Q. Bio-inspired co-deposition strategy of aramid fibers to improve performance of soy protein isolate-based adhesive. Ind. Crops Prod. 2020, 150, 112424. [Google Scholar] [CrossRef]

- Sun, Z.; Ye, R.; Jian, J.; Song, N.; Liu, T.; Fu, Q.; Gao, Z. Effect of pH of PAE resin on the structure andproperties of soybean adhesive. J. For. Eng. 2021, 6, 130–136. [Google Scholar] [CrossRef]

- Xu, Y.; Han, Y.; Chen, M.; Luo, J.; Shi, S.Q.; Li, J.; Gao, Q. Constructing a triple network structure to prepare strong, tough, and mildew resistant soy protein adhesive. Compos. Part B Eng. 2021, 211, 108677. [Google Scholar] [CrossRef]

- Jin, S.; Song, X.; Li, K.; Xia, C.; Li, J. A mussel-inspired strategy toward antimicrobial and bacterially anti-adhesive soy protein surface. Polym. Compos. 2020, 41, 633–644. [Google Scholar] [CrossRef]

- Zeng, G.; Zhou, Y.; Wang, T.; Li, K.; Dong, Y.; Li, J.; Li, J.; Fang, Z.J. A bio-based adhesive reinforced with functionalized nanomaterials to build multiple strong and weak cross-linked networks with high strength and excellent mold resistance. Chem. Eng. J. 2023, 453, 139761. [Google Scholar] [CrossRef]

- Tang, W.; Xu, Y.; Zhao, H.; Wang, Y.; Li, J.; Gao, Q. Synthesis and characterization of catechol-based polysaccharide crosslinking agent and its effect on the properties of soybean protein adhesive. J. For. Eng. 2022, 7, 136–143. [Google Scholar] [CrossRef]

- Jin, S.; Li, K.; Gao, Q.; Zhang, W.; Chen, H.; Li, J.; Shi, S.Q. Multiple crosslinking strategy to achieve high bonding strength and antibacterial properties of double-network soy adhesive. J. Clean. Prod. 2020, 254, 120143. [Google Scholar] [CrossRef]

- Lei, Z.; Jiang, K.; Chen, Y.; Yi, M.; Feng, Q.; Tan, H.; Qi, J.; Xie, J.; Huang, X.; Jiang, Y.J. Study on the bonding performance and mildew resistance of soy protein-based adhesives enhanced by hydroxymethyl l-tyrosine cross-linker. Int. J. Adhes. Adhes. 2022, 117, 103167. [Google Scholar] [CrossRef]

- Xu, Y.; Han, Y.; Chen, M.; Li, J.; Li, J.; Luo, J.; Gao, Q. A soy protein-based film by mixed covalent cross-linking and flexibilizing networks. Ind. Crops Prod. 2022, 183, 114952. [Google Scholar] [CrossRef]

- Qi, G.; Li, N.; Wang, D.; Sun, X.S. Physicochemical properties of soy protein adhesives modified by 2-octen-1-ylsuccinic anhydride. Ind. Crops Prod. 2013, 46, 165–172. [Google Scholar] [CrossRef]

- Luo, J.; Luo, J.; Li, X.; Gao, Q.; Li, J.J. Effects of polyisocyanate on properties and pot life of epoxy resin cross-linked soybean meal-based bioadhesive. J. Appl. Polym. Sci. 2016, 133, 43362. [Google Scholar] [CrossRef]

- Peng, J.; Xie, S.; Liu, T.; Wang, D.; Ou, R.; Guo, C.; Wang, Q.; Liu, Z. High-performance epoxy vitrimer with superior self-healing, shape-memory, flame retardancy, and antibacterial properties based on multifunctional curing agent. Compos. Part B: Eng. 2022, 242, 110109. [Google Scholar] [CrossRef]

- Reinhardt, N.; Breitsameter, J.M.; Drechsler, K.; Rieger, B. Fully Bio-Based Epoxy Thermoset Based on Epoxidized Linseed Oil and Tannic Acid. Macromol. Mater. Eng. 2022, 307, 2200455. [Google Scholar] [CrossRef]

- Zhang, S.; Zhong, T.; Xu, Q.; Su, Z.; Jiang, M.; Liu, P. The effects of chemical grafting 1, 6-hexanediol diglycidyl ether on the interfacial adhesion between continuous basalt fibers and epoxy resin as well as the tensile strength of composites. Constr. Build. Mater. 2022, 323, 126563. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, F.; Moon, K.S.; Wong, C. Novel curing agent for lead-free electronics: Amino acid. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 1020–1027. [Google Scholar] [CrossRef]

- Gambino, G.L.; Lombardo, G.M.; Grassi, A.; Marletta, G. Molecular Modeling of Interactions between l-Lysine and a Hydroxylated Quartz Surface. J. Phys. Chem. B 2004, 108, 2600–2607. [Google Scholar] [CrossRef]

