Abstract

The calamondin (Citrofortunella microcarpa) is a hybrid citrus fruit resulting from the crossing of a mandarin orange with a kumquat. It is a small, round-shaped fruit with thin, smooth skin ranging from orange to dark red. The aroma of the fruit is distinctive and unique. Calamondin is an excellent source of Vitamin C, D-Limonene, and essential oils, providing benefits to the immune system, as well as anti-inflammatory, anti-cancer, anti-diabetic, anti-angiogenic, and anti-cancer properties, and it exhibits various therapeutic effects. It also contains a good amount of dietary fiber from pectin. Its distinctive flavor and high juice content make calamondin juice a popular ingredient in many international cuisines. The juice also contains bioactive compounds, such as phenolics and flavonoids, which are a potential source of antioxidant properties. All parts of the calamondin fruit, including the juice, pulp, seeds, and peel, can be used in various applications, from food products like juices, powders, and candies to non-food uses in herbal medicine and cosmetics, showcasing their versatility and unique properties. This review will examine various bioactive components of calamondin and their related medicinal effects, and provide guidelines for their utilization, processing, and value addition on a commercial scale.

Keywords:

calamondin fruit; peel; phytochemicals; D-limomene; extraction; biological activities; byproducts 1. Introduction

Calamondin (Citrofortunella microcarpa), also known as Calamansi orange, is a hybrid citrus fruit cross between a kumquat and other citrus species. It is classified in the family Rutaceae, which includes plants such as lime, pomelo, and tangerine [1]. It is believed that calamondin originated in China and was then introduced to various regions, including Southeast Asia, India, Hawaii, the West Indies, Central America, and North America. Additionally, calamondin is often planted in the Philippines as an alternative to lime due to its tolerance of pests and diseases [2]. As a result of its resistance to pests and diseases, calamondin has become a crucial economic fruit in those countries, both for domestic consumption and as an export product [1]. The countries that import the most calamondin from Southeast Asia are the United States, Japan, South Korea, Canada, and Hong Kong. Calamondin fruit is commonly utilized in various ways in countries like Malaysia, Singapore, Vietnam, China, and Indonesia, for example, as an ingredient in cooking, medication, and medical cosmetics [1,2,3]. Furthermore, it can also be found in Europe and America, where it is being introduced as potted plants that decorate gardens and have a high commercial value. In many countries, calamondin fruits are mainly grown for household consumption and are sold when there is a surplus [3]. They are used as a substitute for lime in various dishes, such as shrimp paste sauce, salt, chili paste, pickled calamondin fruit, and calamondin fruit juice. Additionally, calamondin fruit juice is an inexpensive vitamin C source. Calamondin fruit comprises two parts: juice and juice byproducts (peel, seeds, pulp). The primary acids present in calamondin are ascorbic, dehydroascorbic, and citric acids. The peel and dregs of the fruit are rich in dietary fiber [1]. The peel also contains flavonoids, such as naringosi, hesperidin, diosmin, diosmetin, and hesperidin. The essential oils of calamondin fruit peel are clear liquids with a distinct fragrance. D-Limonene is the main constituent of the essential oils. The peel of calamondin has been found to have numerous biological and pharmacological benefits, including antioxidant, antibacterial, anti-inflammatory, anti-hyperglycemic, anti-diabetic, anti-angiogenic, and anti-tumor effects [1,2,3,4]. Acquiring knowledge about the various uses and value-added products of calamondin fruits is crucial for its commercialization and addressing malnutrition. This includes understanding its benefits, the chemical compounds it contains, and the potential value-added products that can be made from it to utilize it effectively in the future.

2. General Characteristics of Calamondin Fruit

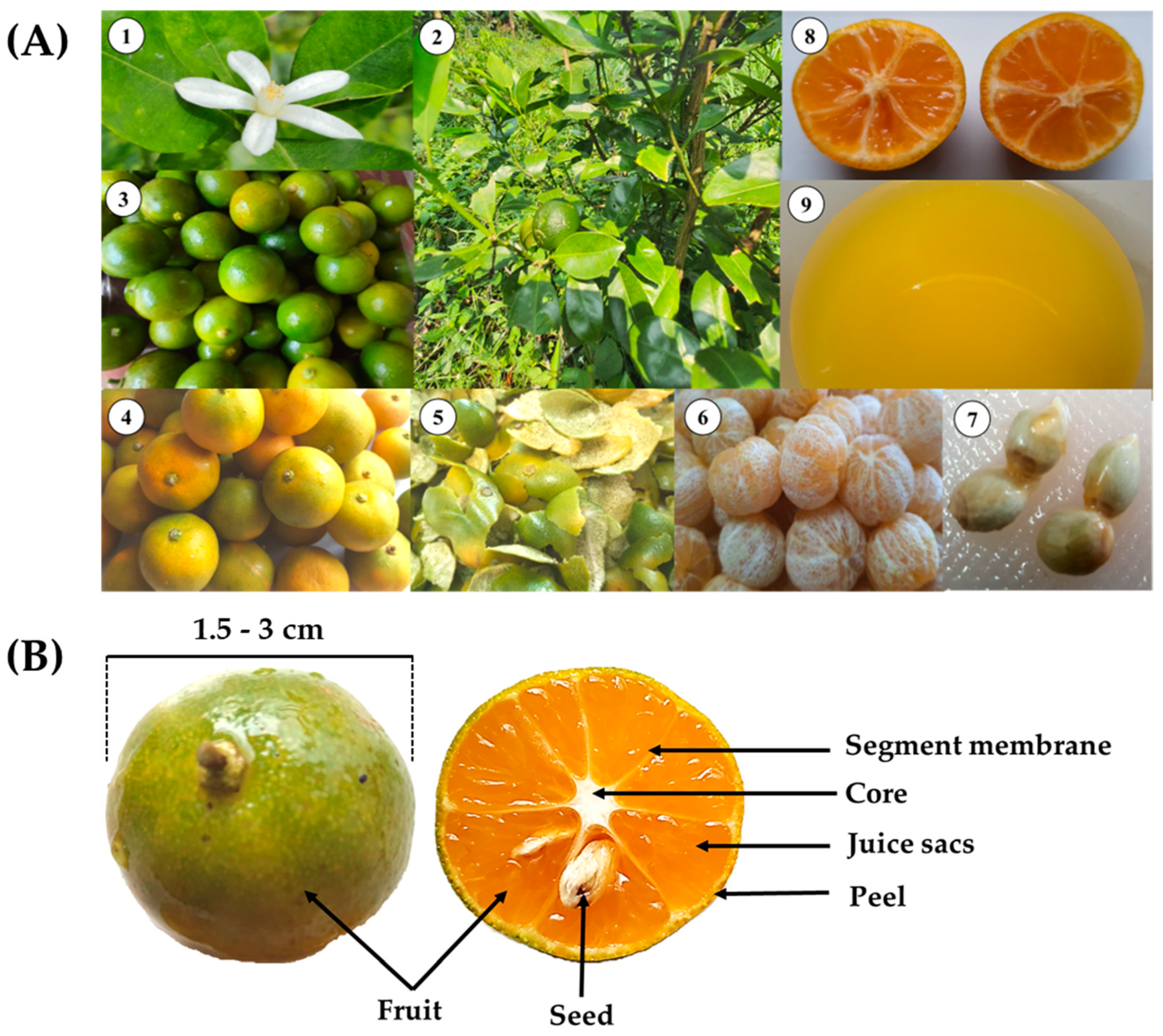

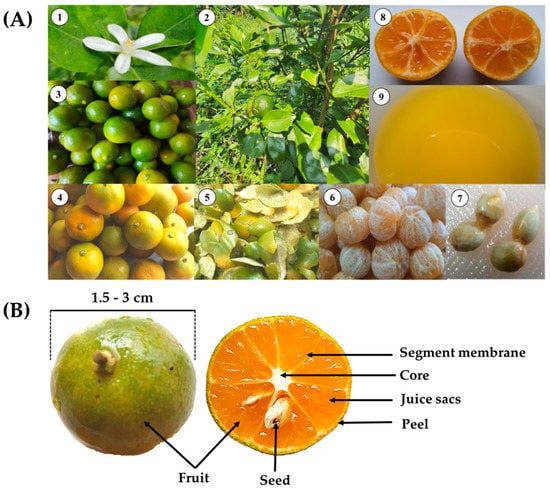

Calamondin is a tropical plant that is widely distributed and easy to grow in many tropical countries. The photographic illustration in Figure 1 shows the essential characteristics and structure of calamondin fruit. Calamondin can be propagated through sexual (seeds) and asexual (cutting, layering, budding, grafting) methods. It has a medium-sized shrub shape, reaching heights of 1.5–3 m, and its branches form dense bushes, giving it an attractive tree shape. Calamondin has oval-shaped leaves that measure 2–4 cm wide and 4–7 cm long, with a glossy surface. It flowers throughout the year, with single flowers appearing in short bouquets along the auxiliaries and branch ends, which are white and have a strong fragrance. Because of these features, it is often planted as an ornamental plant or a potted ornamental plant and bears fruits gradually throughout the year. Calamondin is similar to a lime because it produces more fruits during the rainy season than in the dry season. The fruit is round with a diameter of 1.5–3 cm, has a thin green skin that is fragrant, is divided into 7–10 segments, and has 1–7 seeds per fruit. As it ripens, the fruit turns a bright-orange color with a light-green tinge and is filled with juice [3].

