Exploring the Impact of Various Wooden Barrels on the Aromatic Profile of Aceto Balsamico Tradizionale di Modena by Means of Principal Component Analysis

Abstract

:1. Introduction

2. Results and Discussion

2.1. Identification of the Volatile Compounds by HS-SPME-GC/MSq

- Molecules present in grape must;

- Molecules formed during the cooking process;

- Molecules formed during the fermentation processes, both alcoholic and acetic;

- Molecules formed inside the battery during the product aging phase.

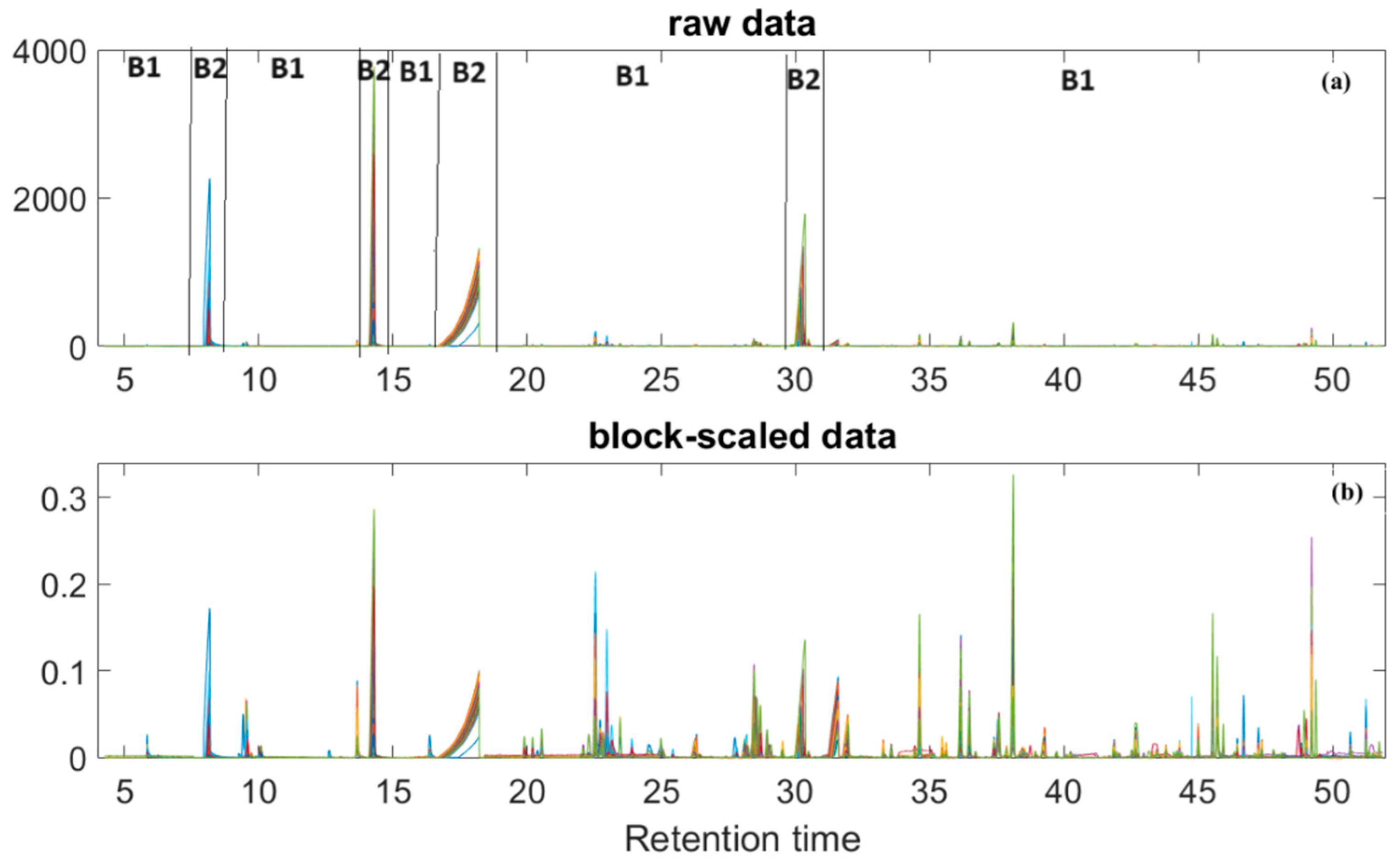

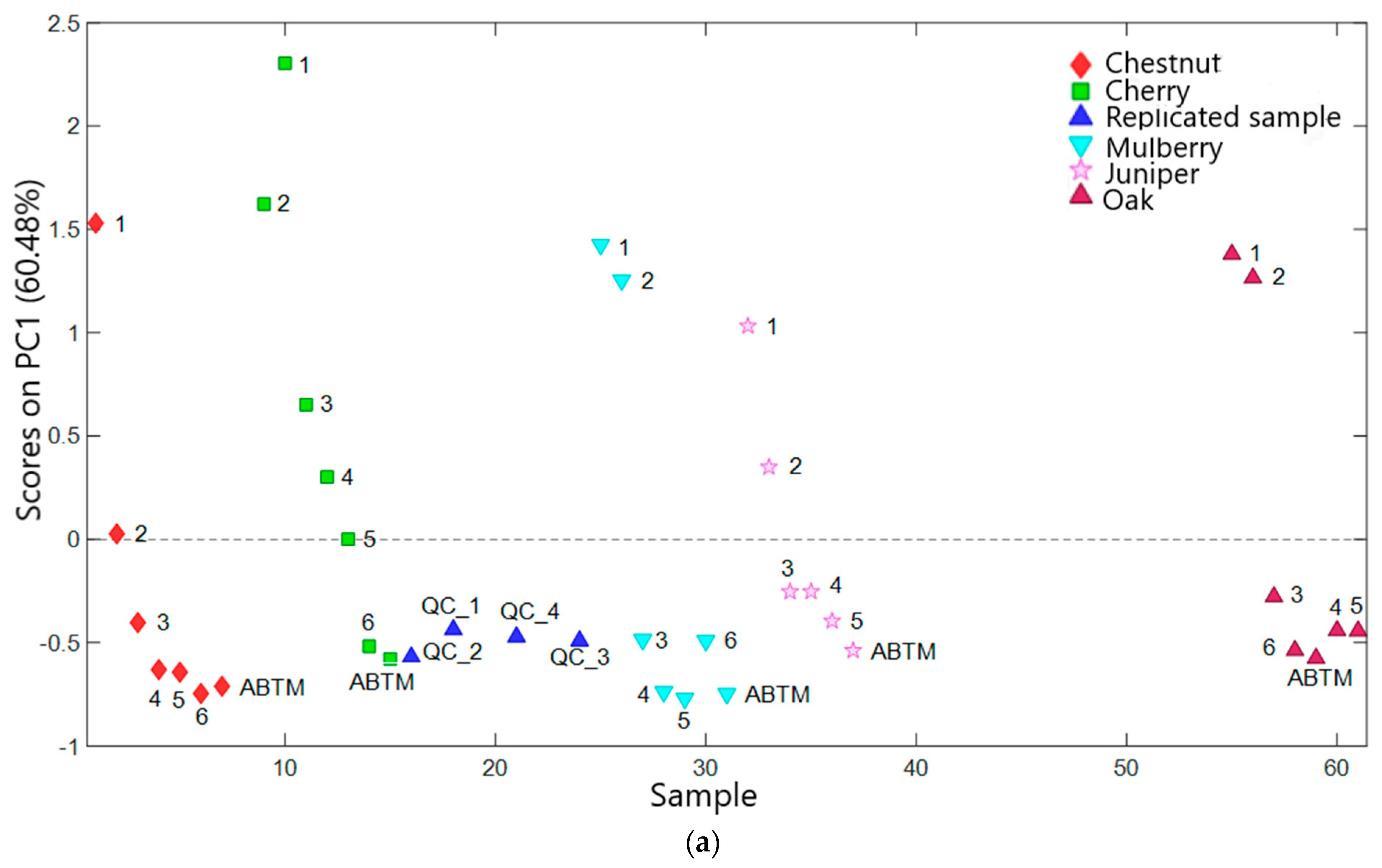

2.2. Evolution of the Volatile Fraction of ABTM: HS-SPME-GC/FID and Multivariate Analysis

3. Materials and Methods

3.1. Sampling

3.2. Determination of Volatile Compounds by HS-SPME-GC/FID and HS-SPME-GC/MSq

3.3. Reagents and Standards

3.4. Multivariate Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABM | Aceto Balsamico di Modena |

| ABTM | Aceto Balsamico Tradizionale di Modena |

| GC-FID | Gas Chromatography-Flame Ionization Detector |

| GC-MS | Gas Chromatography-Mass Spectrometry |

| HS-SPME | Headspace Solid-Phase Micro-Extraction |

| PCA | Principal Component Analysis |

| PDO | Protected Designation of Origin |