- Sun, Y.; Zhong, R.; Zhang, H.; Huang, T.; Yu, J.; Fang, H.; Liang, D.; Guo, Z. Soybean milk derived carbon intercalated with reduced graphene oxide as high efficient electrocatalysts for oxygen reduction reaction. Int. J. Hydrog. Energy 2019, 44, 21790–21802. [Google Scholar] [CrossRef]

- Mousaa, I.; El-Sayyad, G.S.; Ghobashy, M.M. Green materials (DL-methionine/abietic acid)-based epoxy acrylate as promising antimicrobial and antibiofilm agents, and corrosion inhibitors for electron beam curable steel coating in different corrosive media. Prog. Org. Coat. 2022, 166, 106824. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, Y.; Xia, C.; Ahmad, A.; Yang, R.; Li, X.; Shi, S.Q.; Li, J.; Guo, M.; Nadda, A.K. Eco-friendly soy protein isolate-based films strengthened by water-soluble glycerin epoxy resin. Prog. Org. Coat. 2022, 162, 106566. [Google Scholar] [CrossRef]

- Chang, Z.; Zhang, S.; Li, F.; Wang, Z.; Li, J.; Xia, C.; Yu, Y.; Cai, L.; Huang, Z. Self-healable and biodegradable soy protein-based protective functional film with low cytotoxicity and high mechanical strength. Chem. Eng. J. 2021, 404, 126505. [Google Scholar] [CrossRef]

- Li, J.; Jiang, S.; Wei, Y.; Li, X.; Shi, S.Q.; Zhang, W.; Li, J.J. Facile fabrication of tough, strong, and biodegradable soy protein-based composite films with excellent UV-blocking performance. Compos. Part B Eng. 2021, 211, 108645. [Google Scholar] [CrossRef]

- Zeng, Y.; Xu, P.; Yang, W.; Chu, H.; Wang, W.; Dong, W.; Chen, M.; Bai, H.; Ma, P. Soy protein-based adhesive with superior bonding strength and water resistance by designing densely crosslinking networks. Eur. Polym. J. 2021, 142, 110128. [Google Scholar] [CrossRef]

- Kang, H.; Wang, Z.; Zhang, W.; Li, J.; Zhang, S. Physico-chemical properties improvement of soy protein isolate films through caffeic acid incorporation and tri-functional aziridine hybridization. Food Hydrocoll. 2016, 61, 923–932. [Google Scholar] [CrossRef]

- Zhao, S.; Wen, Y.; Wang, Z.; Kang, H.; Li, J.; Zhang, S.; Ji, Y. Preparation and demonstration of poly(dopamine)-triggered attapulgite-anchored polyurethane as a high-performance rod-like elastomer to reinforce soy protein-isolated composites. Appl. Surf. Sci. 2018, 442, 537–546. [Google Scholar] [CrossRef]

- Li, J.; Pradyawong, S.; He, Z.; Sun, X.S.; Wang, D.; Cheng, H.N.; Zhong, J. Assessment and application of phosphorus/calcium-cottonseed protein adhesive for plywood production. J. Clean. Prod. 2019, 229, 454–462. [Google Scholar] [CrossRef]

- Xu, Y.; Xu, Y.; Han, Y.; Chen, M.; Zhang, W.; Gao, Q.; Li, J. The effect of enzymolysis on performance of Soy protein-based adhesive. Molecules 2018, 23, 2752. [Google Scholar] [CrossRef]

- Xu, Y.; Han, Y.; Shi, S.Q.; Gao, Q.; Li, J. Preparation of a moderate viscosity, high performance and adequately-stabilized soy protein-based adhesive via recombination of protein molecules. J. Clean. Prod. 2020, 255, 120303. [Google Scholar] [CrossRef]

- Zeng, G.; Zhou, Y.; Liang, Y.; Zhang, F.; Luo, J.; Li, J.; Fang, Z.J. A hair fiber inspired bio-based adhesive with high bonding strength and mildew tolerance. Chem. Eng. J. 2022, 434, 134632. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, Y.; Li, X.; Li, J.; Shi, S.Q.; Li, J.; Luo, J. Spider Silk Inspired Robust and Photoluminescent Soybean-Protein-Based Materials. Macromol. Mater. Eng. 2021, 306, 2100155. [Google Scholar] [CrossRef]

- Li, C.; Zhang, J.; Yi, Z.; Yang, H.; Zhao, B.; Zhang, W.; Li, J. Preparation and characterization of a novel environmentally friendly phenol–formaldehyde adhesive modified with tannin and urea. Int. J. Adhes. Adhes. 2016, 66, 26–32. [Google Scholar] [CrossRef]

- Dunky, M. Wood adhesives based on natural resources: A critical review: Part I. Protein-based adhesives. In Progress in Adhesion and Adhesives; Mittal, K.L., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2021; pp. 199–332. [Google Scholar] [CrossRef]