Figure 1.

(A) General characteristics of calamondin: (1) flower, (2) stems and leaves, (3) unripe fruits, (4) ripe fruits, (5) peels, (6) peeled fruits, (7) seeds, (8) pulp, and (9) juice. (B) Calamondin fruit structure.

Citrus trees typically have 4–5 growth flushes per year, each with the possibility of producing flowers and fruit. However, most citrus only flowers and sets fruit during the spring flush. Lemons, limes, kumquats, and calamondins are exceptions, as they can flower and produce fruit year round. Calamondin, often grown as a bonsai, constantly blooms, releasing a citrus blossom scent. It may have both fruit and flowers at the same time. Non-spring flush fruit, such as oranges, tangelos, and grapefruits, have a puffy appearance, thick skin, and sheep-nosed shape. Calamondin fruit matures slowly, enhancing its ornamental value in the landscape for longer than other citrus fruits. It can be harvested all year, with peak abundance from November–June and increased sweetness towards the end of the season. However, the thin skin makes calamondins perishable after harvesting. Calamondin fruit may take up to a year to ripen and turn orange. However, an orange color may indicate over-ripeness and loss of flavor. Smaller than a regular lime, with a thin skin, it is best consumed within a week of harvest if not refrigerated. It is recommended to use clippers or scissors to pick the fruit to prevent stem-end tearing, which hastens degradation [4].

The growth stages of calamondin’s flowers, fruit, and seeds, from initiation to commercial maturity, are described by time intervals. Rosillo-Magno and Mapalo [5] reported the morphological study of calamansi fruit, which is essential for crop-breeding programs. The floral, fruit, and seed sections were stained with 1% safranin solution, then examined under a dissecting microscope. Based on distinct morphological events, the development phases are divided into nine stages for flowers, three for fruit, and four for seeds. Flowers take 17 to 23 days from bud creation to anthesis. Fruit requires 78 to 84 days to mature from anthesis to commercial maturity. From flower bud creation to commercial maturity, fruit takes 94 to 101 days, and its skin becomes lustrous and smooth. Cross-pollination can be completed between 17 and 23 days after flower bud development. Immature fruit 59 to 73 days after flower development is suitable for extracting zygote, nucellus, and endosperm tissues for plant tissue culture breeding. The storage conditions can affect the calamondin fruit’s chemical composition and pericarp color. To maintain the chemical composition and color of the fruit, it is essential to store it under appropriate conditions. Good manufacturing practices, such as storing it in the dark and immersing it in benzyl adenine, a synthetic cytokinin, can slow down respiration, deterioration, and chlorophyll degradation. This method will help to slow down the color change of the calamondin fruit peel. Various post-harvest management techniques, such as soaking, pickling, drying, and cooking, are commonly used in Vietnam and the Philippines. Despite their small size, the fruits can be used in their entirety, from the peel and juice to the dregs, and are nutritious and can be processed into various products [6].

3. Chemical Composition and Bioactive Compound of Calamondin Fruit

Fresh calamondin fruit comprises two main components: juice, which accounts for 47.5 g, and byproducts from juicing (peel, seeds, and pulp), which account for 52.5 g. The byproducts are primarily composed of 80% liquid and 20% pulp. Each fruit provides 12 calories, with a low-fat content, 1.2 g of dietary fiber, 37 mg of potassium, 7.3 mg of vitamin C, 54.4 mg of vitamin A, and 8.4 mg of calcium [7]. Studies have also reported on the chemical composition of different parts of the calamondin fruit: the juice contains 0.10% total flavonoids, 6.74% total acid, 0.37% reducing sugar, and 1.68% vitamin E. The fruit pulp has flavonoids at 1.02%, pectin at 5.04%, limonin at 0.03%, and reducing sugar at 4.56%. The fruit peel contains 1.00% flavonoids, 7.14% pectin, 0.51% limonin, 5.98% reducing sugar, and 4.25% essential oils (volatile oils). The fruit seeds contain 0.46% limonin, reducing sugar, and 30.46% essential oils (volatile oils). The fruit dregs also contain 44.83 mg/kg of vitamin B2, 19.31 mg/kg of vitamin B3, 17.55 mg/kg of vitamin B6, and 15.72 mg/kg of vitamin E. The most common amino acids in the fruit residue, as reported by Zou et al. [8], are aspartic acid (4.42 g/kg), proline (3.65 g/kg), cysteine (2.10 g/kg), glutamic acid (1.81 g/kg), and isoleucine (1.00 g/kg) (Table 1). The fresh fruit has a unique flavor that combines the tastes of mandarin and lime with a slight hint of mandarin peel and tartness. Table 2 shows that the volatile intensity of the peel is three times higher than that of the juice.

Table 1.

Chemical composition of various parts of calamondin fruit [8].

Table 2.

Flavor profiles of fresh calamondin peel and juice [9].

Calamondin fruits contain ascorbic, dehydroascorbic, and citric acids as their primary acids. The peel and dregs of the fruit are high in dietary fiber, with a total of 84.25% dietary fiber, 48.49% insoluble fiber, and 35.76% soluble fiber [10]. Although not considered nutrients, the fibers from calamondin fruit play a significant role in the body by promoting regular bowel movements and helping to excrete food waste and toxins the body does not need. This can help to keep the intestines functioning normally and reduce the risk of colorectal cancer [1]. Soluble fiber can absorb a large amount of water and thicken food by increasing the viscosity. Once it reaches the small intestine during digestion, the viscous fiber thickens the intestinal wall, slowing the absorption of sugary foods and preventing sudden drops in blood sugar levels, known as acute hypoglycemia. Soluble fiber can also help reduce cholesterol levels and remove certain metal toxins from the body [11]. The fruit has medicinal properties, including its various organic acids. The fruit juice mixed with salt can alleviate coughing and phlegm, while the ripe fruit can be pickled, dried, or stored to treat sore throats. Raw fruit peels can also be used as a carminative [4,5,6]. Essential oil can be obtained from the peel of calamondin fruit, whether fresh, dried, or frozen. The fruit peel contains various important chemicals (limonene, α-pinene, β-pinene, linalool, geraniol, and citral) similar to those found in other citrus fruits of the Rutaceae family. The fruit peel also contains flavonoids like naringosi, hesperidin, diosmin, diosmetin, and hesperidin, which can protect the walls of blood vessels, reduce their permeability, and increase their elasticity, thus preventing blood vessel rupture and lowering blood pressure [1,12]. Essential oils extracted from the calamondin fruit peel are clear liquids with a distinct aroma. The essential oils of calamondin consist of 25 compounds, with D-Limonene being the most abundant, accounting for about 85% of the total (Table 3). The results of gas chromatograph–mass spectrometer (GC-MS) analysis showed a change in the composition of the calamondin peel oil, with limonene increasing from 90.4% to 92.87%. Santolina remained unchanged, α-terpineol was no longer present, and β-pinene increased from 1.01% to 1.03%, while other chemicals decreased. The improvement in oil content was due to refinement, resulting in a purer white color and distinct scent as unneeded components were removed and the limonene content increased. The essential oil has various benefits, such as preventing nail fungus, promoting restful sleep, treating headaches, stimulating appetite, deodorizing, reducing blood sugar levels, and relieving flatulence. It also can potentially prevent the development of liver, esophageal, colon, and skin cancers [12].

Table 3.

Ingredients of crude and refined calamondin peel oil [12].