| PGI | Protected Geographical Indication |

| TSG | Traditional Specialties Guaranteed |

References

- Bolognini, S. Food Diversity and Typicality in EU and in Italian Law: Protected Designations of Origin (PDOs); Protected Geographical Indications (PGIs); Traditional Speciality Guaranteed (TSGs). In Food Diversity between Rights, Duties and Autonomies; Isoni, A., Troisi, M., Pierri, M., Eds.; LITES—Legal Issues in Transdisciplinary Environmental Studies; Springer International Publishing: Cham, Switzerland, 2018; Volume 2, pp. 91–109. ISBN 978-3-319-75195-5. [Google Scholar]

- Commission Regulation (EC) No 583/2009 of 3 July 2009 Entering a Name in the Register of Protected Designations of Origin and Protected Geographical Indications [Aceto Balsamico Di Modena (PGI)]; Official Journal of the European Union, Ed.: Roma, Italy, 2009; Volume 52.

- Cirlini, M.; Caligiani, A.; Palla, L.; Palla, G. HS-SPME/GC–MS and Chemometrics for the Classification of Balsamic Vinegars of Modena of Different Maturation and Ageing. Food Chem. 2011, 124, 1678–1683. [Google Scholar] [CrossRef]

- Plessi, M.; Bertelli, D.; Miglietta, F. Extraction and Identification by GC-MS of Phenolic Acids in Traditional Balsamic Vinegar from Modena. J. Food Compos. Anal. 2006, 19, 49–54. [Google Scholar] [CrossRef]