- Pang, H.; Wang, Y.; Chang, Z.; Xia, C.; Han, C.; Liu, H.; Li, J.; Zhang, S.; Cai, L.; Huang, Z. Soy meal adhesive with high strength and water resistance via carboxymethylated wood fiber-induced crosslinking. Cellulose 2021, 28, 3569–3584. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Zhong, Z.; Wang, D.; Ratto, J.A.; Sheng, K.; Sun, X.S. Mechanical and water soaking properties of medium density fiberboard with wood fiber and soybean protein adhesive. Bioresour. Technol. 2009, 100, 3556–3562. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.-H.; Zhang, Y.-H.; Fang, B.; Zhang, L.-P.; Shi, J. The effects of thermal-acid treatment and crosslinking on the water resistance of soybean protein. Ind. Crops Prod. 2015, 74, 122–131. [Google Scholar] [CrossRef]

- Li, X.; Wei, Y.; Jiang, S.; Zhou, Y.; Li, J.; Li, K.; Shi, S.Q.; Li, J. Full Bio-Based Soy Protein Isolate Film Enhanced by Chicken Feather Keratin. Macromol. Mater. Eng. 2021, 306, 2100004. [Google Scholar] [CrossRef]

- Liu, S.; Wu, Y.; Du, G.; Yang, H.; Ni, K.; Su, H.; Ran, X.; Zhou, X.; Gao, W.; Yang, L.; et al. H2O2-mediated tannin bio-based wood adhesive inspired by starfish structure and phenol-amine synergy. Ind. Crops Prod. 2022, 188, 115714. [Google Scholar] [CrossRef]

| Sample | RCI a |

|---|---|

| SPI | 21.6 (0.7) b |

| S/G-9% | 15.4 (0.5) |

| S/G/L-3% | 18.9 (0.7) |

| S/G/L-6% | 16.3 (1.0) |

| S/G/L-9% | 21.4 (0.4) |

| S/G/L-12% | 20.6 (0.5) |

| S/G/L-15% | 22.3 (0.9) |

| Sample | Tpeak1 (°C) a | Tpeak2 (°C) a | Tpeak3 (°C) a | Residue (wt.%) | |

|---|---|---|---|---|---|

| T200 °C b | T600 °C c | ||||

| SPI | 218.1 | 304.1 | 400.5 | 93.2 | 26.3 |

| S/G-9% | 220.5 | 313.3 | 407.3 | 93.8 | 26.5 |

| S/G/L-3% | 216.7 | 314.2 | 386.2 | 93.4 | 21.3 |

| S/G/L-6% | 218.7 | 312.4 | 390.4 | 95.1 | 22.7 |

| S/G/L-9% | 220.4 | 314.1 | 411.7 | 94.8 | 26.2 |

| S/G/L-12% | 222.6 | 312.3 | 393.8 | 94.5 | 20.3 |

| S/G/L-15% | 223.8 | 313.4 | 392.2 | 94.2 | 20.9 |

| Sample | DI Water (g) | SPI (g) | GER (g) | Lys (g) |

|---|---|---|---|---|

| SPI | 44 | 6 | - | - |

| S/GER-3% | 44 | 6 | 0.18 | - |

| S/GER-6% | 44 | 6 | 0.36 | - |

| S/GER-9% | 44 | 6 | 0.54 | - |

| S/GER-12% | 44 | 6 | 0.72 | - |

| S/GER-15% | 44 | 6 | 0.90 | - |

| S/G-9% | 44 | 5.46 | 0.54 | - |

| S/G-9%/L-3% | 44 | 5.82 | 0.54 | 0.18 |

| S/G-9%/L-6% | 44 | 5.64 | 0.54 | 0.36 |

| S/G-9%/L-9% | 44 | 5.46 | 0.54 | 0.54 |

| S/G-9%/L-12% | 44 | 5.28 | 0.54 | 0.72 |

| S/G-9%/L-15% | 44 | 5.10 | 0.54 | 0.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Luo, Y.; Wang, Y.; Fei, T.; Dai, L.; Zhang, D.; Ma, H.; Cai, L.; Xia, C. Effects of Lysine on the Interfacial Bonding of Epoxy Resin Cross-Linked Soy-Based Wood Adhesive. Molecules 2023, 28, 1391. https://doi.org/10.3390/molecules28031391

Liang Y, Luo Y, Wang Y, Fei T, Dai L, Zhang D, Ma H, Cai L, Xia C. Effects of Lysine on the Interfacial Bonding of Epoxy Resin Cross-Linked Soy-Based Wood Adhesive. Molecules. 2023; 28(3):1391. https://doi.org/10.3390/molecules28031391

Chicago/Turabian StyleLiang, Yunyi, Yonghong Luo, Yang Wang, Tianyang Fei, Lili Dai, Daihui Zhang, Hongzhi Ma, Liping Cai, and Changlei Xia. 2023. "Effects of Lysine on the Interfacial Bonding of Epoxy Resin Cross-Linked Soy-Based Wood Adhesive" Molecules 28, no. 3: 1391. https://doi.org/10.3390/molecules28031391

APA StyleLiang, Y., Luo, Y., Wang, Y., Fei, T., Dai, L., Zhang, D., Ma, H., Cai, L., & Xia, C. (2023). Effects of Lysine on the Interfacial Bonding of Epoxy Resin Cross-Linked Soy-Based Wood Adhesive. Molecules, 28(3), 1391. https://doi.org/10.3390/molecules28031391