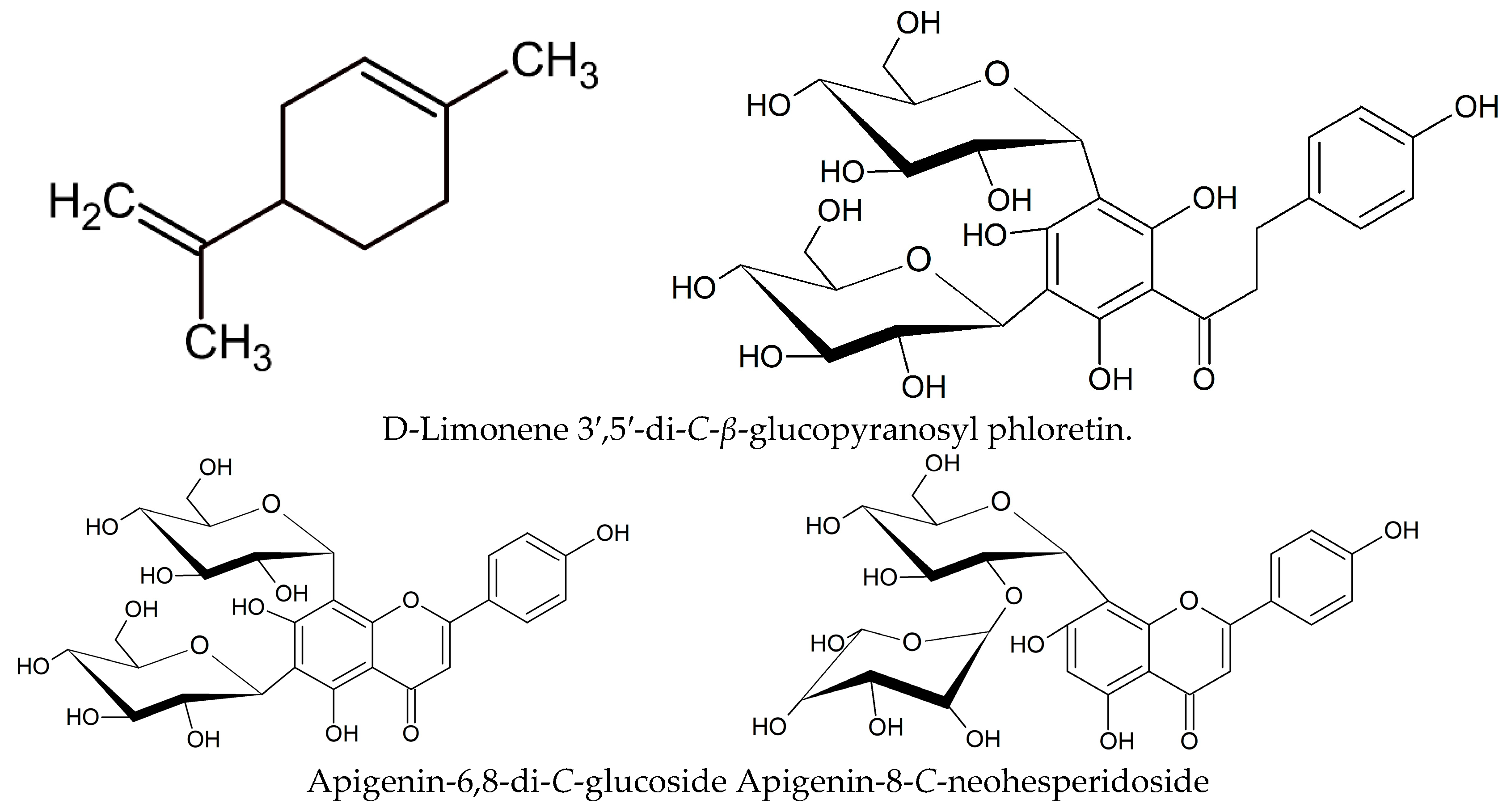

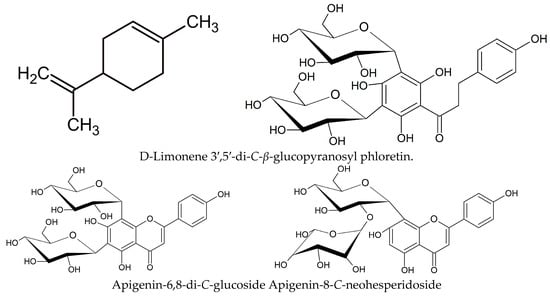

D-Limonene (C10H16) is a hydrocarbon that appears as a clear liquid and is classified as a terpenoid (Figure 2). It belongs to the group of monoterpenes and can be found in various citrus plants, such as oranges and limes, on the surface of the fruit peel. D-Limonene is found naturally in a variety of citrus plants, such as limes, oranges, lemons, and kaffir limes, and is commonly used as a flavoring agent in the food industry, as well as in cosmetic products like shampoos, lotions, and soaps. The limonene can be extracted from the fruit peel using steam or organic solvent. D-Limonene can be extracted using various methods; the primary solvents used for extractions include hexane, methanol, and acetone, and the yield of D-limonene varies with the type of solvent used. D-Limonene has various beneficial biological properties, including anticarcinogenic activity, antioxidant activity, effects on apoptosis, and modulation of the immune system [12,13]. Phenolic compounds, such as flavonoids, possess nutraceutical properties that benefit health. Flavonoids are phenolic compounds containing an aromatic ring with two or more hydroxyl groups in their chemical structure. They are often found in combination with sugar moieties (glucose, rutinose, and neohesperidose) as glycoside compounds [13].

Figure 2.

Chemical structures of D-Limonene; 3′,5′-di-C-β-glucopyranosyl phloretin; apigenin-6,8-di-C-glucoside; and apigenin-8-C-neohesperidoside in calamondin fruit peel.

Currently, D-Limonene is used in various industries, which include the following:

- Food processing, where it can be used as a mask for the bitter taste of alkaloids [14].

- Flavorings for food products with a citrus or lime flavor, such as chewing gum, beverages, etc. [15].

- Pharmaceutical applications, for use as a penetration enhancer for topical creams or lotions [16].

- Perfumery in skin care products, such as lotions, body wash, and soap [17].

- Natural insecticide flavorings [18].

- Organic herbicide products [19].

Furthermore, the peel and juice sacs contain major flavonoids, such as 3′,5′-di-C-β-glucopyranosyl phloretin (DGPP), apigenin-6,8-di-C-glucoside (vicenin-2), and apigenin-8-C-neohesperidoside (Figure 3). Calamondin juice is widely used commercially, producing excess waste, such as seeds, pulp, and peel. These byproducts can be beneficial and help reduce environmental pollution when used as herbal medicine. The juice, peel, pulp, and seeds of calamondin have been found to exhibit various biological and pharmacological properties, including antioxidant activity and antimicrobial, anti-inflammatory, anti-hyperglycemic, anti-diabetic, anti-angiogenic, and anti-tumor properties, particularly in the peel [20,21,22,23,24,25,26,27,28,29,30,31] (as shown in Table 4).

Figure 3.

Calamondin and its processed products: (1) Calamondin candy, (2) Sterilized juice, (3) Dried peel, and (4) Residue powder.

Table 4.

Bioactive compounds of calamondin juice, peel, pulp, and seeds and their bioactivities.

4. Utilization of Calamondin Fruit

The calamondin fruit is used to produce a broad range of processed and non-food items (as illustrated in Figure 3). Calamondin fruit is used as a substitute for lime in various forms, such as freshly squeezed juice, mixed with other fruit juice, syrup, powder, jam, tea, and candy, and is used as a condiment in many savory and sweet dishes. The fibers extracted from the fruit can also partially replace wheat flour in the production of steamed bread. Incorporating 3–6% of dietary fiber powder from the fruit into steamed bread production results in more complex bread; however, it may also decrease the bread’s cohesiveness, specific volume, and elasticity. This proportion of fiber powder is considered an appropriate amount and results in bread products that are high in fiber, which is beneficial for health, as well as phytochemicals and antioxidant capacity [32]. In addition to being used for human consumption, the calamondin fruit is also utilized in cosmetics and skin care products. It is used in forms such as scrubs, massages, applications, rubs, masks, and various other forms for beauty enhancement. The properties of these cosmetics cannot cure, treat, relieve, or have a therapeutic effect on the skin, but they can be used to conceal various dark spots on the skin. Calamondin fruit is also used in cosmeceuticals, skin care products that have the same properties as cosmetics, but can also treat various skin disorders, such as acne, wrinkles, dark spots, and freckles. It also has a healing effect on the skin, similar to medicine [14,21,33].

The fruit is rich in vitamin C, polyphenols, and trace elements. Polyphenols, a type of phenolic compound found in plants, have the potential to scavenge free radicals due to their stable structure after binding to free radicals. The calamondin fruit peel is also rich in tangerine and sinensetin. The fruit extract possesses properties as an antioxidant and skin-whitening agent, making it suitable for use in cosmetic and cosmeceutical products, which enhances the effectiveness of the product [33]. Furthermore, calamondin fruit can also be used to eliminate dandruff, alleviate itchy scalps, promote hair growth, prevent respiratory diseases, stimulate blood circulation, aid in normal digestive function, alleviate symptoms of insect bites, relieve cough, expel phlegm, treat acne, and reduce wrinkles [34].

5. Examples of Calamondin Fruit Processing

5.1. Juice and Juice Concentrate

Calamondin juice has a total soluble solid content of 9.0°Brix, pH of 2.40–3.00, and citric acid of 4.50–5.80% [35]. The best juice is made from mature and sound fruit harvested optimally. The quality of calamondin juice depends on the quality of the fruit. To ensure high quality, the fruit must be fully mature, with the suitable sugar, acid, color, flavor, and firmness levels. Proper handling during harvest, transportation, and storage is crucial for preserving freshness and quality. To maintain the fruit quality and prevent decay, the temperature, humidity, and cleanliness must be regulated during storage to prevent damage from pests, bacteria, molds, yeasts, etc. [36]. Juice extraction can be done with machinery or by hand. For large-scale juice production, standard methods use calamondin fruit juice extractors. For small-scale juice production, pressing, centrifuging, or reaming extractors can be used. Home, retail, and manufacturing locations can access various small-scale juice extractors [35]. Calamondin juice is pasteurized to eliminate harmful and spoilage microorganisms since its acidic nature (pH 4.6) only needs to kill microorganisms in their vegetative state [36]. Research has been done on calamondin-based products, such as concentrated non-alcoholic syrups for beverages, made from calamondin juice, water, and sugar or sugar substitutes and may include added food coloring and flavoring [37]. A study examined the effect of storage time on calamondin fruit squash with 43°Brix and 60°Brix sweetness levels stored at room temperature. The study found that the storage time impacted the squash’s L* and b* values, and more sediment was observed in the 60°Brix sweetness level compared to the 43°Brix level. However, the storage time did not affect the total soluble solids and pH levels of the calamondin fruit squash. The titratable acidity and ascorbic acid levels in calamondin squash decreased as the storage time increased from 2 to 6 weeks. The total microorganisms, including yeast and molds, reached standard levels after ten weeks of storage [10]. A mocktail drink was made using calamondin juice and camote leaf extract, and its physiochemical and sensory qualities were evaluated. The mocktail was marketable, with the optimal composition consisting of 200 g refined sugar, 175 mL calamondin juice extract, and 1200 mL camote leaf extract. The mocktail met taste preferences when made as instructed, with good overall quality [38].