- Cocchi, M.; Durante, C.; Grandi, M.; Manzini, D.; Marchetti, A. Three-Way Principal Component Analysis Of The Volatile Fraction By HS-SPME/GC Of Aceto Balsamico Tradizionale Of Modena. Talanta 2008, 74, 544–547. [Google Scholar] [CrossRef] [PubMed]

- Karoui, R.; De Baerdemaeker, J. A Review of the Analytical Methods Coupled with Chemometric Tools for the Determination of the Quality and Identity of Dairy Products. Food Chem. 2007, 102, 621–640. [Google Scholar] [CrossRef]

- Oliveri, P.; Downey, G. Multivariate Class Modeling for the Verification of Food-Authenticity Claims. TrAC Trends Anal. Chem. 2012, 35, 74–86. [Google Scholar] [CrossRef]

- Dias, C.; Mendes, L. Protected Designation of Origin (PDO), Protected Geographical Indication (PGI) and Traditional Speciality Guaranteed (TSG): A Bibiliometric Analysis. Food Res. Int. 2018, 103, 492–508. [Google Scholar] [CrossRef] [PubMed]

- Fang, G.; Goh, J.Y.; Tay, M.; Lau, H.F.; Li, S.F.Y. Characterization of Oils and Fats by 1H NMR and GC/MS Fingerprinting: Classification, Prediction and Detection of Adulteration. Food Chem. 2013, 138, 1461–1469. [Google Scholar] [CrossRef] [PubMed]