5.2. Pectin

Pectin is a polysaccharide found in the peel and pulp of calamondin fruits, and it functions as a natural cement to help the cell wall hold together. It comprises D-galacturonic acid, methyl lacturonate, and other sugars like rhamnose, galactose, and arabinose. Pectin makes up about 65% of the weight of the peel and pulp and plays a crucial role in maintaining the structural integrity of the fruit [39]. Extracting pectin from the skin of calamondin fruit involves several steps. First, the fruit’s peel, a byproduct of oil extraction, is dried and crushed. The resulting powder is then adjusted to a pH of 1 and treated with citric acid. The mixture is heated in a temperature-controlled bath at 80 °C for 10 min, after which it is filtered to separate the dregs. The filtered solution is then precipitated with ethanol and centrifuged at 4000 rpm for 15 min to obtain jelly pectin. The jelly pectin is then dried at 50 °C for 10 h to obtain pectin from the calamondin fruit peels. The highest yield of pectin from calamondin using ethanol as a solvent was 45.7%, indicating that calamondin pectin has the potential to replace halal gelatin in the food, cosmetics, and pharmaceutical industries [40]. Pectin from citrus fruit peels has various uses in the food industry, including gelling in jams/jellies with sugar and acid [41], thickening [42], stabilizing food products to prevent sedimentation [43], acting as an emulsifier [44], and serving as a prebiotic food for beneficial probiotics [45].

5.3. Tea

Calamondin fruit is commonly used as a raw material in producing various fruit teas and desserts, including calamondin tea [4]. The juice from the fruit is often used in this context due to its low sugar content, pungent aroma, and high levels of ascorbic acid, dehydroascorbic acid, and citric acid [46]. Calamondin fruit tea is made by steeping slices or peels of the fruit in boiling water. This type of tea is popular in Taiwan, particularly during the winter, as it has a warm, comforting aroma and a unique flavor. Additionally, the essential oils found in the fruit can provide a warming sensation when consumed [47]. The whole fruit contains monoterpene alcohols, such as linalool, terpinen-4-ol, and a lot of -terpineol, which can affect the flavor of calamondin fruit teas. The essential oil extracted from calamondin fruit peel has higher sesquiterpenes, such as germacrene D, than those found in whole calamondin fruit oils [48]. A study compared the methods of extracting essential oils from the whole calamondin fruit and its peel. It was found that using heat treatment in the extraction process increased the yield of essential oils from both the fruit and peel. The essential oils from the whole fruit contain monoterpene alcohols, such as linalool and terpinen-4-ol, which contribute to the unique flavor of calamondin fruit teas. The essential oils extracted from the peel have a higher concentration of sesquiterpenes, such as germacrene D, than the whole fruit [49].

5.4. Calamondin Fruit Powder

Calamondin fruit powder, with its high citric acid content and unique sour taste, is commonly used as a flavoring ingredient in a wide range of food and beverage products, including beverages, teas, cocktails, marinated meats, seafood, dairy products, and baked goods [35]. Due to its high antioxidant content, it can also be added to meat and fish products to prevent fat oxidation and extend shelf life [50]. The production of calamondin fruit powder involves several steps (Figure 4): (1) selecting fresh and fully ripe calamondin fruits to ensure good quality powder, (2) sorting and cleaning the fruits to remove any defects or impurities, (3) disinfecting the surface of the fruits to reduce the presence of pathogens, (4) cutting the fruits in half to facilitate water removal and seed removal, (5) drying the fruits in an oven at a low temperature, (6) grinding the dried fruits into a fine powder, (7) packaging the powder in sealed containers to prevent moisture absorption, (8) storing the powder in a cool and dry place, such as a refrigerator, for up to 6 months. This process can produce high-quality calamondin fruit powder with high antioxidant content, which can be used as a flavoring ingredient in food and beverage products and prevent fat oxidation in meat and fish products [40,51]. The leftover fruits from juicing can be dried and ground into powder, which can be used as an ingredient in body scrubs in the spa industry and other cosmetic products [52]. Several drying techniques are used to produce calamondin fruit powder. A study was conducted to determine the optimal conditions for producing the powder using spray drying and to examine its chemical and physical properties. The experiment involved preparing calamondin juice; blending it with maltodextrin at ratios of 10%, 20%, and 30%; and spray drying it at an inlet temperature of 170 °C and a feed rate of 20 RPM. The results showed that maltodextrin at a 10% concentration produced a yellow powder with a distinct calamondin odor and high vitamin C content [53]. The production of a ready-to-drink fruit beverage using calamondin juice and fluidized bed drying was studied. The process involved converting calamondin juice into a powder or agglomerate, adding citric acid, flavor, and color to enhance the flavor, acid–sugar balance, and appearance. The optimal process conditions were 45 °C process temperature, 20 m3/h airflow rate (1.5 m/s air velocity), 3 bars atomization pressure, and 6 g/min pump flow rate. The resulting fruit moisture content was 83.8%, and juice recovery was 35.8%. The analysis showed a total titratable acidity of 5.8%, pH of 2.4, total soluble solid of 8.5, and viscosity of 5.1 cP. The bulk density of the agglomerate was 0.6 g/mL, with a suitable particle size distribution. Compared to diluted calamondin juice, the calamondin drink performed better in a sensory evaluation [54].

Figure 4.

Calamondin powder: (1) grading, (2) cutting and removing seeds, (3) after dehydration, and (4) powder after using a grinder.

5.5. Candy Products

Candy refers to sweet, flavored confections meant to be sucked or chewed. It typically contains sugar as the primary ingredient and may include additional flavorings and ingredients. The physical characteristics of candy can be classified into three types: hard candy, chewy candy, and soft candy [55,56,57]. An example of using calamondin juice to produce hard candy is shown in Figure 4. The process for making calamondin hard candy is as follows: (1) mix glucose syrup and sucrose with calamondin juice as a solvent and simmer, (2) stir until all components are homogenous, (3) increase the temperature to 120–130 °C to raise the sugar concentration, (4) quickly cool the solution down to 70–80 °C, (5) pour the mixture into molds and cool it to room temperature, and (6) package and wrap the candy immediately. A study on the optimal ratio of sucrose to glucose in the development of calamondin fruit candy found that the best ratio was 60% sucrose to 40% glucose. The calamondin fruit candy produced has a bright-yellow color, a citrus aroma and flavor, and a hard texture. Chemical analysis of the candy revealed that it has a moisture content of 1.80%, ash content of 0.15%, reducing sugar content of 68.03%, and total acid content of 2.28% [7]. The high temperatures in the production process can destroy the natural flavor, vitamin C, and other essential compounds in calamondin [58]. As a result, synthetic versions of these compounds are added to commercial candy production [59]. Additionally, low-calorie sweeteners or sugar substitutes, such as sorbitol and mannitol, may replace sugar in sugar-free candy formulas [60].