- Mannina, L.; Marini, F.; Gobbino, M.; Sobolev, A.P.; Capitani, D. NMR and Chemometrics in Tracing European Olive Oils: The Case Study of Ligurian Samples. Talanta 2010, 80, 2141–2148. [Google Scholar] [CrossRef] [PubMed]

- Giudici, P.; Lemmetti, F.; Mazza, S. Balsamic Production: Raw Materials and Processes. In Balsamic Vinegars; Springer International Publishing: Cham, Switzerland, 2015; pp. 61–84. ISBN 978-3-319-13757-5. [Google Scholar]

- Herrera, P.; Durán-Guerrero, E.; Sánchez-Guillén, M.M.; García-Moreno, M.V.; Guillén, D.A.; Barroso, C.G.; Castro, R. Effect of the Type of Wood Used for Ageing on the Volatile Composition of Pedro Ximénez Sweet Wine. J. Sci. Food Agric. 2020, 100, 2512–2521. [Google Scholar] [CrossRef]

- Durante, C.; Cocchi, M.; Grandi, M.; Marchetti, A.; Bro, R. Application of N-PLS to Gas Chromatographic and Sensory Data of Traditional Balsamic Vinegars of Modena. Chemom. Intell. Lab. Syst. 2006, 83, 54–65. [Google Scholar] [CrossRef]

- Natera Marín, R.; Castro Mejías, R.; de Valme García Moreno, M.; García Rowe, F.; García Barroso, C. Headspace Solid-Phase Microextraction Analysis of Aroma Compounds in Vinegar: Validation Study. J. Chromatogr. A 2002, 967, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Chinnici, F.; Durán Guerrero, E.; Sonni, F.; Natali, N.; Natera Marín, R.; Riponi, C. Gas Chromatography–Mass Spectrometry (GC–MS) Characterization of Volatile Compounds in Quality Vinegars with Protected European Geographical Indication. J. Agric. Food Chem. 2009, 57, 4784–4792. [Google Scholar] [CrossRef] [PubMed]

- Castro Mejías, R.; Natera Maríín, R.; de Valme García Moreno, M.; García Barroso, C. Optimisation of Headspace Solid-Phase Microextraction for Analysis of Aromatic Compounds in Vinegar. J. Chromatogr. A 2002, 953, 7–15. [Google Scholar] [CrossRef]

- Xie, Z.; Koysomboon, C.; Zhang, H.; Lu, Z.; Zhang, X.; Chen, F. Vinegar Volatile Organic Compounds: Analytical Methods, Constituents, and Formation Processes. Front. Microbiol. 2022, 13, 907883. [Google Scholar] [CrossRef]

- Callejón, R.M.; Torija, M.J.; Mas, A.; Morales, M.L.; Troncoso, A.M. Changes of Volatile Compounds in Wine Vinegars during Their Elaboration in Barrels Made from Different Woods. Food Chem. 2010, 120, 561–571. [Google Scholar] [CrossRef]

- Ali, K.; Maltese, F.; Choi, Y.H.; Verpoorte, R. Metabolic Constituents of Grapevine and Grape-Derived Products. Phytochem. Rev. 2010, 9, 357–378. [Google Scholar] [CrossRef]

- Carpena, M.; Pereira, A.G.; Prieto, M.A.; Simal-Gandara, J. Wine Aging Technology: Fundamental Role of Wood Barrels. Foods 2020, 9, 1160. [Google Scholar] [CrossRef]

- Su, H.; Chen, H.; Lin, J. Enriching the Production of 2-Methyl-1-Butanol in Fermentation Process Using Corynebacterium Crenatum. Curr. Microbiol. 2020, 77, 1699–1706. [Google Scholar] [CrossRef]