5.6. Essential Oils Extraction

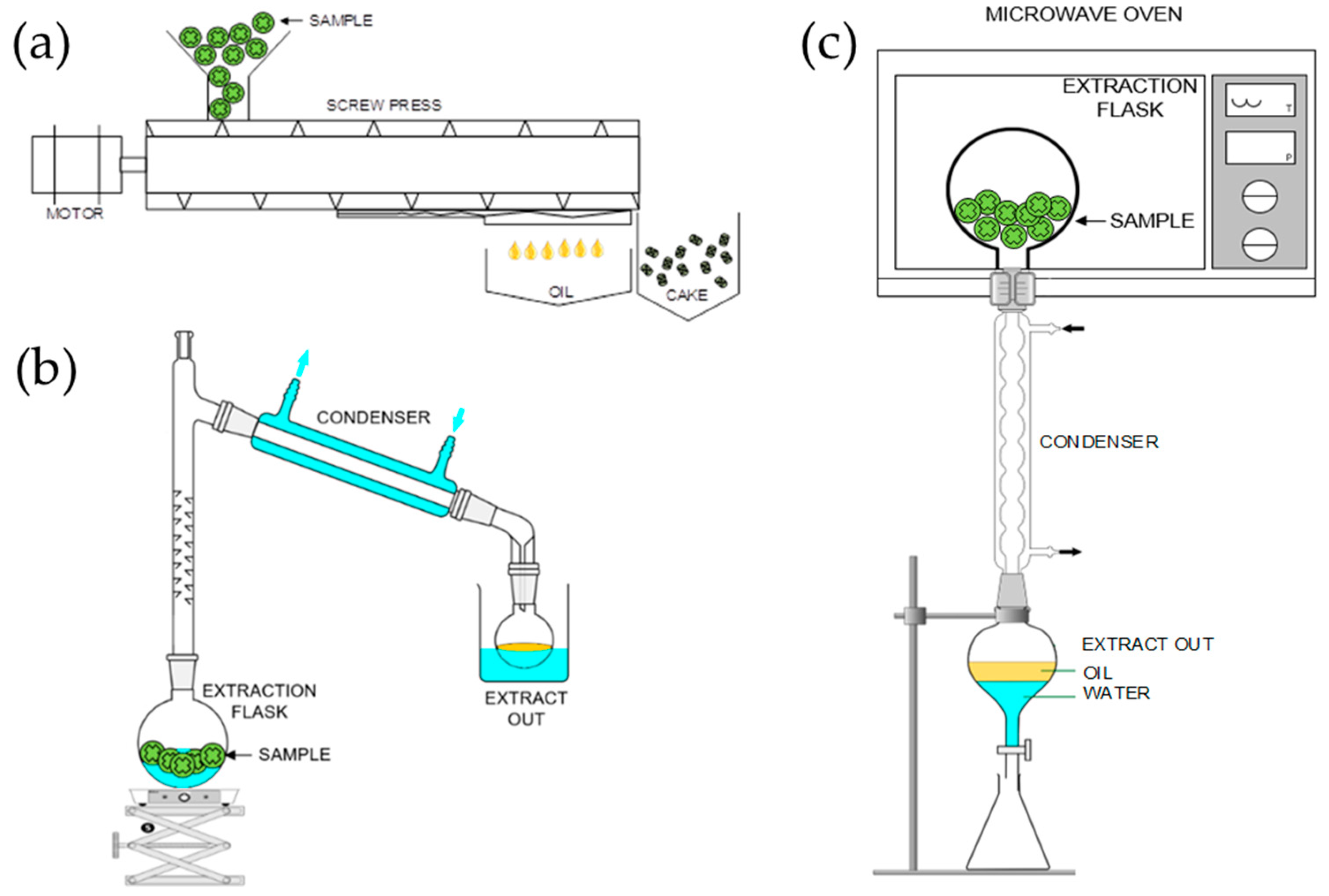

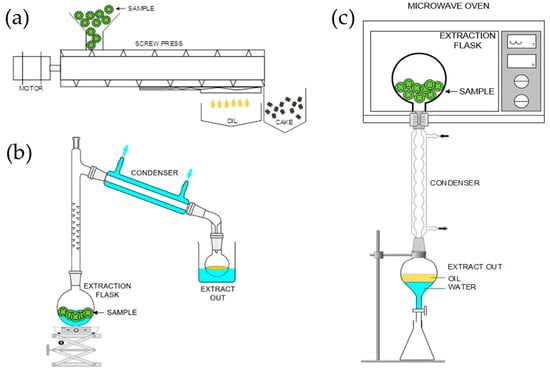

The essential oil derived from citrus fruits is an up-and-coming downstream product with significant potential for growth in the future. The increasing complexity and diversity of human demands, such as for use in the food additive, fragrance, cosmetics, and pharmaceutical industries, will likely drive demand for essential oils [61]. The limited size and thin skin of calamondin fruits may restrict the number of essential oils extracted from them [62]. However, increasing plant production can help maintain the high volume of raw materials necessary to produce essential oil from the peel of calamondin [63]. There are two main ways to increase plant production to meet consumer demand for essential oil: intensifying agricultural inputs and increasing the land used for cultivation. It should be noted that the rind of a mature (medium-ripe and fully ripe) calamondin fruit yields less essential oil than the peel of unripe fruit [61,62,63]. The amount of essential oil that can be extracted from ripe peels is typically lower than that from unripe peels because they are softer, and the biochemical content of the peel has changed [12]. Additionally, the origin of the plant and the method used for extraction can also affect the yield and composition of the essential oil [34,64,65]. Cold pressing or screw presses are traditional methods for extracting essential oils from citrus peels. In some countries, distillation is also commonly used due to its higher yield (0.21% compared to 0.05% for cold pressing) [66]. Modern methods of essential oil extraction include ultrasound-assisted extraction (UAE), microwave-assisted extraction (MAE), supercritical fluid extraction (SFE), and accelerated solvent extraction (ASE) [67,68,69]. These methods have been developed and improved over time and are widely accepted by the industry. The extraction of essential oils from calamondin fruit peel can be done using methods that have the potential to improve the efficiency, safety, energy savings, and sustainability. These methods include the following (Figure 5):

Figure 5.

Schematic diagram: (a) screw press, (b) hydrodistillation, and (c) microwave-assisted distillation.

- (1)

- A screw press uses mechanical force to extract essential oils from plants by breaking down the bulbous cells that store the oils [63]. Extracting essential oils from calamondin fruit peel using a screw press involves reducing the size of the peel with a rough chopping machine and then compressing it with a cold oil screw press. The output of the screw press is divided into two parts: a solid, or dregs, and a liquid containing essential oils. The essential oil is then separated from the other liquids [65]. Using this method, it is possible to extract one kilogram of lime essential oil from the peel by crushing the lime peel and oil glands and allowing the liquid to flow out of the bottom of the machine [70].

- (2)

- Distillation with water, also known as hydrodistillation, uses the principle of pressure extraction from hot water to extract essential oils from plants by breaking down the bulbous cells that store the oils. The process of extracting essential oils from calamondin fruit peel using hydrodistillation involves reducing the size of the peel with a crushing machine, placing it in a round-bottom flask, filling it with water, and boiling it [63,65]. The hot steam carries the essential oil out and condenses it into a liquid. The hydrodistillation process involves heating the round-bottom flask containing the crushed calamondin fruit peel and water until it boils and becomes steam-containing volatile substances. The steam is then cooled to condense it into a liquid, from which the essential oils are separated. Hydrodistillation is a traditional method used in laboratory-scale extraction of plant essential oils. The hydrodistillation process was carried out by adding 50 g of crushed calamondin fruit peel to a flask, along with 250 milliliters of distilled water (at a ratio of 1 g of solids to 5 milliliters of water). The flask was then heated to boiling under atmospheric pressure to initiate the extraction. During the distillation process, volatile aroma compounds and water mix to form azeotropic mixtures and condense. The mixture is then stratified based on the difference in density. Due to incompatibility, the essential oil fractions are collected and separated from the water after 2 h of distillation [71].

- (3)

- Microwave-assisted distillation uses the principle of electromagnetic extraction and the polar properties of molecules within the sample to extract essential oils. The movement caused by microwaves generates friction and heat, affecting plants’ cellular tissues [64]. To extract essential oils from calamondin fruit peel using this method, the peel is first reduced in size by crushing it. After crushing, the calamondin fruit peel is placed in a round-bottom flask and then in a microwave. The microwaves cause friction between the polar molecules, which generates heat and causes the liquid to boil into steam containing essential oils [68]. The steam is then cooled until it condenses back into a liquid, from which the essential oils are separated. Finally, the essential oils are separated from other liquids using a combination of microwave-assisted distillation. This process was carried out in a laboratory microwave oven at atmospheric pressure. A constant power was set in the microwave, and 500 g of fresh calamondin fruit peels were heated at 500 watts for 15 min. [66]. After that, the essential oil fraction was dried with Na2SO4, gathered in a sealed vial, and kept chilled at 4 °C.

Table 5 illustrates the results of the extraction of essential oils from calamondin fruit peel using different extraction methods and conditions. The data show that when compared to steam distillation alone, using a combination of hot water treatment followed by steam distillation led to an increase in the yield of essential oils for calamondin peels. However, it should be noted that hot water treatment followed by steam distillation may cause damage to the tissues in the calamondin peel or the flesh, releasing volatile compounds.

Table 5.

Comparison of essential oils extracted from calamondin fruits by various methods.

6. Possibility of Adding Commercial Fruit Value

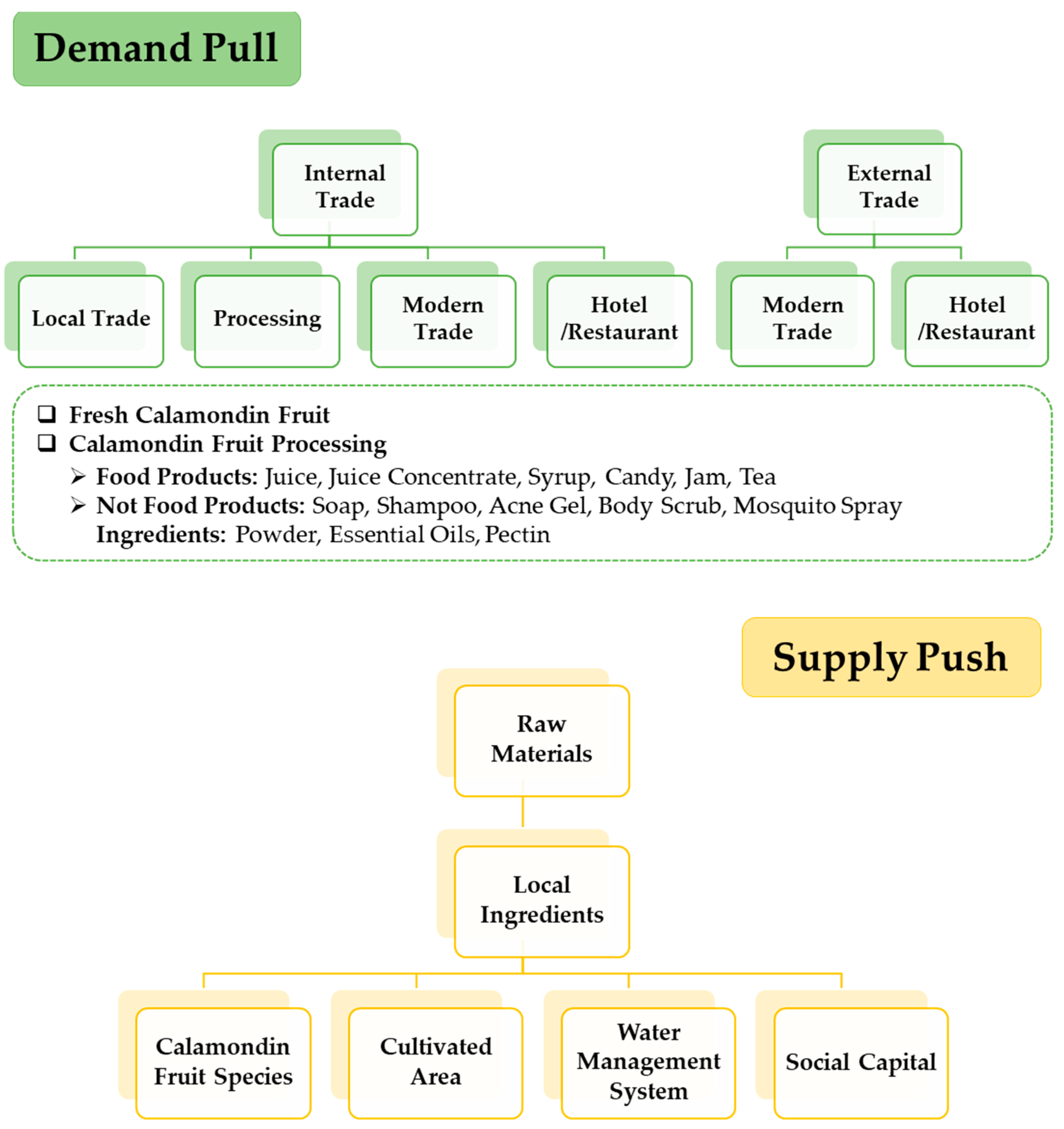

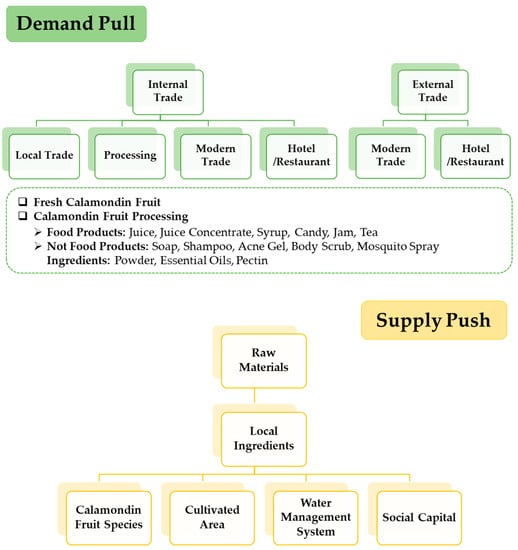

As mentioned earlier, calamondin is a citrus plant native to China and has been widely introduced to various countries in East and Southeast Asia, the Pacific Islands, the USA (Hawaii and Florida), and Central America [69]. In the past, calamondin was not considered a commercial citrus crop; it was primarily grown as an ornamental plant or a rootstock for citrus grafting [70,71]. However, it has become a commercial crop in recent years due to its fruits’ pleasant aroma, flavor, and nutritional value [72,73]. As a result, the global export value of calamondin has increased from USD 111.6 million in 2014 to USD 114.4 million in 2021 [74]. Calamondin fruit is a versatile and nutritious plant that can meet the needs of health-conscious consumers. It also can create added value as it can be used as an excellent substitute for limes when they are in short supply or expensive. Calamondin fruit has a higher juice yield than lime, with an 80% juice content compared to 40% for lime. In the Thai market, for example, the regular selling price of calamondin is USD 0.6 per kg, but during periods of high lime prices, such as November–January, the price of calamondin may increase to as much as USD 1.8 per kg. The domestic market demands up to 1000 kg of calamondin fruit per day, and it has a high demand in the international market, such as Singapore, which imports the fruit from Malaysia and the Philippines [75]. Calamondin is a commercially viable crop that is easy to grow, care for, and maintain. It produces fruit all year round and is rarely affected by disease or insect disturbances. This makes it a popular side crop, often planted around rubber trees and other local crops. Due to the increasing demand for fresh and processed products domestically and internationally, cultivation areas for calamondin have been expanding. It is commonly grown in mixed orchards alongside Thailand’s rubber, durian, and mangosteen trees. It is a versatile and nutritious plant that can be grown commercially and is relatively easy to care for. The cost of cultivation is determined by the planting distance, with the lowest price averaging USD 371 per 1600 square meter. Additionally, it has byproducts from providing water, fertilizer, and pest control from the main crop or natural release, making it popular to grow as a side crop with other local crops [76]. When analyzing the market for calamondin fruit, it is essential to consider both the pull–demand side and the supply–push side (Figure 6). As the demand for fresh and processed products increases at local, provincial, national, and international levels, so does the cultivation of calamondin. This corresponds to the context of Thai society, where fruit is used for both consumption and non-consumer purposes, such as cosmetics. The cultivation of calamondin fruit offers a wide range of benefits, both economically and socially. The growing demand for fresh and processed products, locally and internationally, has increased cultivation areas [73]. The low cost of cultivation and the ability to grow it as a side crop with other plants makes it an ideal crop for smallholder farmers with low-occupancy areas. Furthermore, the production and processing of calamondin products, such as juice, concentrate, and jam, can create jobs and income for farmers and communities, providing stability and prosperity. The Bio-Circular-Green (BCG) economic model is a model of the economy that emphasizes sustainable growth. Since the start of the privatization of agricultural raw materials cultivation, it has added value by paying close attention to every step of the agricultural raw materials production process and using knowledge, technology, and innovation to achieve the efficiency and effectiveness of the business cycle. The BCG model meets at least five Sustainable Development Goals (SDGs) of the United Nations: sustainable production, consumption, tackling climate change, conservation of diversity, and cooperation for sustainable development [77,78]. Additionally, the cultivation of calamondin aligns with the bio-circular-green (BCG) economic policy framework, as it utilizes the fruit’s juice, pulp, and peel to add value and reduce agricultural waste. This helps sustain the environment and supports the local economy by creating jobs and income for farmers and communities.

Figure 6.

Demand and supply of calamondin fruit for commercial scale.

7. Conclusions

Calamondin fruits are an incredibly versatile and beneficial citrus fruit that offer a range of nutritional and economic advantages. These small fruits can be processed into various economically valuable products, such as juices, jams, and flavorings, and are a popular substitute for limes in many cuisines. Furthermore, calamondin cultivation is suitable for both small-holder farmers and larger-sized farmers, making it a profitable option for agriculture. The juice, pulp, seeds, peel, and fruit residue of calamondin fruits contain a rich chemical composition and bioactive compounds, offering a range of potential applications in several industries. These compounds have been shown to possess antioxidant, anti-inflammatory, and antimicrobial properties, among other health benefits, making them a valuable resource for food and beverage production, pharmaceuticals, and cosmetics. Additionally, utilizing different parts of the fruit, such as the peel and seeds, can minimize agricultural waste and add value, supporting the Bio-Circular-Green (BCG) economic model. By promoting a circular economy, we can reduce waste and environmental impacts, while also creating economic opportunities for communities. Overall, the cultivation and processing of calamondin fruits offer a sustainable approach to economic development, social progress, and environmental preservation. Utilizing calamondin fruits in various industries and promoting a circular economy can lead to the creation of economic and social benefits for communities, while simultaneously preserving the environment.

Author Contributions

Conceptualization, N.C. and J.W.; writing—original draft preparation, N.C., K.P., K.V. and J.W.; writing—review and editing, K.V., P.S., V.Y., C.P. and T.P.; visualization, K.V., N.C. and V.Y.; supervision, K.V., P.S. and C.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank farmers in Chanthaburi province, Thailand, for calamondin and information. They would also like to express their gratitude to Burapha University Chanthaburi Campus and King Mongkut’s University of Technology North Bangkok, Thailand, for the additional support to finish this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lou, S.N.; Ho, C.T. Phenolic compounds and biological activities of small-size citrus: Kumquat and calamondin. J. Food Drug Anal. 2017, 25, 162–175. [Google Scholar] [CrossRef] [PubMed]

- Quijano, M.F.; Quijano, G.; Diaz, R. Agricultural Economic Production of Philippine Calamansi Industry: A Basis for Production Local Development Plan. Preprints 2021. [Google Scholar] [CrossRef]

- Kawai, Y.; Baba, T.; Yoshida, M.; Agravante, J.U.; Carmen, D.R.D. Effects of benzyladenine and light on post-harvest calamondin (x Citrofortunella microcarpa) fruit color and quality. Hortic. J. 2018, 87, 324–328. [Google Scholar] [CrossRef]

- Aggie Horticulture. Calamondin—The Most Versatile Citrus. Available online: https://www.biostim.com.au/pdf/Calamondin.pdf (accessed on 30 January 2023).

- Mapalo, N.G.; Rosillo-Magno, A.P. Morphological events on the development of flowers, fruits, and seeds of calamansi (XCitrofortunella microcarpa Bunge). J. Sci. Eng. Tech. 2018, 6, 160–168. [Google Scholar]

- Morton, J. Calamondin. 1987. Available online: https://www.hort.purdue.edu/newcrop/morton/calamondin.html (accessed on 30 January 2023).