- Antonelli, A.; Chinnici, F.; Masino, F. Heat-Induced Chemical Modification of Grape Must as Related to Its Concentration during the Production of Traditional Balsamic Vinegar: A Preliminary Approach. Food Chem. 2004, 88, 63–68. [Google Scholar] [CrossRef]

- Gong, M.; Zhou, Z.; Liu, S.; Zhu, S.; Li, G.; Zhong, F.; Mao, J. Formation Pathways and Precursors of Furfural during Zhenjiang Aromatic Vinegar Production. Food Chem. 2021, 354, 129503. [Google Scholar] [CrossRef]

- Cocchi, M.; Durante, C.; Lambertini, P.; Manzini, S.; Marchetti, A.; Sighinolfi, S.; Totaro, S. Evolution of 5-(Hydroxymethyl)Furfural and Furfural in the Production Chain of the Aged Vinegar Aceto Balsamico Tradizionale Di Modena. Food Chem. 2011, 124, 822–832. [Google Scholar] [CrossRef]

- Zou, J.; Hu, Y.; Li, K.; Liu, Y.; Li, M.; Pan, X.; Chang, X. Chestnuts in Fermented Rice Beverages Increase Metabolite Diversity and Antioxidant Activity While Reducing Cellular Oxidative Damage. Foods 2022, 12, 164. [Google Scholar] [CrossRef] [PubMed]

- Wold, S.; Esbensen, K.; Geladi, P. Principal Component Analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

| Barrel Number | Barrel Material | Producer |

|---|---|---|

| 6 | Mulberry | A |

| 5 | Mulberry | |

| 4 | Mulberry | |

| 3 | Mulberry | |

| 2 | Mulberry | |

| 1 | Mulberry | |

| ABTM | Mulberry | |

| 6 | Chestnut | A |

| 5 | Chestnut | |

| 4 | Chestnut | |

| 3 | Chestnut | |

| 2 | Chestnut | |

| 1 | Chestnut | |

| ABTM | Chestnut | |

| 6 | Juniper | A |

| 5 | Juniper | |

| 4 | Juniper | |

| 3 | Juniper | |

| 2 | Juniper | |

| 1 | Juniper | |

| ABTM | Juniper | |

| 6 | Cherry | A |

| 5 | Cherry | |

| 4 | Cherry | |

| 3 | Cherry | |

| 2 | Cherry | |

| 1 | Cherry | |

| ABTM | Cherry | |

| 6 | Oak | B |

| 5 | Oak | |

| 4 | Oak | |

| 3 | Oak | |

| 2 | Oak | |

| 1 | Oak | |

| ABTM | Oak |

| Ramp Rate (°C/min) | Temperature (°C) | Hold Time (min) | Elapsed Time (min) |

|---|---|---|---|

| 30 | 1.00 | 1.00 | |

| 3.00 | 150 | 0.00 | 40.00 |

| 8.00 | 260 | 14.50 | 28.25 |

| Tot: 69.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durante, C.; Morelli, L.; D’Eusanio, V.; Tassi, L.; Marchetti, A. Exploring the Impact of Various Wooden Barrels on the Aromatic Profile of Aceto Balsamico Tradizionale di Modena by Means of Principal Component Analysis. Molecules 2024, 29, 2647. https://doi.org/10.3390/molecules29112647

Durante C, Morelli L, D’Eusanio V, Tassi L, Marchetti A. Exploring the Impact of Various Wooden Barrels on the Aromatic Profile of Aceto Balsamico Tradizionale di Modena by Means of Principal Component Analysis. Molecules. 2024; 29(11):2647. https://doi.org/10.3390/molecules29112647

Chicago/Turabian StyleDurante, Caterina, Lorenzo Morelli, Veronica D’Eusanio, Lorenzo Tassi, and Andrea Marchetti. 2024. "Exploring the Impact of Various Wooden Barrels on the Aromatic Profile of Aceto Balsamico Tradizionale di Modena by Means of Principal Component Analysis" Molecules 29, no. 11: 2647. https://doi.org/10.3390/molecules29112647