- Pangerapan, R.; Tuju, T.D.J.; Kandou, J.E.A. Sensory quality of candy calamansi (Citrofortunella microcarpa). COCOS 2016, 7, 1–8. [Google Scholar]

- Zou, Y.; Zhang, H.; Zheng, L. Physicochemical characteristics of (Citrus microcarpa) from Hainan. Asian J. Agric. Res. 2020, 12, 58–62. [Google Scholar]

- Romero, J. Investigating the Flavor of Fresh Calamondin Peel and Juice Using Instrumental and Descriptive Sensory Analysis. Master’s Thesis, Master of Science-Texas Woman’s University, Denton, TX, USA, 2020. [Google Scholar]

- Nonmuang, W.; Pongsumran, S.; Mongkontanawat, N. Effect of storage time on some quality parameters of calamondin (Citrus Madurensis Lour.) squash stored at room temperature. Int. J. Agric. Technol. 2016, 12, 1139–1151. [Google Scholar]

- Capuano, E. The behavior of dietary fiber in the gastrointestinal tract determines its physiological effect. Crit. Rev. Food Sci. Nutr. 2017, 57, 3543–3564. [Google Scholar] [CrossRef]

- Tuan, N.V.; Cam, Q.N.T.; Cang, M.H. Research methods of refined oil from peel calamondin (Citrus microcarpa) from Tien Giang Province, Vietnam. E3S Web Conf. 2021, 306, 04021. [Google Scholar] [CrossRef]

- Miller, J.A.; Thompson, P.A.; Hakim, I.A.; Chow, H.H.S.; Thomson, C.A. D-Limonene: A bioactive food component from citrus and evidence for a potential role in breast cancer prevention and treatment. Oncol. Rev. 2011, 5, 31–42. [Google Scholar] [CrossRef]

- Ravichandran, C.; Badgujar, P.C.; Gundev, P.; Upadhyay, A. Review of toxicological assessment of d-limonene, a food and cosmetics additive. Food Chem. Toxicol. 2018, 120, 668–680. [Google Scholar] [CrossRef]

- Palma, C.E.; Cruz, P.S.; Cruz, D.T.C.; Bugayong, A.M.S.; Castillo, A.L. Chemical composition and cytotoxicity of Philippine calamansi essential oil. Ind. Crops Prod. 2019, 128, 108–114. [Google Scholar] [CrossRef]

- Palazzolo, E.; Laudicina, V.A.; Germana, M.A. Current and potential use of citrus essential oils. Curr. Org. Chem. 2013, 17, 3042–3049. [Google Scholar] [CrossRef]

- Aissou, M.; Chemat-Djenni, Z.; Yara-Varon, E.; Fabiano-Tixer, A.S.; Chemat, F. Limonene as an agro-chemical building block for the synthesis and extraction of bioactive compounds. Comptes Rendus Chimi. 2017, 20, 346–358. [Google Scholar] [CrossRef]

- Capili, A.J.S.; Cruz, E.F.A.; Cunanan, K.A. Insecticidal Effect of Calamansi (C. microcarpa) Extracts against Rice Weevils (S. oryzae). Available online: https://ojs.aaresearchindex.com/index.php/AAJMRA/article/view/4100 (accessed on 30 January 2023).

- Ibanez, M.D.; Sanchez-Ballester, N.M.; Blazqez, M.A. Encapsulated limonene: A pleasant lemon-like aroma with promising application in the agri-food industry. A review. Molecules 2020, 25, 2598. [Google Scholar] [CrossRef]

- Yu, M.W.; Lou, S.N.; Ho, C.T. Antioxidant activity and effective compounds of immature calamondin peel. Food Chem. 2013, 136, 1130–1135. [Google Scholar] [CrossRef]

- Lou, S.N.; Hsu, Y.S.; Ho, C.T. Flavonoid compositions and antioxidant activity of calamondin extracts prepared using different solvents. J. Food Drug Anal. 2014, 22, 290–295. [Google Scholar] [CrossRef]

- Shie, P.H.; Huang, R.L.; Lay, H.L. The flavonoids in Citrus madurensis Lour and their anti-hepatitis B virus activity. Pharm. Anal. Acta. 2013, 4, 1000239. [Google Scholar]

- Chanthaphon, S.; Chanthachum, S.; Hongpattarakere, T. Antimicrobial activities of essential oils and crude extracts from tropical Citrus spp. against food-related microorganisms. Sonklanakarin J. Sci. Tech. 2008, 30, 125–131. [Google Scholar]

- Roanisca, O.; Mahardika, R.G. Citrus x Microcarpa Bunge Fruit Extract as Antibacterialagainst Staphylococcus Aureus. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 599, p. 012043. [Google Scholar]

- Alinejhad, D.; Asayesh, M.A.; Asayesh, M. Determination of the anti-inflammatory property of tannins from the rind of calamansi (Citrus microcarpa, Rutaceae). J. Inter. Oral Health 2016, 8, 546–553. [Google Scholar]

- Lou, S.N.; Yu, M.W.; Ho, C.T. Tyrosinase inhibitory components of immature calamondin peel. Food Chem. 2012, 135, 1091–1096. [Google Scholar] [CrossRef] [PubMed]

- Morte, M.Y.T.; Acero, L.H. Potential of Calamansi (Citrofortunella microcarpa) Fruit Peels Extract in Lowering the Blood Glucose Level of Streptozotocin Induced Albino Rats (Rattus albus). Inter. J. Food Eng. 2017, 3, 29–34. [Google Scholar] [CrossRef]

- Lim, S.M.; Loh, S.P. In Vitro antioxidant capacities and anti-diabetic properties of phenolic extracts from selected citrus peels. Inter. Food Res. J. 2016, 23, 211–219. [Google Scholar]

- Barluado, M.J.G.; Lagang, M.J.M.; Gordonas, I.F.M.; Bosas, C.D.B. Antiangiogenic and antioxidant properties of calamansi Citrus macrocarpa. UIC Res. J. 2013, 19, 123–134. [Google Scholar]

- Cubias, J.G.R.; Tagacay, A.C.B.; Ramirez, P.A.P. Preparation of An Antimicrobial Extract from Seeds, Pulp and Peelings of Philippine Calamansi (Citrus Mitis) Fruit against Escherichia coli (2014–2015). Available online: https://www.dlsu.edu.ph/colleges/gcoe/academic-departments/chemical-engineering/thesis-archive/preparation-of-an-antimicrobial-extract-from-seeds-pulp-and-peelings-of-philippine-calamansi-citrus-mitis-fruit-against-escherichia-coli-2014-2015/ (accessed on 30 January 2023).

- Noor, N.A.M.; Murad, M.; Esah, E.M. Physicochemical, antioxidant and microbial properties of fresh black stem sugarcane juice with addition of calamansi Juice. Sains Malays. 2018, 47, 2047–2054. [Google Scholar] [CrossRef]

- Fu, J.T.; Shiau, S.Y.; Chang, R.C. Effect of calamondin fiber on rheological, antioxidative and sensory properties of dough and steamed bread. J. Texture Stud. 2014, 45, 367–376. [Google Scholar] [CrossRef]

- Kim, Y.M.; Seo, S.E. Beneficial effects on cosmetic activity by optimizing the calamondin orange extraction process. Nat. Prod. Commun. 2019, 14, 1–4. [Google Scholar] [CrossRef]

- Kaenla, H. Research and Development on Commercial Calamondin (Citrus mitis Blanco.) Production in the Eastern Region. Available online: https://www.doa.go.th/research/attachment.php?aid=2194 (accessed on 30 January 2023).

- Yang, J. Preparing Shelf-Stable Citrus Juice and Drinks at Home. Available online: https://www.uog.edu/_resources/files/extension/publications/Citrus_Drink.pdf (accessed on 30 January 2023).

- Falguera, V.; Albert, A. Juice Processing: Quality, Safety and Value-Added Opportunity; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Dharmawan, J. Characterization of Volatile Compounds in Selected Citrus Fruits from Asia. Ph.D. Thesis, Chemistry-National University of Singapore, Singapore, 2008. [Google Scholar]

- Vergara, C.A.; Titong, R.D. The Development of Calamansi (Citrofortunella microcarpa) Juice with Camote (Ipomoae batatas) Leaf Extract. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3661285 (accessed on 30 January 2023).

- Narasimman, P.; Sethuraman, P. An overview on the fundamentals of pectin. Int. J. Adv. Res. 2016, 4, 1855–1860. [Google Scholar] [CrossRef]

- Zainudin, N.A.N.; Mohamed, R.M.; Abdullah, S.; Hashim, N.; Hassan, L.S.; Yahya, N.A.M.; Abdullah, N. Oil and Pectin Extraction from Calamansi Lime and Key Lime. 2019. Available online: https://www.tatiuc.edu.my/assets/files/ICTM19-Papers/ICTM-12.pdf (accessed on 30 January 2023).

- Kanmani, P.; Dhivya, E.; Aravind, J.; Kumaresan, K. Extraction and analysis of pectin from citrus peels: Augmenting the yield from citrus limon using statistical experimental design. Iranica. J. Eng. Environ. 2014, 5, 303–312. [Google Scholar] [CrossRef]

- Udonne, J.D.; Ajani, O.O.; Akinyemi, O.P. A comparative study of extraction of pectin from wet and dried peels using water based and microwave methods. Int. J. Sci. Eng. Res. 2016, 7, 416–432. [Google Scholar]

- Rezzoug, S.A.; Maache-Rezzoug, Z.; Sannier, F.; Allaf, K. A Thermomechanical Preprocessing for Pectin Extraction from Orange Peel Optimisation by Response Surface Methodology. Available online: https://hal.science/hal-00414470/file/IJFE_-_Rezzoug_et_al_2008.pdf (accessed on 30 January 2023).

- Duan, X.; Zhu, Y.; Shu, C.; Gao, J.; Liu, F.; Pan, S. Extraction of pectin from satsuma mandarin peel; A comparison of high hydrostatic pressure and conventional extractions in different acids. Molecules 2022, 27, 3747. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, H.; Wang, L.; Liu, F.; Pan, S. Preparation and prebiotic potential of pectin oligosaccharides obtained from citrus peel pectin. Food Chem. 2018, 244, 232–237. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.W.; Sheu, M.J.; Lin, L.Y.; Wu, C.T.; Chiang, H.M.; Lin, W.H.; Lee, M.C.; Chen, H.C. Effect of heat treatments on the essential oils of kumquat (Fortunella margarita Swingle). Food Chem. 2013, 136, 532–537. [Google Scholar] [CrossRef]

- Cuevas-Glory, L.; Sauri-Duch, E.; Pino, J.A. Volatile constituents of peel and leaf oils from calamondin. J. Essent. Oil Bear. Plants 2009, 12, 656–660. [Google Scholar] [CrossRef]

- Cheong, M.W.; Chong, Z.S.; Liu, S.Q.; Zhou, W.; Curran, P.; Yu, B. Characterisation of calamansi (Citrus macrocarpa). Part I: Volatiles, aromatic profiles and phenolic acids in the peel. Food Chem. 2012, 134, 686–695. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.C.; Peng, L.W.; Sheu, M.J.; Lin, L.Y.; Chiang, H.M.; Wu, C.T.; Wu, C.S.; Chen, Y.C. Effects of hot water treatment on the essential oils of calamondin. J. Food Drug Anal. 2013, 21, 363–368. [Google Scholar] [CrossRef]

- Bellucci, E.R.B.; Bis-Souza, C.V.; Dominguez, R.; Bermudex, R.; Barretto, A.C.D.S. Addition of natural extracts with antioxidant function to preserve the quality of meat products. Biomolecules 2022, 12, 1506. [Google Scholar] [CrossRef]

- Yang, J.; Jesus, S.D. Making Calamansi Powder at Home. 2012. Available online: https://www.uog.edu/_resources/files/extension/publications/Calamansi_Powder_2021.pdf (accessed on 30 January 2023).

- MFPs Cheryl & Wendy. How to Use Preserved Citrus. Available online: https://ucanr.edu/sites/sacmfp/files/345081.pdf (accessed on 30 January 2023).

- Hunsapan, N.; Suwannarat, Y.; Ninlanon, W. Available online: http://www.agricul.rbru.ac.th/research_attach/2022-08-01-F1-95768.pdf (accessed on 30 January 2023).

- Lee, S.Y. Physico-chemical characteristics of calamansi juice, agglomerate and drink. J. Trop. Agric. Food Sci. 2000, 28, 183–188. [Google Scholar]

- Lesmayati, S.; Qomariah, R.; Awanis; Anggreany, S. Effect of Gelatin and Citric Acid Concentration on Chemical and Organoleptic Properties of Jelly Citrus. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/1024/1/012025/pdf (accessed on 30 January 2023).

- Spanemberg, F.E.M.; Korzenowski, A.L.; Sellitto, M.A. Effects of sugar composition on shelf life of hard candy: Optimization study using D-optimal mixture design of experiments. J. Food Process Eng. 2019, 42, e13213. [Google Scholar] [CrossRef]

- NPCS Board of Food Technologists. Confectionery Products Handbook (Chocolate, Toffees, Chewing Gum & Sugar Free Confectionery); Asia Pacific Business Press Inc.: Delhi, India, 2013. [Google Scholar]

- Nguyen, T.N.T.; Huynh, T.N.N.; Tran, V.T.; Dang, C.H.; Hoang, K.D.; Nguyen, T.D. Physicochemical characterization and bioactivity evaluation of essential oils from Citrus microcarpa Bunge leaf and flower. J. Essent. Oil Res. 2018, 30, 285–292. [Google Scholar] [CrossRef]

- Wai, C.M. Chemical Components and Aromatic Profiles of Citrus and Coffee in Asia. Ph.D. Thesis, Chemistry-National University of Singapore, Singapore, 2013. [Google Scholar]

- International Sweetenners Association. Low Calorie Sweeteners: Roles and Benefits. Available online: https://www.canderel.nl/public/uploads/files/docs/zoetstoffen%20dossier.pdf (accessed on 30 January 2023).

- Budiarto, R.; Sholikin, M.M. Kaffir Lime Essential Oil Variation in the Last Fifty Years: A Meta-Analysis of Plant Origins, Plant Parts and Extraction Methods. Horticulturae 2022, 8, 1132. [Google Scholar] [CrossRef]

- Chen, H.S.; Yang, K.M.; Huang, T.C.; Wu, M.L. Traditional small-size citrus from Taiwan: Essential oils, bioactive compounds and antioxidant capacity. Medicines 2017, 4, 28. [Google Scholar] [CrossRef]

- Arce, A.; Soto, A. Citrus essential oils: Extraction and deterpenation. Tree For. Sci. Biotechnol. 2008, 2, 1–9. [Google Scholar]

- Dao, P.T.; Nfuyen, M.V.; Tran, Q.N.; Truong Le, D.; Tran, T.Y.N.; Lam, T.V. Experimental and kinetic modeling studies on extraction of essential oil from Vietnamese calamondin (Citrus microcarpa) by hydro-distillation process. Iran. J. Chem. Chem. Eng. 2022, 41, 3744–3754. [Google Scholar]

- Mahato, N.; Sharma, K.; Koteswararao, R.; Sinha, M.; Baral, E.; Cho, M.H. Citrus essential oils: Extraction, authentication and application in food preservation. Crit. Rev. Food Sci. Nutr. 2019, 59, 611–625. [Google Scholar] [CrossRef]

- Hou, H.S.; Bonku, E.M.; Zhai, R.; Zeng, R.; Hou, Y.L.; Yang, Z.H.; Quan, C. Extraction of essential oil from citrus reticulate Blanco peel and its antibacterial activity against Cutibacterium acnes (formerly Propionibacterium acnes). Heliyon 2019, 5, e02947. [Google Scholar] [CrossRef]

- Lou, S.N.; Lai, Y.C.; Hsu, Y.S.; Ho, C.T. Phenolic content, antioxidant activity and effective compounds of kumquat extracted by different solvents. Food Chem. 2016, 197, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.C.Q.; Ngo, H.D.; Tran, T.K.N.; Le, X.T.; Huynh, C.M. Microwave-Assisted Hydrodistillation and Determines Volatile Components of Essential Oils from Calamondin (Citrus microcarpa) Shells. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 991, p. 012124. [Google Scholar] [CrossRef]

- Bousbia, N.; Vian, M.A.; Ferhat, M.A.; Meklati, B.Y.; Chemat, F. A new process for extraction of essential oil from Citrus peels: Microwave hydrodiffusion and gravity. J. Food Eng. 2009, 90, 409–413. [Google Scholar] [CrossRef]

- Boning, C.R. Florida’s Best Herbs and Spices: Native and Exotic Plants Grown for Scent and Flavor, 1st ed.; Pineapple Press Inc.: Sylvania, OH, USA, 2010; pp. 32–33. [Google Scholar]

- Martínez-Cuenca, M.-R.; Primo-Capella, A.; Forner-Giner, M.A. Influence of Rootstock on Citrus Tree Growth: Effects on Photosynthesis and Carbohydrate Distribution, Plant Size, Yield, Fruit Quality, and Dwarfing Genotypes, Plant Growth, Everlon Cid Rigobelo; Intech Open: London, UK, 2016. [Google Scholar]

- Abdullahia, T.M.; Said, M.F.M.; Othman, N.; Malik, S.A. Reforgiato Recupero, G.; Caruso, A.; Potentials of citrus peel waste valorisation for green diesel production: A mini review. CET 2022, 97, 475–480. [Google Scholar]

- Real, R.R.; Digal, L.N. Analyzing marketing margins and their implications in improving performance of small-scale producers in the calamansi chain in Region XI, Southern Philippines. Banwa 2010, 7, 69–91. [Google Scholar]

- Husni, E.; Yeni, F. Chemical Contents Profile of Essential Oil from Calamansi (Citrus microcarpa Bunge) Peels and Leaves and Its Antibacterial Activities. In Proceedings of the 2nd International Conference on Contemporary Science and Clinical Pharmacy 2021 (ICCSCP 2021), Online, 9–10 September 2021; Atlantis Press: Amsterdam, The Netherlands; pp. 316–324. [Google Scholar]

- Tridge. 2023. Export of Clamansi. Available online: https://www.tridge.com/intelligences/calamansi/export (accessed on 30 January 2023).

- Plonjarean, S.; Jindasing, M.; Chinabhark, K.; Paiboon, J.; Chaisri, O. Somjeed Village. 2016. Available online: https://erp.mju.ac.th/openFile.aspx?id=MTk2NzMz (accessed on 30 January 2023).

- Thailand Board of Investment. Thailand’s Bio-Cercular-Green Economy: Living up to Global Challenges. Available online: https://aust-thai.org.au/wp-content/uploads/2021/08/TIR_June_2021-on-BCG.pdf (accessed on 30 January 2023).

- Asia-Pacific Economic Cooperation. Understanding the Bio-Circular-Green (BCG) Economy Model APEC SOM Committee on Economic and Technical Cooperation. Available online: https://www.apec.org/publications/2022/08/understanding-the-bio-circular-green-(bcg)-economy-model (accessed on 30 January 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).